Nanometer bone repairing material and preparation method thereof

A kind of bone repair and nanotechnology, applied in medical science, prosthesis, tissue regeneration, etc., can solve the problems of unstable degradation rate and performance, poor mechanical properties of natural polymer materials, etc., to inhibit osteoclast differentiation, improve Brittleness and mechanical properties, effect of accelerated nucleation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

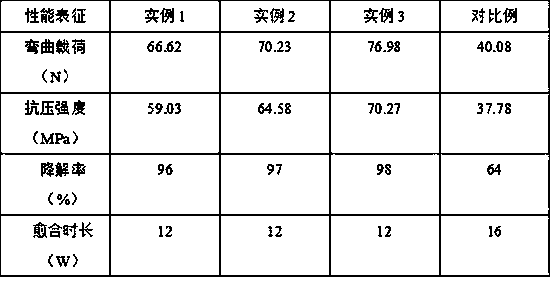

Examples

example 1

[0029]Take 300g of pearls, wash them, air-dry them naturally, put them into a grinder, and grind them through a 400-mesh sieve. Take 100g of sieved pearl powder and add them to 10kg of 1% ethylenediaminetetraacetic acid aqueous solution at 40°C. Stir at 300r / min for 1h, cool to room temperature, put it into a centrifuge, centrifuge at 6000r / min for 10min, remove the precipitate, put it in a vacuum freeze-drying oven, and dry at -30°C for 20h to obtain pearl protein. Take 300g of fresh For catfish swim bladder, remove the blood vessels and mucous membranes in the swim bladder, wash the swim bladder with deionized water for 3 times, drain the washed swim bladder, soak it in 3kg of 5% sodium carbonate solution, stir at 300r / min for 8h, take out Wash the swim bladder with deionized water until the washing liquid is neutral, air-dry it naturally, put it into a pulverizer and crush it, pass through a 60-mesh sieve to obtain a pretreated swim bladder, take 100g of the pretreated swim ...

example 2

[0031] Take 400g of pearls, wash them, dry them naturally, put them into a grinder, and grind them through a 400-mesh sieve. Take 150g of sieved pearl powder and add them to 15kg of 1% ethylenediaminetetraacetic acid aqueous solution. Stir at 350r / min for 1h, cool to room temperature, put it into a centrifuge, centrifuge at 7000r / min for 12min, remove the precipitate, put it in a vacuum freeze-drying oven, and dry at -25°C for 22h to obtain pearl protein. Take 400g of fresh Catfish swim bladder, remove the blood vessels and mucous membranes in the swim bladder, wash the swim bladder with deionized water 4 times, drain the washed swim bladder, soak in 4kg of 5% sodium carbonate solution, stir at 350r / min for 9h, take out Wash the swim bladder with deionized water until the washing liquid is neutral, air-dry it naturally, put it into a pulverizer and crush it, pass through a 60-mesh sieve to obtain a pretreated swim bladder, take 150g of the pretreated swim bladder and add it to ...

example 3

[0033] Take 500g of pearls, wash them, dry them naturally, put them into a grinder, and grind them through a 400-mesh sieve. Take 200g of sieved pearl powder and add them to 20kg of 1% ethylenediaminetetraacetic acid aqueous solution at 50°C. Stir at 400r / min for 2h, cool to room temperature, put it into a centrifuge, centrifuge at 8000r / min for 15min, remove the precipitate, put it in a vacuum freeze-drying oven, and dry at -20°C for 24h to obtain pearl protein. Take 500g of fresh For catfish swim bladder, remove the blood vessels and mucous membranes in the swim bladder, wash the swim bladder with deionized water for 5 times, drain the washed swim bladder, soak it in 5kg of 5% sodium carbonate solution, stir at 400r / min for 10h, take out Wash the swim bladder with deionized water until the washing liquid is neutral, air-dry it naturally, put it into a pulverizer and crush it, pass through a 60-mesh sieve to obtain a pretreated swim bladder, take 200g of the pretreated swim bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com