Absorbable internally-fixed implantable iron-based alloy medical apparatus

A technology for implanting medical devices and iron-based alloys. It is applied in surgical devices, medical science, coatings, etc. It can solve the problems of inflammatory reaction at the implant site, increase the burden of metabolism, and poor imaging performance, so as to reduce the burden of metabolism. , reduce the burden, and accelerate the effect of corrosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Cast low-alloy high-strength steel with an alloy content of <6wt.% to form a billet, cold-draw the billet into ultra-fine steel wires with a diameter of 0.2 mm and perform heat treatment, and cut the steel wires with a diameter of 0.2 mm prepared in the above steps into different lengths Small segment, and then coated with complexing agent triammonium citrate.

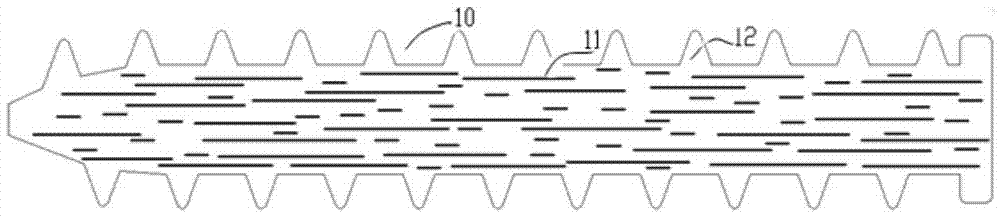

[0054] Heat the polylactic-glycolic acid (PLGA) billet with a weight-average molecular weight of 1.2 million and a polydispersity coefficient of 1.1 to a molten state. Antioxidant vitamin A is dispersed in the PLGA billet; It is used as a reinforcing phase in the PLGA billet, extruded into rods after condensation and solidification, and then machined into such as figure 1 The bone nail 10 shown. The mass ratio of the steel wire reinforcement phase 11 to the poly(lactic-co-glycolic acid) phase 12 is 20:80.

[0055]The bone nail prepared in this example had an initial bending strength of 350 MPa, and the mass pe...

Embodiment 2

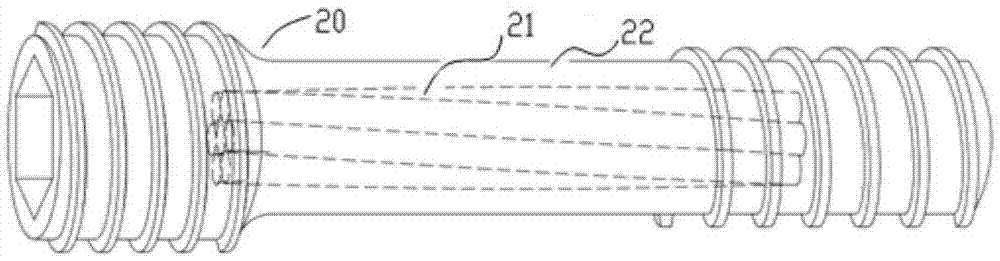

[0057] The powder metallurgy method is used to prepare low-alloy high-strength steel with an alloy content of <6wt.% into a billet, which is then hot-rolled into a wire rod, cold-drawn into a hollow steel wire, and then filled with an antioxidant ascorbyl palmitate in the core of the hollow steel wire. Multi-strand steel wires are twisted into a steel strand, and a hydroxamic acid deferoxamine complexing agent layer is prepared on the surface thereof.

[0058] Polylactic acid (PLA) with a weight average molecular weight of 3 million and a polydispersity coefficient of 1.2 and polylactic acid-methionine with a molecular weight of 250,000 are made into a blend blank; the steel strand prepared by the above steps is placed in the molten poly A blend of lactic acid (PLA) and polylactic acid-methionine is used as a reinforcing phase in the billet, and after curing it is machined into such figure 2 In the compression nail 20 shown, the mass ratio of the steel strand reinforcement ph...

Embodiment 3

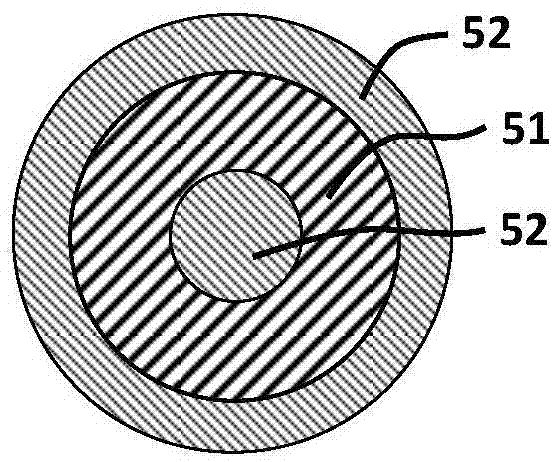

[0061] The low-alloy high-strength steel with an alloy content of <6wt.% is obtained by powder metallurgy, and then hot-rolled into a wire rod, cold-drawn into a hollow steel wire and filled with a complexing agent acetylsalicylic acid, and the multi-strand steel wire is stranded After combining, weave into a two-dimensional mesh, and prepare a hydroxyapatite layer on the surface of the two-dimensional mesh, and then coat the antioxidant ubiquinone.

[0062] The polylactic acid blank with a weight-average molecular weight of 2 million and a polydispersity coefficient of 1.5 is heated to a molten state, and then multi-layer two-dimensional mesh is added to it. After mixing evenly, it is condensed and solidified and machined into a bone nail. All the two-dimensional mesh in the bone nail The extension direction of the mesh is consistent, and the mass ratio of the two-dimensional mesh to the polylactic acid blank is 25:75.

[0063] The material of the bone nail prepared in this e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com