Lactobacillus plantarum liquid fermentation culture medium and culture method and application thereof

A technology of Lactobacillus plantarum and liquid fermentation, applied in the field of lactic acid bacteria culture and fermentation, can solve the problems of high production cost and complex fermentation technology process, reduce production cost, solve the complex fermentation technology process, and solve the problem of high production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] This embodiment is used to illustrate the Lactobacillus plantarum liquid fermentation medium and the culture method thereof provided by the present invention.

[0023] The components of the Lactobacillus plantarum fermentation medium used in this example are: glucose 30g / L, soybean meal powder 12g / L, Saccharomyces cerevisiae extract 10g / L, dipotassium hydrogen phosphate 2g / L, ammonium chloride 10g / L, chloride Sodium 5g / L, calcium carbonate 10g / L, magnesium sulfate 0.2g / L, manganese sulfate 0.05g / L, water 1L, sterilized at 115°C for 30min.

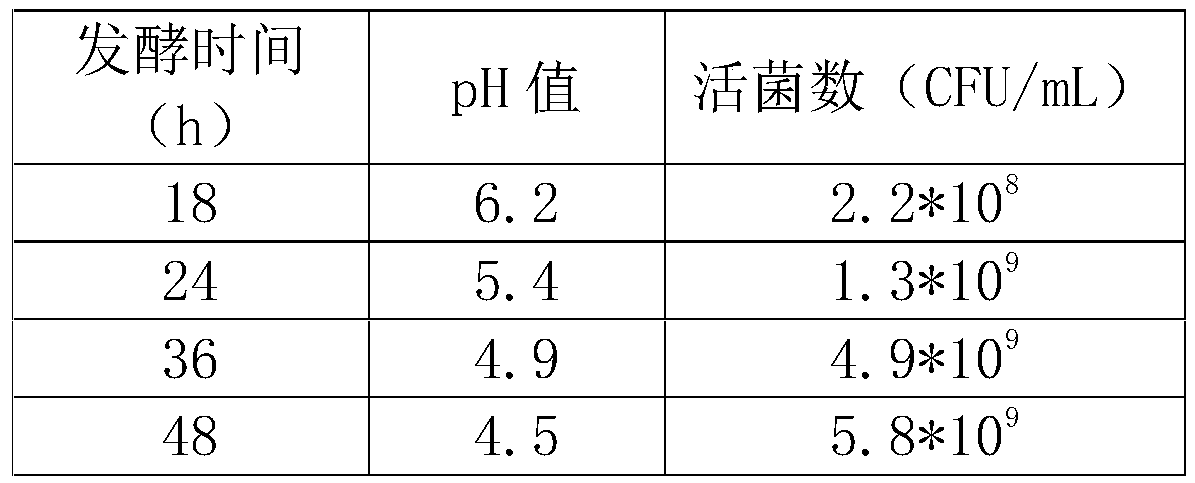

[0024] The fermentation culture method of Lactobacillus plantarum is as follows: use liquid MRS medium as the activation medium, anaerobically culture at 35°C for 18 hours to prepare Lactobacillus plantarum seed liquid, then insert 5% inoculation amount into Lactobacillus plantarum fermentation medium, and then use no Bacterial sodium hydroxide was used to adjust the pH to 7.5, the temperature was controlled at 35°C, anaerobic cultur...

Embodiment 2

[0030] This embodiment is used to illustrate the Lactobacillus plantarum liquid fermentation medium and the culture method thereof provided by the present invention.

[0031] The components of the Lactobacillus plantarum fermentation medium used in this example are: glucose 20g / L, soybean meal powder 10g / L, Saccharomyces cerevisiae extract 10g / L, dipotassium hydrogen phosphate 2g / L, ammonium chloride 5g / L, chloride Sodium 5g / L, calcium carbonate 5g / L, magnesium sulfate 0.2g / L, manganese sulfate 0.05g / L, water 1L, sterilized at 115°C for 30min.

[0032] The fermentation culture method of Lactobacillus plantarum is as follows: use liquid MRS medium as the activation medium, anaerobically culture at 35°C for 18 hours to prepare Lactobacillus plantarum seed liquid, then insert 5% inoculation amount into Lactobacillus plantarum fermentation medium, and then use no Bacterial sodium hydroxide was used to adjust the pH to 7.5, the temperature was controlled at 35°C, anaerobic culture ...

Embodiment 3

[0034] This embodiment is used to illustrate the Lactobacillus plantarum liquid fermentation medium and the culture method thereof provided by the present invention.

[0035] The components of the Lactobacillus plantarum fermentation medium used in this example are: glucose 20g / L, soybean meal powder 15g / L, Saccharomyces cerevisiae extract 8g / L, dipotassium hydrogen phosphate 2g / L, ammonium chloride 8g / L, chloride Sodium 5g / L, calcium carbonate 8g / L, magnesium sulfate 0.2g / L, manganese sulfate 0.05g / L, water 1L, sterilized at 115°C for 30min.

[0036] The fermentation culture method of Lactobacillus plantarum is as follows: use liquid MRS medium as the activation medium, anaerobically culture at 35°C for 18 hours to prepare Lactobacillus plantarum seed liquid, then insert 5% inoculation amount into Lactobacillus plantarum fermentation medium, and then use no Bacterial sodium hydroxide was used to adjust the pH to 7.5, the temperature was controlled at 35°C, anaerobic culture w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com