Weather-proof cold heading steel wire rod for 1000MPa-grade fastener and production method of weather-proof cold heading steel wire rod

A production method and fastener technology, applied in the field of iron and steel metallurgy, can solve problems such as discussion, safety of finished fasteners, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

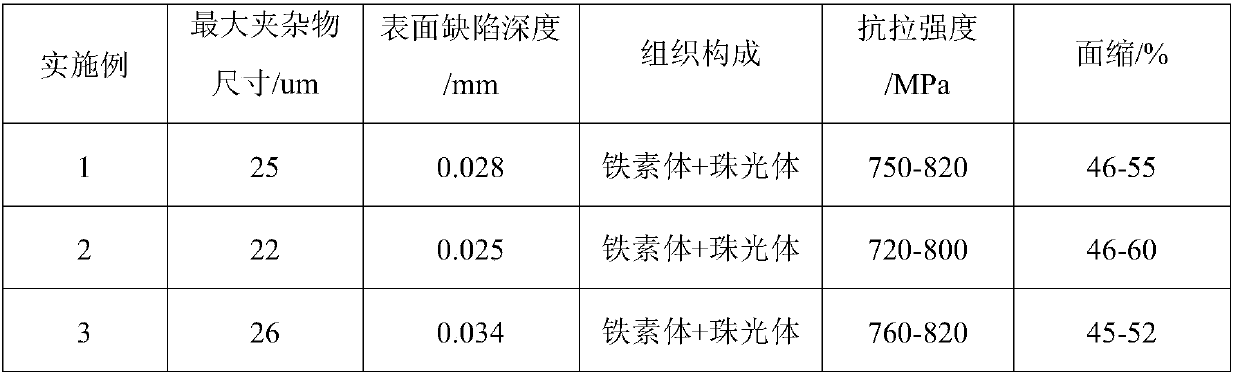

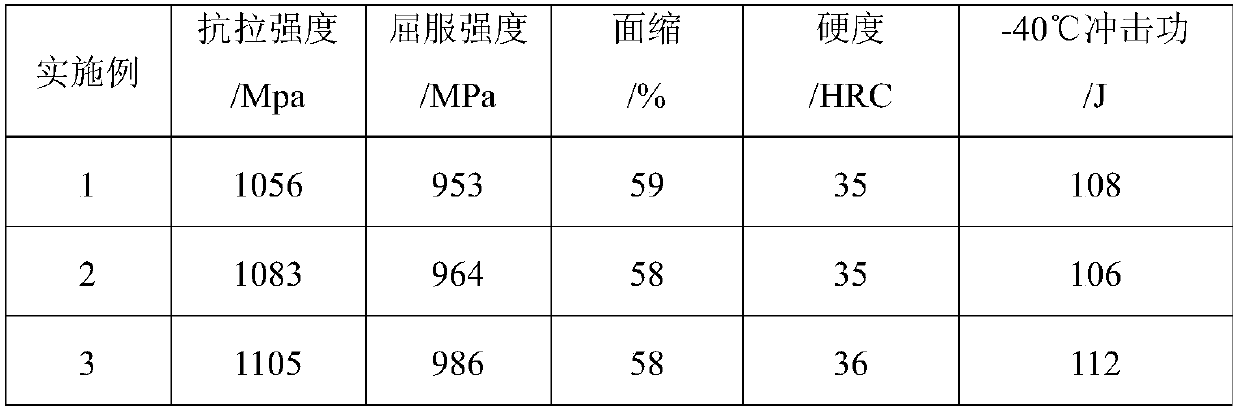

Embodiment 1

[0043] According to the chemical composition of the 1000MPa weather-resistant cold heading steel wire rod in the present invention, the refining time is 30 minutes, the argon gas flow rate is 200NL / min, the argon blowing time is 20 minutes, and after standing for 25 minutes, it is poured into a section size of 280 *For a 380mm bloom, the degree of superheat is 23°C, the current intensity of electromagnetic stirring in the mold is 450A, and the current intensity of electromagnetic stirring in the solidification end is 500A. The 280*380mm bloom is heated and rolled into a steel billet with a section size of 155*155mm, and then the steel billet is inspected and the surface defect position is ground. Then use qualified steel billet to roll in high speed wire rod mill The rolling process of the wire rod is as follows: heat the billet to 1075°C, keep it warm for 110 minutes, and the temperature difference of the passing rod is 26°C; control the rolling start temperature to 970°C, t...

Embodiment 2

[0045] According to the chemical composition of the 1000MPa weather-resistant cold heading steel wire rod in the present invention, the refining time is 40 minutes, the argon flow rate is 180NL / min, the argon blowing time is 30 minutes, and after standing for 30 minutes, it is poured into a section size of 280 *For a 380mm bloom, the degree of superheat is 22°C, the current intensity of electromagnetic stirring in the mold is 450A, and the current intensity of electromagnetic stirring at the end of solidification is 550A. The 280*380mm bloom is heated and rolled into a steel billet with a section size of 155*155mm, and then the steel billet is inspected and the surface defect position is ground. Then use qualified steel billet to roll in high speed wire rod mill For wire rod, the rolling process is as follows: heat the billet to 1050°C, keep it warm for 120 minutes, and the temperature difference of the passing rod is 25°C; control the rolling start temperature to 980°C, the ...

Embodiment 3

[0047] According to the chemical composition of the 1000MPa weather-resistant cold heading steel wire rod in the present invention, the refining time is 40 minutes, the flow rate of argon gas is 220NL / min, the time of argon blowing is 30 minutes, and after standing for 30 minutes, it is poured into a section size of 280 *For a 380mm bloom, the degree of superheat is 24°C, the current intensity of electromagnetic stirring in the mold is 500A, and the current intensity of electromagnetic stirring at the solidification end is 500A. The 280*380mm bloom is heated and rolled into a billet with a section size of 155*155mm, and then the billet is inspected for flaws and the surface defects are ground. Then use qualified steel billet to roll in high speed wire rod mill For wire rod, the rolling process is as follows: heat the billet to 1100°C, keep it warm for 120 minutes, and the temperature difference of the passing rod is 25°C; control the rolling start temperature to 930°C, the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com