Method and production device for continuously producing alkyl glucoside

A technology for alkyl glycosides and production equipment, which is applied in the field of continuous production of alkyl glycosides and production equipment, can solve the problems of easy accumulation at the bottom of equipment, deepened product color, slow reaction speed, etc., and achieves elimination of color effects and impurities. The effect of removing and avoiding deposits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

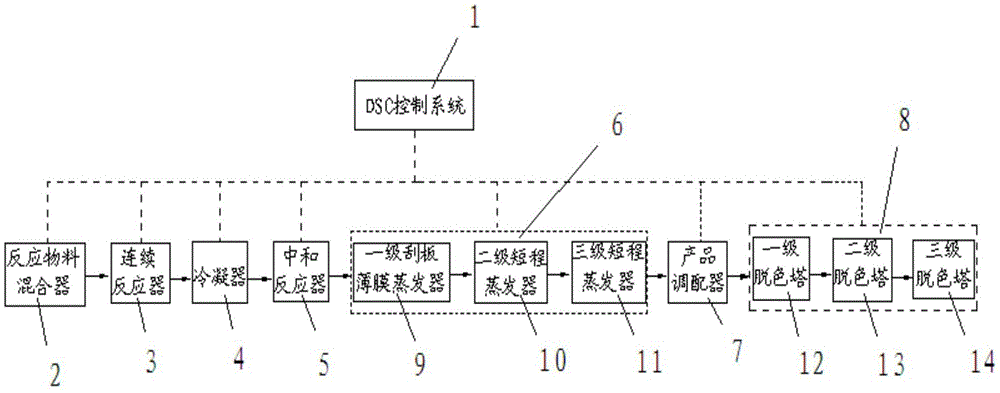

[0027] This embodiment relates to a group of methods for the continuous production of alkyl glycosides, in figure 1 in the production facility shown.

[0028] Such as figure 1 As shown, the production device for continuous production of alkyl glycosides includes a DSC control system 1, and the DSC control system 1 is used to regulate and control the reaction material mixer 2, continuous reactor 3, condenser 4, neutralization reactor 5, And the operation of continuous dealcoholization device 6, product blender 7, and continuous decolorization device 8; described continuous reactor 3 is horizontal, rake type stirring, and is divided into three reaction zones; described continuous dealcoholization device 6 comprises The first-stage scraper film evaporator 9, the second-stage short-range evaporator 10 and the third-stage short-range evaporator 11 arranged in sequence, the continuous decolorization device includes a first-stage decolorization tower 12, a second-stage decolorizatio...

Embodiment 11

[0031]Add anhydrous glucose, C12-14 fatty alcohol and dodecylbenzenesulfonic acid into the reaction material mixer in a molar ratio of 1:3.5:0.03, and under the control of the DSC control system, the uniformly mixed reaction raw materials are continuously added to In the continuous reactor, at a vacuum degree of 10-15mmHg and a temperature of 110°C, stay for reaction for 3 hours, then enter the condenser to cool down to 60°C, then enter the neutralization reactor, and adjust by continuously adding the mixture of MgO and sodium hydroxide The pH is 9, and a milky white reaction mixture containing alkyl glycosides and fatty alcohols is obtained. The reaction mixture enters a continuous dealcoholization device, and at a vacuum degree of 4mmHg and a temperature of 130°C, the unreacted C12-14 fatty alcohols are removed to obtain the product alkanes Alkyl glycosides are prepared by adding water to form an alkyl glycoside solution with a content of 50%, and finally decolorized by a con...

Embodiment 12

[0034] Add glucose monohydrate, C16-18 fatty alcohol and p-toluenesulfonic acid in a molar ratio of 1:4:0.04 to the reaction material mixer, and under the control of the DSC control system, the uniformly mixed reaction raw materials are continuously added to the continuous reactor In the reactor, stay in the reaction for 2.5 hours at a vacuum degree of 15-20mmHg and a temperature of 150°C, then enter the condenser to cool down to 70°C, then enter the neutralization reactor, and adjust the pH by continuously adding the mixture of NaO and sodium hydroxide. 9.5, to obtain a milky white reaction mixture containing alkyl glucoside and fatty alcohol. The reaction mixture enters a continuous dealcoholization device, and at a vacuum degree of 3mmHg and a temperature of 150°C, the unreacted C16-18 fatty alcohol is removed to obtain the product alkyl glycoside , adding water to prepare an alkyl glycoside solution with a content of 50%, and finally decolorizing through a continuous decolo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com