Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

120 results about "Calcium hydride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calcium hydride is the chemical compound with the formula CaH₂, and is therefore an alkaline earth hydride. This grey powder (white if pure, which is rare) reacts vigorously with water liberating hydrogen gas. CaH₂ is thus used as a drying agent, i.e. a desiccant.

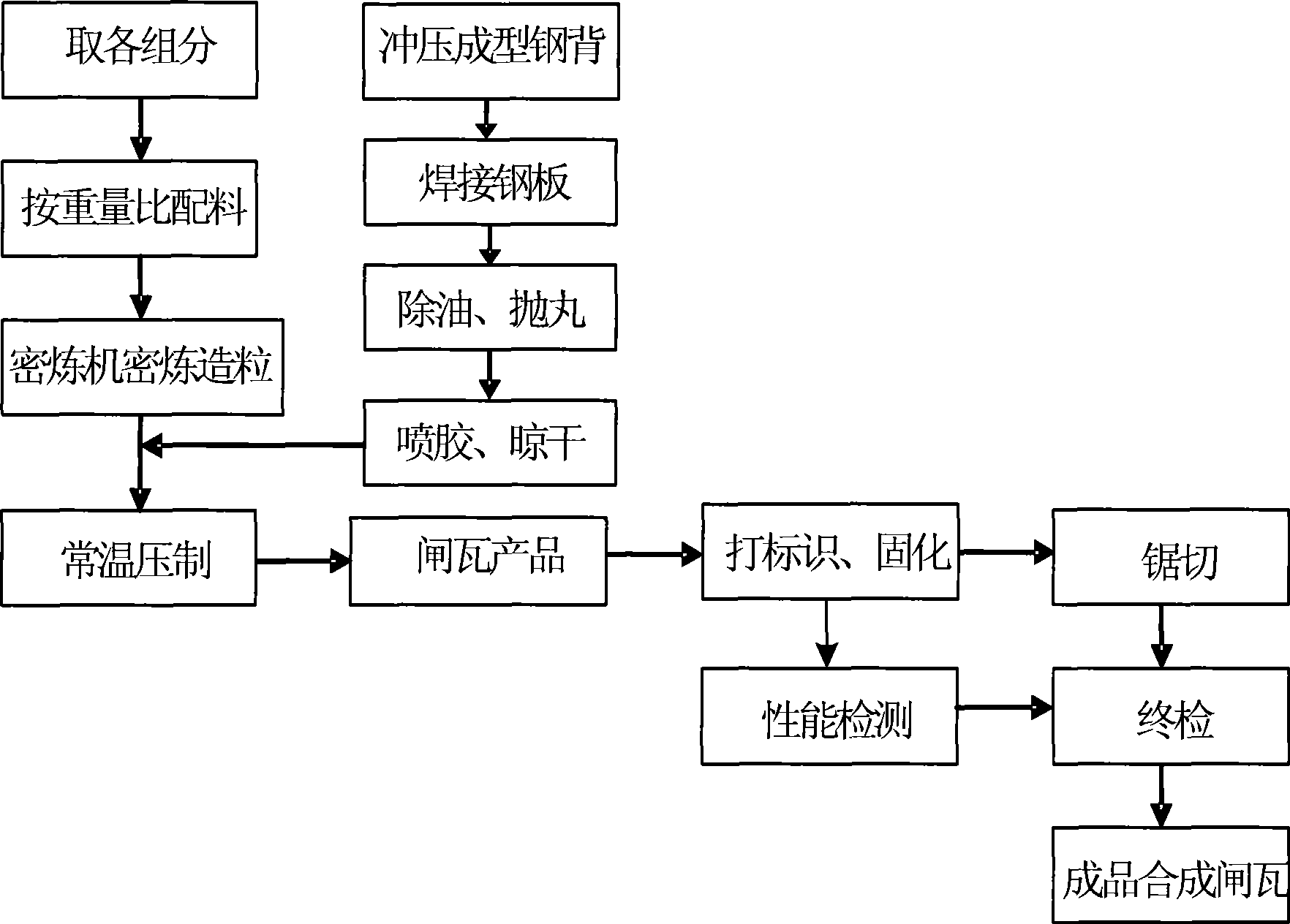

High friction composite brake shoe for railway freight car and manufacture method thereof

ActiveCN101391611AHigh compressive strengthHigh impact strengthBraking membersBrake arrangement with braking memberFiberEngineering

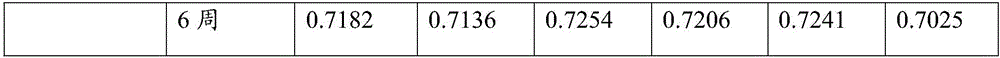

The invention discloses a high friction composite brake shoe for a railway wagon and a manufacturing method thereof. The composite brake shoe comprises: a steel back and a brake shoe body which is fixed on the steel back, wherein, the brake shoe body is prepared by materials which are synthesized by various components with the following weight ratio: 8 to13 parts of nitrile butadiene rubber, 2 to10 parts of styrene butasiene rubber, 5 to10 parts of cresol modified A-stage phenolic resin, 15 to 30 parts of steel fiber, 10 to 15 parts of magnesium oxide, 5 to 10 parts of calcined petroleum coke, 2 to 5 parts of silicon carbide, 10 to25 parts of mineral fiber, 5 to 10 parts of calcium hydride, 10 to 20 parts of barium sulfate, 5 to 10 parts of graphite, 1 to 5 parts of molybdenum disulfide, 1 to 5 parts of carbon black, 1 to 3 parts of sulfur and 1 to 3 parts of enhancer. The brake shoe can be used in the railway heavy-duty high-speed wagon and has stable friction performance and better wear resistance; the brake shoe can effectively inhibit the phenomena of metal inlay, cracks, dropping blocks and the like and reduce the damages on wheels; and the brake shoe is characterized by better impact resistance performance and good weatherability.

Owner:BEIJING RAILWAY STAR FORTUNE HIGH TECH

Method for synthesizing high-viscosity polyphenylene terephthalamide

The invention relates to a method for synthesizing high-viscosity polyphenylene terephthalamide, and belongs to the technical field of polymer synthesis. The method comprises the following steps of: adding dissolution-helping salt into N-methyl pyrrolidone first, adding p-phenylenediamine for dissolution, adding paraphthaloyl chloride for polymerization, and washing and drying an obtained reaction product to obtain the polyphenylene terephthalamide. An acid absorbent used by the synthesis method is calcium hydride, the calcium hydride can react with hydrogen chloride produced in a polymerization reaction, and generated calcium chloride is a cosolvent in a solvent system and is favorable for the stability of a reaction system; and the calcium hydride can remove trace water in the reaction system, so that the influence of water on polyphenylene terephthalamide (PPTA) polymerization is eliminated. Moreover, the unreacted calcium hydride can be easily removed in the subsequent washing step after the PPTA polymerization is finished.

Owner:TSINGHUA UNIV

Calcium-magnesium hydrogen producing agent

InactiveCN102783691AOut-of-the-boxStrong reducing agentCosmetic preparationsToilet preparationsWrinkle skinSkin elasticity

The invention discloses a calcium-magnesium hydrogen producing agent, of which the main component is a hydrogen producing agent. The hydrogen producing agent is selected from one or various combination of calcium hydride, magnesium hydride, calcium hydroxide magnesium, magnesium-magnesium hydride, calcium-calcium hydride, magnesium-calcium hydride, calcium-magnesium hydride, calcium-magnesium-magnesium hydride, calcium-magnesium-calcium hydride, calcium-magnesium-magnesium hydride-calcium hydride, coral calcium hydroxide magnesium, Na MgH3, and Mg2FeH6. the calcium-magnesium hydrogen producing agent can be added into water, beverage or wine as an additive, or can be coated on the surface of skin or taken as soaking liquid to remove internal or surface active oxygen. The calcium-magnesium hydrogen producing agent has a remarkable prompting effect for recovering various oxidized damages, relieving discomfort caused by drinking, diluting stain and wrinkle of the skin, recovering skin elasticity, and delaying senescence.

Owner:李志林

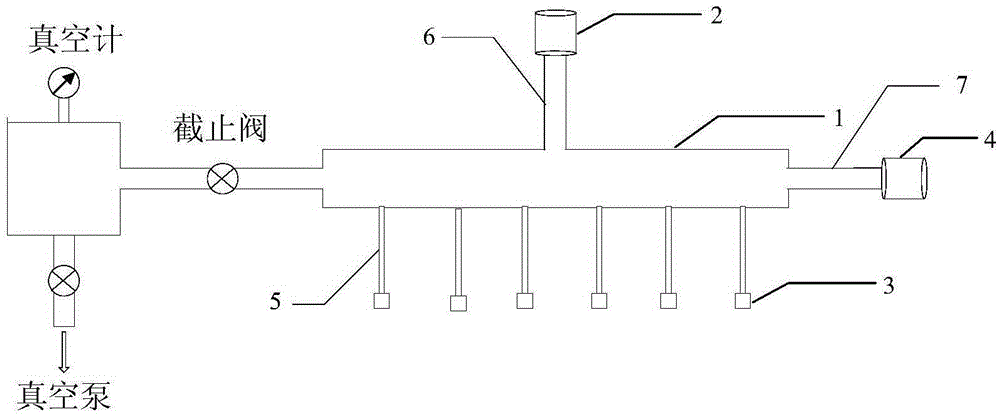

Atom gas chamber inner wall coating method for slowing down atomic spin relaxation

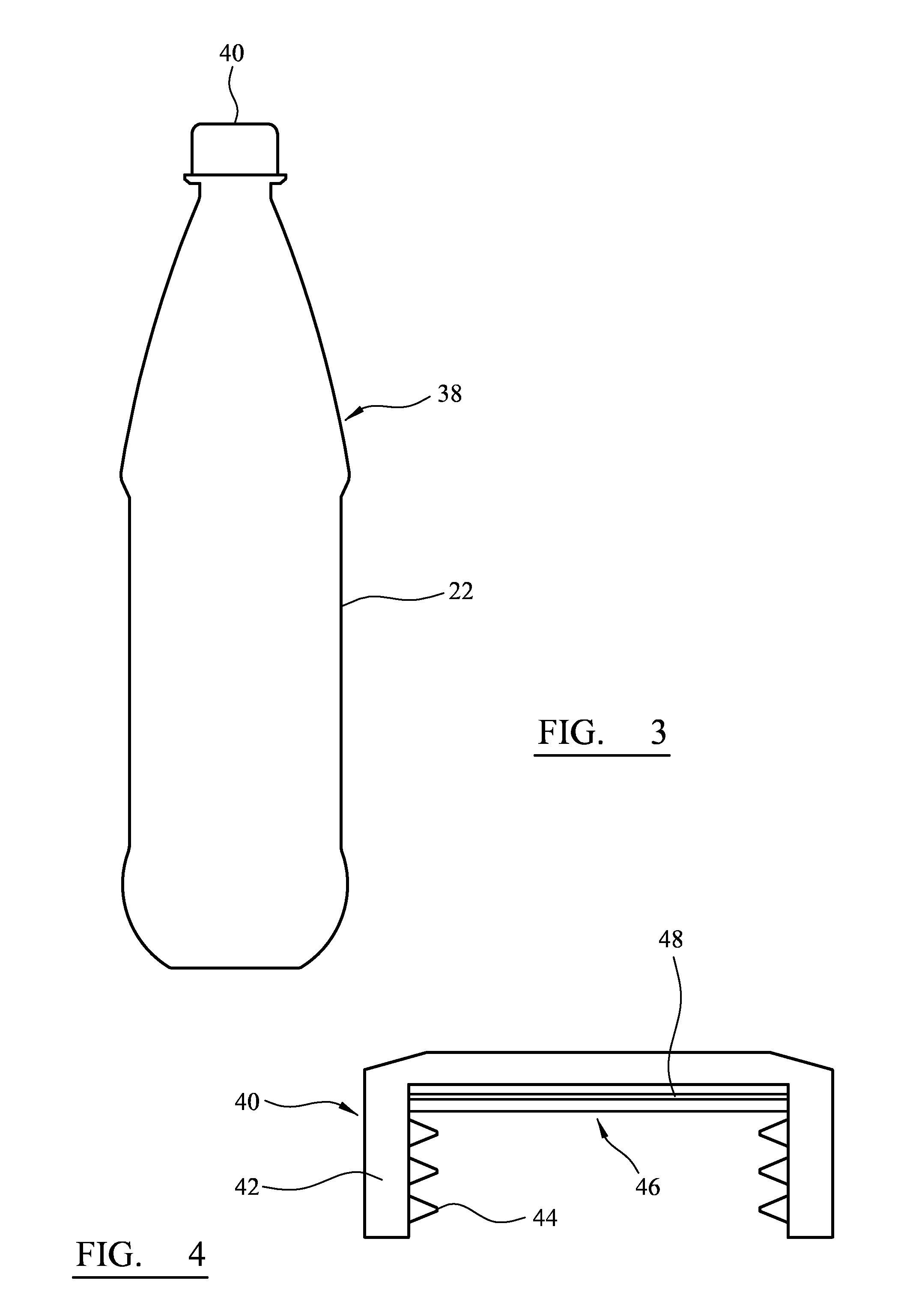

ActiveCN105256286AIncreased process safetyImprove stabilityChemical vapor deposition coatingHigh pressureBottle

The invention provides an atom gas chamber inner wall coating method for slowing down atomic spin relaxation. The method includes the steps that firstly, rubidium atom steam is injected into an atom gas chamber; then, hydrogen with the pressure intensity of 10 Torr to 100 Torr is released into the atom gas chamber through hydride solid gas release agents (such as titanium hydride and calcium hydride), the pressure intensity is kept for tens to hundreds of hours at the temperature 50 DEG C to 150 DEG C, and a layer of rubidium hydride thin film can be attached to the inner wall of the atom gas chamber; and finally, hydrogen left in the gas chamber is evacuated, and the coating process is finished. Hydrogen is generated through the solid gas release agents in the coating process; compared with a traditional method that a high-pressure hydrogen bottle is used as a hydrogen source, the process safety is improved when rubidium hydride coating is conducted on the inner wall of the atom gas chamber, and hydrogen left in the gas chamber after rubidium hydride coating is evacuated; and compared with the method for directly sealing hydrogen in the gas chamber, stability of performance of the atom gas chamber is easily improved.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

Synthesis method of celecoxib

InactiveCN102391184AHigh purityHigh yieldOrganic chemistryPhenylhydrazine hydrochlorideClaisen condensation

The invention relates to a synthesis method of celecoxib, which comprises the following specific steps of: 1, carrying out claisen condensation on p-methylacetophenone and trifluoroacetic acid ethyl esters in an aprotic organic solvent under the catalysis of alkali to obtain 1-(4-methylphenyl)-4,4,4-trifluoro-1,3-butanedione; and 2, reacting the obtained 1-(4-methylphenyl)-4,4,4-trifluoro-1,3-butanedione with sulfonamide-phenylhydrazine hydrochloride to obtain celecoxib, wherein in the step 1, the alkali for catalysis is selected from one or more of sodium hydride, potassium hydride, lithium hydride and calcium hydride. The synthesis method of celecoxib provided by the invention is easy to operate, high in yield, high in product purity and easy for industrial production.

Owner:JIANGXI SYNERGY PHARMA

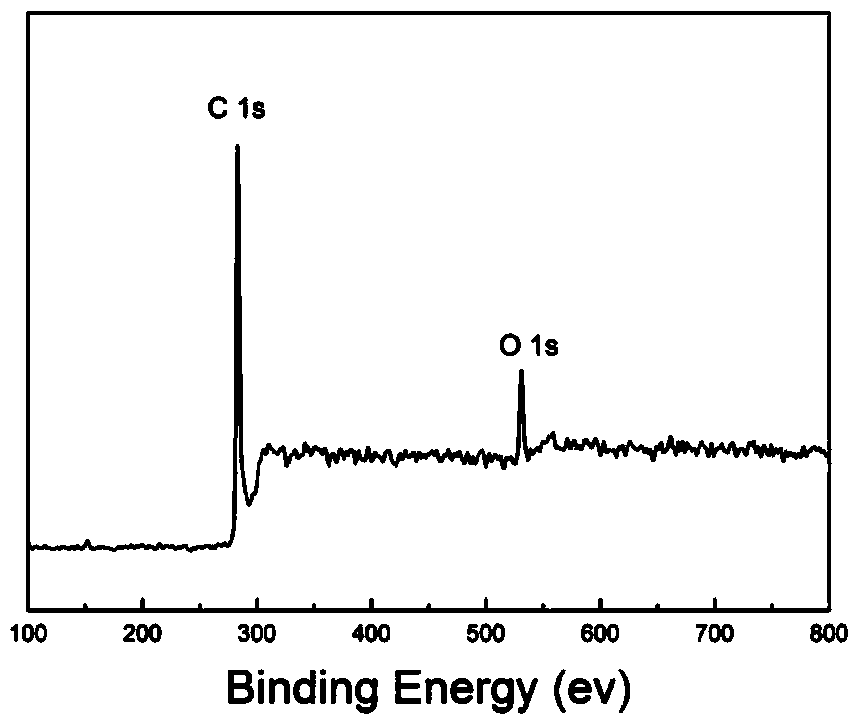

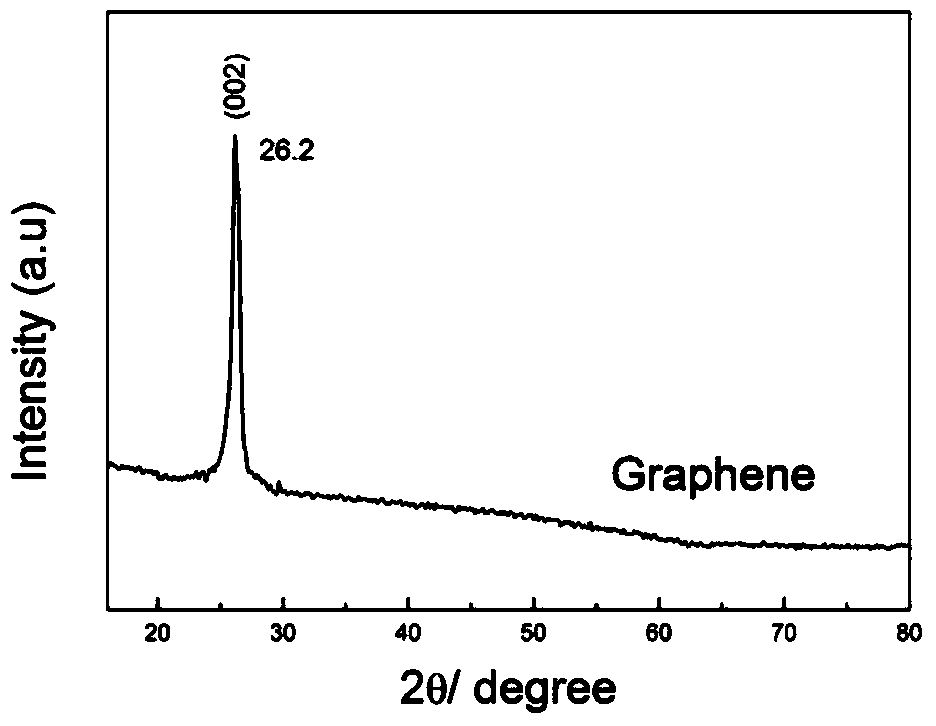

Method and device for preparing graphene through processing dry ice by shock waves

The invention discloses a method and a device for preparing graphene through processing dry ice by shock waves, and belongs to the field of material processing. Firstly, the dry ice is selected as a carbon source, calcium hydride, lithium aluminum hydride or sodium borohydride is selected as a reducing agent, and the dry ice and the reducing agent are evenly mixed in a mass ratio of 2:1-4:1 to prepare a raw powder material; and then the raw powder material is shocked to induce a chemical reaction through the instantaneous high temperature and high pressure produced by high-speed impact of flying pieces driven by explosive detonation so as to obtain the high-quality graphene. The method for preparing the graphene is low in cost, simple in process, short in consumed time and capable of realizing industrial production. In addition, a way to deal with the global warming problem is provided, and the dry ice can be turned into the useful graphene.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Packing Material for a Micro-Adsorption Column for Drying and/or Purification of Dissolved Organic or Biological Analytes and Micro-Adsorption Column and use thereof

InactiveUS20100258494A1Rapid and efficient separationQuick analysisComponent separationOther chemical processesSodium BentonitePack material

The invention relates to a packing material for a micro-adsorption column for drying and / or purification of dissolved organic or biological analytes, such as toxins, antibiotics, vitamins, hormones, pesticides and similar, containing at least one drying agent which contains magnesium sulphate and at least one further drying agent selected from the group comprising aluminium oxide, calcium chloride, calcium hydride, calcium oxide, calcium sulphate, potassium hydride, silica gel, copper sulphate, magnesium oxide, magnesium perchlorate, molecular sieves, sodium hydroxide, phosphorus pentoxide, sulphuric acid on silica, phosphorus pentoxide on silica and 0.5 to 90 wt. % of a naturally-occurring or synthetic support with large internal surface such as zeolite, diatomic earths, bentonite, silicon dioxide or similar. The invention further relates to a micro-adsorption column packed with the above and use thereof.

Owner:ERBER AG

Calcium fortified acidic beverages

A calcium fortified acidic beverage, wherein the calcium comprises: 1) calcium citrate, calcium malate, or calcium malic citrate formed in situ from citric acid, malic acid, and compounds of malic acid and citric acid, respectively, and either Calcium salts selected from calcium hydride, calcium oxide, calcium carbonate and their mixtures are reacted to form; ii) calcium chloride; iii) calcium gluconate lactate. Calcium-fortified acidic beverages are stable for extended periods of time at room temperature and elevated temperature without the formation of calcium precipitates.

Owner:萨拉 A 卡拉比尼 +2

Corrosion resistant aerated building block and making method thereof

InactiveCN105272337AImprove mechanical propertiesImprove fire resistanceCeramicwareCrack resistanceSlag

The invention discloses a corrosion resistant aerated building block and a making method thereof. The corrosion resistant aerated building block is made from, by weight, 23-27 parts of waste concrete, 28-36 parts of quartz sand, 16-29 parts of pine sawdust, 13-21 parts of porous ceramsite, 18-34 parts of zirconium-silicon slag, 32-46 parts of high sulfate resistance Portland cement, 17-33 parts of pumice, 14-26 parts of kyanite, 22-34 parts of marine dredged sludge, 11-22 parts of desulfurized gypsum, 19-28 parts of calcium carbide slag, 10-15 parts of hawthorn fruit seed powder, 8-12 parts of sodium polystyrene sulfonate, 3.5-5 parts of calcium hydride and a proper amount of water. The aerated building block has the advantages of strong corrosion resistance, strong resistance to acids, alkali, salts and other corrosive media, high strength, good durability, impermeability, low heat conduction coefficient, good crack resistance, safety, environmental protection and durability.

Owner:MAANSHAN JIECHUANG PLASTIC TECH CO LTD

Preparation method of polylactic acid-polyethylene glycol block copolymer

A process for preparing the polylactic acid-polyethanediol block copolymer is prepared through the copolymerizing reaction between polyethanediol and lactide at 130-160 deg.C under -0.08-0.01 MPa and existance of calcium hydride for 8-12 hr, adding acetone for dissolving, deposition in distilled water and then in absolute alcohol, and vacuum drying.

Owner:BEIJING TIANRUNXING BIO TECH DEV

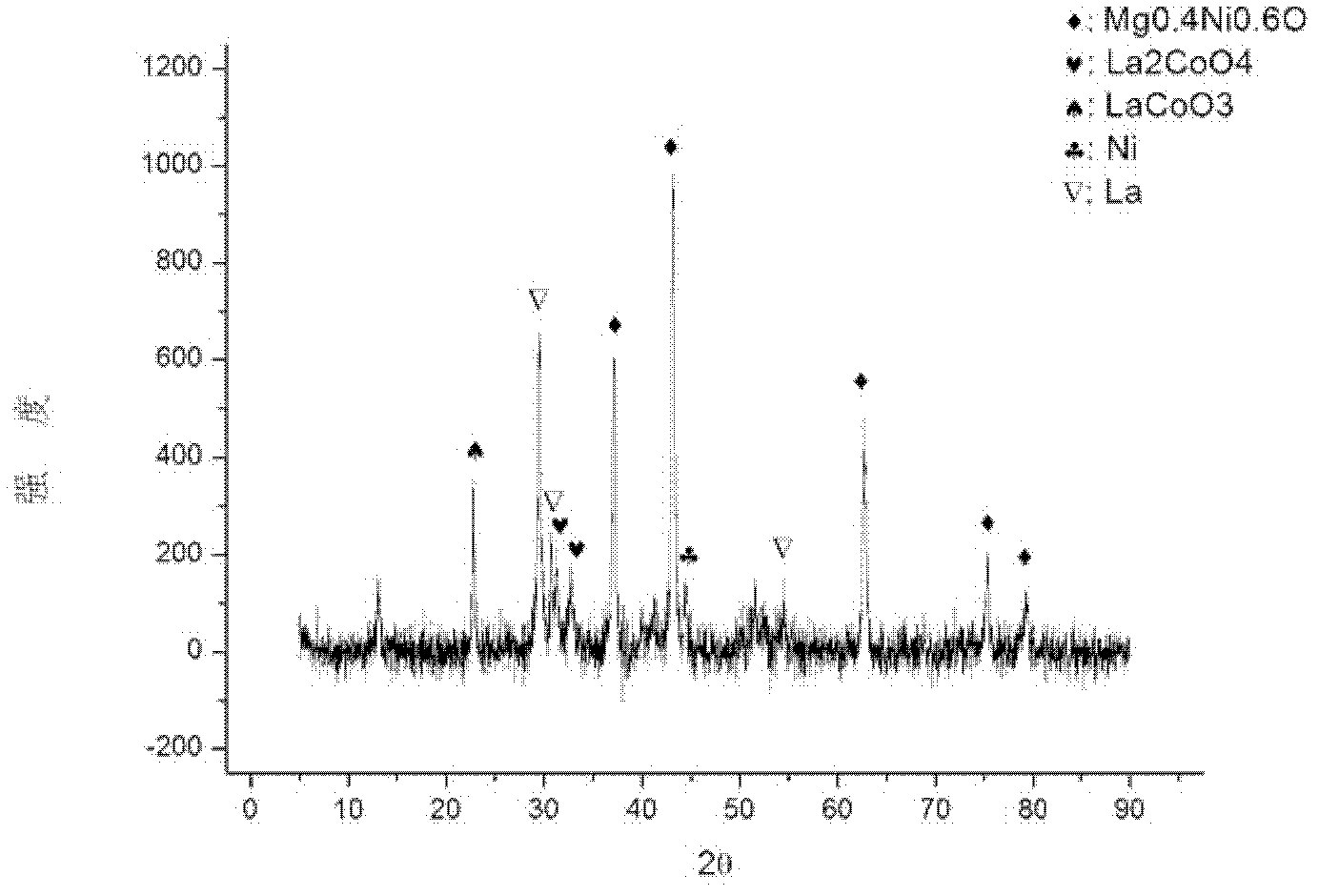

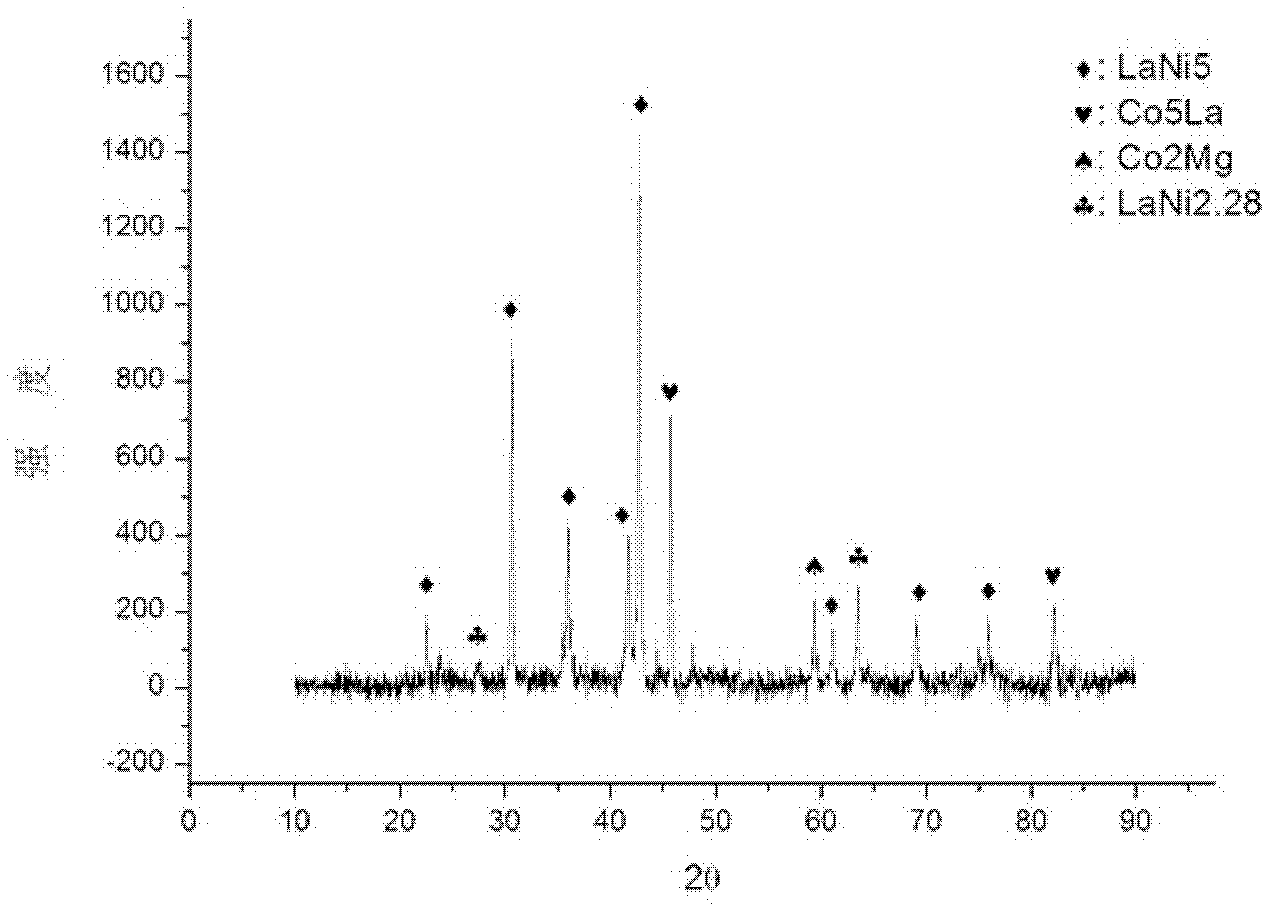

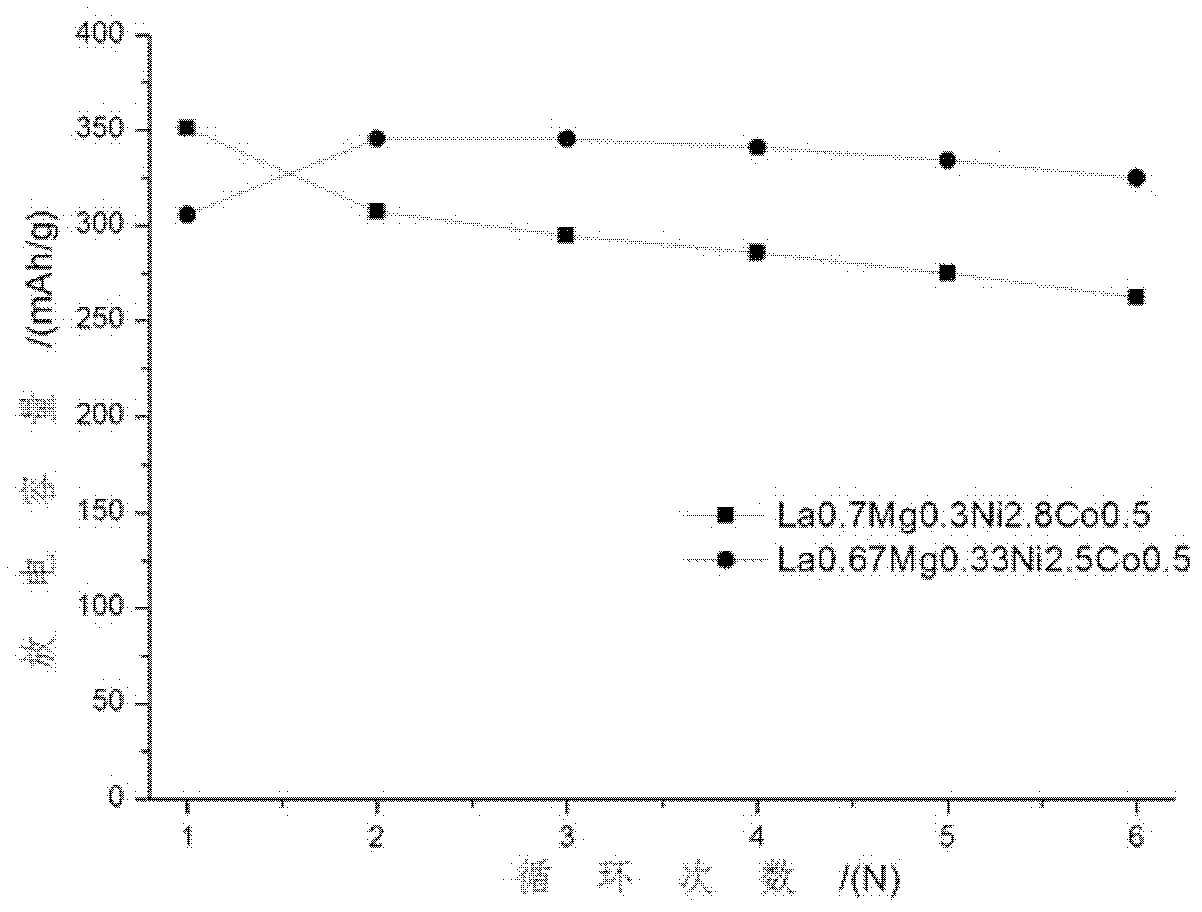

Preparation method of hydrogen storage alloy material

InactiveCN102586651AImproved hydrogen uptake kineticsHigh hydrogen storage capacityRare earthStructural formula

The invention discloses a preparation method of a hydrogen storage alloy material. A structural formula of the material is ABx(x=3.0-3.5), wherein a chemical constituent of an element on A side is Lz1-yMgy, and y is 0.25-0.33; and B is NipCoz (Mn Al3)w, p is 2.5-3.3, z is 0-0.5, and w is 0-0.1. The preparation method comprises the following steps of: (1) adopting oxalic acid-ethanol solution as a precipitator, taking saline solution of rare earth, magnesium, nickel and various doped metal as raw materials, preparing a precipitate, and washing, filtering, drying and firing the precipitate to obtain an alloy oxide precursor; and (2) taking calcium hydride as reducing agent, and high-purity hydrogen as reducing atmosphere, carrying out reduction in a vacuum / atmosphere tubular furnace, and rinsing, soaking, washing and drying the reduzate to obtain hydrogen storage alloy powder. According to the preparation method, the rare earth oxide and metal salt are adopted as the raw materials, so that the adoption of expensive pure metal is avoided, the cost can be obviously reduced, the prepared alloy powder has mall granularity, the compositions are uniform, the discharge capacity is high, the performance is stable, and the hydrogen storage alloy material can be used as a negative active material of a large-power nickel-hydrogen battery.

Owner:HUAZHONG UNIV OF SCI & TECH

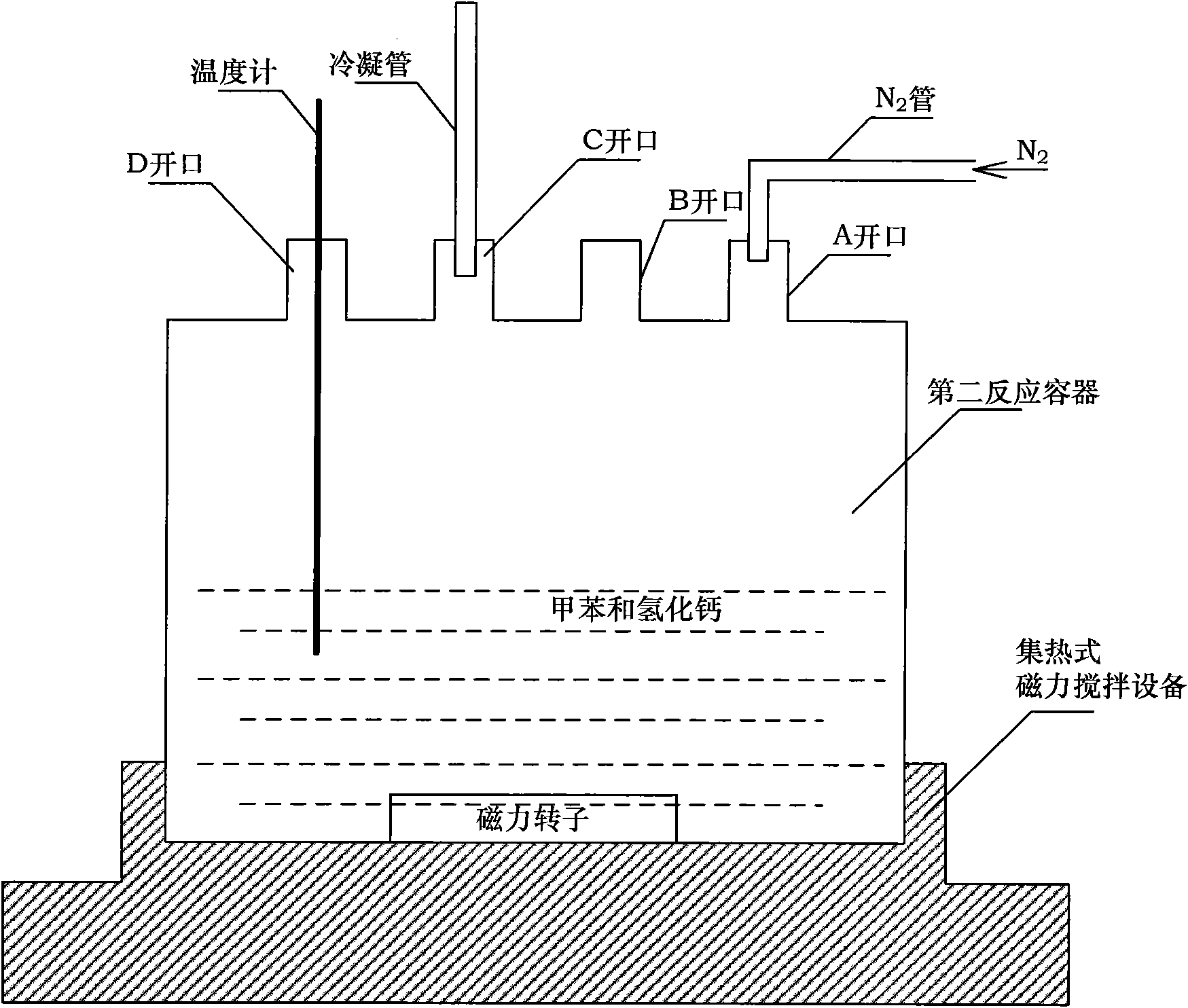

Preparation method of SiC-SiAlCN glass ceramics

The invention discloses a preparation method of SiC-SiAlCN glass ceramics, which comprises the following steps: preparing anhydrous methylbenzene by using methylbenzene and calcium hydride, and mixing the anhydrous methylbenzene and PCS (polycarbosilane) to obtain a PCS methylbenzene solution; preparing PAS (periodicacidschiff) by using metallic aluminium organic matter and polysilazane, and mixing the anhydrous methylbenzene and the PAS to obtain a PAS methylbenzene solution; then treating ceramic precursor polymer alloy prepared by mixing the PCS methylbenzene solution and the PAS methylbenzene solution with different ratio by adopting a post vacuum-solidifying atmosphere high-temperature pyrolytic process to obtain the SiC-SiAlCN glass ceramics which can be stably used at the temperature of 1400-1500 DEG C. SiC crystal particles in the SiC-SiAlCN glass ceramics prepared by the invention are dispersed and distributed in SiAlCN amorphous phases and are obtained from PCS micro-area crystallization in curing materials, and an SiAlCN covalent bond amorphous phase is obtained after a PAS area is pyrolyzed.

Owner:BEIHANG UNIV

Purification method for acetonitrile

InactiveCN102746188AEfficient removalSafe and easy purification processCarboxylic acid nitrile purification/separationChemical industryPurification methods

The invention discloses a purification method for acetonitrile. The method comprises the steps of using industrial grade acetonitrile as raw material, successively adding anhydrous aluminum chloride, potassium permanganate and sulfuric acid and carrying refluxing and distilling respectively, adding calcium hydride for drying, adding a 4A molecular siev for adsorption and purification, and finally performing distillation method to obtain purified acetonitrile. The purity of the acetonitrile obtained by the purification method provided by the invention is greater than 99.8%. Compared with the existing technology, the purification process is safe, simple, energy-saving and emission-reducing. The added purifying agent can be recycled after treatment, and the requirements of green chemical industry and environmental protection are met. The acetonitrile product obtained by the purification method has the advantages of stable quality and high purity, and has prospect for industrial production.

Owner:TAICANG HUSHI REAGENT

Preparation method of high-purity vanadium powder

The invention discloses a preparation method of high-purity vanadium powder. The preparation method comprises the following steps: mixing vanadium-containing material with alkali metal or alkaline-earth metal chloride salt and then mixing with calcium hydride; then, carrying out vacuum thermal reduction to obtain a reduction product; washing the reduction product with ammonium chloride solution, alkaline liquor and acid liquor sequentially; and finally, carrying out dehydrogenation treatment to obtain high-purity vanadium powder. The preparation method has the advantages of being low in cost and energy consumption, moderate in reaction condition and safe in operation.

Owner:CHONGQING UNIV

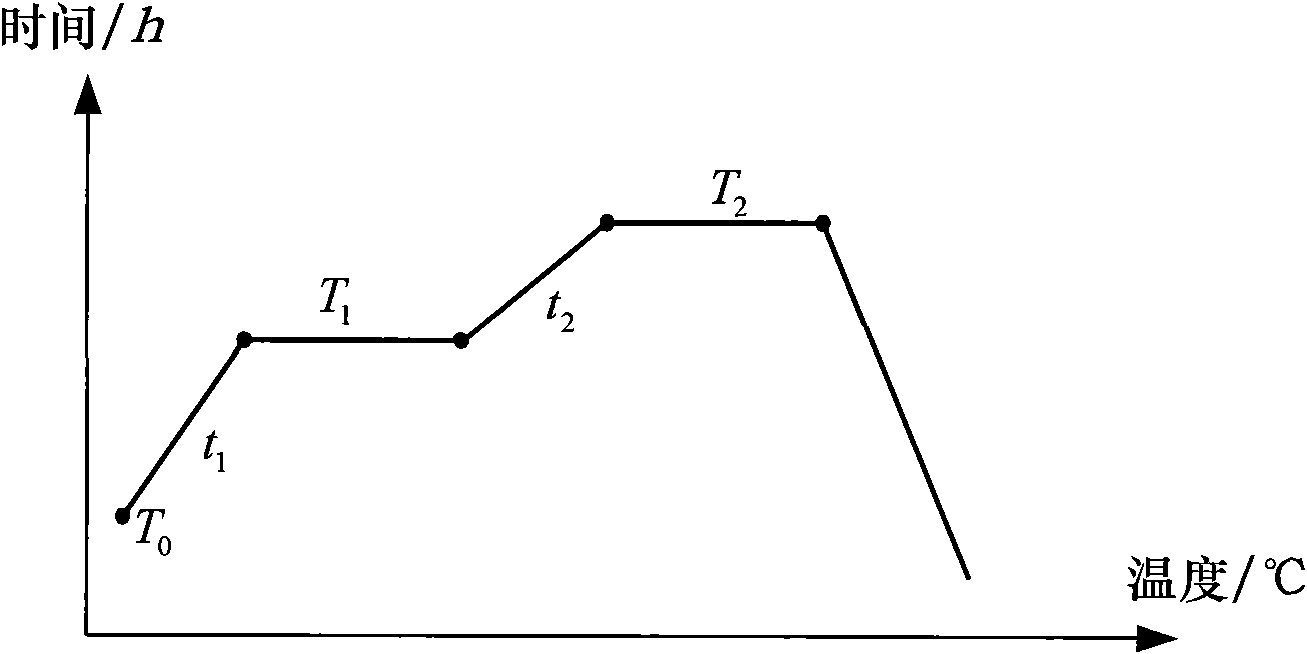

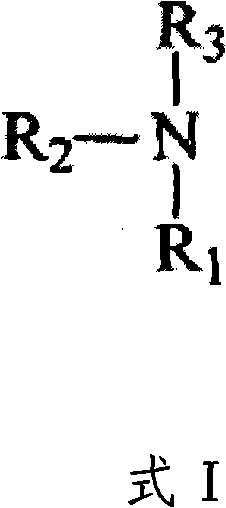

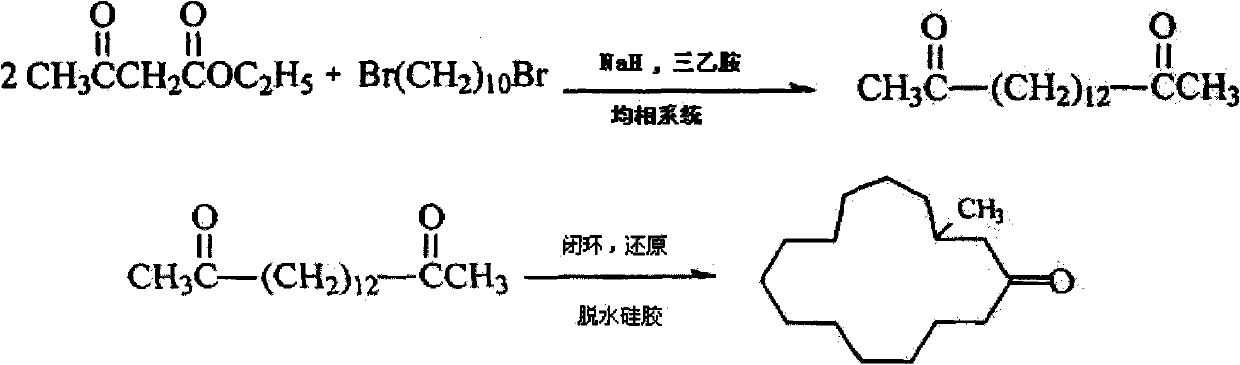

Process for preparing musk ketone

InactiveCN102146027AOptimize the synthetic process routeOrganic compound preparationCarbonyl compound preparationAcetic acidOrganic base

The invention relates to a process for preparing musk ketone, which comprises the following steps of: adopting catalyzing ethyl acetoacetate and 1,10-dibromodecane as raw materials to generate 2,15-hexadecanedione through sodium hydride (calcium hydride or a mixture formed by sodium hydride and calcium hydride) and organic base under the homogeneous condition; and then adding dehydrated silica gel to perform a closed loop and hydrogenation reduction reaction so as to prepare 3-methyl cyclopentadecanone. The reaction time is short (2 to 4 hours). The yield is greatly improved (by over 90 percent). The technology has mild reaction, high yield and few three wastes and is suitable for industrial production.

Owner:高旌

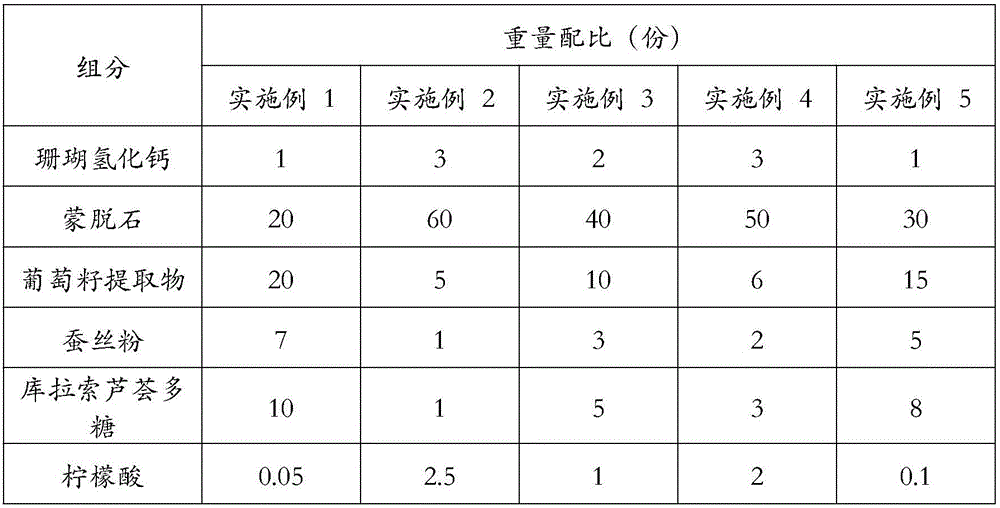

Mask powder with oxidation-resistant effect and preparation method thereof

InactiveCN106491376ASolve permeabilitySolve the problem that is not easy to storeCosmetic preparationsToilet preparationsFiberBound property

Owner:聚吉减肥塑形科学技术研究院(广州)有限公司

Scavenging oxygen

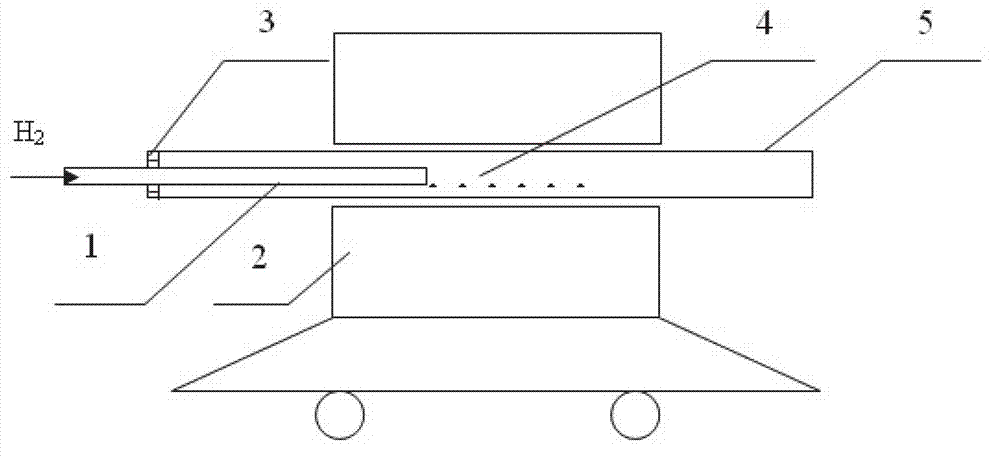

ActiveUS20120111757A1Increase response rateSmall amount of catalystCapsClosure lidsProduced waterCalcium hydride

A closure (40) for a container incorporates calcium hydride and a matrix material as a hydrogen-generating composition. In use, hydrogen is generated which reacts with oxygen permeating a container associated with the closure and a catalyst associated with the container catalyses reaction of the hydrogen and oxygen to produce water, thereby scavenging the oxygen. The composition of calcium hydride and matrix is also claimed.

Owner:COLORMATRIX HLDG

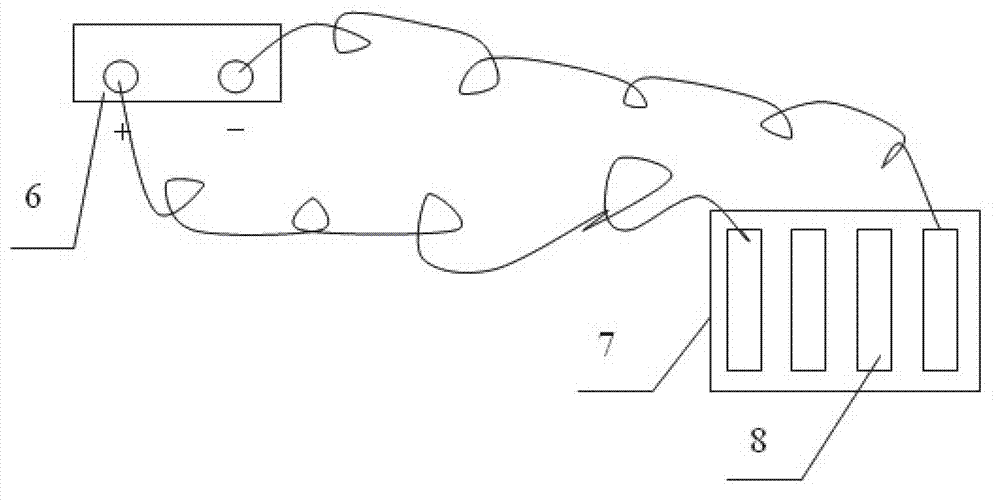

Method and device for preparing active calcium hydride

ActiveCN102826511ALittle pollutionHas the function of human healthAlkali/alkaline-earth/beryllium/magnesium hydridesFurnace temperatureClean energy

The invention relates to a preparation technology of active calcium hydride, and provides a method and a device for preparing the active calcium hydride. The method comprises the steps of: uniformly scattering calcium hydride powder as a raw material at a middle section of a quartz reaction tube of a horizontal tube-type electric heating furnace, wherein two ends of the quartz reaction tube are not sealed and are in a dried air environment at normal pressure; lastingly introducing dried hydrogen by micro-flow, and controlling the furnace temperature at 300-700 DEG C, wherein the reaction time is 8-12 hours; under the reaction condition, preparing solid active calcium hydride powder by a way that calcium hydride absorbs hydrogen and oxygen at the same time, wherein the molecular formula of the solid active calcium hydride powder is CaH2.2H.2O. The method is concise in preparation technology, mild in operation condition and less in environmental pollution and resource consumption. The prepared solid active calcium hydride powder can release hydrogen and oxygen at the same time in the water so as to be used as a storage carrier of a clean energy source, and the released hydrogen anions have the health-care action on the human body.

Owner:ZHEJIANG HUAKANG PHARMA +2

Preparation method for aluminium alloy/borohydride hydrogen-production system

The invention relates to a preparation method for an aluminium alloy / borohydride hydrogen-production system. The system employs aluminium powder, a metal hydride and a metal salt as raw materials; aluminium alloy powder is obtained through ball-milling mixing, heating dehydrogenation fusion, cooling condensation and scraping collection, and then is mixed with a borohydride, and the mixture is subjected to tabletting for forming the aluminium alloy / borohydride hydrogen-production system, wherein the metal hydride is one of sodium hydride, calcium hydride, strontium hydride and sodium aluminium hydride, the metal salt is one of chlorine salts or nitrates of nickel, cobalt, iron, palladium, rhodium and platinum, aluminum accounts for 80-98.5% by mole of total aluminium alloy, the hydride accounts for 1-9% by mole of total aluminium alloy, and the metal salt accounts for 0.5-19% by mole. The preparation method is capable of improving the hydrolysis kinetics of aluminium / borohydride, and also improving the unit-mass hydrogen storage value of a hydrogenation system. The prepared aluminium alloy / borohydride hydrogen-production system has the advantages of being high in hydrogen storage value, convenient to carry, safe, reliable and the like, and has wide application prospect on portable hydrogen source application.

Owner:CHINA JILIANG UNIV

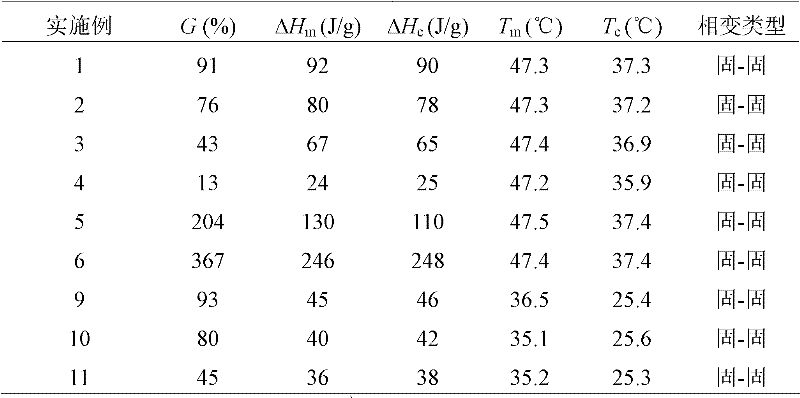

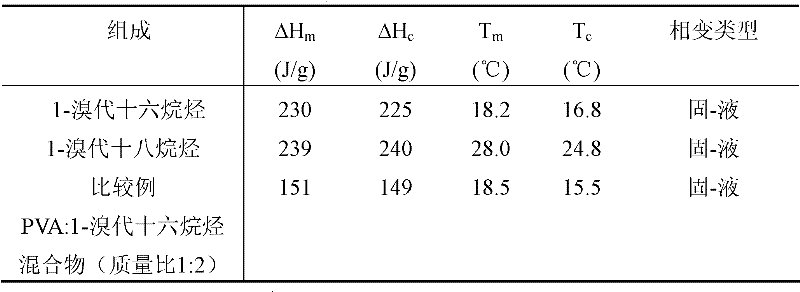

Preparation method of comb-type polymer phase change energy storage material

InactiveCN102199231AQuick responseImprove thermal stabilityHeat-exchange elementsAlkanePolymer dissolution

The invention discloses a preparation method of a comb-type polymer phase change energy storage material. The preparation method comprises the following steps: firstly, dissolving polymers such as dried poval and the like in a solvent the amount of which is 2-4 times that of the polymers, and then carrying out metallization reaction on the mixture and one of calcium hydride, sodium hydride, potassium hydride, sodium methoxide, sodium ethoxide, potassium methoxide or potassium ethoxide; stirring and reacting for 1-4 hours in the solvent at the temperature of 30-60 DEG C so as to obtain a polymer metalized product with an active group; adding at leas one of 1-halognated n-alkanes, wherein the molar ratio of the 1-halognated n-alkane to the polymers such as poval and the like is (0.1:1)-(6:1), and the adding speed is controlled at 1-10mL / min; adding a catalyst the weight of which is 0.01-1% of that of the polymers such as poval and the like; and stirring and carrying out grafting reaction for 4-12 hours in the solvent at the temperature of 30-90 DEG C; and washing the obtained product for impurity removal and drying, so as to obtain the comb-type polymer phase change energy storage material.

Owner:TIANJIN POLYTECHNIC UNIV

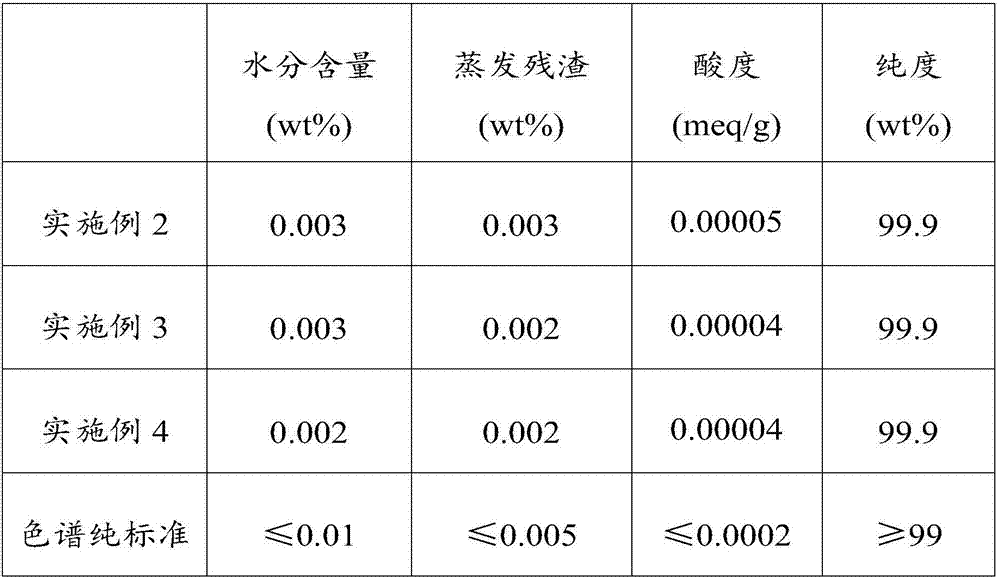

Preparation method for chromatographic grade N,N-dimethyl formamide

ActiveCN102516112AMeets the requirements of chromatography grade N,N-dimethylformamideEasy to separateCarboxylic acid amide separation/purificationCalcium hydroxideFiltration membrane

The present invention relates to a preparation method for chromatographic grade N,N-dimethyl formamide. The method comprises the following steps that: (1) a raw material N,N-dimethyl formamide flows through a calcium hydroxide adsorption column; (2) the N,N-dimethyl formamide after the adsorption and alumina are subjected to vacuum distillation, wherein the distillation is performed under a condition of 5-10 mmHg; (3) the distilled liquid is filtered by using a 0.45 mum microporous filtration membrane, and is subjected to bottling and storing through nitrogen filling to obtain the chromatographic grade N,N-dimethyl formamide. According to the present invention, the N,N-dimethyl formamide with the content of about 99.5% is adopted as the raw material, the calcium hydride column is adopted to adsorb the water and other impurities in the N,N-dimethyl formamide, the alumina is adopted to presinter to the temperature of 500-600 DEG C, and the vacuum distillation treatment is performed, such that the N,N-dimethyl formamide product with the purity more than 99.9% is prepared through the treatments of adsorbing, drying, and vacuum distillation, and the product can meet the chromatographic grade (HPLC) N,N-dimethyl formamide application requirements of the user.

Owner:天津市康科德科技有限公司

Process for manufacturing metal containing powder

The invention provides a process for manufacturing metal containing powder, the process comprising the steps of: (a) mixing at least one metal oxide powder with Ca or Mg granules and / or calcium hydride in granule or powder form to form a mixture; (b) maintaining said mixture under an H2 atmosphere, at a temperature between 1000 DEG C and 1500 DEG C for 1-10 hours, followed by: (c) recovering metal containing powder. In one embodiment, metal hydride powder is recovered. In another embodiment the process further includes between steps (b) and (c): (d) switching the H2 atmosphere to an Ar atmosphere and maintaining the mixture thereunder for a period of 20 minutes to 5 hours, followed by: (e) cooling under Ar atmosphere, wherein metal powder is recovered in step (c).

Owner:HOGANAS AB

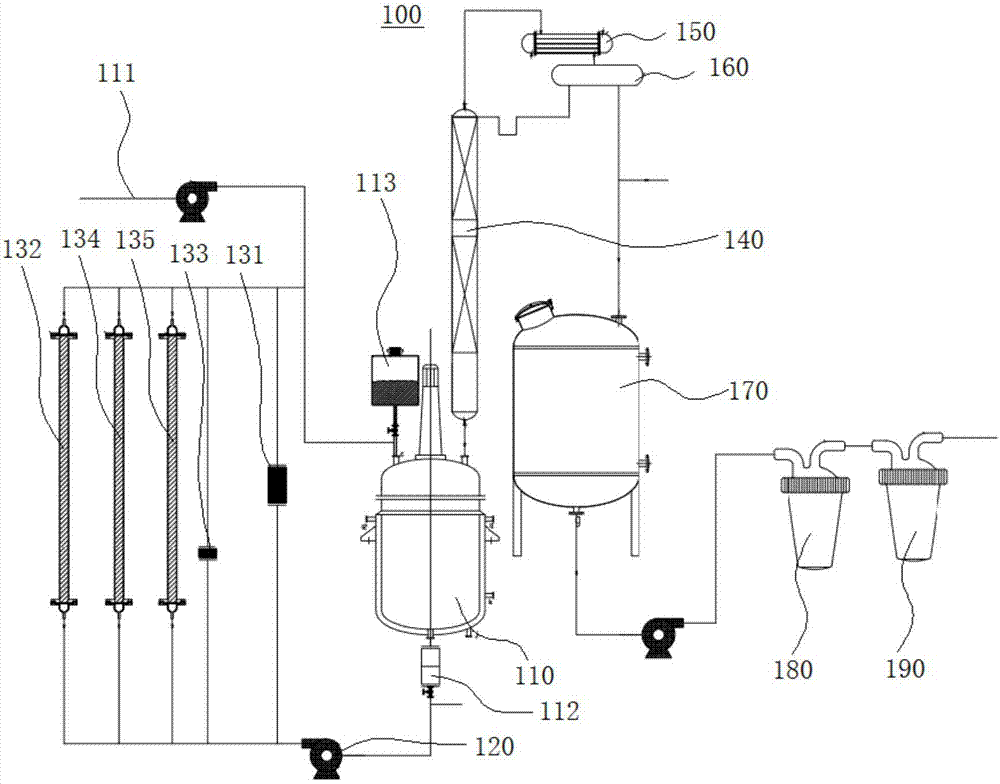

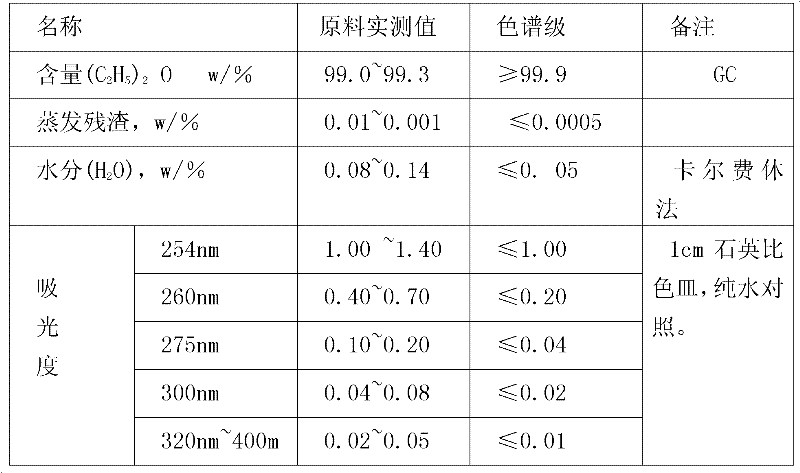

Chromatographically pure ethyl ether and preparation method and production system thereof

InactiveCN107501056AImprove qualityHigh yieldEther separation/purificationActivated carbonMolecular sieve

Chromatographically pure ethyl ether and a preparation method and a production system thereof relate to the technical field of purification of chemical products. The preparation method is characterized in that industrial ethyl alcohol serves as a raw material and is subjected to oxidation impurity removal and a neutral reaction at first and then 4A molecular sieve adsorption, calcium hydride adsorption, basic alumina adsorption and activated carbon adsorption to obtain a rectifying stock solution, and at last, the rectifying stock solution is rectified. The preparation method is low in production cost, can prepare the chromatographically pure ethyl ether with good quality and high yield, and meets the requirements of chromatographically pure reagents. The production system comprises a 4A molecular sieve column, a calcium hydride column, a basic alumina column and an activated carbon adsorption column which are arranged in parallel and constitute a circulation line with a reaction kettle, and a gas-phase outlet of the reaction kettle is communicated with a gas-phase inlet in the bottom of a rectifying column. The production system is specially used for preparing the chromatographically pure ethyl ether, is high in production efficiency, can obtain the product with high purity, and can realize large-scale industrial production of the chromatographically pure ethyl ether.

Owner:HUBEI ENG UNIV

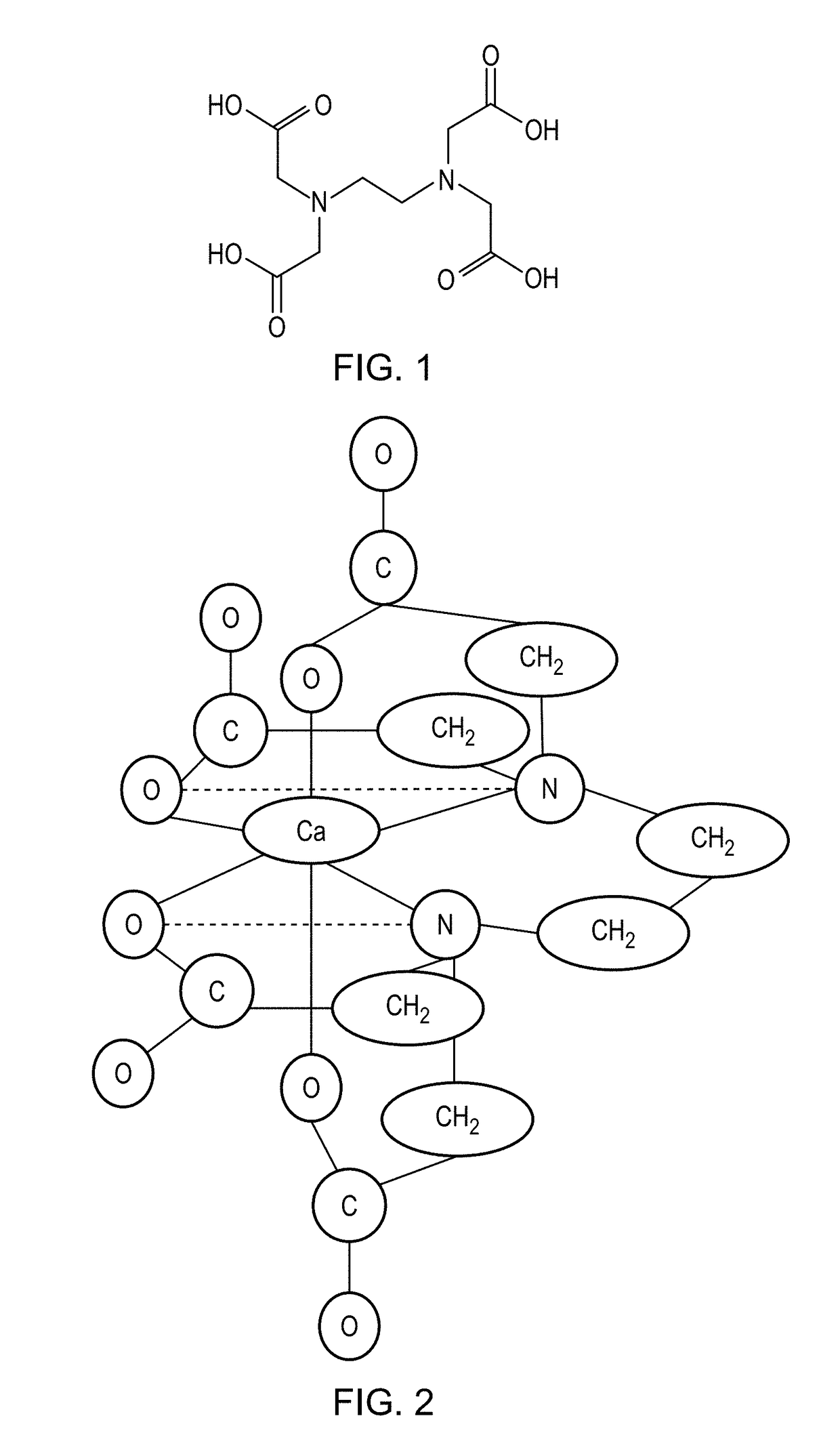

Magnetic material and a method of synthesising the same

ActiveUS20180130579A1Fast heatingHeating evenlyTransportation and packagingMetal-working apparatusEthylenediamineDissolved iron

A process for producing Co, Al alloyed NdFeB nanoparticles, by a microwave assisted combustion process, followed by a reduction diffusion process, includes the steps of: preparing a first solution of boric acid dissolved in 4 N HNO3, dissolving iron nitrate nonahydrate, neodymium nitrate hexahydrate, cobalt nitrate hexahydrate, aluminium nitrate, the first solution in deionized water to form a second solution, adding glycine to the second solution in a molar ratio of 1:1 to form a third solution, subjecting the third solution to microwave radiation, thereby forming an first powder of NdFeCoAlB oxides, mixing the first powder with calcium hydride in a mass ratio of 1:1.1 (NdFeCoAlB oxides:CaH2) to form a second powder, compacted into a powder block, annealing the second powder in a vacuum furnace, washing the annealed second powder with a solution of ethylenediaminetetraacetic acid; and vacuum drying the second powder.

Owner:ROLLS ROYCE PLC

Method for purifying dichloromethane

InactiveCN102746105AEfficient removalSafe and easy purification processHalogenated hydrocarbon separation/purificationChemical industryMolecular sieve

The invention discloses a method for purifying dichloromethane. The method comprises the steps of using industrial grade dichloromethane as a raw material, dropwise adding sulfuric acid with mass fraction of 95-98%, shaking, washing with sodium carbonate solution with mass fraction of 9.5-10.5% to separate the dichloromethane, then sequentially adding calcium hydride for drying and a 4A molecular sieve for adsorbing and purifying, and finally carrying out rectification for collecting purified dichloromethane. The purity of the dichloromethane obtained by the purifying method is higher than 99.5%. Compared with the prior art, the purifying process is safe, simple and convenient, energy is saced, emission is reduced, the added purifying agents can be recycled after treatment, requirements for green chemical industry and environment protection are met, and dichloromethane products obtained by the purifying method are stable in quality and have prospects of industrial production.

Owner:TAICANG HUSHI REAGENT

Method for preparing titanium powder

The invention discloses a method for preparing titanium powder, and belongs to the technical field of rare metal refining. A technical problem solved by the method is to provide a titanium powder preparation process with low cost, milder conditions and safer operation. The method for preparing the titanium powder comprises the following steps: A, mixing titanium-containing materials with calcium oxide, pressing, molding, and sintering to obtain a sintered product; B, breaking the sintered product obtained in step A, mixing with calcium hydride, pressing and molding to obtain a pre-reduced blank; C, reducing the pre-reduced blank obtained in step B by vacuum heat to obtain a crude product; D, acid pickling, washing and drying the crude product obtained in step C to obtain the titanium powder. The method for preparing the titanium powder adopts a low-cost titanium-containing material as a raw material, and reduces energy consumption due to formation of a calcium titanate intermediate anduse of vacuum thermal reduction, greatly reduces preparation cost of the titanium powder, and the obtained titanium powder has a purity of more than 99% and a yield of the titanium powder is larger than 98% and the method provides an efficient way for production of titanium powder.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD +1

Purification method for high-purity organic solvent normal propyl alcohol

InactiveCN102746115AHigh puritySimple purification methodHydroxy compound separation/purificationActivated carbonPurification methods

The invention relates to a purification method for high-purity organic solvent normal propyl alcohol. The method includes steps: subjecting raw normal propyl alcohol to removal of high ultraviolet absorption impurities by the aid of activated carbon, utilizing desiccants such as anhydrous calcium sulfate or calcium hydride for drying and dehydration, rectifying, filtering and packaging to obtain the high-purity organic solvent normal propyl alcohol. By the purification method for the high-purity organic solvent normal propyl alcohol, chromatographic-grade normal propyl alcohol products with the purity higher than 99.8% can be obtained, the yield is higher than 95%, the acceptance rate is higher than 93%, and application requirements of users in aspects of scientific researches, subject studies and the like of the high-purity organic solvent (HPLC) normal propyl alcohol can be met. In addition, compared with conventional methods, the purification method for the high-purity organic solvent normal propyl alcohol is high in product purity, simple and convenient to operate and stable in product quality and can be used for large-scale production.

Owner:天津康科德医药化工有限公司

Hydrogen-rich water or hydrogen-rich beverage preparation method

InactiveCN106387578AIncrease productivityLow costGaseous food ingredientsCalcium hydroxideSustained Release Tablet

The invention provides a hydrogen-rich water or hydrogen-rich beverage preparation method. According to the technical scheme of the invention, firstly, calcium hydroxide is prepared into tablets or calcium hydroxide as an effective ingredient is prepared into sustained-release tablets, sustained-release granules or microcapsules. Secondly, the obtained product is placed into a container, wherein water or beverage can permeate into the container or can be accommodated inside the container. In this way, the water / beverage can react with calcium hydride reaction to generate hydrogen. The mass ratio of the effective ingredient calcium hydroxide to auxiliary materials is 1:0 to 1:5. The mass ratio of an adhesive and a controlled-release agent in the auxiliary materials is 1:2 to 2:1.

Owner:TIANJIN TIDAI MEDICINE SCI & TECH

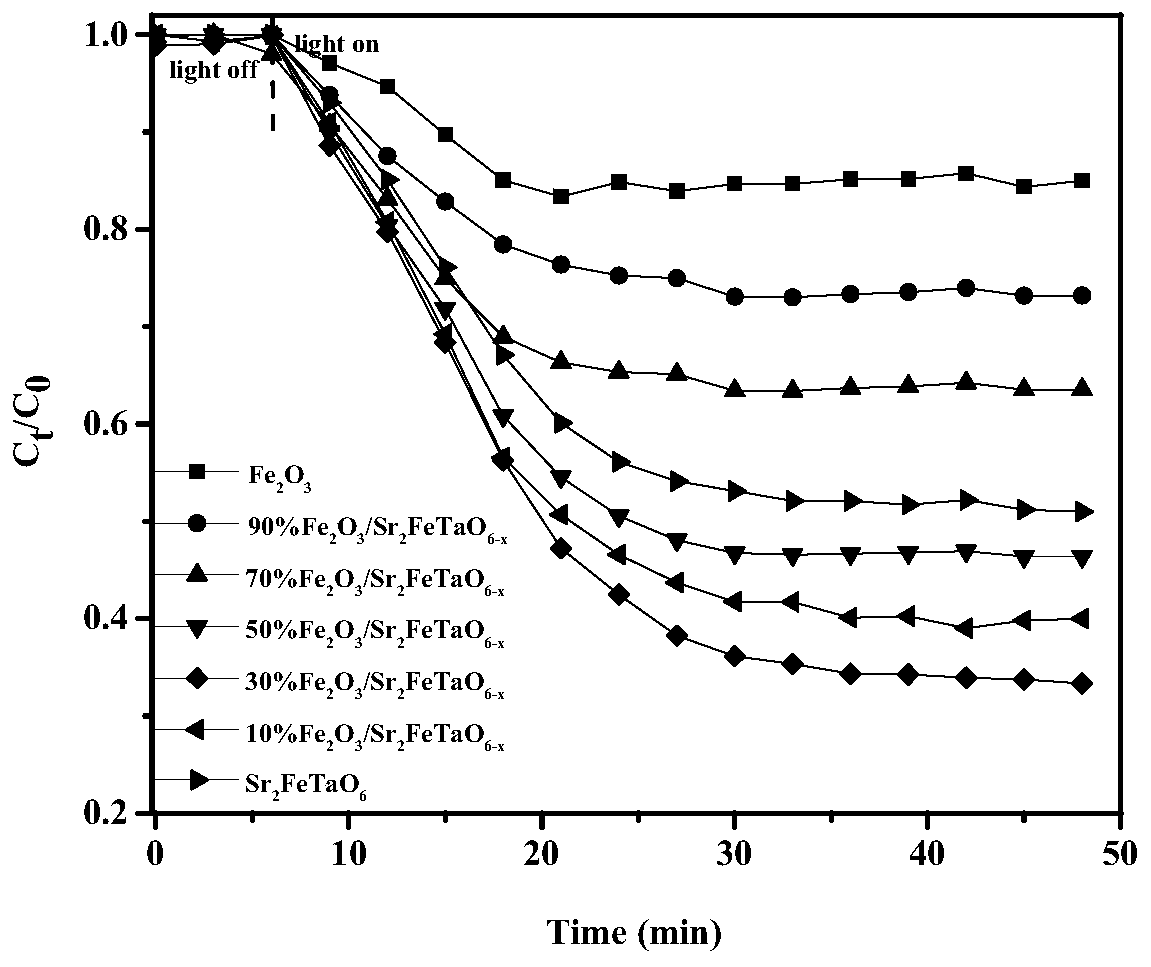

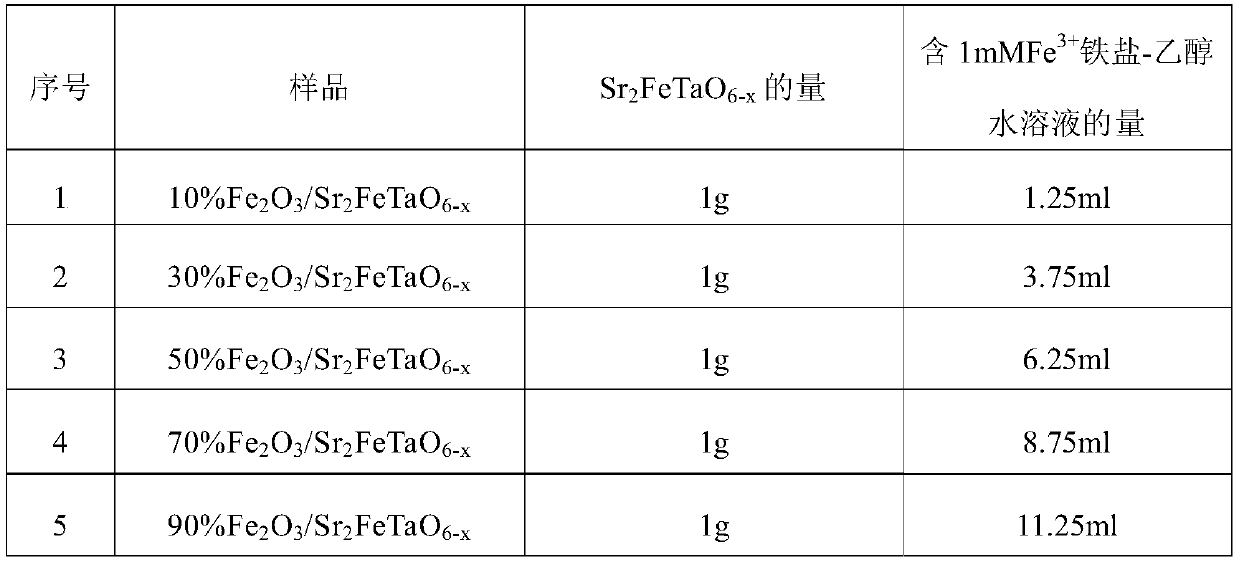

Fe2O3/Sr2FeTaO6-x photocatalyst, preparation method and application thereof

ActiveCN110860295APromote photocatalytic degradationStrong interface forceHeterogenous catalyst chemical elementsDispersed particle separationPtru catalystNitric oxide

The invention discloses a Fe2O3 / Sr2FeTaO6-x photocatalyst, a preparation method and application thereof. The preparation method includes the steps of: dissolving oleic acid in anhydrous ethanol, adding sodium oleate, then adding tantalum pentachloride, an organic ferric salt and an organic strontium salt, performing stirring, then carrying out hydrothermal reaction, and then conducting flushing and drying to obtain Sr2FeTaO6 powder; mixing the Sr2FeTaO6 powder with calcium hydride, and conducting calcination to obtain dark red Sr2FeTaO6-x; preparing a ferric salt ethanol water solution, addingSr2FeTaO6-x, stirring the substances violently, carrying out hydrothermal reaction, then performing natural cooling, and conducting washing and drying to obtain the Fe2O3 / Sr2FeTaO6-x photocatalyst. The invention provides a brand-new preparation method of the photocatalyst on the basis of a hydrothermal-calcium hydride modification method, the Fe2O3 / Sr2FeTaO6-x composite semiconductor system withhigh interfacial force can be finally synthesized, and photocatalytic degradation of nitric oxide is greatly improved.

Owner:YANCHENG INST OF TECH

Method for purifying chromatographic grade butyl acetate

InactiveCN102417450AHigh purityEasy to separateCarboxylic acid esters separation/purificationActivated carbonNitrogen

The invention relates to a method for purifying chromatographic grade butyl acetate. The method comprises the following steps of: absorbing a raw material, namely butyl acetate by using activated carbon and an activated alumina column to remove organic impurities, calcium hydride or magnesium sulfate, drying and dehydrating, rectifying, filtering, further removing impurities, and performing nitrogen-infilling packaging to obtain a high purity liquid chromatography (HPLC) grade butyl acetate product. By the method, a chromatographic grade butyl acetate product with the purity of more than 99.9 percent can be obtained, the yield is over 93 percent, the qualification rate is over 93 percent, and application requirements of customers of a HPLC reagent butyl acetate on aspects such as scientific experiments, subject research and the like can be met; meanwhile, compared with the conventional method, the invention has the advantages that: the product has high purity and stable quality, and the method is easy to operate and is suitable for large-scale production.

Owner:天津市康科德科技有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com