Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

71 results about "Lithium metaborate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium metaborate (LiBO₂) is a chemical compound.

Composite positive electrode of lithium ion battery as well as preparation method and application to all-solid-state battery thereof

ActiveCN103956458AShorten migration distanceIncrease energy densityCell electrodesSecondary cellsSolid state electrolyteTin dioxide

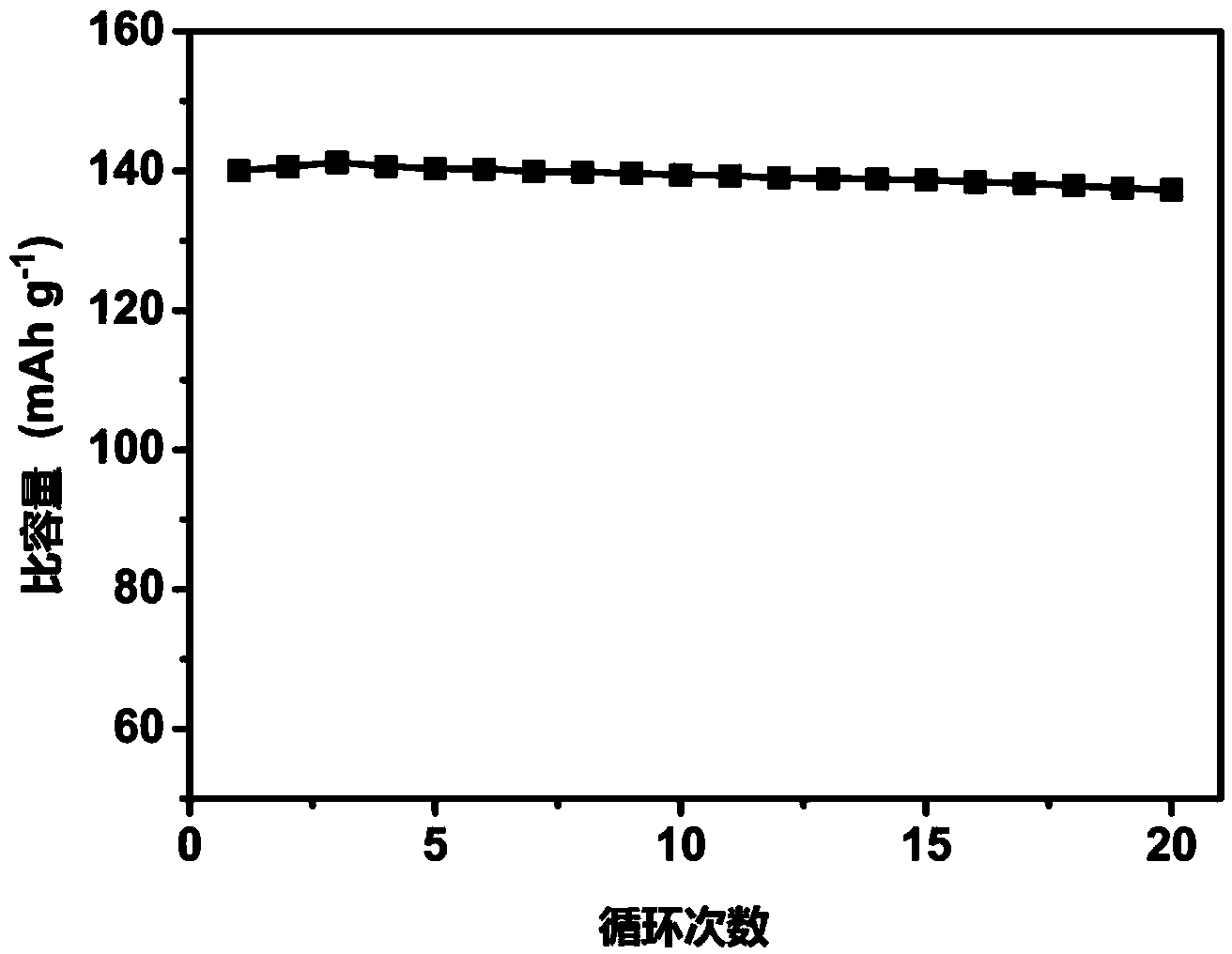

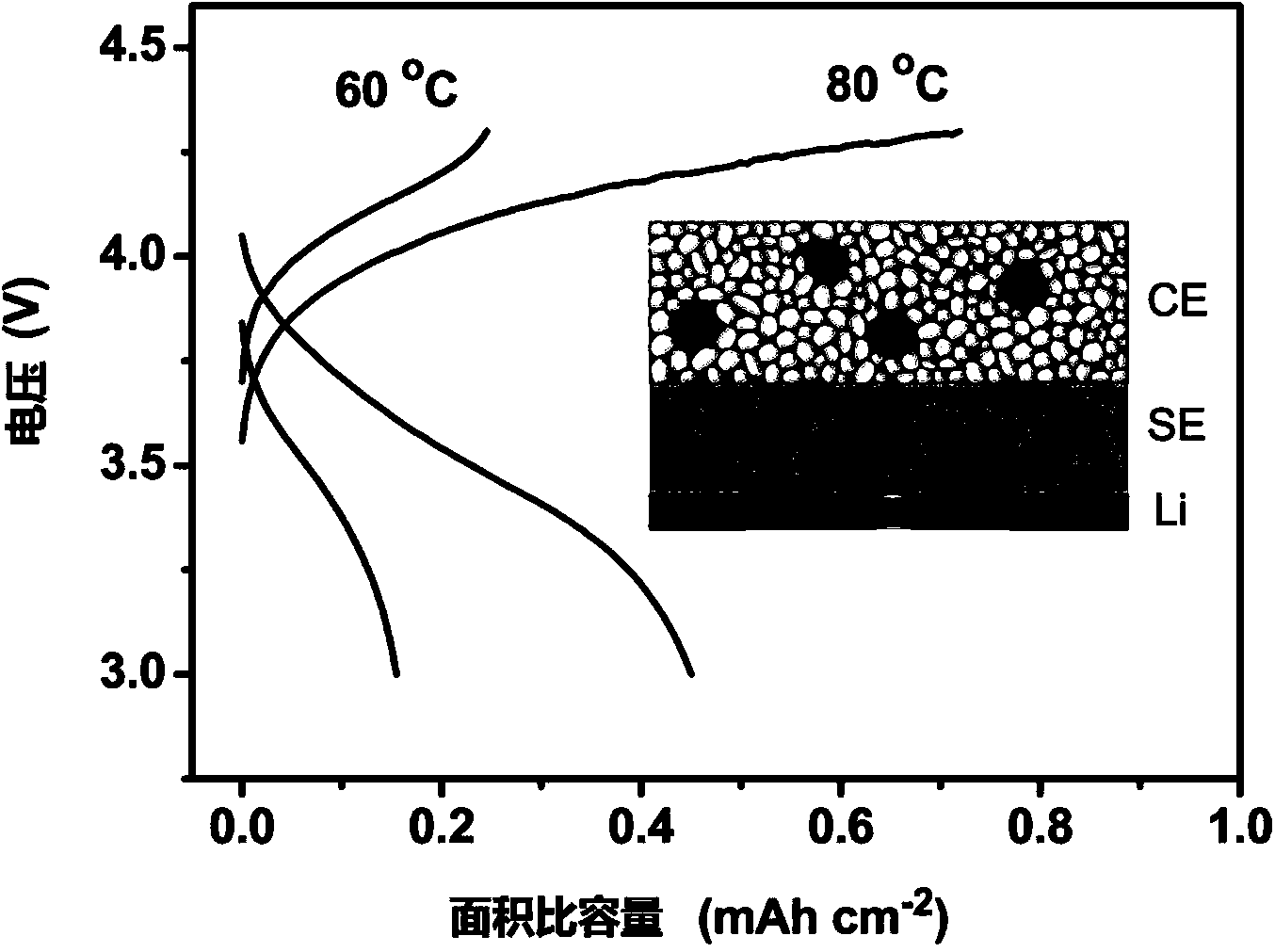

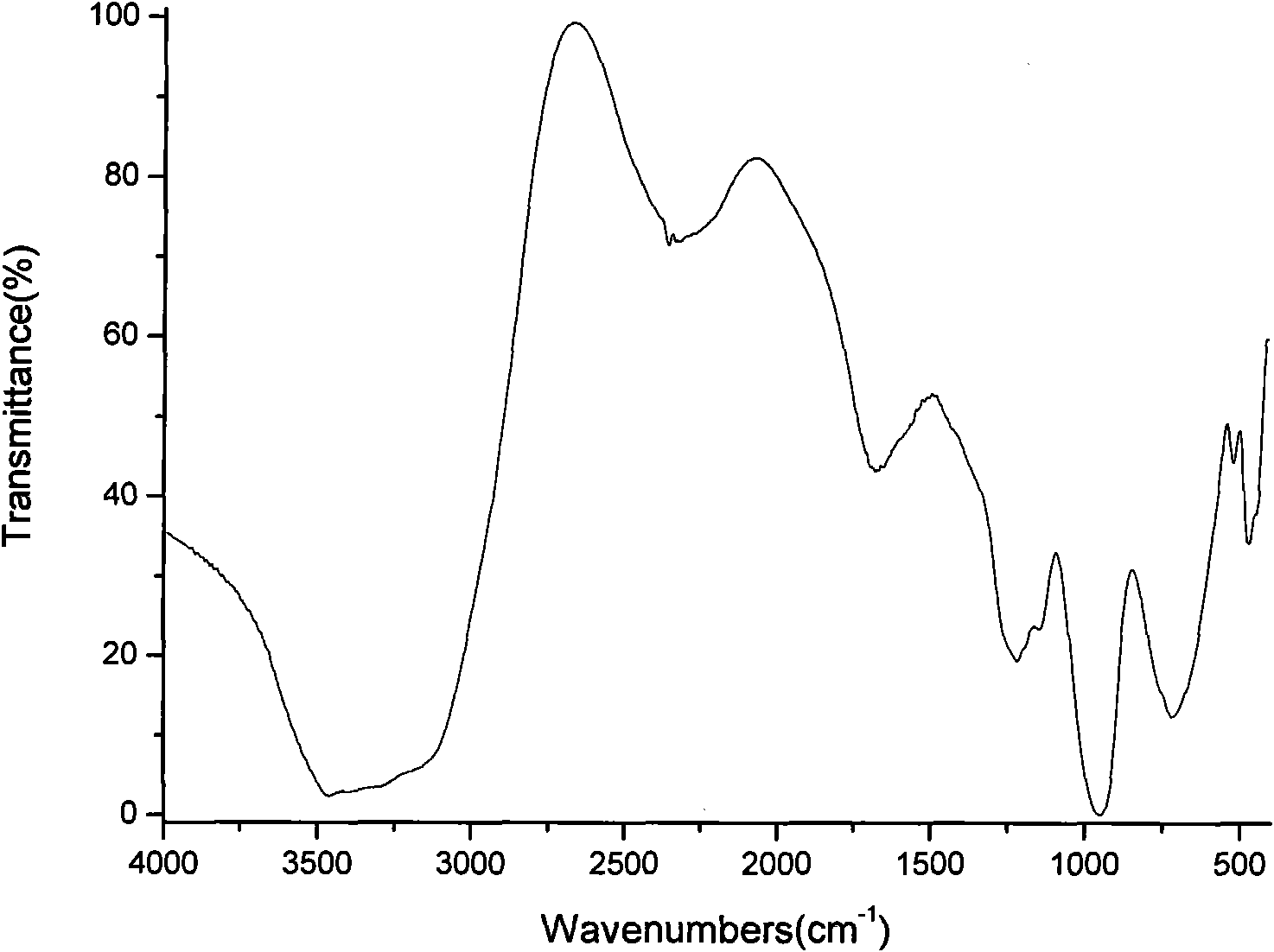

The invention discloses a composite positive electrode of a lithium ion battery as well as a preparation method and application to an all-solid-state battery thereof. The composite positive electrode of the lithium ion battery comprises a positive active material, inorganic solid electrolyte and a conductive oxide additive, wherein the positive active material is any one of lithium cobaltate, lithium manganate, lithium iron phosphate and nickel-cobalt-manganese ternary material; the inorganic solid electrolyte is at least one of lithium borate, lithium metaborate and lithium fluoride; the conductive oxide additive is any one of indium tin oxide, indium oxide, tin dioxide, zinc oxide, nickel oxide and ferroferric oxide. The method comprises the steps of (1) mixing the positive active material, the inorganic solid electrolyte and the conductive oxide additive, carrying out ball milling, drying, and carrying out tabletting to obtain a ceramic piece; and (2) sintering the ceramic piece to obtain the composite positive electrode. The composite positive electrode is good in mass ratio capacity, area ratio capacity and cycle performance, can be used for preparing the all-solid-state lithium ion battery, and can be used at high temperature.

Owner:TSINGHUA UNIV

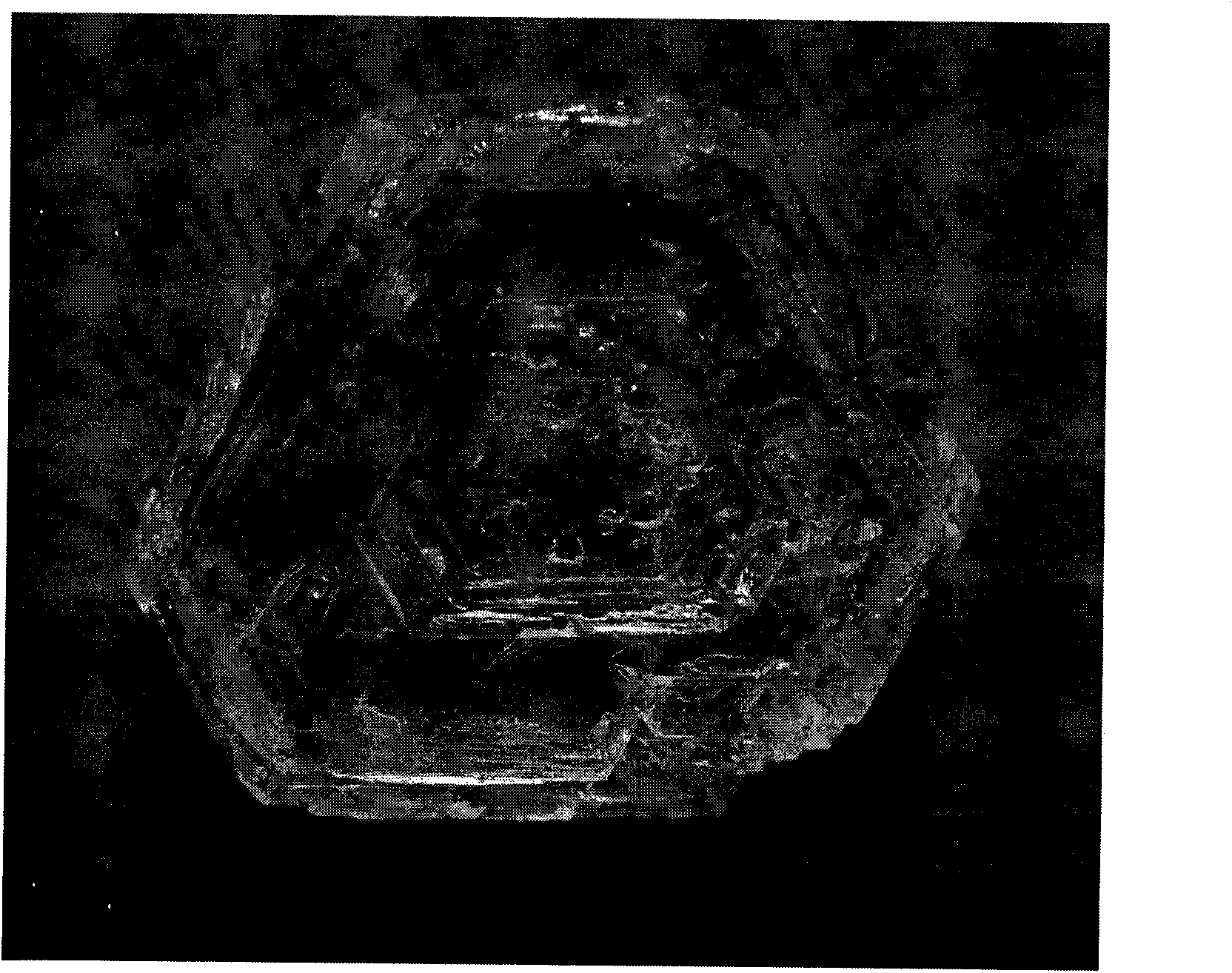

Lithium metaborate octo-hydrate nonlinear optical crystal, preparation method thereof and application thereof

InactiveCN101603203ASimple and fast operationEasy to operatePolycrystalline material growthFrom normal temperature solutionsNonlinear optical crystalSpace group

The invention relates to a lithium metaborate octo-hydrate nonlinear optical crystal, a preparation method thereof and application thereof. The molecular formula of the crystal is LiBO2.8H2O and belongs to a trigonal system, the space group is P3, and the molecular weight is 193.87. By adopting a water solution method and slowly volatilizing moisture within 3 to 30 days, the crystal is obtained; and the crystal with good quality is selected as a seed crystal, and then forms the centimeter-sized lithium metaborate octo-hydrate nonlinear optical crystal with large size through a program cooling or constant temperature method. The nonlinear optical effect of the crystal is 0.6 time of that of a KDP crystal, and the ultraviolet absorption edge is less than 90 nanometers. The growth process of the crystal has simple operation and low cost; and the used reagent is an inorganic raw material with the advantages of low toxicity, short growth period, stable physicochemical properties, and the like. The nonlinear optical crystal can be widely applied in nonlinear optical devices such as frequency doubling converters, optical parameter oscillator, and the like.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

Vitrification reagent for preparing glass melt piece for X fluorescence analysis and use method thereof

ActiveCN101509847AShorten the analysis cycleQuick analysisMaterial analysis using wave/particle radiationPreparing sample for investigationPlatinumVitrification

The invention provides a glass reagent for preparing glass fuse pieces used for metallurgical flux X-ray fluorescence analysis, consisting of anhydrous lithium tetraborate or mixture of anhydrous lithium tetraborate and lithium metaborate, and boric acid. A method for preparing the glass fuse pieces includes: firstly adding the anhydrous lithium tetraborate or the mixture of anhydrous lithium tetraborate and lithium metaborate in the metallurgical flux, then fusing at a high temperature for 12-15mins in a platinum yellow pot, preparing the glass fuse pieces after cooling; or fully mixing the boric acid with the anhydrous lithium tetraborate or the mixture of the anhydrous lithium tetraborate and lithium metaborate in advance, preparing the fast fused glass reagent and then mixing with the metallurgical flux, then fusing at the high temperature for 12-15mins in the platinum yellow pot, and preparing the glass fuse pieces after cooling. The glass reagent has accurate and stable analysis results, and greatly shortens the analysis period of the metallurgical fusing agent.

Owner:MAANSHAN IRON & STEEL CO LTD

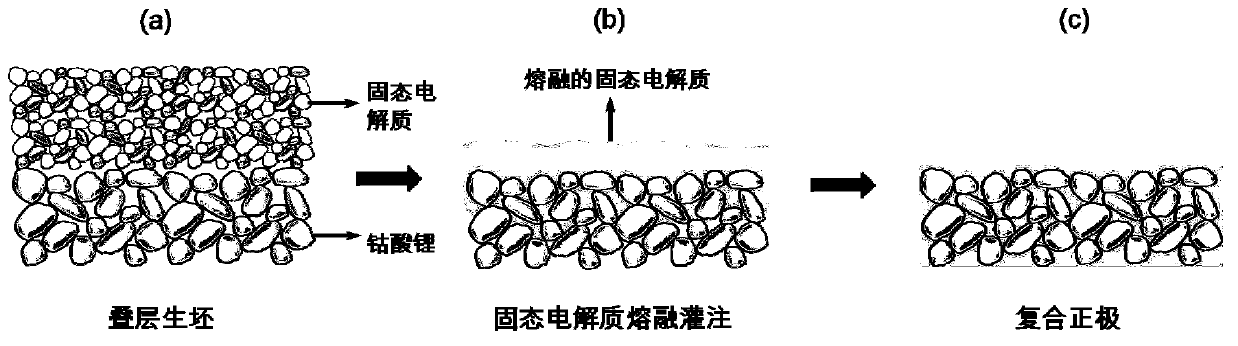

Lithium-ion battery composite positive electrode as well as preparation method and application thereof

ActiveCN103346292AImprove electrochemical performanceShorten migration distanceFinal product manufactureCell electrodesSolid state electrolyteLithium metaborate

The invention discloses a lithium-ion battery composite positive electrode as well as a preparation method and an application thereof. The composite positive electrode consists of a three-dimensional skeleton structure and inorganic solid electrolyte, wherein the three-dimensional skeleton structure is formed by connecting positive active substance particles, and the inorganic solid electrolyte is filled in the gaps of the skeleton; the positive active substance is one of lithium cobaltate, lithium manganate, lithium iron phosphate or nickel cobalt manganese ternary material; the inorganic solid electrolyte is at least one of lithium borate, lithium metaborate and lithium fluoride. The preparation method comprises the following steps of: respectively pressing the positive active substance and the inorganic solid electrolyte into green-ware, the laminating the inorganic solid electrolyte green-ware above the positive active substance green-ware, and further sintering the inorganic solid electrolyte green-ware and the positive active substance green-ware to obtain a lithium-ion battery composite positive electrode with high performance. The composite positive electrode only consists of the positive active substance and the inorganic solid electrolyte, no conductive agent or bond is added, and good mass specific capacity, good area specific capacity and good cycling performance can be achieved. The lithium-ion battery composite positive electrode can be used for preparing a liquid electrolyte lithium ion battery and a full-solid lithium ion battery.

Owner:TSINGHUA UNIV

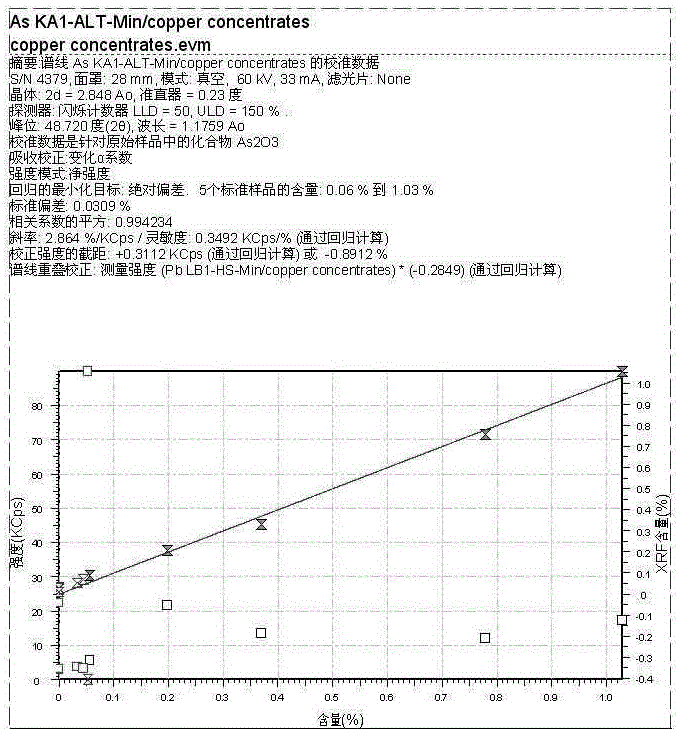

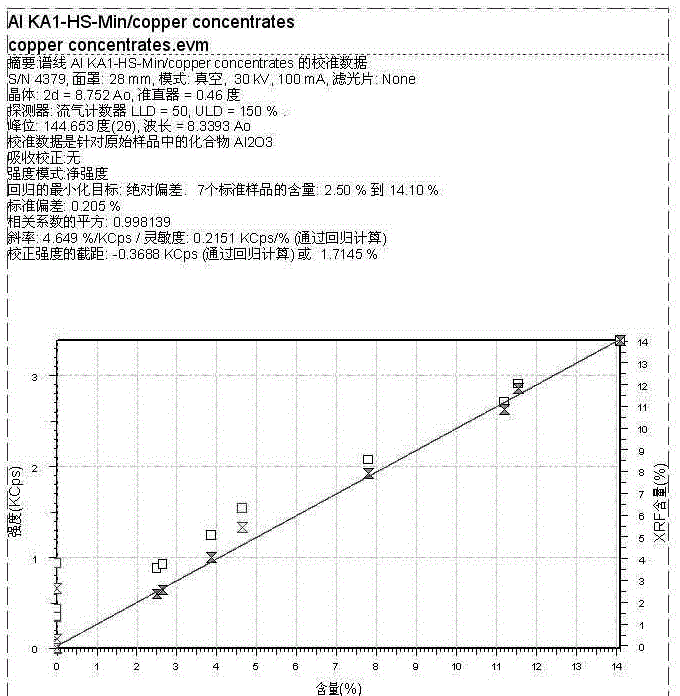

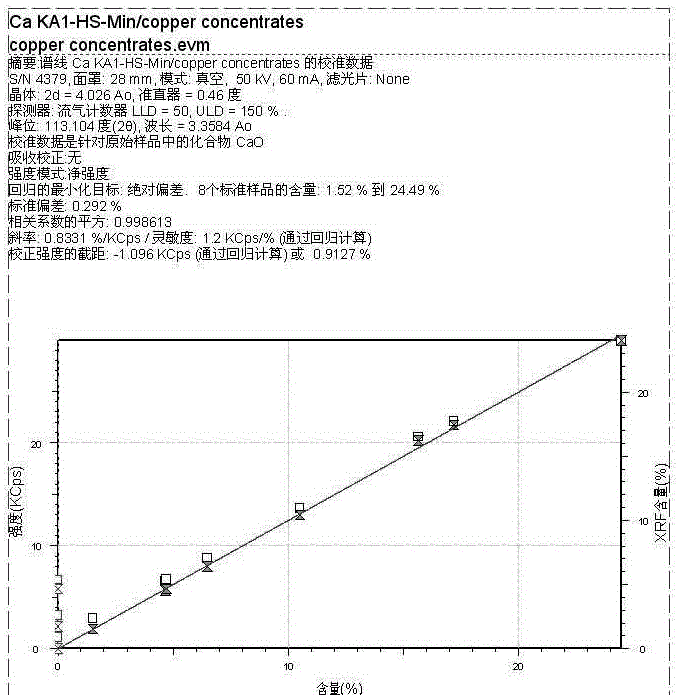

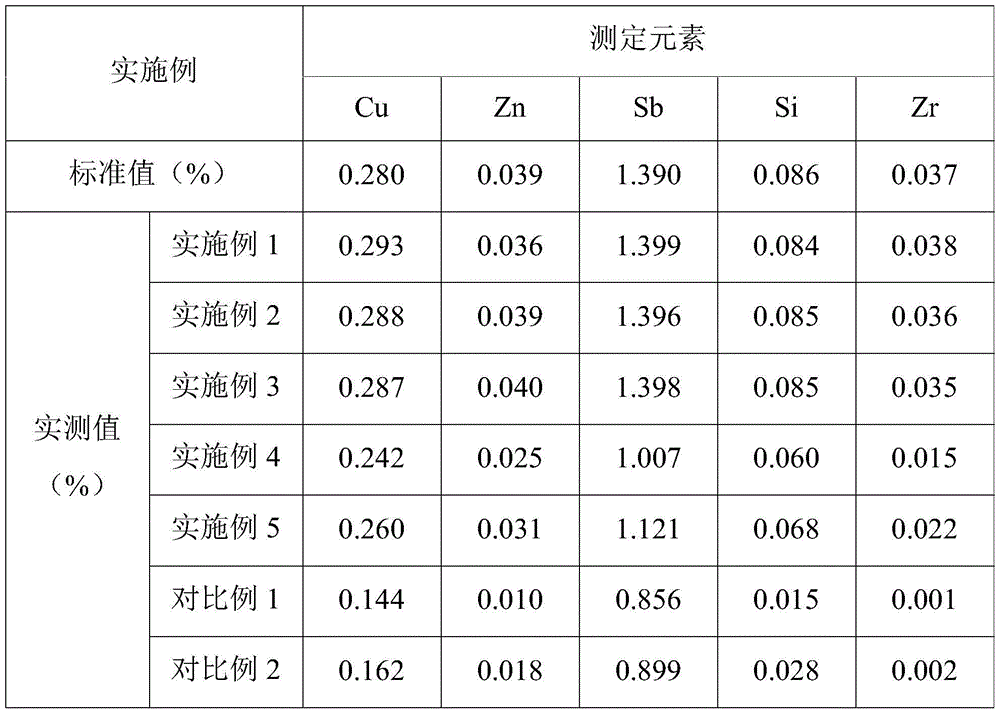

Melting flaking method of copper concentrate for X-ray fluorescent spectrometry

InactiveCN105806865ARetention stabilityWon't be lostMaterial analysis using wave/particle radiationPreparing sample for investigationLithium metaborateFluorescence

The invention discloses a melting flaking method of copper concentrate for X-ray fluorescent spectrometry. A lithium tetraborate and lithium metaborate mixed solvent serves as a base in a platinum crucible, sodium carbonate, silica, lithium nitrate and a copper concentrate sample are weighed, put into the platinum crucible in sequence and stirred evenly, the mixture is covered with a lithium tetraborate and lithium metaborate mixed solvent, put into a 600 DEG C muffle furnace, taken out after 15 min and then melted with a sample smelting furnace at 800 DEG C, a releasing agent is added and fully shaken evenly, the mixture is poured into a mould, cooled and then taken out, and sample flakes are obtained. By means of the method, it is guaranteed that sulfur in copper concentrate can remain in the sample flakes stably rather than be lost due to high temperature in the preparation process. The method is suitable for determination of the content of copper, sulfur, lead, zinc, manganese, arsenic, iron, silicon, aluminum, magnesium, calcium and other elements in copper concentrate.

Owner:NANTONG ENTRY EXIT INSPECTION & QUARANTINE BUREAU OF THE PEOPLES REPUBLIC OF CHINA

Method for simultaneously determining content of phosphorus, magnesium, iron, aluminum, silicon, calcium, titanium, manganese and strontium in phosphorite by adopting ICP-AES

InactiveCN106290318ANo distractionNo apparent interferencePreparing sample for investigationAnalysis by thermal excitationLithium metaborateLithium bromide

The invention relates to the technical field of analysis test, and in particular relates to a method for simultaneously determining content of phosphorus, magnesium, iron, aluminum, silicon, calcium, titanium, manganese and strontium in phosphorite by adopting inductively coupled plasma atomic emission spectrometry (ICP-AES). Specifically, lithium metaborate is a non-oxidant solvent with a high melt point, has high decomposition capacity for a majority of test samples, and can effectively decompose rocks and minerals difficult to dissolve. The method comprises the following steps: placing a phosphorite test sample into a platinum crucible, adding the lithium metaborate solvent and a lithium bromide releasing agent, melting and decomposing the phosphorite sample by using a high-frequency sample melting machine, pouring in a polytetrafluoroethylene beaker with 10 percent nitric acid at a high temperature by virtue of a magnetic stirrer, after the primary sample melting acidification sizing, performing matrix matching by adopting a national grade-I phosphorite, establishing a standard curve by adopting a Yttrium internal standard method, and determining the content of phosphorus pentoxide, magnesium oxide, iron oxide, aluminum oxide, silicon dioxide, calcium oxide, titanium oxide, manganese oxide and strontium oxide in the phosphorite by adopting the ICP-AES. The method has the advantages of rapidness, convenience and accuracy, and is particularly suitable for batch determining the phosphorite samples.

Owner:YUNNAN PHOSPHATE CHEM GROUP CORP

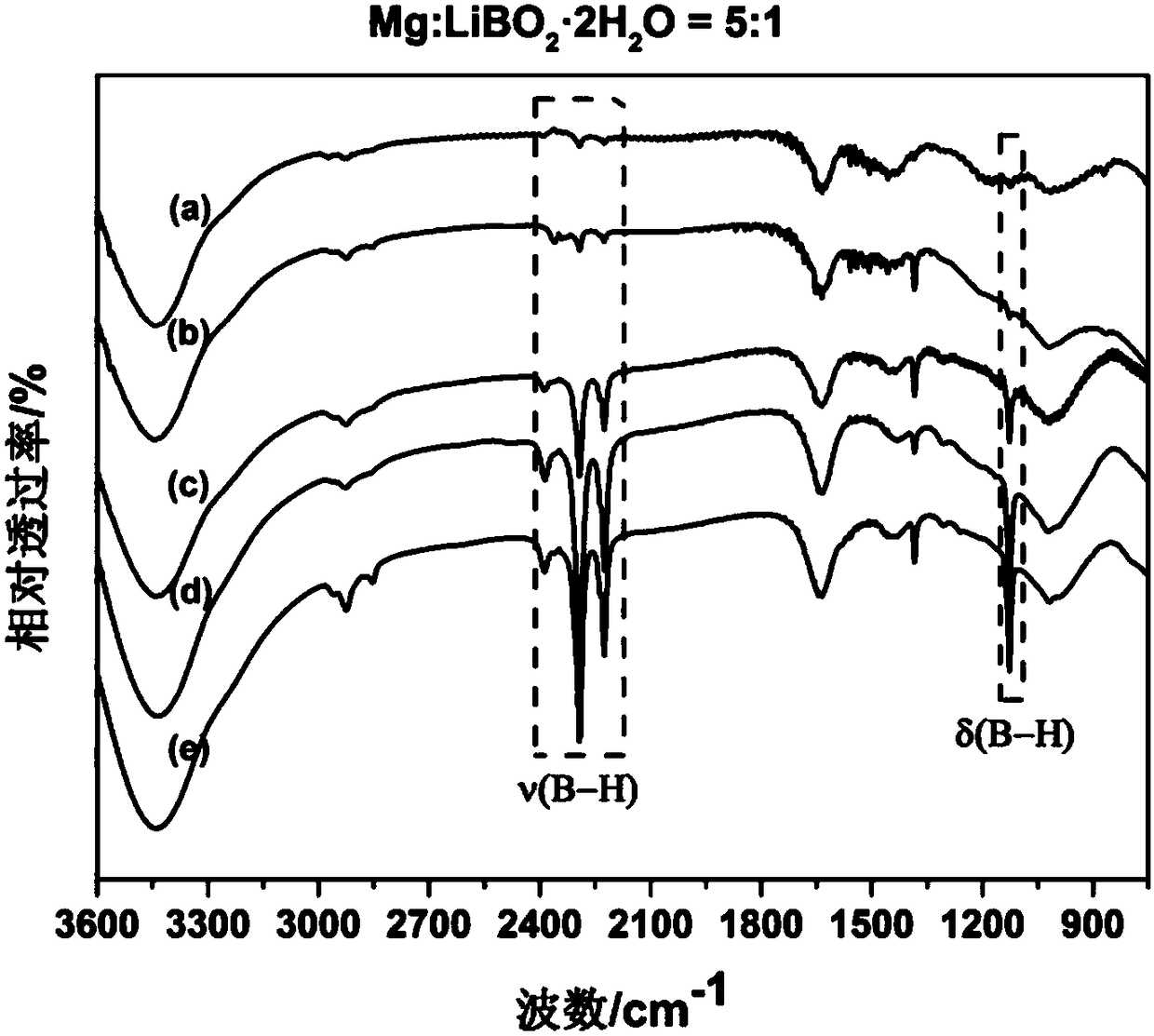

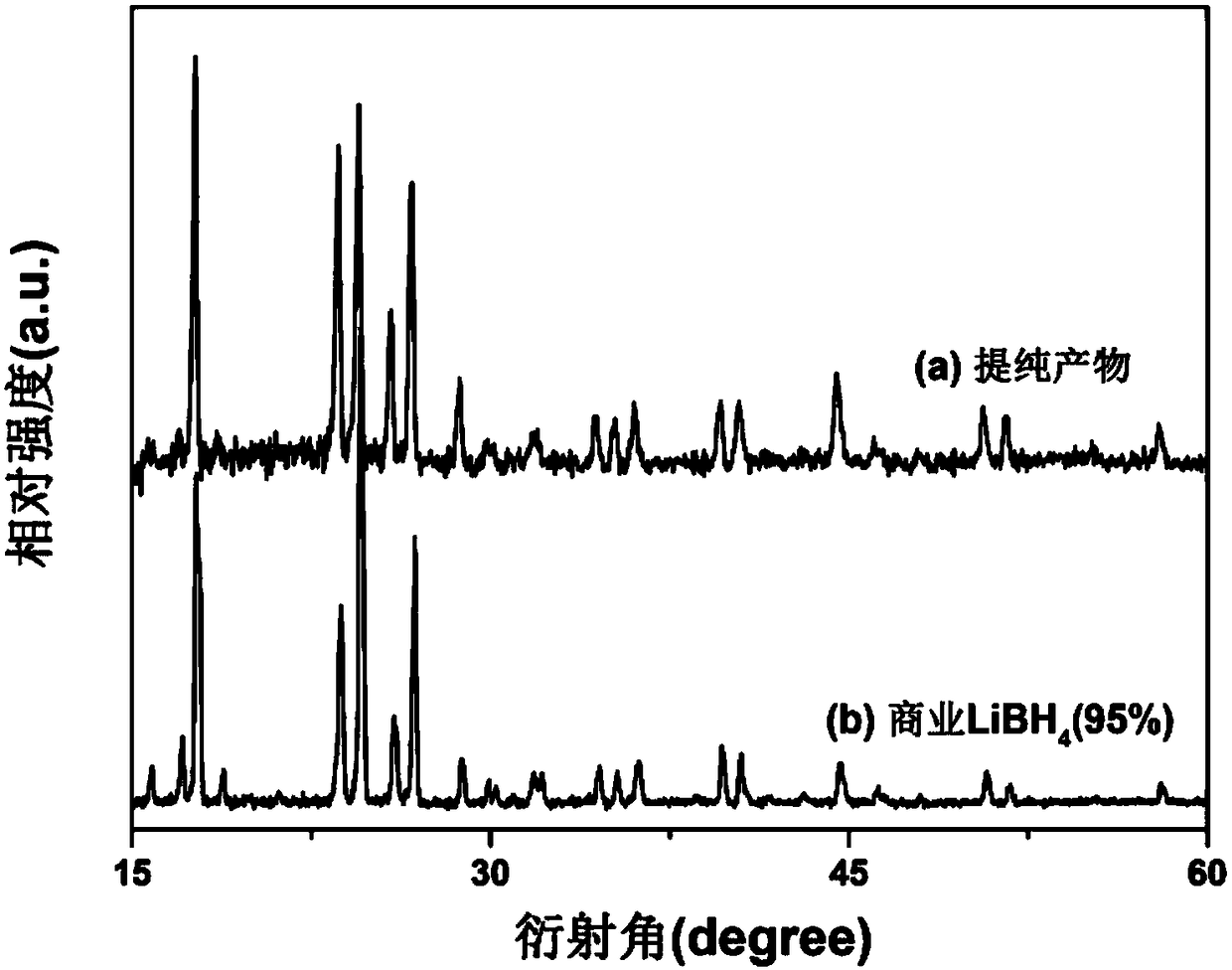

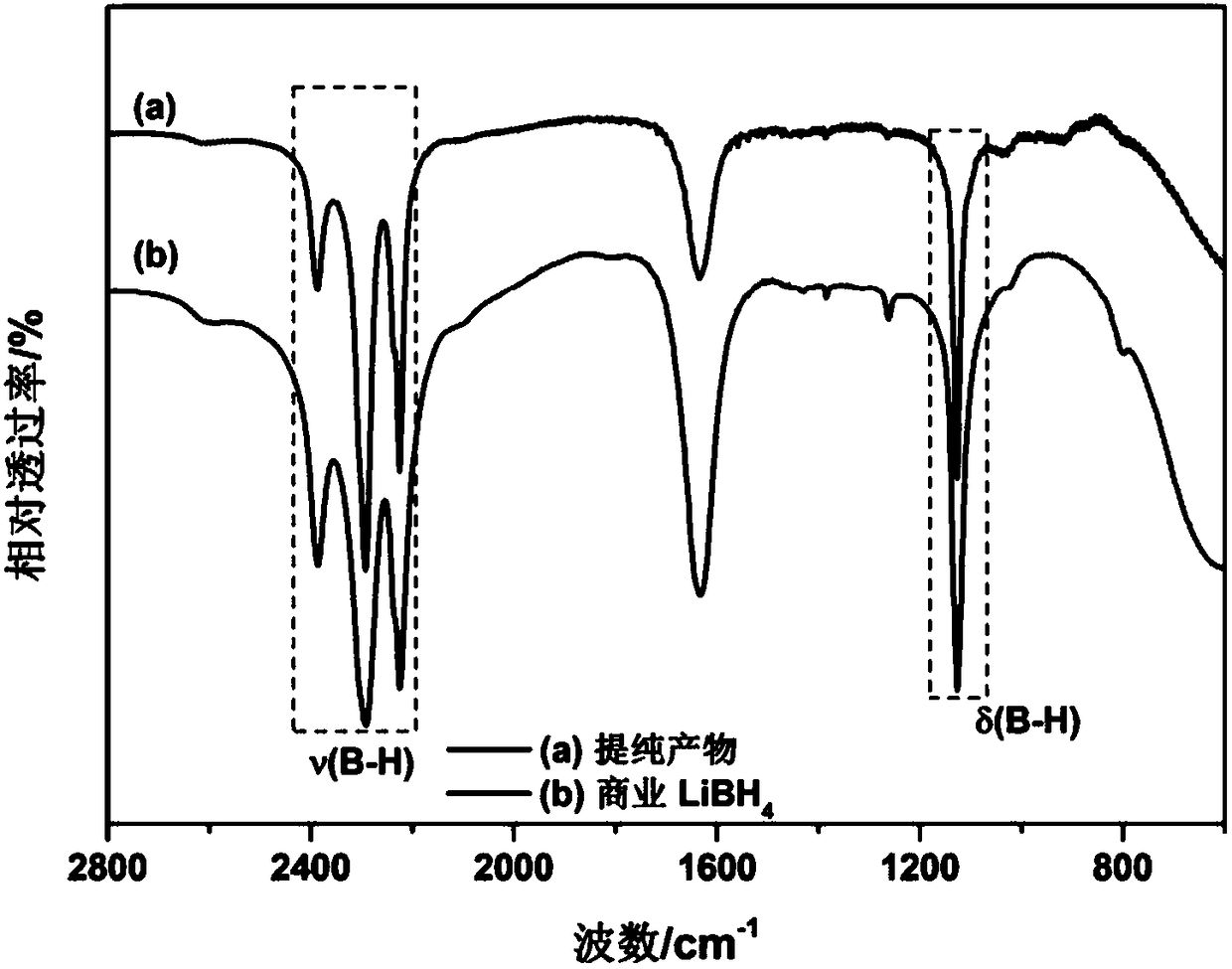

Method for preparing lithium borohydride by room-temperature solid-phase ball milling

ActiveCN108285131AWide variety of sourcesAvoid high temperature and pressureReversible hydrogen uptakeMonoborane/diborane hydridesLithium metaborateRoom temperature

The invention discloses a method for preparing lithium borohydride by room-temperature solid-phase ball milling. The method comprises the following steps: under a non-oxidizing atmosphere at room temperature, uniformly mixing a magnesium-containing reducing agent with a lithium metaborate-containing reducing material, carrying out solid-phase ball milling, and carrying out separation and purification to obtain the lithium borohydride. The preparation method provided by the invention has the advantages of simple process, controllable and adjustable reaction process, mild reaction conditions, low energy consumption, low cost, high yield, no pollution, good safety and realization of cyclic utilization of boron resources, and has important practical significance.

Owner:SOUTH CHINA UNIV OF TECH

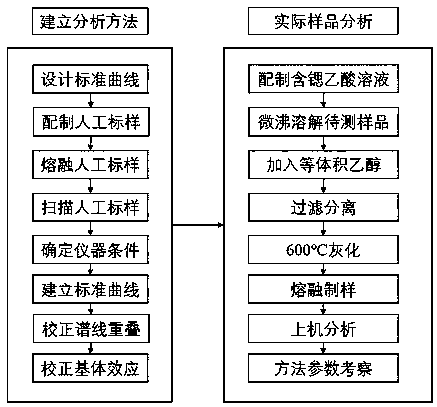

Method for detecting silicon dioxide, aluminum sesquioxide, calcium oxide and magnesium oxide in acetylene sludge

InactiveCN105784747AReduce pollutionFast wayMaterial analysis using wave/particle radiationLithium metaborateSilicon dioxide

The invention provides a method for detecting silicon dioxide, aluminum sesquioxide, calcium oxide and magnesium oxide in acetylene sludge. The detection method comprises the steps that 1, a sample to be detected is mixed with mixed flux, and then high temperature melting is conducted, and after the mixture is cooled, a glass sheet is obtained, wherein the weight ratio of the mixed flux to the sample to be tested is (17-18): 1, the mixed flux comprises lithium tetraborate and lithium metaborate, the weight ratio of lithium tetraborate to lithium metaborate is (2.9-3.1): 1, and the high temperature melting temperature is 1000-1100 DEG C; 2, fluorescence intensity of silicon, aluminum, calcium and magnesium in the glass sheet is detected through a fluorescence spectrophotometer, and according to a predetermined standard curve of the fluorescence intensity and the element content, the content of silicon, aluminum, calcium and magnesium in the sample to be tested is obtained, and the content of silicon dioxide, aluminum sesquioxide, calcium oxide and magnesium oxide is further obtained. The detection method is small in environmental pollution, fast, convenient and easy to operate and short in cycle; the detection and analysis requirements can be completely met, and the detection result is high in accuracy and precision.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Preparation of lithium ion battery taking graphene loaded nano titanium dioxide as cathode material

InactiveCN106784774AGood chemical stabilityHigh hydrogen overpotentialMaterial nanotechnologyFinal product manufactureLithium metaborateHigh energy

The invention relates to a lithium ion battery preparation technology, and aims to provide a preparation method of a lithium ion battery taking graphene loaded nano titanium dioxide as a cathode material. The preparation method comprises the following steps: carrying out ball grinding mixing on glucose monohydrate, urea and lithium metaborate, then heating the mixture for three times, and cooling the mixture to room temperature; mixing and grinding an obtained carbon-loaded nano boron lithium alloy with acetylene black and a Nafion solution, blending the materials to prepare paste, and coating nickel foam with the paste; drying the nickel foam in shade, and pressing the nickel foam for molding, thus obtaining an anode; arraying a cathode, a membrane and the anode in order to form a battery structure, wherein electrolyte takes LiPF6 as a solute and takes a mixture of ethylene carbonate, methyl carbonate and dimethyl carbonate as a solvent, and the electrolyte contains lithium hexafluorophate. The preparation method has the advantages of high chemical stability and extremely high hydrogen overpotential; the possibility of hydrogen generation is completely eliminated; a high-capacity safe lithium ion battery is prepared. The open circuit voltage of the lithium ion battery is 1.8V, and the hydrogen generation during charging can be effectively suppressed; a safe and reliable high-energy power battery is provided for an electric automobile.

Owner:ZHEJIANG UNIV

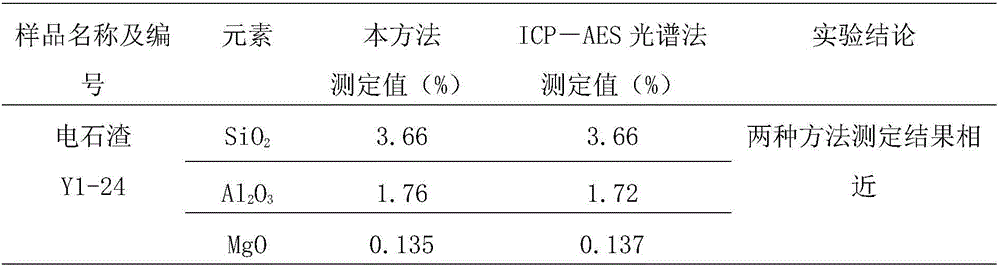

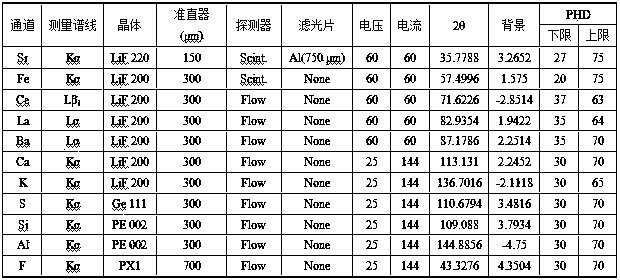

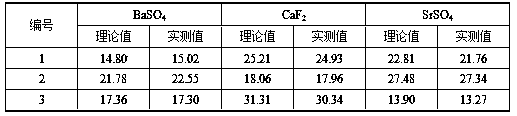

X-ray fluorescence spectrometry method for simultaneously analyzing fluorspar, barite and celestite

InactiveCN108051468AReduce consumptionPromote development and utilizationMaterial analysis using wave/particle radiationLithium metaborateRare earth

The invention discloses an X-ray fluorescence spectrometry method for simultaneously analyzing fluorspar, barite and celestite in ores quantitatively. The X-ray fluorescence spectrometry method comprises the following specific processes: preparing an artificial standard substance by mixing a barite standard substance, a fluorite standard substance, rare earth ore standard substance, strontium sulfate and strontium carbonate, fusing the artificial standard substance by using a mixed fusing agent (the ratio of lithium tetraborate to lithium metaborate is 12:22), scanning obtained standard samples to determine an instrument condition, correcting a matrix effect, and then establishing a standard curve; treating a sample to be tested by using a strontium-containing acetic acid solution, filtering, separating an interferent, ashing a precipitate and filter paper, then adding the mixed fusing agent (the ratio of lithium tetraborate to lithium metaborate is 12:22) for fusing, and analyzing according to the standard curve. An X-ray fluorescence spectrometer is selected as an analytical instrument, pretreatment operation is simplified, and simultaneous quantitative analysis of three components, namely the fluorite, the barite and the celestite, in the ore is achieved; the X-ray fluorescence spectrometry method is suitable for analyzing the single ore or the ore containing the fluorite, the barite and the celestite.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

Diode and display panel

ActiveCN103078061ASimple manufacturing processReduce manufacturing costSolid-state devicesSemiconductor/solid-state device manufacturingLithium metaborateManufacturing technology

The invention discloses a diode and a display panel. The diode comprises a cathode, an anode and an electron transmission layer, wherein the cathode and the anode are arranged opposite to each other; the electron transmission layer is formed between the cathode and the anode; an alkali metal compound serving as an electron injection layer is doped in the electron transmission layer; and the alkali metal compound includes at least one of lithium metaborate, potassium silicate, lithium tetra(8-hydroxyquinolinato)boron and alkali metal acetate. According to the mode mentioned above, the manufacture technology and process of the diode can be effectively simplified, the process yield is improved, and the manufacture cost of the diode is increased.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Preparation method for PVDF porous nanofiber membrane

InactiveCN103668781AResistant to solution corrosionGood film formingNon-woven fabricsLithium metaborateLithium chloride

The invention discloses a preparation method for a PVDF porous nanofiber membrane. The preparation method comprises the steps that (1) alkyl alcohol amine poly oxygen ethane ether, lithium perchlorate, acetone, lithium metaborate, tetramethylurea, lithium oxalate, single-walled carbon nanotubes, lithium lactate, lithium citrate, polyvinylidene fluoride, vinyl trimethoxy silane, lithium phosphate, methyl ethyl acetone, lithium carbonate, dimethyl sulfoxide, dilithium silicate, hexafluoroisopropanol, tetrahydrofuran and lithium chloride are added into a water solution, heated and stirred to be dissolved, and cooled to the room temperature; (2) then, polyvinylpyrrolidone is added and stirred to be dissolved to obtain a spinning solution; (3) electrostatic spinning is carried out on the obtained spinning solution; (4) a copper net is used as a receiver to obtain the fiber membrane, and the obtained fiber membrane is impregnated with ethyl alcohol for 3h. The PVDF porous nanofiber membrane prepared through the method has the corrosive resistance to solutions, the good membrane-forming performance and the good interfacial compatibility.

Owner:CHANGSHU LIYUAN MEMBRANE TECH

Sensitive and reliable testing method for synchronously testing multiple components in chrome drainage sand

ActiveCN103674983AHigh emission intensityHigh sex ratioMaterial analysis using wave/particle radiationLithium metaborateReal time analysis

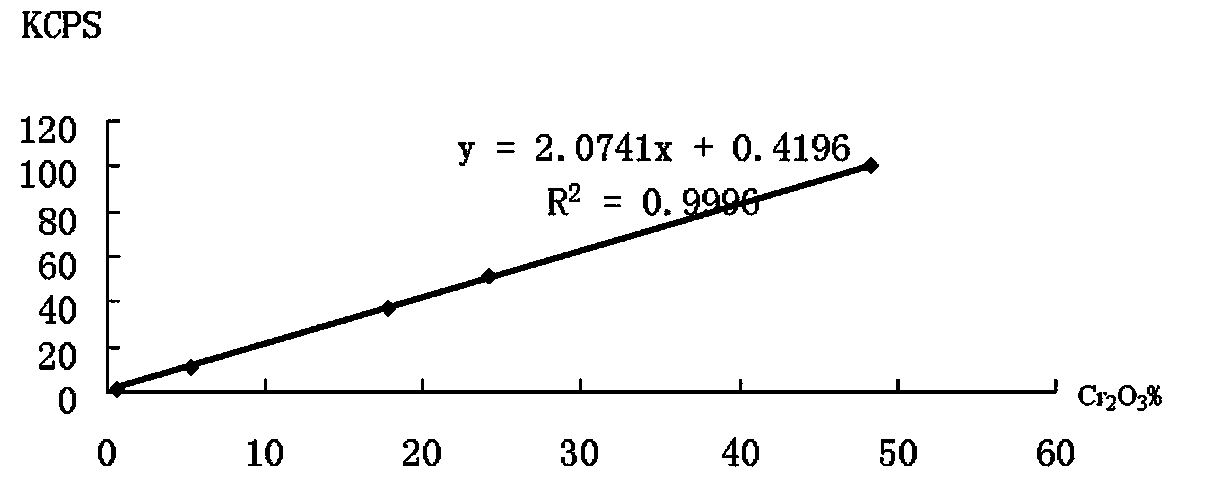

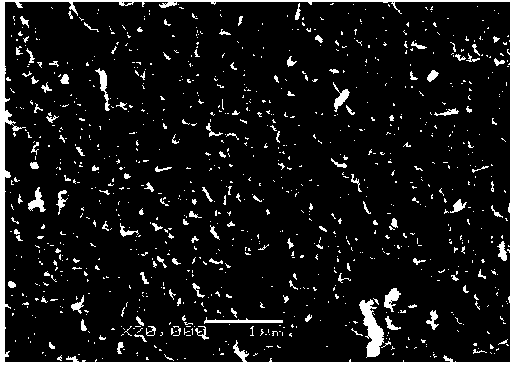

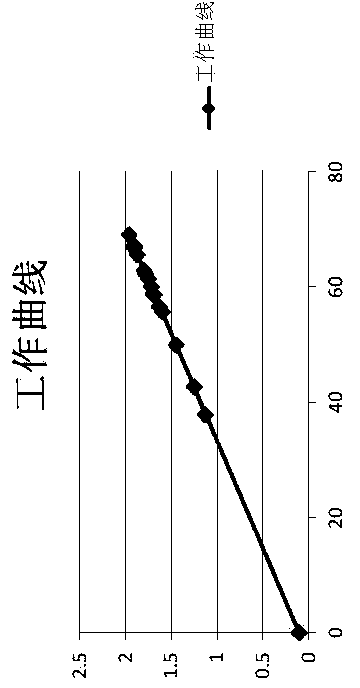

The invention discloses a sensitive and reliable testing method for synchronously testing multiple components in chrome drainage sand, and belongs to the technical field of metallurgical material test and analysis. A standard sample consists of dichromate, silica, clay brick, magnalium brick, vanadium-titanium magnetite tailing, vanadium slag and steel slag; and the content of each component is required to cover the content range of each corresponding to-be-tested component in the chrome drainage sand. The testing method comprises the following steps: weighing 6.0000 g of mixed flux of lithium tetraborate and lithium metaborate, 0.1500 g of standard sample or to-be-tested sample powder, and 0.0200g of a demoulding agent respectively, uniformly mixing, melting for 18-22 min at 1140-1160 DEG C, and venting and cooling melt to obtain a standard sheet or a test sheet; testing the standard sheet by using an X-ray fluorescence spectrometer, establishing an analyzing working curve, and correcting a matrix effect; testing the sample under the same conditions, and in combination with the analyzing working curve, obtaining the content testing result of each component. The testing method is high in accuracy, reproducibility and stability and is applicable to rapid determination of massive samples; by the testing method, real-time analysis data can be provided for industrial production; therefore, the testing method has relatively high popularization and application values.

Owner:WUKUN STEEL

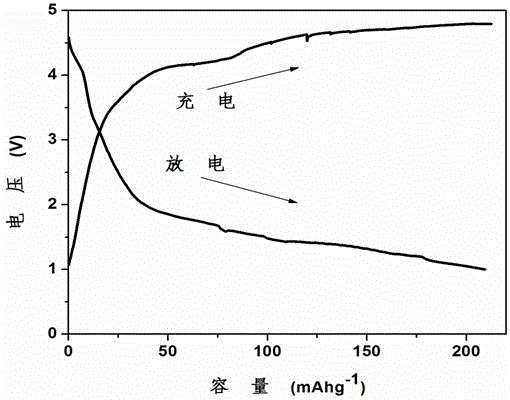

Preparation method of anode material manganese-lithium borate for lithium ion battery

The invention discloses a preparation method of anode material manganese-lithium borate for a lithium ion battery, which comprises the following steps: (1) dissolving lithium metaborate, lithium acetate, manganese acetate and glucose in deionized water and stirring uniformly; (2) putting into a cold trap for pre-freezing, taking out after the pre-freezing is ended, putting into a drying frame, placing the drying frame above the cold trap, setting the temperature in the cold trap to be -50 DEG C to -20 DEG C, starting a vacuum pump, setting the vacuum degree to be below 15Pa and drying for 20-24 hours; and (3) heating to the temperature of 350 DEG C to 450 DEG C at a speed of 1-5 DEG C per minute under the protection of argon, stabilizing the temperature for 4-6 hours, then heating to the temperature of 600 DEG C to 700 DEG C at the speed of 1-5 DEG C per minute, stabilizing the temperature for 4-6 hours, introducing the argon and naturally cooling to room temperature to obtain the anode material manganese-lithium borate. By adopting the preparation method disclosed by the invention, the operation is simple, the reproducibility is good, a precursor material is small in particle size, the particle size of a material obtained through sintering can be well controlled, a good carbon coating effect is achieved, a good electron conduction performance is realized, and the charge-discharge specific capacity for the first time is high.

Owner:CENT SOUTH UNIV

Detection reagents and method for detecting iron ores by X fluorescent spectrometry

ActiveCN103529067AExtended use timeImprove accuracyMaterial analysis using wave/particle radiationPlatinumLithium metaborate

The invention provides detection reagents and a method for detecting iron ores by an X fluorescent spectrometry, and belongs to the steel-making industrial field. The invention aims to solve existing problems of glass sheets in the prior art of detection reagents and methods for detecting iron ores by X fluorescent spectrometry by means of resetting ingredients of internal standard cobalt powder and a glass fuse sheet. For the first time, lithium tetraborate-lithium metaborate, cobalt sesquioxide, lithium nitrate and lithium bromide are employed to prepare internal standard cobalt powder. Then anhydrous lithium tetraborate-lithium metaborate mixed fusing agent, a sample, the internal standard cobalt powder, lithium nitrate and lithium bromide are employed to prepare a glass fuse sheet. The dosage of the fusing agent is reduced and the detection cost is lowered. The service time of a platinum yellow crucible is prolonged, and the detection cost is further lowered. The accuracy of analysis results is raised.

Owner:吉林建龙钢铁有限责任公司

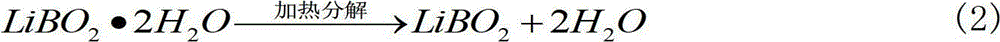

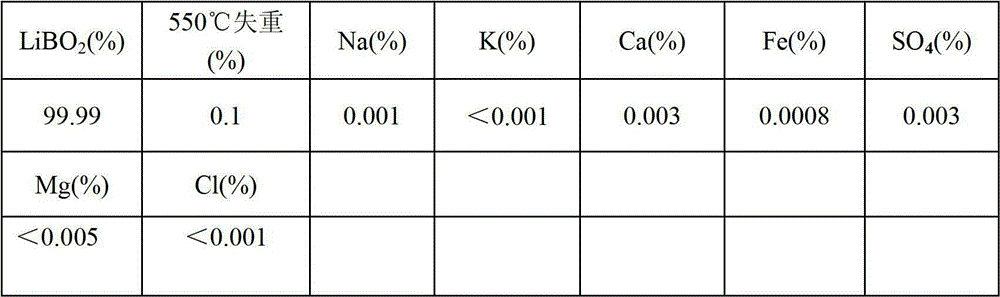

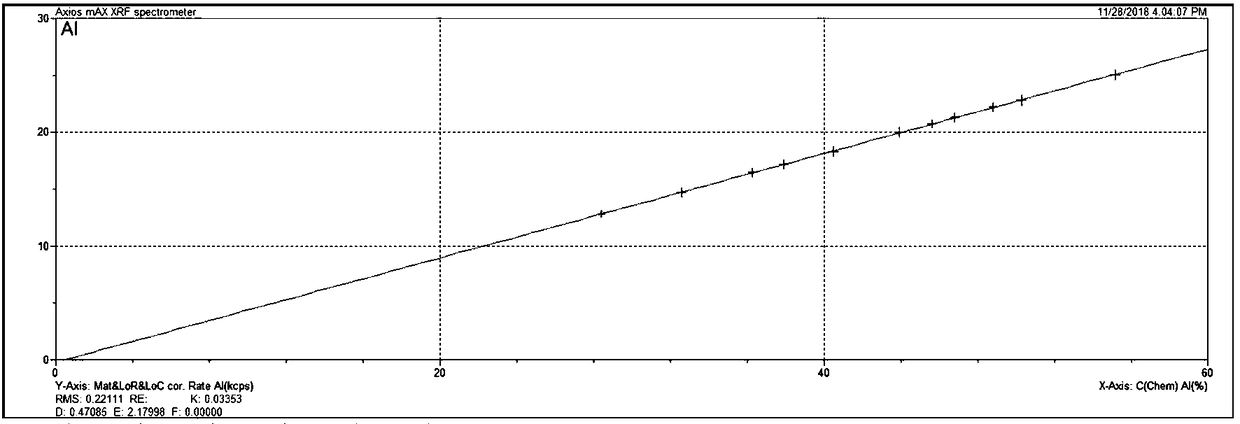

Preparation method of anhydrous lithium metaborate

The invention belongs to the technical field of preparation of inorganic compound lithium metaborate, and particularly discloses a preparation method of anhydrous lithium metaborate. The method comprises the following steps: dissolving lithium hydroxide in boiling water, and filtering to remove impurities; slowly adding boracic acid after being purified in hot lithium hydroxide solution, wherein the amount of boracic acid is slightly smaller than theoretical reacting weight; depositing so that the solution is cooled and crystallized to prepare lithium metaborate wet material; and then obtaining the finished product of anhydrous lithium metaborate through the steps of low-temperature primary drying, cracking, high-temperature secondary drying and the like. According to the method, lithium metaborate is prepared from lithium hydroxide and boracic acid through liquid phase reaction, the utilization rates of lithium hydroxide and boracic acid are improved, the yield coefficient of the system can reach more than 90%, the purity of the product can reach 99.99% and is higher than that of the product in the prior art, and the method is more suitable for the market requirements nowadays.

Owner:HUBEI BAIJIERUI ADVANCED MATERIALS

Method for determining impurities in glass by using X-ray fluorescence spectrometry

InactiveCN107367521ALow melting pointImprove liquidityMaterial analysis by measuring secondary emissionLithium metaborateMass ratio

The invention relates to a method for determining impurities in glass by using X-ray fluorescence spectrometry. The method comprises the following steps: 1) weighing a standard glass fiber and a to-be-determined glass fiber, separately and uniformly mixing the standard glass fiber and the to-be-determined glass fiber with a mixed solvent under stirring, then separately adding ammonium iodide drop by drop so as to obtain two mixtures, heating the two mixtures to 1100 to 1300 DEG C within 10 min, and then subjecting the mixtures to fusing at 1100 to 1300 for 15 to 25 min so as to obtain a standard glass sample sheet and a to-be-determined glass sample sheet, wherein the mixed solvent is composed of lithium tetraborate and lithium metaborate in a mass ratio of 35: 65; and 2) detecting the standard glass sample sheet and the to-be-determined glass sample sheet by using an X-ray fluorescence spectrometer, determining a linear relation between intensity and content, drawing a calibration curve and calculating the content of impurities in glass. The method provided by the invention has high detection sensitivity and good reproducibility.

Owner:SUZHOU LANSCI INSTR

Blade deposit sediment measuring method for turbine

InactiveCN101923016AReduce usageShorten the timePreparing sample for investigationAnalysis by electrical excitationLithium metaborateSteam turbine blade

The invention provides a blade deposit sediment measuring method for a turbine, which comprises the following steps: collecting a deposit sediment sample; heating and fusing the mixture of the deposit sediment sample, lithium tetra borate and lithium metaborate; taking out the mixture obtained by fusing and cooling to room temperature; socking the mixture into a hydrochloric acid or salpeter solution; heating the solution and stirring; carrying out constant volume on the solution; and measuring the solution to obtain the components in the deposit sediment sample. The blade deposit sediment measuring method for the turbine provided by the invention processes the blade deposit sediment into the solution at a time, so that the method can measure the main body component of the mainly contained deposit sediment on the related instrument at a time.

Owner:EAST CHINA ELECTRIC POWER TEST & RES INST

Combined type demoulding method for fusion in X-ray fluorescence analysis of iron oxide ore

InactiveCN107543748AShort demoulding action timeGood effectPreparing sample for investigationLithium metaborateLithium bromide

The invention discloses a combined type demoulding method for fusion in X-ray fluorescence analysis of iron oxide ore. The method comprises the following steps: (1) a mixed solvent of anhydrous lithium tetraborate and lithium metaborate, cobalt powder, a sample and lithium nitrate are uniformly mixed, the mixture is added into an au-pt alloy crucible, and a lithium bromide solution is added; (2) after a primary heating stage and a secondary heating stage, a fusion stage begins, and potassium iodide is added during 180-200 seconds of the fusion stage; (3) after a self-cooling stage and an air-cooling stage, a sample piece is numbered and the crucible is inversed in order to take the sample piece out. Under the effects of a double releasing agent, the releasing effect is greatly improved, requirements on smoothness of the au-pt alloy crucible are reduced, and average usage life of the au-pt alloy crucible is increased from 170 times of fusion to more than 600 times of fusion; service life of the au-pt alloy crucible is increased by three times or above, recasting maintenance cost of the au-pt alloy crucible is reduced, operation cost is reduced, and economic benefit is improved.

Owner:抚顺新钢铁有限责任公司

Lithium metaborate hydrogen storage composite material adulterated with lithium hydride and preparation method thereof

ActiveCN104909337ALow hydrogen release temperatureFast hydrogen release rateHydrogenLithium metaboratePhysical chemistry

A lithium metaborate hydrogen storage composite material adulterated with lithium hydride consists of LiBO2 and LiH, the molar ratio of the abovementioned two ingredients is LiBO2:LiH=0.5-2:1. The preparation method of the lithium metaborate hydrogen storage composite material adulterated with the lithium hydride mainly comprises the steps of under the protection of argon, mixing the LiH and the LiBO2 uniformly according to the abovementioned molar ratio, then putting the mixture in a ball-milling pot so as to carry out ball-milling treatment, the ball-milling time being 1-5 hours, the ball-to-powder weight ratio is 10-40:1, the revolving speed being 200-500r / min, the ball-milling mode being positive / reverse intermittent ball-milling, pausing for 15min when carrying out ball-milling for 15min each time, cooling down to the indoor temperature naturally after the ball-milling is finished, taking out the composite material prepared under the protection of the argon and carrying out sealed package, and obtaining the lithium metaborate hydrogen storage composite material adulterated with the lithium hydride. According to the lithium metaborate hydrogen storage composite material adulterated with the lithium hydride, the preparation method is simple, the raw material is easy to obtain, the cost is cheap, the hydrogen desorption temperature is low, the hydrogen desorption rate is fast, and the lithium metaborate hydrogen storage composite material adulterated with the lithium hydride is conducive to industrialized volume production.

Owner:YANSHAN UNIV

Method for preparing molybdenum iron glass fuse pieces

InactiveCN106645242AMeet the use requirementsQuality improvementMaterial analysis by measuring secondary emissionLithium metaborateLithium carbonate

The invention relates to the technical field of quantitative analysis of X-ray fluorescence spectrums, and discloses a method for preparing molybdenum iron sample glass fuse pieces. The method includes the process steps: grinding samples; performing pre-oxidation for the samples; preparing glass molten mass. The method particularly includes the steps: paving the bottom with mixed flux of lithium tetraborate and lithium metaborate; directly mixing lithium carbonate, sodium nitrate and molybdenum iron samples; gradually rising the temperature and oxidizing at the temperature lower than 700 DEG C; adding ammonium bromide reagents; preparing the glass fuse pieces at the temperature of 1100 DEG C. According to the method, the excellent molybdenum iron glass fuse pieces are simply, conveniently and rapidly prepared, use requirements of an X-ray fluorescence analysis method are met, and large-batch actual production inspection is rapidly finished in a high-quality manner.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Fluorescence detection method of zirconia content in TFT glass

InactiveCN105651745AExpand the scope of detectionAccurate measurementPreparing sample for investigationFluorescence/phosphorescenceLithium metaborateFluorescence

The invention discloses a fluorescence detection method of the zirconia content in TFT glass. The method comprises: a, finely grinding a glass sample to obtain glass powder; b, mixing the glass powder obtained from the step a with a fusing agent and a releasing agent for fusion sample preparation to obtain a fused glass sheet, wherein the mass ratio of the glass powder to the fusing agent to the releasing agent is 1: (0.5-2): (0.01-0.1), and the fusing agent is a mixture of lithium tetraborate and lithium metaborate with the mass ratio being (1-5): 1; and c, performing fluorescence detection of the fused glass sheet obtained from the step b to obtain the zirconia content in the glass sample. According to the method, the zirconia content in glass can be quickly, accurately, and efficiently measured.

Owner:ZHENGZHOU XUFEI OPTOELECTRONICS TECH +1

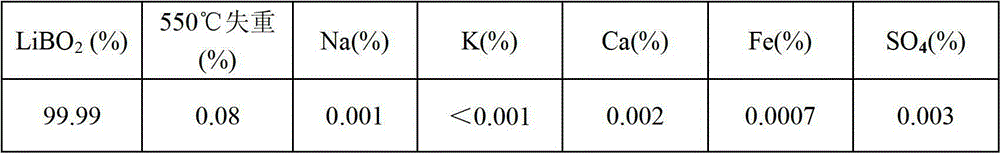

Rapid analysis method suitable for aluminum, iron and silicon content in aluminum iron alloy

InactiveCN109444197AThe result is accurateBest analysis conditionsMaterial analysis using wave/particle radiationPreparing sample for investigationLithium metaborateBarium peroxide

The invention discloses a rapid analysis method suitable for aluminum, iron and silicon content in an aluminum iron alloy, and relates to the technical field of aluminum iron alloy component analysis.The method comprises the following steps of: treating a sample to be analyzed; performing wall build-up treatment in a crucible; uniformly mixing the sample to be analyzed, barium peroxide and lithium carbonate, spreading the mixture in the crucible, and adding lithium metaborate for covering the surface; performing pre-oxidization, adding a demolding agent for fusing, and cooling to obtain a glass-like sample sheet to be analyzed; selecting high-purity aluminum powder, pure iron and high-purity oxide SiO2 to prepare a series of calibration samples, and preparing a calibration sample sheet according to the previous steps; determining the spectral line intensity of aluminum, iron and silicon in the calibration sample sheet with an X-ray fluorescence spectrometer, and establishing working curves of aluminum, iron and silicon according to the measurement result; determining the fluorescence intensity of the sample sheet to be analyzed according to the working curves to obtain the contentof aluminum, iron and silicon in the sample sheet to be analyzed. By adopting the method, the problems of complex flow and low efficiency in the existing chemical component determination method for the aluminum iron alloy are solved.

Owner:LIUZHOU IRON & STEEL

Nickel Flux Composition

InactiveUS20090016486A1X-ray/infra-red processesMaterial analysis using wave/particle radiationLithium metaborateX-ray

In the x-ray fluorescence analysis of minerals, ores and other materials, chemicals containing lithium and boron are melted together at high temperatures to produce lithium borate compounds which are then cooled and reduced in size to a powder or coarse material. Such material is known as x-ray flux and is usually represented or specified in the final commercial product as ratios of lithium tetraborate to lithium metaborate. The x-ray flux is melted with materials to be analyzed and cast into discs which are then analyzed by an x-ray fluorescence spectrograph. In this invention, thulium has been added, mixed and melted with the x-ray flux such as to function as an internal quantitative standard for the analysis of nickel ore, nickel concentrates or other nickel containing substances, when such flux is mixed and melted with the nickel containing samples to be analyzed.

Owner:X RAY FLUX

Method for rapidly measuring major, minor, and trace components in granite by X-ray fluorescence spectrum

PendingCN108680593AThe pre-processing process is simpleThe detection process is fastMaterial analysis using wave/particle radiationLithium metaborateElemental analysis

The invention belongs to the field of fluorescence spectrum detection, and particularly relates to a method for rapidly measuring major, minor, and trace components in granite by an X-ray fluorescencespectrum. The method comprises the following steps: preparing a sample by using a fusing method, after performing lithium nitrate preoxidation on the sample, selecting a lithium tetraborate and lithium metaborate mixed reagent of which a mass ratio is 12:22 as a fusing agent, using ammonium iodide as a releasing agent, and preparing a fusing piece. A standard substance, such as the granite, is used as a calibration sample, and an elemental analysis range is further enlarged by artificially synthesizing the sample, the absorption enhancement effect between elements is calibrated through a changed theoretical Alpha-coefficient method, and an X-ray fluorescence spectrum method for 15 components of silicon dioxide, aluminum oxide, potassium oxide, sodium oxide, ferric oxide, calcium oxide, magnesium oxide, manganese oxide, phosphorus pentoxide, titanium dioxide, barium, strontium, sulfur, rubidium and zirconium in the granite is established. The method has the advantages of simple pretreatment, rapid detection speed, low cost, simultaneous analysis of major, minor, and trace elements and the like, and is capable of greatly improving the detection efficiency.

Owner:LONGYAN UNIV

Lithium tetrafluoroborate preparation method

ActiveCN104326482ARaw materials are easy to getNot corrosiveTretrafluoboric acidBoratesLithium metaborateLithium carbonate

The invention discloses a lithium tetrafluoroborate preparation method comprising the following steps: mixing lithium carbonate, lithium hydroxide monohydrate or anhydrous lithium hydroxide and boric acid and boric oxide to obtain lithium metaborate, crushing the lithium metaborate to obtain lithium metaborate powder, and mixing the lithium metaborate powder and ammonium fluoride or ammonium bifluoride for vacuum negative pressure burning reaction to obtain the lithium tetrafluoroborate product. The lithium tetrafluoroborate preparation method uses a solid lithium source and a solid boron source as raw materials for preparation of the lithium tetrafluoroborate, the process has the advantages that raw materials are easily obtained, non-toxic and non-corrosive, product quality is high, no side reaction is produced, and the method is environmentally friendly and high in efficiency, and the like.

Owner:SHANGHAI CHINA LITHIUM INDAL

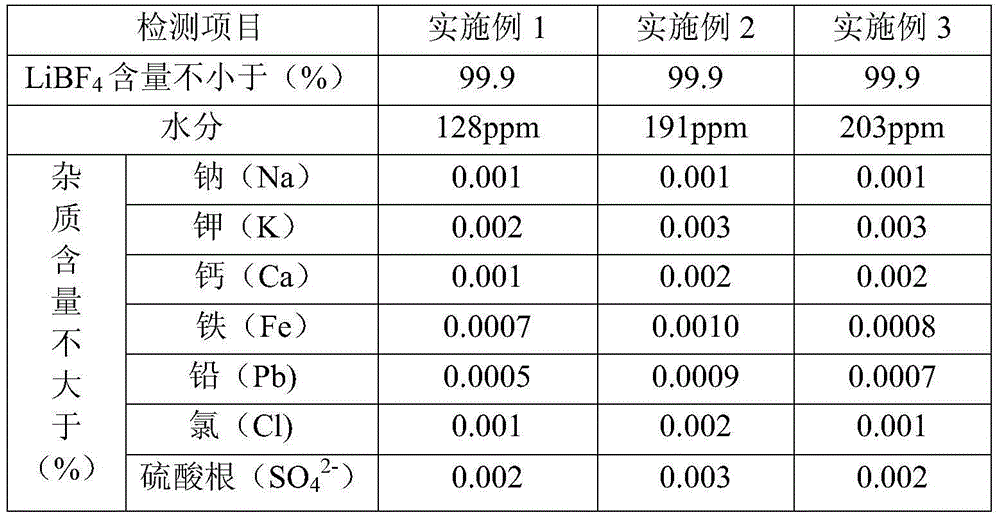

Preparation method of low moisture lithium tetrafluoroborate

ActiveCN104528752ASynthesis process control is simpleReduce pollutionTretrafluoboric acidBoratesLithium metaborateFiltration

The invention belongs to the preparation technology field of electrolyte lithium salt for a lithium ion battery, and particularly discloses a preparation method of low moisture lithium tetrafluoroborate. The preparation method comprises the following steps that dihydrate lithium metaborate is dissolved in pure water so that seriflux is prepared, the seriflux is added to hydrofluoric acid to react so that a lithium tetrafluoroborate rough solution is prepared, a small amount of boric acid is added into the solution and performs reacting completely, lithium tetrafluoroborate crystals are prepared through filtration, evaporation and concentration, cooling crystallization and centrifugal separation, the crystals are dissolved in absolute ethyl alcohol and subject to the first drying, the materials are subject to the second drying in vacuum environment, and the low moisture lithium tetrafluoroborate is obtained. According to the preparation method, the technology is simple, the energy consumption is low, the operability is strong, and the method is suitable for industrial production.

Owner:HUBEI BAIJIERUI ADVANCED MATERIALS

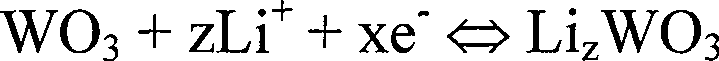

An inorganic full-solid electric driven color-changing part making method

InactiveCN100498493CLarge modulation rangeShort reaction timeTenebresent compositionsNon-linear opticsLithium metaborateDichroic glass

The invention provides an inorganic all-solid state electrochromism component and the preparation method thereof. The component has the structure that a tungsten oxide film, a compound film of lithium metaborate and lithium sulfate, a nickel oxide film and an indium tin oxide film are deposited in turn on a tin doped indium oxide glass substrate. The preparation method has the following steps: tin doped indium oxide conductive glass is incised into substrates, the size of which is suitable to that of an instrument and equipment, and the substrates are ultrasonic washed in turn in acetone, anhydrous alcohol and demineralized water; the sputter foil cavity of a multi-target magnetic control sputtering apparatus which is loaded with the substrates is vacuumized to 1*10<-4> Pa; then the tungsten oxide film, the compound film of lithium metaborate and lithium sulfate, the nickel oxide film and the indium tin oxide film are deposited in turn. The invention has great value in the research and the application of dichroic glass, an antidazzle viewfinder, an information display screen and an energy conservation promoting window according as the electrochromism component prepared by the method of the invention has the performance of changing the transmittivity of visible light, and has the characteristics of wide modulation range and short action time.

Owner:BEIHANG UNIV

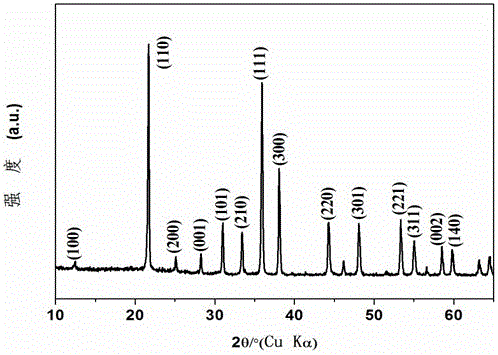

A kind of preparation method of lithium manganese borate lithium ion battery cathode material

ActiveCN103833044BWide variety of sourcesImprove controllabilityCell electrodesBoratesMANGANESE ACETATECarbon coating

Owner:CENT SOUTH UNIV

Method determining impurity content in stannic oxide electrode material

InactiveCN105628683AEasy to handleImprove the success rate of sample preparationPreparing sample for investigationAnalysis by thermal excitationLithium metaborateStrong acids

The invention discloses a method determining impurity content in a stannic oxide electrode material. The method comprises: adding the stannic oxide electrode into lithium tetraborate and lithium metaborate serving as a flux and mixed proportionally for melting, taking a fuse piece after cooling, adding water and inorganic strong acid to dissolve to obtain a solution to be determined, and then determining the solution to be determined by adopting an inductive coupling plasma emission spectrometer. By adopting the method disclosed by the invention, the high compactness stannic oxide electrode material can be fully dissolved, sampling is simple, various impurity elements in the stannic oxide electrode can be determined, a determined result is accurate and an analysis error is small.

Owner:TUNGHSU TECH GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com