Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Rapid and cost-effective" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

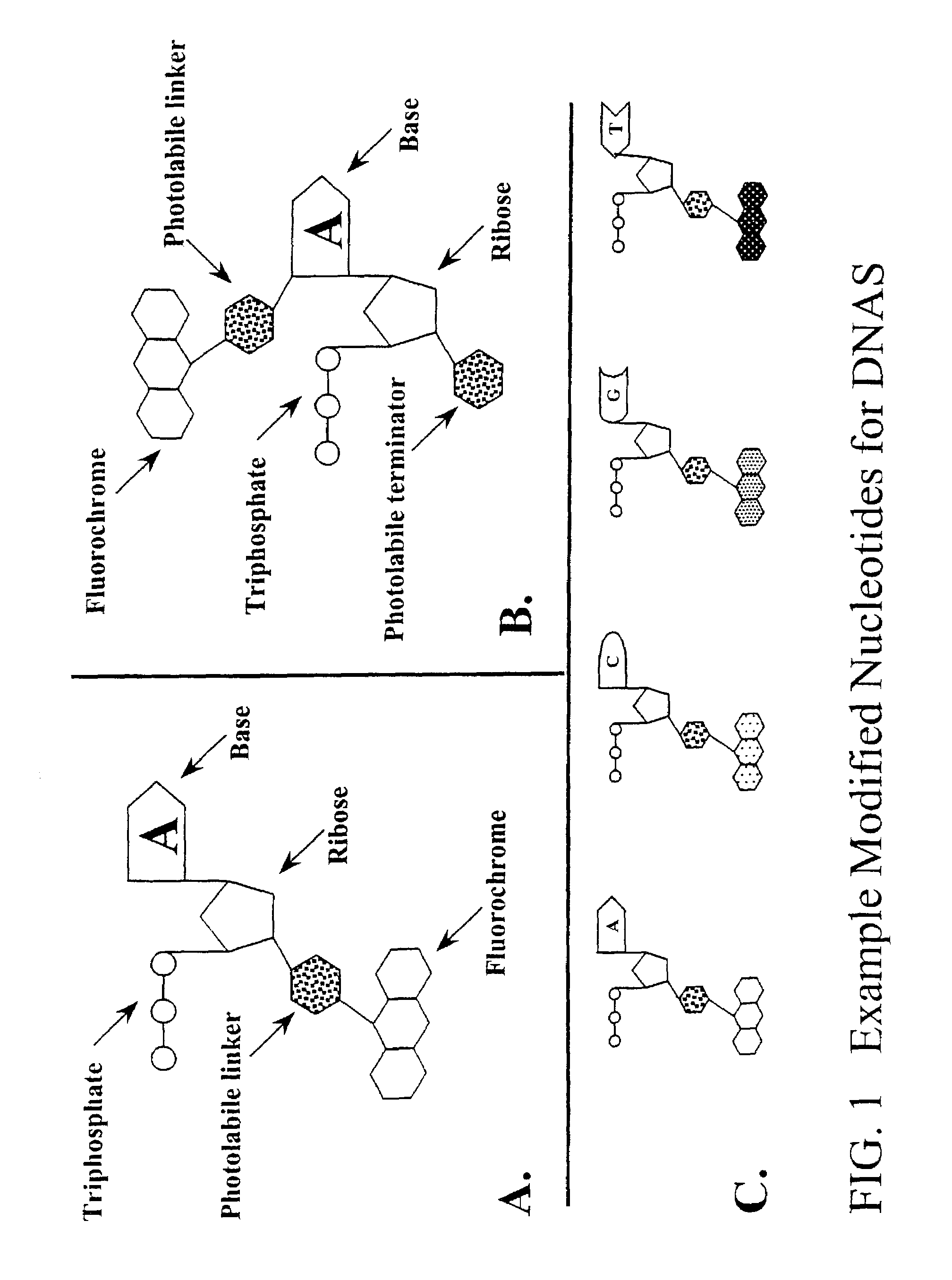

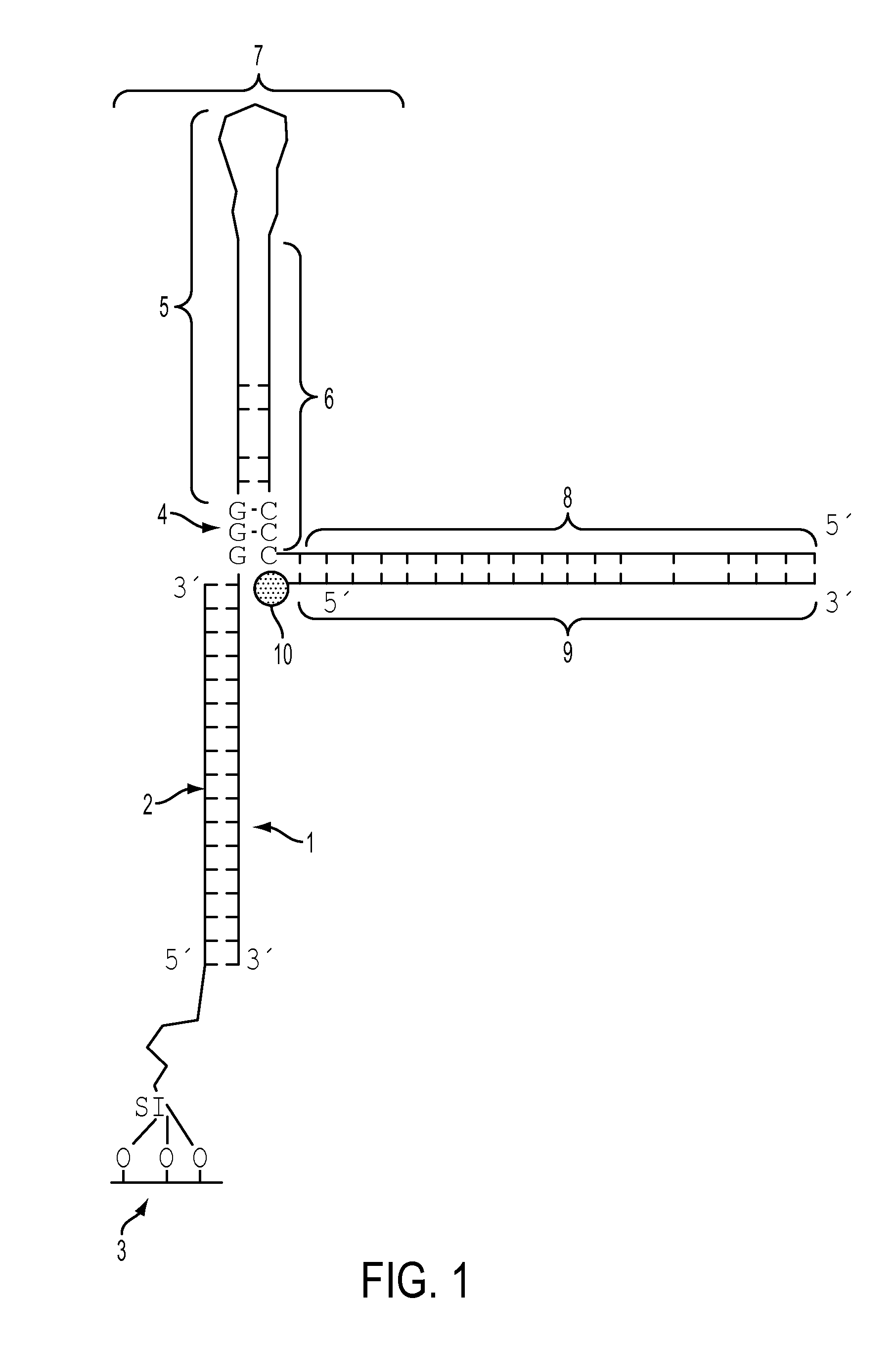

Method for direct nucleic acid sequencing

InactiveUS7270951B1Eliminate needRapid and cost-effectiveSugar derivativesMicrobiological testing/measurementNucleotideNucleic acid sequencing

The present invention provides a novel sequencing apparatus and the methods employed to determine the nucleotide sequence of many single nucleic acid molecules simultaneously, in parallel. The methods and apparatus of the present invention offer a rapid, cost effective, high through-put method by which nucleic acid molecules from any source can be readily sequenced without the need for prior amplification of the sample or prior knowledge of any sequence information.

Owner:ALERE SAN DIEGO INC

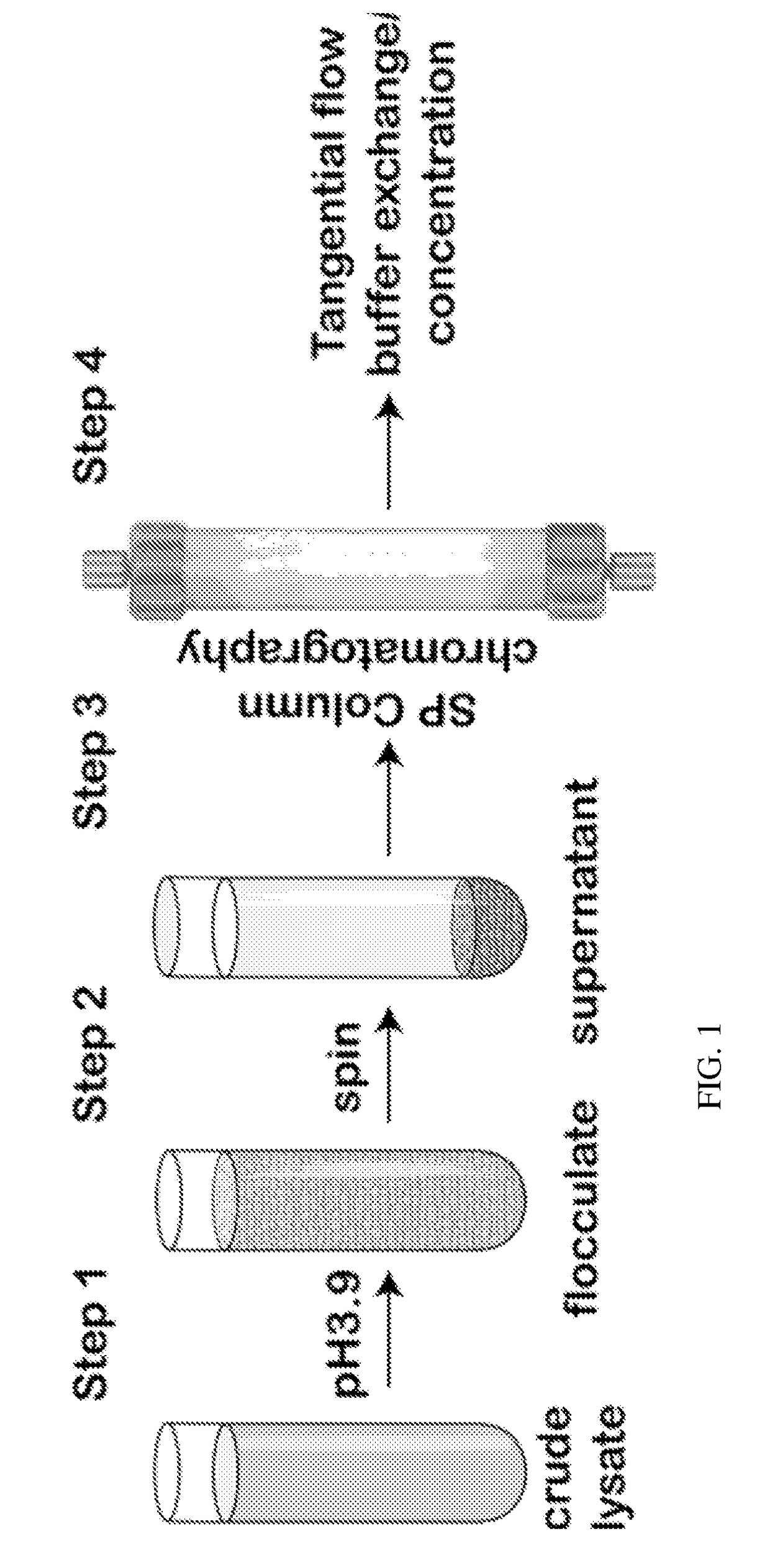

Compositions and methods for purifying recombinant adeno-associated virus

ActiveUS20170130208A1Easy to purifyRapid and cost-effectiveViral/bacteriophage medical ingredientsSsDNA virusesAdeno-associated virusVirology

Provided herein are compositions and methods related to purification of recombinant adeno-associated virus (rAAV) particles.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

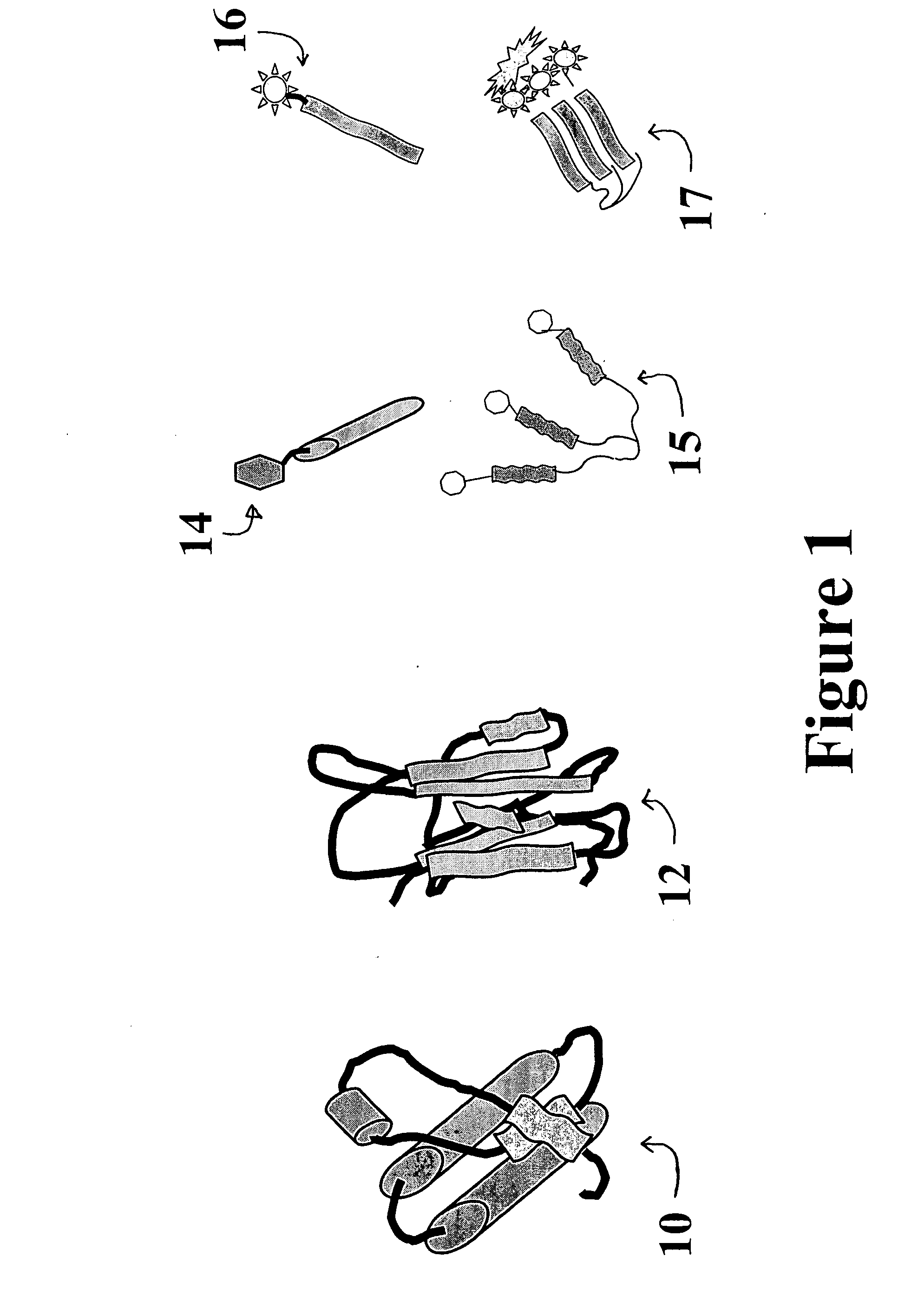

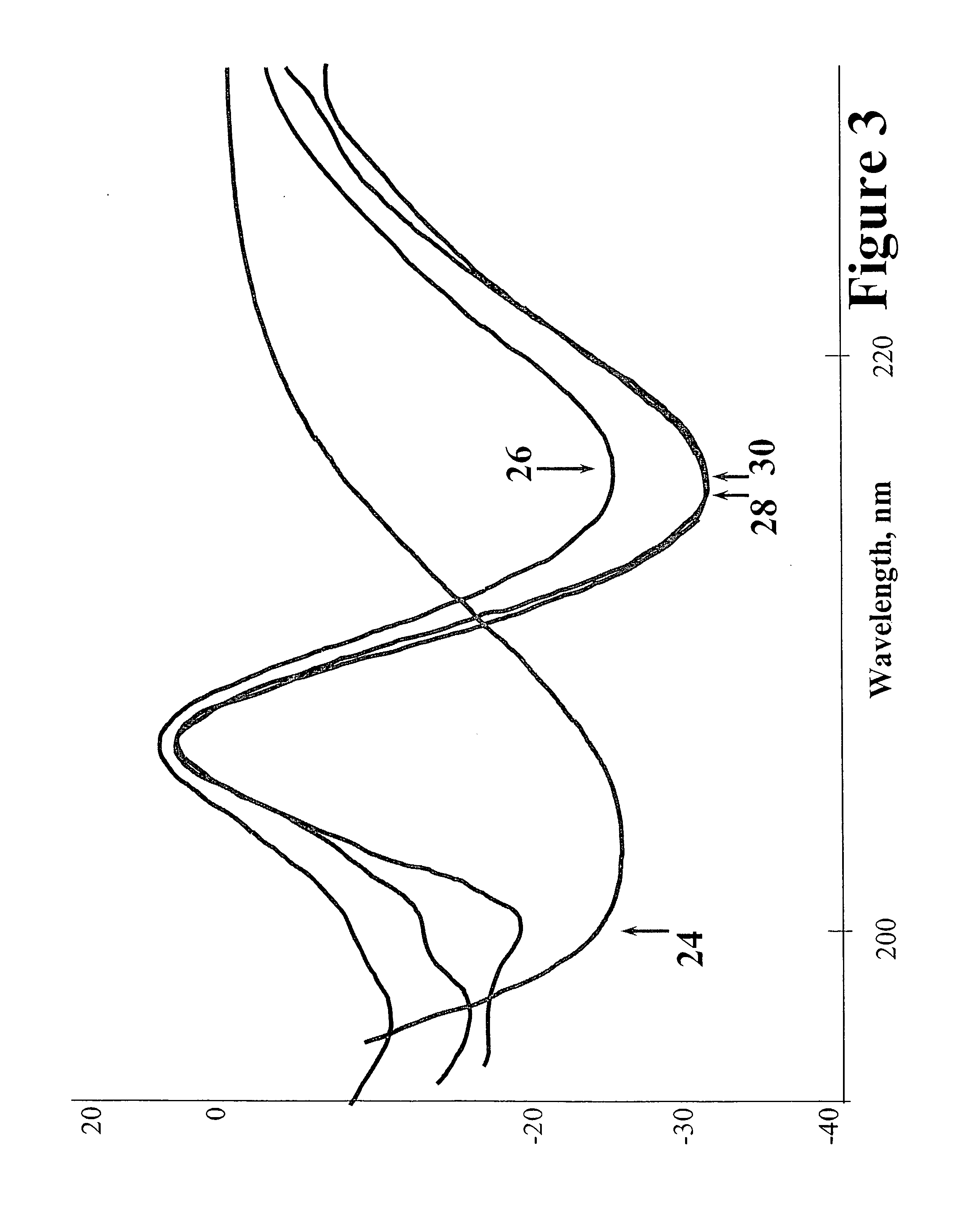

Misfolded protein sensor method

ActiveUS20060286672A1Easy to detectRapid and cost-effectivePeptide preparation methodsDepsipeptidesCrystallographyDendrimer

A catalytic conformational sensor method for detecting abnormal proteins and proteinaceous particles. The method is based on the interaction of a peptide fragment or probe with an abnormal proteinaceous particle. The interaction catalyzes transformation of the probe to a predominately beta sheet conformation and allows the probe to bind to the abnormal proteinaceous particle. This in turn, catalyzes propagation of a signal associated with the test sample-bound probe. As a result signals can be propagated even from samples containing very low concentrations of abnormal proteinaceous particles. The peptide probes can be designed to bind to a desired peptide sequence or can even be based on dendrimer structure to control further aggregate propagation.

Owner:PRESYMPTO INC

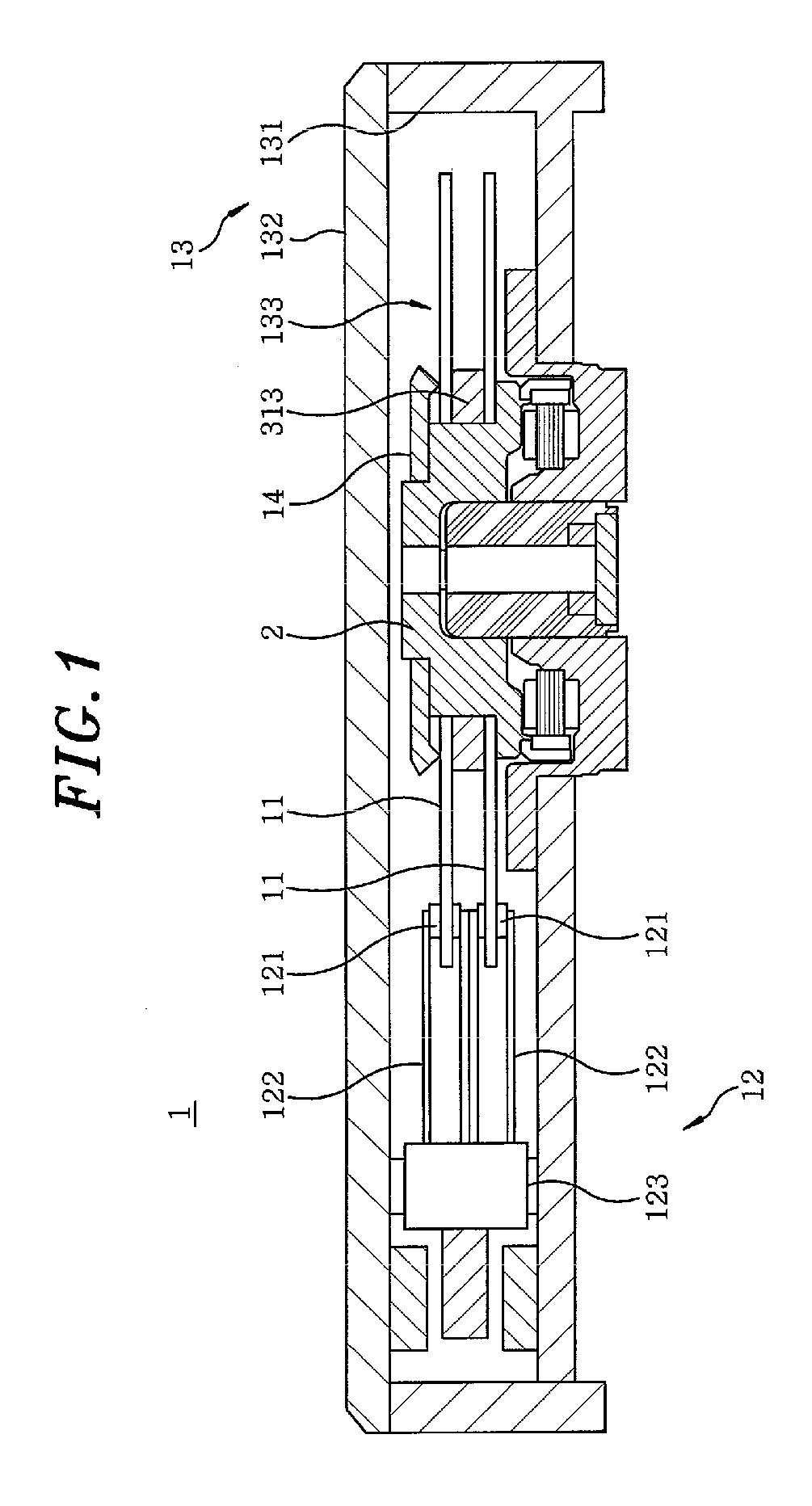

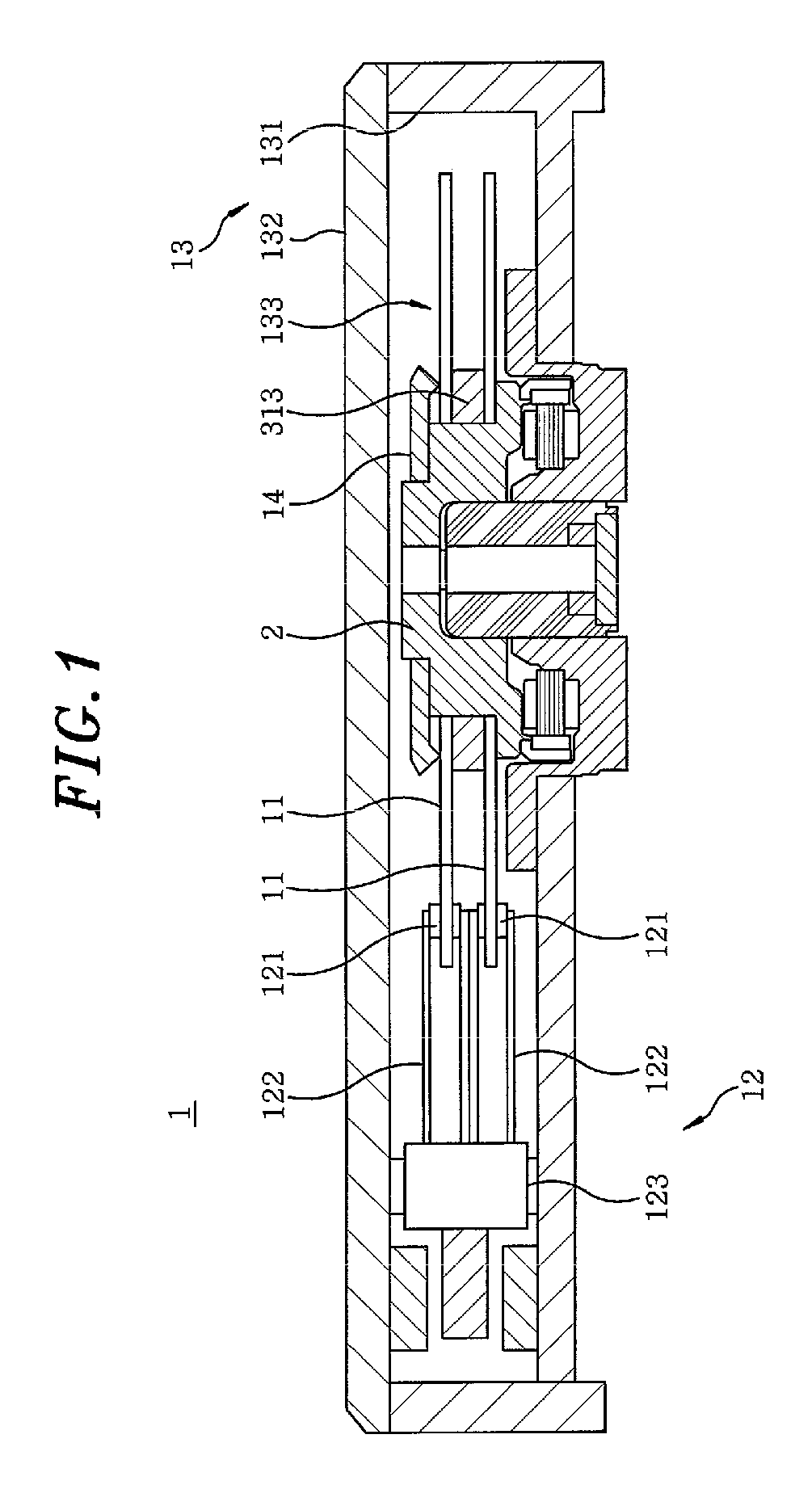

Oil-repellent film forming method, motor manufacturing method and motor

ActiveUS20090152969A1Rapidly taskReduce thermal deformationFurnaces without endless coreBearing assemblyMaterials scienceMetal

A method is for forming an oil-repellent film on a metallic part in a dynamic fluid pressure bearing mechanism used for a motor. The method includes applying a flowable oil-repellent agent on an application region of the metallic part; arranging an induction coil in the vicinity of the metallic part; and affixing the oil-repellent agent onto the metallic part by applying an induction heating to the metallic part by supplying an AC current with a frequency of about 5 to 100 kHz to the induction coil. Further, a motor includes a dynamic fluid pressure bearing mechanism including a metallic part on which an oil-repellent film is formed by the above method; a stator unit; and a rotor unit supported by the dynamic fluid pressure bearing mechanism in a manner rotatable with respect to the stator unit.

Owner:NIPPON DENSAN CORP

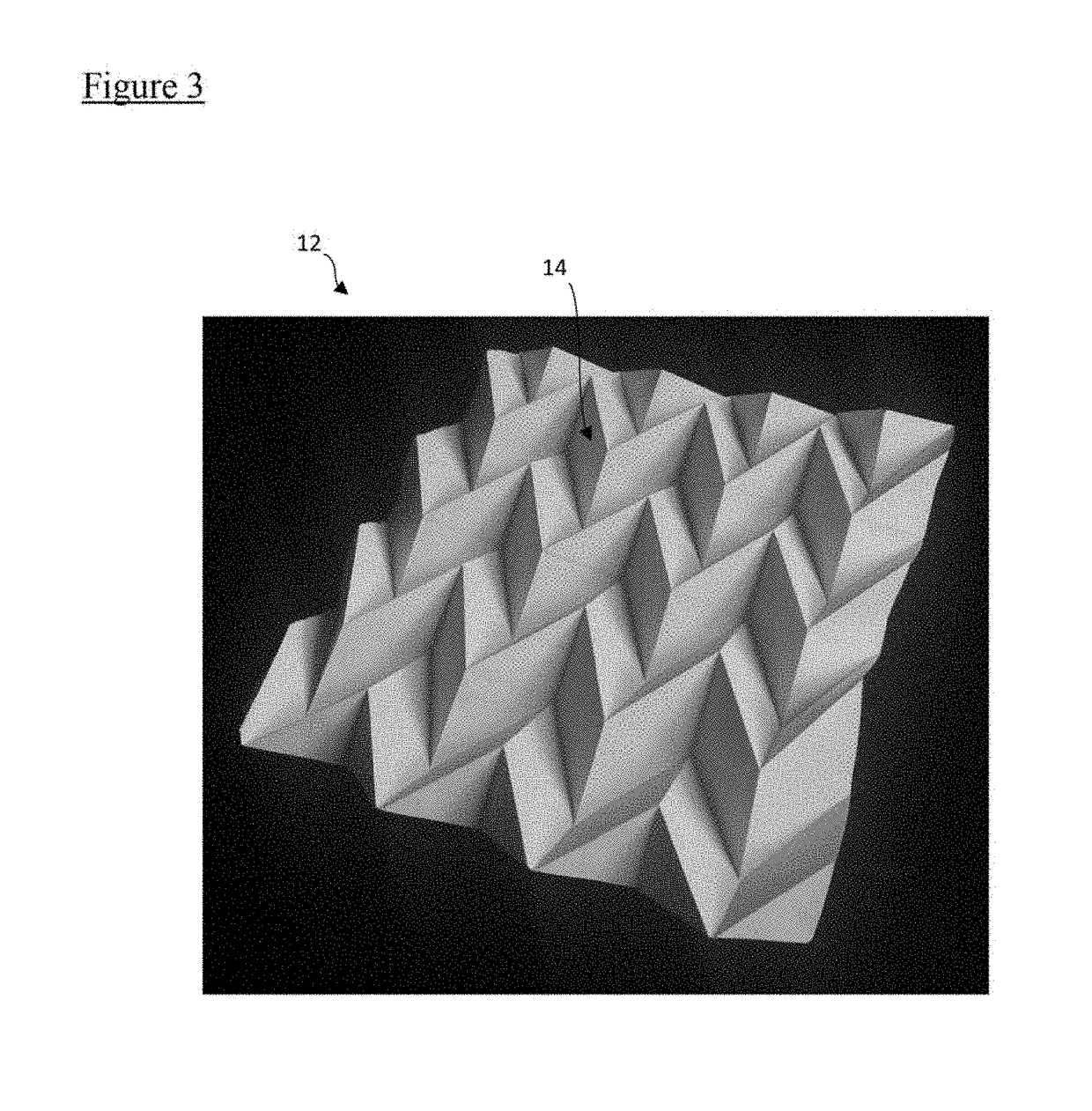

Helmet insert

InactiveUS20190075876A1Strong and lightweight structureGood energy absorbing propertiesSport apparatusHelmetsEngineeringMechanical engineering

An insert for a helmet comprises a plurality of layers, each layer being of a Miura-Ori fold geometry.

Owner:PEMBROKE BOW LTD

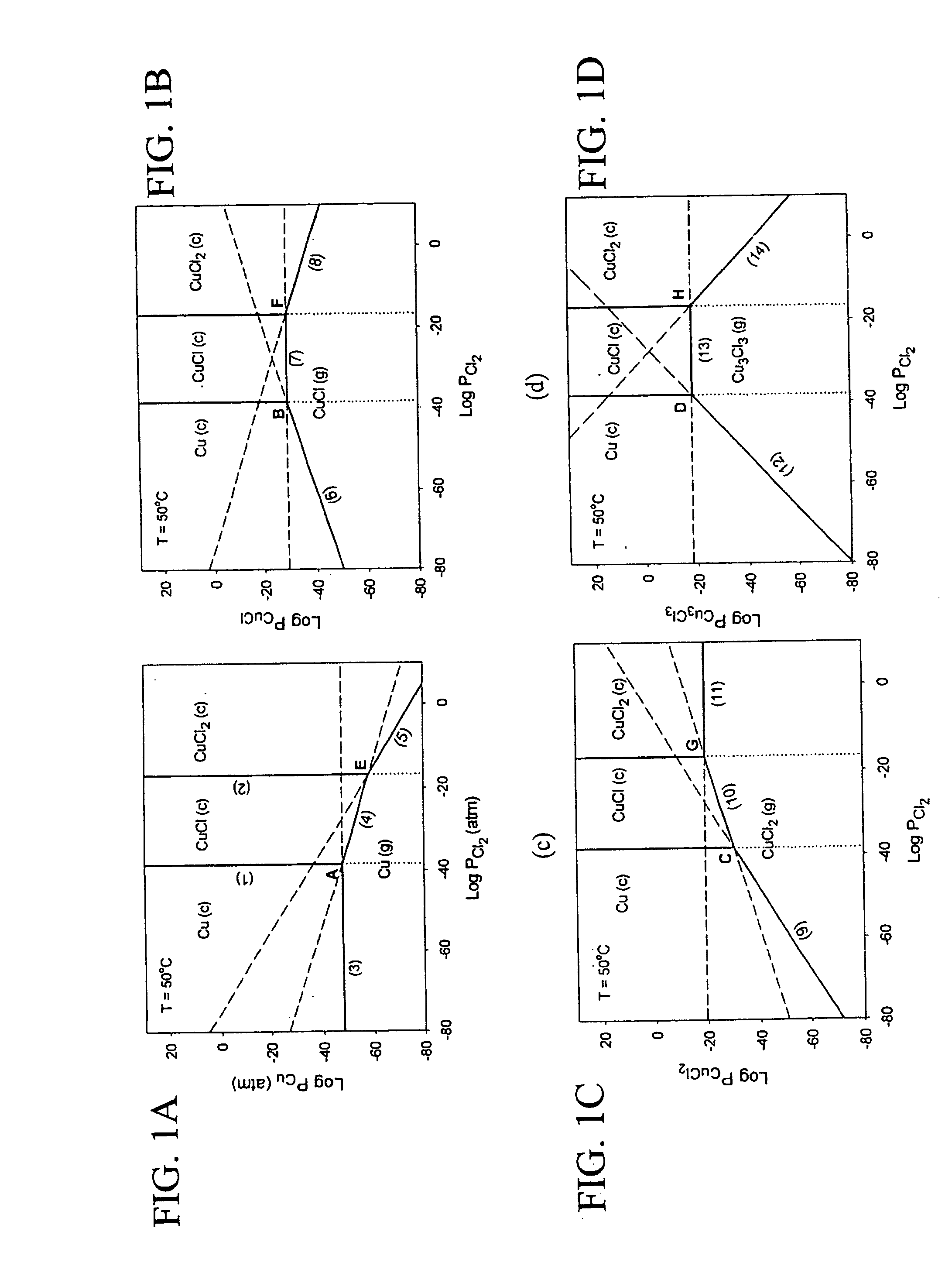

Process for low temperature, dry etching, and dry planarization of copper

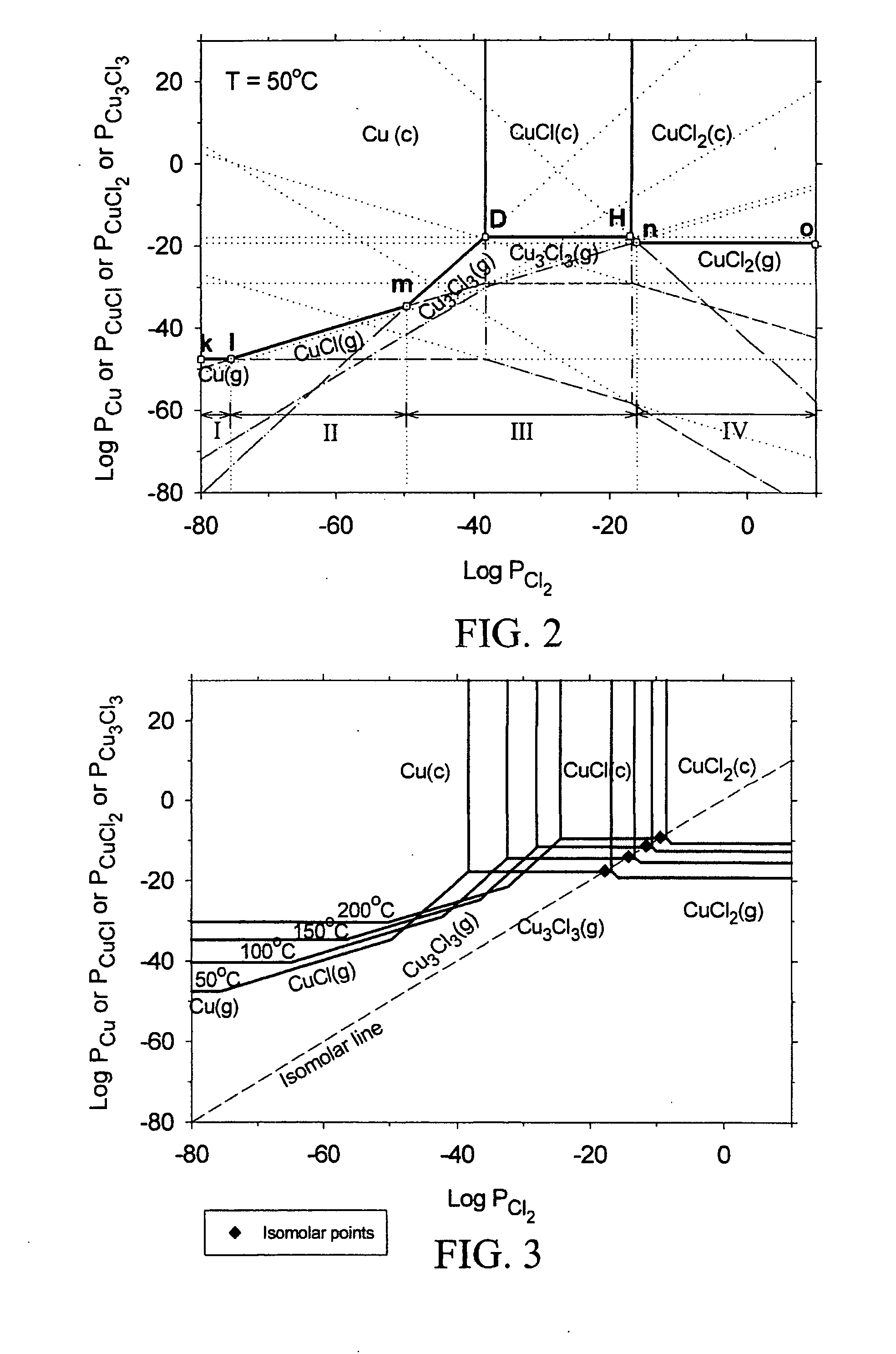

InactiveUS20060014394A1Rapid and cost-effectiveDecorative surface effectsSemiconductor/solid-state device manufacturingHydrogenSufficient time

The subject invention pertains to a method and apparatus for etching copper (Cu). The subject invention can involve passing a halide gas over an area of Cu such that CuX, or CuX and CuX2, are formed, where X is the halide. Examples of halides which can be utilized with the subject matter include, but are not necessarily limited to, Cl, Br, F, and I. Once the CuX, or CuX and CuX2, are formed the subject invention can then involve passing a reducing gas over the area of Cu for a sufficient time to etch away at least a portion of the CuX, or CuX2, respectively. With respect to a specific embodiment in which CuX and CuX2 are produced when the halide gas is passed over the area of Cu, the reducing gas can be passed until essentially all of the CUX2 is etched and at least a portion of the CuX is etched. Examples of reducing gases which can be utilized with the subject invention include, but are not necessarily limited to, hydrogen gas and hydrogen gas plasma. The subject invention can accomplish the etching of Cu by passing the reducing gas over the Cu so as to be on a CuX2—Cu3X2 metastable line when etching CuX2 and to be a CuY—CuX metastable line, where Y is the reducing gas element, when etching CuX. FIGS. 5, 6, and 8, show such metastable lines for Cu, with X being Cl, from temperatures ranging from 50° C. to 200° C. These can be extrapolated to other temperatures, for other halides, and / or other reducing gases. The subject invention can be used to, for example, etch partial into a layer of Cu, through a layer of Cu, or to smooth a Cu surface.

Owner:KULKARNI NAGRAJ S

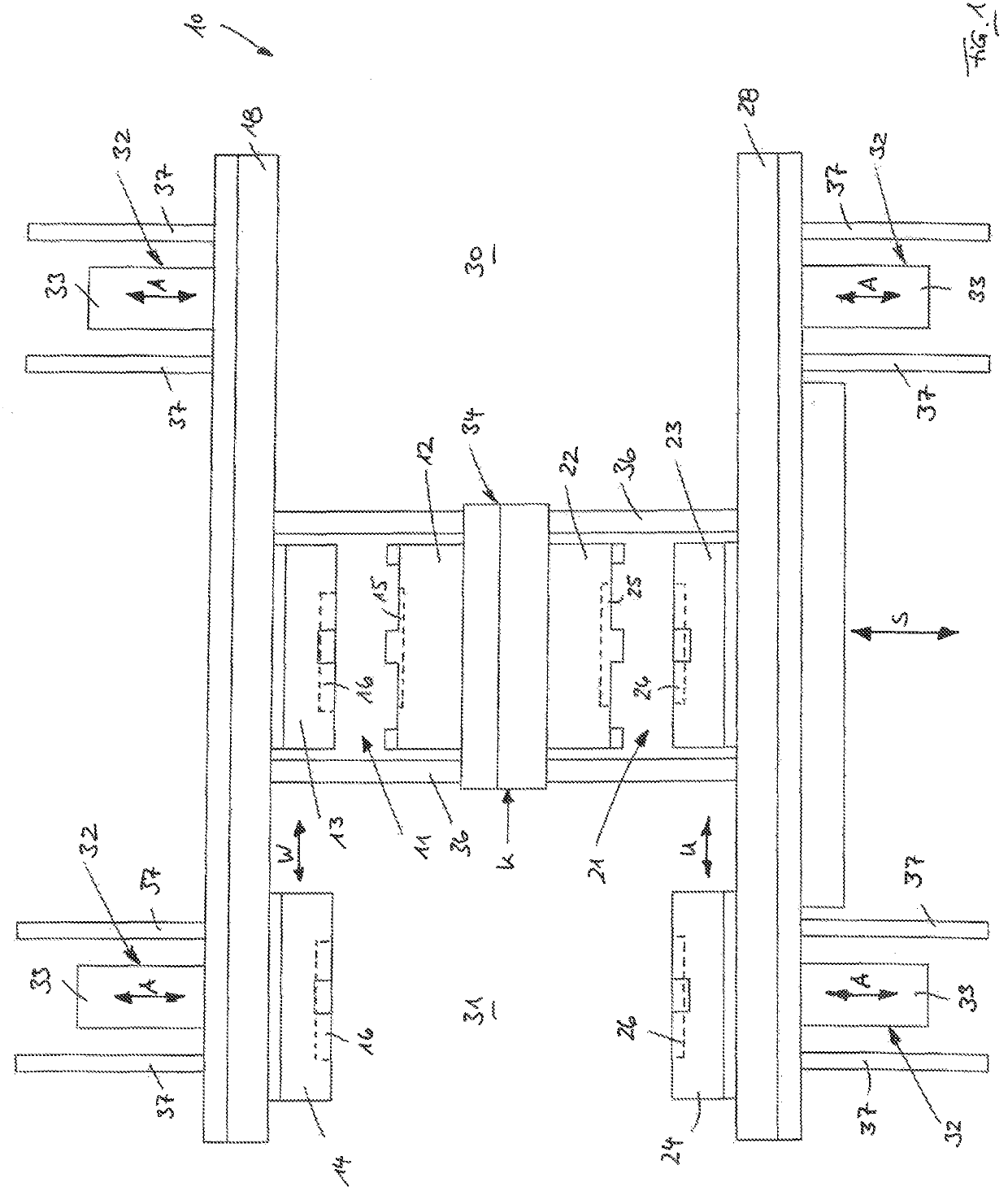

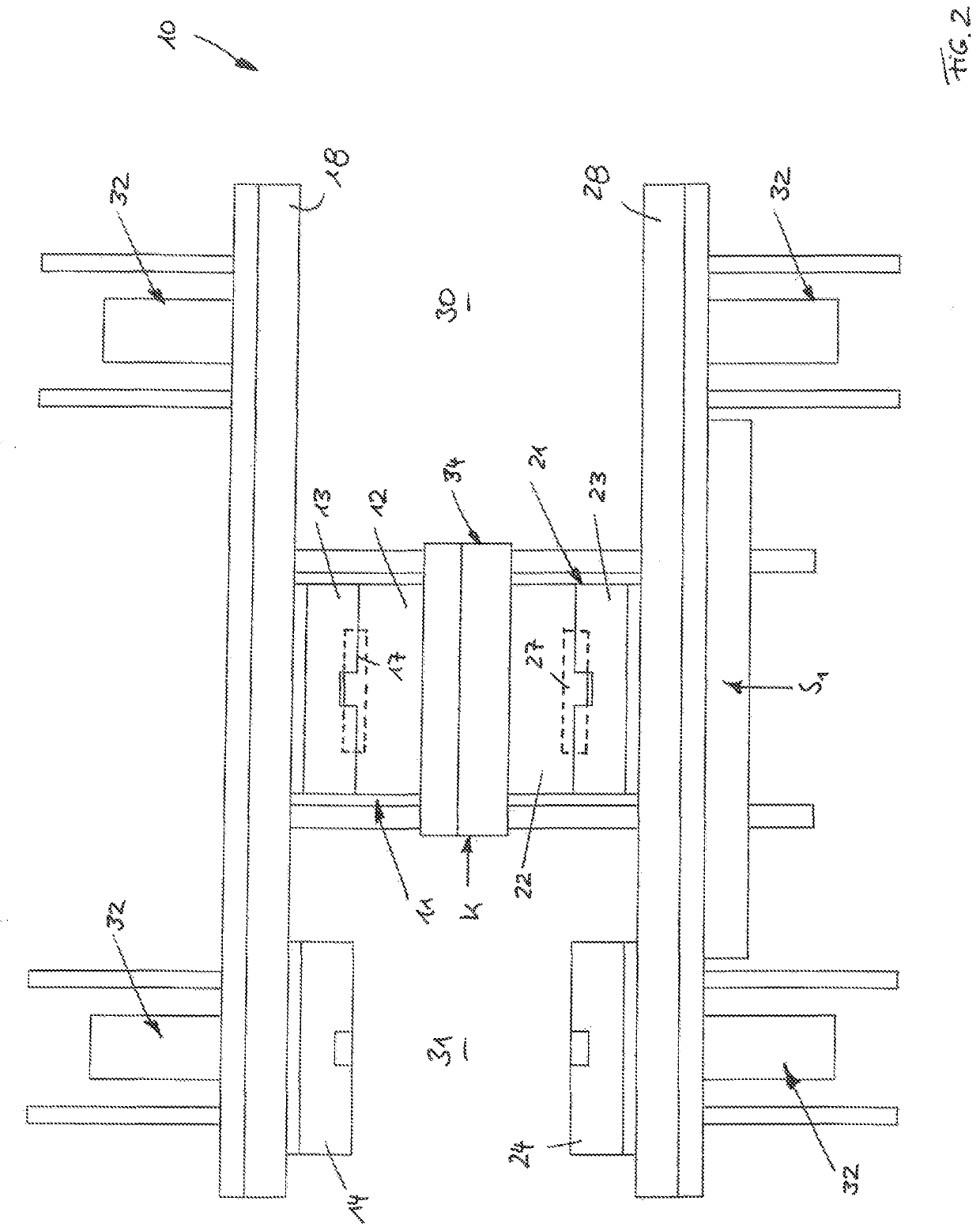

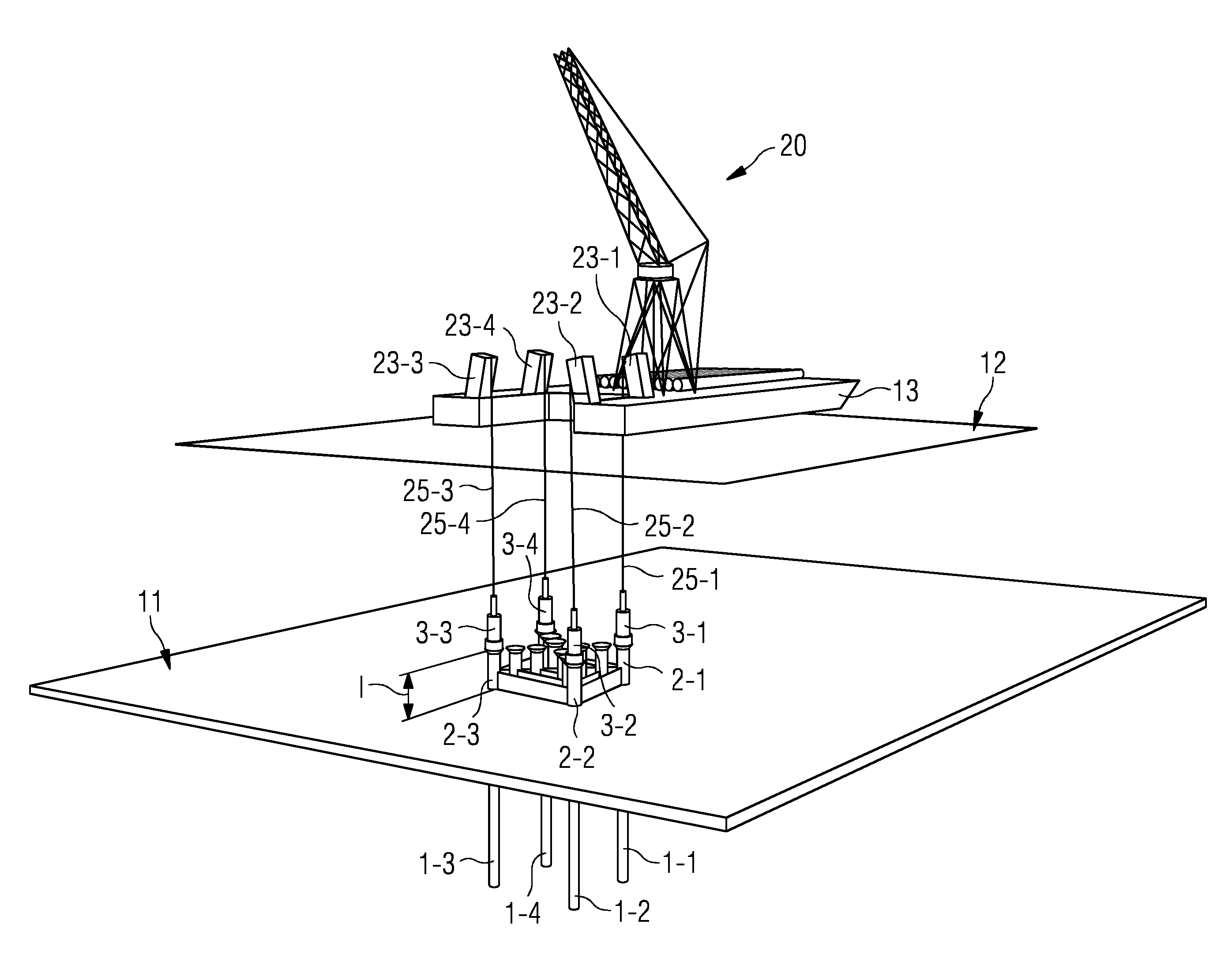

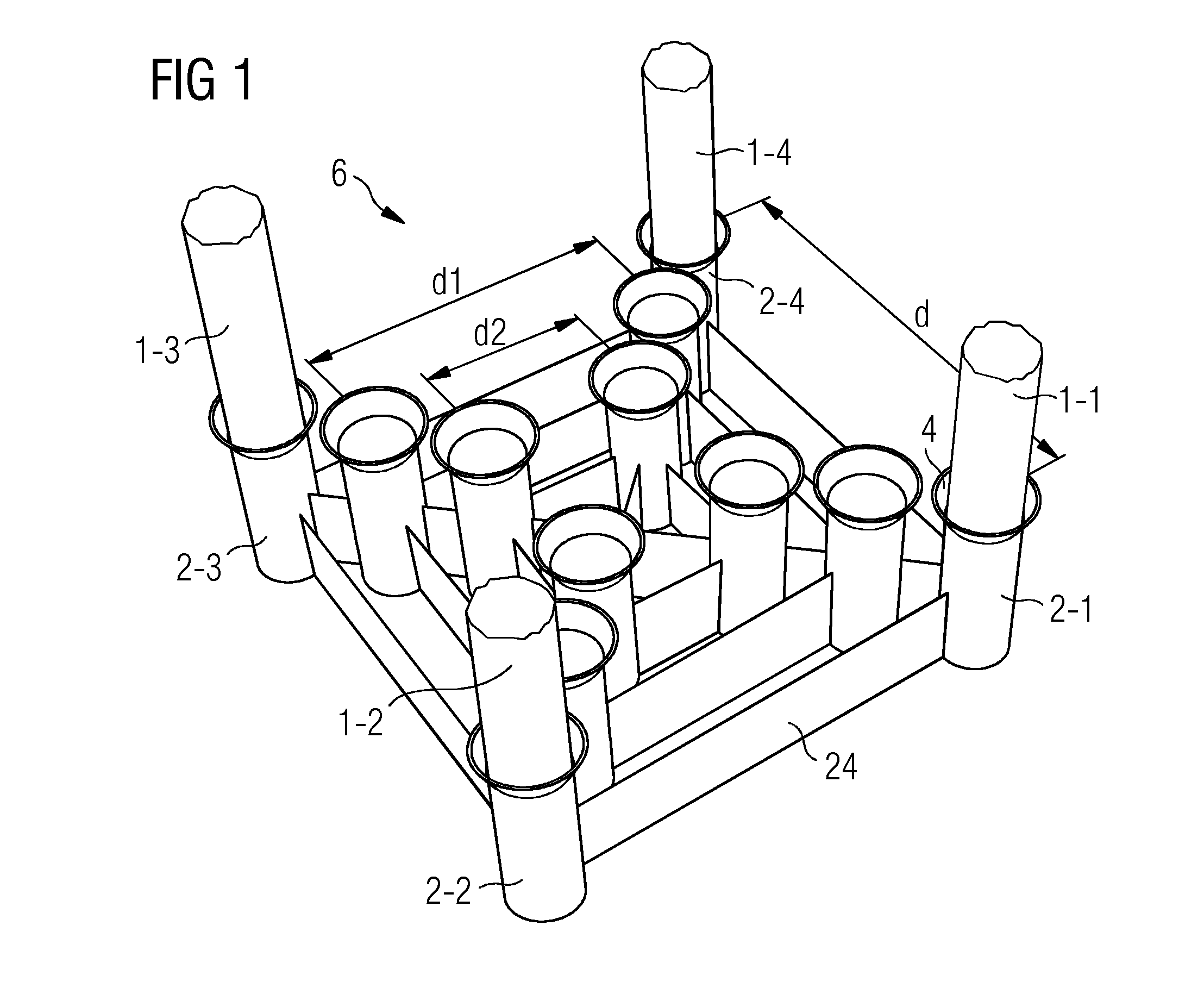

Method and device for driving a multiplicity of piles into a seabed

ActiveUS20130243532A1Rapid and cost-effectiveCost-effective operationArtificial islandsWind motor supports/mountsEngineeringSeabed

A plurality of piles is arranged in frame elements in an axially displaceable manner. Hammers are positioned on the piles. After driving of the piles into a seabed, the hammers are connected to the frame elements, wherein the frame elements together with the hammers are lifted to the surface of the water and to the seaborne vessel by a crane.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

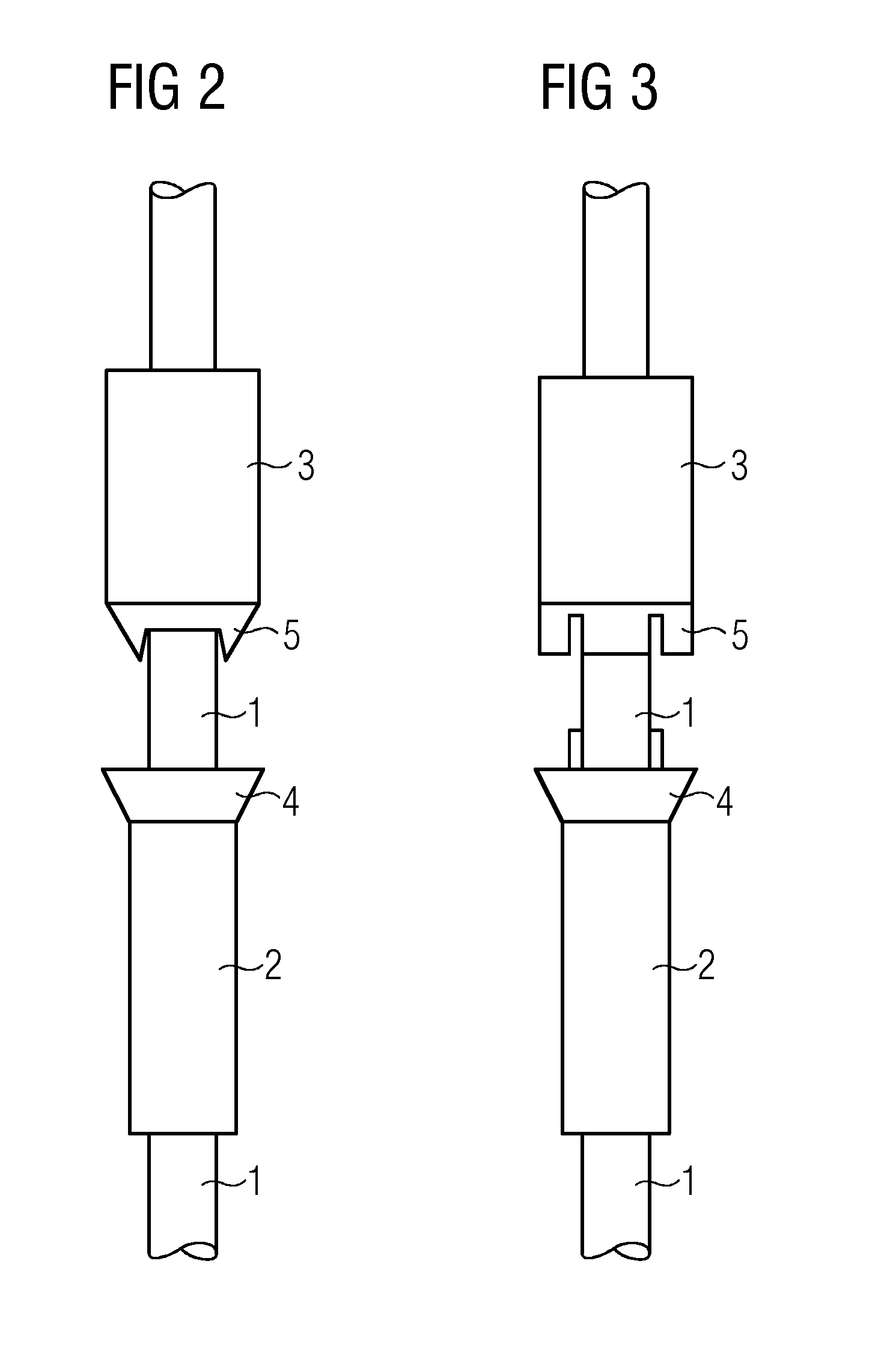

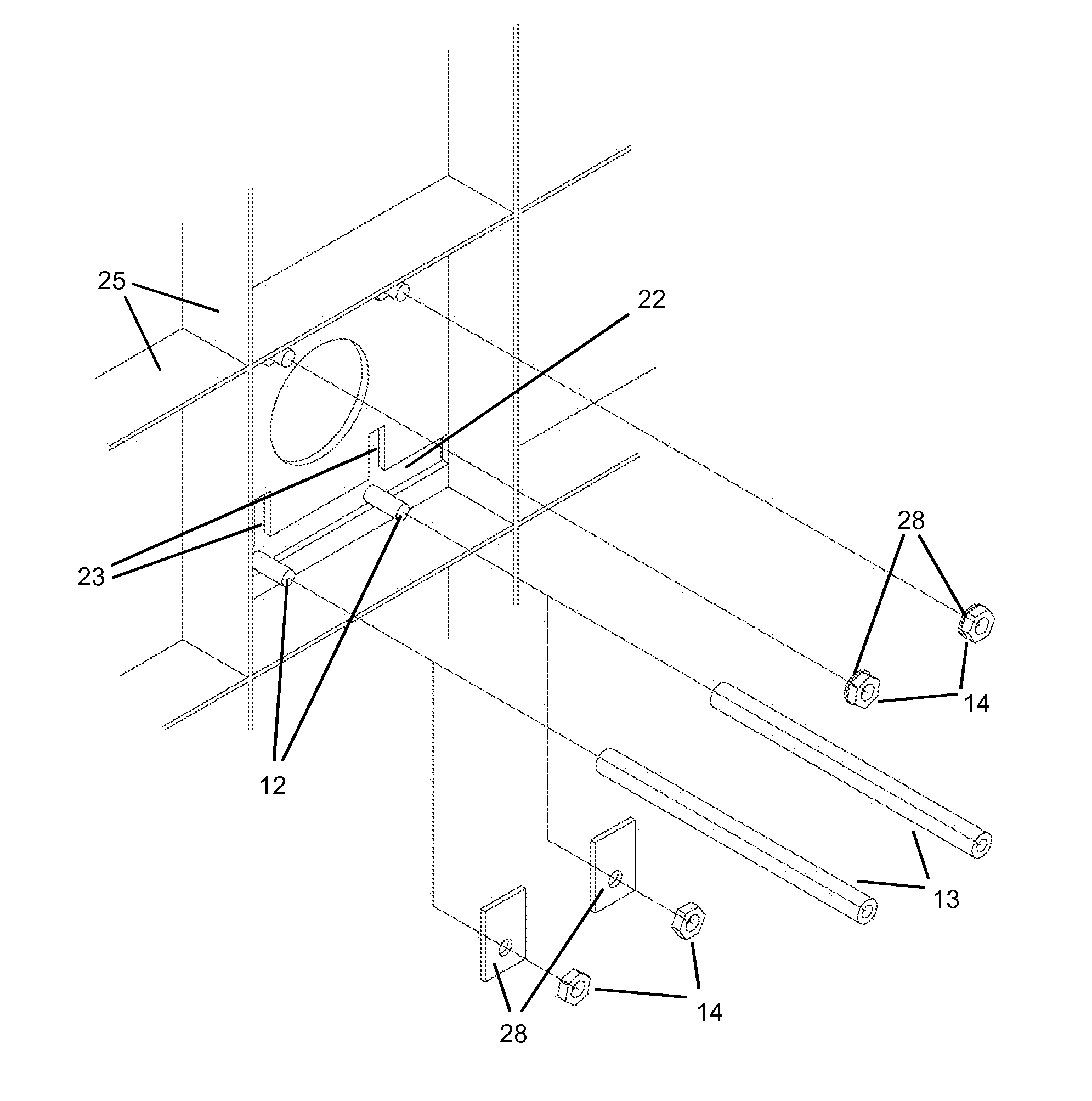

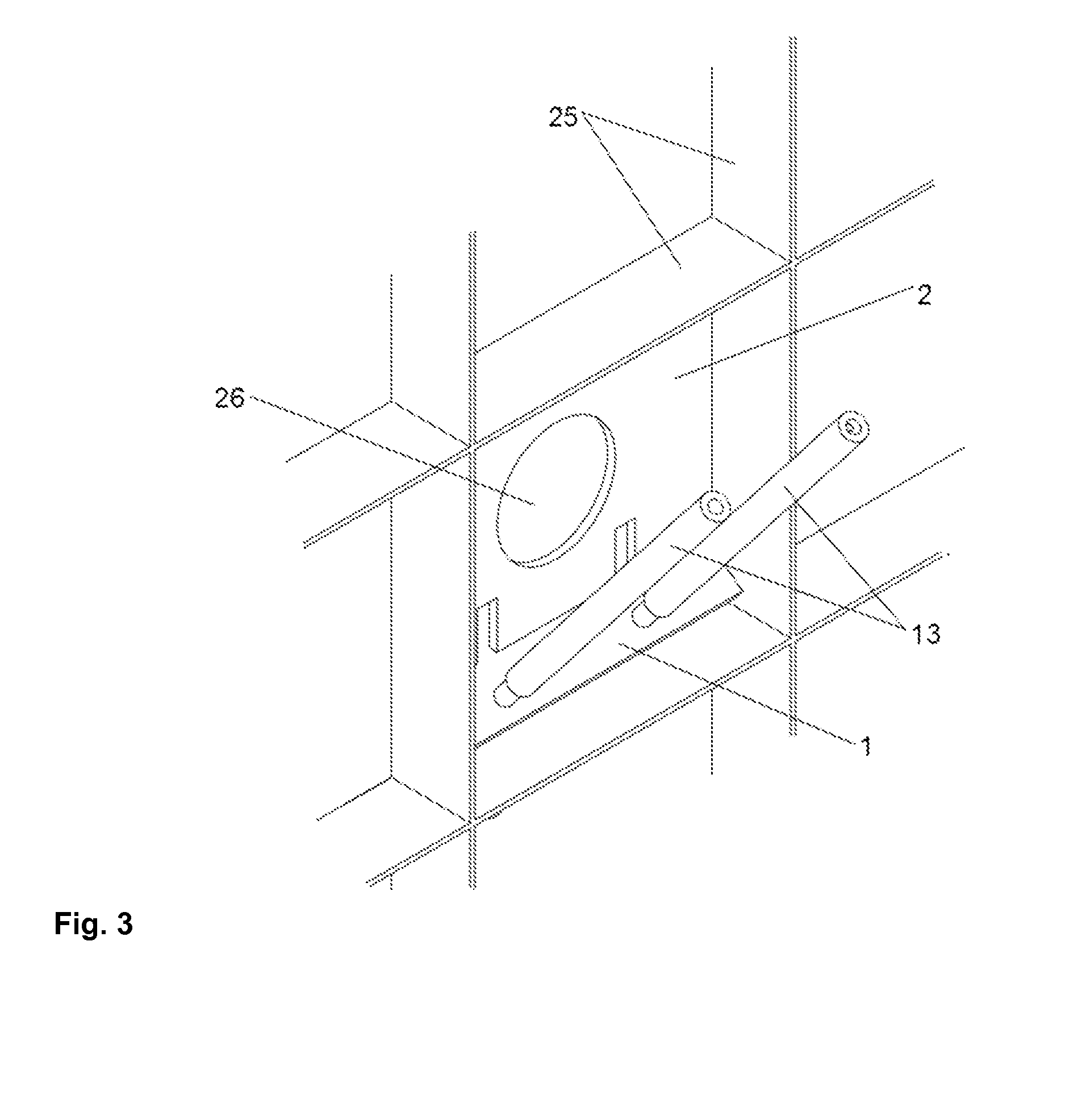

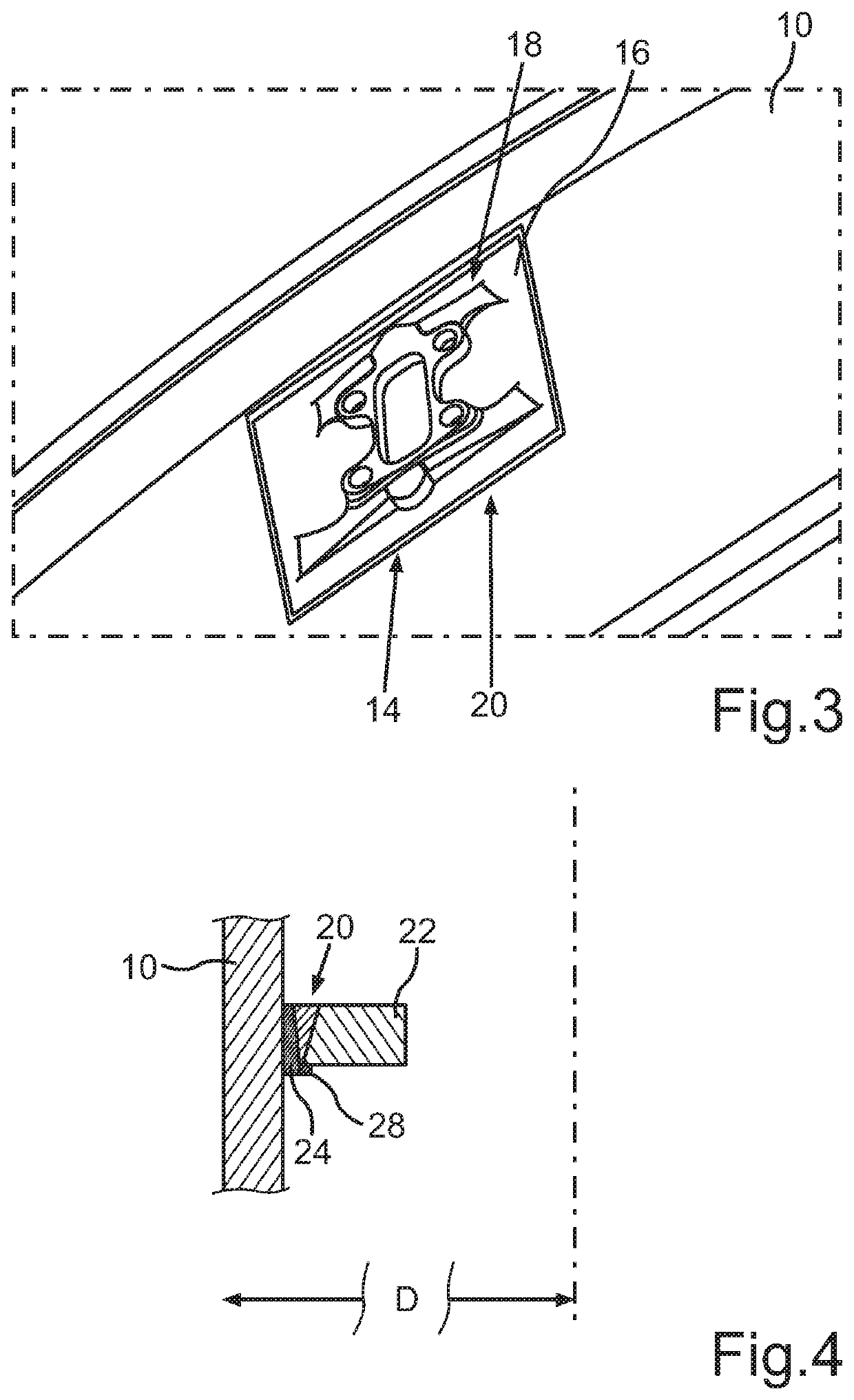

Method for producing a drywall

The invention relates to a method for producing a drywall. In the method, a panel made of a plurality of paneling boards (3) placed alongside one another is fixed to a frame structure (1). According to the invention, fixation elements (5) are first affixed to a substructure (2) in the edge area of a paneling board (3) and / or in the joint area (4) of two adjacent paneling boards (3). Then, by means of a clamping tool (7) for example, fastening elements (6) are set alongside the fixation elements (5), the respective paneling board (3) being simultaneously clamped between the substructure (2) and the fastening element (6).

Owner:KNAUF GIPS KG

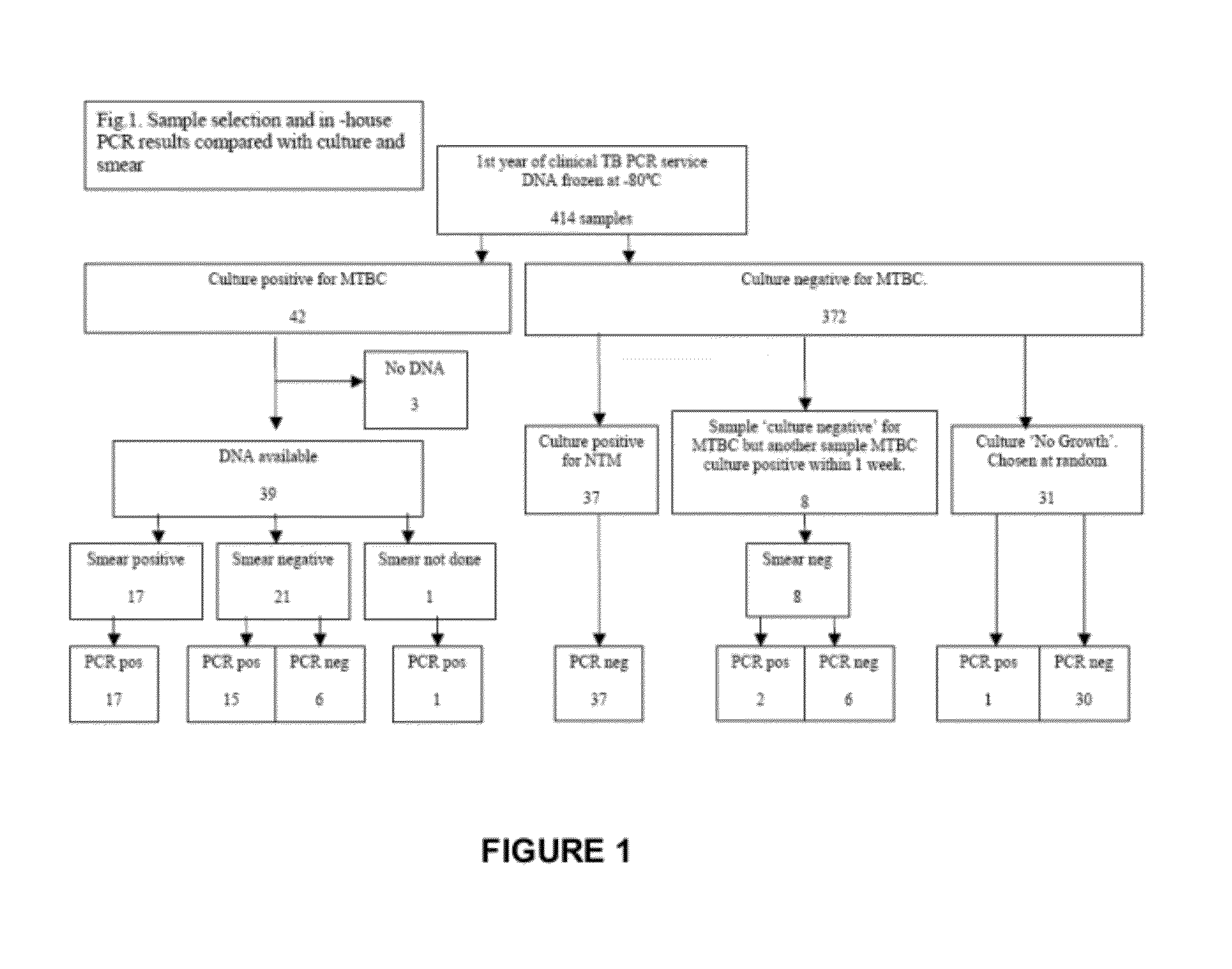

Method and/or primers for the detection of mycobacterium tuberculosis

InactiveUS20120100545A1Rapid and cost-effective diagnosticRapid and cost-effective and prognosticSugar derivativesMicrobiological testing/measurementMicrobiologyOligonucleotide

The invention provides oligonucleotide(s) for simple, specific and / or sensitive test(s) for the presence of Mycobacterium tuberculosis. In particular, the present invention provides oligonucleotide(s) for test(s) for Mycobacterium tuberculosis. Kit(s) comprising the oligonucleotide(s) for use as probe(s) and / or primer(s) useful in the test(s) are also provided.

Owner:TAN TOCK SENG HOSPITAL PTE LTD +1

Method of producing a microwave filter

InactiveUS6523248B1Rapid and cost-effectiveProduce rapidly and simplyWaveguidesElectromagnetsEdge surfaceElectrically conductive

The invention relates to a method for producing a microwave filter (700), comprising making at least one through-cutout (750) in a first electrically conductive plate (740) shaped as a rectangle, with a short side and a long side, inserting the first plate (740) between a second (710) and a third (730) electrically conductive plate (710), the first plate being arranged parallel to the second and the third plate, making electrical connections (794, 795) between said three plates for interconnecting those edge surfaces on the plates which coincide with the direction of propagation of the electrical signals, as a result of which a space comprising one or more cavities is formed. The first plate (740) is arranged so that the extent of its short side coincides with the E-field of the microwave signals when they propagate in the filter (700), and the extent of its long side coincides with the direction of propagation of the electrical signals.

Owner:TELEFON AB LM ERICSSON (PUBL)

Device and process for manufacturing a component formed of a plurality of moldings made of plastic and welded together

InactiveUS20200009772A1Improve accuracyRapid and cost-effectiveCoatingsPolymer sciencePolymer chemistry

For manufacturing a component formed of a plurality of moldings, which are made of plastic, are welded together. A first molding is manufactured in a first mold that has a first mold part and is then transported with the first mold part into a welding station. Correspondingly, a second molding is manufactured in a second mold that has a second mold part and is transported with the second mold part into the welding station. The mold parts holding the moldings are moved towards one another in the welding station such that the moldings are welded together. Additional moldings are manufactured in the molds simultaneously with the welding of the moldings.

Owner:GEBR KRALLMANN GMBH +1

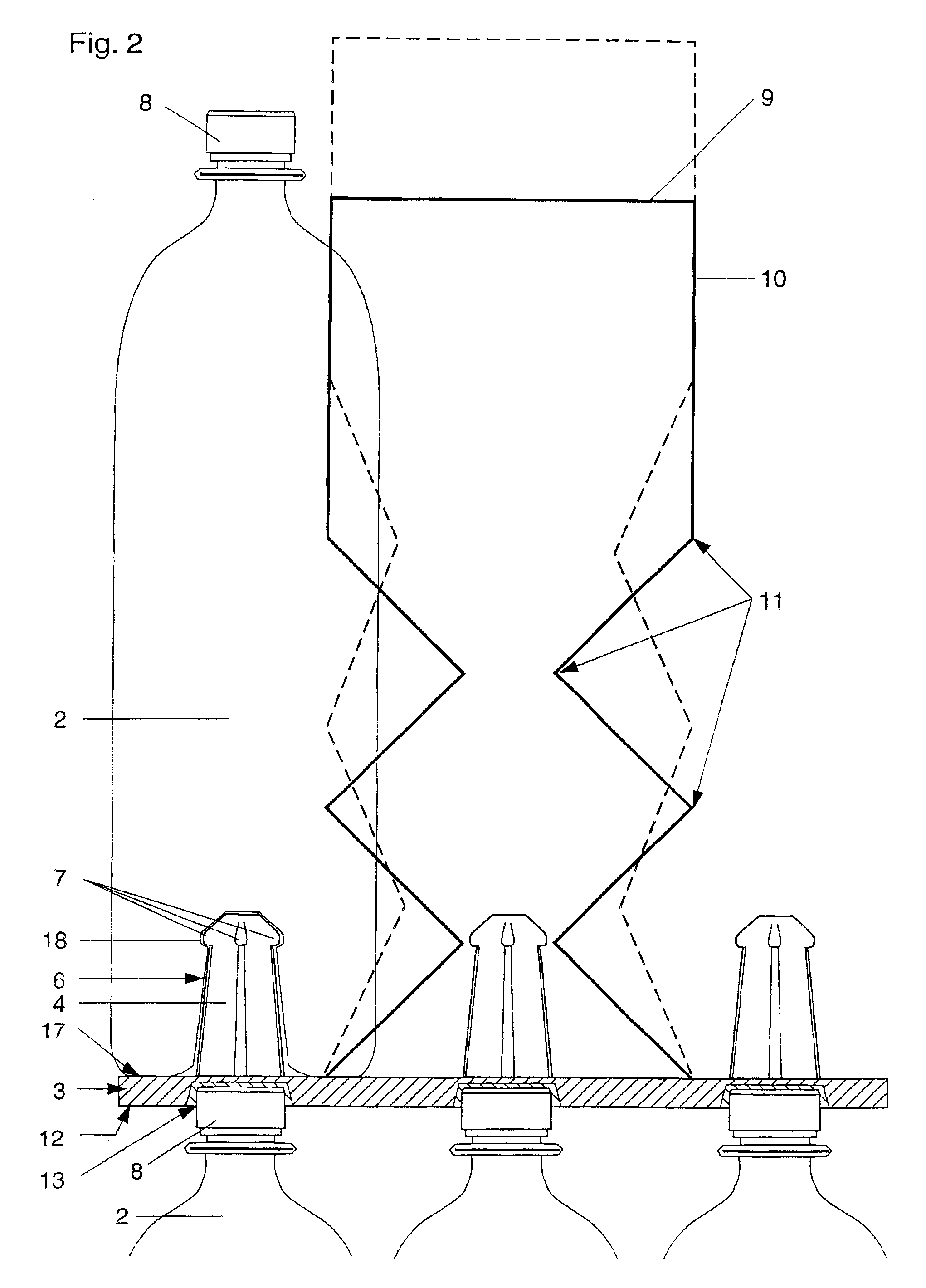

Fixture for recycling bottles and recycling bottle

A fixture for recycling bottles made of plastics, which includes a base plate and means for anchoring the bottles arranged on the upper side of the base plate and engaging in indentations provided on the bottle bottoms, and a recycling bottle made of plastics to be used with such a fixture and including an indentation on its bottle bottom. In order to facilitate handling of the bottles for recycling purposes and to enable the automated determination of possible deposits for the bottles as well as the simple and rapid recyclability of the bottles, it is provided that the anchoring means, in a sense oriented away from the upper side of the base plate, have decreasing cross sections and barb-shaped formations. Thus, the optimum support of the bottles on the fixture is safeguarded. Preferably, the base plate is located within the projection of the bottles onto the base plate.

Owner:PROF BIRKMAYER UNDHEITSPROD

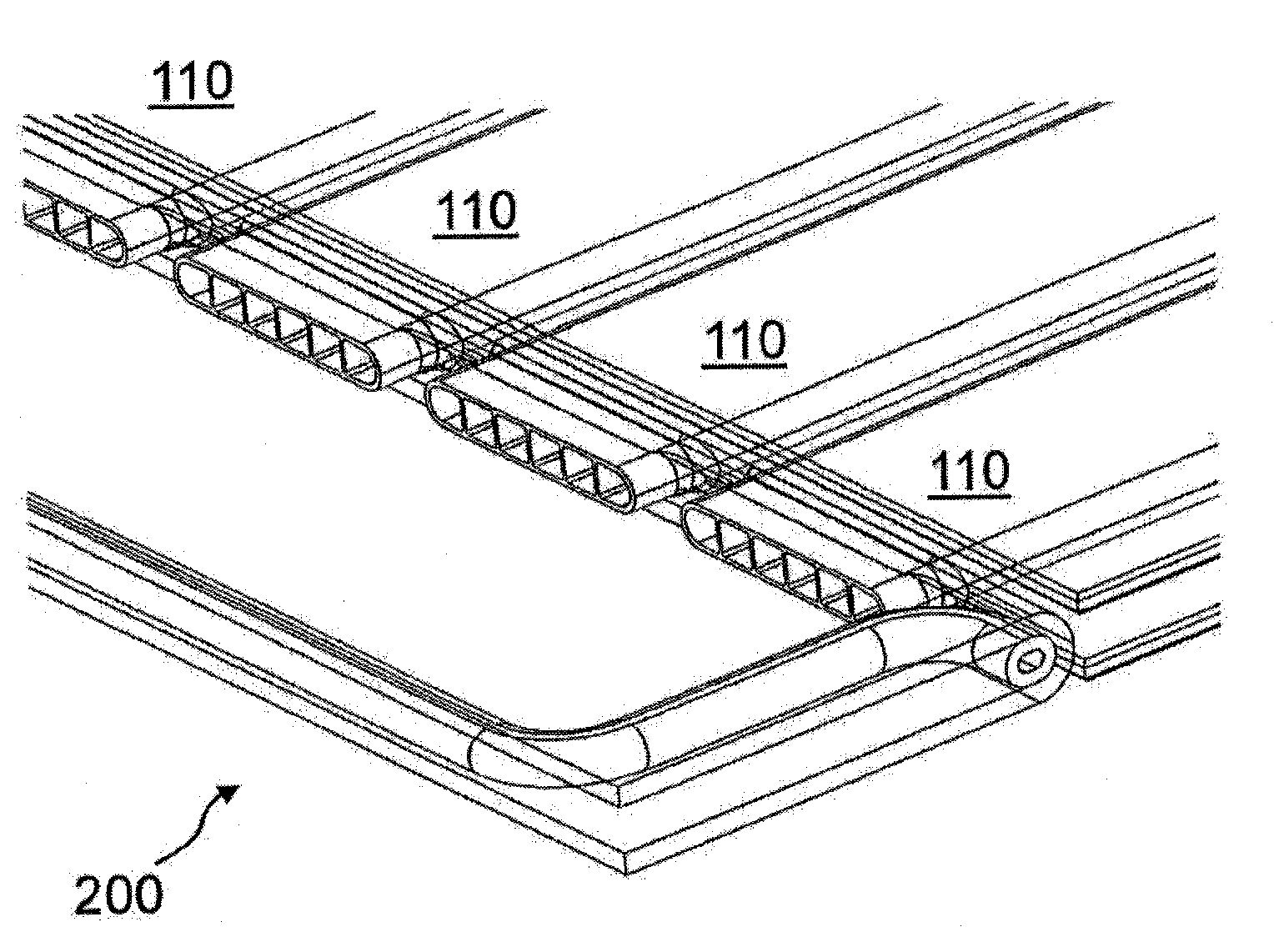

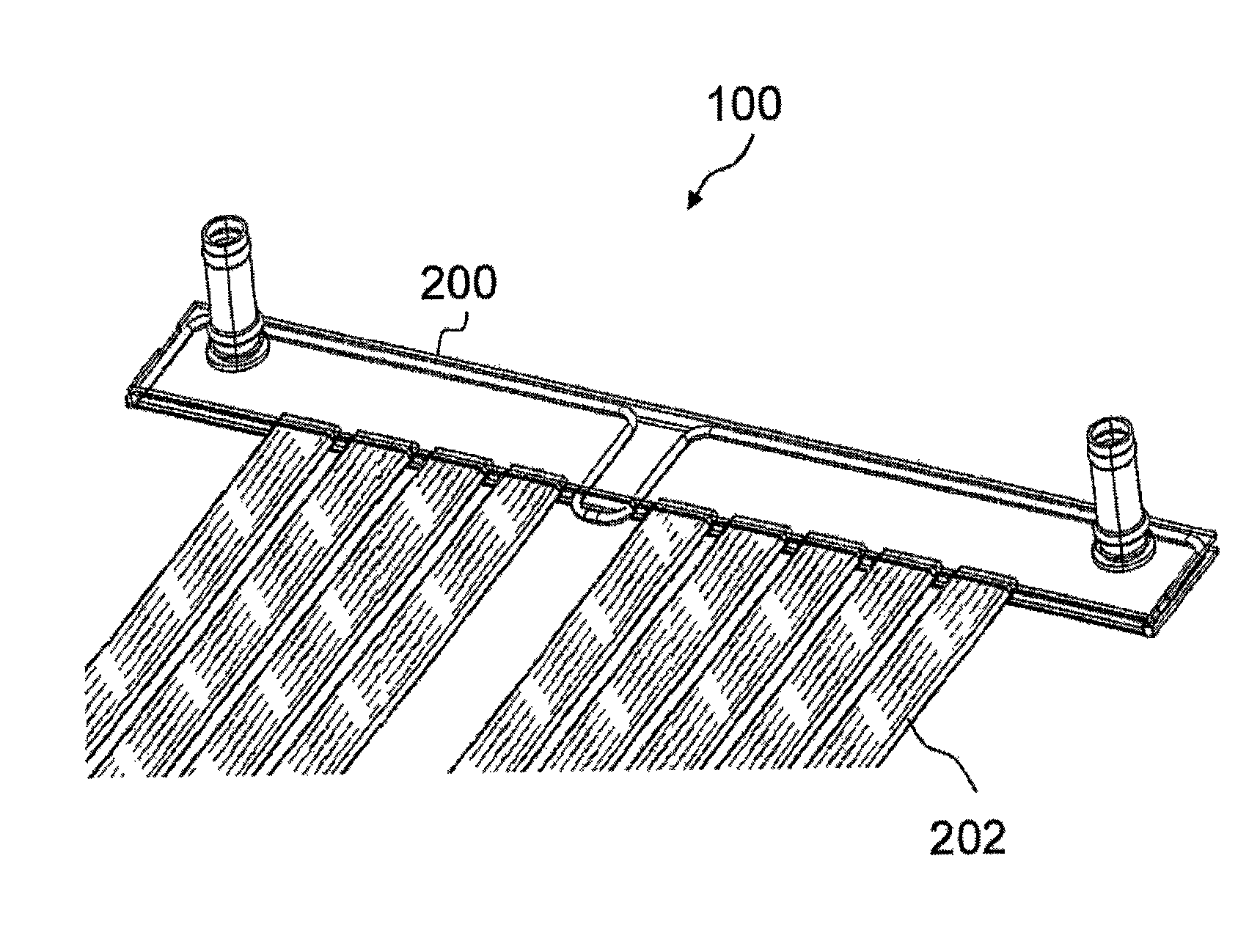

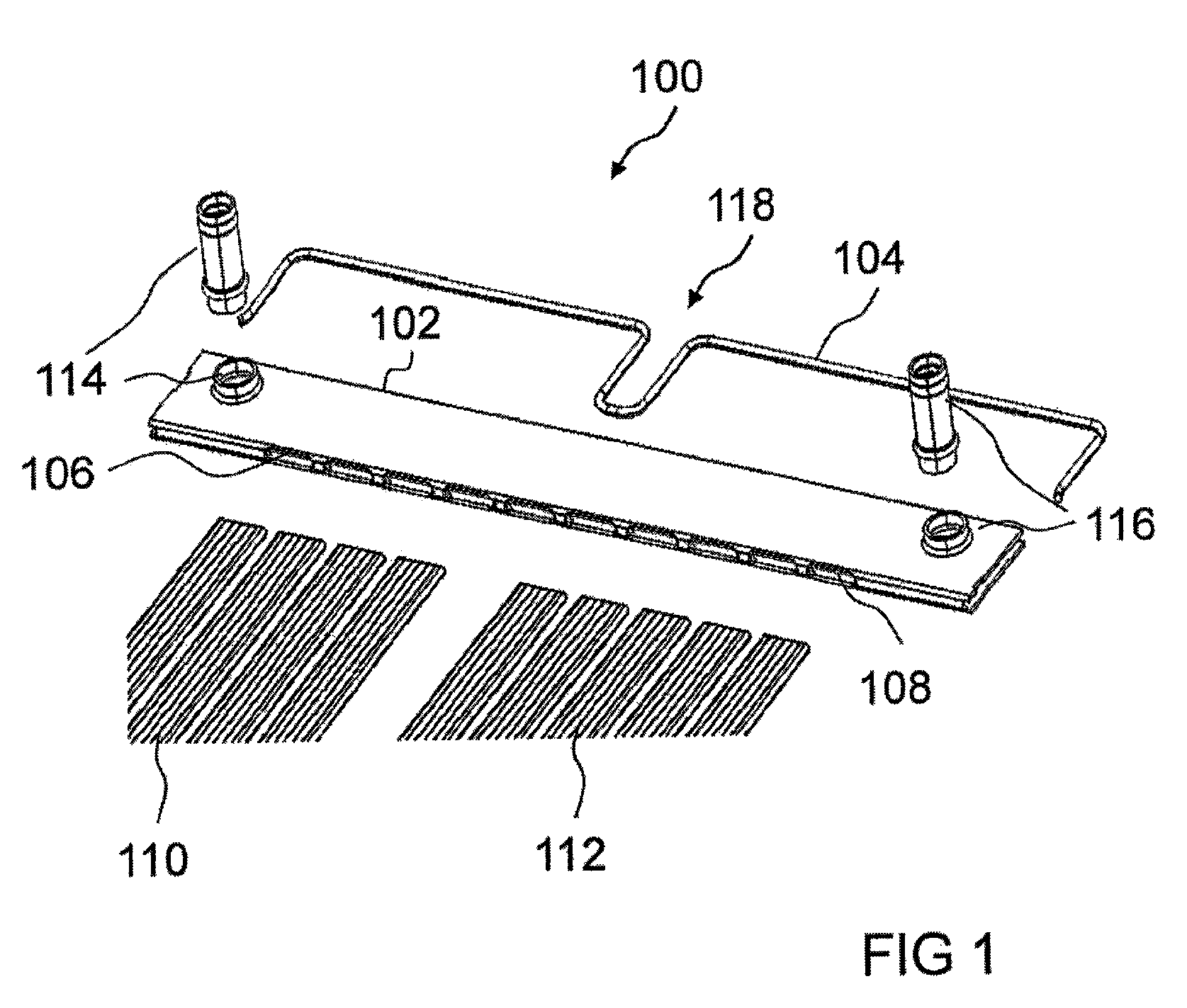

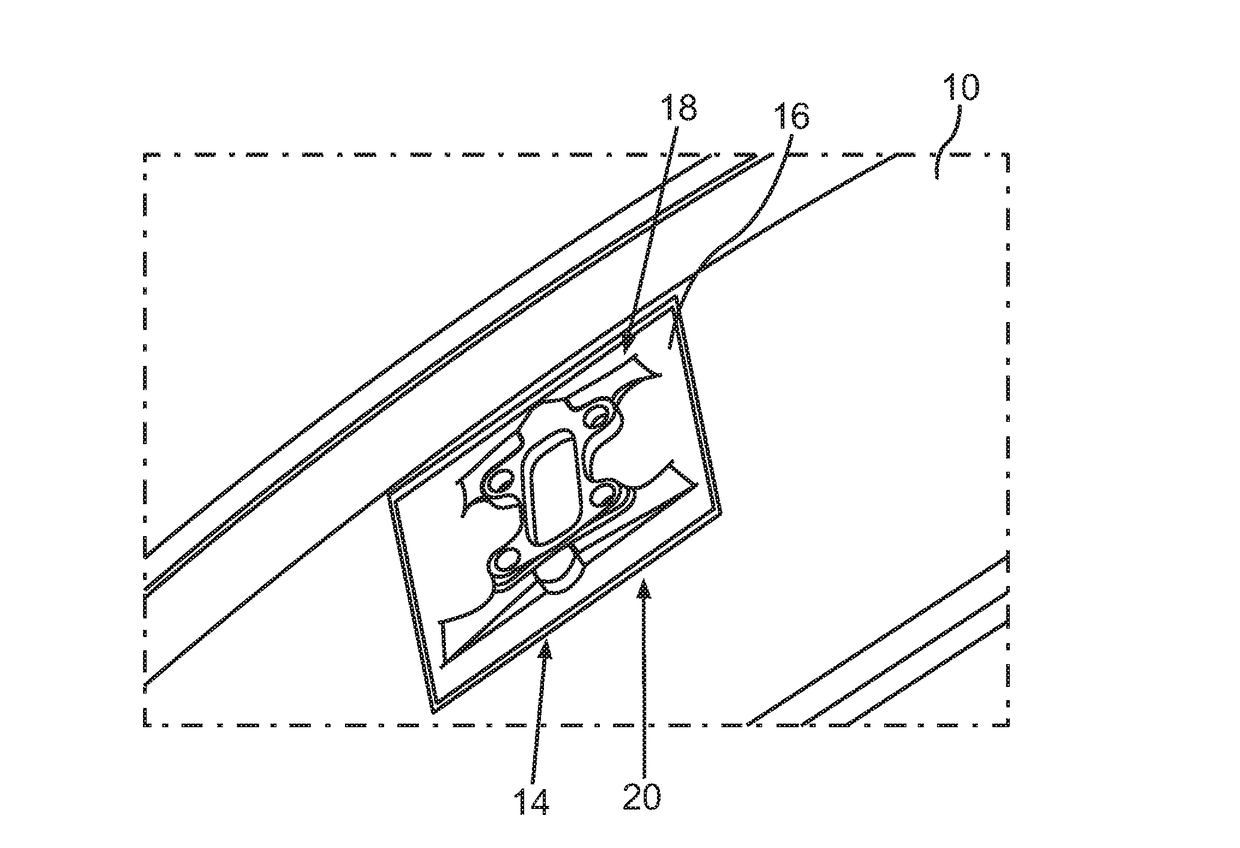

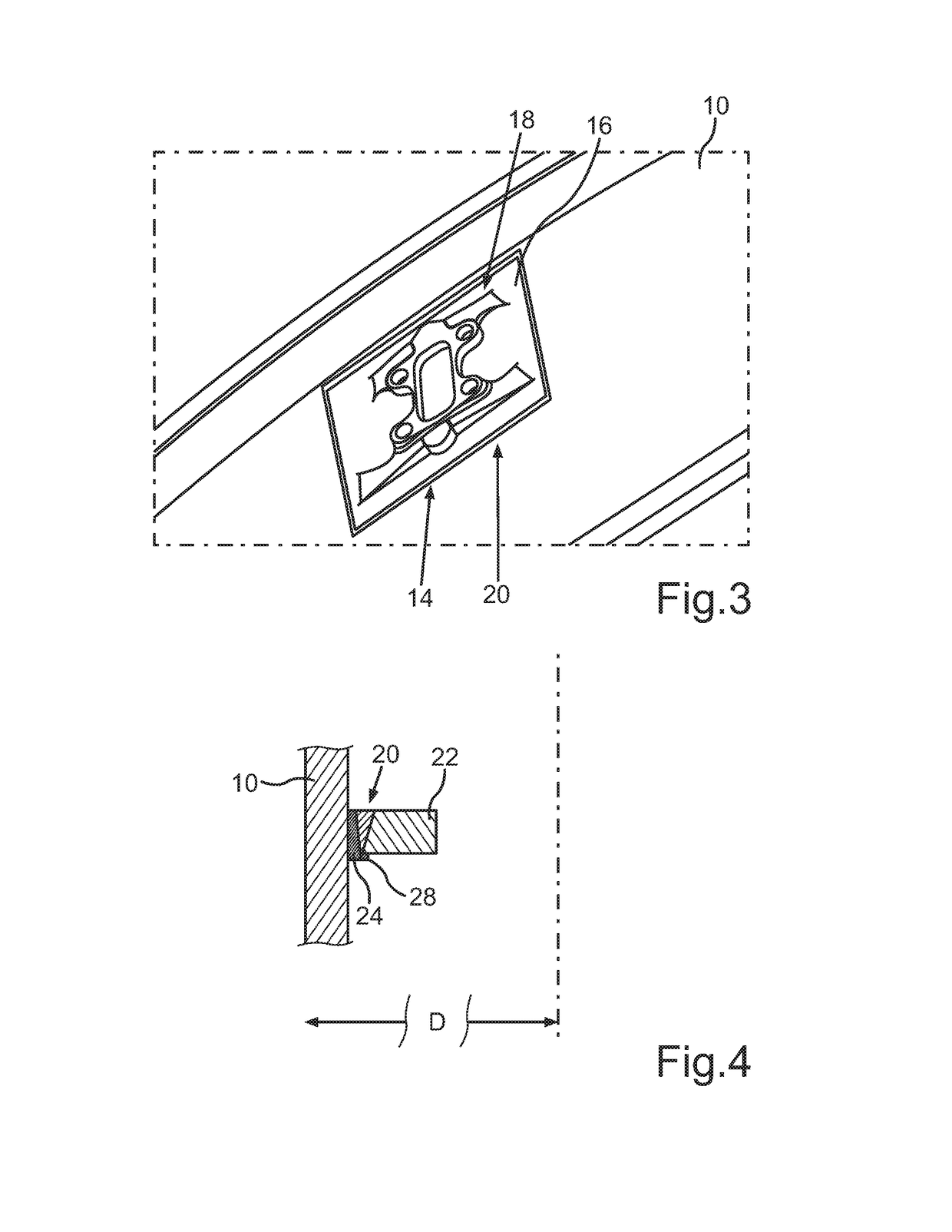

Accumulator for a cooling fluid and heat exchanger

ActiveUS20130014915A1Speed up heat exchangeEasy to manufactureCapsLarge containersPlate heat exchangerEngineering

An accumulator for a cooling fluid is provided that includes a floor. The floor has an interface for connecting a chamber of the accumulator to at least one cooling tube. The floor also has an opening that extends at least over a partial area of the chamber. The accumulator furthermore has a lid that is embodied in such a way as to seal the opening of the floor in a fluid-tight manner. The lid is embodied as wire or extrusion profile.

Owner:MAHLE INT GMBH

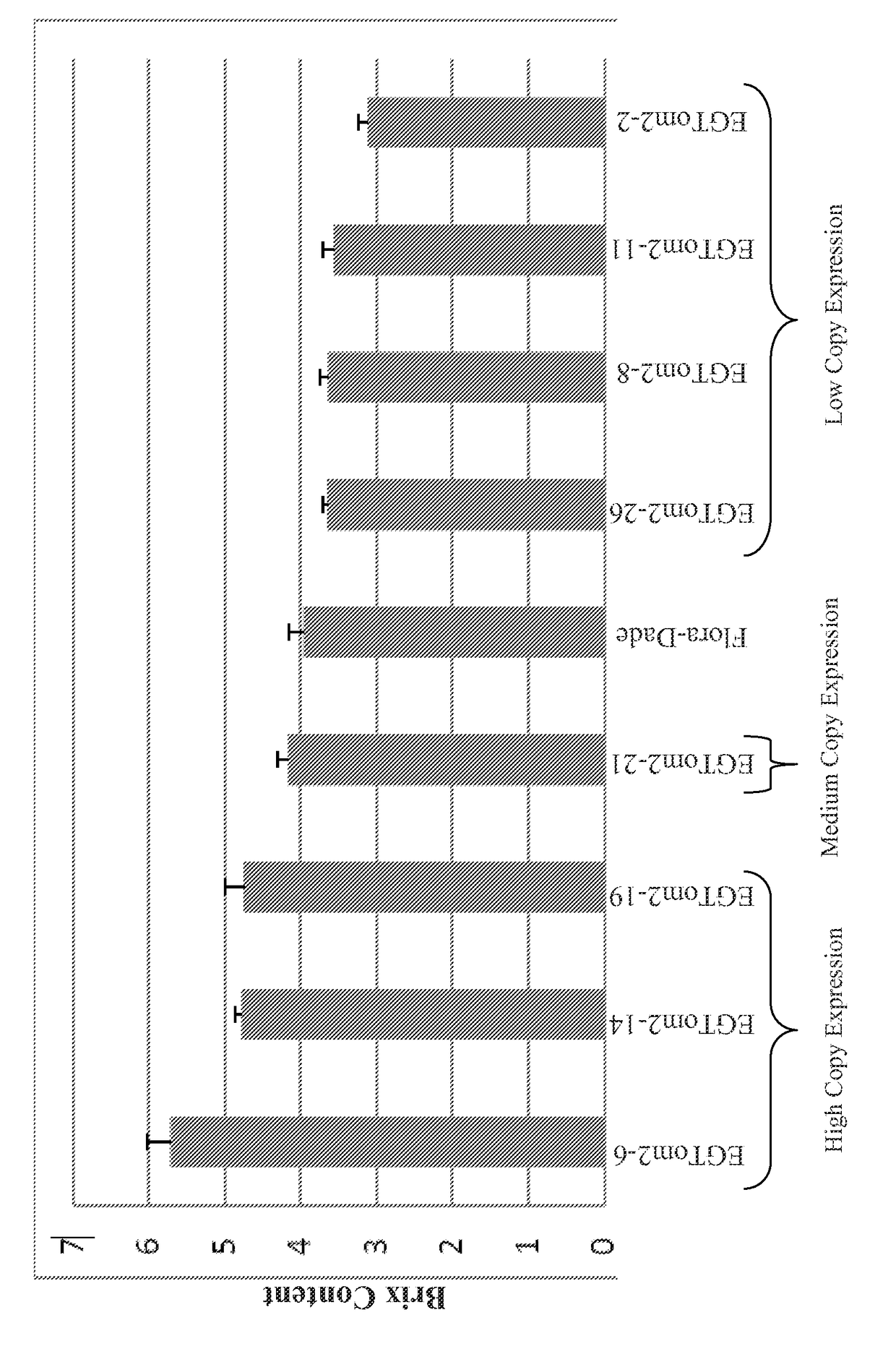

Identification and use of tomato genes controlling salt/drought tolerance and fruit sweetness

InactiveUS9862962B2Increase productionImprove adaptabilityPlant peptidesVector-based foreign material introductionSweetnessNucleic acid sequencing

The present invention provides the identification and use of EGTom1 and / or EGTom2, homologs of EGTom1 and / or EGTom2, orthologs of EGTom1 and / or EGTom2, paralogs of EGTom1 and / or EGTom2, and fragments and variations thereof for altering salt tolerance, drought tolerance and / or sugar content of fruit (sweetness) in plants. The invention relates to the identification and use of nucleic acid sequences for salt / drought tolerance and fruit sweetness in plants.

Owner:EG CROP SCI INC

Accumulator for a cooling fluid and heat exchanger

An accumulator for a cooling fluid is provided that includes a floor. The floor has an interface for connecting a chamber of the accumulator to at least one cooling tube. The floor also has an opening that extends at least over a partial area of the chamber. The accumulator furthermore has a lid that is embodied in such a way as to seal the opening of the floor in a fluid-tight manner. The lid is embodied as wire or extrusion profile.

Owner:MAHLE INT GMBH

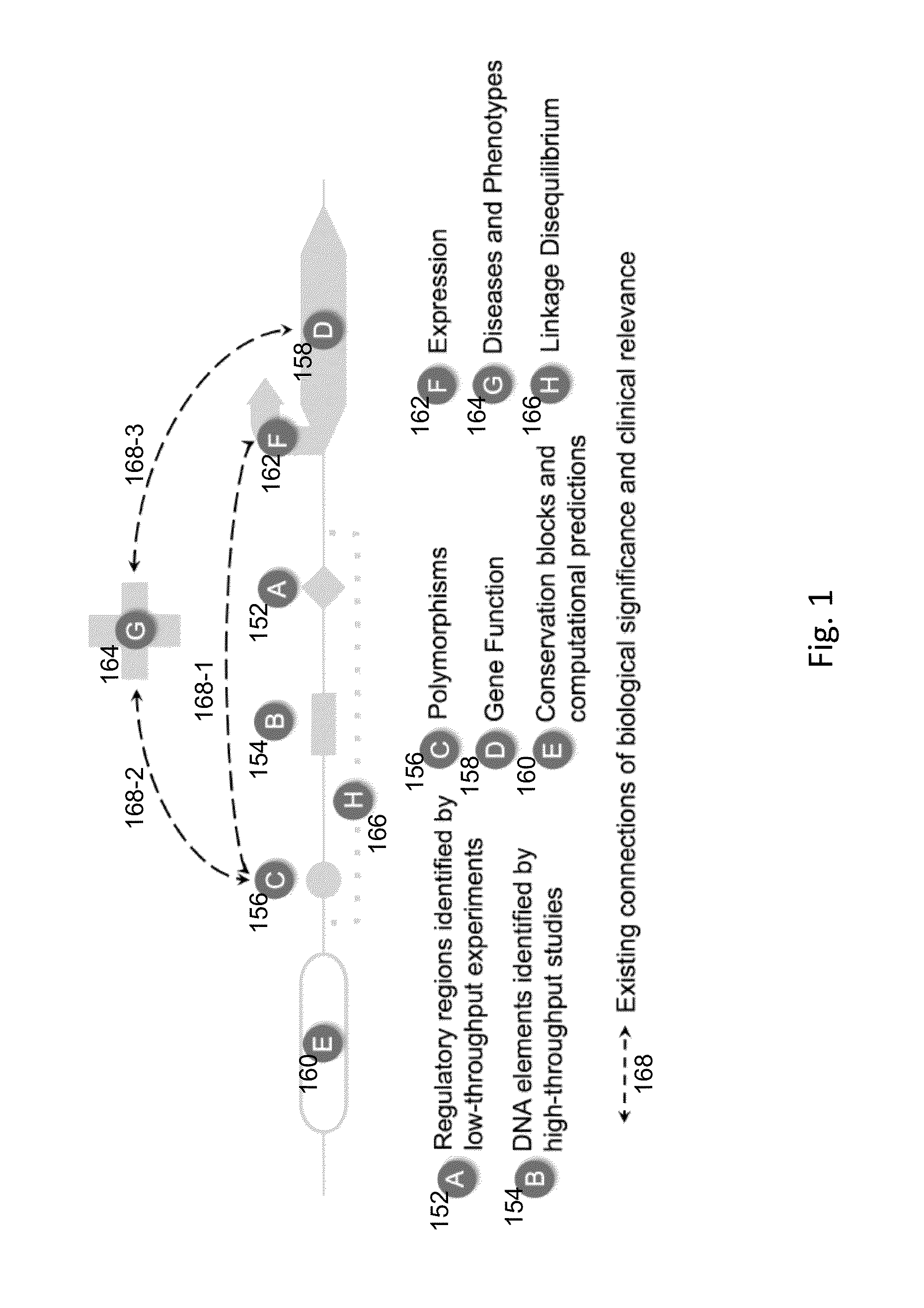

Method and System for the Use of Biomarkers for Regulatory Dysfunction in Disease

Measuring of the binding of a transcription factor (using, for example, chromatin immunoprecipitation) according to the present invention is provides an improved marker for a disease. These markers can be used in diagnostics for diseases where a transcription factor binding event plays a role. Additionally, they can be used to adjust disease risk profiles for healthy individuals as with typical genetic variants.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

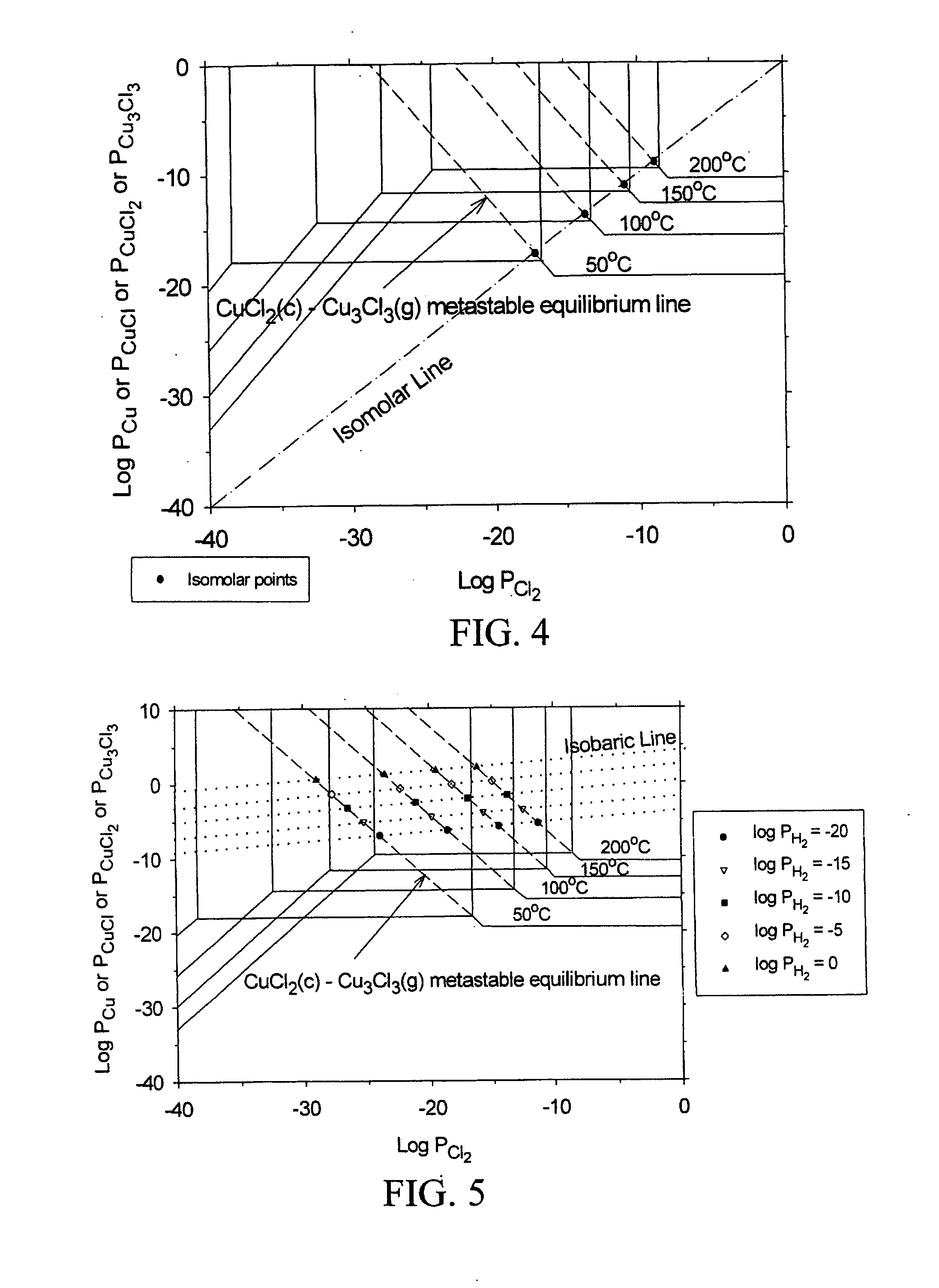

Adapter for electrical plug-in connections on fuel-injection valves

InactiveUS20030134531A1Firmly connectedRapid and cost-effectiveFuel injection apparatusCouplings bases/casesFuel injectionElectrical and Electronics engineering

An adapter (1) is described for connecting an electrical plug-in connector (4) of a fuel injector to a counterplug (6), whose first end (3) is pluggable into a plug-in connector (4) of the fuel injector and whose second end (5) is pluggable into counterplug (6) of the electrical line. A first seal (7) being positioned between the first end (3) of the adapter (1) and the plug-in connector (4) of the fuel injector and a second seal (8) being positioned between the second end (5) of the adapter (1) and the counterplug (6).

Owner:ROBERT BOSCH GMBH

Oil-repellent film forming method, motor manufacturing method and motor

InactiveUS7973440B2Reduce distortionRapid and cost-effectiveBearing assemblyManufacturing dynamo-electric machinesMaterials scienceAc current

A method is for forming an oil-repellent film on a metallic part in a dynamic fluid pressure bearing mechanism used for a motor. The method includes applying a flowable oil-repellent agent on an application region of the metallic part; arranging an induction coil in the vicinity of the metallic part; and affixing the oil-repellent agent onto the metallic part by applying an induction heating to the metallic part by supplying an AC current with a frequency of about 5 to 100 kHz to the induction coil. Further, a motor includes a dynamic fluid pressure bearing mechanism including a metallic part on which an oil-repellent film is formed by the above method; a stator unit; and a rotor unit supported by the dynamic fluid pressure bearing mechanism in a manner rotatable with respect to the stator unit.

Owner:NIDEC CORP

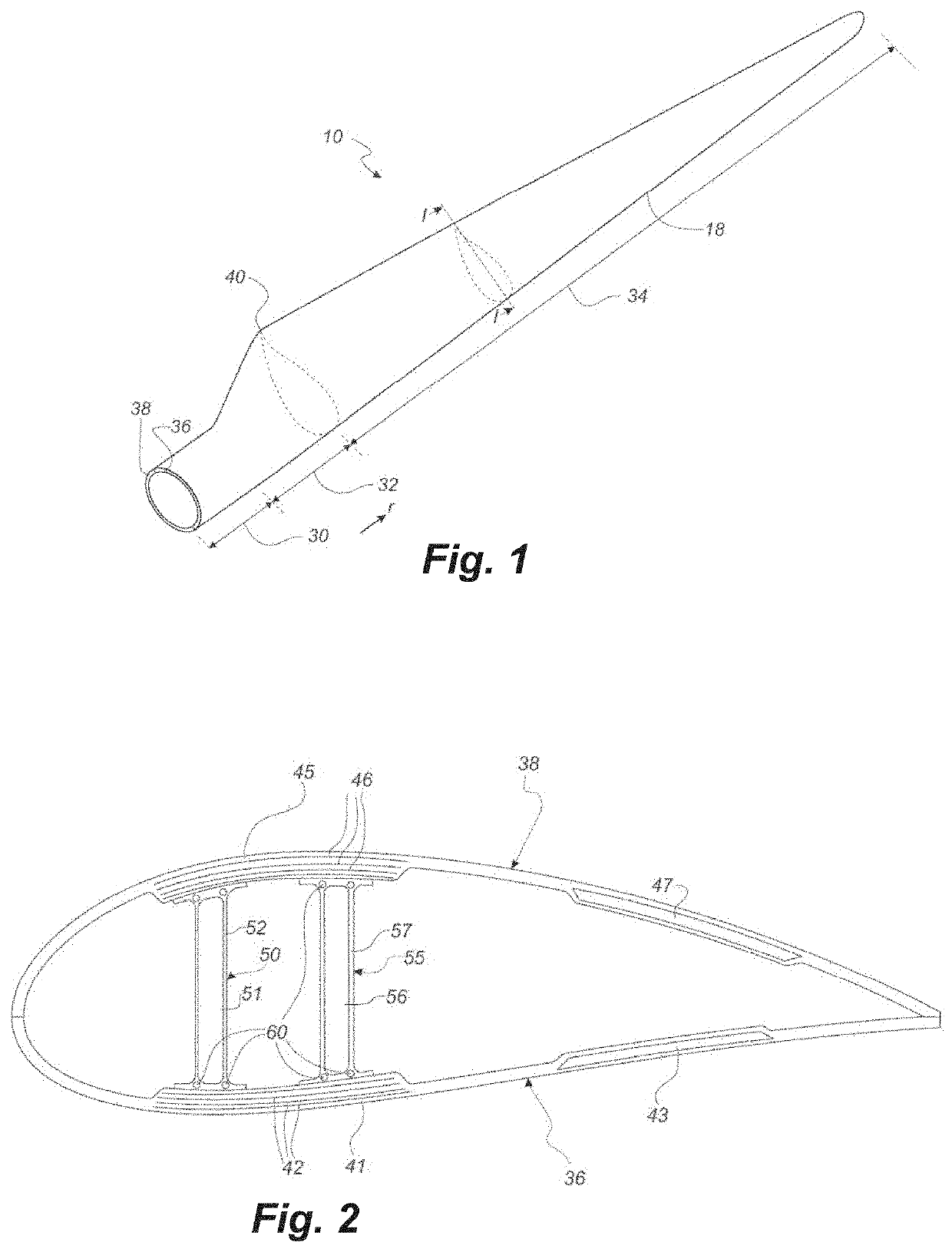

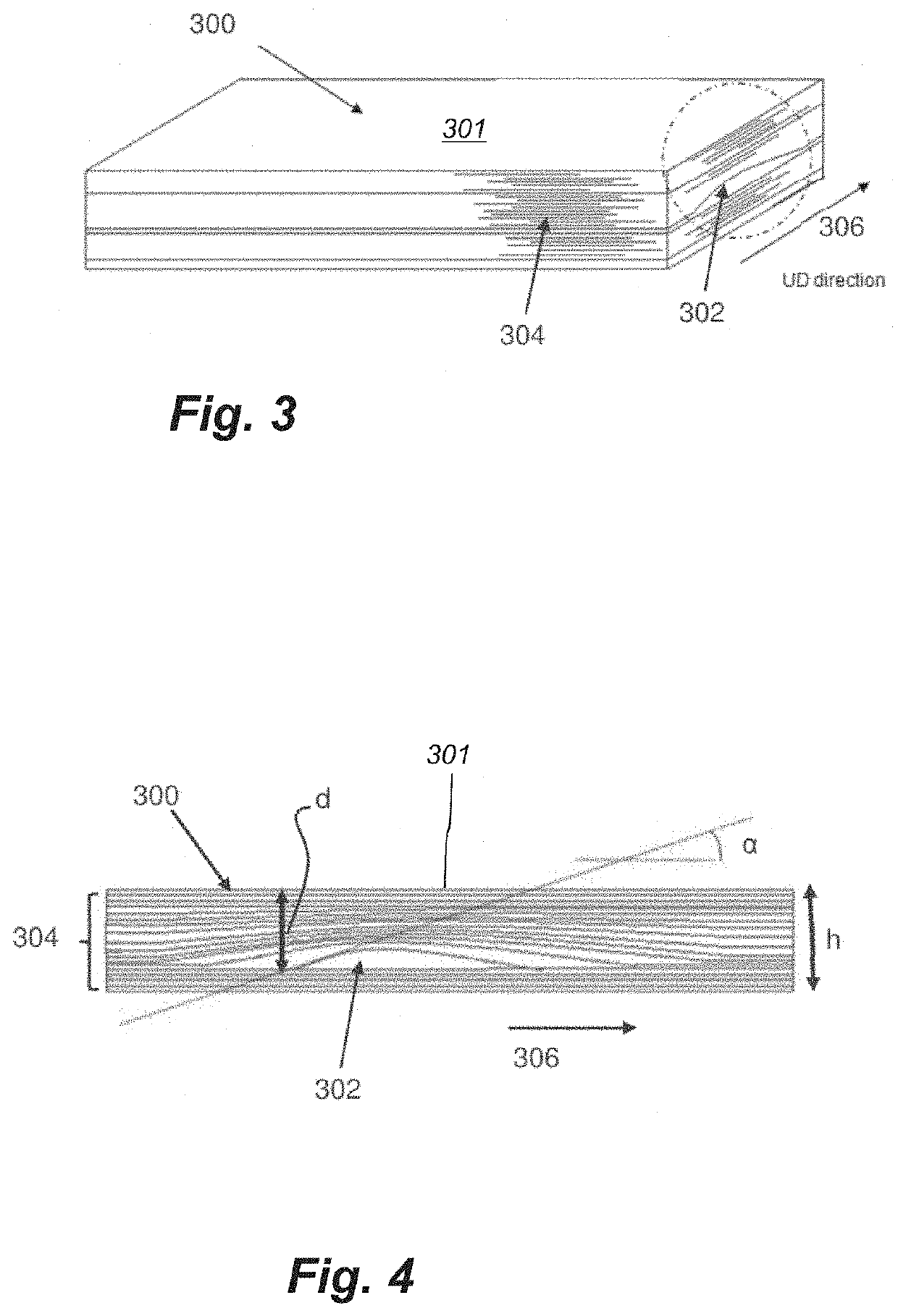

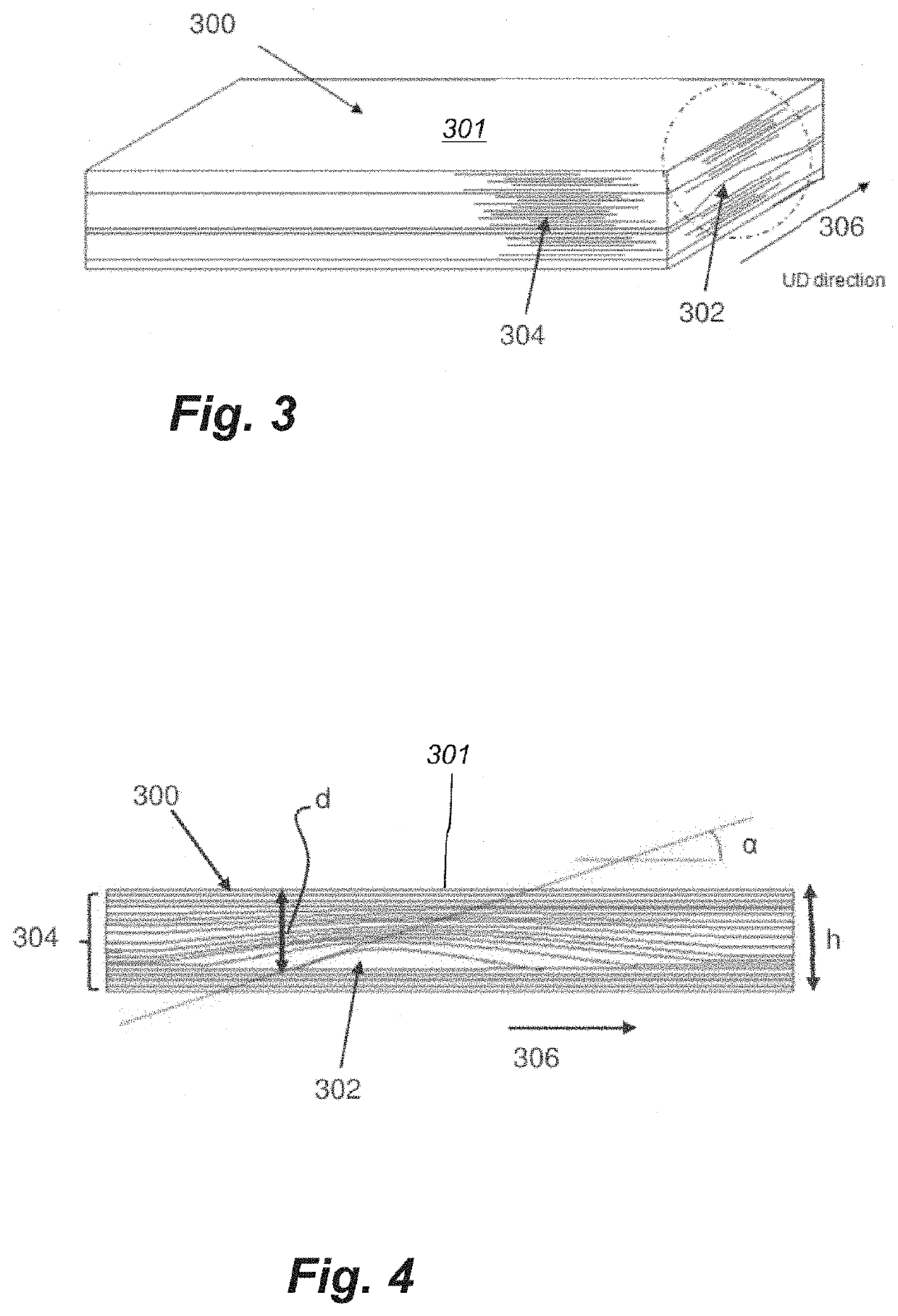

Dual scan method for detecting a fibre misalignment in an elongated structure

ActiveUS20200158664A1Less time-consumingMore cost-effectiveFinal product manufactureUsing optical meansTurbine bladeDual Scan

The present disclosure relates to a method for detecting a fibre misalignment in an elongated structure, such as a wind turbine blade component. The elongated structure has a length along a longitudinal direction and comprises a plurality of stacked reinforcing fibre layers. The plurality of fibre layers comprises fibres having an orientation aligned, unidirectionally, substantially in the longitudinal direction. The method comprises scanning a surface of the elongated structure for identifying one or more surface irregularities, selecting one or more regions of interest comprising said one or more surface irregularities, examining said region of interest using penetrating radiation, and determining a position and / or size of the fibre misalignment based on said examining step.

Owner:LM WIND POWER US TECH APS

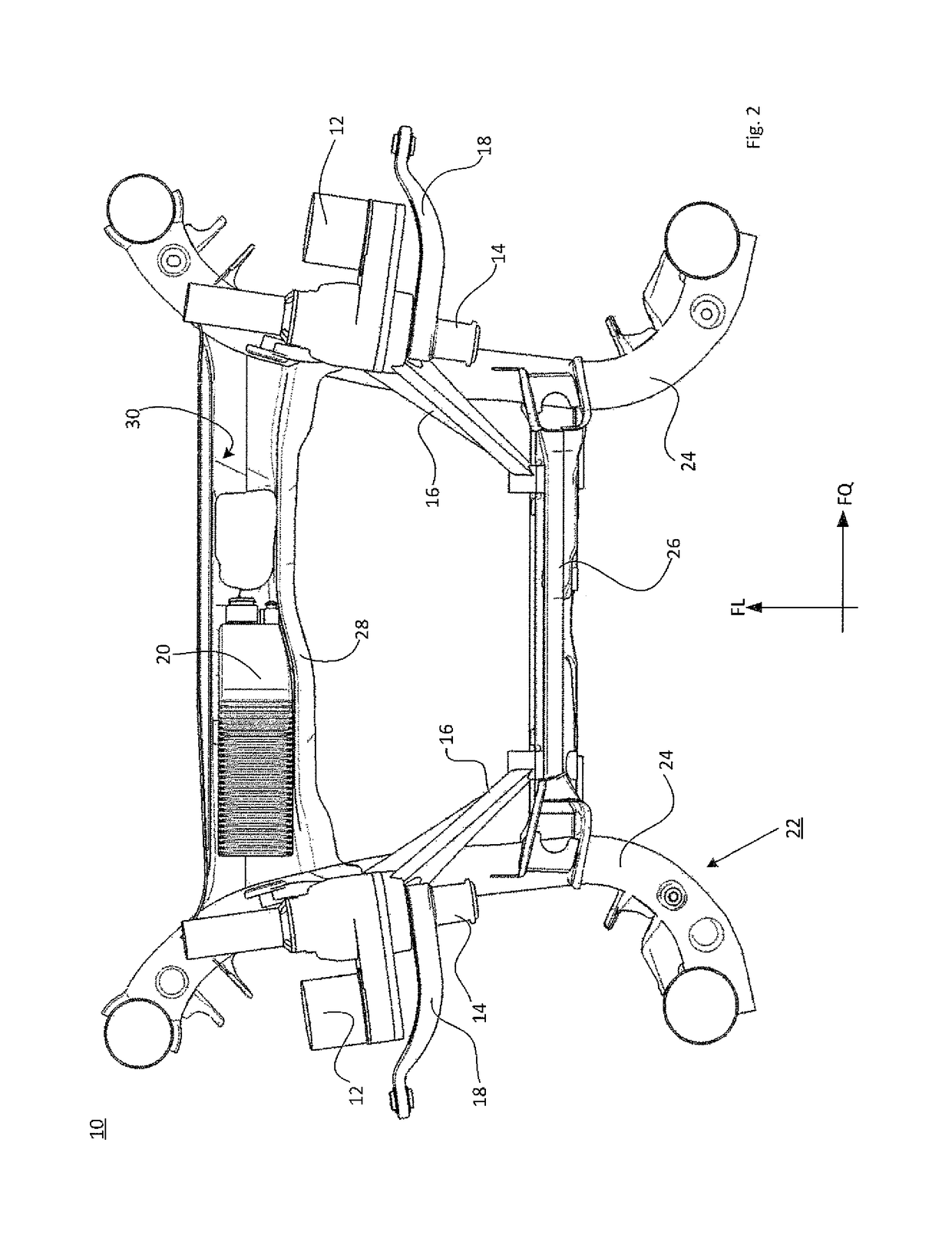

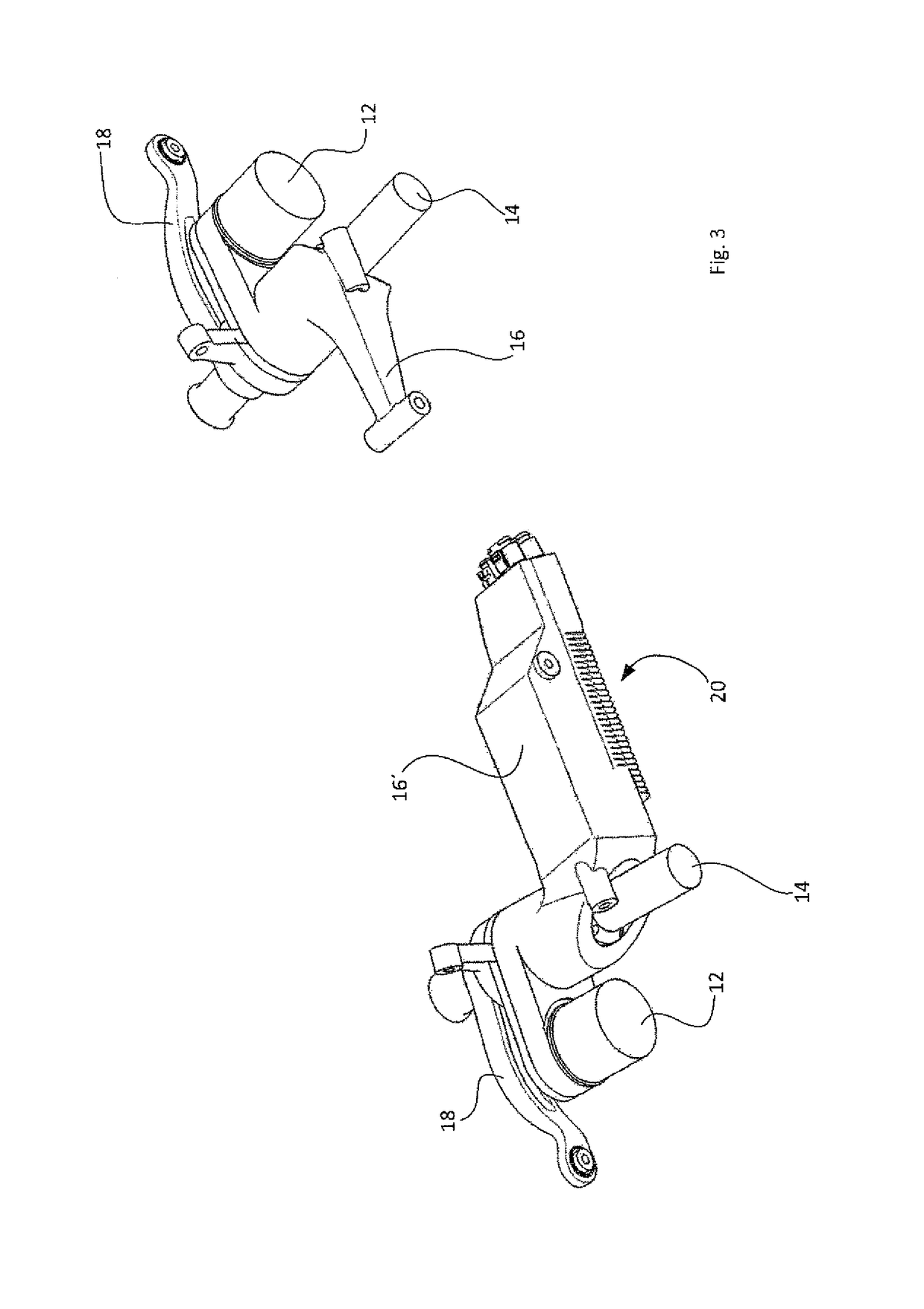

Actively adjustable wheel suspension for the wheels of an axle of a motor vehicle

ActiveUS10166833B2Excessive overall dimensionRapid and cost-effectiveUnderstructuresResilient suspensionsMotorized vehicleControl theory

An actively adjustable wheel suspension for the wheels of an axle of a motor vehicle, wherein each wheel is articulated on the body side of the motor vehicle via a plurality of wheel control elements, includes for each wheel on the axle a rotary actuator which is supported on the body side and includes a torsion bar. The two rotary actuators can be activated for active adjustment via a control unit, with the rotary actuators and the torsion bars of the rotary actuators being oriented in motor vehicle longitudinal direction. The rotary actuators include each at least one strut, which is oriented in motor vehicle transverse direction, for torque support.

Owner:AUDI AG

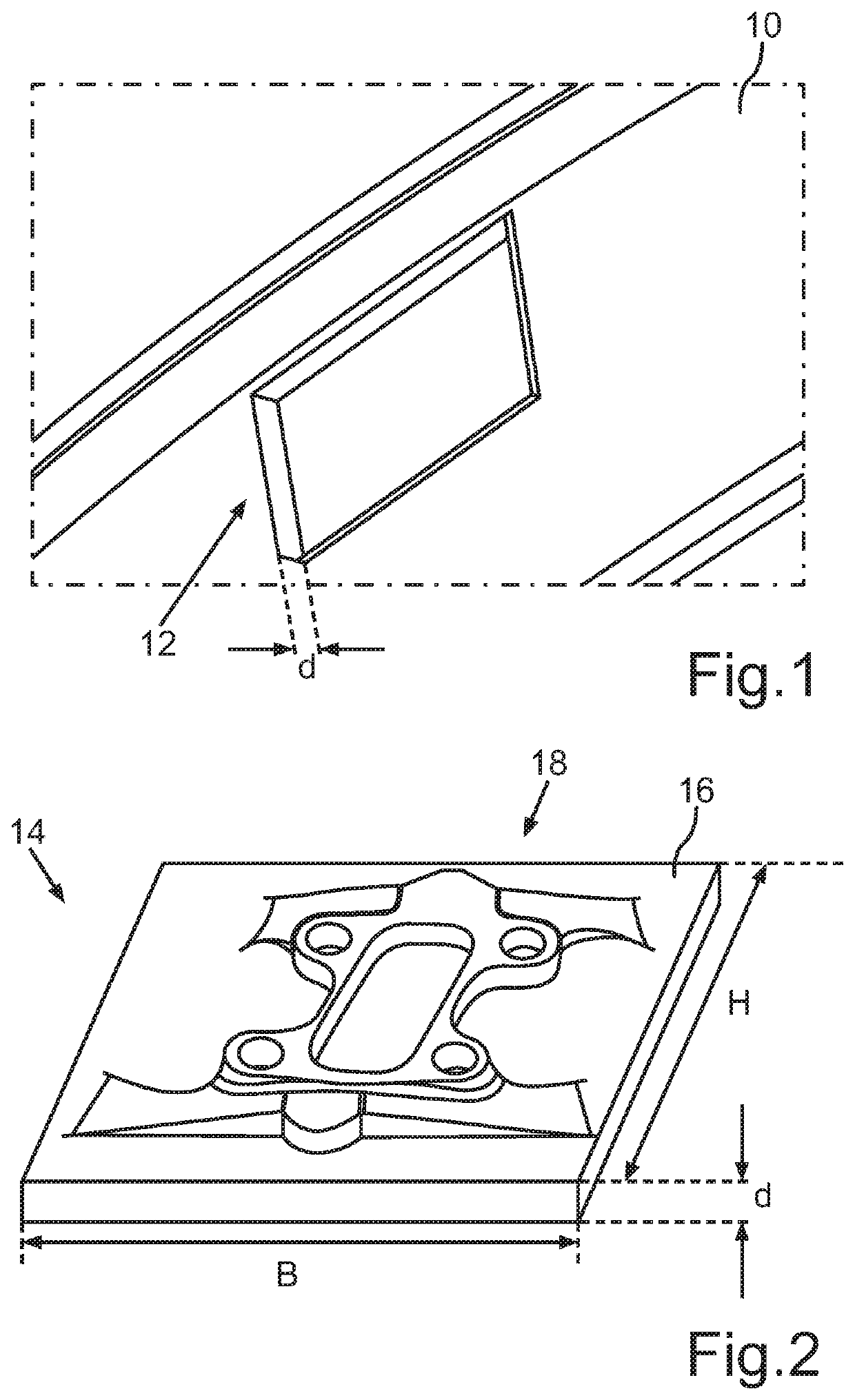

Method for manufacturing a housing of a turbomachine and turbomachine housing

ActiveUS20170276023A1Rapidly and cost-effectively manufacturedRapid and cost-effectiveTurbinesAdditive manufacturing apparatusEngineeringGas turbines

The invention relates to a method for manufacturing a housing of a turbomachine, in particular a gas turbine. The method comprises at least the steps: providing a housing blank (10), manufacturing a housing element (14), producing an assembly opening (12) corresponding to the housing element (14) in the housing blank (10), arranging the housing element (14) in the assembly opening (12), and joining the housing element (14) to the housing blank (10) by means of a welding method. In addition, the invention relates to a turbomachine housing.

Owner:MTU AERO ENGINES GMBH

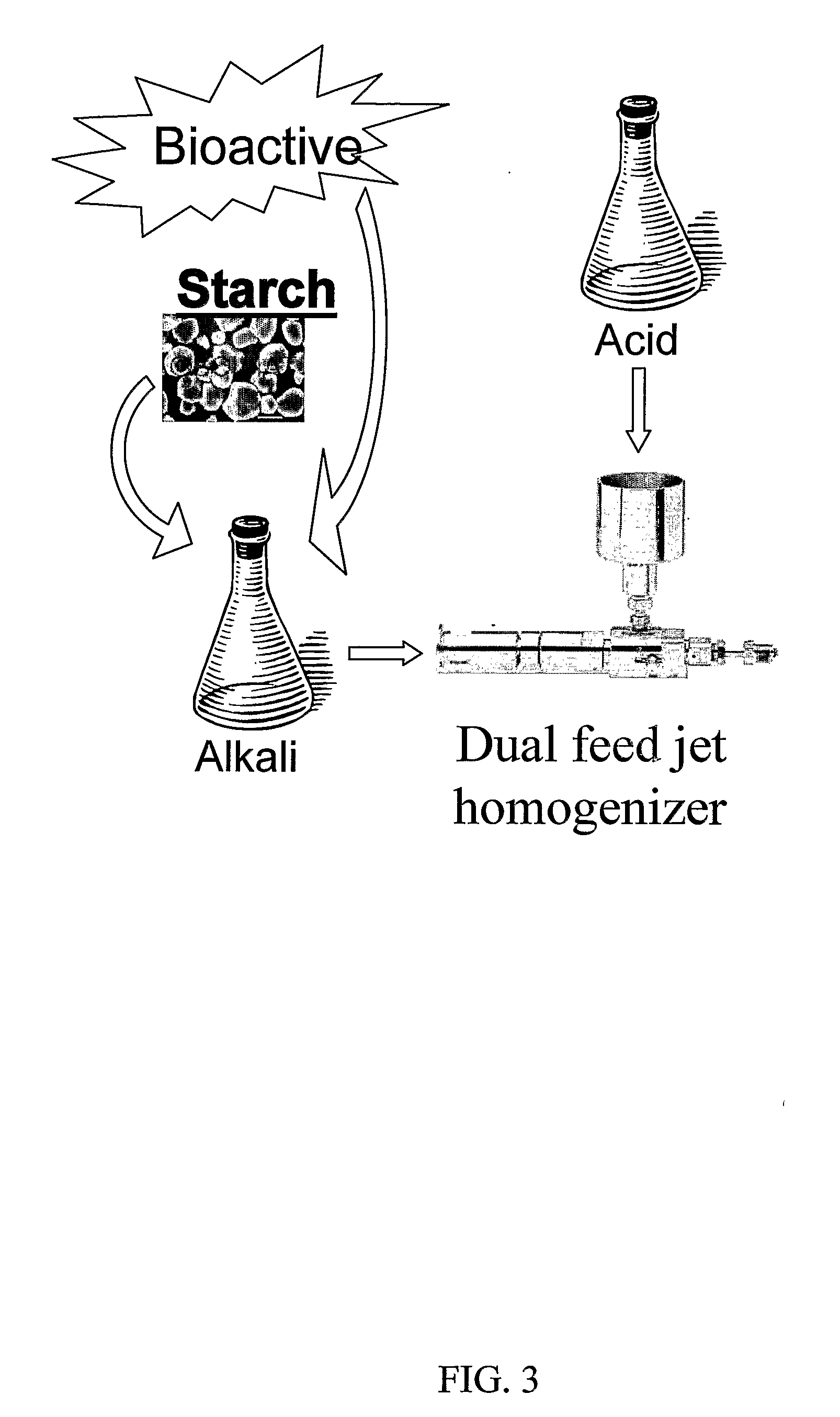

Non-covalent complexes of bioactive agents with starch for oral delivery

InactiveUS20100008982A1Efficiently and reliably generatingReadily converted to dry compositionBiocidePowder deliveryIntestinal structureActive agent

The present invention relates to particles comprising non-covalent complexes which comprise starch and an active agent and dry compositions containing such particles for the oral delivery of the active agents. Preferably the particles are degraded and release the active agent within the intestines, protecting the active agent from degradation in the stomach. The present invention further relates to methods for preparing suspensions of these particles having a uniform particle size in the range of several microns.

Owner:TECHNION RES & DEV FOUND LTD

Method and device for driving a multiplicity of piles into a seabed

ActiveUS8696248B2Rapid and cost-effectiveRapid of pluralityArtificial islandsWind motor supports/mountsEngineeringSeabed

A plurality of piles is arranged in frame elements in an axially displaceable manner. Hammers are positioned on the piles. After driving of the piles into a seabed, the hammers are connected to the frame elements, wherein the frame elements together with the hammers are lifted to the surface of the water and to the seaborne vessel by a crane.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

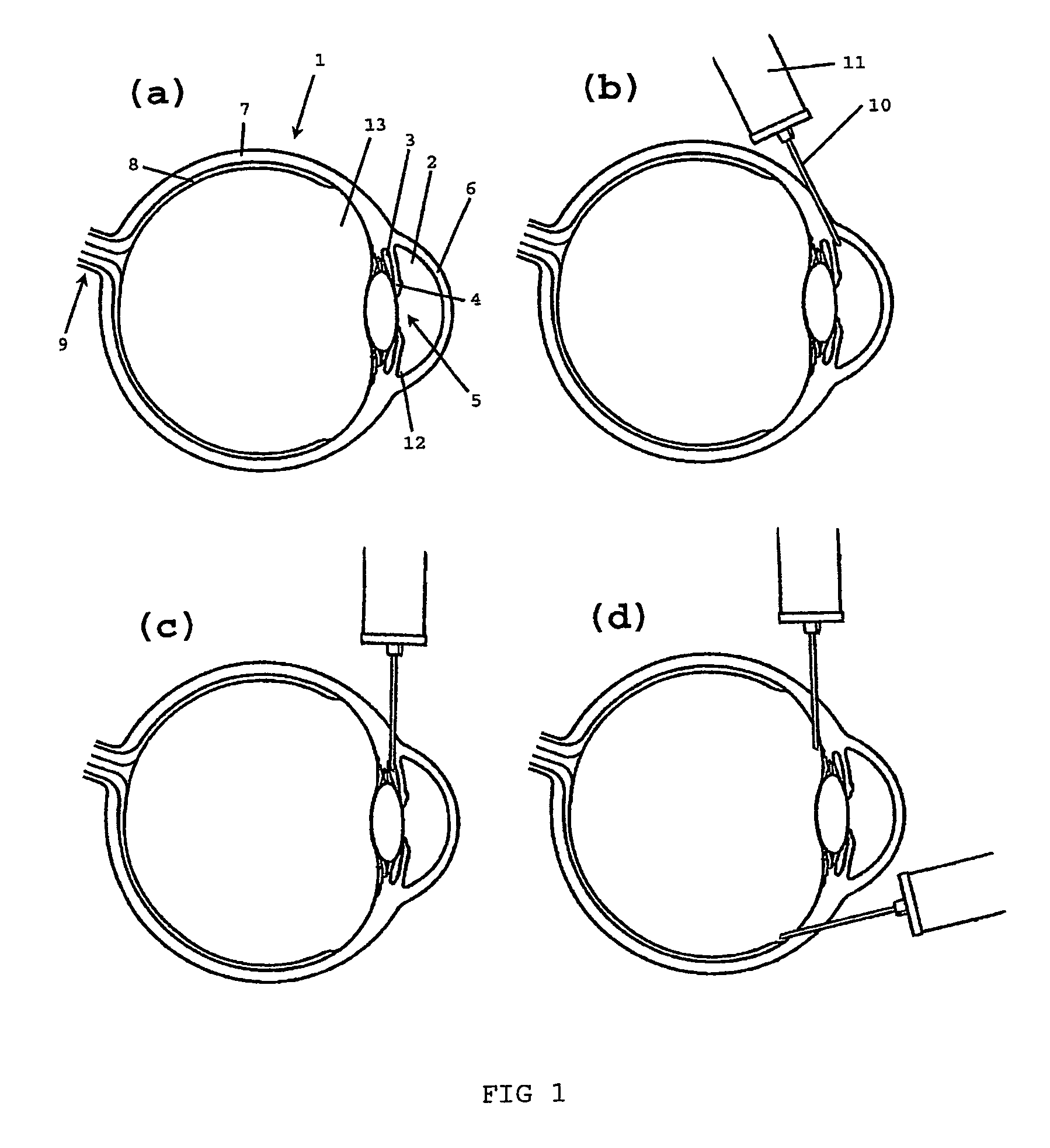

Use of a viscoelastic composition for treating increased intraocular pressure

ActiveUS8721622B2Increase pressureRapid and cost-effectiveSenses disorderPharmaceutical delivery mechanismIntraocular pressureFistula

A viscoelastic medium is useful for the manufacture of a medicament, such as a medical device, for treatment of increased intraocular pressure in the eye of a human or animal. The medicament is administerable into at least one sclerally penetrating fistula of the eye such that the fistula is filled with the medicament. The medium is also useful in a method of treating increased intraocular pressure in the eye of a human or an animal in need thereof, comprising the step of injecting the viscoelastic medium into at least one sclerally penetrating fistula in the eye such that the fistula is filled with the medium.

Owner:Q MED AB

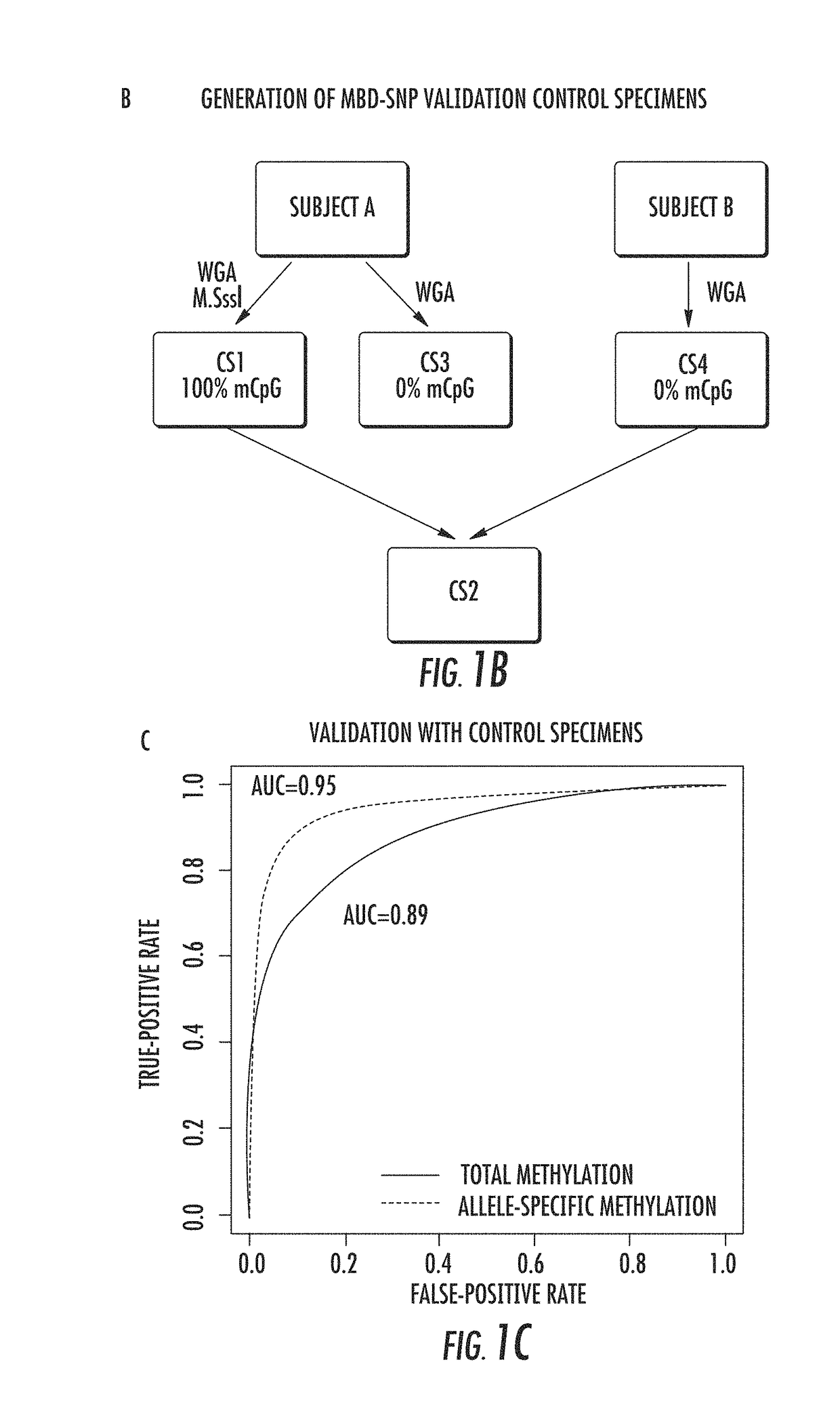

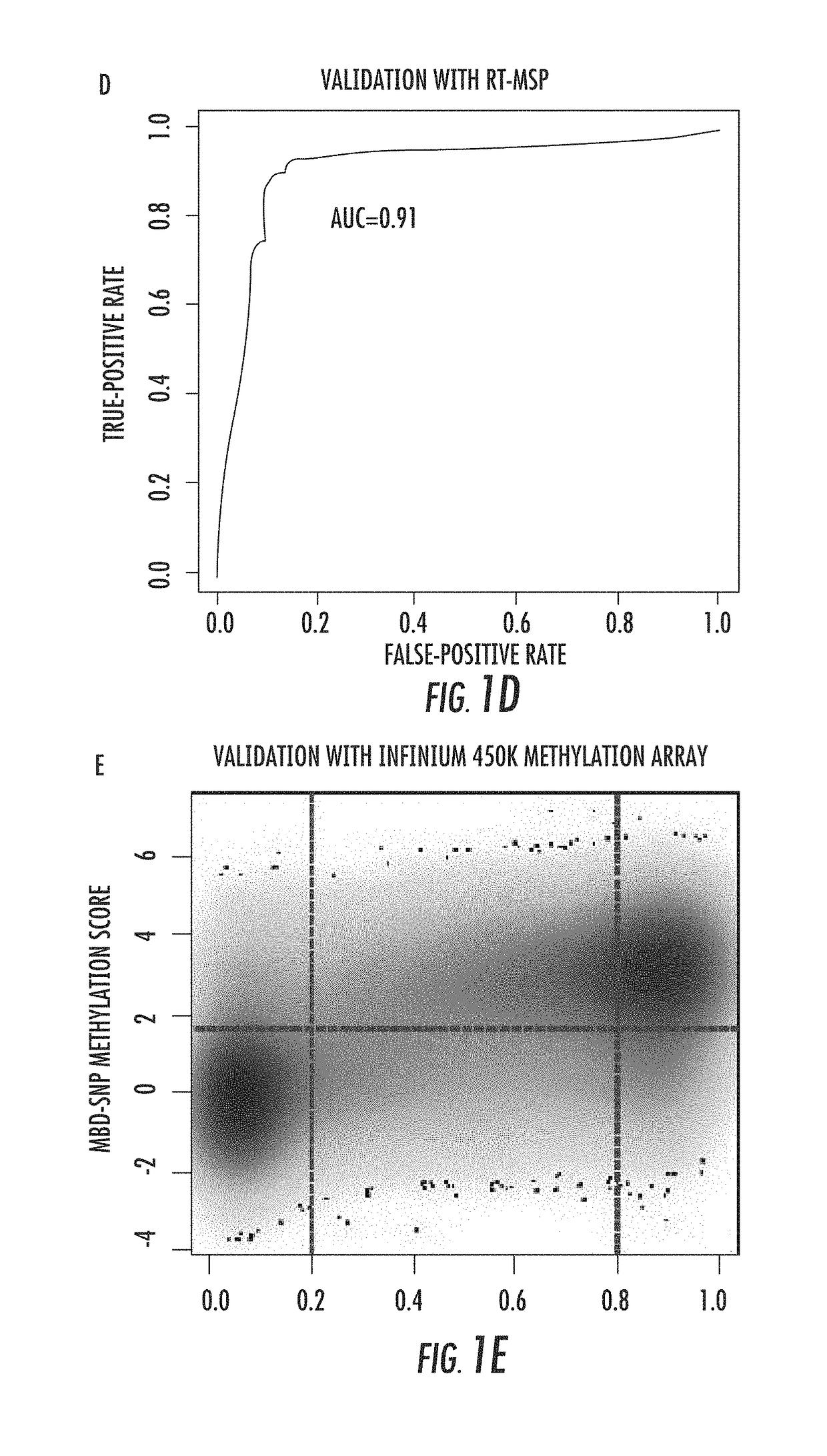

DNA methylation markers for metastatic prostate cancer

ActiveUS20180100196A1Rapid and cost-effectiveMicrobiological testing/measurementDNA methylationGenome scale

The present invention relates to the field of cancer. More specifically, the present invention provides methods and compositions useful for assessing prostate cancer. In a specific embodiment, present inventors have developed and applied a new technology and associated computation methods enabling simultaneous genome-scale analysis of genetic (copy number) and epigenetic (total methylation (TM) and allele-specific methylation (ASM) alternation, This method, called MBD-SNP, features affinity enrichment or methylated genomic DNA fragments using a methyl-binding domain polypeptide.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

Method and system for the use of biomarkers for regulatory dysfunction in disease

Measuring of the binding of a transcription factor (using, for example, chromatin immunoprecipitation) according to the present invention is provides an improved marker for a disease. These markers can be used in diagnostics for diseases where a transcription factor binding event plays a role. Additionally, they can be used to adjust disease risk profiles for healthy individuals as with typical genetic variants.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Wall for receiving wear plates and method for replacing wear plates

ActiveUS20150336742A1Absorbs stressRapid and cost-effectiveConveyorsPackagingEngineeringMechanical engineering

Owner:TAKRAF

Dual scan method for detecting a fibre misalignment in an elongated structure

ActiveUS11054373B2Less time-consumingMore cost-effectiveFinal product manufactureUsing optical meansTurbine bladeDual Scan

The present disclosure relates to a method for detecting a fibre misalignment in an elongated structure, such as a wind turbine blade component. The elongated structure has a length along a longitudinal direction and comprises a plurality of stacked reinforcing fibre layers. The plurality of fibre layers comprises fibres having an orientation aligned, unidirectionally, substantially in the longitudinal direction. The method comprises scanning a surface of the elongated structure for identifying one or more surface irregularities, selecting one or more regions of interest comprising said one or more surface irregularities, examining said region of interest using penetrating radiation, and determining a position and / or size of the fibre misalignment based on said examining step.

Owner:LM WIND POWER US TECH APS

Method for manufacturing a housing of a turbomachine and turbomachine housing

ActiveUS10634008B2Rapidly and cost-effectively manufacturedRapid and cost-effectiveTurbinesAdditive manufacturing apparatusGas turbinesIndustrial engineering

The invention relates to a method for manufacturing a housing of a turbomachine, in particular a gas turbine. The method comprises at least the steps: providing a housing blank, manufacturing a housing element, producing an assembly opening corresponding to the housing element in the housing blank, arranging the housing element in the assembly opening, and joining the housing element to the housing blank by means of a welding method. In addition, the invention relates to a turbomachine housing.

Owner:MTU AERO ENGINES GMBH

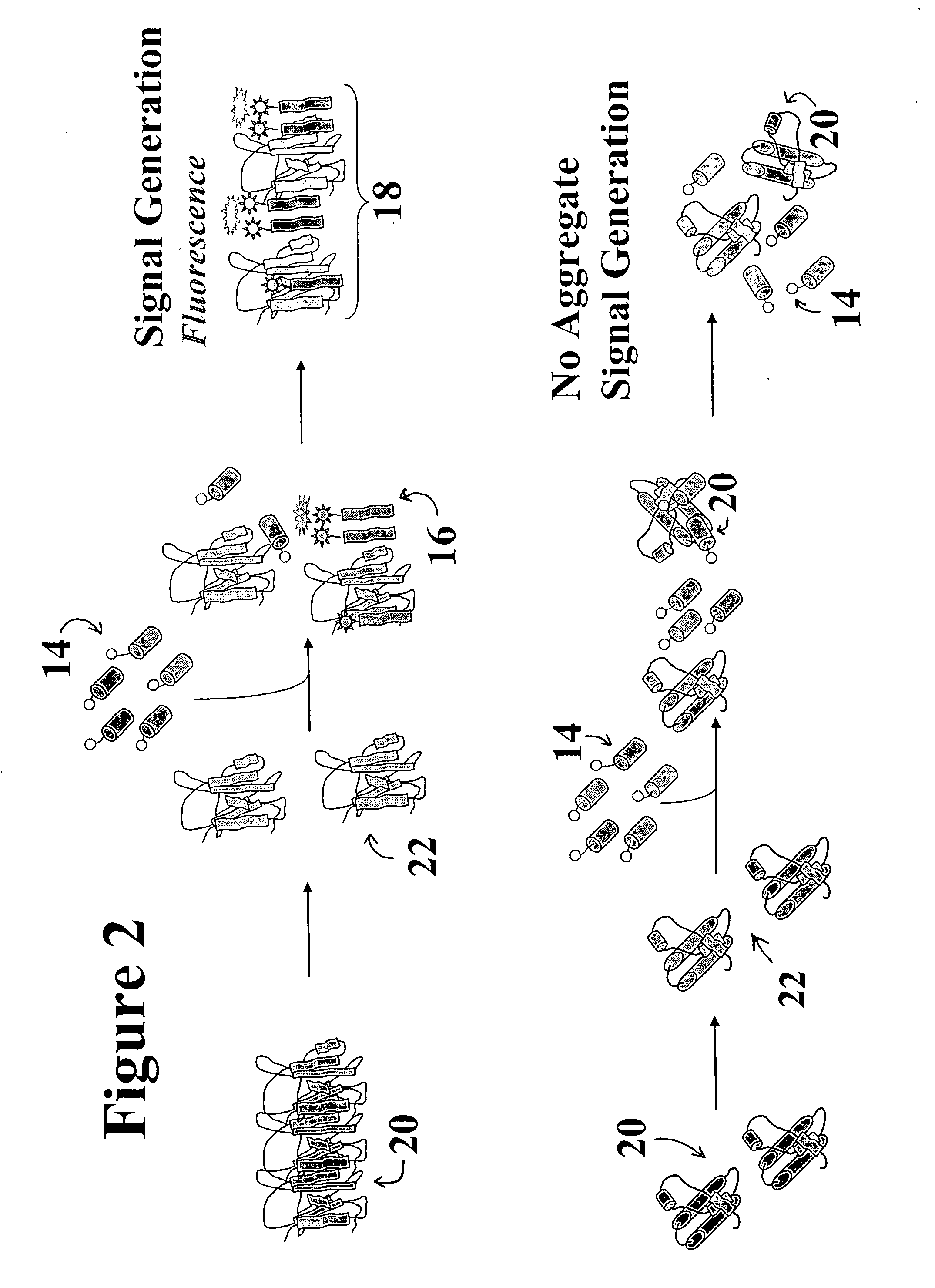

Methods for Detecting and Measuring Specific Nucleic Acid Sequences

InactiveUS20140106983A1Rapid and cost-effectiveSimple methodMicrobiological testing/measurementLibrary screeningFluorophoreNucleic acid sequencing

The invention provides novel oligonucleotides and methods of using the same for detection or measurement of specific nucleic acid molecules. The invention also features nucleic acid arrays comprising the oligonucleotides of the invention. An oligonucleotide of the invention comprises (1) a reporter-binding sequence capable of hybridizing to a fluorrophore-labeled reporter sequence and (2) a hairpin-forming sequence capable of forming a stem-loop. Formation of the stem-loop modifies (e.g., quenching) the fluorescence signals of the reporter sequence when the reporter sequence is hybridized to the oligonucleotide. This can be achieved, for example, by bringing one or more guanine based in the oligonucleotide into close proximity to the fluorophore(s) of the reporter sequence by virtue of the formation of the stem-loop. Disruption of the stem-loop, such as by hybridization of a target sequence to at least part of the hairpin-forming sequence, produces a detectable change in the fluorescence signals.

Owner:BOARD OF RGT NEVADA SYST OF HIGHER EDUCATION ON BEHALF OF THE UNIV OF NEVADA RENO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com