Free-flowing particulate honey product comprising crystallised natural honey and process for producing thereof

A technology of natural honey and honey, applied in the field of food industry, can solve problems such as reducing taste, and achieve the effect of prolonging the natural properties of honey

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

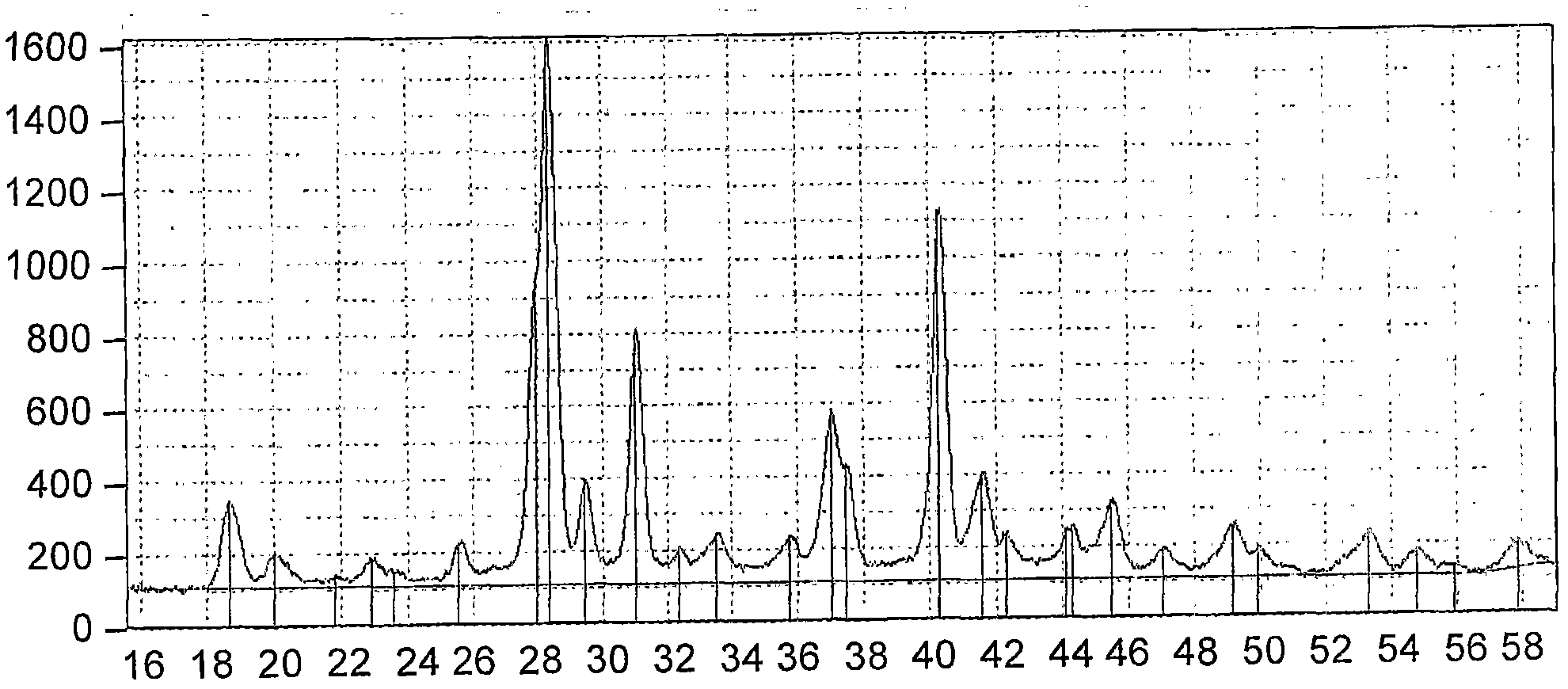

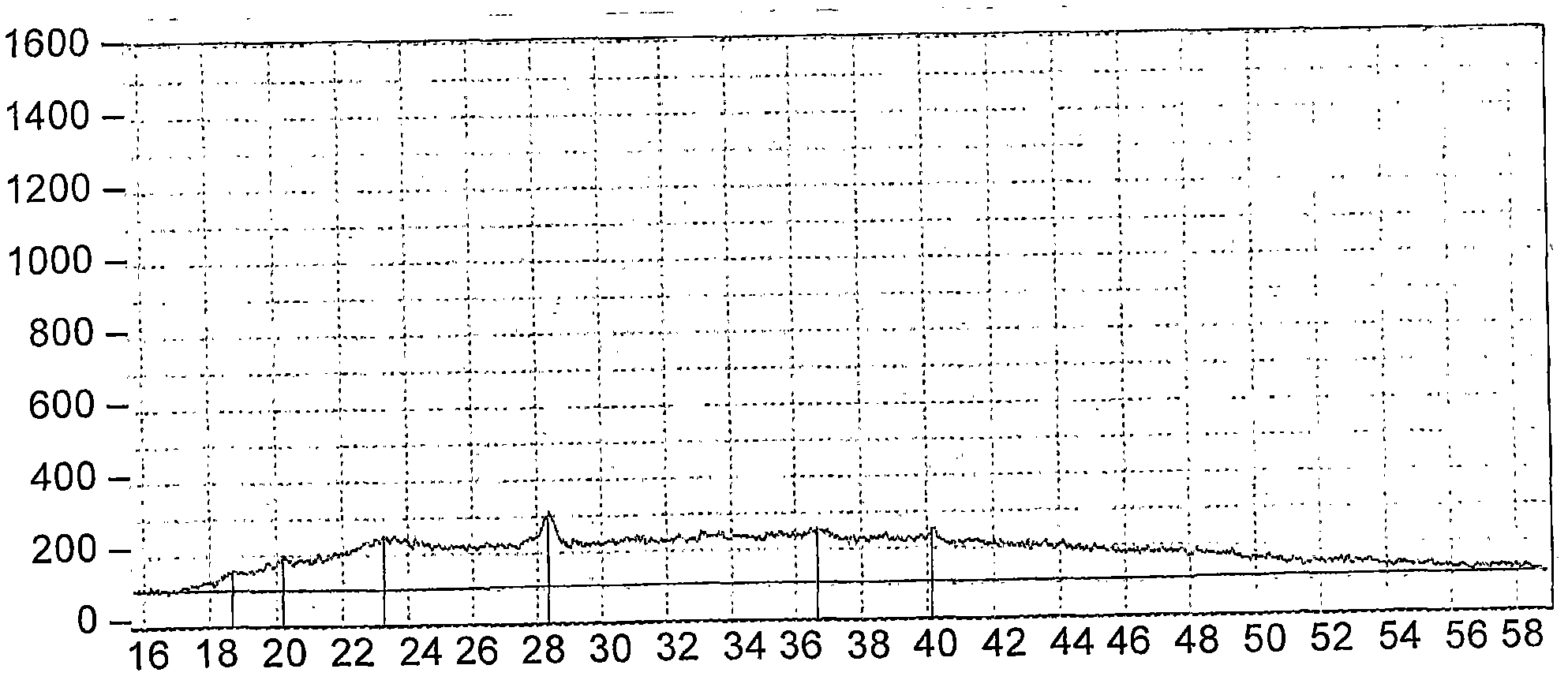

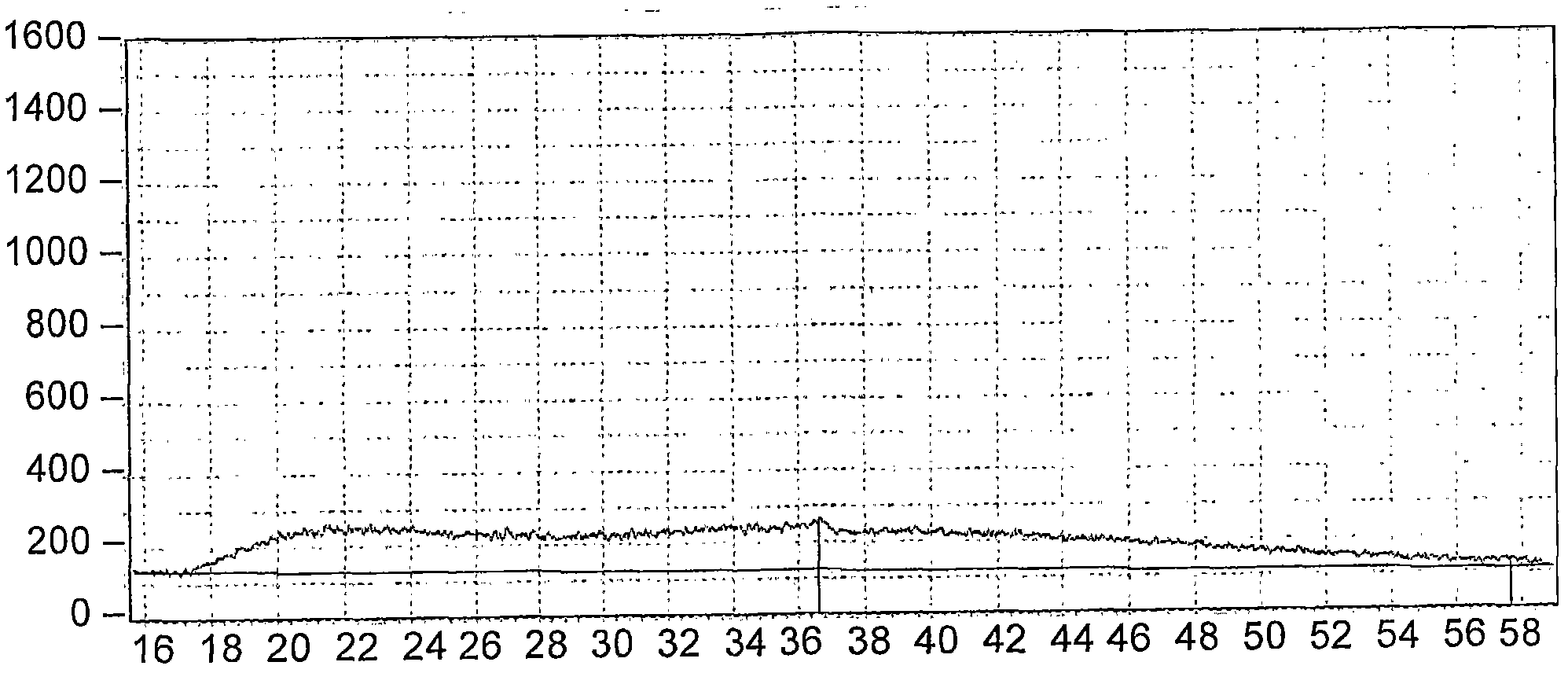

Image

Examples

Embodiment 1

[0088] Example 1 Preparation of granular honey product in a blender

[0089] A. Place 300 g of a 1:1.7 (honey:glucose) mixture of buckwheat honey (with 18% humidity) and dextrose monohydrate in the mixing vessel of a 15-speed blender (Braun MR-6550-M CA MN) , and mixed at 6,000 rpm for 20 seconds at room temperature. The obtained granulated hazel honey product has a particle size of 100 microns to 5 mm. This product can be further sieved into finer fractions to obtain the desired particle size.

[0090] B. In the above experiment, after 25 seconds the stirring speed was increased to a maximum of 10,500 rpm and mixing was continued for an additional 12 seconds. A dry light brown powder is obtained with a particle size ranging from 100 microns to 5 mm.

Embodiment 2

[0092] 100 g honey and 170 g glucose were fed into a food chopper Bosch MMR 0801. The food processor was turned on to 2,000 rpm and the product was obtained after 30 seconds. The product includes granules with a size of 1 to 10 mm and powders smaller than 1 mm. The mixture is optionally further sieved to obtain a uniform particle product having a predetermined size range. The product obtained is air-dried at ambient temperature for 3-4 days, preferably 5-7 days, resulting in a product with increased particle hardness.

Embodiment 3

[0094] 14 kg of honey (18% humidity) were loaded into an attritor mixer IS-120 (Molmash, Russia) equipped with a water cooling jacket and stirring was started at 16 rpm. While stirring, chemically pure glucose (humidity 6%) was added in portions. After 24 kg of glucose had been added and the mixture thickened and homogeneous, the speed was switched to 3,000 rpm. Cold water at a temperature of up to 18°C is fed into the cooling jacket during the process. The process was completed within 7 minutes, obtaining about 38 kg of granules containing honey. The size of these particles is mainly from 5 to 30 mm and smaller. The particles can be further sieved and classified into finer fractions to obtain a product of desired particle size and properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com