Preparation method of porous bi-phase calcium phosphate/calcium sulfate composite scaffold for bone tissue engineering

A biphasic calcium phosphate and bone tissue engineering technology, applied in the field of biomedical artificial bone graft materials, can solve the problems of unbearable load, slow degradation rate, non-degradability, etc., achieve the advantage of compressive strength, and promote bone growth. , the effect of degradation rate advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation method of the porous biphasic calcium phosphate / calcium sulfate composite scaffold described in this embodiment specifically includes the following steps:

[0025] (1) The organic foam carrier with regular through-holes is prepared by laser processing and forming technology, and the organic foam carrier is obtained;

[0026] (2) Mix 5g of distilled water and 10g of silica sol evenly to obtain solution A;

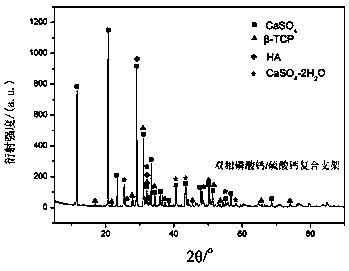

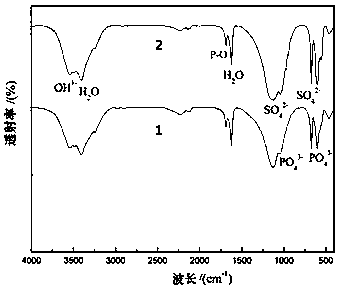

[0027] (3) Mix 5g of biphasic calcium phosphate powder containing 15wt% HA and 85wt% β-TCP with 25g of egg white to obtain slurry B;

[0028] (4) Add solution A to slurry B at a volume ratio of 2:5, and stir with a glass rod to obtain impregnated slurry C;

[0029] (5) Place the organic foam carrier prepared in step (1) in the impregnating slurry and impregnate twice. Each impregnation is heated by a microwave heater at 50°C for 2 minutes, and finally dried in an oven at 50°C for 12 hour, obtain the impregnated green body;

[0030] (6) Place the imp...

Embodiment 2

[0041] The preparation method of the porous biphasic calcium phosphate / calcium sulfate composite scaffold in this embodiment specifically includes the following steps:

[0042] (1) The organic foam carrier with regular through-holes is prepared by laser processing and forming technology, and the organic foam carrier is obtained;

[0043] (2) Mix 5g of biphasic calcium phosphate powder containing 25wt% HA and 75wt% β-TCP with 15g of egg white to obtain slurry B;

[0044] (3) Add 10g of distilled water to the slurry B at a volume ratio of 2:1, and stir with a glass rod to obtain the impregnation slurry C;

[0045] (5) Place the organic foam carrier prepared in step (1) in the impregnating slurry, and impregnate once. Each impregnation is heated by a microwave heater at 30°C for 1min, and finally dried in an oven at 40°C for 6 hour, obtain the impregnated green body;

[0046] (6) Place the impregnated body in a muffle furnace for heat treatment. The heat treatment process is 1°...

Embodiment 3

[0052] The preparation method of the porous biphasic calcium phosphate / calcium sulfate composite scaffold in this embodiment specifically includes the following steps:

[0053] (1) The organic foam carrier with regular through-holes is prepared by laser processing and forming technology, and the organic foam carrier is obtained;

[0054] (2) Mix 10g of distilled water and 20g of silica sol evenly to obtain solution A;

[0055] (3) Mix 5g of biphasic calcium phosphate powder containing 20wt% HA and 80wt% β-TCP with 35g of silica sol to obtain slurry B;

[0056] (4) Add solution A to slurry B at a volume ratio of 2:4, and stir with a glass rod to obtain impregnated slurry C;

[0057] (5) Place the organic foam carrier prepared in step (1) in the impregnating slurry and impregnate three times. Each impregnation is heated by a microwave heater within the range of 50°C for 3min, and finally dried in an oven at 50°C for 12h , to obtain the impregnated green body;

[0058] (6) Pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com