Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36 results about "Glucose monohydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

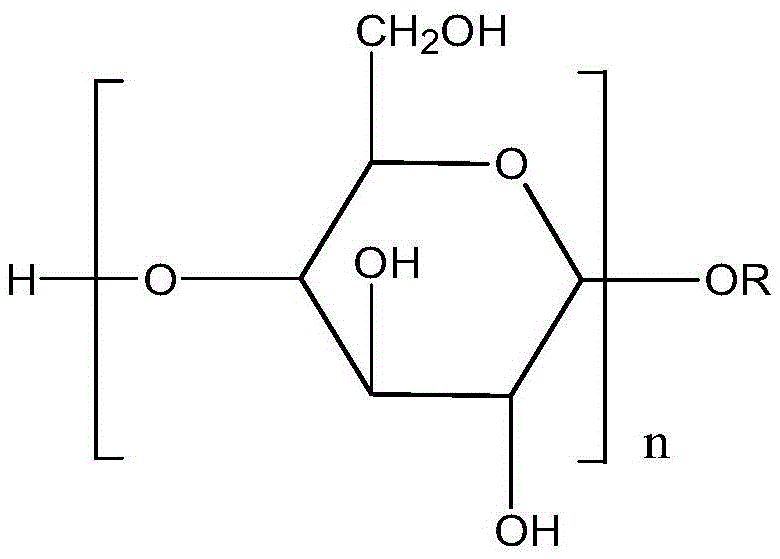

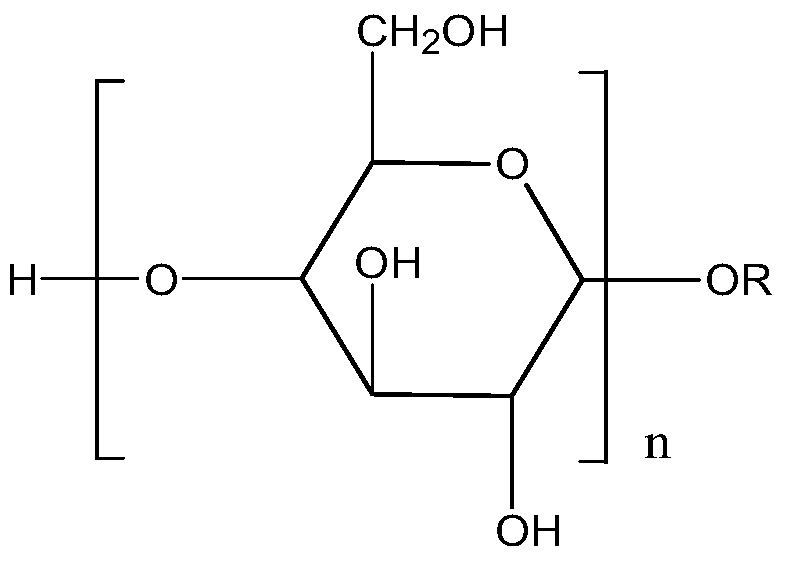

Dextrose Monohydrate (D-glucose) is a sugar that’s a stable, odorless, white crystalline powder or colorless crystal.

Nonreactive health powdered suckling pig creep compound feed and preparation method thereof

InactiveCN102885236AIncrease feed intakeImprove Gut HealthFood processingAnimal feeding stuffBiotechnologyPhytase

The invention discloses a nonreactive health powdered suckling pig creep compound feed and a preparation method thereof, wherein the feed is prepared from the following materials: corn, broken rice, puffed corn starch, puffed soybean meal, dehulling soybean meal, fermented soybean meal, white fish meal, flour, plasma protein flour, whey powder, fruit sugar, glucose monohydrate, bean oil, calcium formate, calcium biphosphate, salt, enveloped slow release acidulant, choline chloride, suckling pig compound premix, zinc oxide, yeast cell wall polysaccharides, sodium glutamate, arazyme, lipidase, Clostridium butyricum, essential oils, L-lysine hydrochloride, DL methionine, L-threonine, tryptophan and phytase. Based on the physiological characteristics of suckling pig and by the combination of various materials, the feed is supplementary in nutrition and high in design of amino acid and daily ration of energy without adding antibiotics, and Clostridium butyricum and various essential oils are used for protecting the health; therefore, the feed intake of suckling pig can be increased, the weight growth rate is increased, the diarrhea rate after ablactation is reduced, the intestine health of suckling pig can be improved, the immunity is improved, and the survival rate of suckling pig is increased.

Owner:HUAIAN ZHENGCHANG FEED

Formula and preparation method of composite carbon source for denitrification

PendingCN108793401AIncrease concentrationReduce transportationWater treatment compoundsTreatment with anaerobic digestion processesSodium acetateReaction temperature

The invention relates to a formula and a preparation method of a composite carbon source for denitrification, and relates to prevention and control of water pollution. The formula comprises the following components: 0 to 20% of calcium acetate, 5% to 25% of sodium acetate, 5% to 40% of glucose, 0 to 20% of ethanol, and 40% to 70% of water, of which the total amount is 100%. The formula at least comprises sodium acetate, glucose and water, and the mass percent of the carbon source material in the carbon source formula is 30% to 60%. The preparation method comprises the following steps: injecting tap water into a reaction kettle and stirring, adding calcium hydroxide, and injecting acetic acid; controlling the reaction temperature and pH, and reacting to generate a calcium acetate solution;adding sodium acetate trihydrate until completely dissolved; adding glucose monohydrate and stirring until completely dissolved; when the temperature of the solution is lowered to room temperature, adding ethanol. The solution is pumped out of the reaction kettle to a storage tank for standing, and a supernatant liquid is the prepared composite carbon source for denitrification.

Owner:石泰山

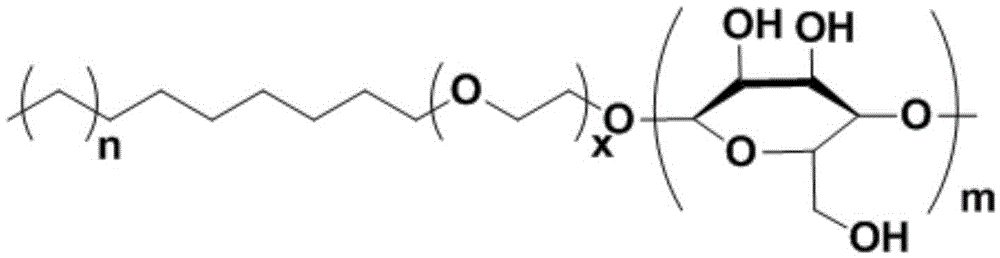

Preparation method of polyol glucoside

ActiveCN101948491AHigh viscosityStrong water retentionSugar derivativesSugar derivatives preparationGlycerolWater flow

The invention relates to a preparation method of polyol glucoside, which mainly comprises the following steps: adding glycerol and glucose monohydrate into a reactor in a heating state; then, cooling, adding an acid catalyst, and then decompressing to enable a reaction system to be maintained at high temperature for a certain time; and after water flows out of the reaction system, adding an acid neutralizing agent until the reaction system is weakly alkaline to obtain a product.

Owner:YANCHENG CITY CHUNZHU AROMA

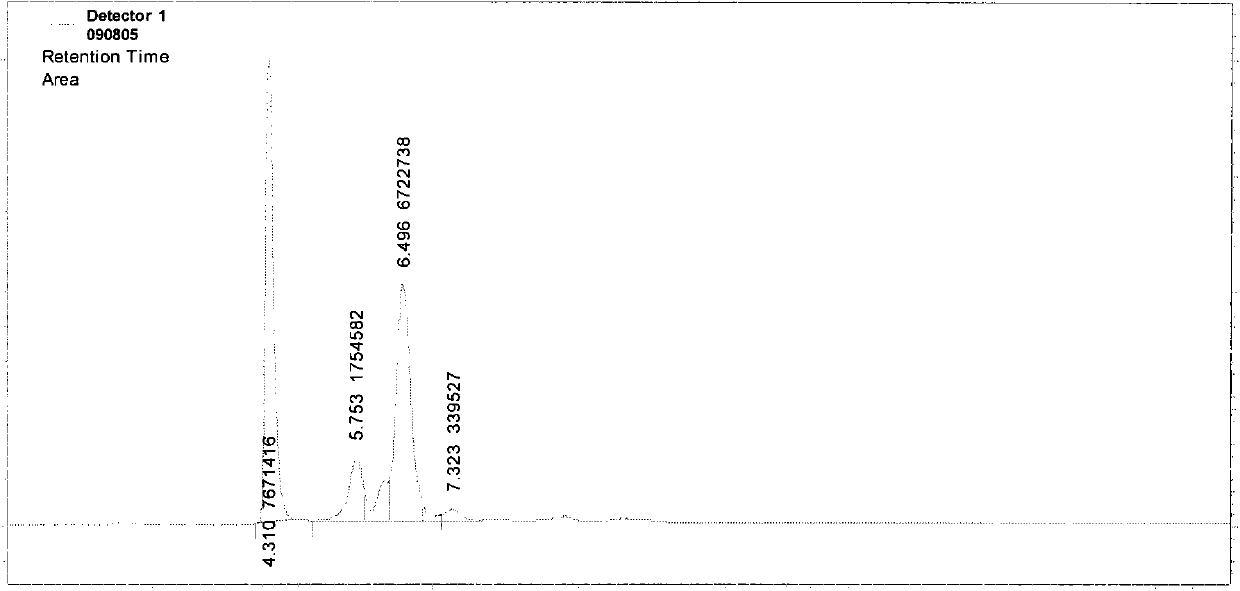

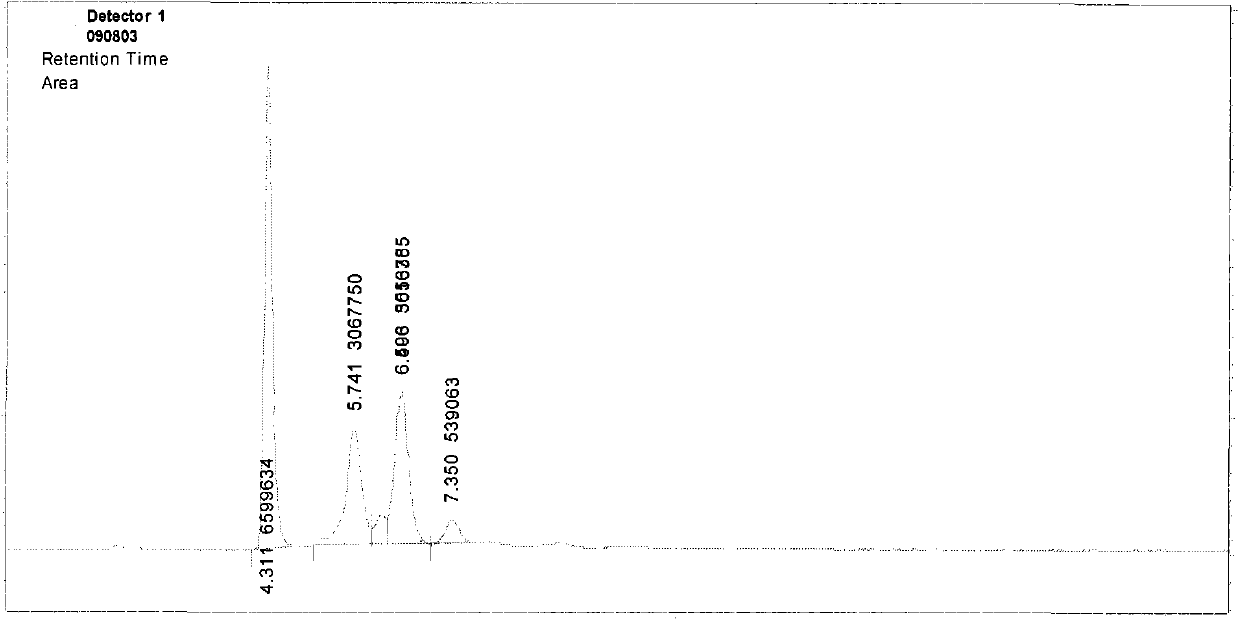

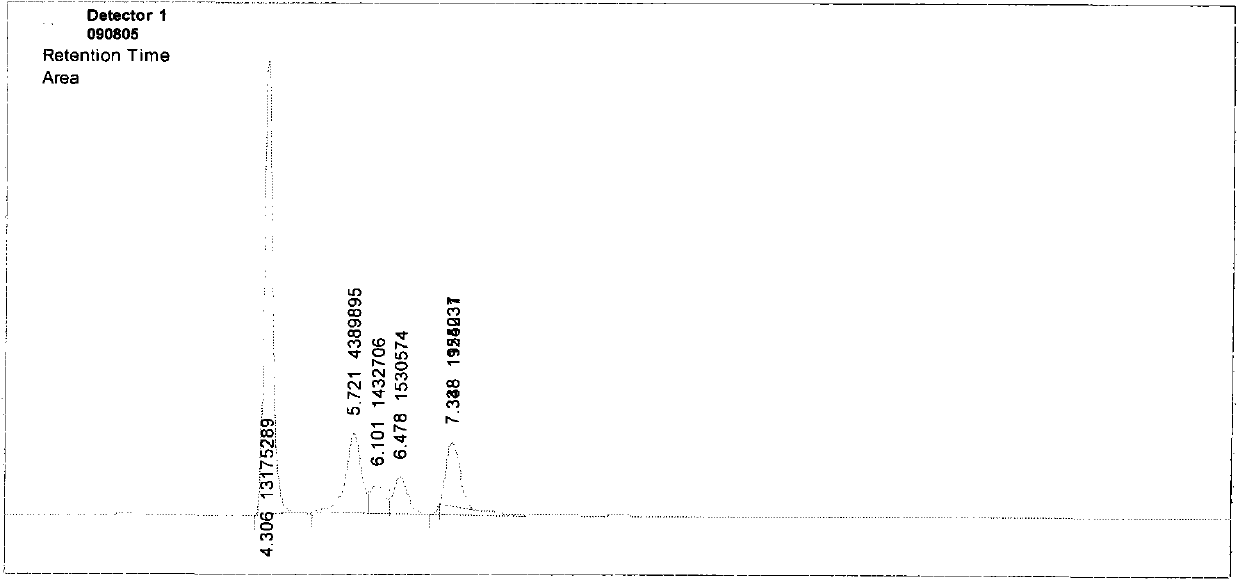

Operation technology of glucose crystal

The invention is a glucose crystallization operating process, and its character: it adopts step crystal growth, step by step, pours the syrup made by liquefying, saccharifying, refining and concentrating in a crystallizing kettle with a stirrer and corresponding adds in crystal seeds, preserves the heat and grows the crystals in each step, and controls to lower the temperature according to the crystallization curve to crystallize. It can make uniform crystallization, uneasy to form broken crystals and false crystals, thus enhancing the crystallizing effect, largely saving the crystal seeds, reducing the production cost and providing a feasible way for producing alpha-glucose monohydrate.

Owner:MAOMING COLLEGE

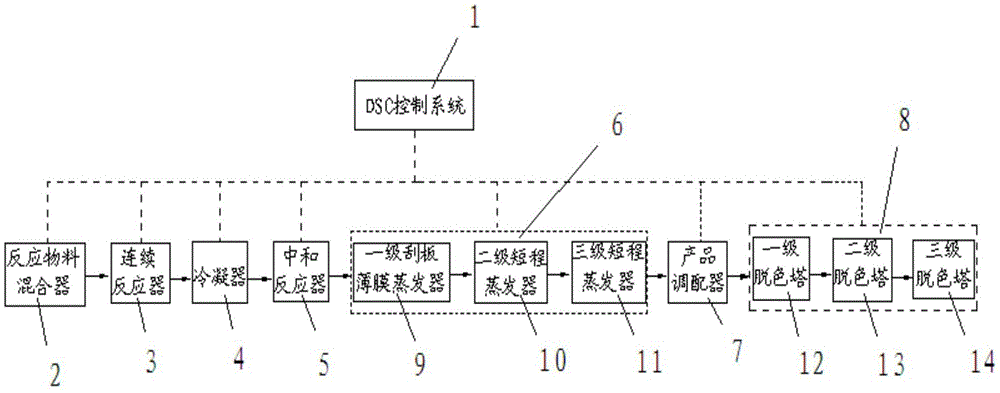

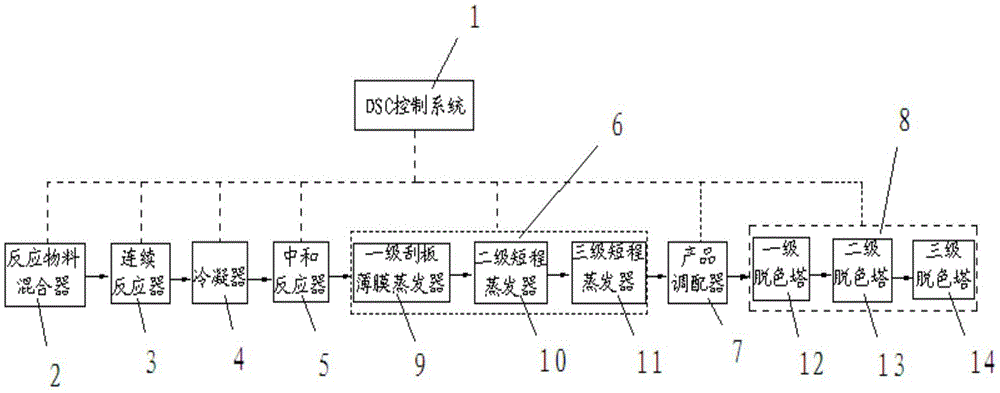

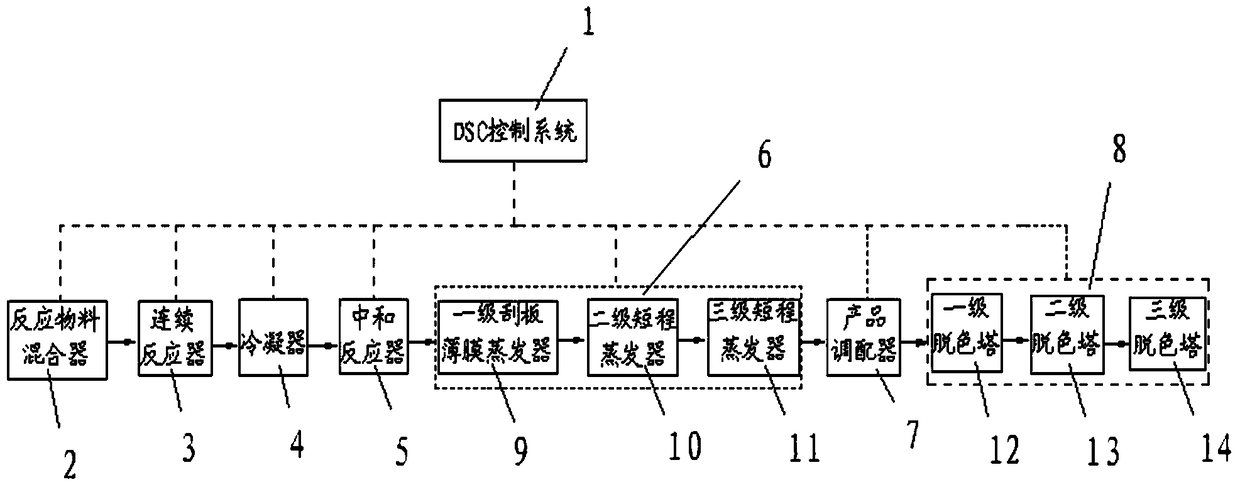

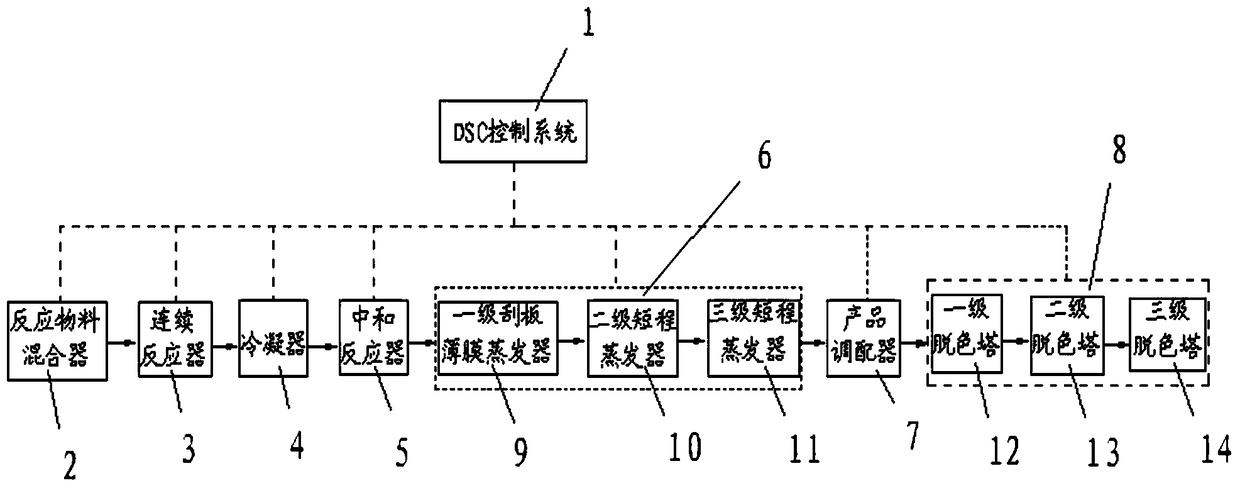

Method and production device for continuously producing alkyl glucoside

ActiveCN105418699AAvoid depositionReduce or even eliminate residual sugar contentSugar derivativesSugar derivatives preparationEcological safetyEvaporation

The invention relates to a method for continuously producing alkyl glucoside. According to the method, anhydrous glucose or glucose monohydrate and fatty alcohol carry out reactions continuously; then the reaction product is subjected to a continuous three grade vacuum distillation alcohol removing treatment, which comprises primary scraping plate evaporation, secondary short term evaporation, and tertiary short term evaporation, to remove fatty alcohol, and finally the reaction product is subjected to a continuous three-grade counter current discoloring treatment, which adopts ozone as the discoloring agent, so as to produce colorless, transparent, high purity and high quality alkyl glucoside. The obtained alkyl glucoside is colorless, transparent, and tasteless, and has the advantages of stable quality, high surface activity, good ecological safety, good intermiscibility, and low production cost. At the same time, the invention also relates to a production device capable of producing alkyl glucoside continuously, and has the advantages of high automation degree, short procedure, and suitability for large scale industrial production.

Owner:河北合佳医药科技集团股份有限公司

Dextrose hydrate in powder form and a process for the preparation thereof

The invention relates to a dextrose hydrate in powder form, having a dextrose content at least equal to 98%, an α crystalline form content at least equal to 95%, a water content greater than 1%, a compressibility determined according to a test A, at least equal to 70 N. The invention also relates to a process for the preparation thereof and to the use of said dextrose hydrate in powder form as a sweetener, osmotic agent, nutrient or excipient, particularly in compositions intended for the food, pharmaceutical, chemical and agrochemical sectors.

Owner:ROQUETTE FRERES SA

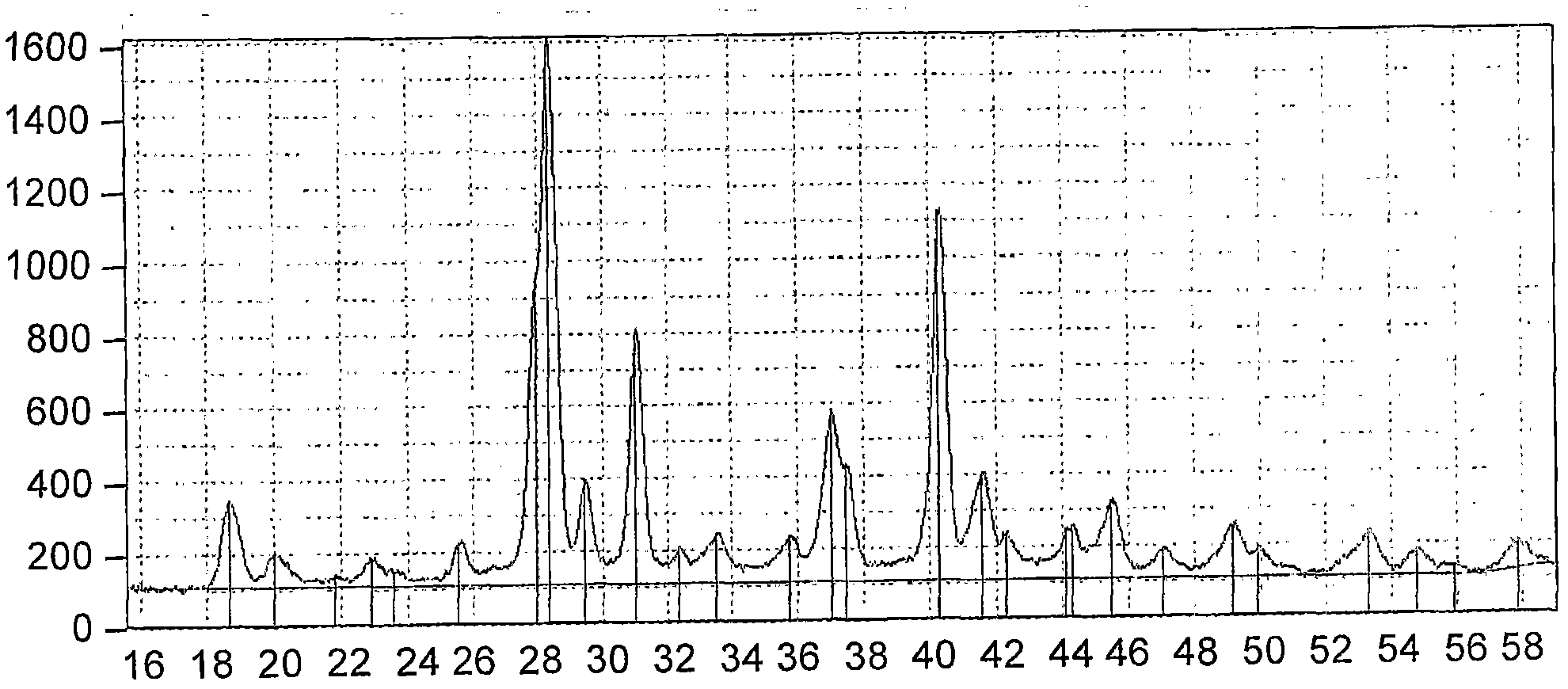

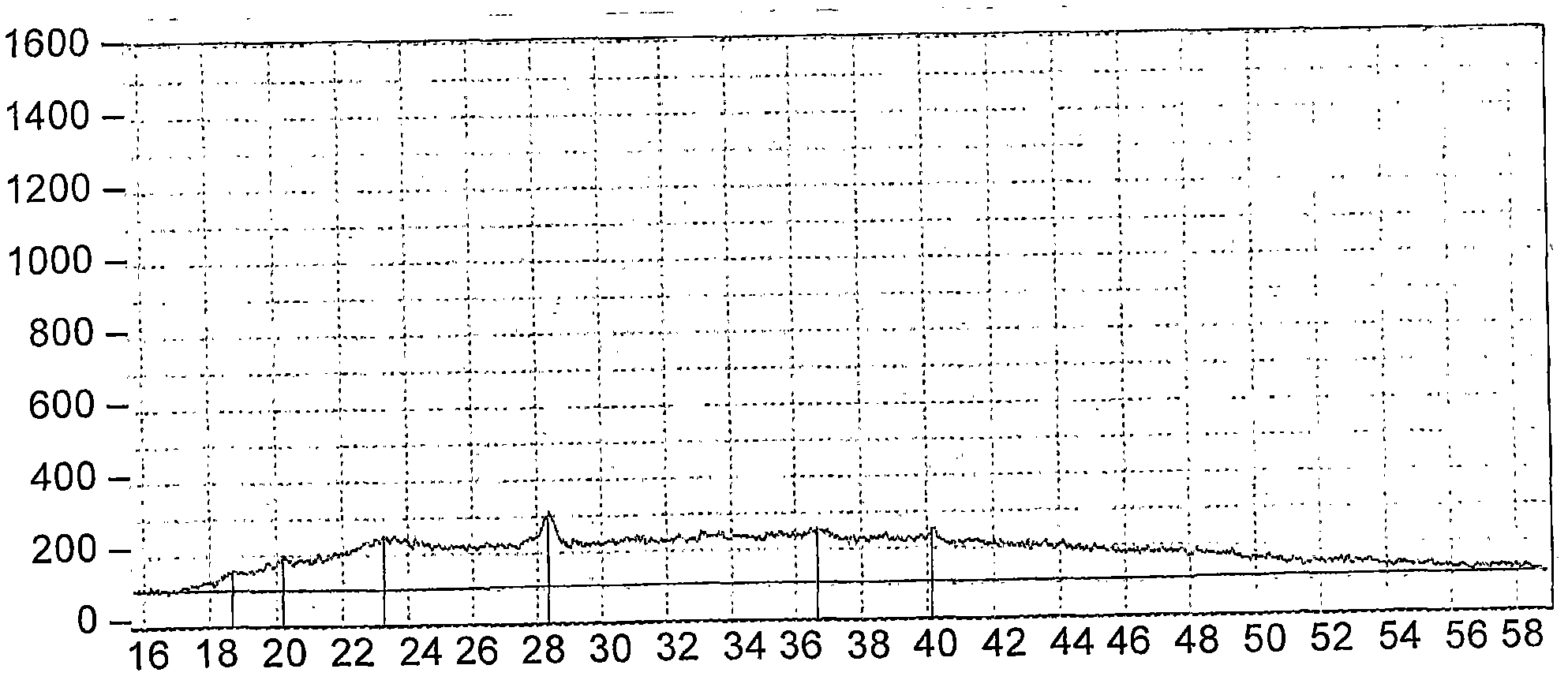

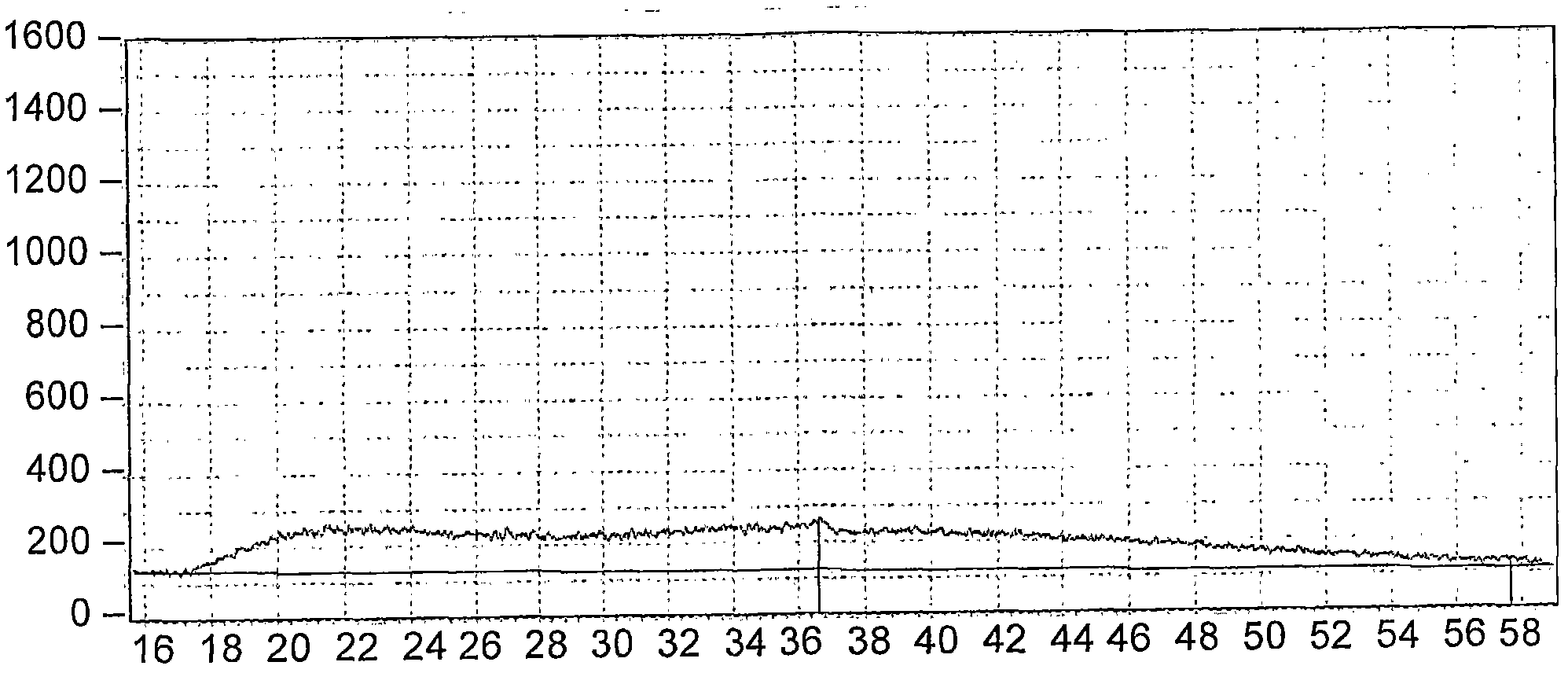

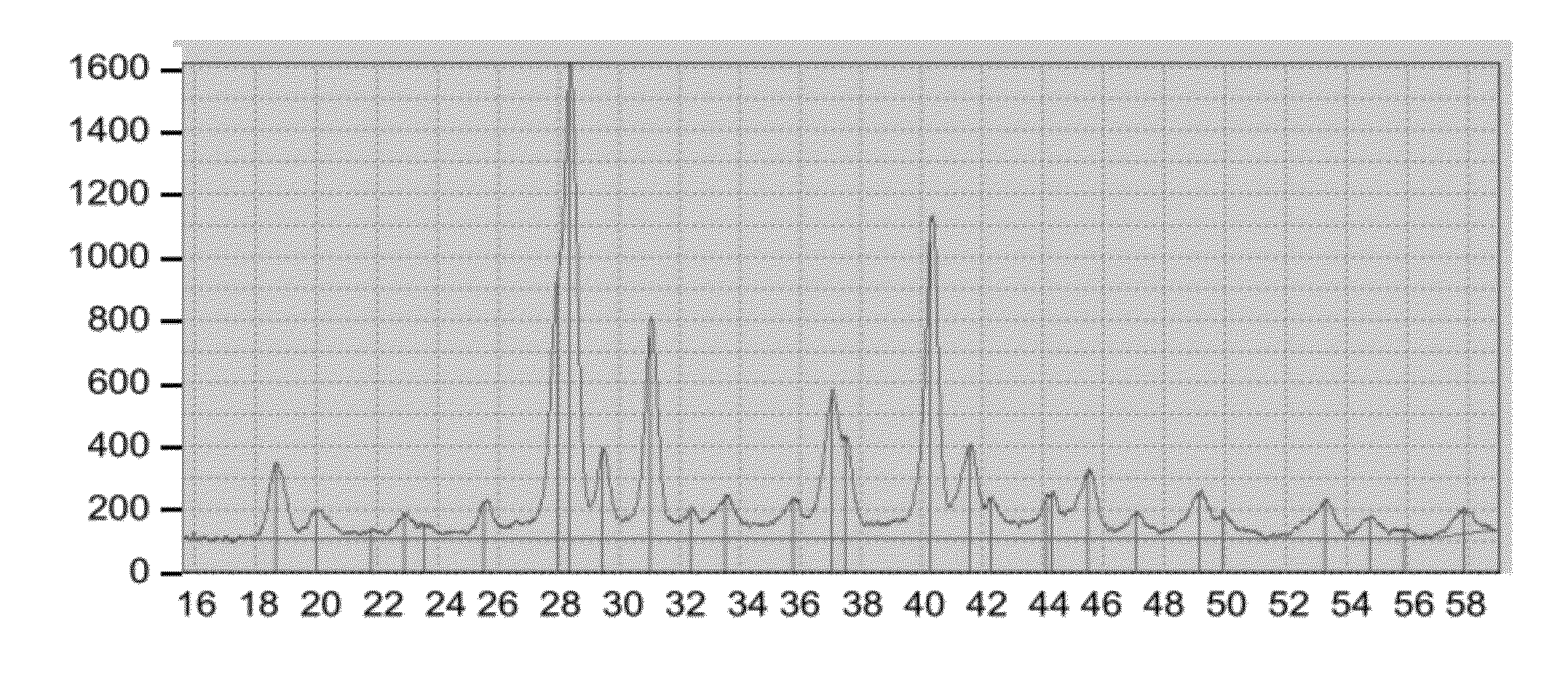

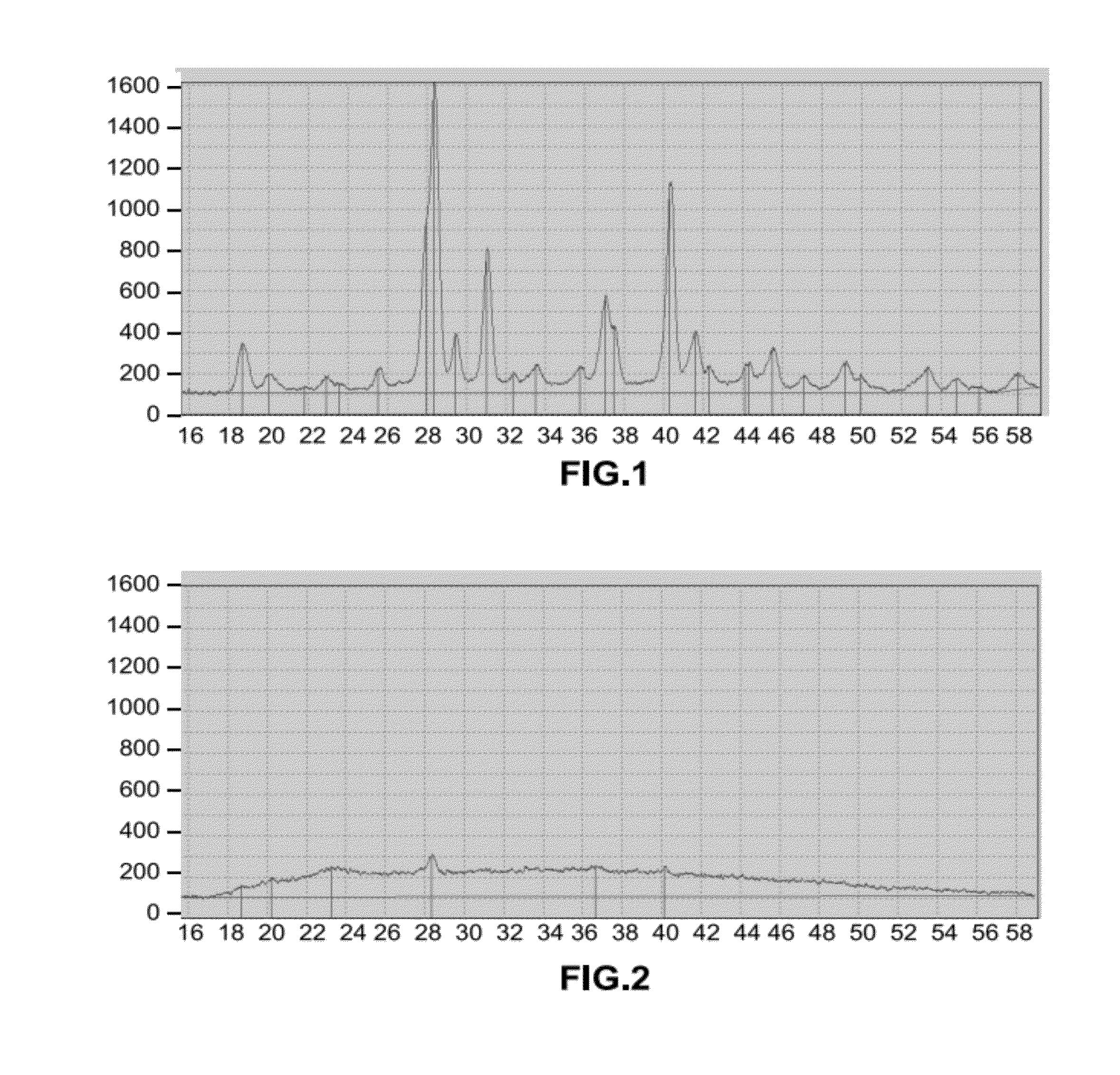

Free-flowing particulate honey product comprising crystallised natural honey and process for producing thereof

The invention provides a free-flowing particulate honey product comprising crystallized natural bee honey and a process for producing thereof. The free flowing particulate honey product comprises crystals of natural honey in admixture with glucose and is characterised by X-ray powder diffraction pattern having peaks in degrees 20 that are identified as characteristic peaks of crystalline glucose monohydrate, and diastase index not less than 90% of the diastase index of a crude honey used to prepare the product, calculated based upon the weight of the crude honey. The product retains all the healthy and biologically active properties of natural honey and can be used as a sugar substitute, or as a component of food mixtures, such as dry cereals, muesli, tea, coffee, drink mixtures, and also for preparing beverages, bakery, confectionary, as well as cosmetic and hygienic formulations.

Owner:V·B·保拓拉斯基

Oral rehydration composition and methods thereof

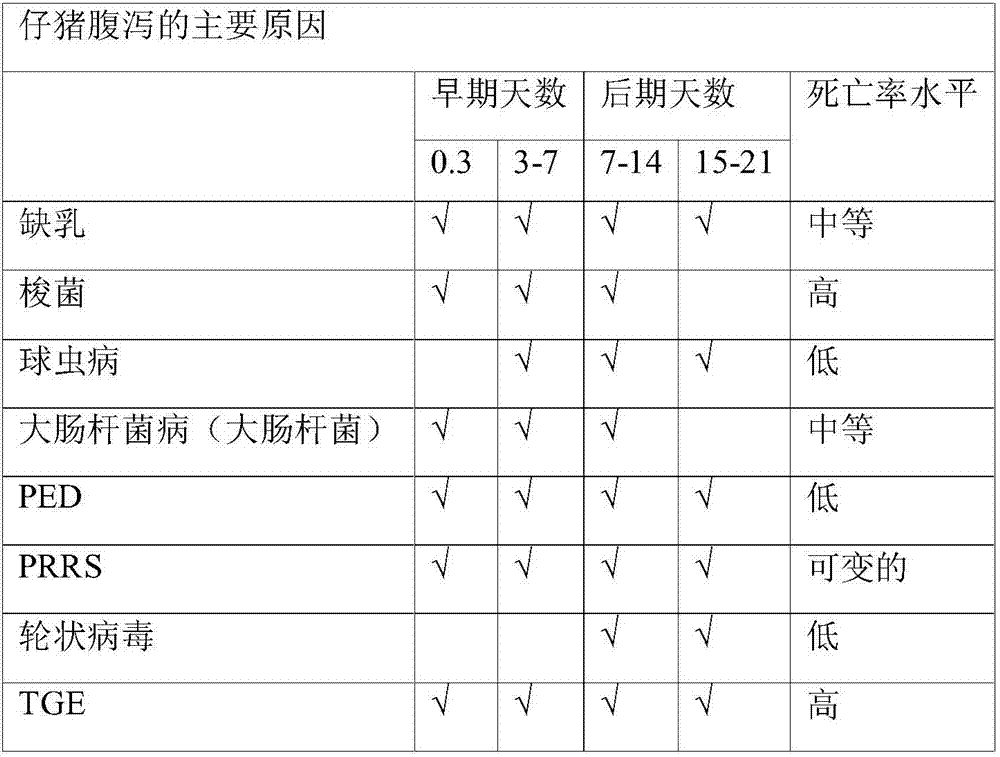

An oral rehydration composition comprising the following: 1-glutamic acid in a range of about 0.01% to about 0.40% w / w and monosodium glutamate in a range of about 0.05% to about 0.80% w / w; about 1.50% w / w glucose monohydrate; about 0.20% w / w sodium chloride; about 0.15% w / w potassium chloride; about 0.35% w / w glycine; about 0.30% w / w trisodiumcitrate; about 0.15% w / w sodium dihydrogen phosphate; about 0.10% w / w xanthan gum; 85% Steviol Glycoside extract in a range of about 0.01% to about 0.03% w / w; about 0.20% w / w citric acid monohydrate; hydrolyzed whey in a range of about 0.15% to about 1.00% w / w; about 1.00% w / w hydrolyzed wheat; comprises cereals as a protein source; comprises enzyme co-factors; comprises a monosaccharide. The oral rehydration composition can be used on humans or animals that suffer from diarrhea.

Owner:KALMARNA

Oral rehydration composition and methods thereof

ActiveCN107205464AOrganic active ingredientsMetabolism disorderMonosodium glutamateCitric Acid Monohydrate

Owner:TONISTER INT LTD

Linezolid injection

InactiveCN108158981ALow impurity contentSimple production processAntibacterial agentsOrganic active ingredientsAnhydrousCitric acid

The invention relates to a linezolid injection, which comprises 2.0 mg / mL linezolid, 1.64 mg / mL sodium citrate dehydrate, 0.85 mg / mL anhydrous citric acid, 50.24 mg / mL glucose monohydrate, and a proper amount of hydrochloric acid / sodium hydroxide, wherein the PH value is adjusted to 4.8 (4.7-4.9), and a proper amount of water for injection is added to achieve the total volume of 1.0 mL. The preparation steps comprise: (1) weighing, (2) pretreatment, (3) liquid preparing, and (4) filling, wet sterilization and packaging, wherein 50-70% of the theoretical volume of water for injection and 0.012mg / mL active carbon are added in the preparation step (2), and 10-30% of the theoretical volume of water for injection and 0.003 mg / mL active carbon are added in the preparation step (3). According tothe present invention, the prepared linezolid injection has advantages of low impurity content, less impurity component and good stability.

Owner:CHENGDU GUOHONG PHARMA

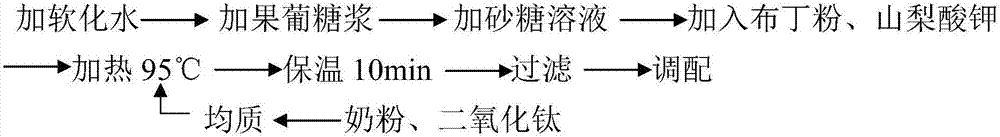

Yogurt jam pudding containing active probiotics and preparation method thereof

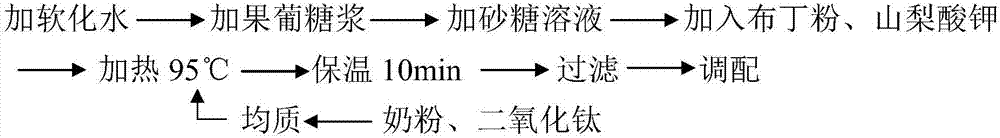

InactiveCN107960603AExtended shelf lifeRetain vitalityFood preservationFood ingredient for microbe protectionSoftened waterWhole milk

The present invention discloses a yogurt jam pudding containing active probiotics and a preparation method thereof. The yogurt jam pudding comprises the following components in parts by weight: 28-32parts of white granulated sugar, 90-110 parts of high fructose corn syrup, 25-35 parts of glucose monohydrate, 10-15 parts of pudding powder, 20-28 parts of whole milk powder, 15-20 parts of skim milkpowder, 1.8-2.5 parts of essences, 2.0-2.5 parts of citric acid, 1.4-1.8 parts of malic acid, 4.2-4.6 parts of potassium sorbate, 2.0-3.0 parts of titanium dioxide, 660-700 parts of softened water, 18-22 parts of a lactic acid bacterium fermented raw solution and 75-85 parts of a blueberry, strawberry and cranberry jam. The yogurt jam pudding is simplified in processing flows during the preparation. The milk and other materials in an early stage are sterilized, the sterilized materials are cooled, the cooled materials are inoculated with bacteria, then the sterile jam is added, then the materials are subjected to a sterile filling method, the pudding product contains the probiotics, and the preparation method extends shelf life of the product, enables the shelf life of the yogurt jam pudding to be extended to 45 days, and can realize industrial production.

Owner:湖南新中意食品有限公司

Composite antioxidant of roasted nuts and method for processing roasted nuts by using composite antioxidant

PendingCN110637879APrevent oxidationGood effectEdible seed preservationBiotechnologyDextrose Monohydrate

The invention provides a composite antioxidant of roasted nuts and a method for processing the roasted nuts by using the composite antioxidant, and belongs to the technical field of composite antioxidants. The composite antioxidant includes the following components, in percentages by mass: 0.1-0.5% of papain, 15-25% of tert-butylhydroquinone, 10-20% of sodium erythorbate, 10-25% of citric acid monohydrate and 35-45% of glucose monohydrate. The method for processing the roasted nuts by using the composite antioxidant comprises the following steps: firstly, enzymolysis is performed on nuts by using the papain, enzyme deactivation treatment is performed, the tert-butylhydroquinone, the sodium erythorbate, the citric acid monohydrate and the glucose monohydrate are used to prepare a compound antioxidant solution, the nuts are soaked by using the compound antioxidant solution, after the soaking is completed, draining is performed, and baking is performed. The shelf life of the roasted nutsprocessed by the composite antioxidant can reach 9-12 months, and the detection value of a use amount of the TBHQ is 19-22 mg / kg, and is far lower than a national standard in China.

Owner:河北绿岭康维食品有限公司 +1

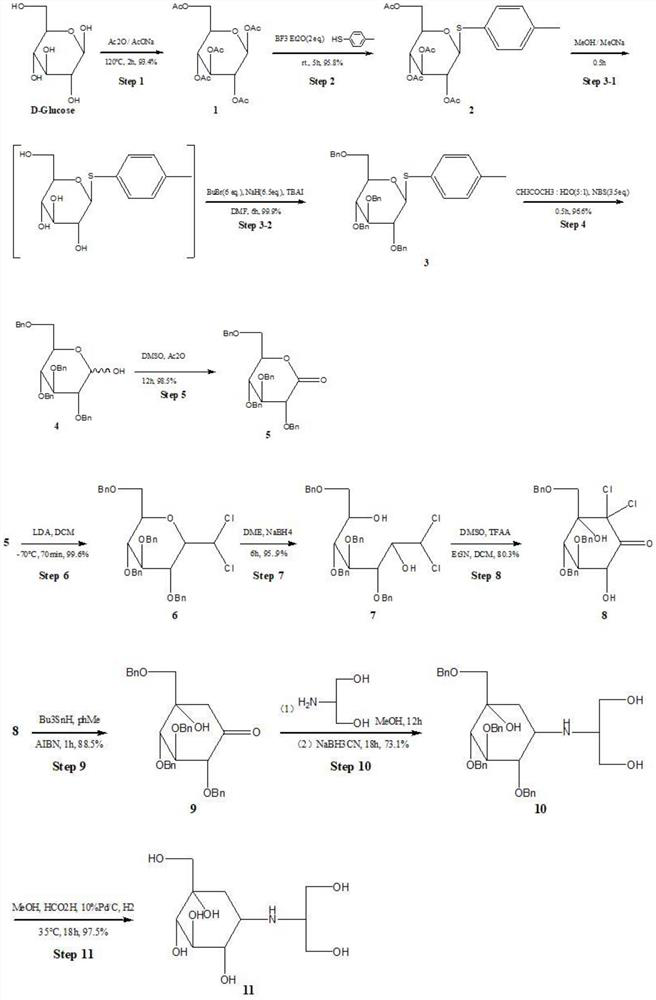

Synthesis method of voglibose

PendingCN113214094AMild reaction conditionsEasy to operateEsterified saccharide compoundsSugar derivativesSodium acetateBiochemical engineering

The invention provides a synthesis method of voglibose, and solves the technical problems that in an existing synthesis method of voglibose, raw materials are difficult to obtain, high in price, large in investment, low in yield and not suitable for industrial production. The synthesis method comprises the steps: synthesizing a compound V by taking glucose monohydrate and sodium acetate as raw materials through eleven reaction steps; and preparing a compound VIII from the compound V through an addition reaction, a ring-opening reaction and an aldol condensation reaction, and thus obtaining voglibose through amination reduction of the compound VIII. The synthesis method of voglibose can be widely applied to the technical field of voglibose synthesis methods.

Owner:WEIFANG TIANFU CHEM TECH

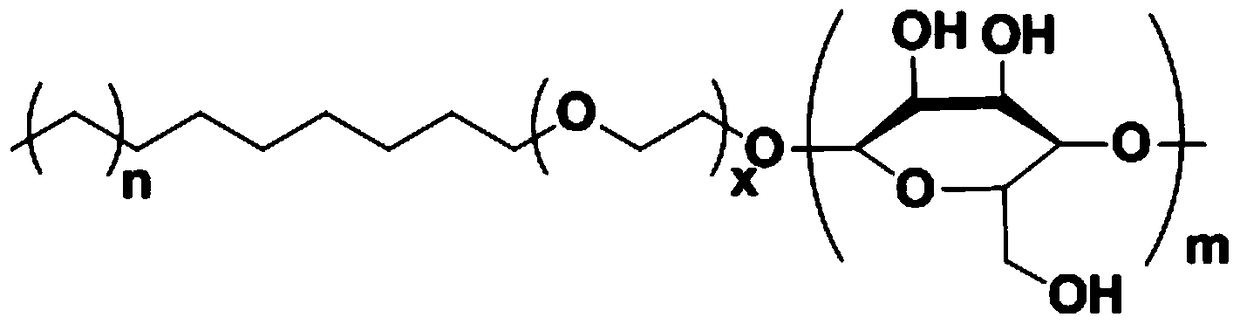

Method and production apparatus for continuously producing alkyl ethoxy polyglycoside

ActiveCN105669786AAvoid depositionEasy to solveSugar derivativesSugar derivatives preparationSolubilityEvaporation

The invention relates to a method for continuously producing alkyl ethoxy polyglycoside. The method includes: 1) a continuous reaction to anhydrous glucose or glucose monohydrate with a fatty alcohol-polyoxyethylene ether compound, 2) continuous three-stage vacuum distillation alcohol removal treatment including first-stage scraper blade thin film evaporation, second-stage short-range evaporation and third-stage short-range evaporation to remove the fatty alcohol-polyoxyethylene ether compound, and 3) continuous three-stage countercurrent discoloring treatment with ozone as a discoloring agent to produce the alkyl ethoxy polyglycoside which is colorless, transparent, high-purity and high-quality. The alkyl ethoxy polyglycoside is colorless, transparent, high-purity and high-quality, has excellent surface activity and bio-degradability, good water solubility, strong hard water resistance and alkaline resistance, and low production cost. The invention also relates to a production apparatus for continuously producing the alkyl ethoxy polyglycoside. The apparatus has high automation degree and short technical process and is suitable for large-scale industrial production.

Owner:河北合佳医药科技集团股份有限公司

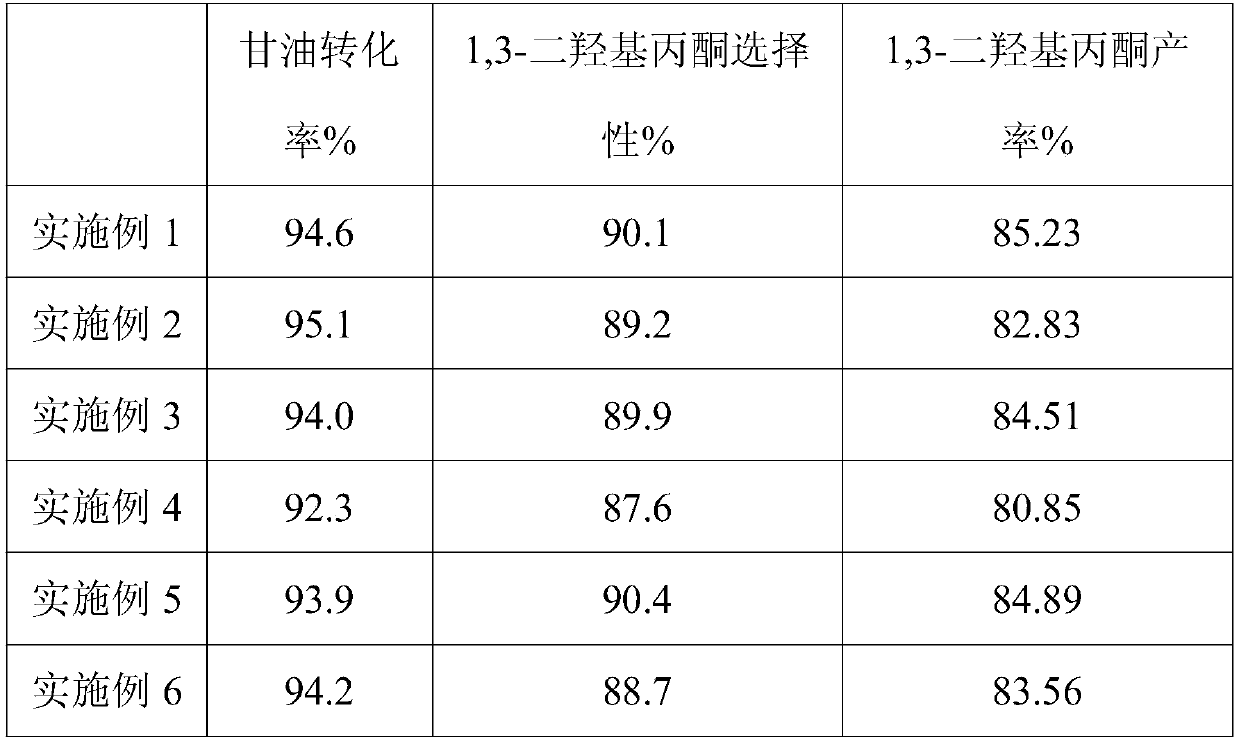

Catalyst to prepare 1,3-dihydroxyacetone and preparation method thereof

ActiveCN109569599ASimple structureStrong adsorptionOrganic compound preparationCatalyst activation/preparationCarbon compositesCerium nitrate

The invention discloses a catalyst to prepare 1,3-dihydroxyacetone and a preparation method thereof. The preparation method includes the steps of (1) preparing ZnAl-HTLc, to be specific, dissolving azinc salt and an aluminum salt in deionized water to obtain solution A, preparing solution B with Na2CO3 and NaOH, quickly mixing the solution A and the solution B, allowing refluxing reaction, centrifugally washing, and drying to obtain ZnAl-HTLc; (2) preparing a composite supporter, to be specific, adding the prepared ZnAl-HTLc into glucose monohydrate solution, mixing well, transferring the mixture to a polytetrafluoroethylene reactor, allowing hydrothermal reaction, cooling, and washing to obtain ZnAl-HTLc / carbon composite supporter; (3) preparing the catalyst, to be specific, preparing asolution with platinum chloride, neodymium nitrate and cerium nitrate, adding the solution to the composite supporter, impregnating, drying, calcining, and activating with hydrogen to obtain the catalyst. The catalyst has good activity, selectivity and stability and has a good application prospect.

Owner:JIANGXI NORMAL UNIV

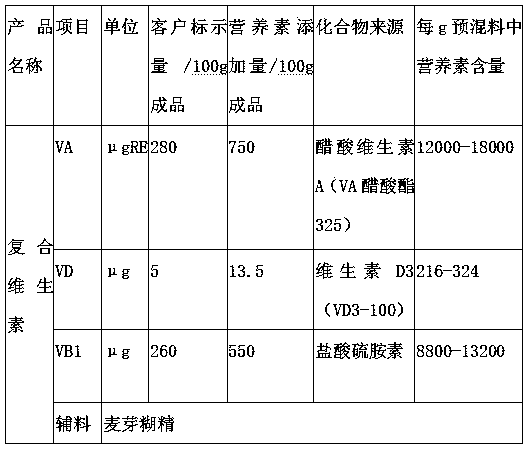

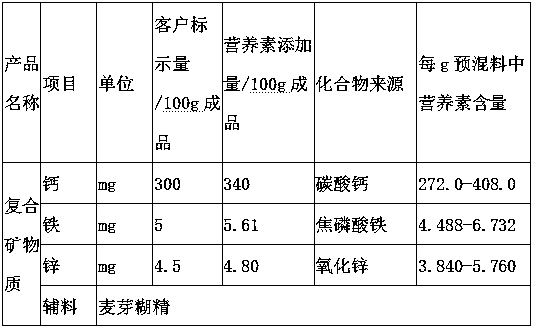

Rice flour capable of invigorating stomach and promoting digestion

PendingCN111513240AEffective digestionPromote digestionVitamin food ingredientsFood ingredient functionsBiotechnologyDextrose Monohydrate

The invention discloses rice flour capable of invigorating stomach and promoting digestion, and belongs to the technical field of food processing. The rice flour includes, by weight in parts, 195-205parts of rice, 48-52 parts of D-glucose monohydrate, 1.2-1.6 parts of yam powder, 10-15 parts of corn grit, 8.2-8.6 parts of whole milk powder, 1.2-1.6 parts of chicken's gizzard-membrane powder, 1.2-1.6 parts of malt powder, 2.4-3.2 parts of hawthorn powder, 2.2-2.6 parts of complex minerals and 0.10-0.14 part of multi-vitamins. The complex minerals and the multi-vitamins contain a variety of minerals and vitamins, so that the rice flour is scientific and reasonable in proportion and contributes to the healthy growth of infants; and the rice flour is reasonable in formula and can effectivelypromote the digestion of the infants and enhance the digestive ability of the infants, so that the rice flour is suitable for promotion and use.

Owner:江西高美高健康食品有限公司

Method for preparing 1,3-dihydroxyacetone catalyst from glycerinum

ActiveCN109499581ASimple structureStrong adsorptionOrganic compound preparationCarbonyl compound preparationCarbon compositesDihydroxyacetone

The invention discloses a method for preparing a 1,3-dihydroxyacetone catalyst from glycerinum. The method comprises the following steps: (1) preparing ZnAl-HTLc, namely dissolving a zinc salt and analuminum salt into deionized water so as to obtain a solution A, preparing a solution B from Na2O3 and NaOH, rapidly mixing the solution A with the solution B, carrying out a backflow reaction, carrying out centrifugal washing and drying after the reaction so as to obtain ZnAl-HTLc; (2) preparing a composite carrier, namely uniformly mixing the prepared ZnAl-HTLc into a glucose monohydrate solution, transferring the mixture into a polytetrafluoroethylene reaction kettle, carrying out a hydrothermal reaction, cooling, washing, and drying so as to obtain a ZnAl-HTLc / carbon composite carrier; and(3) preparing a catalyst, namely preparing solutions from cupric nitrate, lanthanum nitrate and cobalt nitrate respectively, putting the solutions into the composite carrier simultaneously, soaking,drying, roasting, and carrying out hydrogen activation, thereby obtaining the catalyst. The catalyst prepared by using the method is high in activity, selectivity and stability, and is wide in application prospect.

Owner:JIANGXI NORMAL UNIV

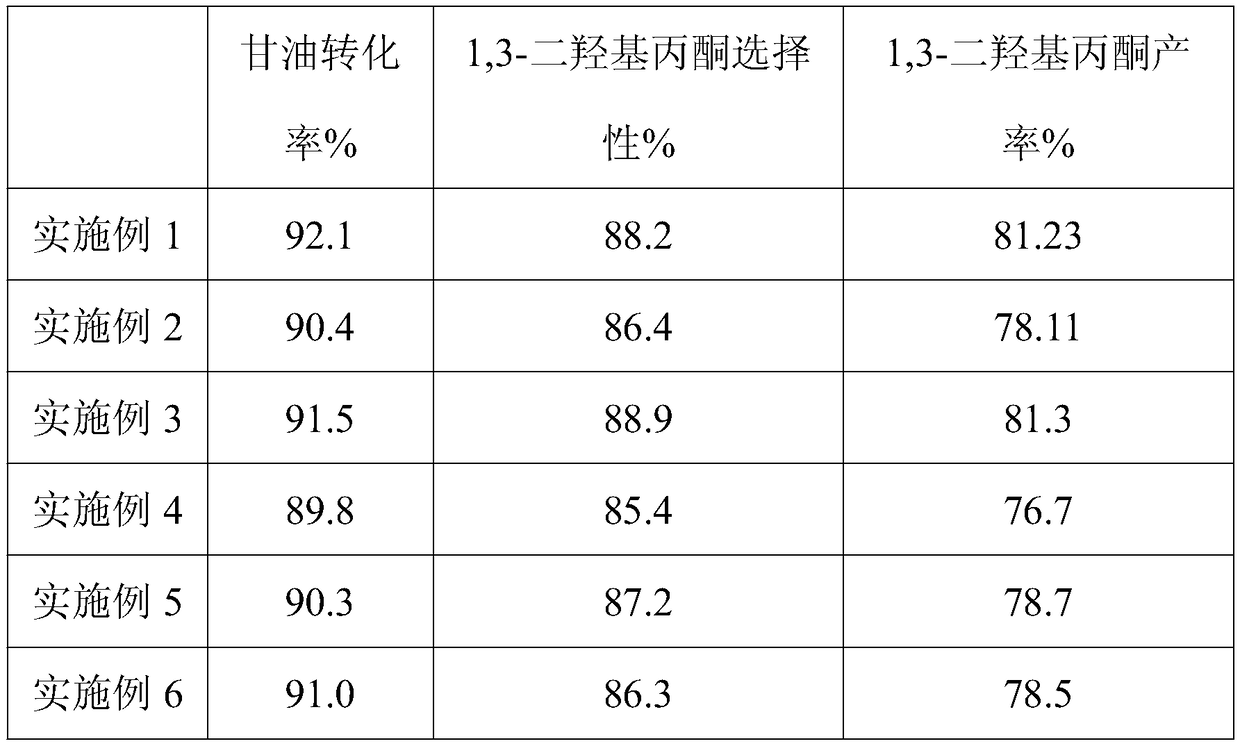

Lactobacillus plantarum liquid fermentation culture medium and culture method and application thereof

PendingCN110205276APromote mass reproductionFast growth and reproductionBacteriaMicroorganism based processesDipotassium phosphateManganese

The invention discloses a lactobacillus plantarum liquid fermentation culture medium. The lactobacillus plantarum liquid fermentation culture medium comprises the following components: 20-30 g / L of glucose, 10-15 g / L of soybean meal, 5-10 g / L of a saccharomyces cerevisiae extract, 2-5 g / L of dipotassium phosphate, 5-10 g / L of ammonium chloride, 3-6 g / L of sodium chloride, 5-10 g / L of calcium carbonate, 0.2-0.5 g / L of magnesium sulfate and 0.02-0.05 g / L of manganese sulfate. The invention also discloses a culture method for fermentation of lactobacillus plantarum liquid and application of thefermentation medium in the culture method for fermentation of the lactobacillus plantarum liquid. According to the invention, the glucose monohydrate, the soybean meal, the saccharomyces cerevisiae extract and the ammonium chloride thereof are adopted as raw materials, the composition of the medium is optimized, the technical method of fermentation operation is simplified, the viable count of lactobacillus plantarum is obviously improved, meanwhile, the production cost is reduced, and the production process is simplified.

Owner:XIAMEN HUIYING ANIMAL TECH

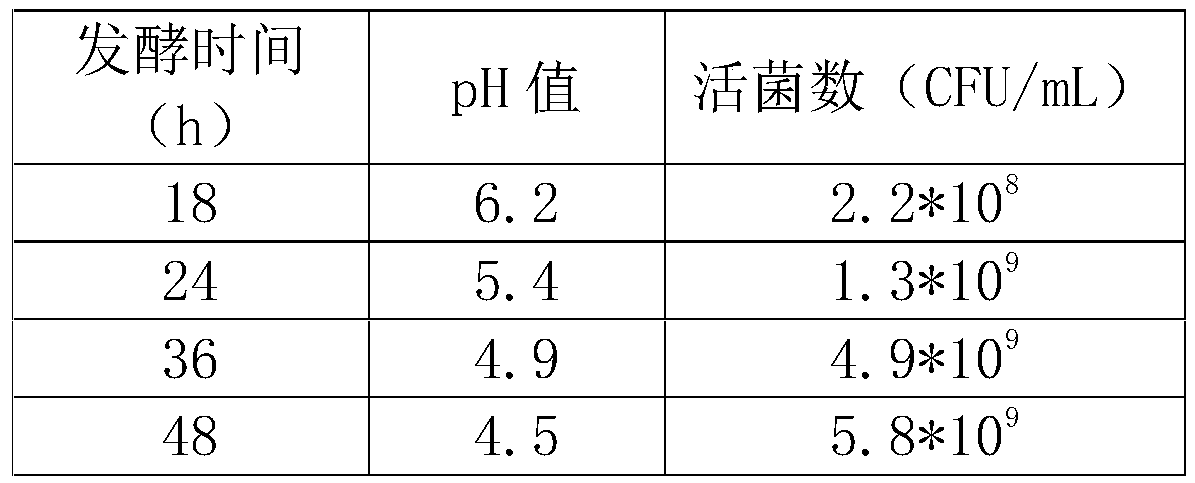

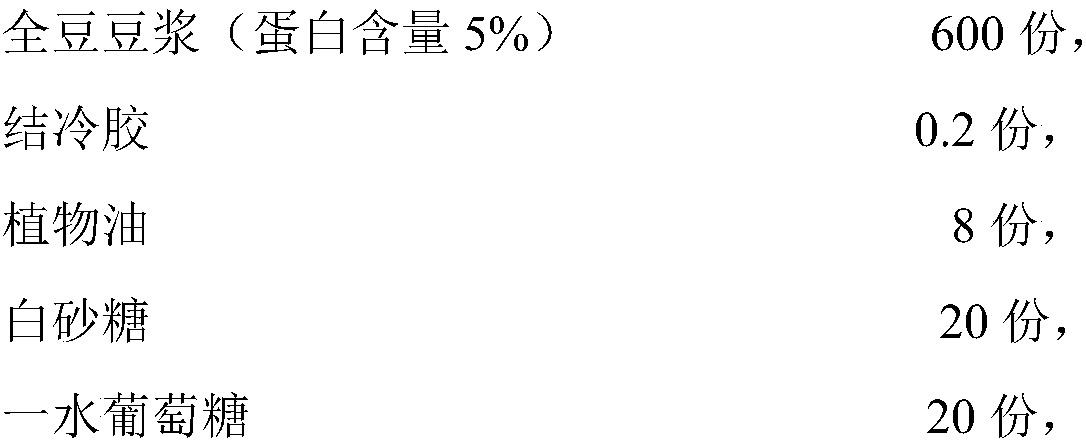

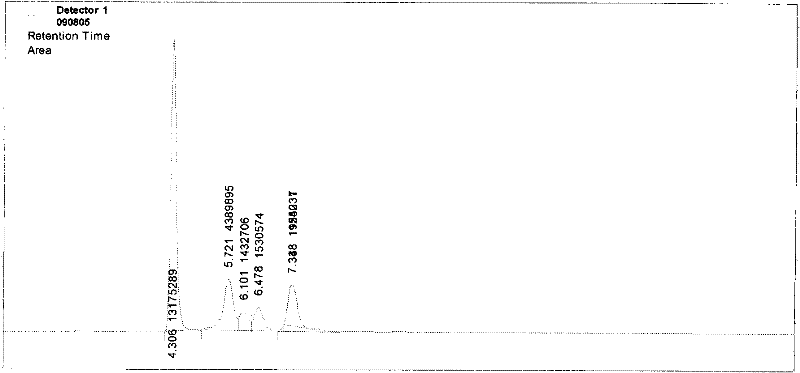

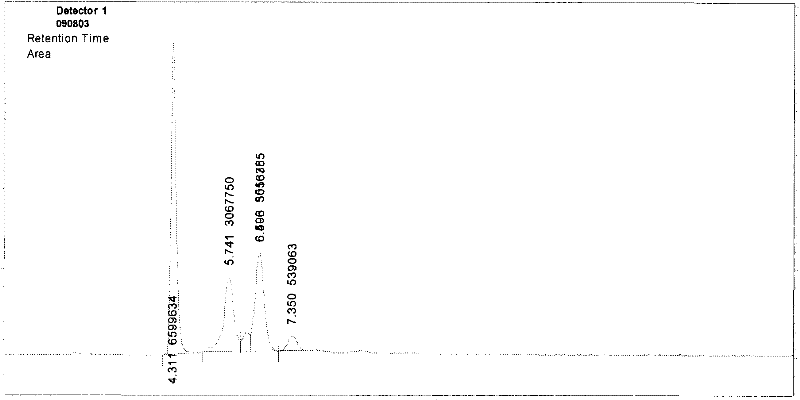

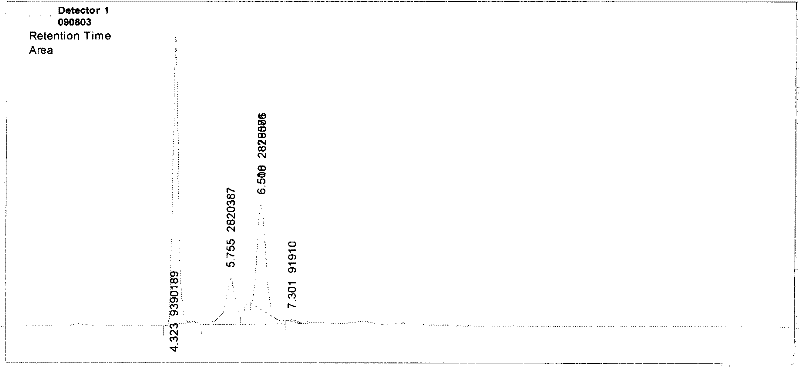

Full-bean brown fermented soybean milk and preparation method thereof

PendingCN111134198ASolve the problem that the viscosity is not conducive to the browning reactionSolve processing problemsMilk substitutesFood scienceBiotechnologyMaillard reaction

The invention provides full-bean brown fermented soybean milk and a preparation method thereof. The method comprises the following steps: mixing whole soybean milk, gellan gum, vegetable oil, white granulated sugar, glucose monohydrate, starch, isomaltulose, sodium carbonate and water to obtain soybean milk, and carrying out primary homogenization on the soybean milk at 55-65 DEG C; carrying out browning on the homogenized soybean milk at 95-98 DEG C for 2-5h; cooling the browned soybean milk, and performing fermenting by using lactobacillus paracasei and lactic acid bacteria; and adding pectin and soybean polysaccharide into the fermented soybean milk, carrying out secondary homogenization at 55-65 DEG C, carrying out sterilization after homogenization, and then carrying out cooling to less than or equal to 35 DEG C to obtain the whole soybean brown fermented soybean milk. According to the invention, a Maillard reaction and fermentation technology are applied to production of whole soybean milk, and the prepared soybean milk not only removes the bean smell which is difficult to accept, but also solves the problem of bean dreg treatment. After browning, lactic acid bacteria are added for fermentation to provide sour taste for the whole soybean milk, so that the sour taste is coordinated, and use of food additives in subsequent acid adjusting links is reduced.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Rice flour capable of improving immunity

PendingCN111513239AImprove adsorption capacityEliminate secretionVitamin food ingredientsFood ingredient functionsBiotechnologyDextrose Monohydrate

The invention discloses rice flour capable of improving immunity, and belongs to the technical field of food processing. The rice flour comprises the following raw materials in parts by weight: 190-210 parts of rice, 48-52 parts of glucose monohydrate, 1.2-1.6 parts of pumpkin powder, 10-15 parts of corn grits, 8.2-8.6 parts of whole milk powder, 5.2-6.0 parts of soybean protein isolate, 0.2-0.6 part of L-sodium ascorbate, 2.2-2.6 parts of composite minerals and 0.10-0.14 part of composite vitamins. The composite minerals and the composite vitamins contain various minerals and vitamins, are scientific and reasonable in compounding ratio, and can contribute to healthy growth of babies. The rice flour disclosed by the invention is reasonable in formula, can effectively contribute to growth of babies and improve the immunity of the babies, and is suitable for popularization and use.

Owner:江西高美高健康食品有限公司

Oral rehydration composition and methods thereof

Owner:KALMARNA

Preparation method of polyol glucoside

ActiveCN101948491BHigh viscosityStrong water retentionSugar derivativesSugar derivatives preparationGlycerolWater flow

The invention relates to a preparation method of polyol glucoside, which mainly comprises the following steps: adding glycerol and glucose monohydrate into a reactor in a heating state; then, cooling, adding an acid catalyst, and then decompressing to enable a reaction system to be maintained at high temperature for a certain time; and after water flows out of the reaction system, adding an acid neutralizing agent until the reaction system is weakly alkaline to obtain a product.

Operation technology of glucose crystal

The invention is a glucose crystallization operating process, and its character: it adopts step crystal growth, step by step, pours the syrup made by liquefying, saccharifying, refining and concentrating in a crystallizing kettle with a stirrer and corresponding adds in crystal seeds, preserves the heat and grows the crystals in each step, and controls to lower the temperature according to the crystallization curve to crystallize. It can make uniform crystallization, uneasy to form broken crystals and false crystals, thus enhancing the crystallizing effect, largely saving the crystal seeds, reducing the production cost and providing a feasible way for producing alpha-glucose monohydrate.

Owner:MAOMING COLLEGE

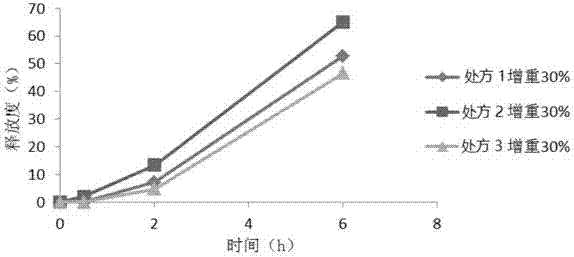

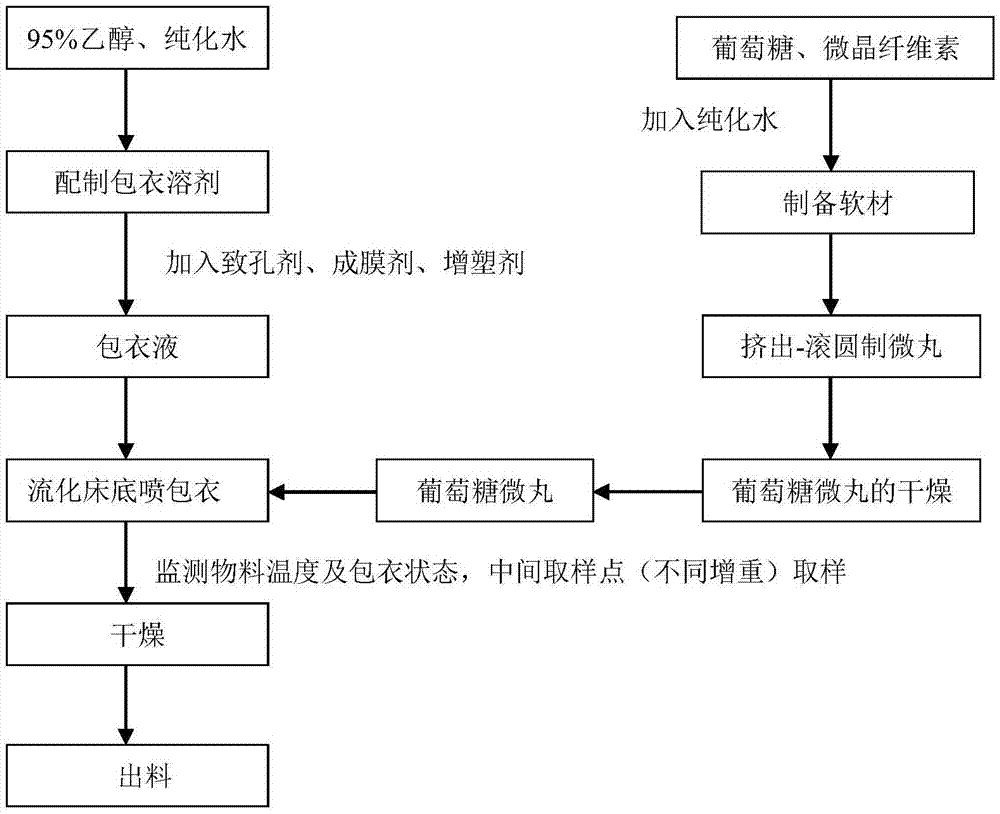

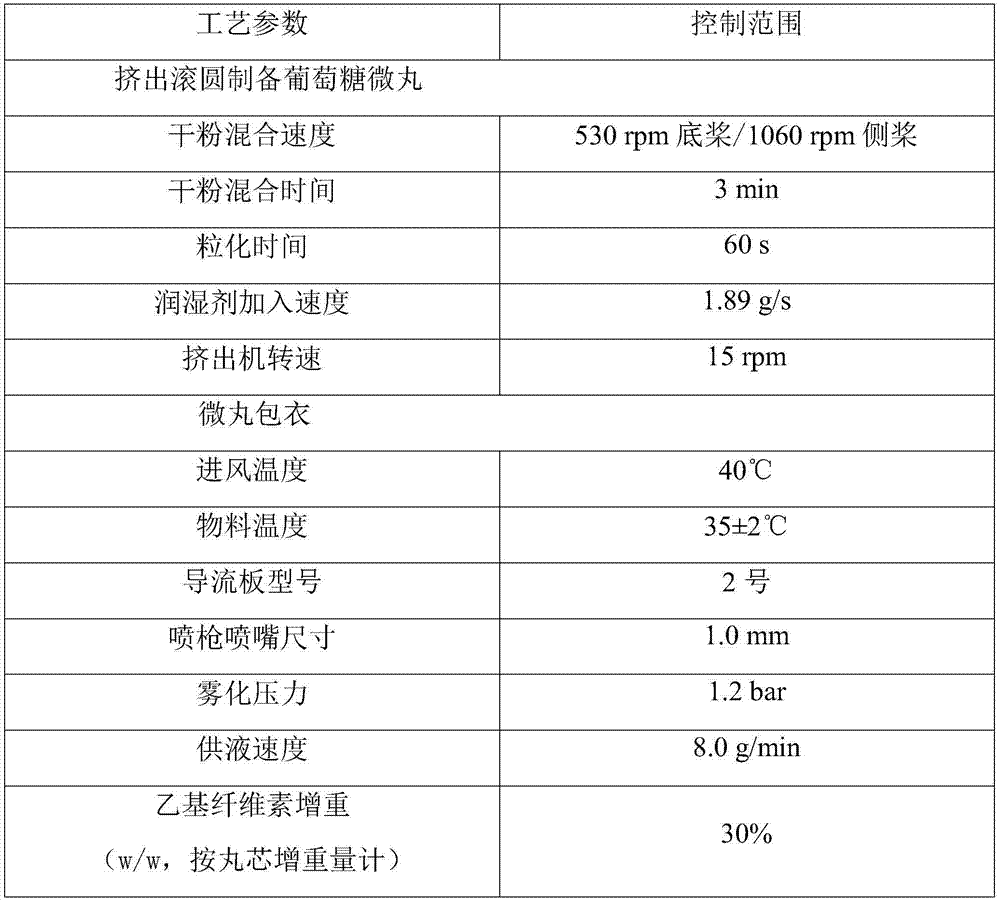

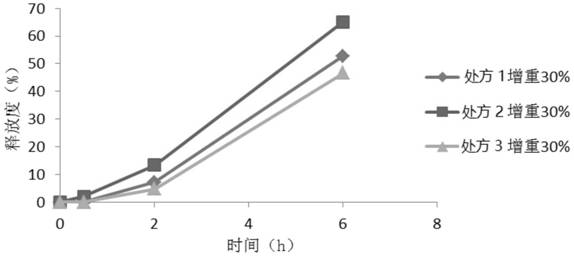

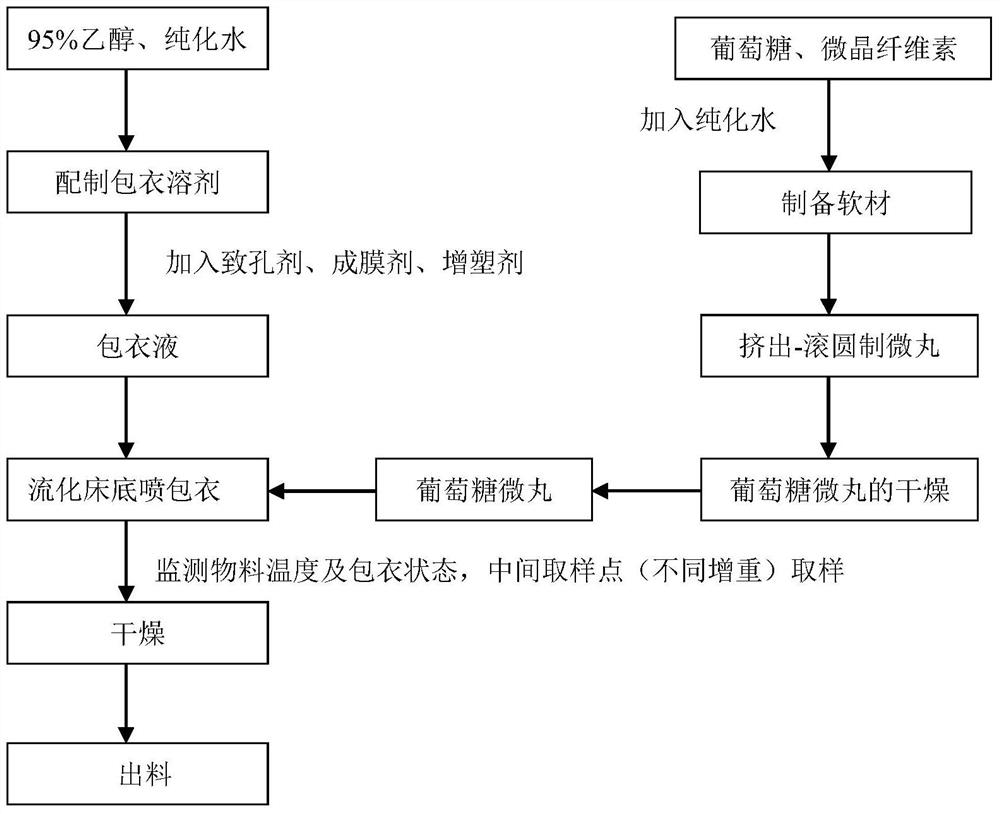

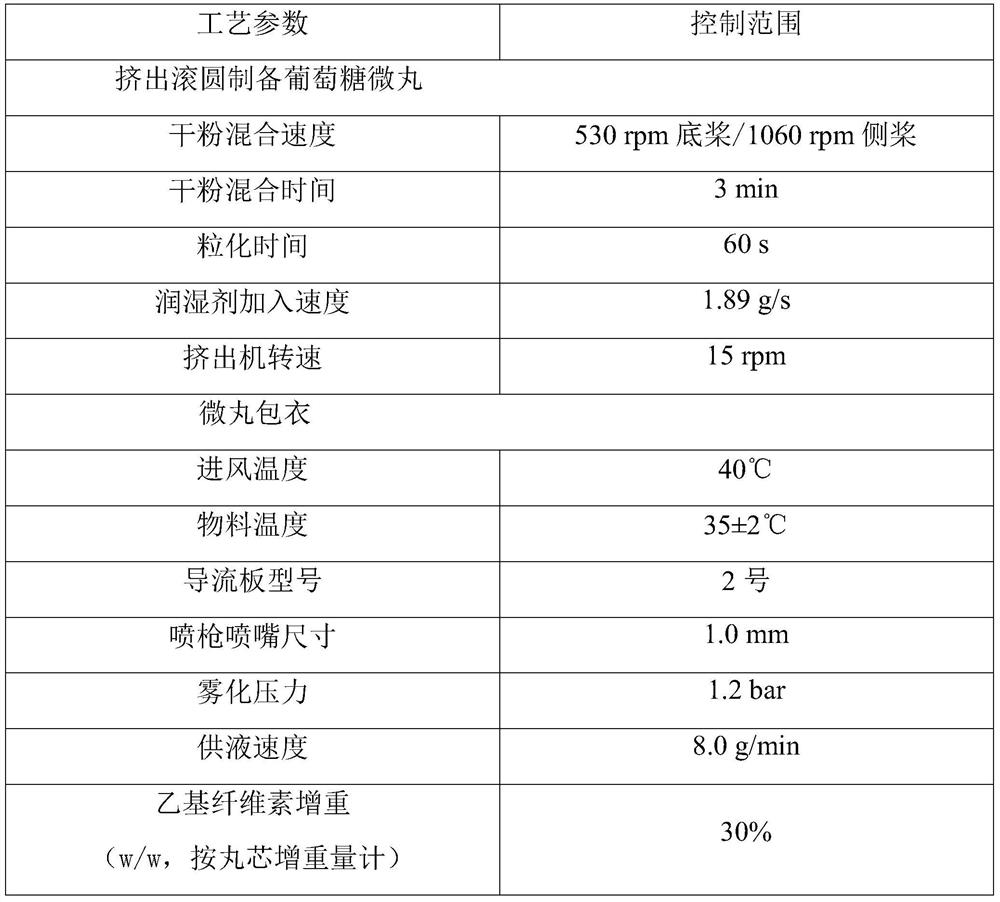

Sustained-release glucose preparation for treating glycogen storage diseases

ActiveCN106913558AGood slow releaseOrganic active ingredientsMetabolism disorderPharmaceutical formulationFilm coating

The invention provides a sustained-release glucose preparation for treating glycogen storage diseases and a preparation method thereof, belonging to the field of medicinal preparations. The sustained-release glucose preparation is composed of two parts, i.e., a glucose pill core and a film coating and prepared from glucose monohydrate, microcrystalline cellulose, ethyl cellulose, hydroxypropyl cellulose, triethyl citrate, ethanol and purified water by using a modern preparation technology. Results of release-rate determination experiments prove that the sustained-release glucose preparation provided by the invention has good sustained-release performance and can be gradually and slowly released within 6 h; the release rates of sustained-release glucose preparations prepared according to three different prescriptions are 40 to 70% within 6 h; so the sustained-release glucose preparation can replace raw core starch and be used for treatment of glycogen storage diseases.

Owner:PEKING UNION MEDICAL COLLEGE HOSPITAL CHINESE ACAD OF MEDICAL SCI +2

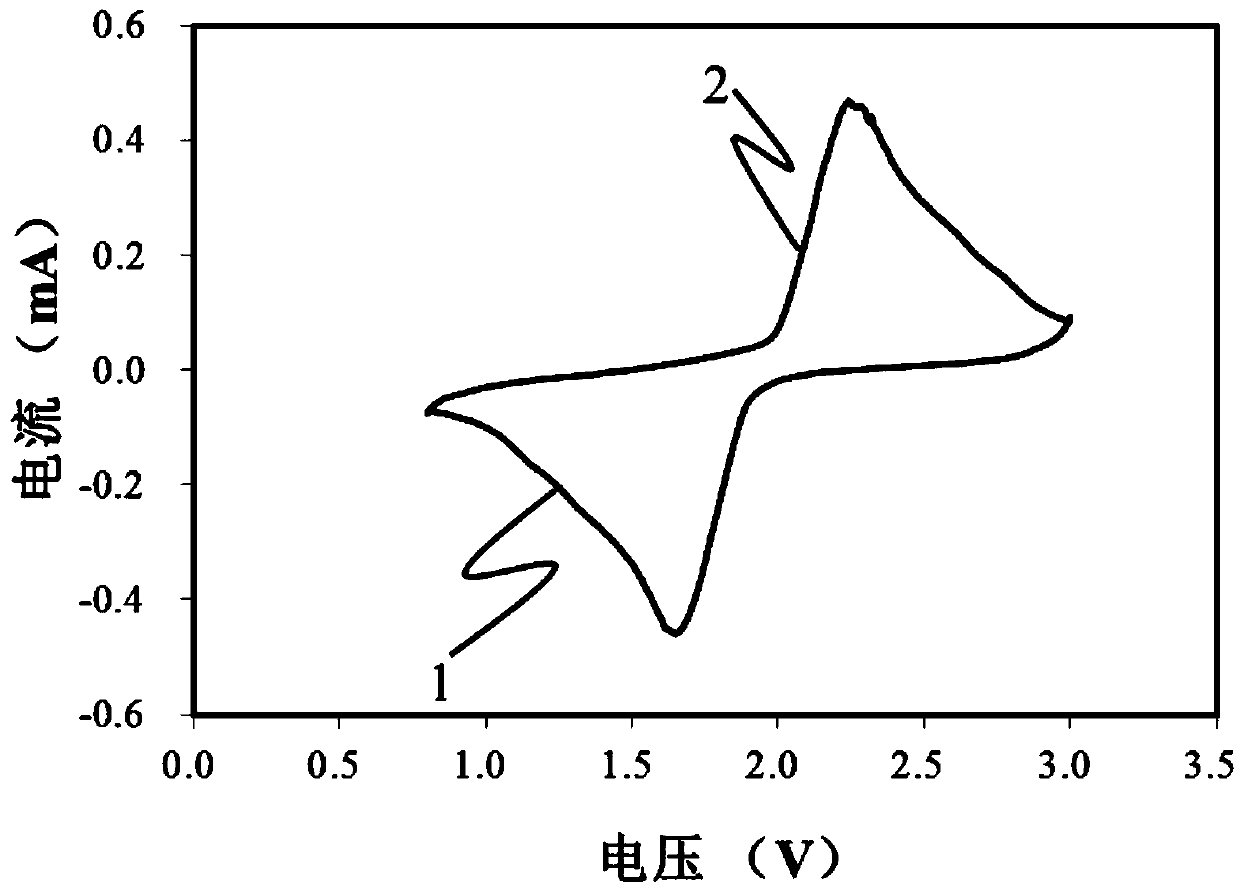

Preparation method of gel polymer lithium ion battery

InactiveCN106784547BGood chemical stabilityIncrease the specific capacity of lithium storageCell electrodesFinal product manufactureHigh energyNitrogen gas

The invention relates to the preparation technology of a gel lithium ion battery, and aims to provide a preparation method for a gel-state polymer lithium ion battery. The preparation method comprises the steps of performing ball milling and mixing on glucose monohydrate, melamine, metaboric acid and NaCl-KCl eutectic salt, and heating the mixture in a nitrogen atmosphere for three times and then cooling to the room temperature; cleaning off salt content by deionized water and performing vacuum drying; performing mixing and grinding on obtained graphene-loaded nanometer boron and acetylene black, and Nafion-PEO co-mixed resin solution, and mixing the mixture into paste shape to coat foamed nickel; drying in the shade and pressing and shaping to obtain a negative electrode; performing arrangement on a positive electrode, a diaphragm and the negative electrode in sequence and performing pressing and shaping, and then carrying out heat treatment in a nitrogen atmosphere to obtain a film electrode, and immersing the film electrode in an electrolyte for 2h to obtain a cell; and assembling a button type gel-state polymer lithium ion battery by the cell. By adoption of the preparation method, a free-state electrolyte does not exist, so that the safety of the lithium ion battery can be remarkably improved, the electrode structural stability can be improved, high-current discharge can be promoted, and a safe and reliable high-energy power battery can be provided for an electric vehicle.

Owner:ZHEJIANG UNIV

Rice noodles capable of moistening intestines and relaxing bowels

PendingCN111513242APromote growthImprove developmentVitamin food ingredientsFood ingredient functionsBiotechnologyBanana powder

The invention discloses rice noodles capable of moistening the intestines and relaxing the bowels, and belongs to the technical field of food processing. The rice noodles comprise the following raw materials in parts by weight: 185-190 parts of rice, 48-52 parts of glucose monohydrate, 8-12 parts of fructo-oligosaccharides, 10-15 parts of corn grits, 8.2-8.6 parts of whole milk powder, 1.2-1.6 parts of hemp seed powder, 2.4-3.2 parts of banana powder, 1.2-1.6 parts of chrysanthemum powder, 2.2-2.6 parts of composite mineral and 0.10-0.14 parts of composite vitamin. The composite mineral and the composite vitamin contain various minerals and vitamins, and the rice noodles are scientific and reasonable in proportion, can contribute to healthy growth of infants, are reasonable in formula, caneffectively help the infants to moisten the intestines and relax the bowels, and are suitable for popularization and application.

Owner:江西高美高健康食品有限公司

Process for the continuous production of alkyl glycosides

ActiveCN105418699BHigh degree of automationShort processSugar derivativesSugar derivatives preparationEcological safetyEvaporation

Owner:河北合佳医药科技集团股份有限公司

Method for continuous production of alcohol ether glycosides

ActiveCN105669786BHigh degree of automationShort processSugar derivativesSugar derivatives preparationSolubilityEvaporation

The invention relates to a method for continuously producing alkyl ethoxy polyglycoside. The method includes: 1) a continuous reaction to anhydrous glucose or glucose monohydrate with a fatty alcohol-polyoxyethylene ether compound, 2) continuous three-stage vacuum distillation alcohol removal treatment including first-stage scraper blade thin film evaporation, second-stage short-range evaporation and third-stage short-range evaporation to remove the fatty alcohol-polyoxyethylene ether compound, and 3) continuous three-stage countercurrent discoloring treatment with ozone as a discoloring agent to produce the alkyl ethoxy polyglycoside which is colorless, transparent, high-purity and high-quality. The alkyl ethoxy polyglycoside is colorless, transparent, high-purity and high-quality, has excellent surface activity and bio-degradability, good water solubility, strong hard water resistance and alkaline resistance, and low production cost. The invention also relates to a production apparatus for continuously producing the alkyl ethoxy polyglycoside. The apparatus has high automation degree and short technical process and is suitable for large-scale industrial production.

Owner:河北合佳医药科技集团股份有限公司

A glucose sustained-release preparation for treating glycogen accumulation disease

ActiveCN106913558BGood slow releaseOrganic active ingredientsMetabolism disorderPharmaceutical formulationSustained-Release Preparations

The invention provides a sustained-release glucose preparation for treating glycogen storage diseases and a preparation method thereof, belonging to the field of medicinal preparations. The sustained-release glucose preparation is composed of two parts, i.e., a glucose pill core and a film coating and prepared from glucose monohydrate, microcrystalline cellulose, ethyl cellulose, hydroxypropyl cellulose, triethyl citrate, ethanol and purified water by using a modern preparation technology. Results of release-rate determination experiments prove that the sustained-release glucose preparation provided by the invention has good sustained-release performance and can be gradually and slowly released within 6 h; the release rates of sustained-release glucose preparations prepared according to three different prescriptions are 40 to 70% within 6 h; so the sustained-release glucose preparation can replace raw core starch and be used for treatment of glycogen storage diseases.

Owner:PEKING UNION MEDICAL COLLEGE HOSPITAL CHINESE ACAD OF MEDICAL SCI +2

Free-flowing particulate honey product comprising crystallised natural honey and process for producing thereof

InactiveUS20120237608A1Reduce the amount of solutionImprove suppression propertiesCosmetic preparationsDough treatmentParticulatesX-ray

The invention provides a free-flowing particulate honey product comprising crystallized natural bee honey and a process for producing thereof. The free flowing particulate honey product comprises crystals of natural honey in admixture with glucose and is characterised by X-ray powder diffraction pattern having peaks in degrees 2θ that are identified as characteristic peaks of crystalline glucose monohydrate, and diastase index not less than 90% of the diastase index of a crude honey used to prepare the product, calculated based upon the weight of the crude honey. The product retains all the healthy and biologically active properties of natural honey and can be used as a sugar substitute, or as a component of food mixtures, such as dry cereals, muesli, tea, coffee, drink mixtures, and also for preparing beverages, bakery, confectionary, as well as cosmetic and hygienic formulations.

Owner:LIABILITY MEDOVYY DOM

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com