Melted sampling method for aluminum magnesium calcium iron alloy for X-ray fluorescence spectrum analysis

A fluorescence spectrum, aluminum-magnesium-calcium-iron technology, which is applied in the field of analysis and detection, can solve the problems of high melting temperature, strong corrosion of sample preparation vessels, infeasibility, etc., and achieves the effects of simple operation, short sample preparation time and good reproducibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

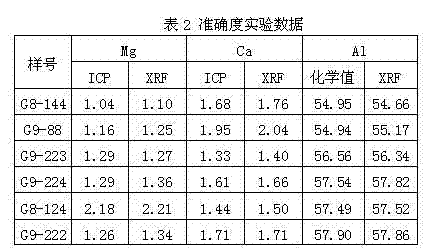

Image

Examples

Embodiment 1

[0020] Embodiment 1: This fusion sample preparation method is completed through the following steps:

[0021] 1. Weigh 7.0000g of lithium tetraborate in a platinum crucible, melt it at 1000°C, slowly rotate the crucible after taking it out, and hang a layer of protective wall with a certain height and uniformity in the platinum crucible;

[0022] 2. Weigh 0.2000g aluminum magnesium calcium iron sample, 0.5000g potassium iodide and 1.5000g lithium carbonate, put them into a platinum crucible, and mix well;

[0023] 3. Uniformly cover 2.0000g of lithium tetraborate on the surface of the mixed sample mixture;

[0024] 4. Put the platinum crucible into the muffle furnace that has been heated to 800°C for pre-oxidation. During this process, the platinum crucible should be preheated at the furnace door for 1.5 minutes, and then slowly enter the furnace step by step for about 18 minutes. After the oxidation is complete The sample should be a flowable liquid, and there are no black p...

Embodiment 2

[0027] Embodiment 2: This fusion sample preparation method is completed through the following steps:

[0028] 1. Weigh 5.0000g of lithium tetraborate in a platinum crucible, melt it at 1050°C, slowly rotate the crucible after taking it out, and hang a layer of protective wall with a certain height and uniformity in the platinum crucible;

[0029] 2. Weigh 0.5000g aluminum magnesium calcium iron sample, 0.5000g potassium iodide and 2.5000g lithium carbonate, put them into a platinum crucible, and mix well;

[0030] 3. Evenly cover the surface of the mixed sample mixture with 1.0000g of lithium tetraborate;

[0031] 4. Put the platinum crucible into the muffle furnace that has been heated to 800°C for pre-oxidation. During this process, the platinum crucible should be preheated at the furnace door for 1.0min, and then slowly enter the furnace step by step for about 15min. After the oxidation is complete The sample should be a flowable liquid, and there are no black particles in...

Embodiment 3

[0034] Embodiment 3: This fusion sample preparation method is completed through the following steps:

[0035] 1. Weigh 8.0000g of lithium tetraborate in a platinum crucible, melt it at 1050°C, slowly rotate the crucible after taking it out, and hang a protective wall with a certain height and uniformity in the platinum crucible;

[0036] 2. Weigh 0.2500g aluminum magnesium calcium iron sample, 0.5000g potassium iodide and 2.5000g lithium carbonate, put them into a platinum crucible, and mix well;

[0037] 3. Uniformly cover 3.0000g of lithium tetraborate on the surface of the above sample mixture that has been mixed;

[0038] 4. Put the platinum crucible into the muffle furnace that has been heated to 800°C for pre-oxidation. During this process, the platinum crucible should be preheated at the furnace door for 2.0 minutes, and then slowly enter the furnace step by step for about 20 minutes. After the oxidation is complete The sample should be a flowable liquid, and there are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com