Preparation method of anhydrous lithium metaborate

A technology of lithium metaborate and boric acid, which is applied in the field of preparation of anhydrous lithium metaborate, can solve the problems of strict process and equipment material requirements, deep processing, etc., and achieve the effect of convenient and safe industrial production, reducing energy consumption and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

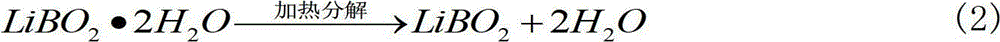

Method used

Image

Examples

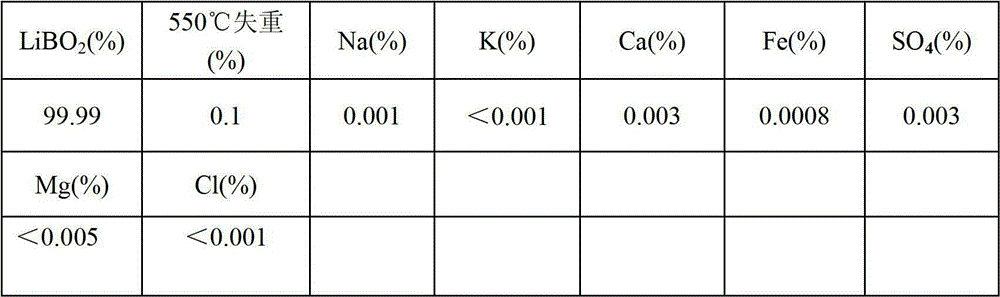

Embodiment 1

[0026] A preparation method of anhydrous lithium metaborate, the steps are as follows:

[0027] 1. Purification of raw materials: dissolve 5Kg lithium hydroxide monohydrate with 20Kg boiled pure water and then filter while hot until clarified to obtain lithium hydroxide net liquid; dissolve 7Kg boric acid with 7Kg boiled pure water and then filter while hot until clarified. Obtain boric acid clean solution;

[0028] 2. Neutralization ingredients: add 13.25Kg boric acid net liquid to the filtered 25Kg lithium hydroxide net liquid while hot (wherein the amount of boric acid substance in the boric acid net liquid is 90% of the amount of lithium hydroxide substance in the lithium hydroxide net liquid %) neutralization, keep the reaction temperature ≧70°C, stir for 15 minutes under heat preservation to make the reaction fully, and prepare for centrifugation immediately after settling for 20 minutes;

[0029] 3. Centrifugal separation: Separation temperature ≧ 50°C, centrifuge spee...

Embodiment 2

[0036] A preparation method of anhydrous lithium metaborate, the steps are as follows:

[0037] 1. Raw material purification: Dissolve 5Kg lithium hydroxide monohydrate with 20Kg boiled pure water and then filter while hot until clarified to obtain lithium hydroxide net liquid; dissolve 7.2Kg boric acid with 7.2Kg boiled pure water and filter while hot to Clarify to obtain boric acid net liquid;

[0038] 2. Neutralization ingredients: add 14Kg boric acid net liquid to the filtered 25Kg lithium hydroxide net liquid while hot (wherein the amount of boric acid in the boric acid net liquid is 95% of the amount of lithium hydroxide in the lithium hydroxide net liquid ) for neutralization, keep the reaction temperature ≧70°C, stir for 15 minutes under heat preservation to make the reaction fully, and prepare for centrifugation immediately after settling for 20 minutes;

[0039] 3. Centrifugal separation: Separation temperature ≧ 50°C, centrifuge speed 1500r / min, separation time 20 ...

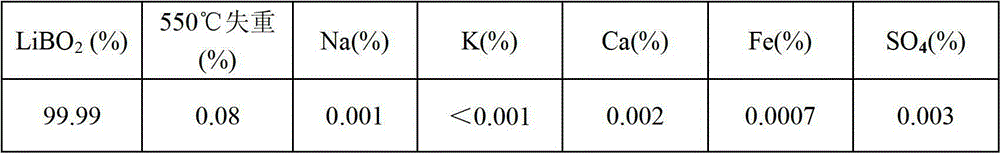

Embodiment 3

[0047] A preparation method of anhydrous lithium metaborate, the steps are as follows:

[0048] 1. Raw material purification: Dissolve 5Kg lithium hydroxide monohydrate with 20Kg boiled pure water and then filter while hot until clarified to obtain lithium hydroxide net liquid; dissolve 7.5Kg boric acid with 7.5Kg boiled pure water and then filter while hot to Clarify to obtain boric acid net liquid;

[0049] 2. Neutralization ingredients: Add 14.27Kg boric acid net liquid to the filtered 25Kg lithium hydroxide net liquid while it is hot (wherein the amount of boric acid in the boric acid net liquid is 97% of the amount of lithium hydroxide in the lithium hydroxide net liquid %) neutralization, keep the reaction temperature ≧70°C, stir for 15 minutes under heat preservation to make the reaction fully, and prepare for centrifugation immediately after settling for 20 minutes;

[0050] 3. Centrifugal separation: Separation temperature ≧ 50°C, centrifuge speed 1800r / min, separation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com