Low-fat, low-sugar and high-protein chocolate product and preparation method thereof

A chocolate and high-protein technology, applied in the field of food processing, can solve the problems of high fat and sugar content, achieve the effects of reducing whitening, increasing crispness, and improving appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

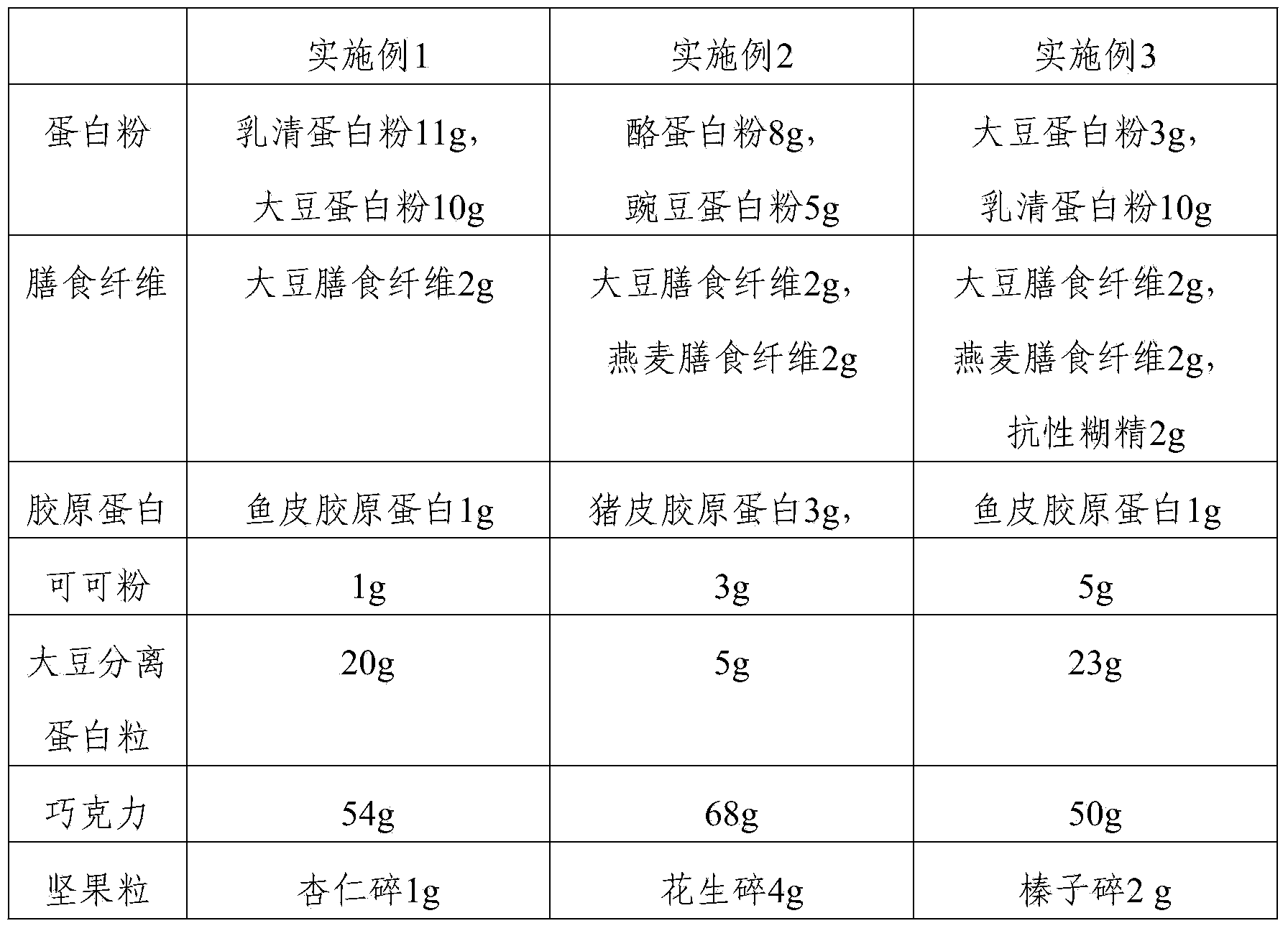

[0036] 1) Accurately weigh the ingredients in Table 1;

[0037] 2) Melt the chocolate at low temperature, the melting temperature is 25°C to form a chocolate slurry;

[0038] 3) Add protein powder, collagen, dietary fiber, and cocoa powder to the chocolate slurry in step 2), and stir evenly;

[0039] 4) When the slurry obtained in step 3) is heated to 35°C, quickly add soybean protein isolate and nuts;

[0040] 5) Pour the slurry obtained in step 4) into a hexagonal mold;

[0041] 6) Cool the molded product obtained in step 5) at -5°C, and take it out of the package after 15 minutes.

Embodiment 2

[0043] Accurately weigh each composition in Table 1, prepare chocolate product according to the step of embodiment 1, difference is:

[0044] In the step 2), the melting temperature is 35°C;

[0045] In the step 4), when the temperature of the slurry reaches 45°C, quickly add soybean protein isolate particles and nut particles;

[0046] In step 5), pour the slurry obtained in step 4) into a bear-shaped mold;

[0047] In the step 6), the molded product obtained in the step 5) is cooled at -5°C for 25 minutes, then taken out and packaged.

Embodiment 3

[0049] Accurately weigh each composition in Table 1, prepare chocolate product according to the step of embodiment 1, difference is:

[0050] In the step 2), the melting temperature is 30°C;

[0051] In the step 4), when the temperature of the slurry reaches 40°C, quickly add soybean protein isolate particles and nut particles;

[0052] In step 5), pour the slurry obtained in step 4) into a heart-shaped mold;

[0053] In step 6), the molded product obtained in step 5) is cooled at 0°C for 20 minutes and then taken out of the package.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com