Preparation method of anode material manganese-lithium borate for lithium ion battery

A technology for lithium-ion batteries and positive electrode materials, which is applied in the field of preparation of lithium-ion battery positive electrode materials, and can solve the problems of long experimental period of sol-gel method and hydrothermal method, difficulty in electronic and ion conductivity, and high noise of mechanical ball milling method, etc. problem, to achieve the effect of high initial reversible charge-discharge specific capacity, high reproducibility, and high charge-discharge specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

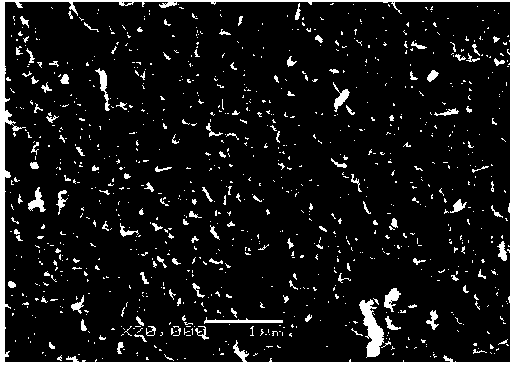

Image

Examples

Embodiment 1

[0028] Take 4.99g of lithium metaborate, 0.20g of lithium acetate, 17.31g of manganese acetate, and 3.60g of glucose, dissolve them in 150ml of deionized water, and stir them magnetically in a beaker for 5 hours to obtain a gel-like mixture; On the freezer shelf, put them together into the cold trap for pre-freezing for 5 hours. The pre-freezing temperature is set at -50°C. Put it above the cold trap, cover it with a plexiglass cover, and the lower end of the cover is in full contact with the "O"-shaped sealing ring. Set the temperature in the cold trap to -50°C, start the vacuum pump, and set the vacuum degree to below 15Pa. After drying for 24 hours, open it. Inflate the vacuum valve, stop the work of the vacuum pump and compressor in turn, and obtain the precursor; raise the temperature of the obtained precursor to 400°C at a rate of 5°C per minute under the protection of argon with a purity of 99.999%, keep the temperature for 5 hours, and then increase the temperature at a...

Embodiment 2

[0033] Take 4.99g of lithium metaborate, 0.20g of lithium acetate, 17.31g of manganese acetate, and 13.50g of glucose, dissolve them in 200ml of deionized water, and stir them magnetically in a beaker for 5 hours to obtain a gel-like mixture; Put them together on the freezer shelf into the cold trap for 7h pre-freezing. The pre-freezing temperature is set at -30°C. Put it on the top of the cold trap, cover it with a plexiglass cover, and the lower end of the cover is in full contact with the "O"-shaped sealing ring. Set the temperature in the cold trap to -40°C, start the vacuum pump, and set the vacuum degree below 15Pa. After drying for 23 hours, open it. Inflate the vacuum valve, stop the work of the vacuum pump and compressor in turn to obtain the precursor; under the protection of argon gas with a purity of 99.999%, the temperature of the obtained precursor is raised to 400°C at a rate of 5°C per minute, and the temperature is kept constant for 5h. Raise the temperature t...

Embodiment 3

[0036] Take 4.99g of lithium metaborate, 0.20g of lithium acetate, 17.31g of manganese acetate, and 13.50g of glucose, dissolve them in 200ml of deionized water, and stir them magnetically in a beaker for 5 hours to obtain a gel-like mixture; On the freezing rack, put them together into the cold trap for pre-freezing for 6 hours. The pre-freezing temperature is set at -40°C. Put it above the cold trap, cover it with a plexiglass cover, and the lower end of the cover is in full contact with the "O"-shaped sealing ring. Set the temperature in the cold trap to -30°C, start the vacuum pump, and set the vacuum degree to below 15Pa. After drying for 24 hours, open it. After the vacuum valve is inflated, stop the work of the vacuum pump and compressor in turn to obtain the precursor; under the protection of argon gas with a purity of 99.999%, the temperature of the obtained precursor is raised to 400 °C at a rate of 5 °C per minute, and the temperature is maintained for 5 hours. Rais...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com