Method for preparing lithium borohydride by room-temperature solid-phase ball milling

A lithium borohydride, room temperature solid-phase technology, applied in the field of preparation of high-capacity hydrogen storage materials, can solve problems such as hindering the formation of LiBH4, difficulty in recycling boron resources, and restrictions on large-scale applications, so as to achieve controllable reaction process and source of raw materials Wide range of effects suitable for large-scale production and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Prepare lithium borohydride by solid phase ball milling at room temperature, the steps are as follows:

[0059] At room temperature, in a glove box with 0.1MPa argon atmosphere, take Mg and LiBO 2 2H 2 O (the molar ratio is 5:1) is mixed, put into the ball mill pot and seal it, and then place it on a high-energy pendulum ball mill (QM-3C) for ball milling. The rotation speed is 1200 rpm, the ball milling time is 20 hours, the operation mode is alternate restart, each operation is 30 minutes and then pauses for 30 minutes, so alternately;

[0060] After the ball milling, use distilled diethyl ether to dissolve and extract the mixture after the ball milling and filter to obtain a clear filtrate. After the clear filtrate is vacuum-dried, a white powder is obtained;

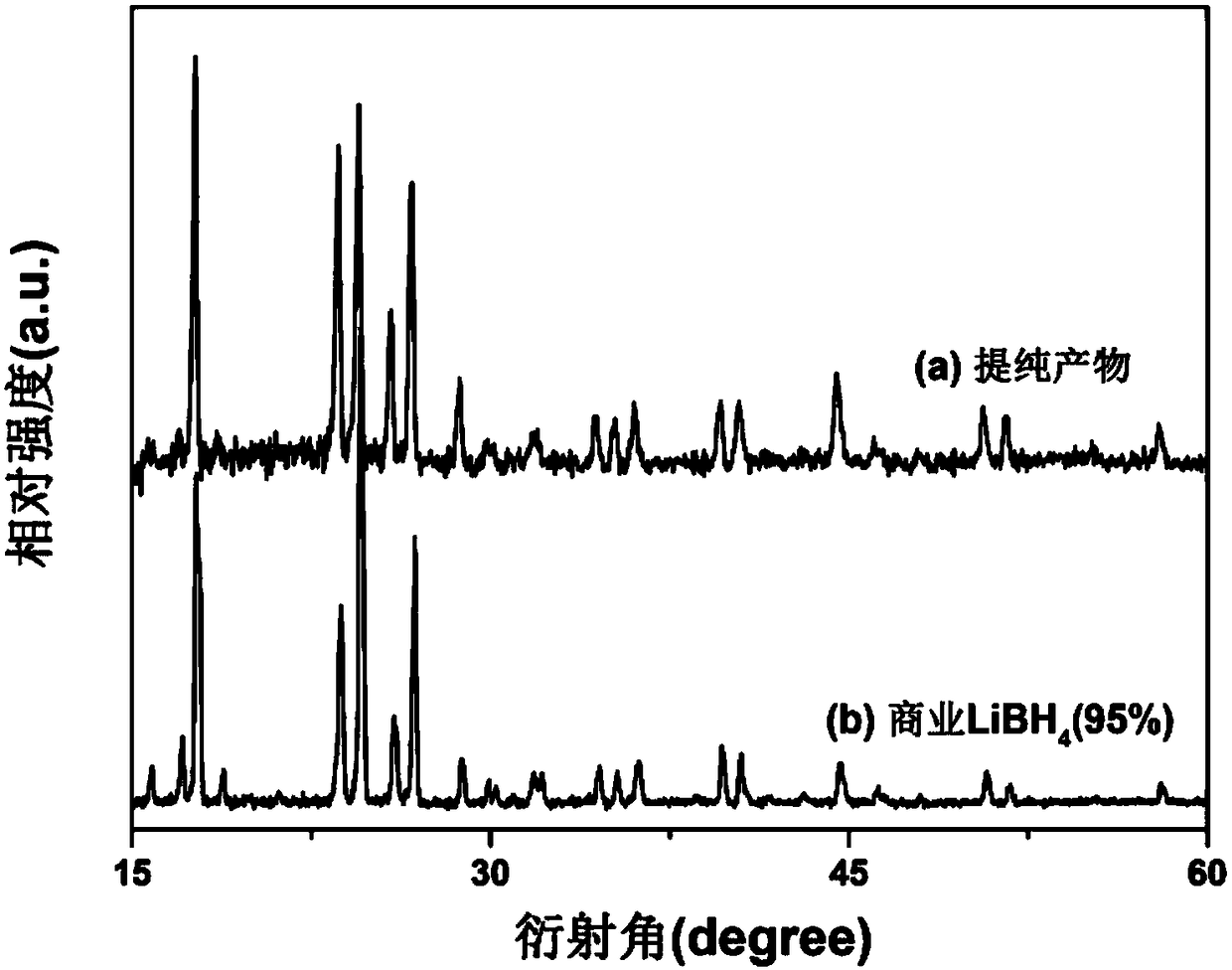

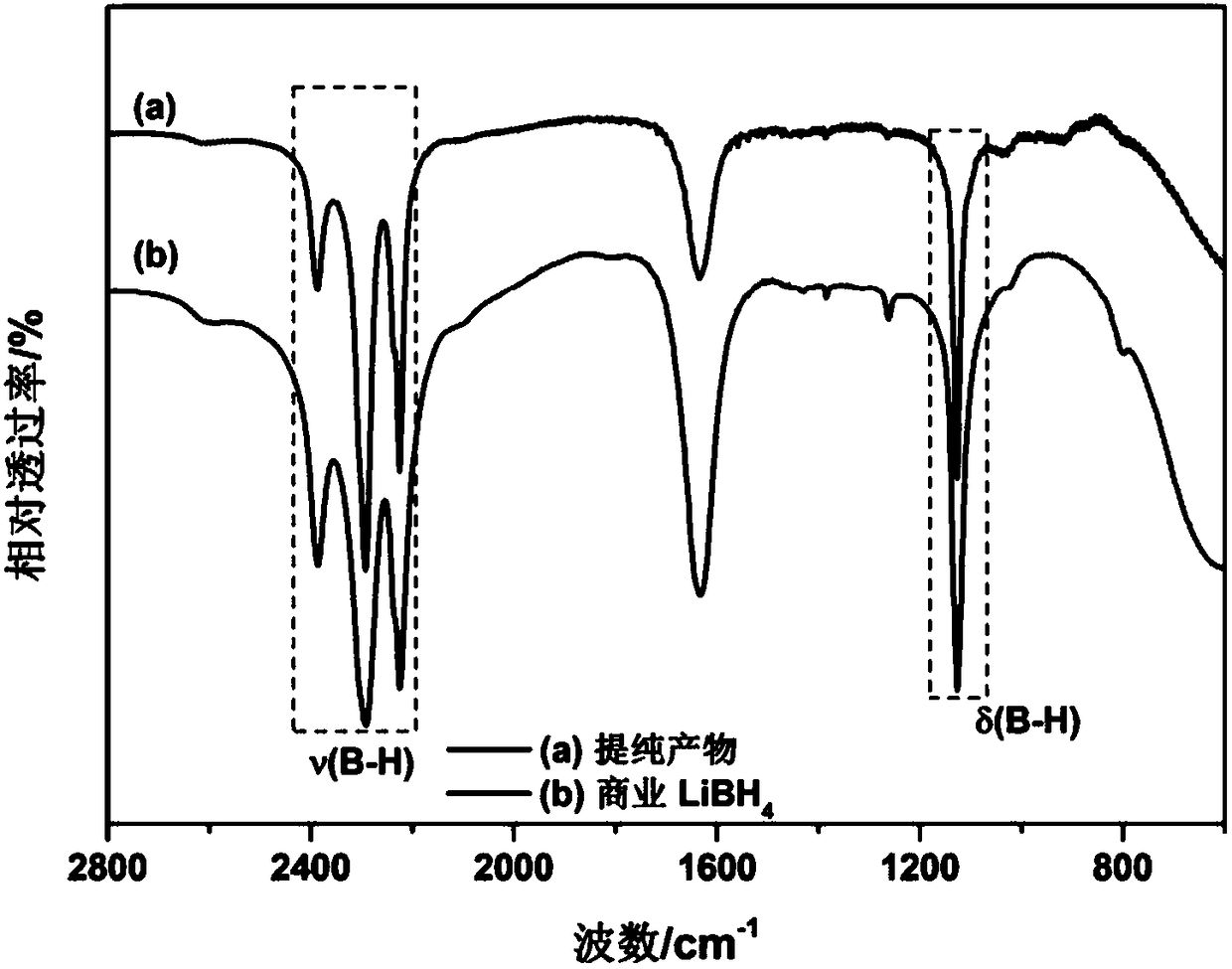

[0061] The resulting white powder was mixed with commercial LiBH 4 (95%) XRD comparison picture as shown figure 2 shown by figure 2 It can be seen that the obtained white powder is high-purity lithium ...

Embodiment 2

[0064] Prepare lithium borohydride by solid phase ball milling at room temperature, the steps are as follows:

[0065] At room temperature, in a glove box with 0.1MPa argon atmosphere, take Mg and LiBO 2 2H 2 O (the molar ratio is 4.5:1) mixed, put into the ball mill pot and seal it, then put it on the high-energy pendulum type ball mill (QM-3C) for ball milling, the ball-to-material ratio is 50:1, the ball milling speed is 1200 rpm, ball milling The time is 5 hours, and the operation mode is to restart alternately, and stop for 30 minutes after each operation for 30 minutes, and so on alternately.

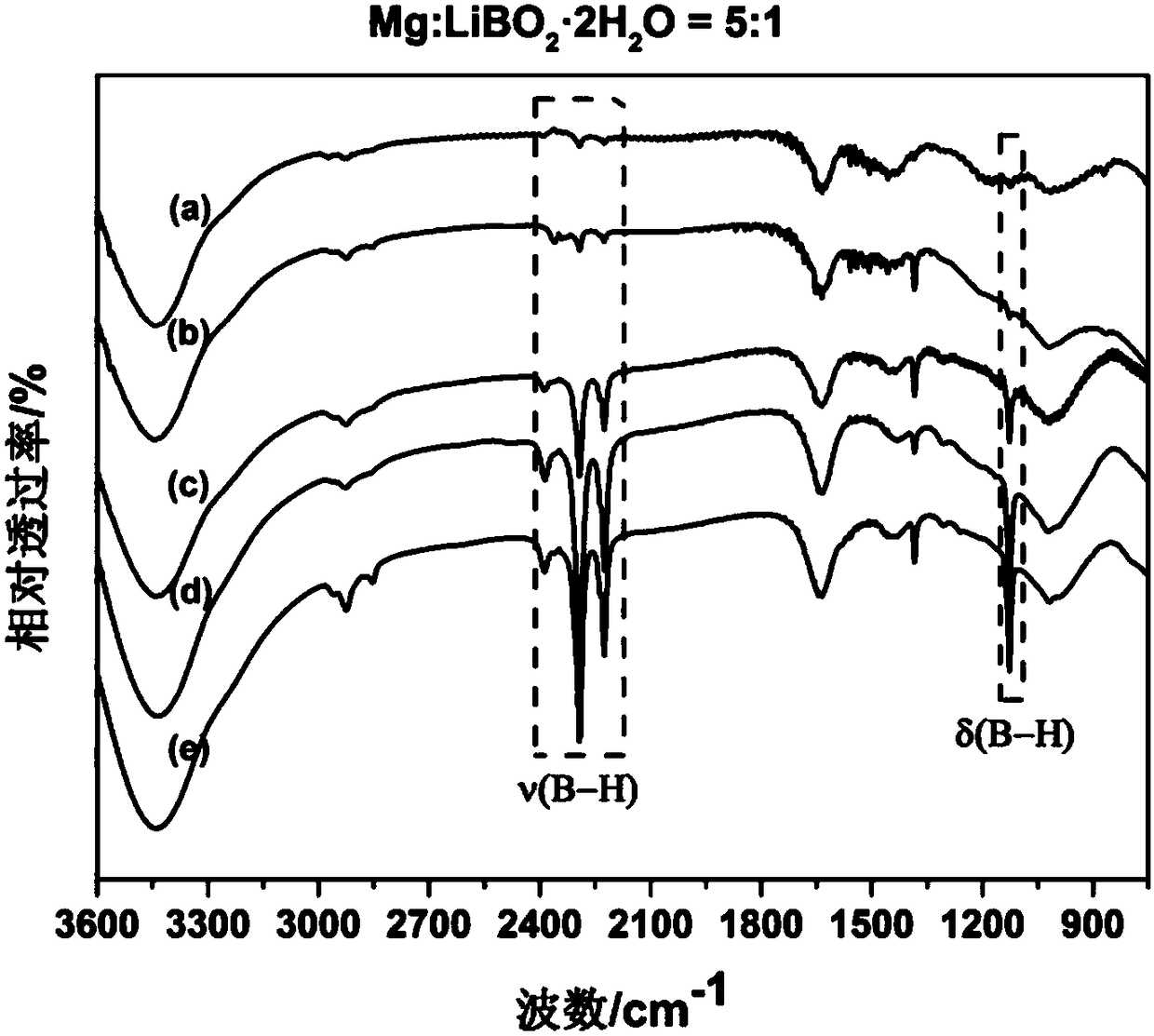

[0066] The infrared spectrum of the mixture after ball milling is shown as Figure 4 As shown by the curve a in the Figure 4 From the curve a in the figure, we can see that in the infrared spectrum curve 2200~2400cm -1 and 1125cm -1 The peak that appears at corresponds to the vibrational absorption peak of the B-H bond, proving the generation of lithium borohydride.

[0067...

Embodiment 3

[0069] Prepare lithium borohydride by solid phase ball milling at room temperature, the steps are as follows:

[0070] At room temperature, in a glove box with 0.1MPa argon atmosphere, take Mg and LiBO 2 2H 2 O (the molar ratio is 4.5:1) mixed, put into the ball mill pot and seal it, then put it on the high-energy pendulum type ball mill (QM-3C) for ball milling, the ball-to-material ratio is 50:1, the ball milling speed is 1200 rpm, ball milling The time is 10h, and the operation mode is alternate restart, each time running for 30 minutes and then stopping for 30 minutes, so alternately.

[0071] The infrared spectrum of the mixture after ball milling is shown as Figure 4 shown in curve b, with Figure 7 The curve a in is consistent, given by Figure 4 From the curve b in the figure, we can see that in the infrared spectrum curve 2200~2400cm -1 and 1125cm -1 The peak that appears at corresponds to the vibrational absorption peak of the B-H bond, proving the generation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com