Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

185results about How to "Increase corrosion rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

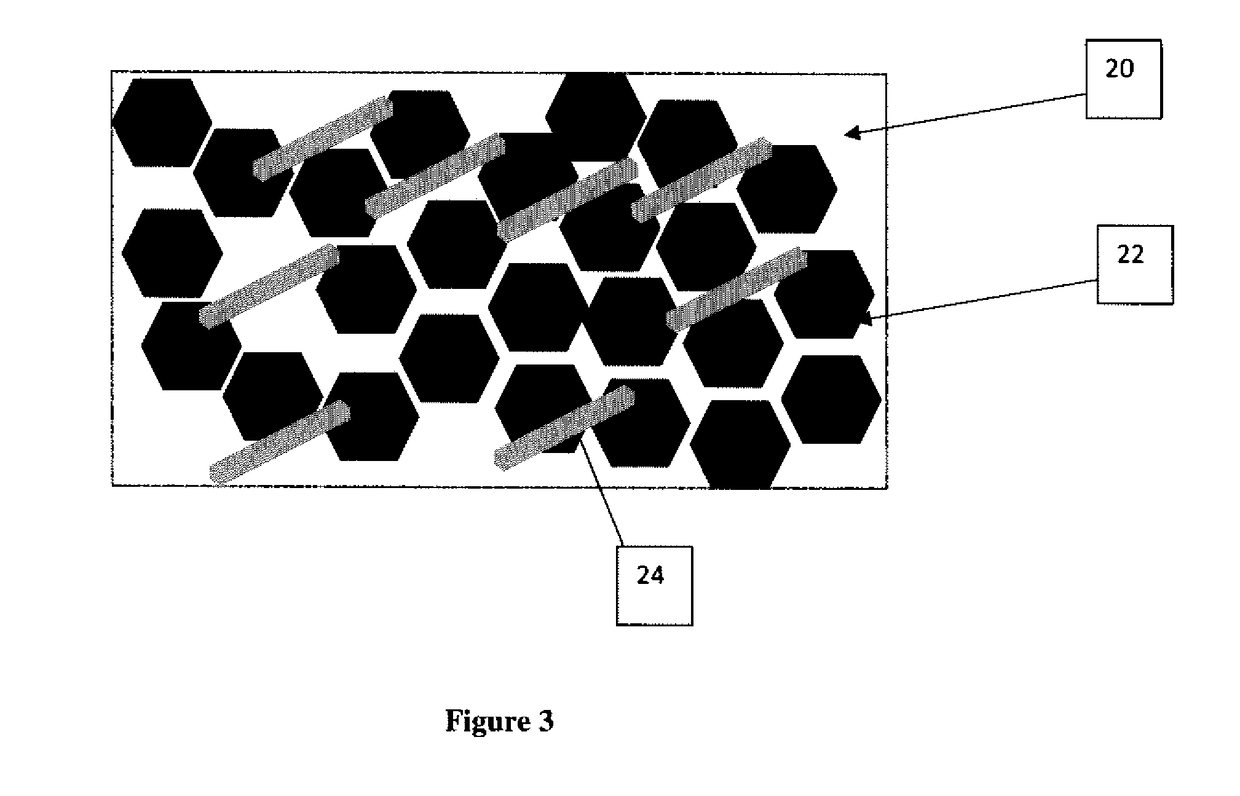

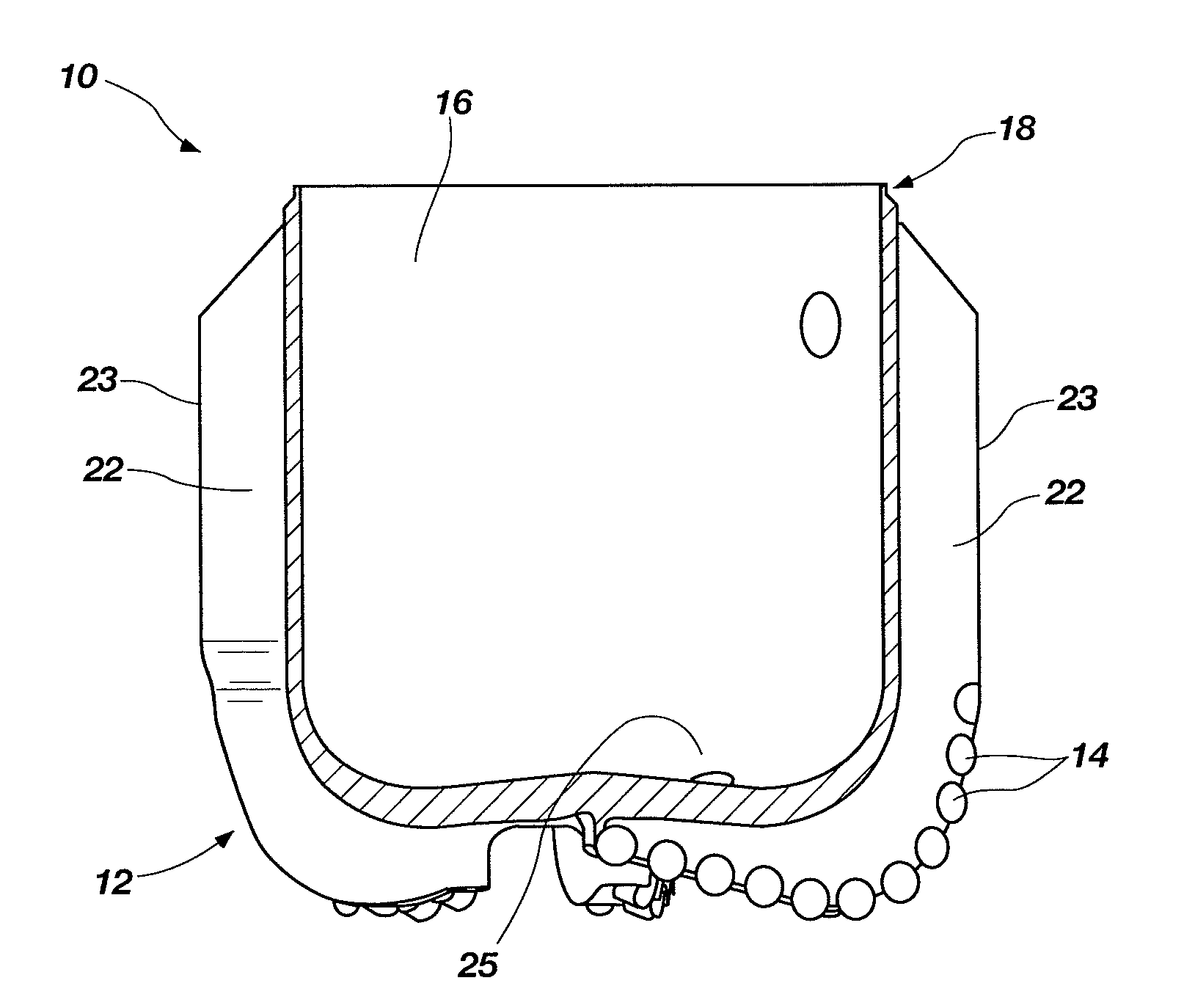

Degradable medical device

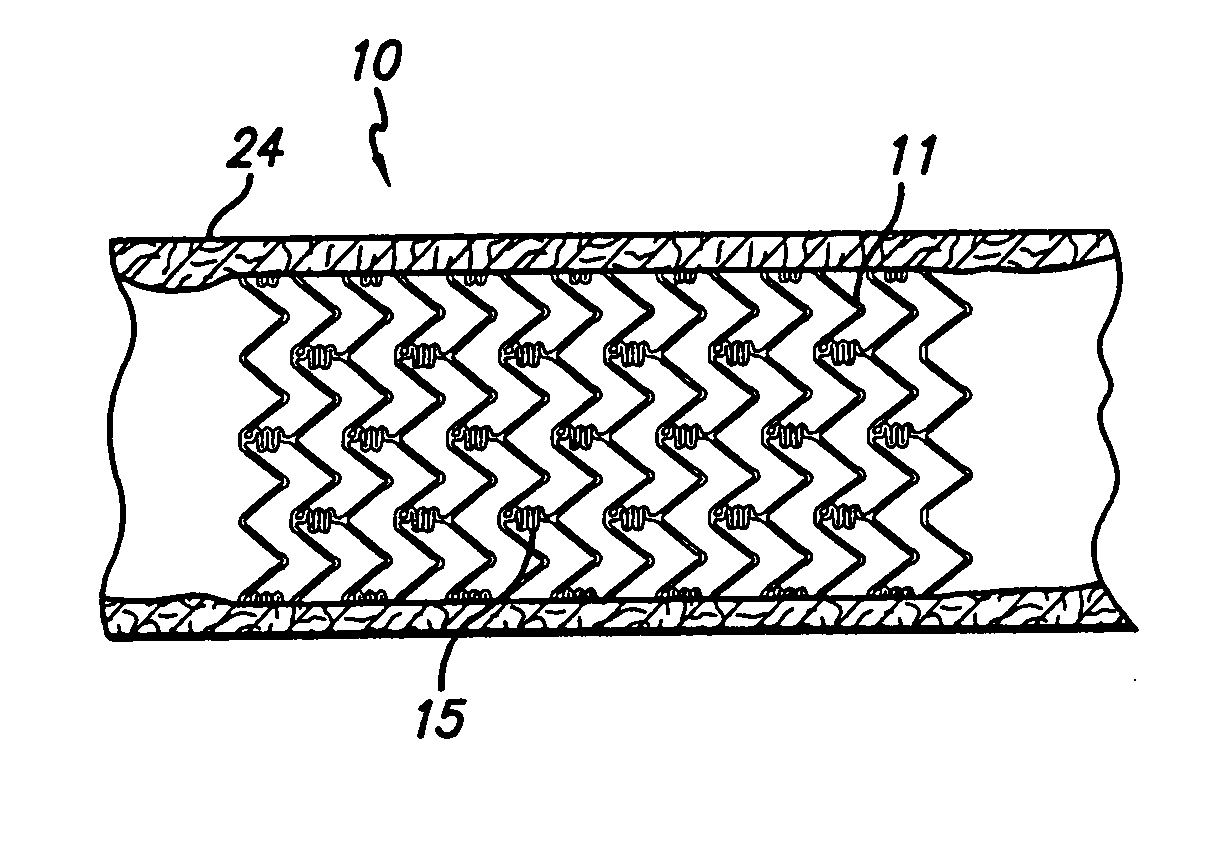

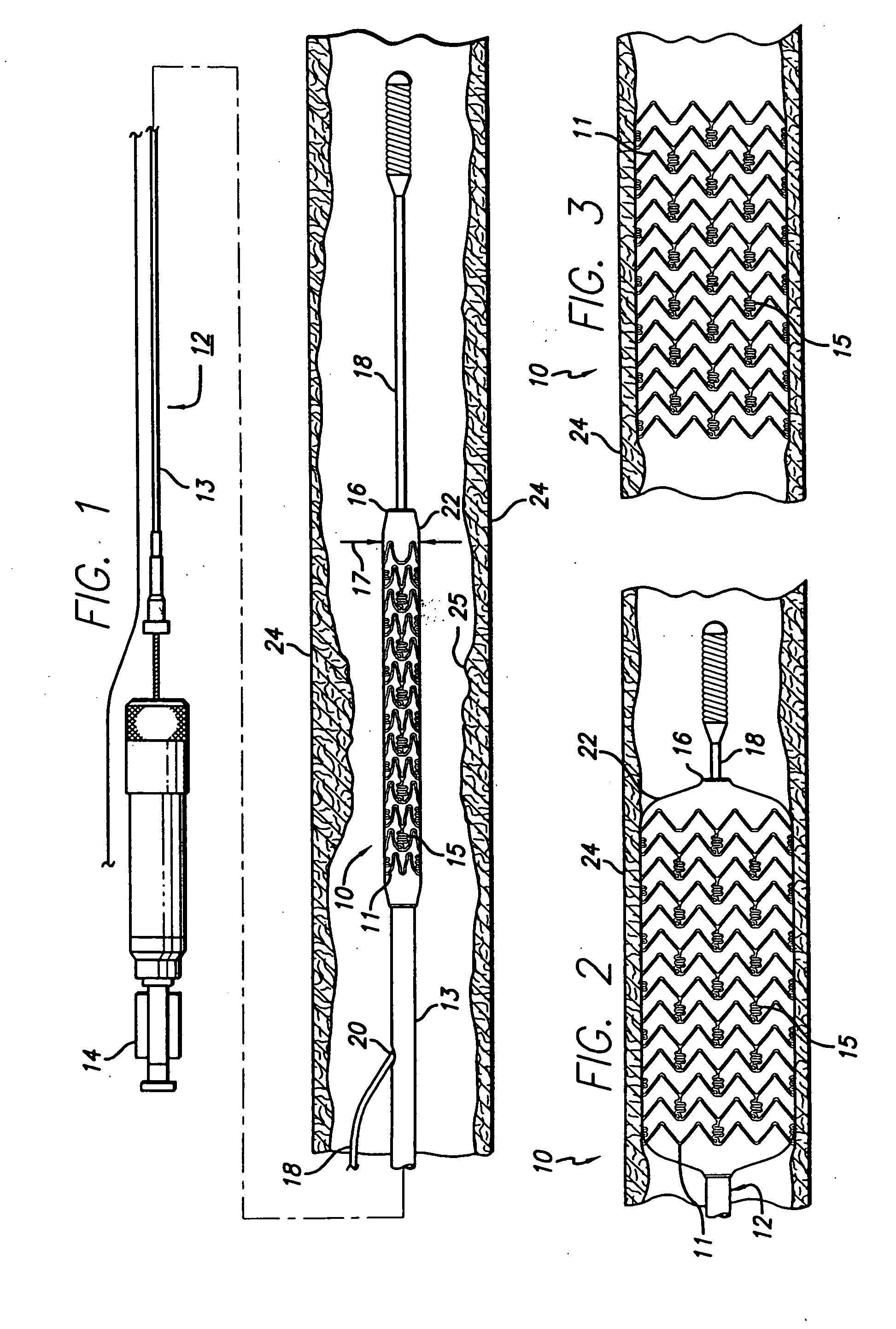

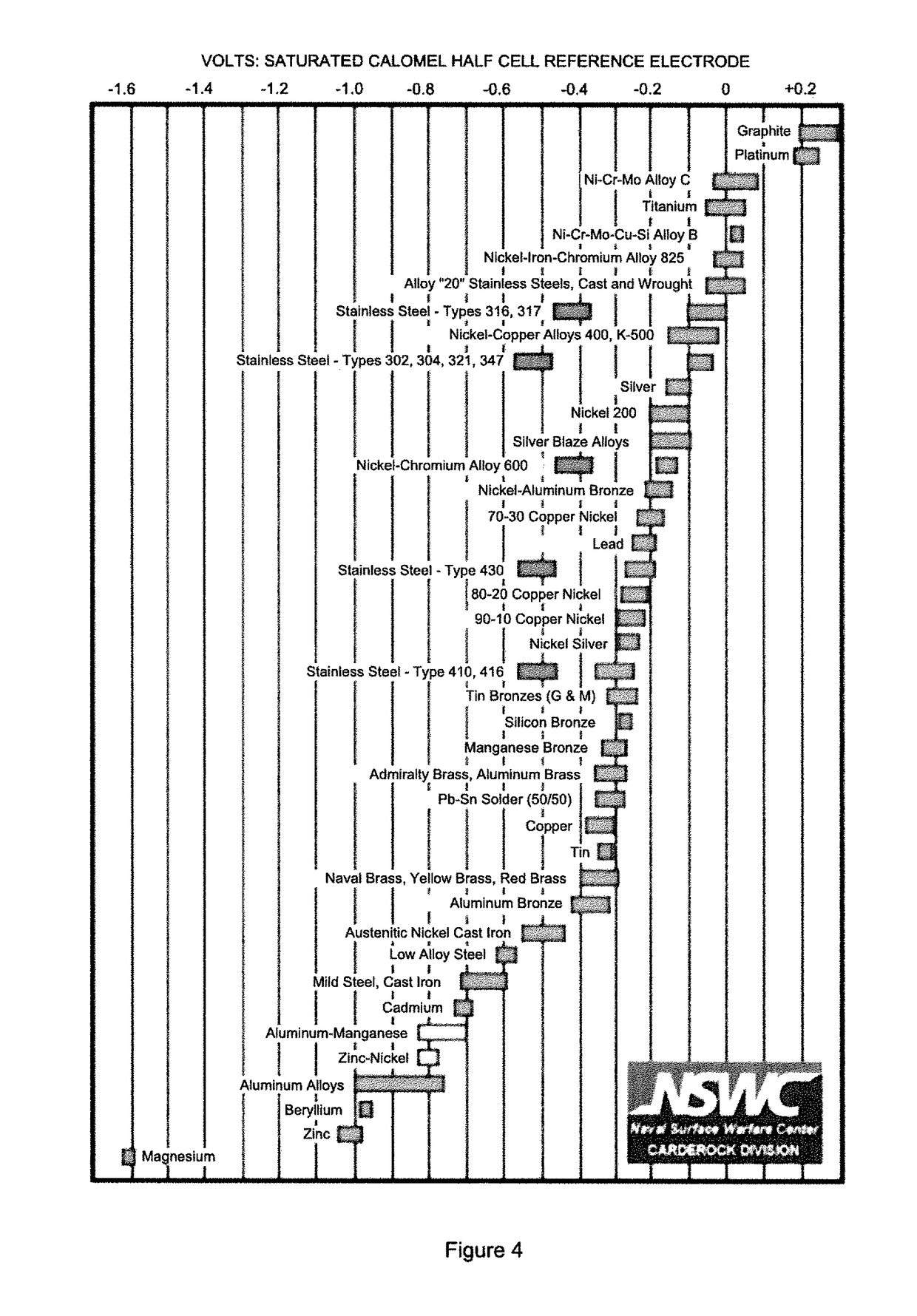

An implantable medical device is provided that degrades upon contact with body fluids so as to limit its residence time within the body. The device is formed of a porous corrodible metal to simultaneously provide high strength and an accelerated corrosion rate. The corrosion rate of a device formed of metal subject to self-dissolution or of a combination of metals subject to galvanic corrosion is accelerated by its porous structure. Coating the corrodible metallic device with a degradable polymer serves to delay the onset of corrosion of the underlying metallic structure.

Owner:KLEINE KLAUS +1

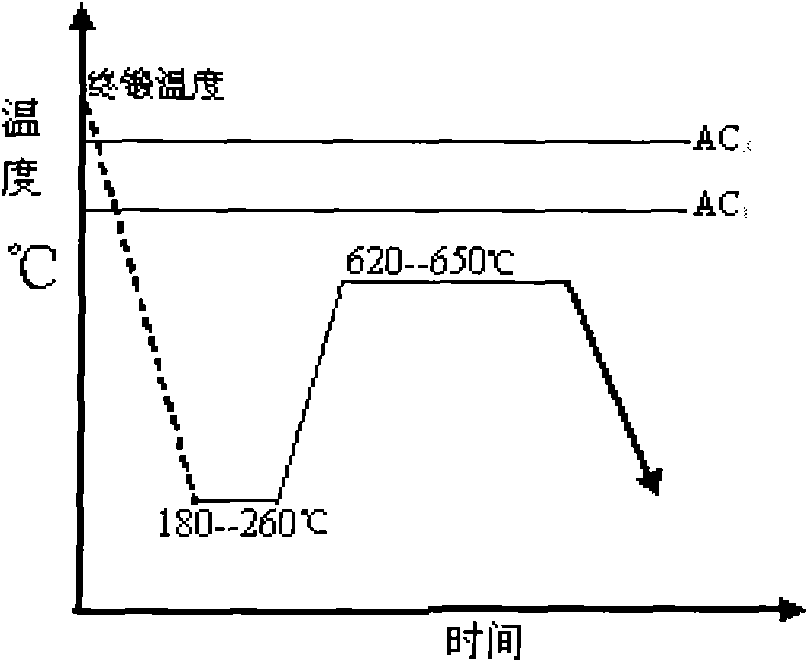

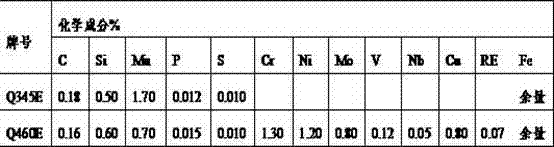

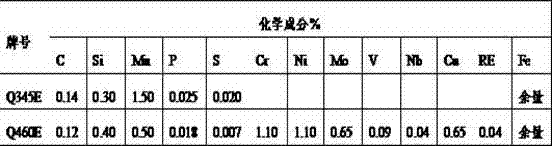

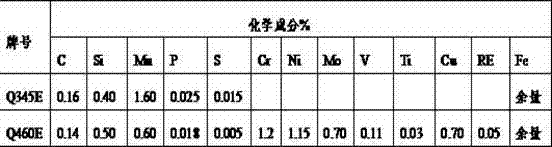

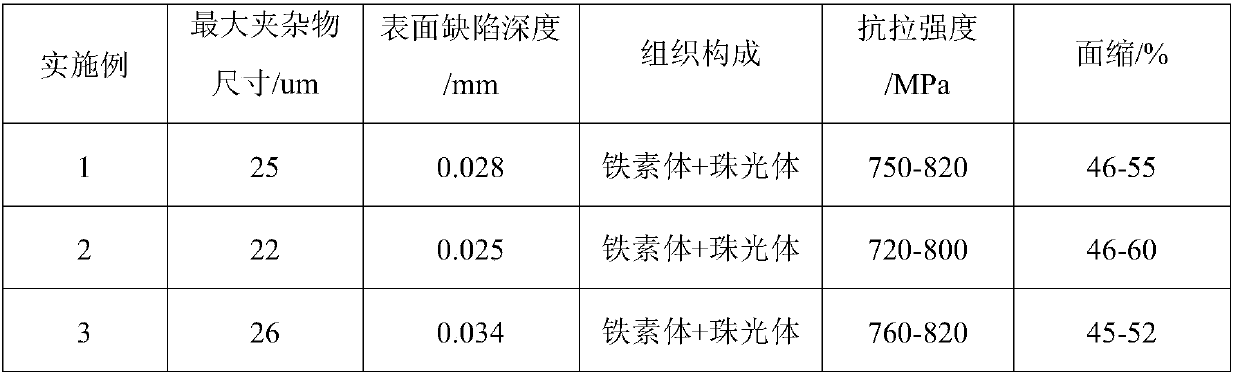

Wind power flange alloy steel and preparation technology of parts thereof

The invention discloses wind power flange alloy steel and a preparation technology of parts thereof. The alloy steel comprises the following chemical compositions: carbon, silicon, manganese, phosphorus, sulfur, chromium, molybdenum, vanadium, nickel, copper, nitrogen, oxygen, hydrogen, rare earth and the balance of iron and the inevitable impurities. The preparation technology of the alloy steel parts comprises the following steps: pretreating molten iron, smelting in a converter, performing external refining, casting steel ingots, performing flame cleaning, heating, forging, slowly cooling, performing heat treatment, machining, performing flaw detection, inspecting, packaging and warehousing. Compared with the existing alloy steel used in the wind power generation at home and aboard, the alloy steel disclosed by the invention has higher tensile strength, yield strength, elongation after fracture and reduction of area, particularly higher low-temperature impact toughness. The atmosphere corrosion resistance and the sea atmosphere corrosion resistance are increased by two levels.

Owner:江阴同庆机械制造有限公司

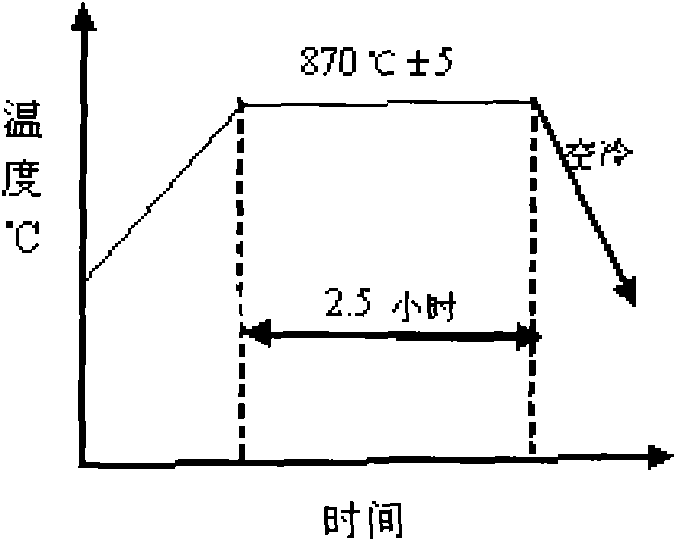

Material used in offshore wind power equipment, and workpiece manufacturing process

ActiveCN102851609AHigh yield strengthHigh tensile strengthFurnace typesHeat treatment furnacesRare earthImpurity

The invention discloses a material used in offshore wind power equipment, and a workpiece manufacturing process. The material comprises the chemical components of carbon, silicon, manganese, phosphorous, sulfur, chromium, nickel, molybdenum, vanadium, copper and rare earth, and balance of iron and inevitable impurities. According to the invention, through steps of high-quality molten iron selecting, KR molten iron pre-treating, top and bottom composite converter blowing, argon blowing treating, LF furnace refining, VD vacuum degassing treating, round billet continuous casting, heap cooling, sawing and blanking, billet heating, free forging, punching, fine coining, heat treating, mechanical processing, flaw detecting, inspecting, packaging, storing, and the like, a material used in key components of offshore wind power equipment of more than 5 megawatts can be produced. The material is advantageous than Q345E-performance steel, high yield strength, good low-temperature impact toughness, and better marine-atmosphere-corrosion resistance. The invention adopts a serried of optimizing technical measures upon smelting and manufacturing processes of the steel, such that user requirements are satisfied.

Owner:JIANGYIN HENGRUN HEAVY IND

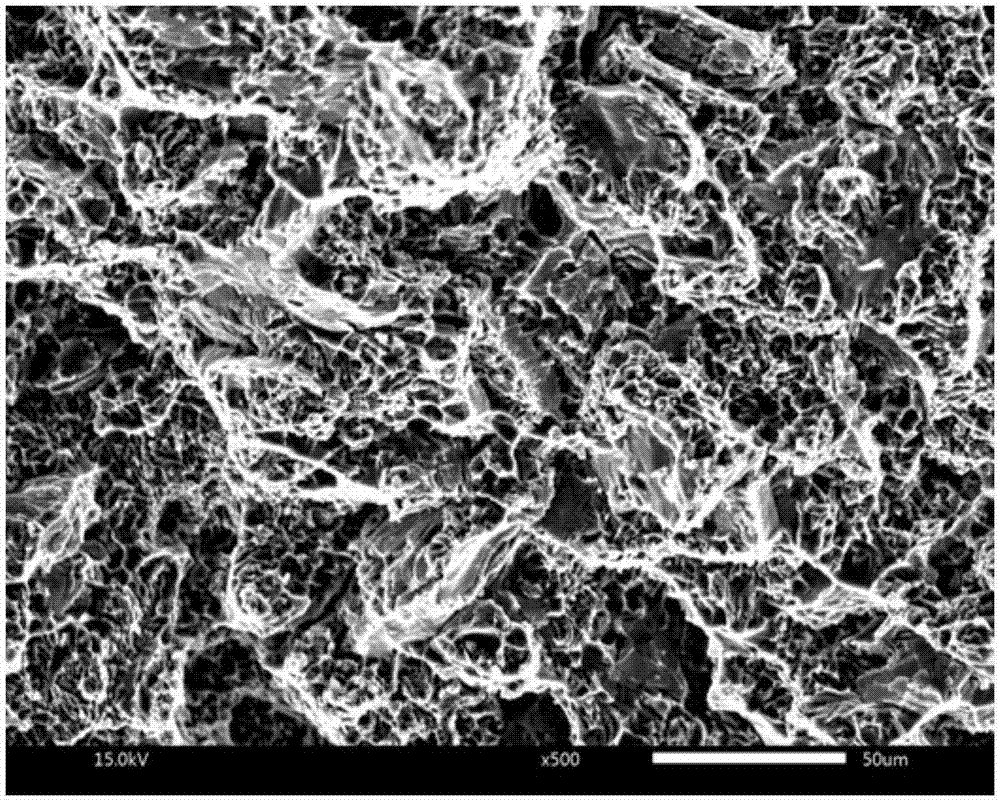

Surface treated metal and surface treatment method thereof and metal resin complex and preparation method of metal resin complex

ActiveCN103451701AIncrease corrosion rateReduce corrosion rateAnodisationPore diameterAnodic oxidation

The invention provides a surface treated metal and a surface treatment method thereof and a metal resin complex and a preparation method of the metal resin complex. The surface treated metal comprises a metal body and an anodic oxidation film layer which is located on the surface of the metal body, the anodic oxidation film layer includes a barrier layer which is in contact with the metal body and a loose layer located on the outer surface of the barrier layer, the loose layer contains anodic oxidation film micropores, the pore diameter of the anodic oxidation film micropores is 10 nm-800 mum, the barrier layer contains barrier layer corrosion pores, the pore diameter of the barrier layer corrosion pores is 10 nm-800 mum, the metal body includes a corrosion layer which is in contact with the barrier layer, the corrosion layer contains metal corrosion pores, the pore diameter of the metal corrosion pores is 10 nm-1 mm, the metal is aluminum alloy or aluminum, the bonding force between the metal and resin is strong, and the surface treated metal is simple in process, is easy for large-scale production, and has no pollution.

Owner:BYD CO LTD

Solder removing liquid, preparation method and application thereof

The invention provides solder removing liquid, a preparation method and application thereof. The solder removing liquid comprises the following components in percentage by weight: 15-50 percent of nitric acid, 1-20 percent of ferric nitrate or ferric chloride, 1-5 percent of sulfoacid and the balance of water. The solder removing liquid provided by the invention has the advantages of strong oxidability, high speed of dissolving solder, simpleness and easiness of raw materials, low preparation cost, no containing of a stabilizing agent and simple formulation and favorability of recycling valuable metals in waste liquid; and the waste solder removing liquid formed after desoldering can stand to generate beta-stannic acid sediment and is convenient for recovering tin metal.

Owner:GEM CO LTD

Preparation method of metal resin complex and metal resin complex prepared thereby

The invention provides a preparation method of an aluminum alloy resin complex and the aluminum alloy resin complex prepared thereby. The preparation method of the aluminum alloy resin complex comprises the following steps: S1, anodic oxidation: a metal substrate with a surface comprising an anodic oxidation film layer is obtained by anodic oxidation of a pretreated metal substrate, and the metal substrate is an aluminum alloy substrate or aluminum substrate; S2, treatment with an etching liquid: the metal substrate containing the anodic oxidation film layer and obtained by the step S1 is immersed in the etching liquid for treatment to obtain a surface treated metal substrate; S3, injection: the surface of the surface treated metal substrate is injected with a resin composition, and then the metal resin complex is obtained after molding; and the etching liquid contains HCl and a soluble halogen acid salt, or contains H3PO4 and a soluble phosphate. In the metal resin complex, the binding force between aluminum alloy and resin is strong, and the process is simple, and is easy for large-scale production.

Owner:BYD CO LTD

Galvanically-Active In Situ Formed Particles for Controlled Rate Dissolving Tools

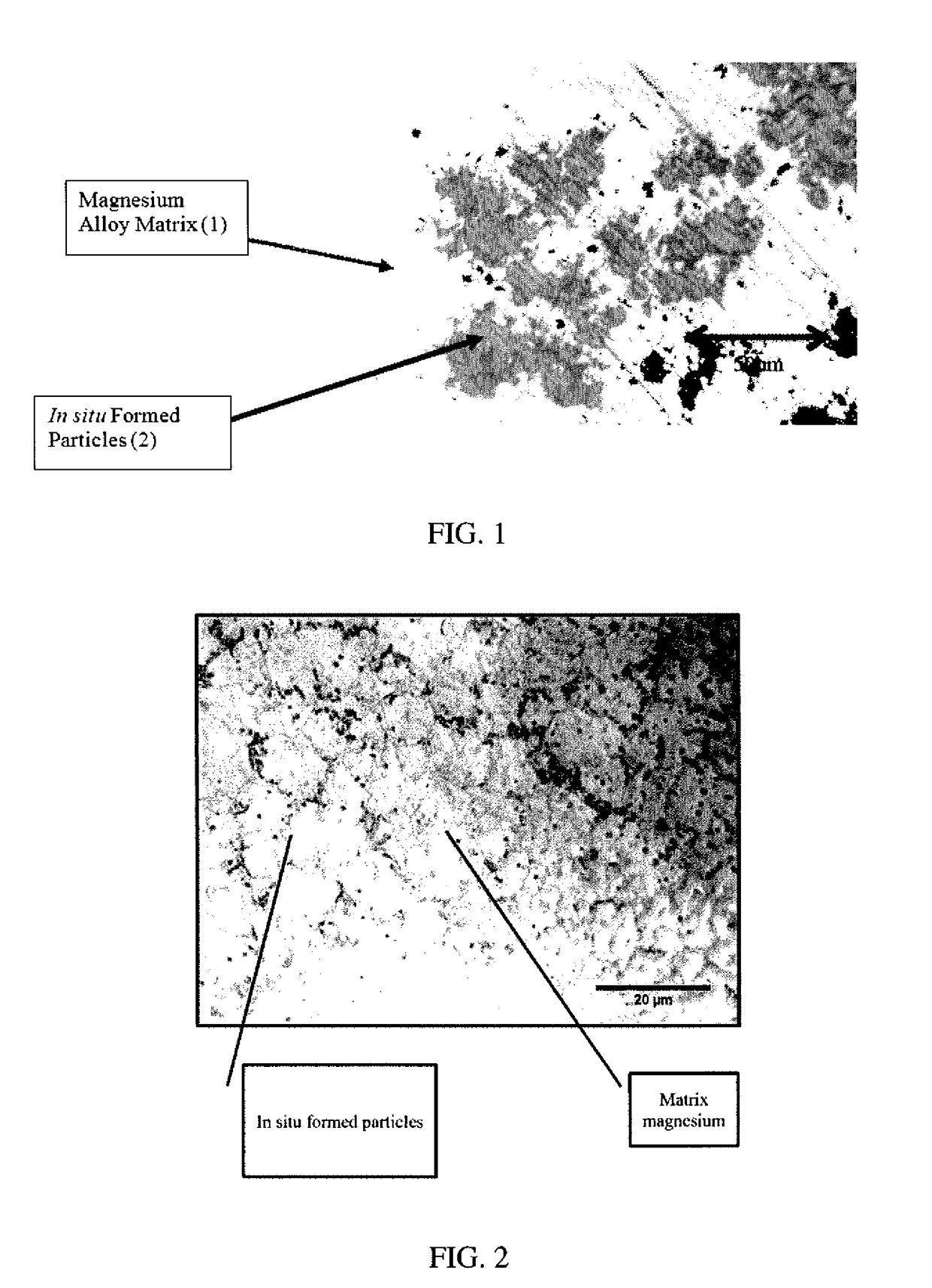

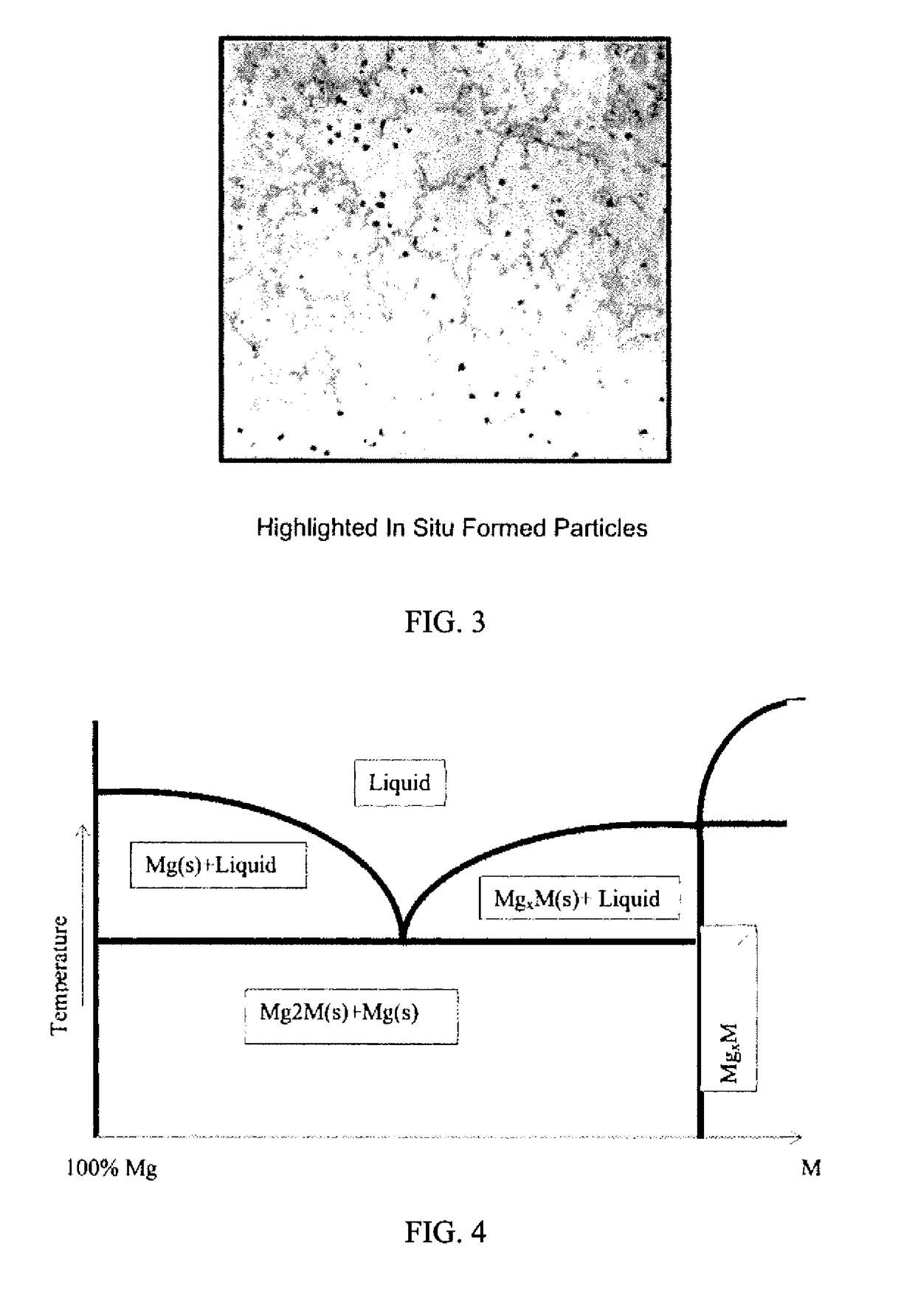

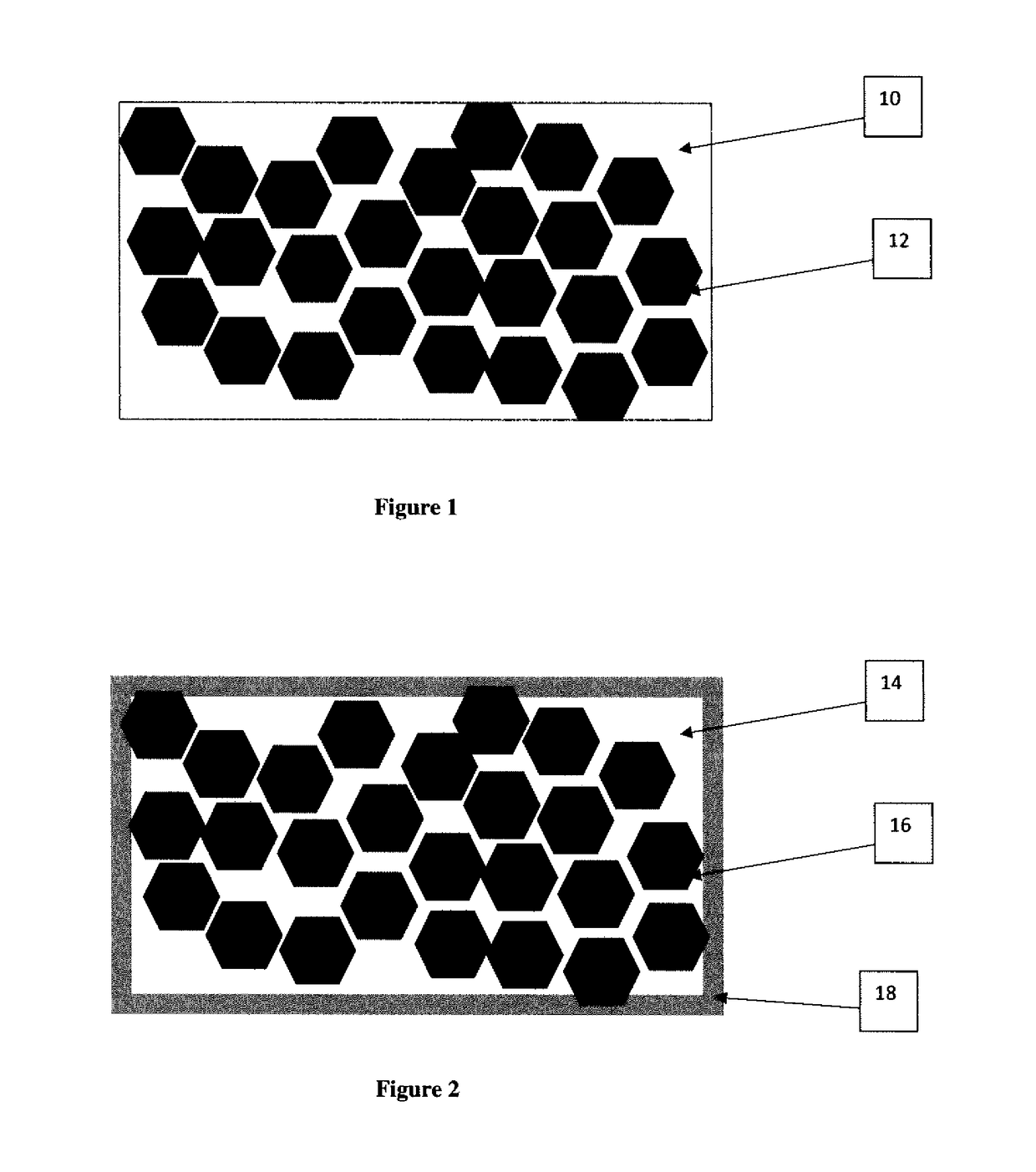

ActiveUS20190054523A1High incipient melting pointIncrease corrosion rateTransportation and packagingMetal-working apparatusAlloyElectrochemistry

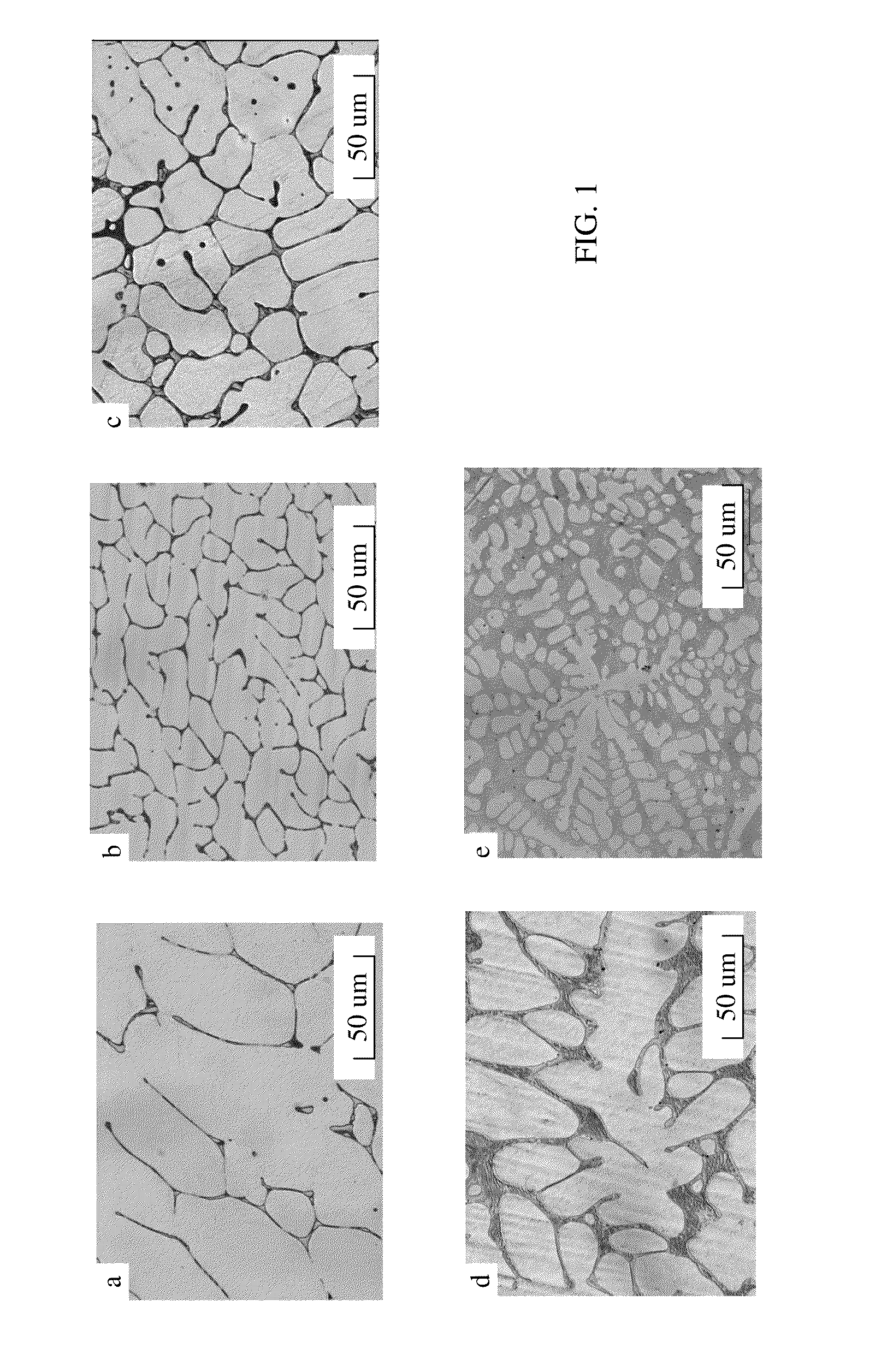

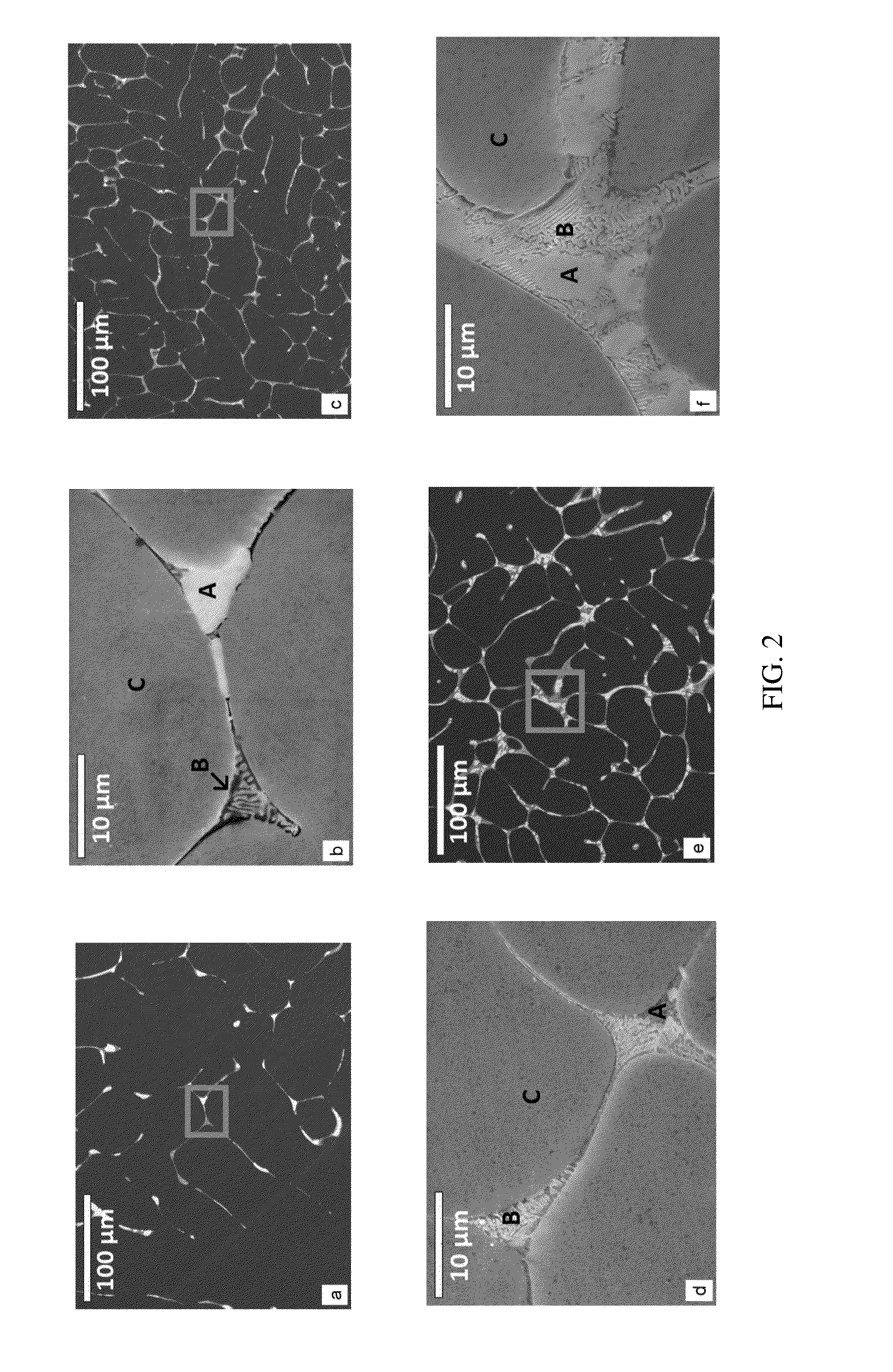

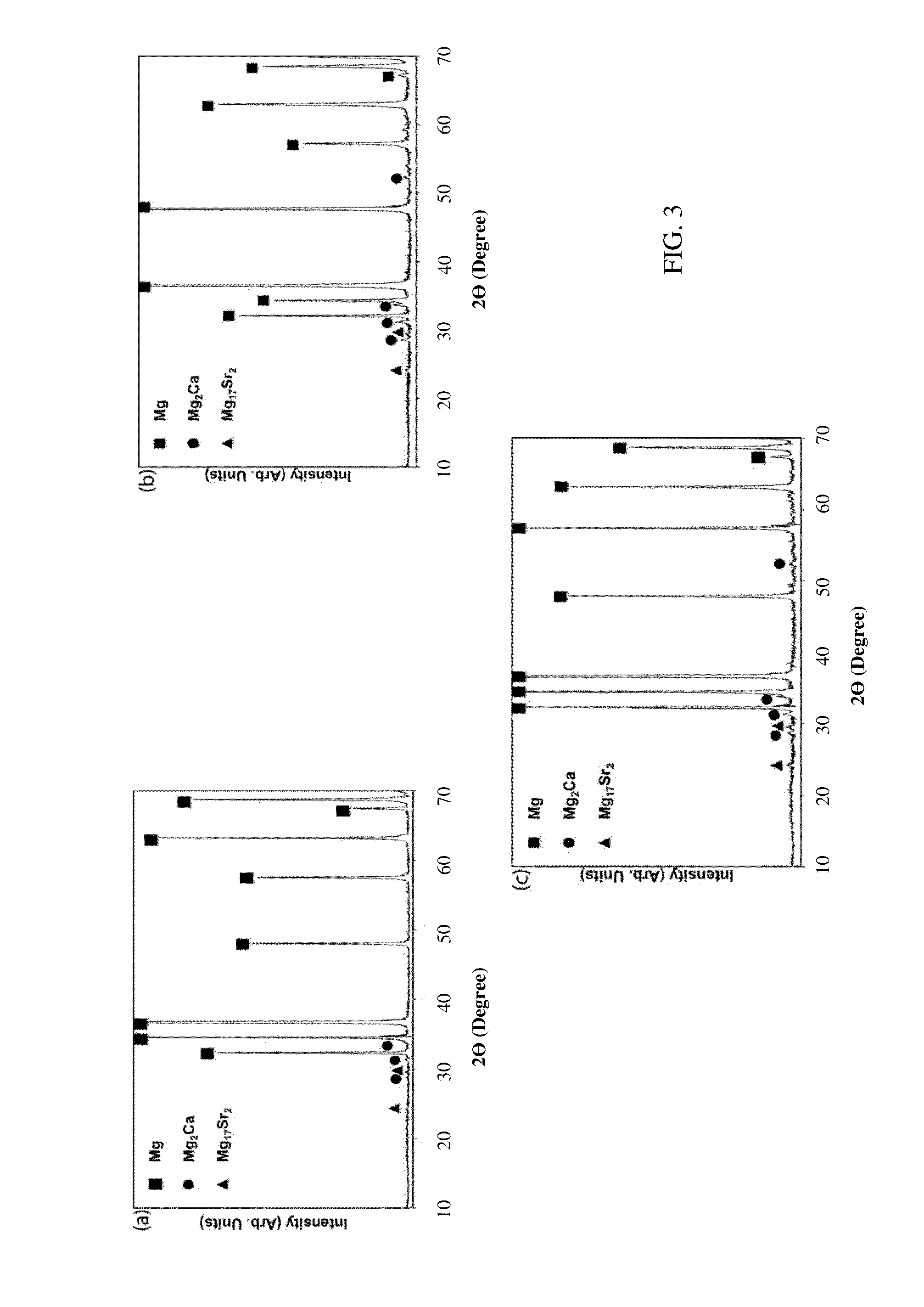

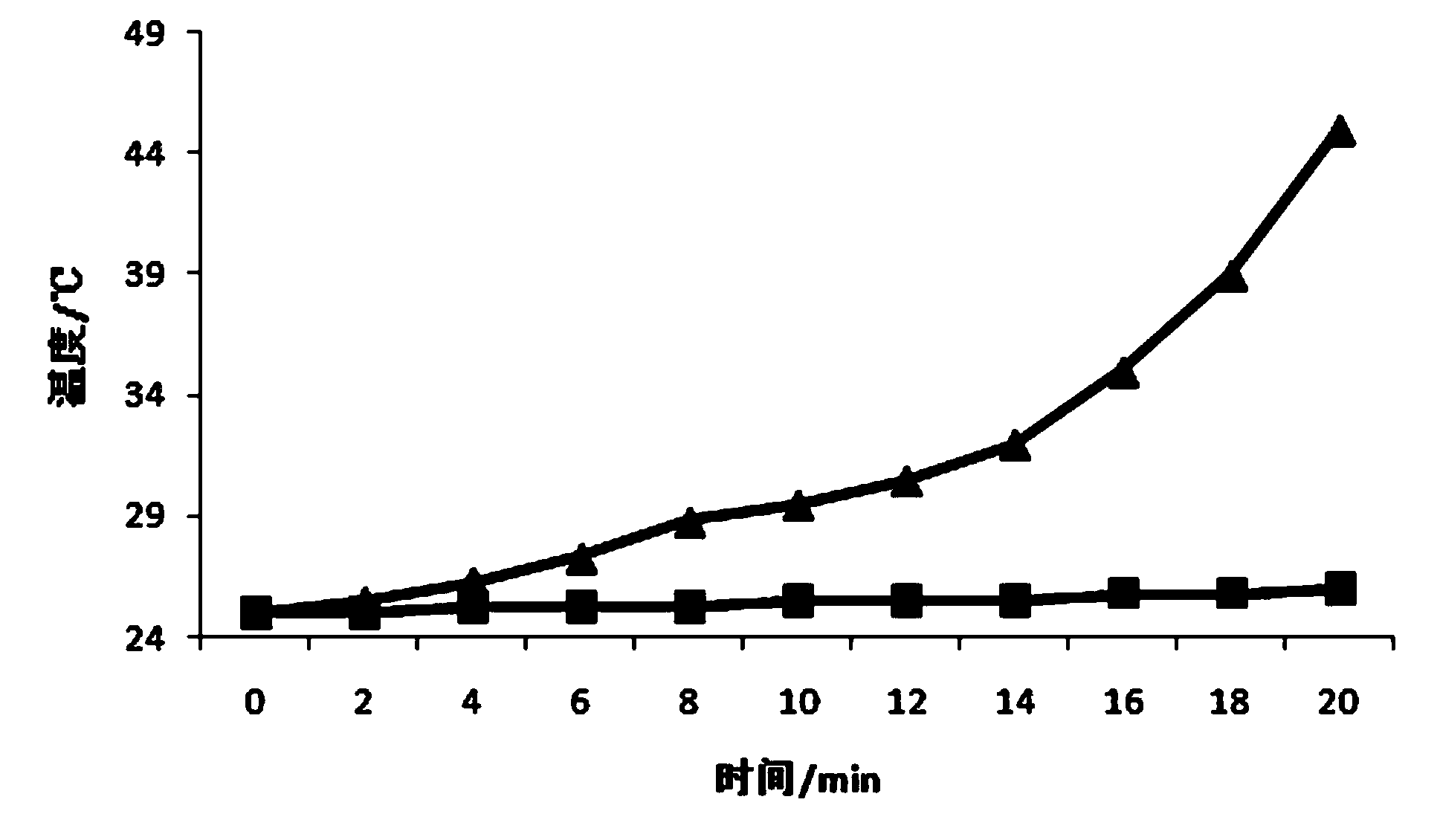

A tastable, moldable, and / or extrudable structure using a metallic primary alloy. One or more additives are added to the metallic primary alloy so that in situ galvanically-active reinforcement particles are formed in the melt or on cooling from the melt. The composite contains an optimal composition and morphology to achieve a specific galvanic corrosion rate in the entire composite. The in situ formed galvanically-active particles can be used to enhance mechanical properties of the composite, such as ductility and / or tensile strength. The final casting can also be enhanced by heat treatment, as well as deformation processing such as extrusion, forging, or rolling, to further improve the strength of the final composite over the as-cast material.

Owner:TERVES

Degradable Metal Matrix Composite

The present invention relates to the composition and production of an engineered degradable metal matrix composite that is useful in constructing temporary systems requiring wear resistance, high hardness, and / or high resistance to deformation in water-bearing applications such as, but not limited to, oil and gas completion operations.

Owner:TERVES

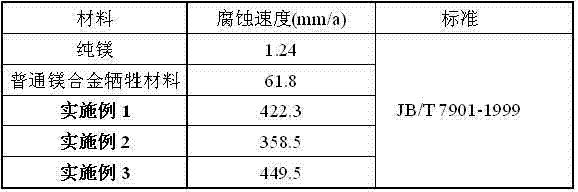

Rapid-corrosion magnesium alloy product and preparation method thereof

The invention relates to a rapid-corrosion magnesium alloy product. The alloy product comprises the following components in percentage by weight: 1-6% of aluminum, 1-6% of zinc, 1-3% of iron, 5-15% of copper, 0.1-1% of silver, 0.1-1.2% of nickel and the balance of magnesium. Meanwhile, the invention also discloses a preparation method of the alloy product. The effects of aluminum and zinc are fully utilized to improve the strength and hardness of the magnesium alloy, copper, iron, silver and nickel are used for improving the corrosion rate; by regulating and controlling the ratio among metal elements, the mechanical properties and corrosion rate are greatly increased and thus the purposes that the magnesium alloy product can be used as a structural member and can protect a device and the magnesium alloy product can be rapidly dissolved under certain conditions are achieved.

Owner:中国石油化工股份有限公司西南油气分公司工程技术研究院 +1

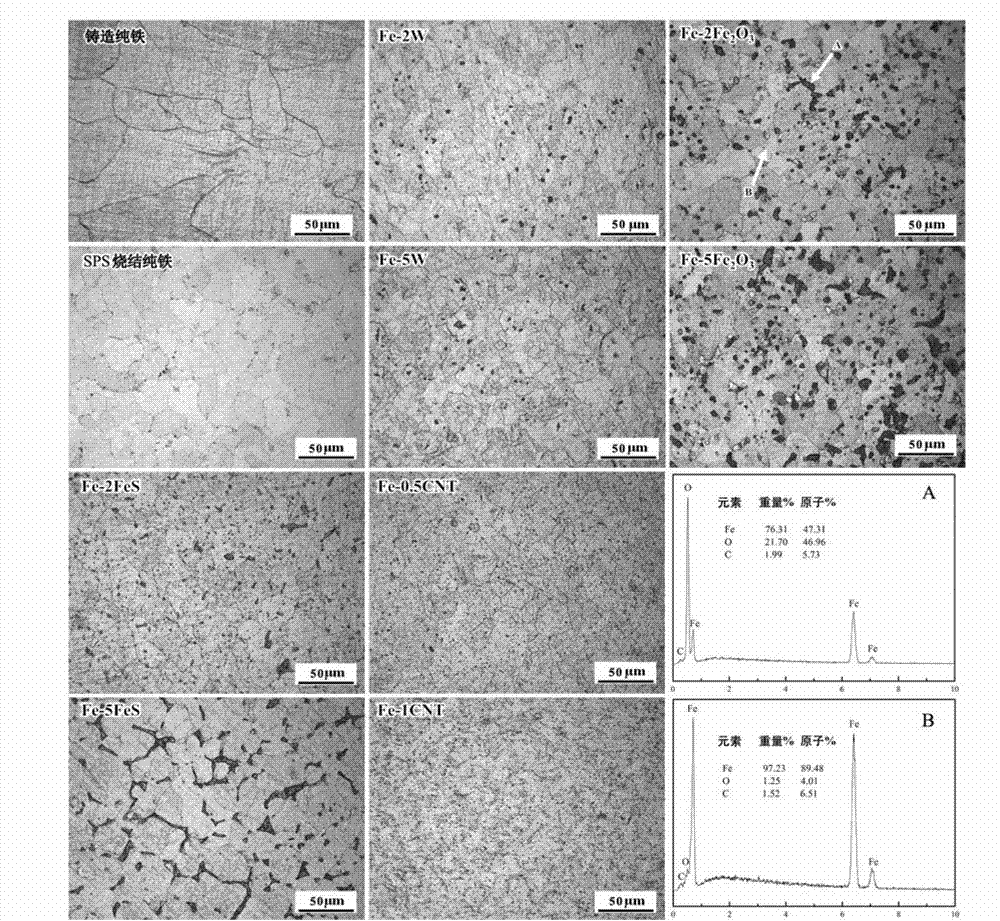

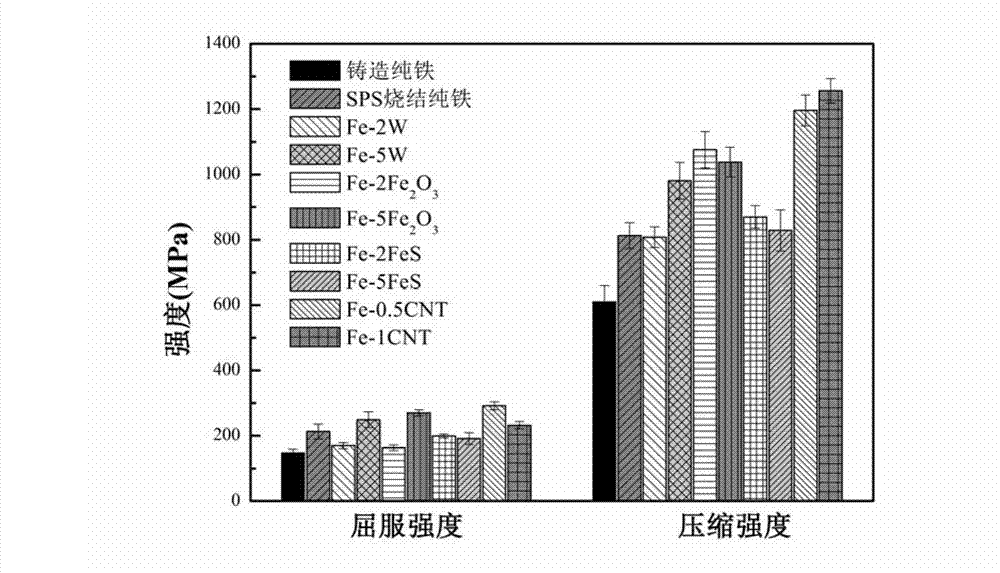

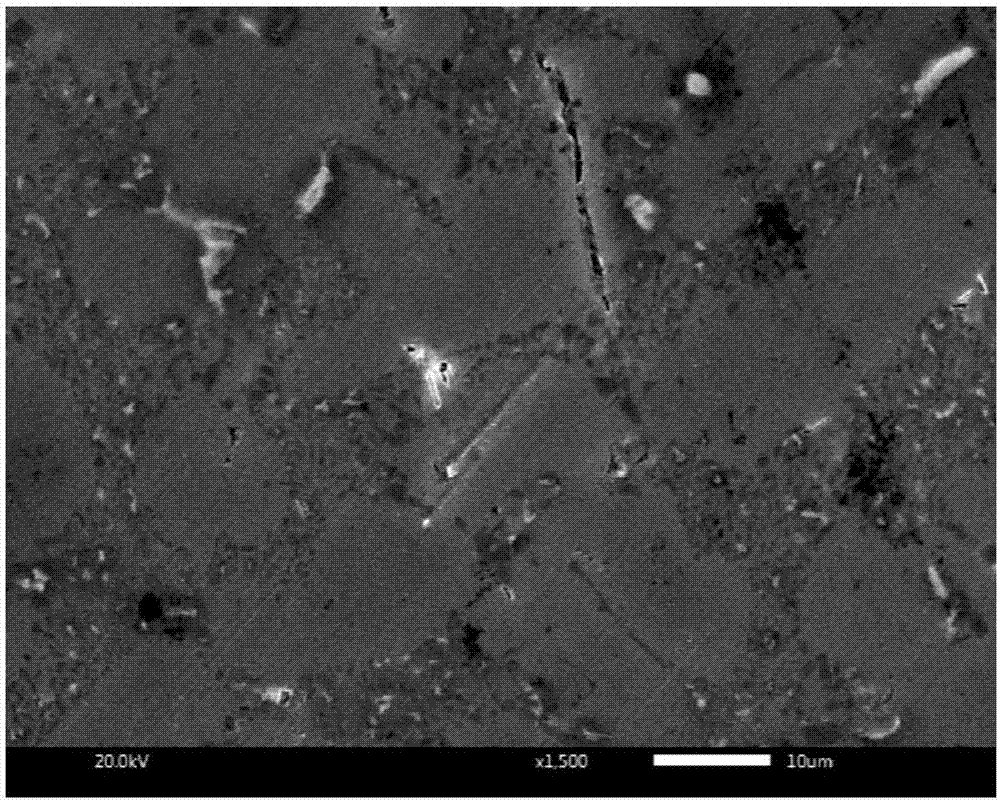

Iron-based composite material used for full-degradation cardiovascular support and preparation method thereof

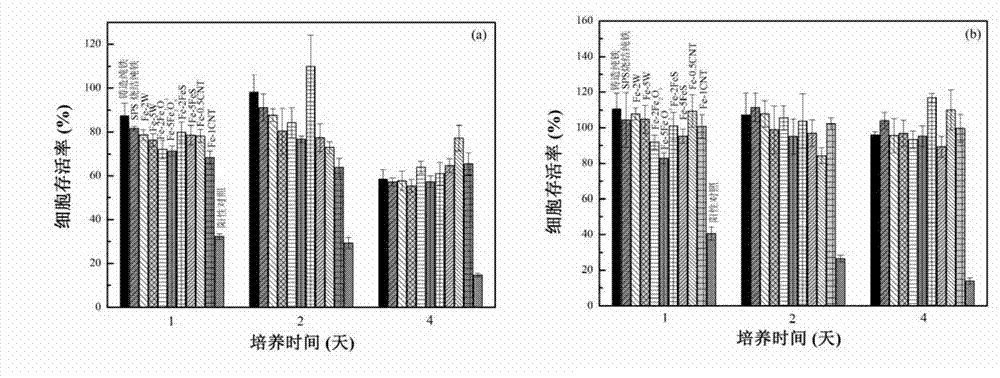

InactiveCN102961787AFulfil requirementsIncrease corrosion rateSurgeryCoatingsCardiovascular stentCarbon nanotube

The invention discloses an iron-based composite material used for a full-degradation cardiovascular support and a preparation method thereof. The iron-based composite material comprises Fe and any one of W, Fe2O3, FeS and carbon nano tube, wherein the content of any one of W, Fe2O3, FeS and carbon nano tube is 0-10% and more than 0% in the iron-based composite material in percent by weight. The preparation method of the iron-based composite material comprises the following steps of: mixing iron powder with any one of tungsten powder, Fe2O3 powder, FeS powder and carbon nano tube powder, then carrying out spark plasma sintering or sintering by virtue of powder metallurgy, and cooling, so that the iron-based composite material is obtained. The iron-based composite material used for full-degradation cardiovascular support disclosed by the invention overcomes the defects of the traditional inert metal support such as late thrombosis and restenosis; and a secondary phase harmless to a human body is selected as a strengthening phase of the composite material, so that corrosion rate of an iron base in a body fluid environment is increased, and corrosion of the iron base is more uniform.

Owner:PEKING UNIV

Method for zero-valent metal and carbon combination internal electrolysis catalysis reduction of nitrate nitrogen in water zero-valent metal and carbon combination

InactiveCN103193298APromote reductionIncrease corrosion rateWater contaminantsWater/sewage treatment by reductionWater processingPollution

The invention belongs to the water processing technology application field, relates to a method for removing nitrate nitrogen in water, and especially relates to a method for the zero-valent metal and carbon combination internal electrolysis catalysis reduction of a pollutant nitrate nitrogen in water. A technological principle of the method is characterized in that the reductibility of a zero-valent metal elementary substance and the internal electrolysis effect of the zero-valent metal elementary substance and conductive substances comprising active carbon and the like are utilized to accelerate the transfer of electrons in a solid-liquid phase interface, so nitrate nitrogen is rapidly reduced and removed, and the zero-valent metal can prolong the service life because of the internal electrolysis effect, thereby the reaction efficiency is improved. The method is characterized in that the granular or powdery zero-valent metal and a carbon material are directly added to or are mixed and then added to water containing nitrate nitrogen, stirring is carried out in a certain strength under reacting, and nitrate is directly reduced on the surface of the metal, and is reducibly degraded under the action of nascent state hydrogen [H] generated by an electrode reaction in the internal electrolysis process. The method has the advantages of simple operation, convenient management, less secondary pollution and high reaction time and space efficiency.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Water and waste water purification method for improving reactivity of zero-valent iron through magnetic field pretreatment

InactiveCN103332766AIncrease corrosion rateHigh reactivityWater/sewage treatment by electrochemical methodsPurification methodsPollution

The invention belongs to the technical field of water and waste water treatment, and relates to a water and waste water purification method for improving reactivity of zero-valent iron through magnetic field pretreatment. The method is characterized by pretreating the zero-valent iron by utilizing the magnetic field, and adding the pretreated zero-valent iron into a relevant reactor for purifying the water or waste water. The method aims at the application of the zero-valent iron in environment pollution improvement. The zero-valent iron is pretreated in the magnetic field, and a passive film on the surface of the zero-valent iron is destroyed, so that the corrosion rate of the zero-valent iron can be accelerated, and the removal rate of the contaminant can be improved. The method can be used not only for improving the reactivity of unused zero-valent iron but also for improving the reactivity of used zero-valent iron with the passive film on the surface. Compared with the prior art, the method is simple to use, does not consume any chemical substance, and is environment-friendly and energy-saving, after the reaction, no toxic metal ions are left, and the method has no ecotoxicity.

Owner:TONGJI UNIV

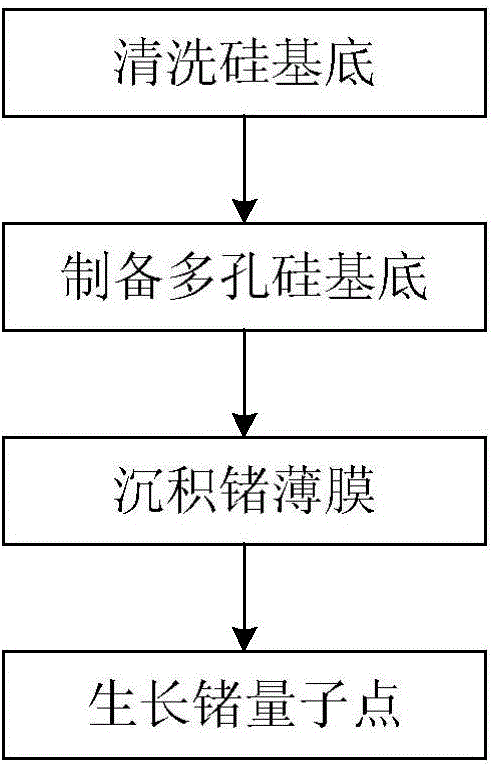

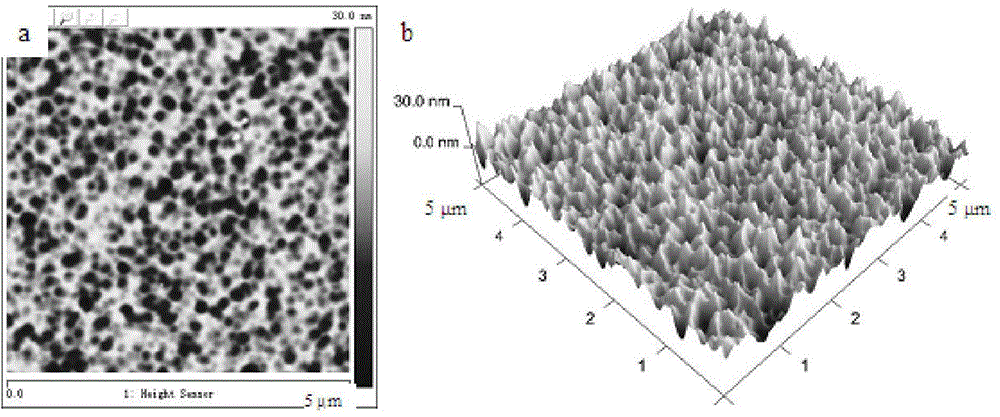

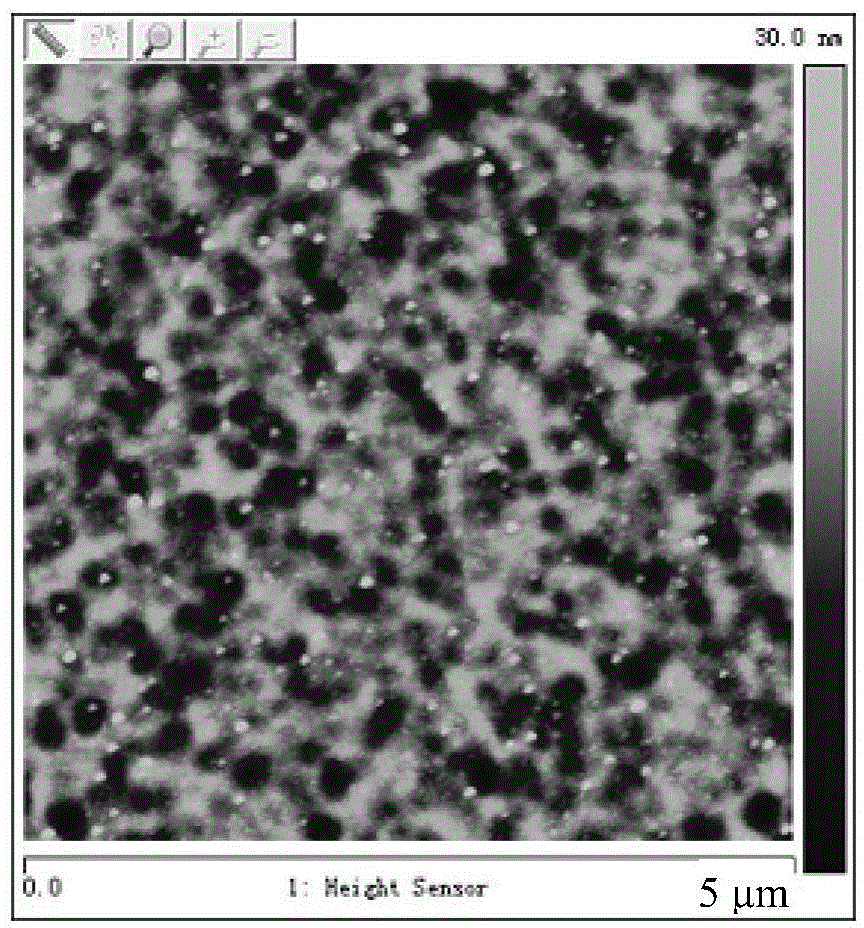

Composite structure silicon-based germanium quantum dot material and preparation method and application thereof

ActiveCN104377257ALarge specific surface areaHigh densityFinal product manufactureVacuum evaporation coatingQuantum dotQuantum

The invention relates to a composite structure silicon-based germanium quantum dot material. The composite structure material comprises a porous silicon substrate and germanium quantum dots growing on the porous silicon substrate. An ultrasonic enhancement method is used for improving the corrosion rate of the silicon substrate and the evenness of holes, and the growing process of magnetron sputtering and later-period annealing is adopted on the aspect of quantum dot growth; the composite structure silicon-based germanium quantum dot material has high photoelectric converting efficiency; the safety of a preparation method is high, operation is easy, and a good industrialization prospect can be achieved.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

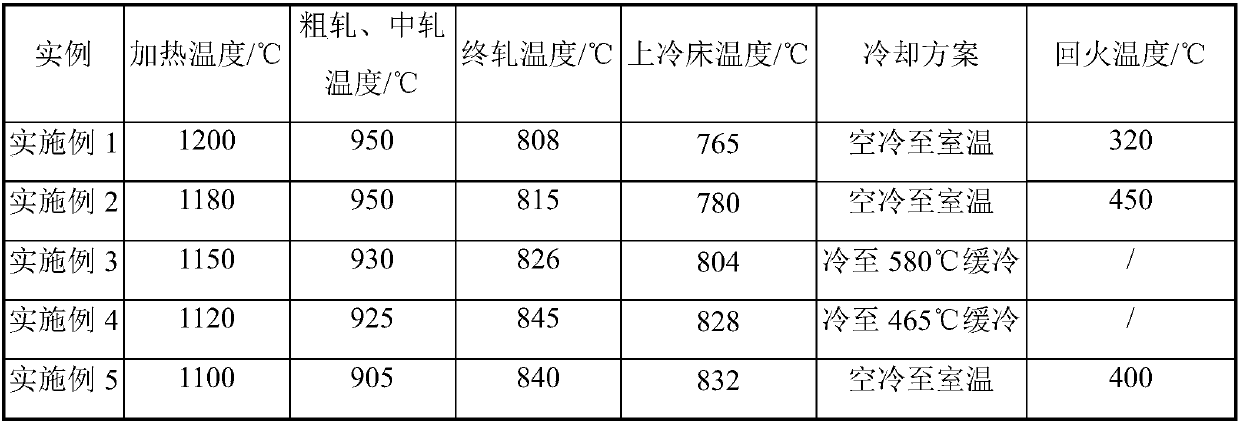

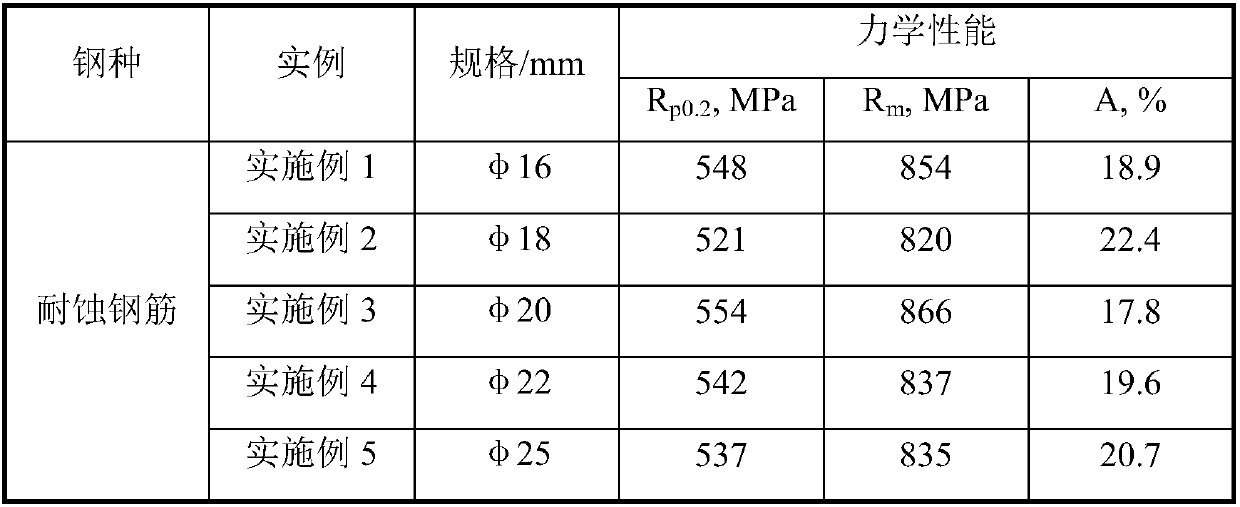

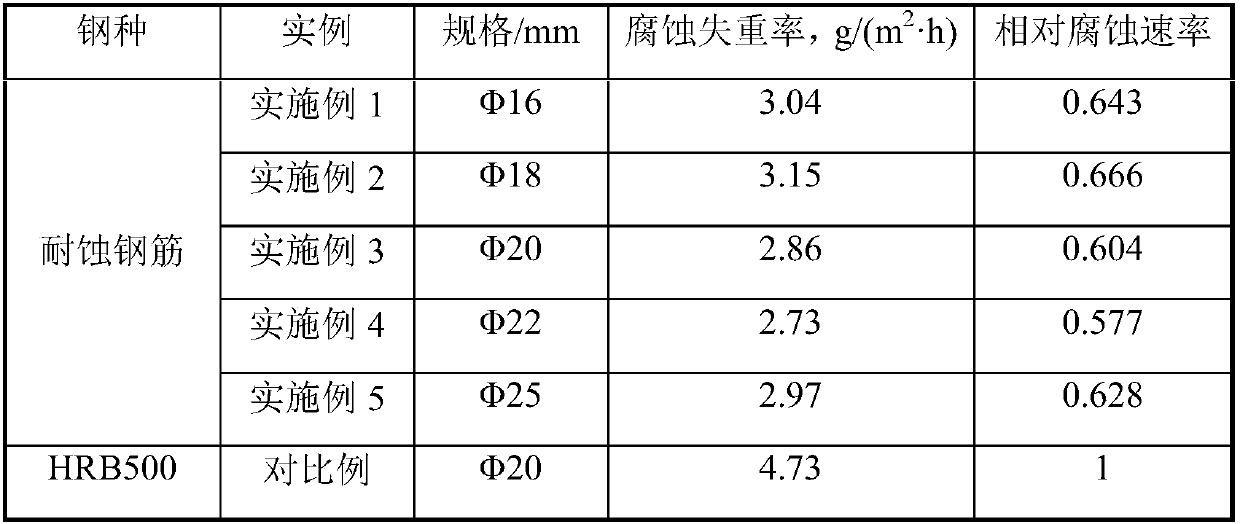

Corrosion-resisting rebar with yield strength in 500 MPa grade and production method

InactiveCN107723603AIncrease corrosion rateGood toughening effectProcess efficiency improvementChemical compositionRebar

The invention discloses a corrosion-resisting rebar with the yield strength in 500 MPa grade and a production method, and belongs to the technical field of corrosion-resisting steel for construction.The rebar comprises, by weight, the chemical components including 0.05-0.10% of C, 0.30-0.60% of Si, 1.20-1.50% of Mn, 1.00-1.50% of Cr, 0.10-0.20% of Ni, 0.20-0.40% of Cu, 0.10-0.20% of Mo, 0.06-0.10% of V, 0.010-0.025% of Ti, 0.035% or less of P, 0.010% or less of S and the balance Fe and inevitable residual impurity elements. According to the rebar, by adding small amounts of the alloying elements and fully using each individual element and the synergistic action among the elements, the corrosion resistance performance of the rebar is improved; the production method of the rebar comprises the steps of conventional smelting and casting and adoption of a controlled rolling and controlled cooling technology on a bar mill; noble metal elements in the rebar are low in contents, the toughness, the weldability and the corrosion resistance performance of the rebar are excellent, resources are saved, and the production cost is low.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

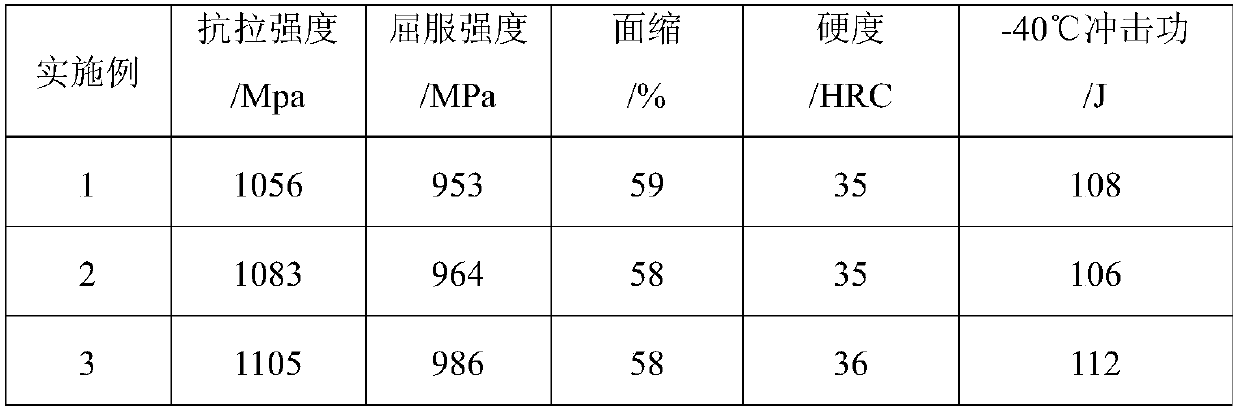

Weather-proof cold heading steel wire rod for 1000MPa-grade fastener and production method of weather-proof cold heading steel wire rod

The invention provides a weather-proof cold heading steel wire rod for a 1000MPa-grade fastener and a production method of the weather-proof cold heading steel wire rod. The steel wire rod comprises the following components in percentage by weight: 0.25%-0.55% of C, 0.10%-0.40% of Si, 0.80%-1.20% of Mn, smaller than or equal to 0.035% of P, smaller than or equal to 0.040% of S, 0.40%-0.70% of Cr, 0.15%-0.45% of Ni, 0.20%-0.40% of Cu, 0.15%-0.45% of Mo, and the balance of Fe and inevitable impurity elements. The production method comprises the steps of molten iron pretreatment, converter smelting, LF furnace refining, continuous casting, continuous rolling, billet cleaning, heating, rolling and finishing. Various properties of a 1000MPa-grade weather-proof connecting pair manufactured byusing the cold heading steel wire rod provided by the invention meet the standard requirements. The corrosion rate of the steel wire rod in the accelerated corrosion test is lower than 1 / 3 of that ofthe common cold heading steel.

Owner:ANGANG STEEL CO LTD

Glass erosion liquid and preparation method thereof

The invention relates to a vitreous etching bath, which comprises 0.5%-8% microcosmic salt, 0.5%-8% pyrophosphate, 0.01%-0.5% inorganic alkaline, 5%-45% surface activator and 39%-93% water. The preparing method comprises the following steps: adding the microcosmic salt and the pyrophosphate in the water, heating in order to dissolve; adding inorganic alkaline and non-ionic surface activator and mixing. The invention can remove greasy dirt, fingerprint, particles and sio2 for buffed glass base plate, which can removes the impurity and Ceo2 on the glass, achieves the request of the environmental protection.

Owner:天津晶岭电子材料科技有限公司

Bioresorbable iron-based alloy stent

Owner:BIOTYX MEDICAL (SHENZHEN) CO LTD

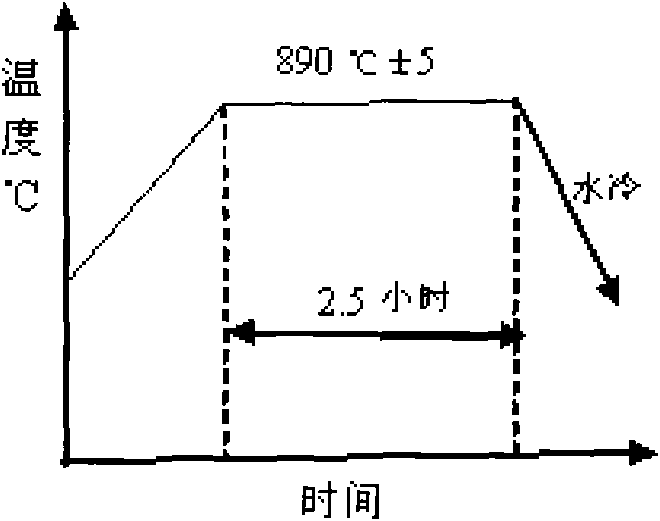

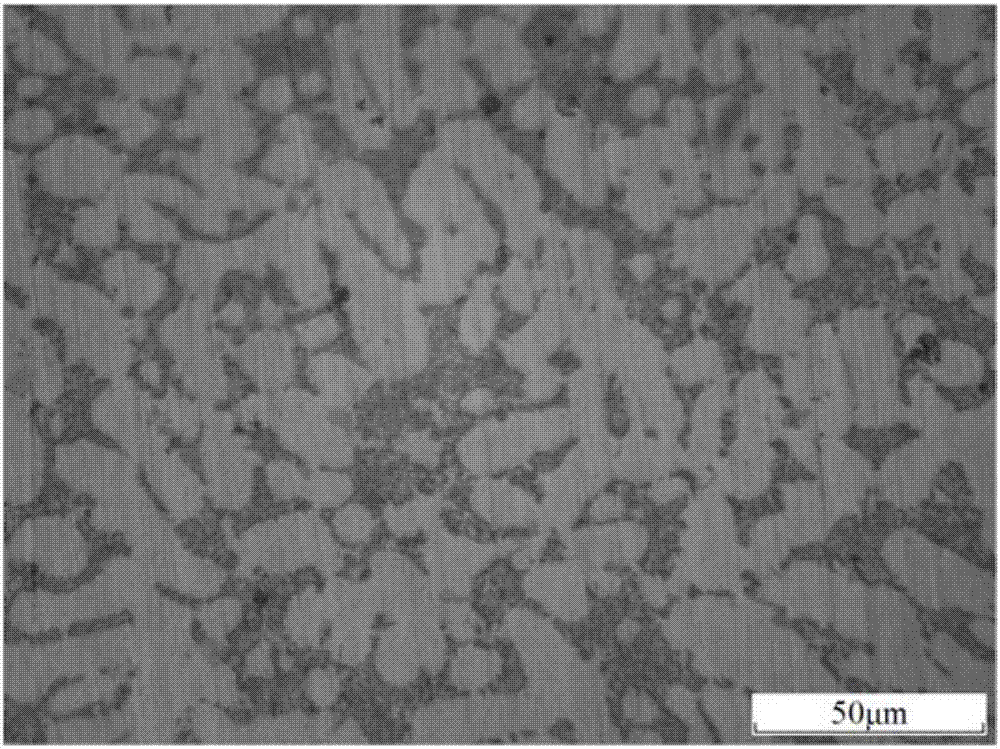

Displaying method for austenite grain boundary of intermediate-carbon alloy rare earth steel

InactiveCN102507294AQuality improvementIncrease corrosion ratePreparing sample for investigationAlcoholAustenite grain

The invention provide a displaying method for austenite grain boundary of intermediate-carbon alloy rare earth steel, belongs to the technical field of physical detection and is used for solving the problem that intermediate-carbon alloy rare earth steel can not clearly display austenite grains. The displaying method is characterized by comprising the steps of: preparing a corrosive according to the following reagent ratio: 20 mL of distilled water, 1-2 g of picric acid and 10-20 mL of Xigujing; preparing a sample, wherein the ground and polished surface of the sample is guaranteed to have no scratch, pock, pit, stain and other defects; adding the corrosive to a culture dish according to the reagent ratio, stirring with a glass rod so that the reagents are sufficiently reacted, and after stirring, placing absorbent cotton at the bottom of the culture dish; and placing the ground and polished sample in the culture dish with the ground surface downward, taking out the sample after the sample is eroded for 5 min, rinsing the sample in a great deal alcohol, immediately wiping the surface mucous membrane of the sample with the absorbent cotton, washing with alcohol, blow-drying and observing under a metallurgical microscope. According to the invention, a specific corrosive and an appropriate corroding method are adopted, so that the austenite grain boundary can be clearly displayed.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

LPSO-phase strengthened degradable high-temperature magnesium alloy and preparation method thereof

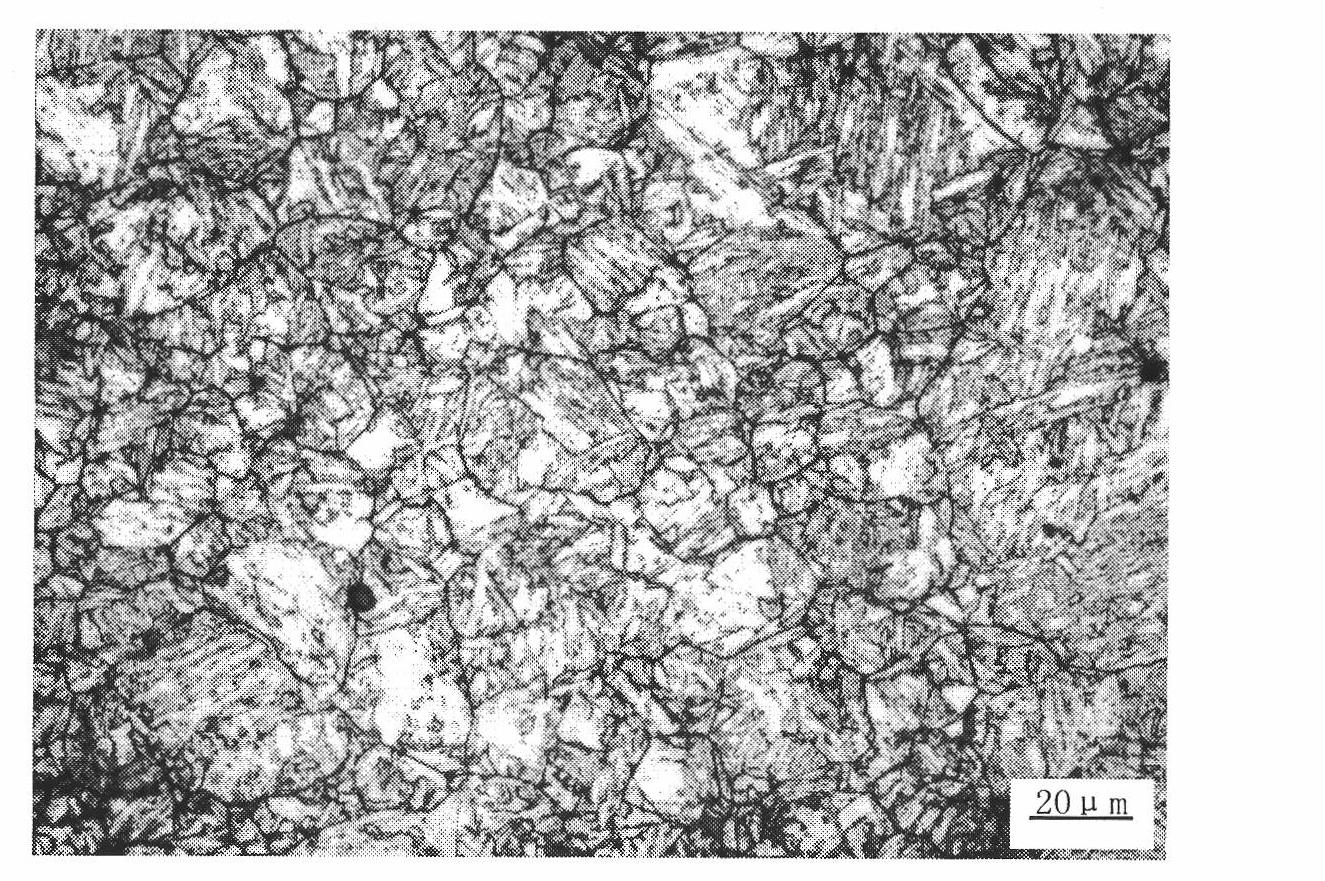

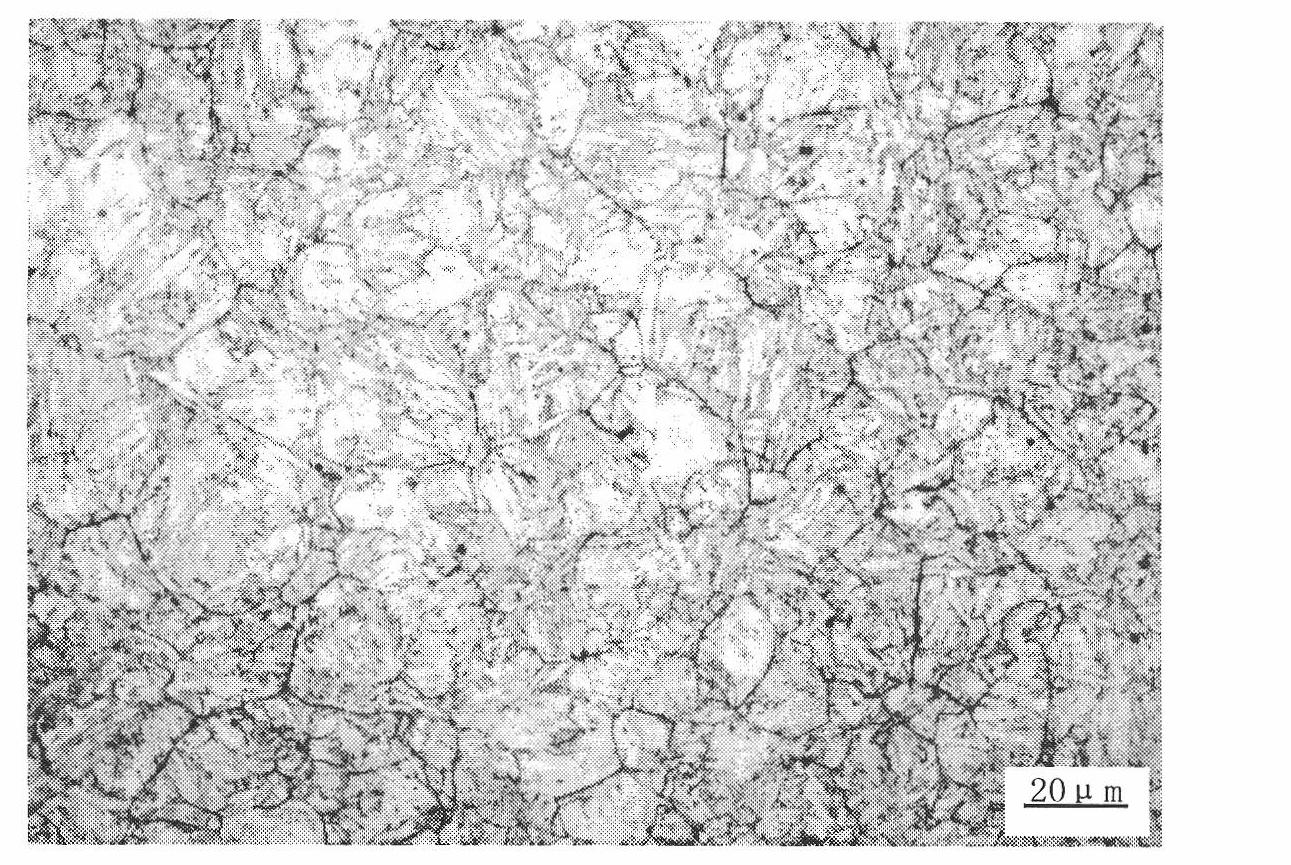

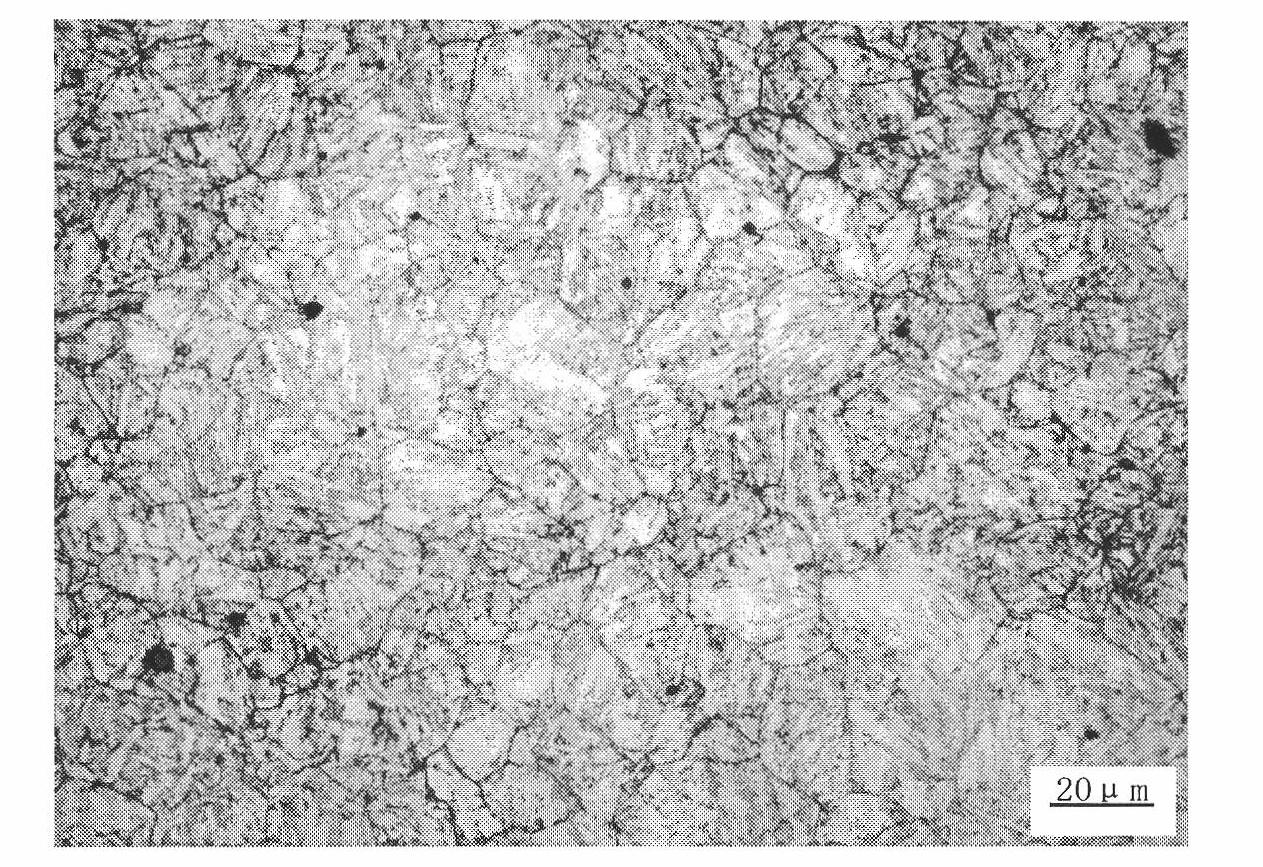

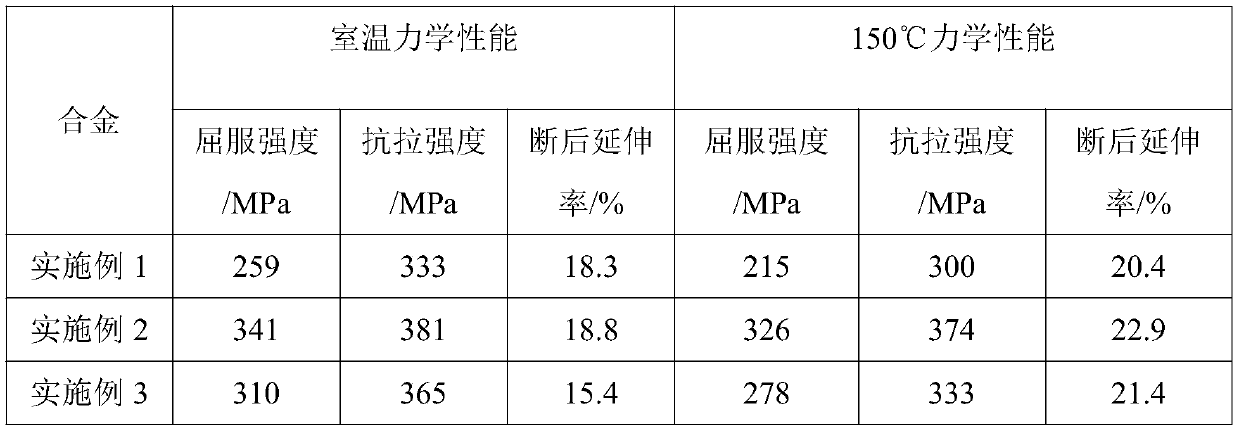

ActiveCN111235450AHigh strengthImprove plasticitySealing/packingDynamic recrystallizationContinuous casting

The invention discloses an LPSO-phase strengthened degradable high-temperature magnesium alloy and a preparation method thereof. The magnesium alloy comprises components in percentage by weight as follows: 12%-18% of rare earth elements (Gd and Ho), 1.5%-6% of transitional elements (Cu, Ni and Zn), 0.2%-0.8% of Zr and the balance Mg. The LPSO phase of the magnesium alloy has a special long-periodstructure, and according to dislocation and grain boundary hindrance effects, dynamic recrystallization promoting effect, grain size refining effect and coordination deformation of the LPSO phase, comprehensive mechanical properties of the alloy can be improved. The preparation method of the magnesium alloy adopts a semi-continuous casting process and a homogenizing treatment and extrusion process, the magnesium alloy with room-temperature tensile strength of 330 MPa or higher, room-temperature elongation of 15% or higher, 150-DEG C tensile strength of 300 MPa or higher, 150-DEG C elongation of 20% or higher, high mechanical properties and good degradation rate is obtained. The LPSO-phase strengthened degradable high-temperature magnesium alloy can be widely applied to a packer tool bridgeplug for fracturing construction of oil and gas fields.

Owner:XI AN JIAOTONG UNIV

High-hardness corrosion-resistance aluminum-silicon-copper series cast aluminum alloy obtained through zirconium-strontium composite microalloying and magnesium alloying and preparing method

Disclosed is a high-hardness corrosion-resistance Al-Si-Cu series cast aluminum alloy obtained through Zr-Sr composite microalloying and Mg alloying. The high-hardness corrosion-resistance aluminum-copper-silicon cast aluminum alloy of the zirconium strontium composite microalloying and the magnesium alloying is characterized in that the aluminum alloy is mainly composed of aluminum (Al), silicon (Si), cuprum (Cu), magnesium (Mg), zirconium (Zr), strontium (Sr) and ferrum (Fe). A preparing method comprises sequentially the following steps that (1), pure Al and Al-Si intermediate alloy are molten and then are heated to 850 DEG C, and then Al-Cu, Al-Zr and Al-Sr intermediate alloy are added in sequence; and (2), after all intermediate alloys and metals are molten, the temperature is adjusted to 750 DEG C, and pure Mg is added; and after the pure Mg is molten, hexachloroethane is added for refining and degassing until no gas escapes, the melt is deslagged and cast into an ingot after standing and heat preservation for 5-10 min. According to the high-hardness corrosion-resistance aluminum-silicon-copper series cast aluminum alloy obtained through the zirconium-strontium composite microalloying and the magnesium alloying and the preparing method, the casting-state texture of the aluminum alloy is compact, the indoor temperature non-notch impacting tenacity average value is 16.35 J / cm2, the tensile strength is 262.132 MPa, the ductility is 5.645%, and meanwhile, the uniform corrosion rate is 0.321081508 mm / y when the aluminum alloy is soaked for 93 h in 3.5% NaCl water solution under the temperature of 37 DEG C.

Owner:JIANGSU UNIV

Environment-friendly monocrystalline silicon piece texturing liquid and preparation method thereof

InactiveCN105113009AEffective control of surface tensionImprove surface propertiesAfter-treatment detailsBetaineGlycerol

The invention discloses environment-friendly monocrystalline silicon piece texturing liquid. The environment-friendly monocrystalline silicon piece texturing liquid is characterized by being prepared from, by weight, 0.5-1 part of sodium hydroxide, 3-5 parts of additives, 2-4 parts of sodium citrate, 0.5-1 part of dodecyl dimethyl betaine, 0.2-0.4 part of coco fatty acid diethanol amide, 0.01-0.02 part of konjac glucomannan, 1-2 parts of glycerin, 0.1-0.2 part of polysorbate-80 and 80-100 parts of water. By means of the environment-friendly monocrystalline silicon piece texturing liquid, the consistency and the repeatability of the texturing technology are effectively improved, and the density of the texturization surface is increased, so that the efficiency of a solar cell is improved, and the production quality is improved; IPA is not contained, environmental protection and human health are facilitated, the main raw materials are easy to degrade, residues in the environment do not exist, pollution does not exist, and the environment-friendly monocrystalline silicon piece texturing liquid is green and environmentally friendly.

Owner:CHINALAND SOLAR ENERGY

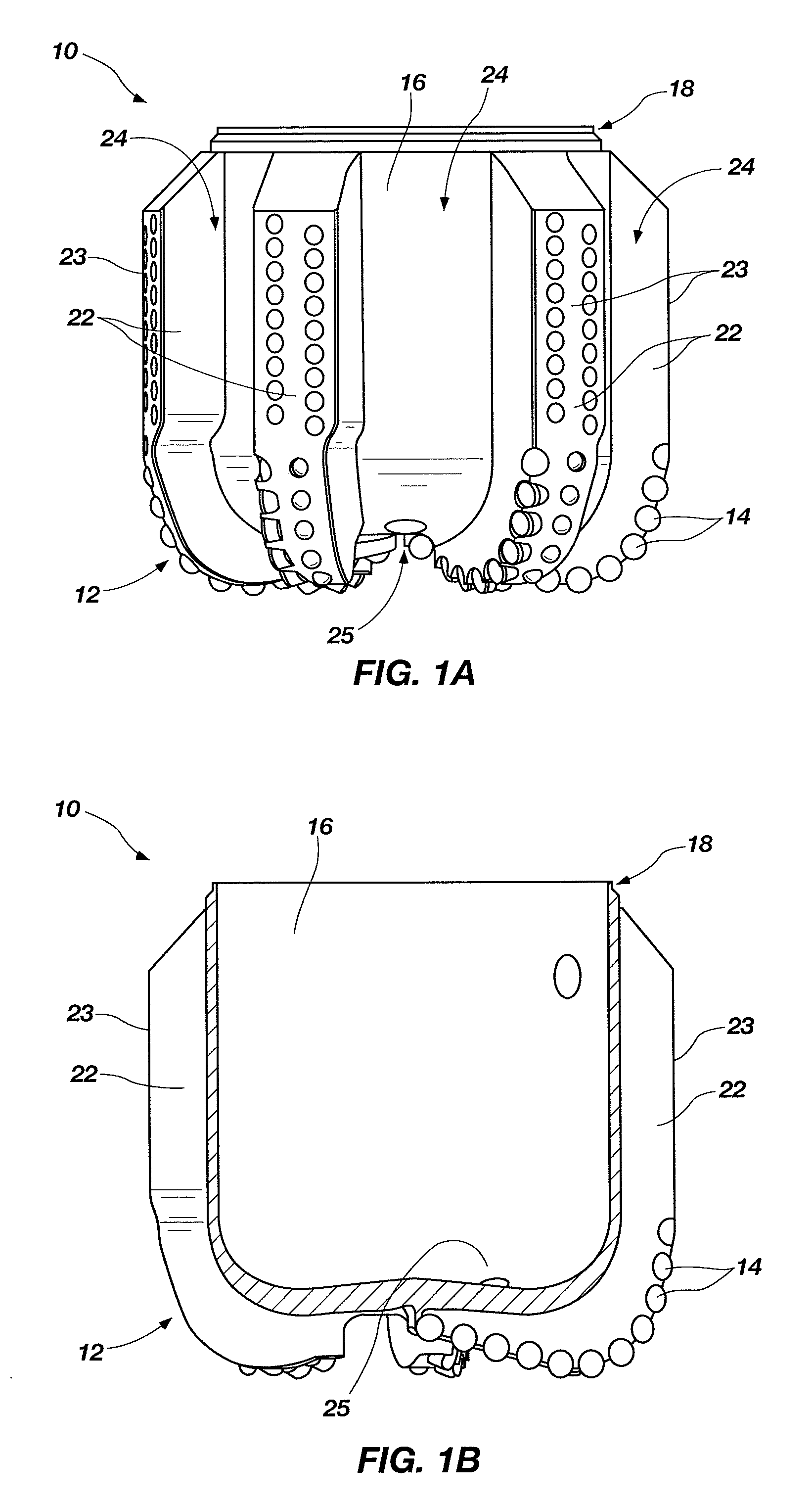

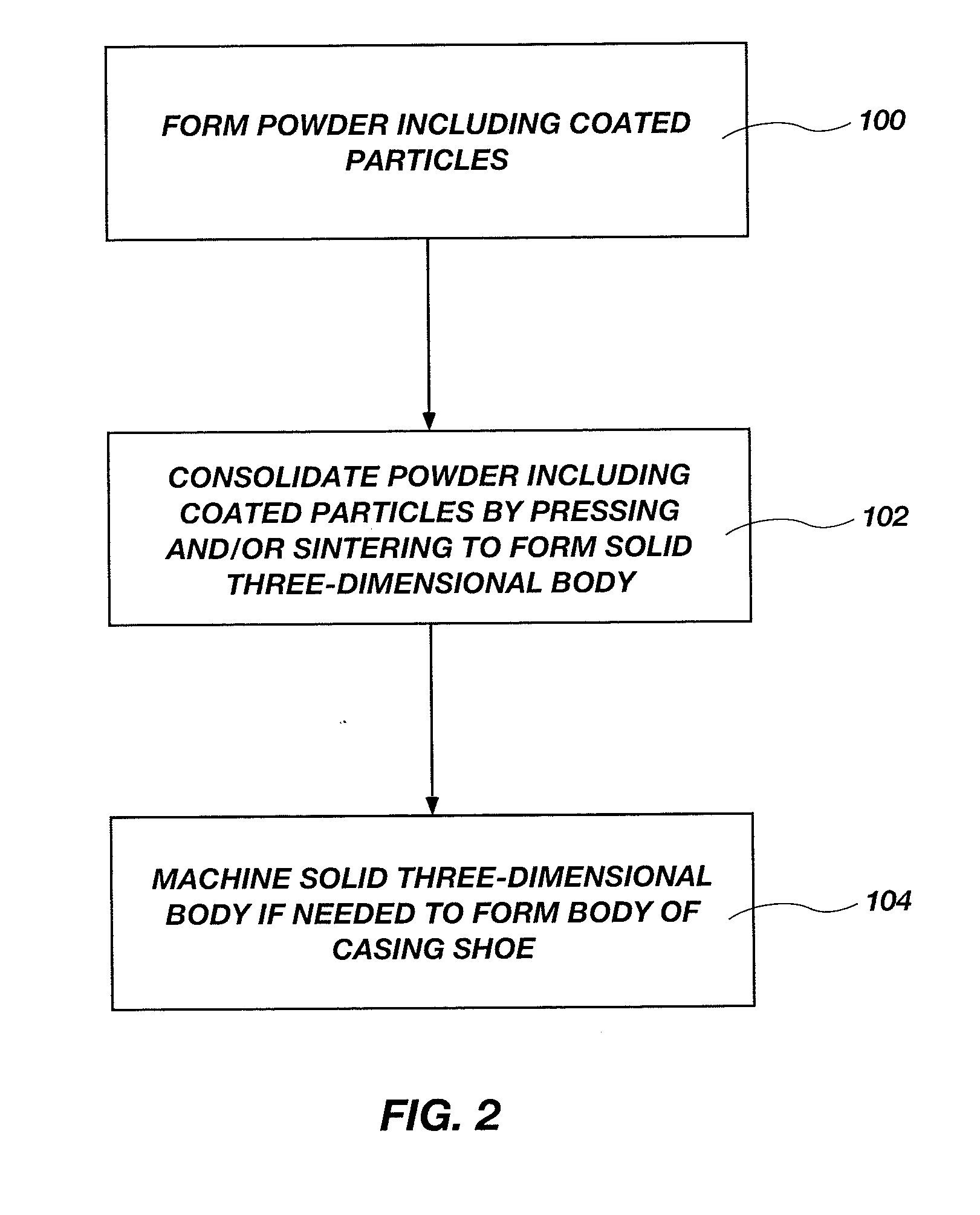

Corrodable boring shoes for wellbore casing, and methods of forming and using such corrodable boring shoes

ActiveUS20120255743A1Increase corrosion rateDrilling rodsTransportation and packagingEngineeringWellbore

Earth-boring casing shoes include a crown configured for at least one of drilling and reaming a wellbore when the crown is attached to a section of casing and the casing is advanced into a wellbore. The crown includes a body comprising a corrodible composite material, and at least one cutting structure carried on the body. The casing shoes further include connection structure configured for attachment to a section of casing. Methods are used to form such casing shoes, and such casing shoes are used to install casing within wellbores.

Owner:BAKER HUGHES INC

Absorbable internally-fixed implantable iron-based alloy medical apparatus

ActiveCN106924822AReduce dosageIncrease corrosion rateSuture equipmentsCoatingsAntioxidantMechanical property

Owner:BIOTYX MEDICAL (SHENZHEN) CO LTD

Bioabsorbable Medical Device or Medical Device Component and Preparation Method Thereof

ActiveUS20150151027A1Perfect balance pointImprove radial strengthStentsSurgeryHardnessUltimate tensile strength

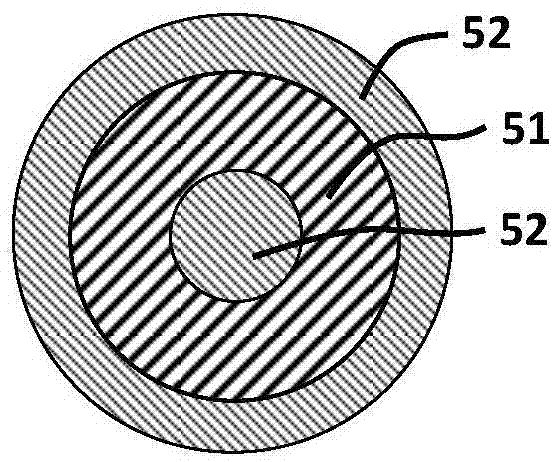

A bioabsorbable medical device or a medical device component comprises an absorbable component prepared by subjecting a prefabricated component of an iron-based raw material to ion nitriding. Substance composition inside the absorbable component changes with the depth from the surface. The absorbable component comprises at least a first part and a second part. The first part surrounds the second part. Hardness of the first part is higher than hardness of the second part. An interface exists between the first part and the second part. A crack generated in the first part is impeded by the interface when extending to the second part. On the premise of ensuring radial stand strength, the bioabsorbable medical device or medical device component and a preparation method thereof reduce wall thickness of an iron-based stand, improve a stand corrosion rate and malleability, and achieve broader adaptability.

Owner:BIOTYX MEDICAL SHENZHEN CO LTD

Method for rapidly evaluating performance of weather-resistant steel rust layer for power transmission tower in industrial atmospheric environment

PendingCN112394025AEffectively evaluate durabilityIncreased durabilityWeather/light/corrosion resistancePreparing sample for investigationEnvironmental engineeringAtmospheric sciences

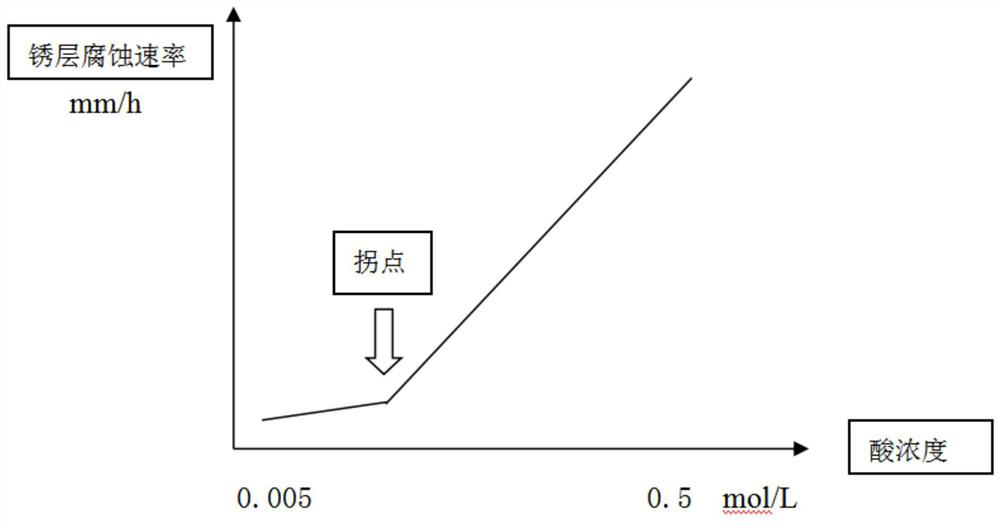

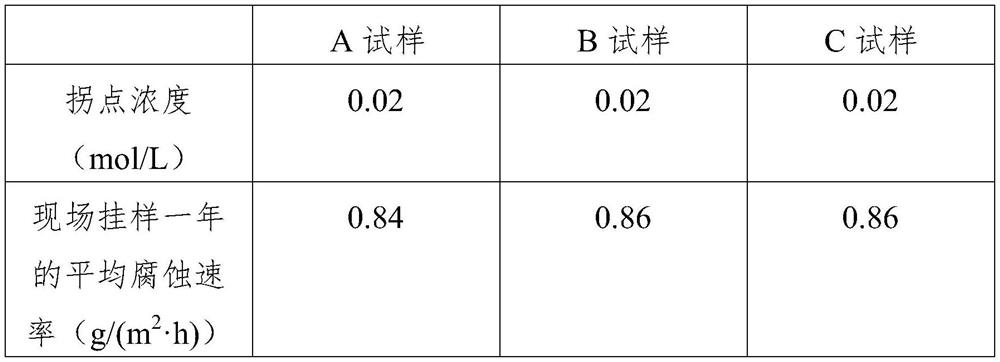

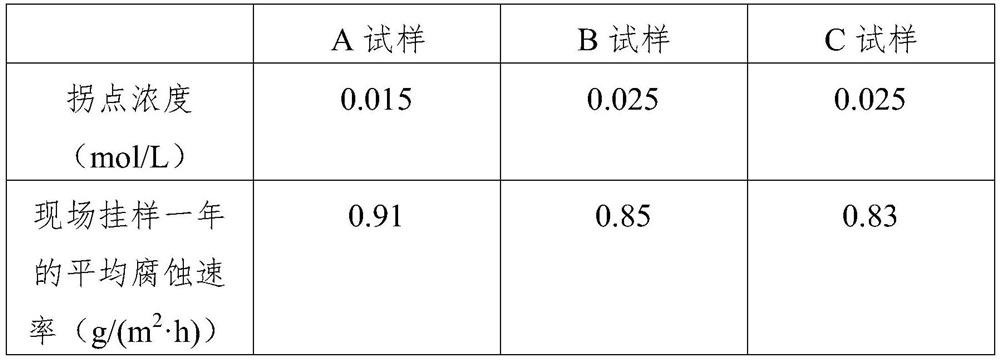

The invention discloses a method for rapidly evaluating the performance of a weather-resistant steel rust layer for a power transmission tower in an industrial atmospheric environment, and belongs tothe technical field of performance evaluation of the weather-resistant steel rust layer. According to the method, NaCl with the concentration of 0.5% is added into a traditional simulated corrosion solution according to the service characteristics of a simulated industrial atmospheric corrosion environment, so that the corrosion rate is increased, and a corrosion mechanism is not changed; a brokenline graph is drawn by using multiple groups of sample data, inflection point coordinates are taken as corrosion resistance evaluation values, so that the durability of weather-resistant steel in theindustrial atmospheric environment is effectively evaluated; test results show that a soaking test and a week soaking test in the industrial environment show similar rules, the corrosion rate can beincreased by the soaking test, the test period is effectively shortened, and equipment is cheap, operation is easy, and popularization significance is achieved.

Owner:STATE GRID FUJIAN ELECTRIC POWER CO LTD +1

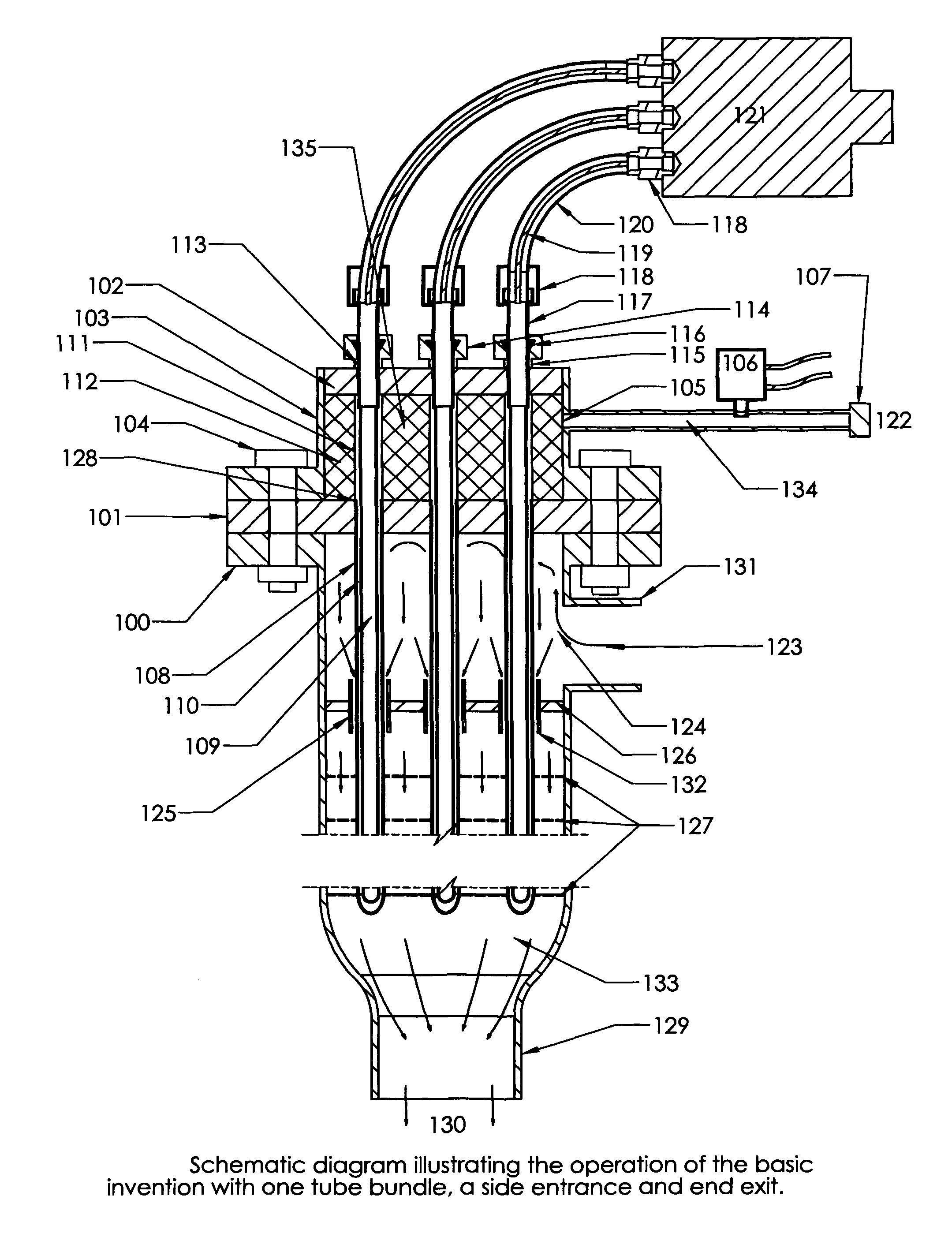

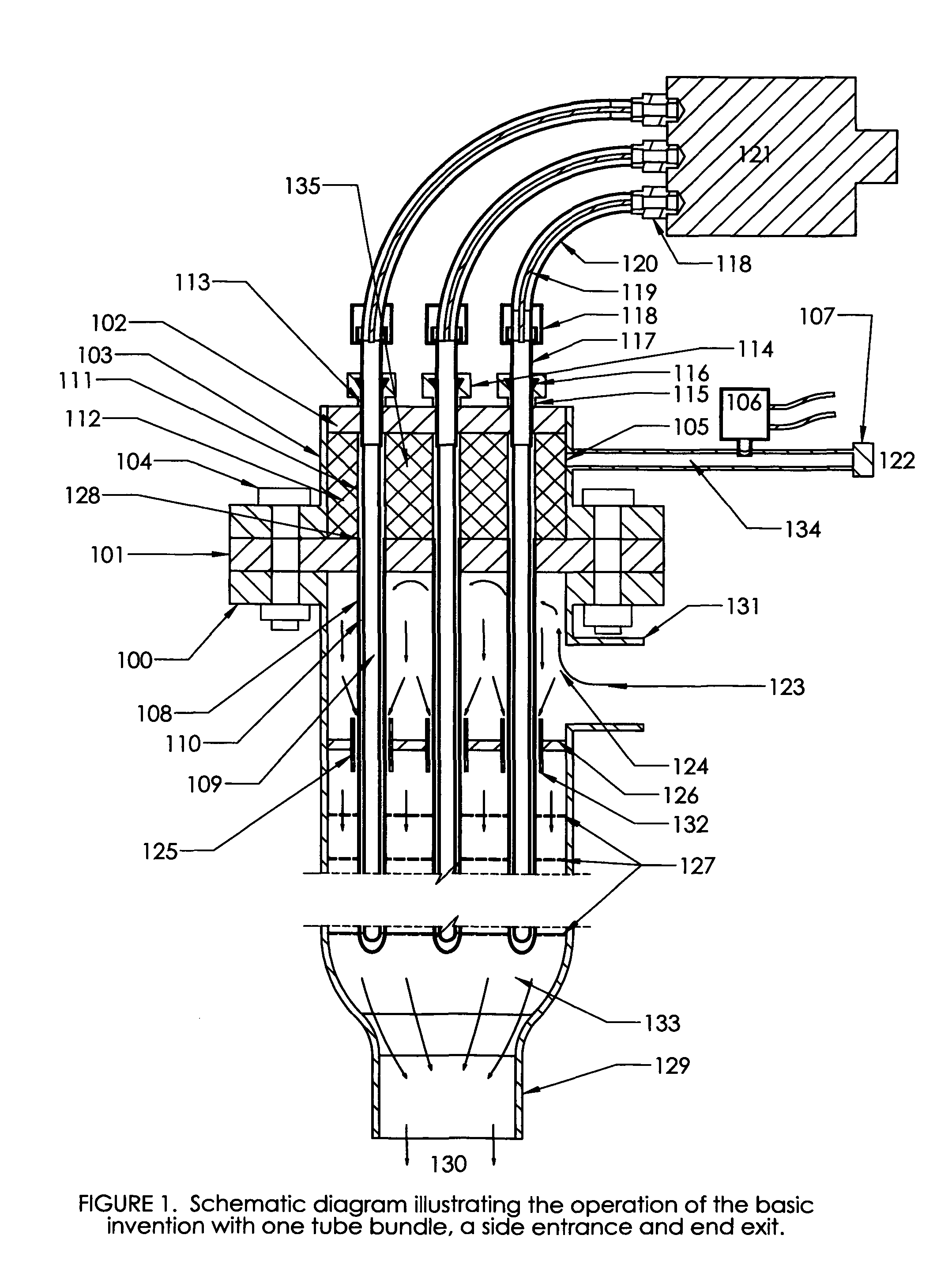

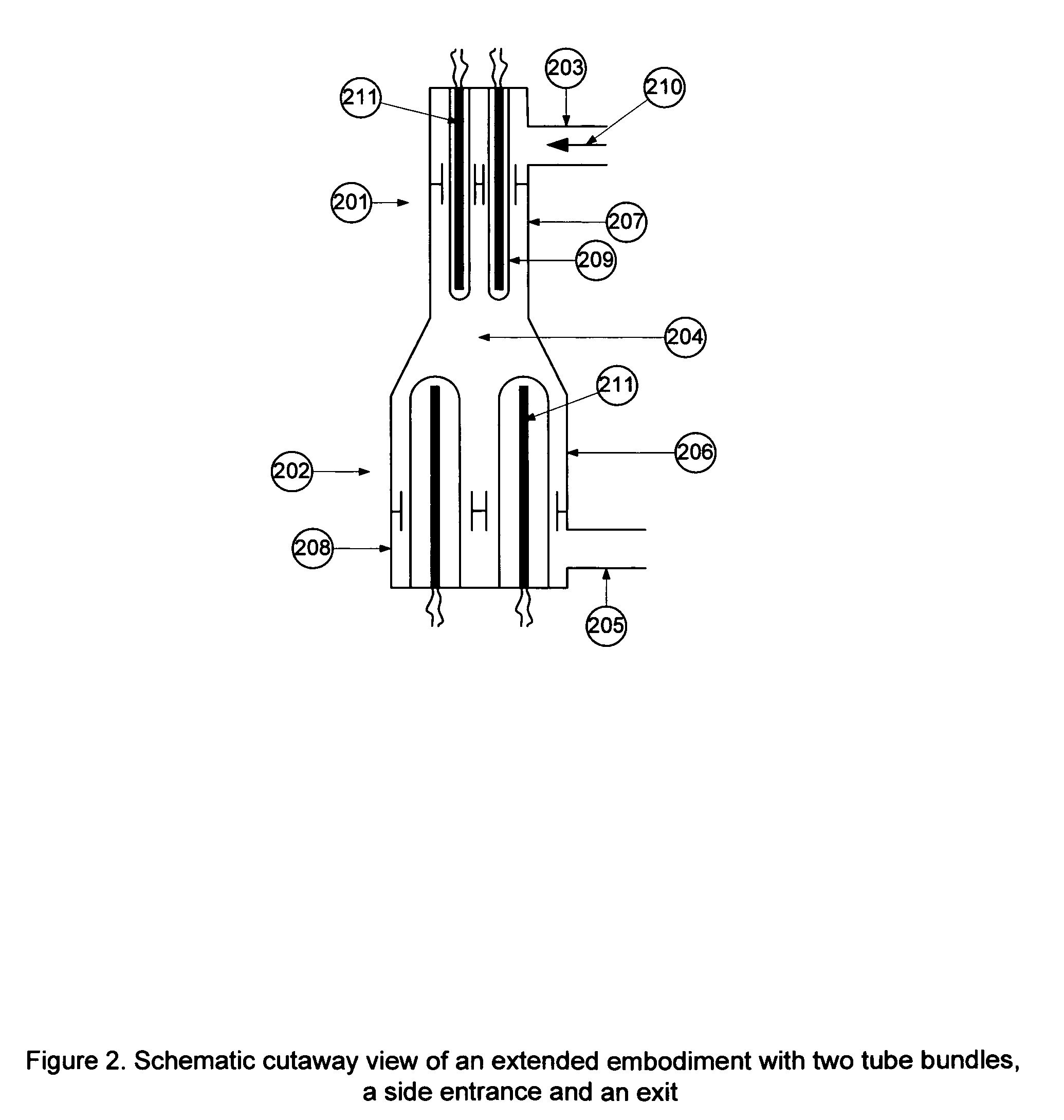

Dual wall axial flow electric heater for leak sensitive applications

ActiveUS8260126B2Reduce riskReduction and elimination of overheatingHeating fuelAir heatersHeat fluxHeater Rod

A dual wall axial flow electric heater for leak sensitive applications provides an improved corrosion and leak resistant assembly and includes protective tubes over electrical heater rods, double tubesheets spaced apart by a plenum and leak detectors positioned to sensor leaks through the walls of the protective tubes. The design includes the option of two or more tube bundles with each inserted into opposite ends of a shell surrounding the tube sheets and heaters. The design provides ease of maintenance since each heater rod can be replaced independently while the unit is in service. Variable heat flux is provided from standard single flux heater rods by providing protective tubes of varying diameters. A built-in thermowell is provided to allow the rod temperatures to be monitored directly. Hot spots are avoided by the use of turning baffles and vibration is avoided by use of spider baffles to support the tubes.

Owner:LORD LTD LP

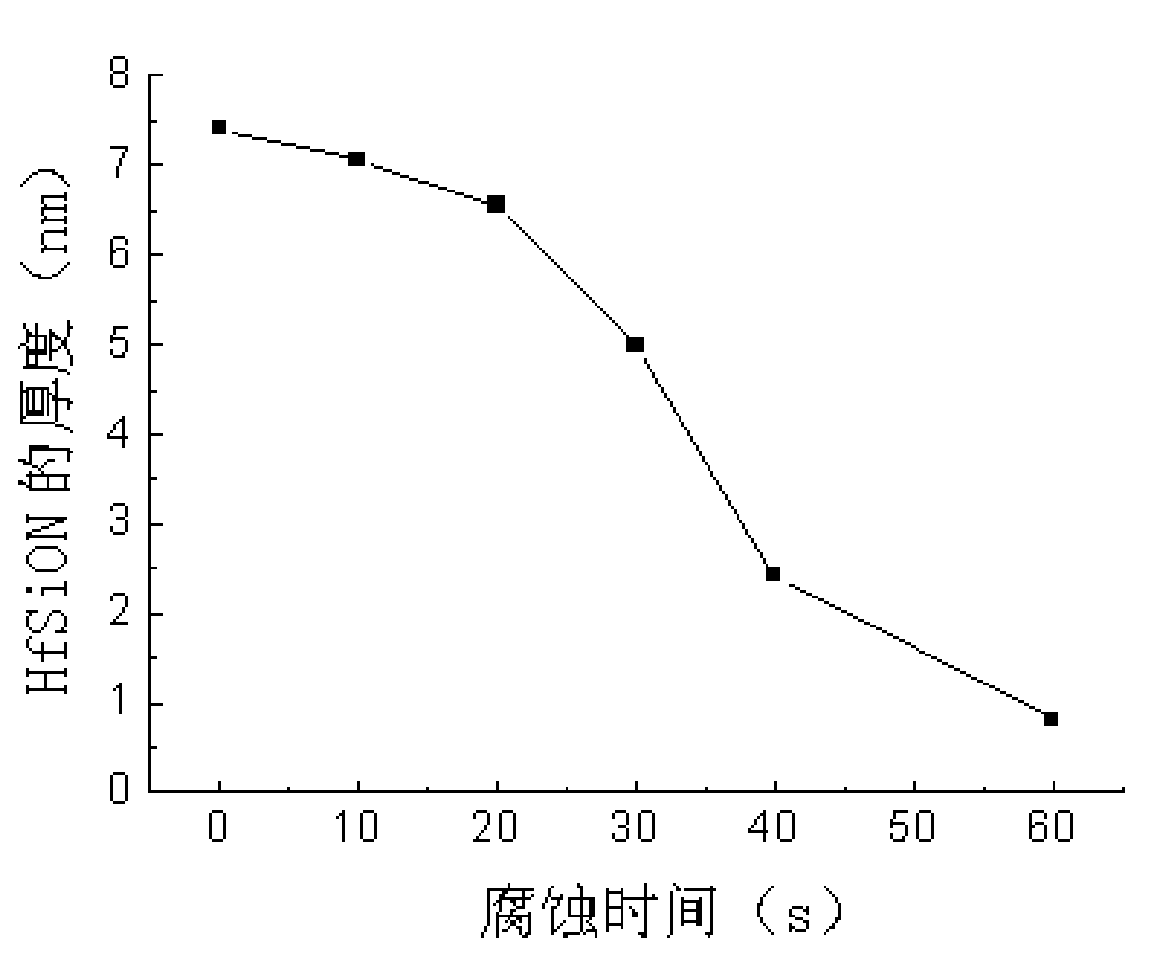

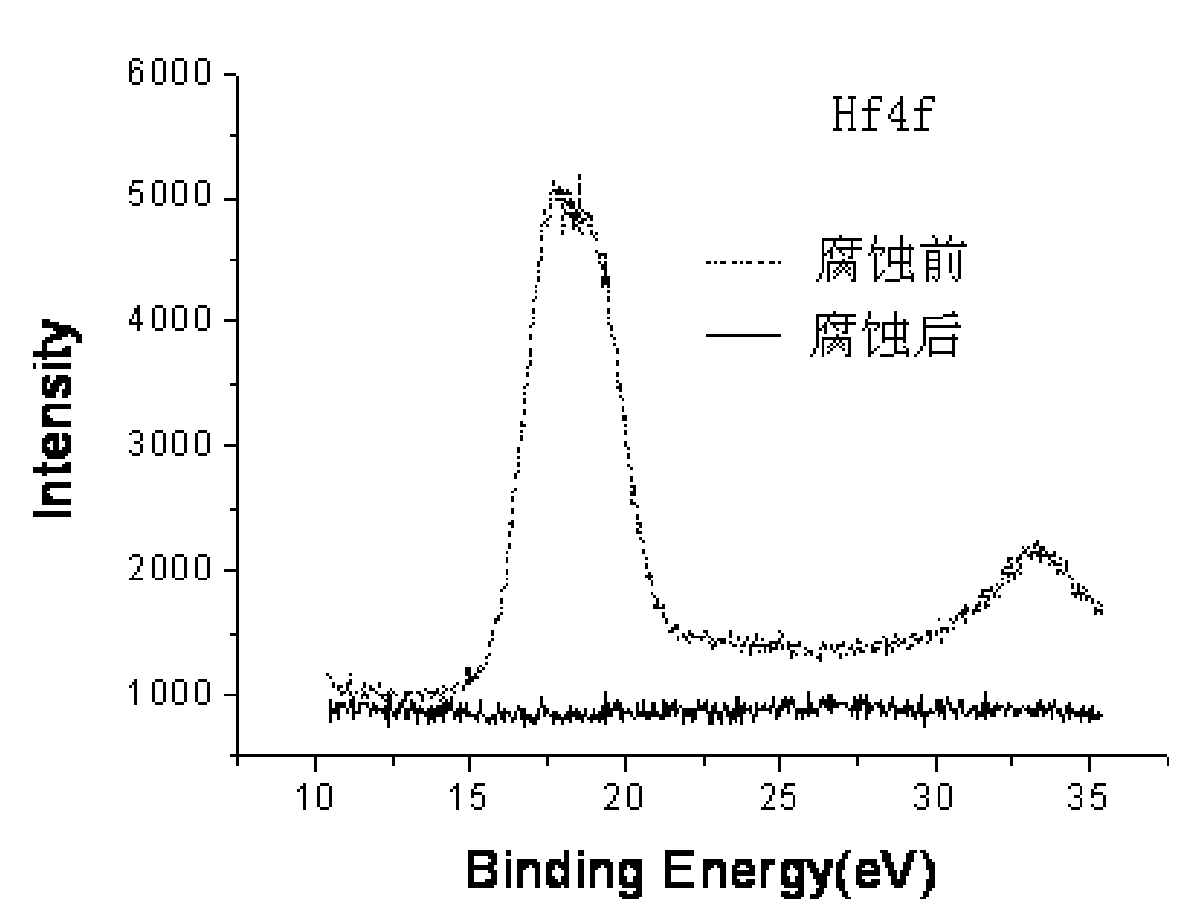

Corrosive agent and corrosion method of HfSiON high-K gate dielectric material

ActiveCN101619457ASpeed up corrosionAchieve selective removalSemiconductor/solid-state device manufacturingSemiconductor devicesHydrofluoric acidGate dielectric

The invention relates to a corrosive agent of an HfSiON high-K gate dielectric material and a corrosion method by using the corrosive agent, which belong to the technical field of integrated circuit manufacture. The corrosive agent comprises 0.19-4.83 percent by weight of hydrofluoric acid. The corrosion method by using the corrosive agent comprises the following steps: forming the HfSiON high-K gate dielectric material on an Si substrate, an Si / SiO2 interface layer or Si / SiON interface layer, and soaking the HfSiON high-K gate dielectric material in the corrosive agent for wet method corrosion. The corrosive agent is used for carrying out corrosion on the HfSiON high-K gate dielectric material and can reduce the hydrolysis of the hydrofluoric acid, thereby the corrosion speed of the HfSiON high-K gate dielectric material is improved, the corrosion speed of field oxide region SiO2 can be reduced, and the selection ratio of HfSiON to the field oxide region SiO2 can be further improved.

Owner:SOI MICRO CO LTD

High Corrosion-Resistant Aluminum Alloy Brazing Sheet, Method of Manufacturing Such Sheet, and Corrosive-Resistant Heat Exchanger Using Such Sheet

ActiveUS20160167177A1Improve corrosion resistanceSolve the lack of resistanceFurnace typesHeat treatment process controlFilling materialsImpurity

ProblemTo provide an aluminum alloy brazing sheet, featuring a good brazing property that prevents diffusion of molten filler material in a core material of the aluminum alloy brazing sheet during a brazing process and exhibiting a superior corrosion resistance to an exhaust gas condensate water after the brazing process, a method of manufacturing the aluminum alloy brazing sheet, and a high corrosion-resistant heat exchanger using the aluminum alloy brazing sheet.Resolving MeansA high corrosion-resistant aluminum alloy brazing sheet comprises a core material composed of an aluminum alloy, a sacrificial anode material cladded on one surface of the core material, and a filler material composed of an Al / Si-based alloy and cladded on another surface of said core material, and is characterized in that the sacrificial anode material is composed of an aluminum alloy which contains Si falling within a range of 2.5-7.0 mass %, Zn falling a range of 1.0-5.5 mass %, Fe falling within a range of 0.05-1.0 mass %, and which is composed of the balance Al and the inevitable impurities, and that a clad thickness of the sacrificial anode material falling within a range of 25-80 μm. Also, there is provided a method of manufacturing the aluminum alloy brazing sheet, and a high corrosion-resistant heat exchanger using the aluminum alloy brazing sheet.

Owner:FURUKAWA SKY ALUMINUM CORP

High-corrosion-resistant aluminum alloy brazing sheet, method of manufacturing such sheet, and corrosive-resistant heat exchanger using such sheet

ActiveUS20120279694A1Improve corrosion resistanceSpeed up heat exchangeFoundry mouldsWelding/cutting media/materialsFilling materialsImpurity

ProblemTo provide an aluminum alloy brazing sheet, featuring a good brazing property that prevents diffusion of molten filler material in a core material of the aluminum alloy brazing sheet during a brazing process and exhibiting a superior corrosion resistance to an exhaust gas condensate water after the brazing process, a method of manufacturing the aluminum alloy brazing sheet, and a high corrosion-resistant heat exchanger using the aluminum alloy brazing sheet.Resolving MeansA high corrosion-resistant aluminum alloy brazing sheet comprises a core material composed of an aluminum alloy, a sacrificial anode material cladded on one surface of the core material, and a filler material composed of an Al / Si-based alloy and cladded on another surface of said core material, and is characterized in that the sacrificial anode material is composed of an aluminum alloy which contains Si falling within a range of 2.5-7.0 mass %, Zn falling a range of 1.0-5.5 mass %, Fe falling within a range of 0.05-1.0 mass %, and which is composed of the balance Al and the inevitable impurities, and that a clad thickness of the sacrificial anode material falling within a range of 25-80 μm. Also, there is provided a method of manufacturing the aluminum alloy brazing sheet, and a high corrosion-resistant heat exchanger using the aluminum alloy brazing sheet.

Owner:DENSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com