Preparation method of metal resin complex and metal resin complex prepared thereby

A metal resin, composite technology, applied in metal layered products, chemical instruments and methods, coatings, etc., can solve the problems of poor metal-resin bonding, unfavorable safety production, splashing of corrosive liquid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

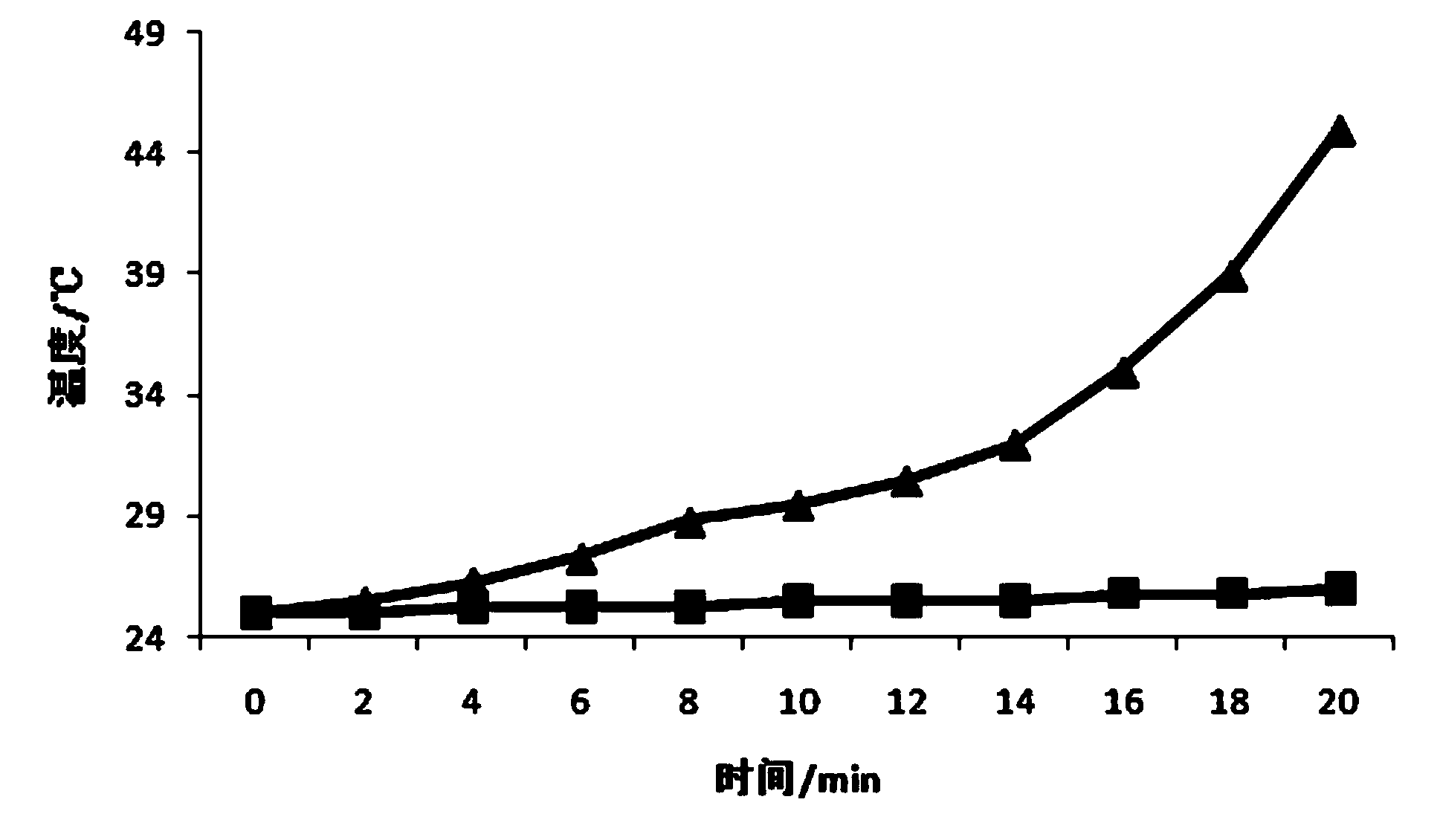

Image

Examples

preparation example Construction

[0017] The invention provides a method for preparing a metal-resin composite, comprising the following steps:

[0018] S1, anodic oxidation: anodize the pretreated metal substrate to obtain a metal substrate with an anodized film layer on the surface, and the metal substrate is an aluminum alloy substrate or an aluminum substrate; anodization is required by those skilled in the art Known anodic oxidation technology, the present invention preferably includes putting the pretreated metal substrate as an anode into sulfuric acid or phosphoric acid with a concentration of 15wt%-20wt%, and electrolysis at a temperature of 10-30°C and a voltage of 5V-35V for 1-10min A metal substrate with a 1-20um thick anodized film layer on the surface is obtained. The equipment for anodizing uses known anodizing equipment, such as an anodizing tank. Preferably, the thickness of the anodized film layer prepared by anodic oxidation is 1-5um.

[0019] S2, etching solution treatment: immerse the me...

Embodiment 1

[0044] This example prepares an aluminum alloy resin composite body;

[0045]1. Pretreatment: Cut the commercially available 1mm thick 6063 aluminum alloy plate into 15mm*80mm rectangular pieces, put it into a polishing machine for grinding, then degrease and clean it, and then put the aluminum alloy substrate into Alkaline etching treatment for 10s in lye with a sodium hydroxide content of about 40g / L at 60°C, rinse with water, and then put in HNO 3 The neutralization tank with a content of about 6% was neutralized for 30 seconds, and then cleaned with water to obtain a pre-treated aluminum alloy sheet;

[0046] 2. Surface treatment 1: Put the above aluminum alloy sheet as an anode into H with a concentration of about 15wt%. 2 SO 4 In the anodizing tank, electrolyze at 15V for 5 minutes at 18°C, and bake at 80°C for 20 minutes;

[0047] 3. Surface treatment 2: Prepare 500ml of a mixed aqueous solution containing 5wt% HCl and 10wt% sodium chloride in a beaker, put it in a c...

Embodiment 2

[0052] Aluminum alloy resin composites A2 and B2 were prepared in the same manner as in Example 1, except that surface treatment 2 was to prepare 500ml of a mixed aqueous solution containing 5wt% HCl and 10wt% sodium chloride in a beaker, and put it at 25°C The temperature was raised to 25°C in a constant temperature tank, and 10 PCS of the aluminum alloy sheets obtained above were immersed in it, and were taken out after 10 minutes, then put into a beaker filled with water for 2 minutes, and then the aluminum alloy was dried in an oven at 80°C. Using the same method as in Example 1, it was measured that a 6-7um thick loose layer, an 85-100nm thick barrier layer and a 20nm-40um corrosion layer were obtained on the surface of the aluminum alloy sheet after electrolysis. The pore diameter of the micropores of the anodized film in the loose layer is 15nm-1um; the pore diameter of the corrosion pores of the barrier layer in the barrier layer is 16-800nm; the pore diameter of the al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com