Rapid-corrosion magnesium alloy product and preparation method thereof

A rapid corrosion, magnesium alloy technology, applied in the field of metal alloy materials, to achieve the effect of increasing corrosion rate, improving mechanical properties, and protecting equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

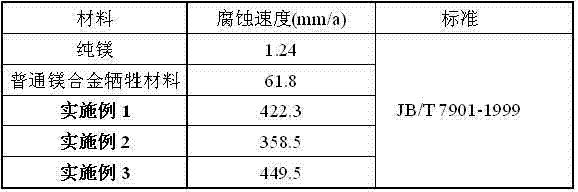

Examples

Embodiment 1

[0020] Example 1 A rapid corrosion magnesium alloy product, the alloy product is composed of the following weight percentage (g / g): 1% aluminum, 6% zinc, 1% iron, 10% copper, 0.1% silver, 0.1% nickel, balance magnesium.

[0021] The preparation method of the rapid corrosion magnesium alloy product comprises the following steps:

[0022] ⑴Pretreatment of magnesium-copper alloy containing 30% copper: Cut the magnesium-copper alloy containing 30% copper into small pieces of 20mm×20mm×20mm, and remove oxides and oil stains on the surface according to conventional methods, and then After cleaning with anhydrous alcohol, dry at a temperature of 101° C. to constant weight to obtain the pretreated magnesium-copper alloy.

[0023] ⑵Pretreatment of aluminum-nickel alloy containing 50% nickel: Cut the aluminum-nickel alloy containing 50% nickel into small pieces of 10mm×10mm×10mm, remove oxides and oil stains on the surface according to conventional methods, and then After cleanin...

Embodiment 2

[0027] Example 2 A rapidly corroding magnesium alloy product consisting of the following components by weight percentage (g / g): 6% aluminum, 1% zinc, 3% iron, 5% copper, 1% silver, 1.2% nickel, balance magnesium.

[0028] The preparation method of the rapid corrosion magnesium alloy product comprises the following steps:

[0029] (1) Pretreatment of magnesium-copper alloy containing 30% copper is the same as Example 1 .

[0030] ⑵ Pretreatment of aluminum-nickel alloy containing 50% nickel Example 1 .

[0031] (3) Carry out pretreatment on magnesium ingots, aluminum ingots and zinc ingots at the same time Example 1 .

[0032] ⑷ Carry out pretreatment to iron powder and silver powder respectively Example 1 .

[0033] (5) Add 711g of pretreated magnesium ingot, 48g of aluminum ingot, 10g of zinc ingot, 167g of pretreated magnesium-copper alloy, 24g of pretreated aluminum-nickel alloy, 30g of dry iron powder, and 10g of dry silver powder in sequence In the smelting ...

Embodiment 3

[0034] Example 3 A rapid corrosion magnesium alloy product, the alloy product is composed of the following weight percentage (g / g): 3% aluminum, 3% zinc, 2% iron, 15% copper, 0.5% silver, 0.5% nickel, balance magnesium.

[0035] The preparation method of the rapid corrosion magnesium alloy product comprises the following steps:

[0036] (1) Pretreatment of magnesium-copper alloy containing 30% copper is the same as Example 1 .

[0037] ⑵ Pretreatment of aluminum-nickel alloy containing 50% nickel Example 1 .

[0038] (3) Carry out pretreatment on magnesium ingots, aluminum ingots and zinc ingots at the same time Example 1 .

[0039] ⑷ Carry out pretreatment to iron powder and silver powder respectively Example 1 .

[0040] (5) Add 410kg of pretreated magnesium ingot, 25g of aluminum ingot, 30g of zinc ingot, 500g of pretreated magnesium-copper alloy, 10g of pretreated aluminum-nickel alloy, 20g of dry iron powder, and 5g of dry silver powder in sequence In the sm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com