Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

103 results about "Fused glass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fused glass is glass that has been fired in a kiln at a range of high temperatures from 593 °C to 816 °C. There are 3 main distinctions for temperature application and the resulting effect on the glass. Firing in the lower ranges of these temperatures 593–677 °C is called slumping. Firing in the middle ranges of these temperatures 677–732 °C is considered "tack fusing". Firing the glass at the higher spectrum of this range 732–816 °C is a "full fuse". All of these techniques can be applied to one glass work in separate firings to add depth, relief and shape.

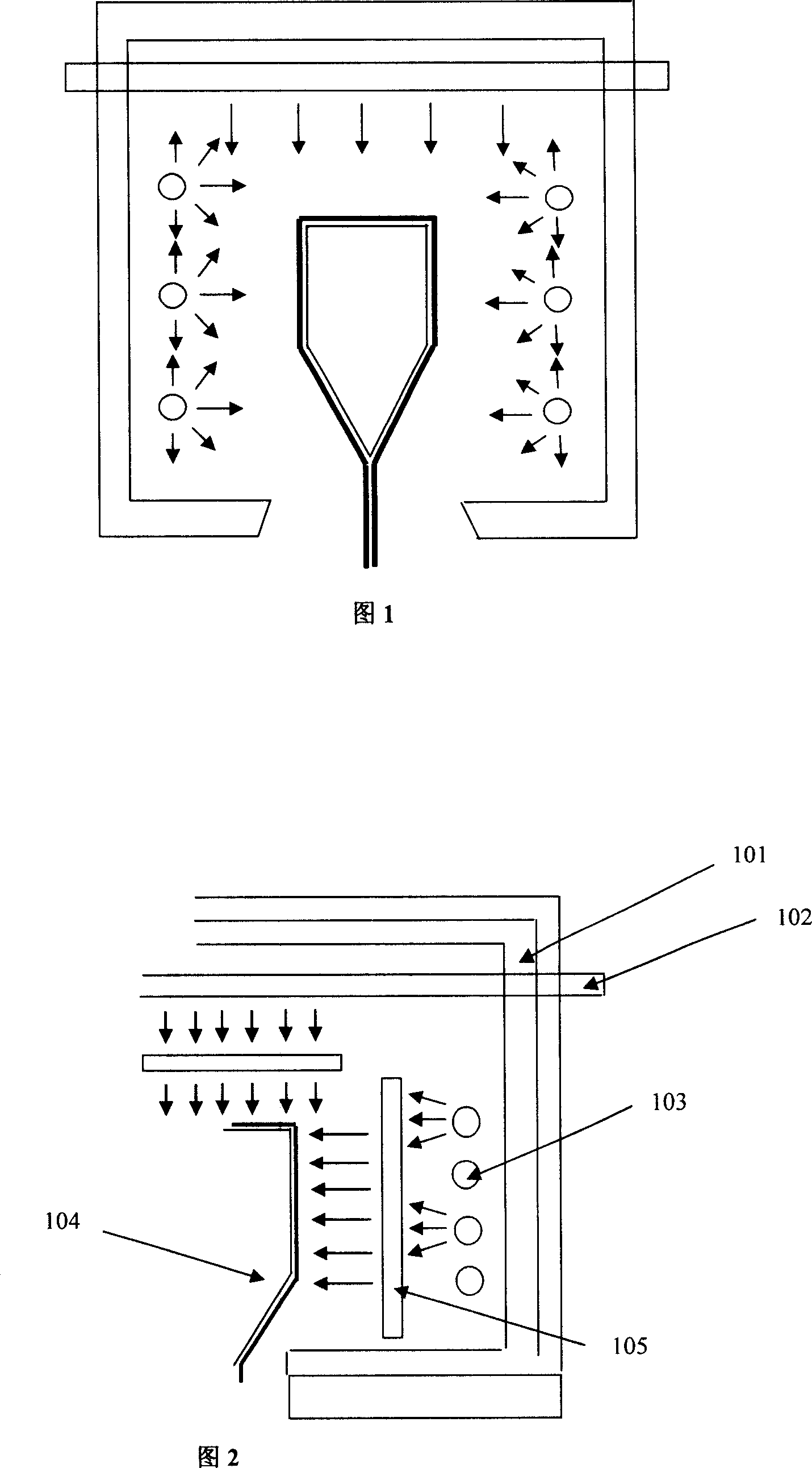

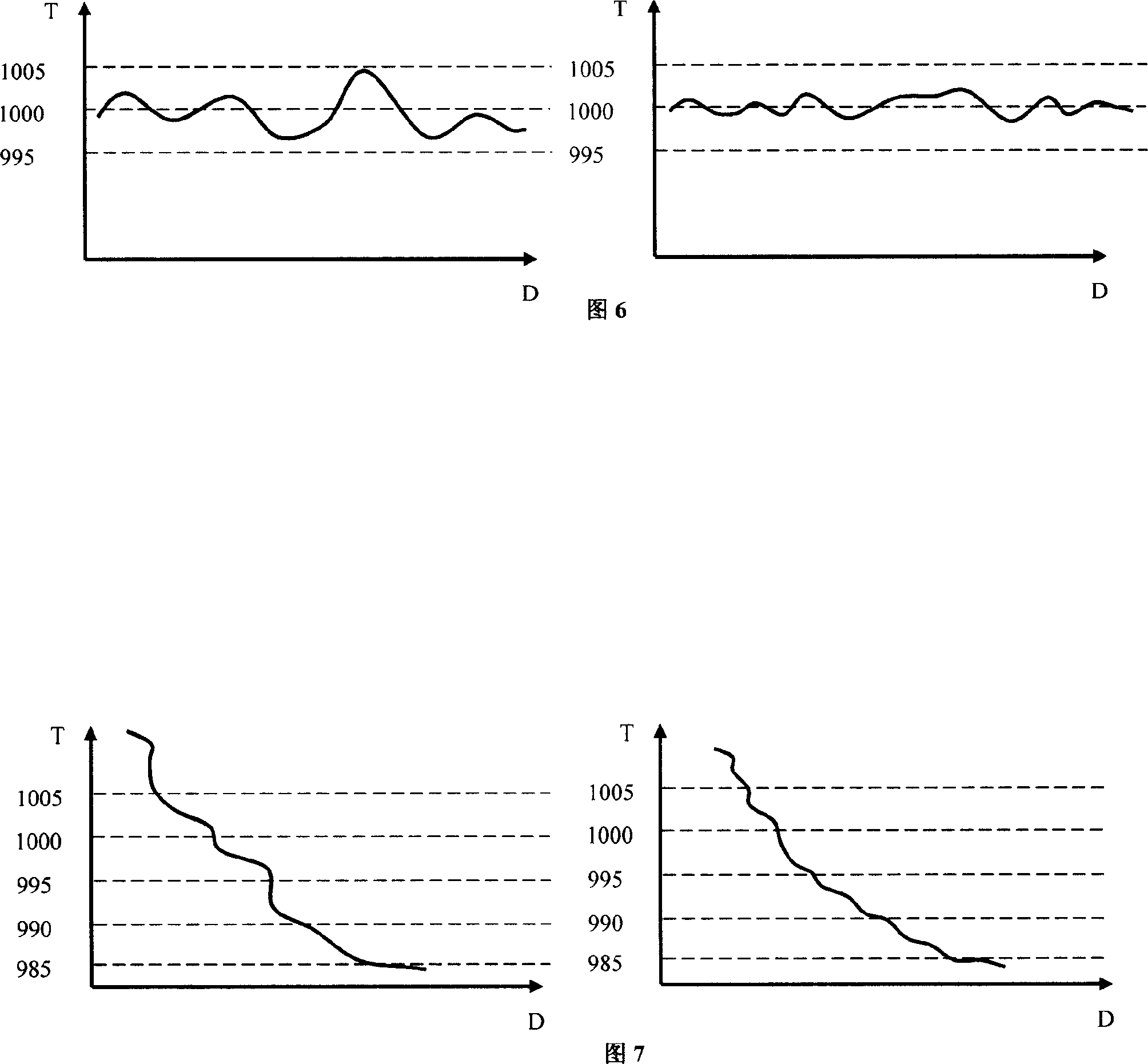

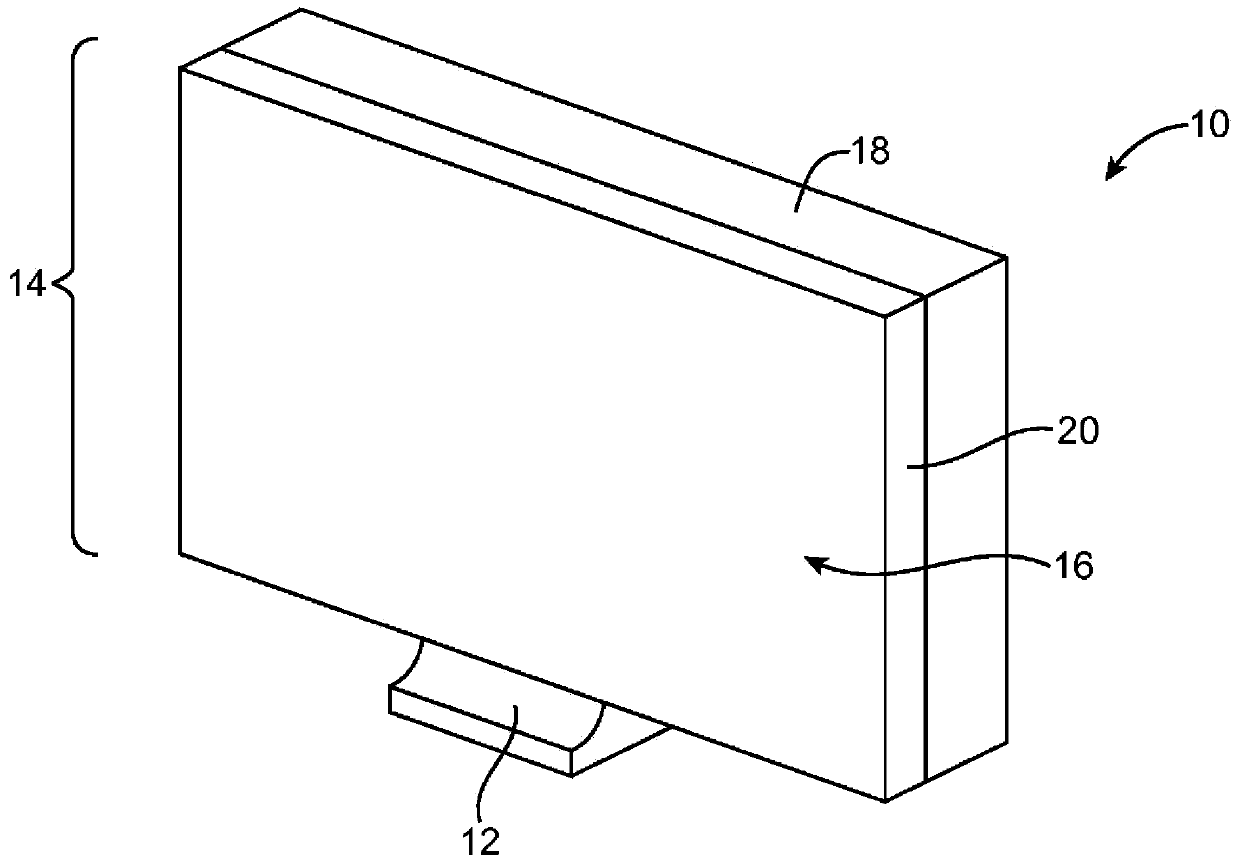

Device and method for controlling glass-board thickness evenness

InactiveCN101028964AControl the degree of heat transferHigh blacknessGlass forming apparatusThermal energyBrick

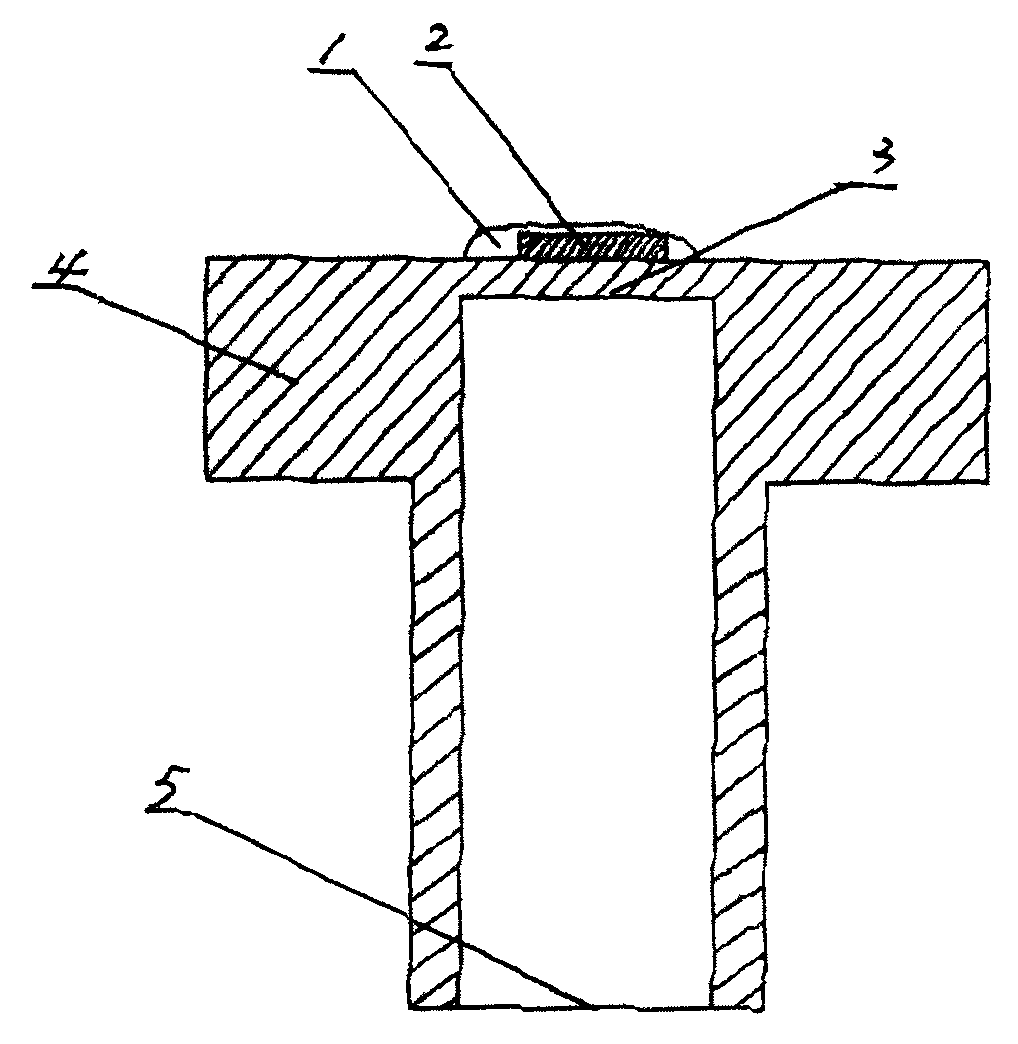

An apparatus for controlling the thickness uniformity of glass plate is composed of supporting frame, the upper, lower, left and right insulating refractory brick layers for enclosing whole apparatus, and two closed cavities containing at least one fluid tube and arranged at both sides of glass plate for collecting the heat to heat the fused glass in irradiation mode. Its method features that the distance between said apparatus and fused glass and the relative position between fused glass and heating element are regulated for controlling the temp of fused glass.

Owner:HENAN ANCAI HI-TECH +1

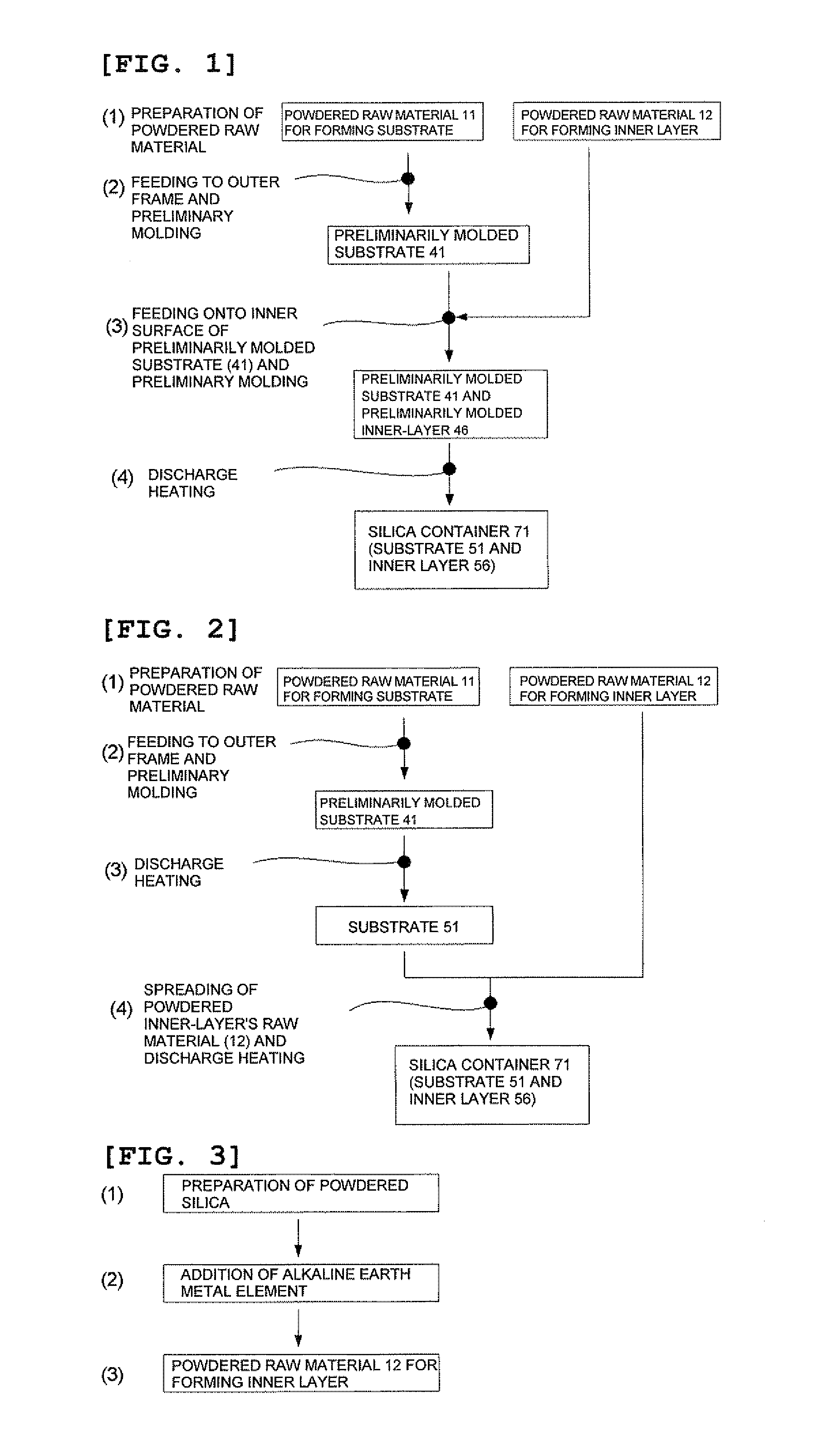

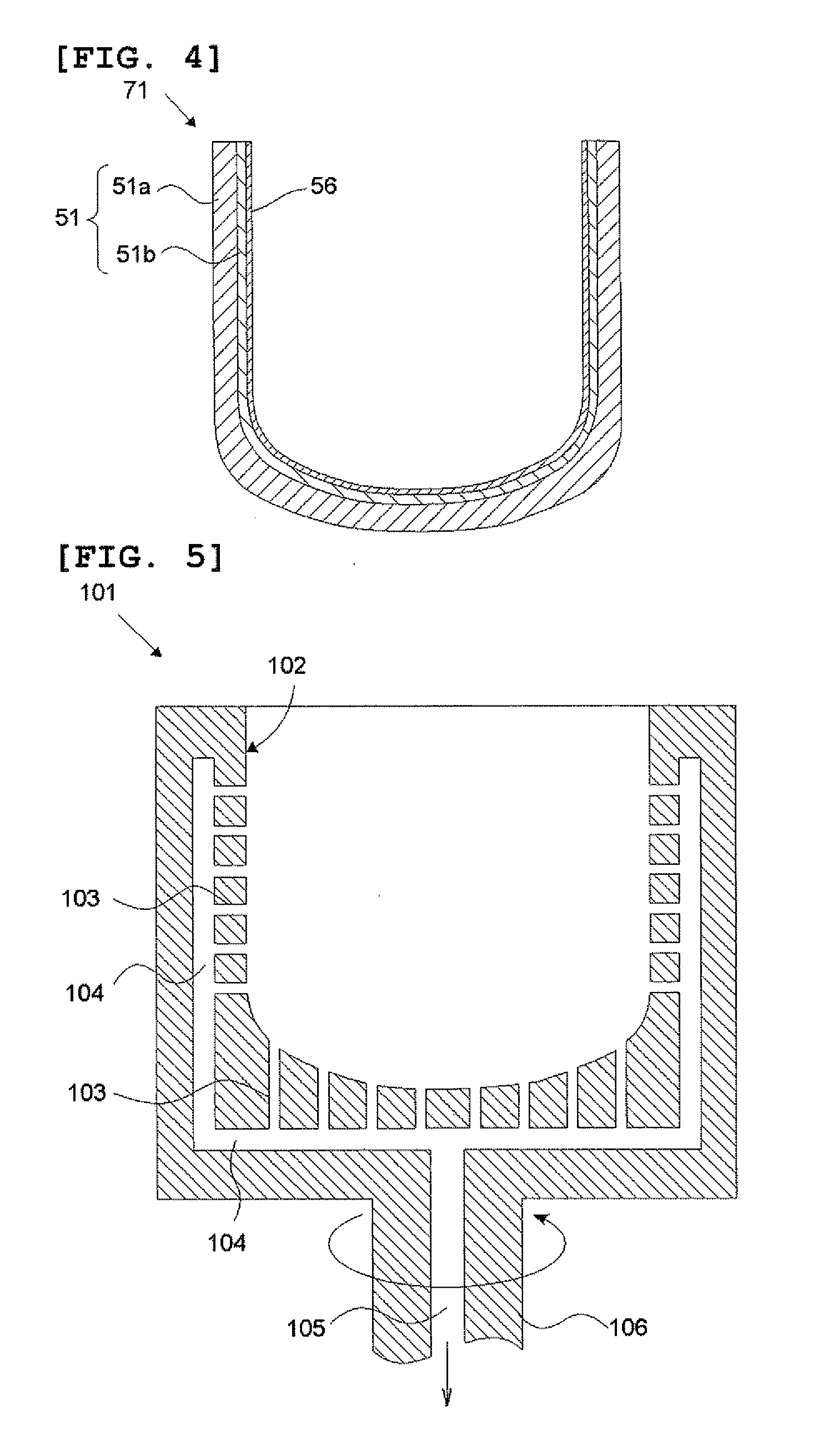

Silica container and method for producing the same

InactiveUS20110272322A1Increased durabilitySuppress generationAfter-treatment apparatusPolycrystalline material growthHydrogenFused glass

The present invention is a method for producing a silica container having a substrate containing gaseous bubbles in its outer peripheral part and an inner layer comprised of a transparent silica glass formed on an inner surface of the substrate, wherein a powdered raw material for forming a substrate containing Li, Na, and K with the total concentration of 50 or less ppm by weight and a powdered raw material for forming an inner layer containing Ca, Sr, and Ba with the total concentration of 50 to 2000 ppm by weight are prepared; a preliminarily molded substrate is formed in a frame; a preliminarily molded inner layer is formed on an inner surface of the preliminarily molded substrate; and the preliminarily molded substrate and molded inner layer are heated from inside thereof by a discharge-heat melting method under a gas atmosphere containing a hydrogen gas or a helium gas or a gas mixture thereof with the ratio of more than 10% by volume thereby making an outer peripheral part of the preliminarily molded substrate to a sintered body and an inner peripheral part of the preliminarily molded substrate and the preliminarily molded inner layer to a fused glass body. With this, a method for producing a silica container, producible with a low cost and having a high durability and dimensional precision, and a container of this sort can be provided.

Owner:SHIN ETABU QUARTZ PRODS

Microcrystalline glass and preparation method thereof

The invention relates to a kind of microcrystalline glass and a preparation method thereof. The preparation raw materials include 10-90wt% of iron, vanadium and titanium-containing tailings, 5-50wt% of fluorite tailings, 1-50wt% of dolomite and 0-20wt% of soda ash. The preparation method of the microcrystalline glass comprises the following steps: uniformly mixing and fusing raw materials in proportion so as to obtain fused glass fluid; and shaping the fused glass fluid, then cooling the shaped glass fluid, and carrying out heat treatment on the obtained product so as to obtain the microcrystalline glass. The microcrystalline glass provided by the invention can be widely used for manufacturing high wear-resisting, acid and alkali erosion resistant and impact resistant products, and the performance of the microcrystalline glass is far higher than that of cast stone, thereby not only solving the pollution problem of tailings and manufacturing high-technical-content and high value-added products.

Owner:承德华富玻璃技术工程有限公司

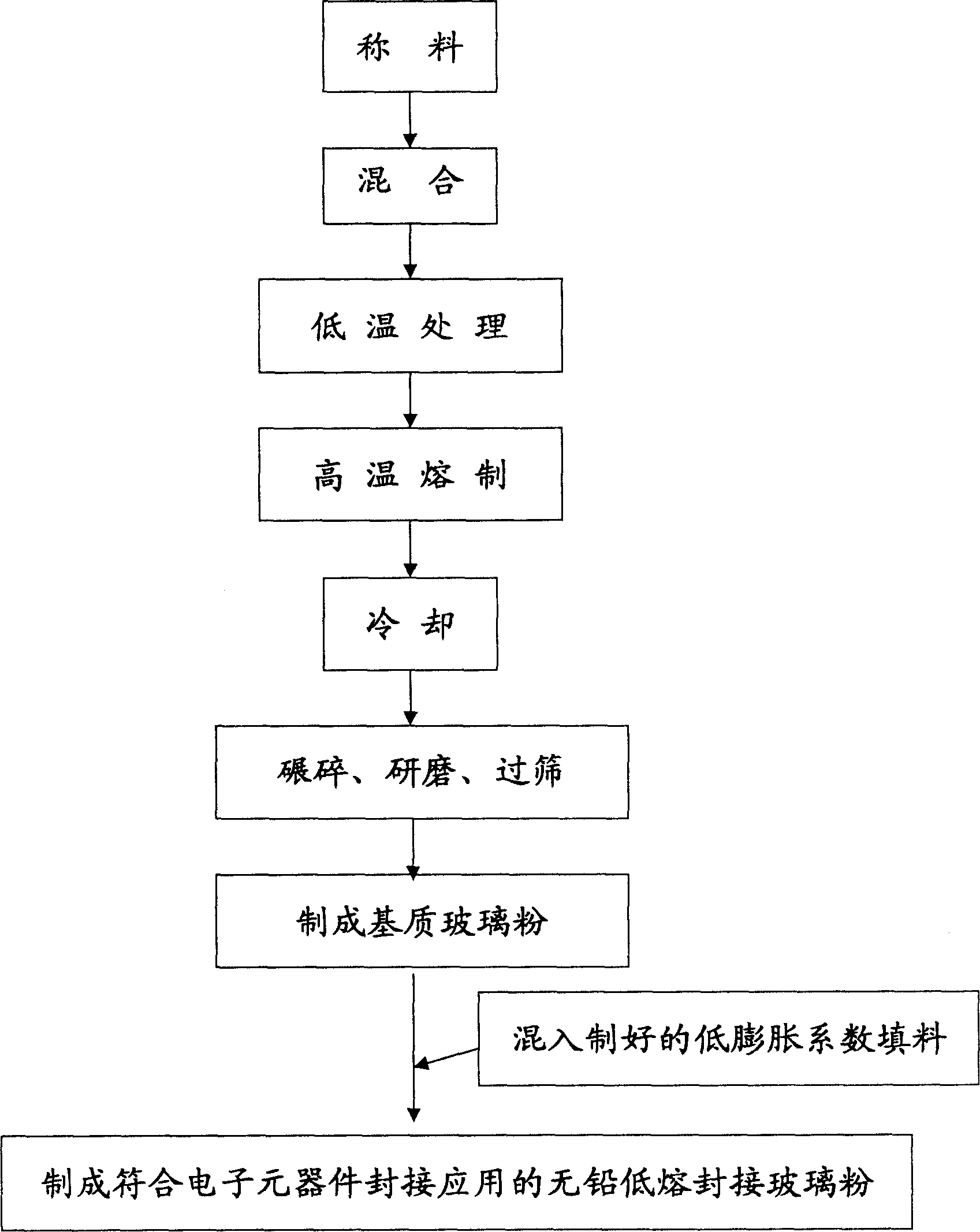

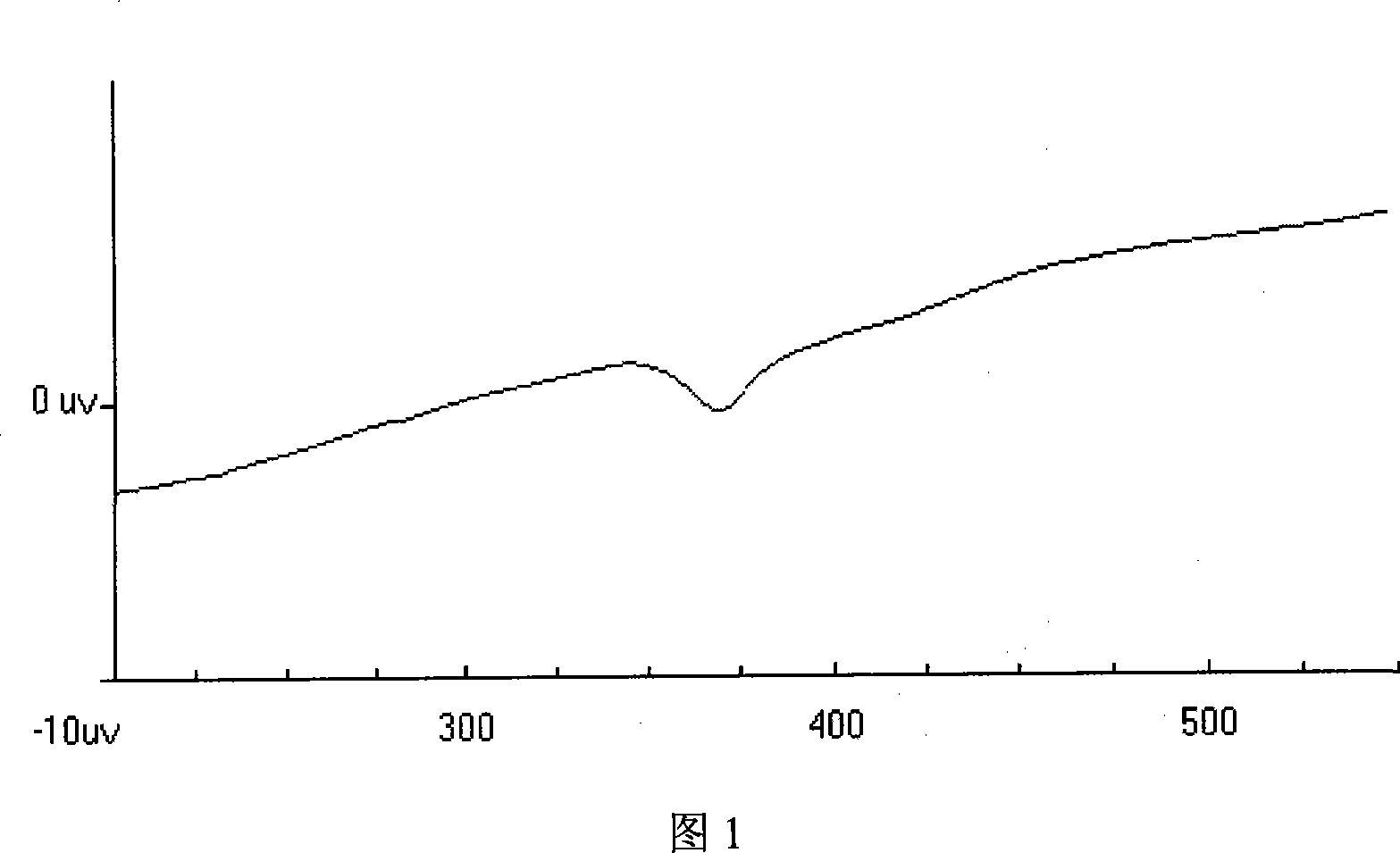

Rare earth elements doped sealing by fusing glass powder without lead, and manufacturing method

ActiveCN1915877ALower the sealing temperatureSmall expansion coefficientRare-earth elementFused glass

This invention relates to lead-free and low-melting-point sealing glass powder doped with rare earth oxides. The sealing glass powder is composed of base glass oxides (V2O5-P2O5-Sb2O3) and mixed rare earth oxides at a weight ratio of 100: (0.0013-10), preferential 100: (0.3-6.0). The mixed rare earth oxides are La2O3, CeO2, Y2O3 and Nd2O3 at a weight ratio of (0.001-5.0): (0.1-10.0): (0.001-8.0): (0.001-6.0). This invention adopts the modification technique by adopting rare earth oxides, thus can reduce the sealing temperature of the glass, save energy, raise productivity, improve chemical stability of the glass, and reduce expansion coefficient of the glass. The glass powder can be used for nontoxic and nonpollutive sealing of electronic elements.

Owner:CHINA BUILDING MATERIALS ACAD

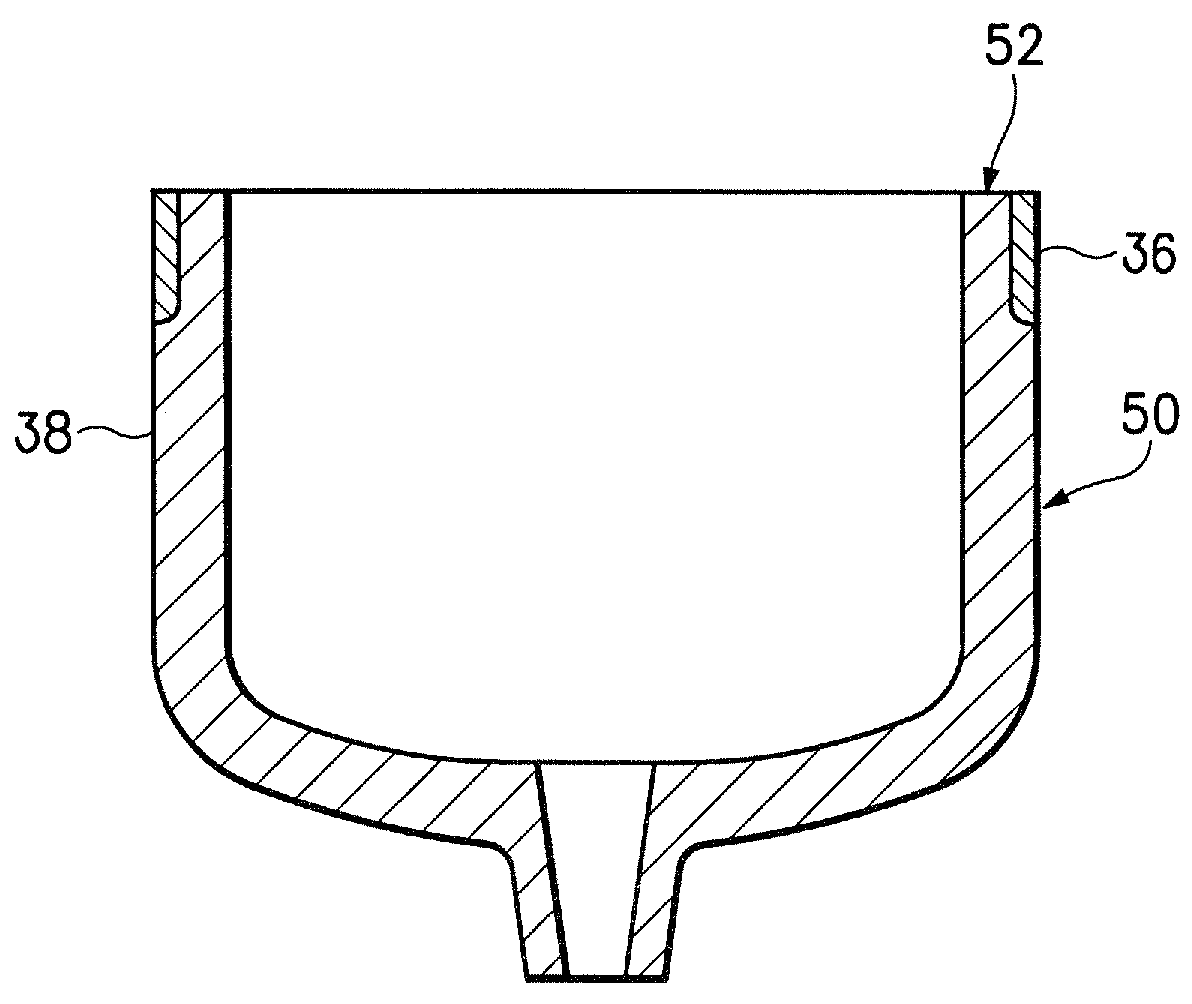

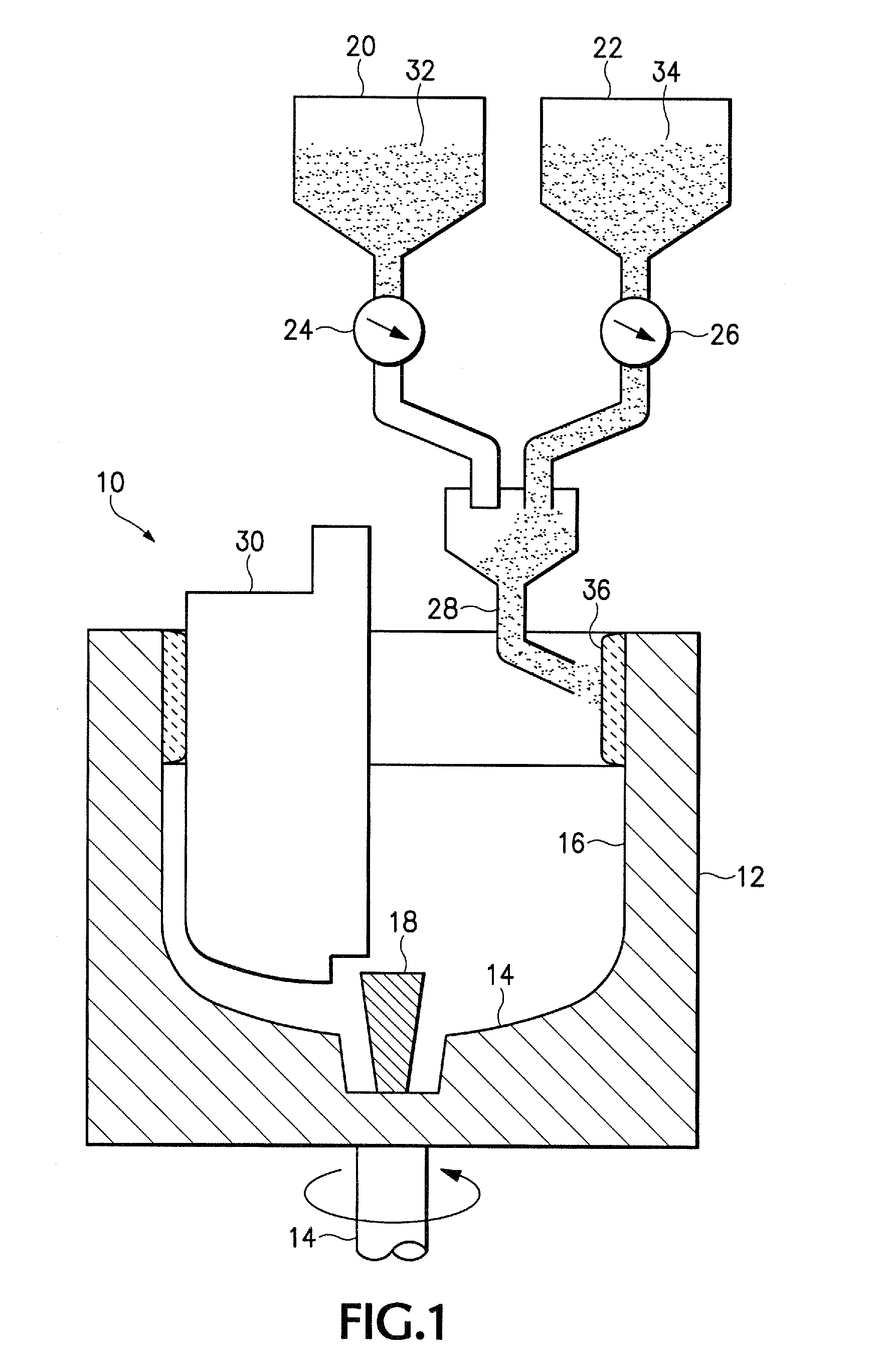

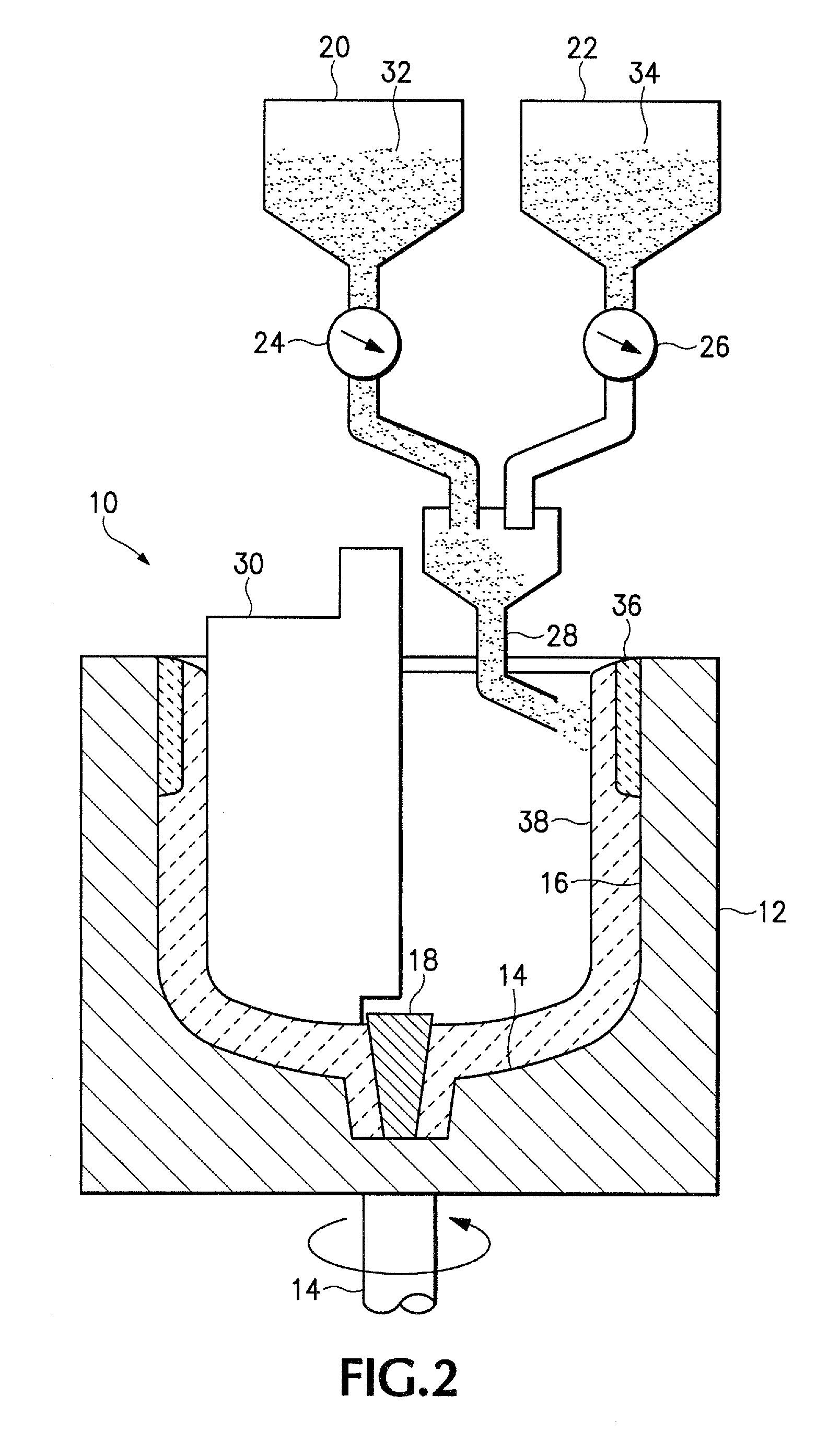

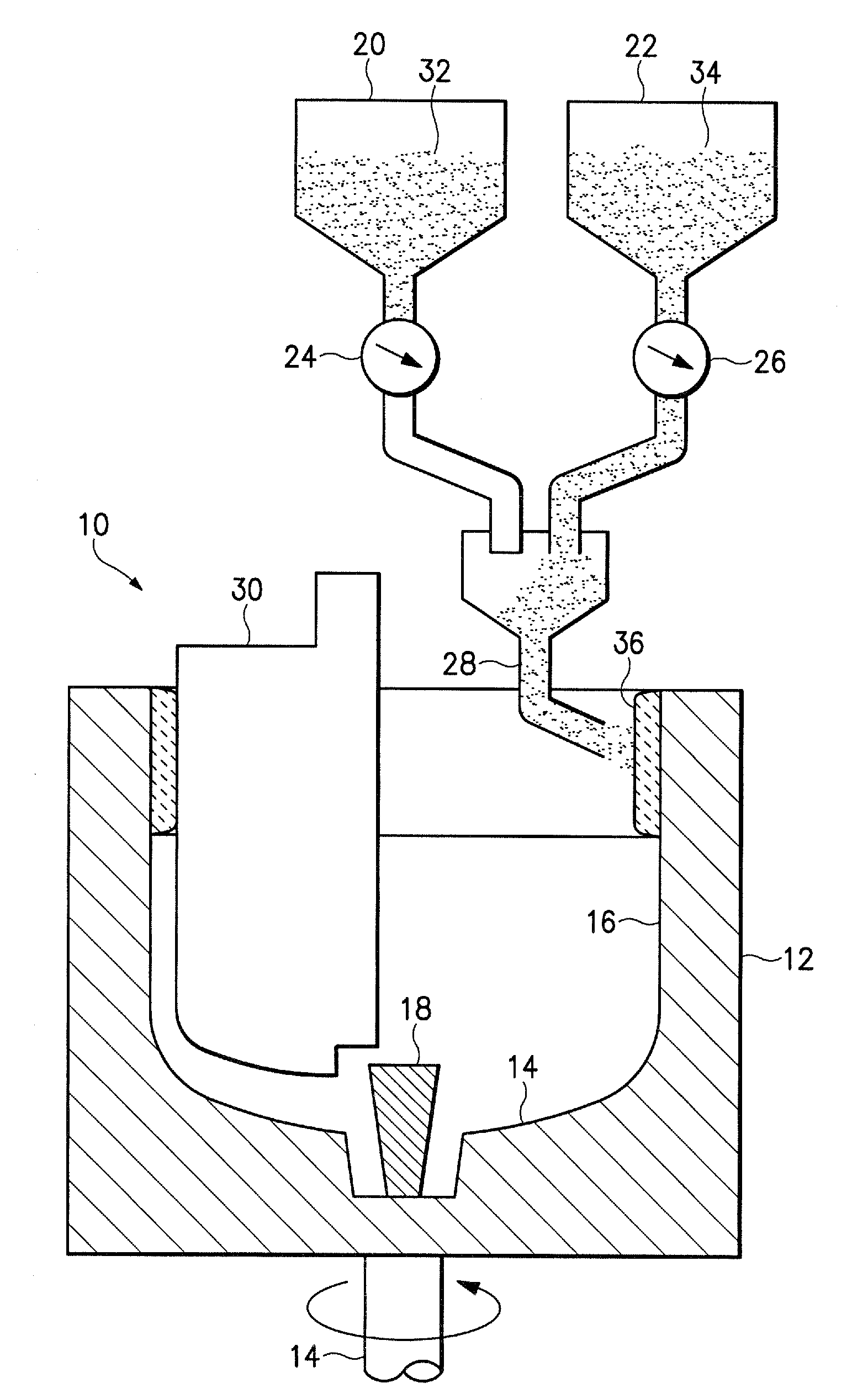

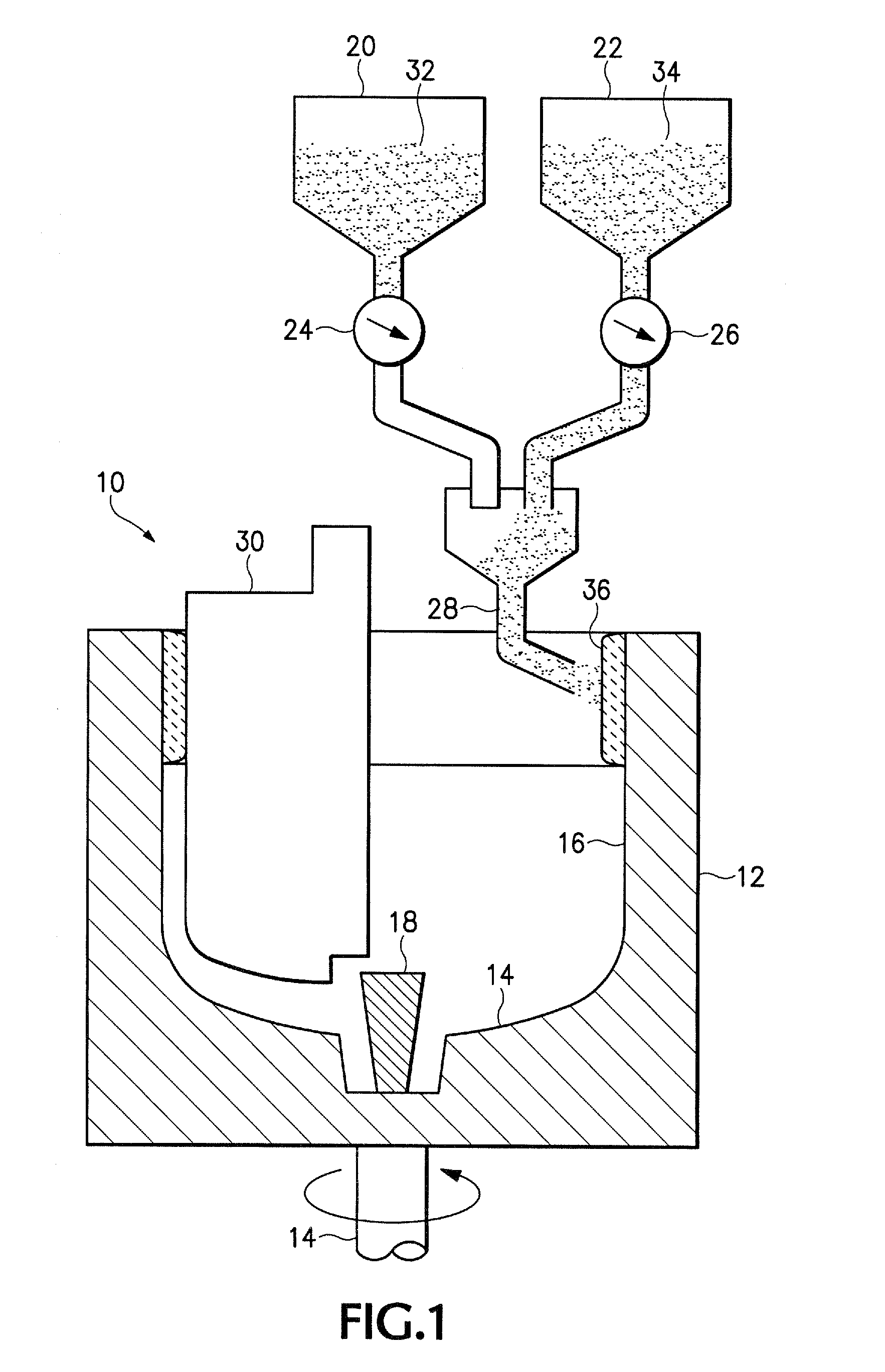

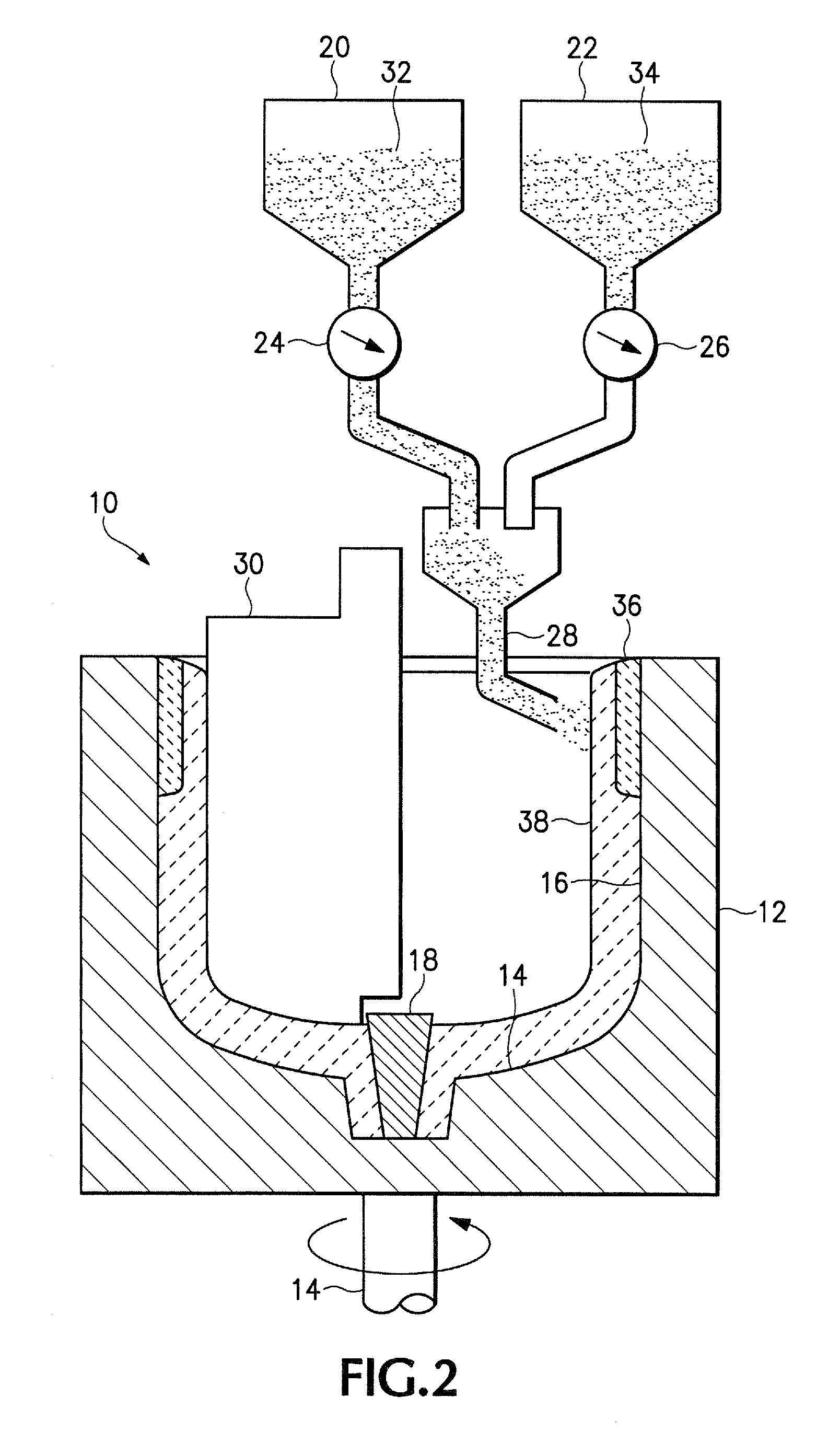

Crucible having a doped upper wall portion and method for making the same

ActiveUS20080141929A1Difficult to controlEasy to processAfter-treatment apparatusPolycrystalline material growthFused glassSilicon dioxide

A fused glass crucible includes a collar of doped aluminum silica that defines uppermost and outermost surfaces of the crucible. The melt line that defines the surface of molten silicon in the crucible may be substantially at the lower end of the collar or slightly above it. Crystallization of the collar makes it hard and therefore supports the remaining uncrystallized portion of the crucible above the melt line. The melt line may also be below the lower end of the collar, especially if the melt is drawn down or poured early in the process. Because there is little or no overlap or because the overlap does not last long, the doped aluminum collar is not damaged by the heat of from the melt.

Owner:SHIN ETABU QUARTZ PRODS

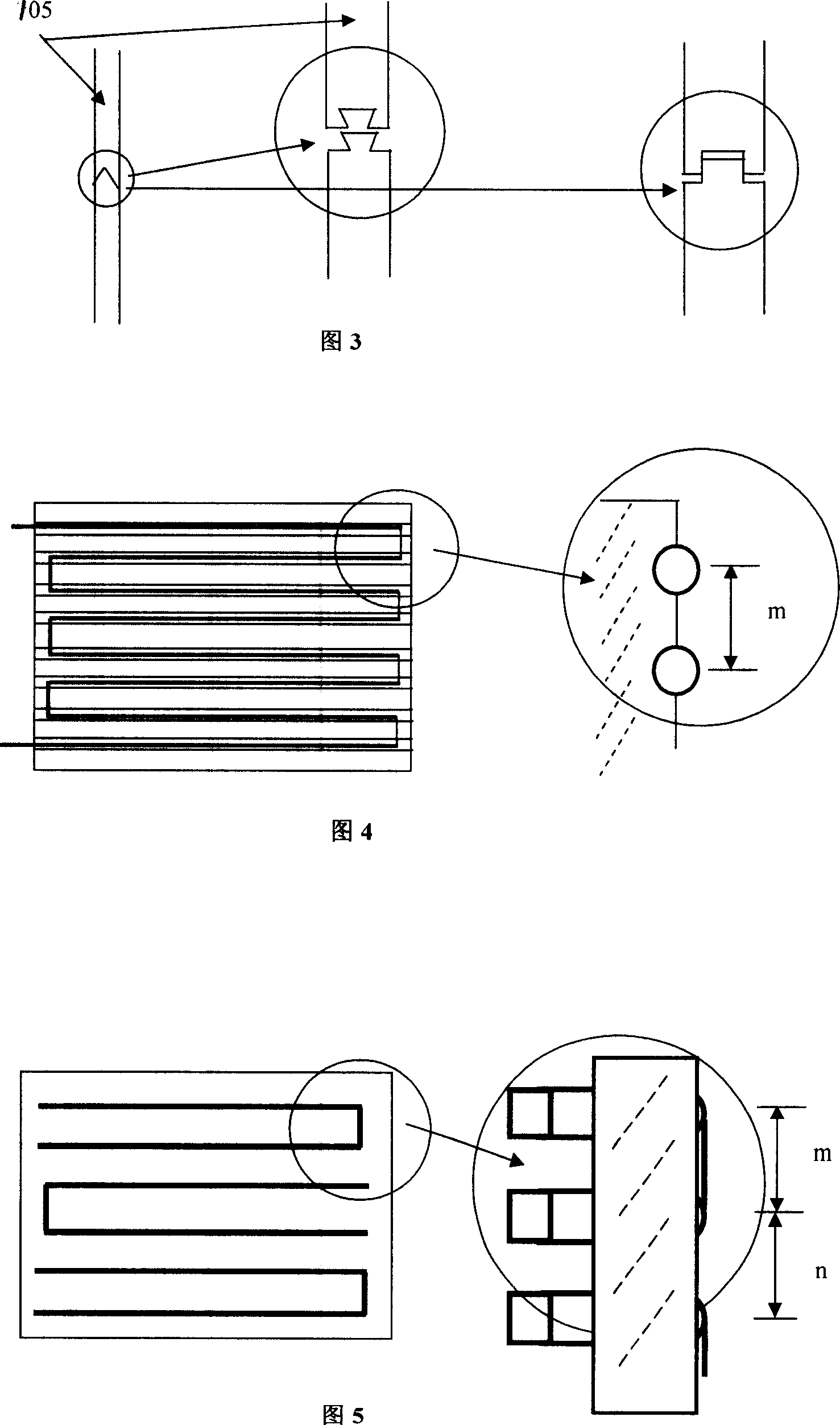

Temperature equality device and temperature equality method in glass forming

InactiveCN101012098AReduce thicknessReduce curvature changesGlass forming apparatusThermal energyDisplay device

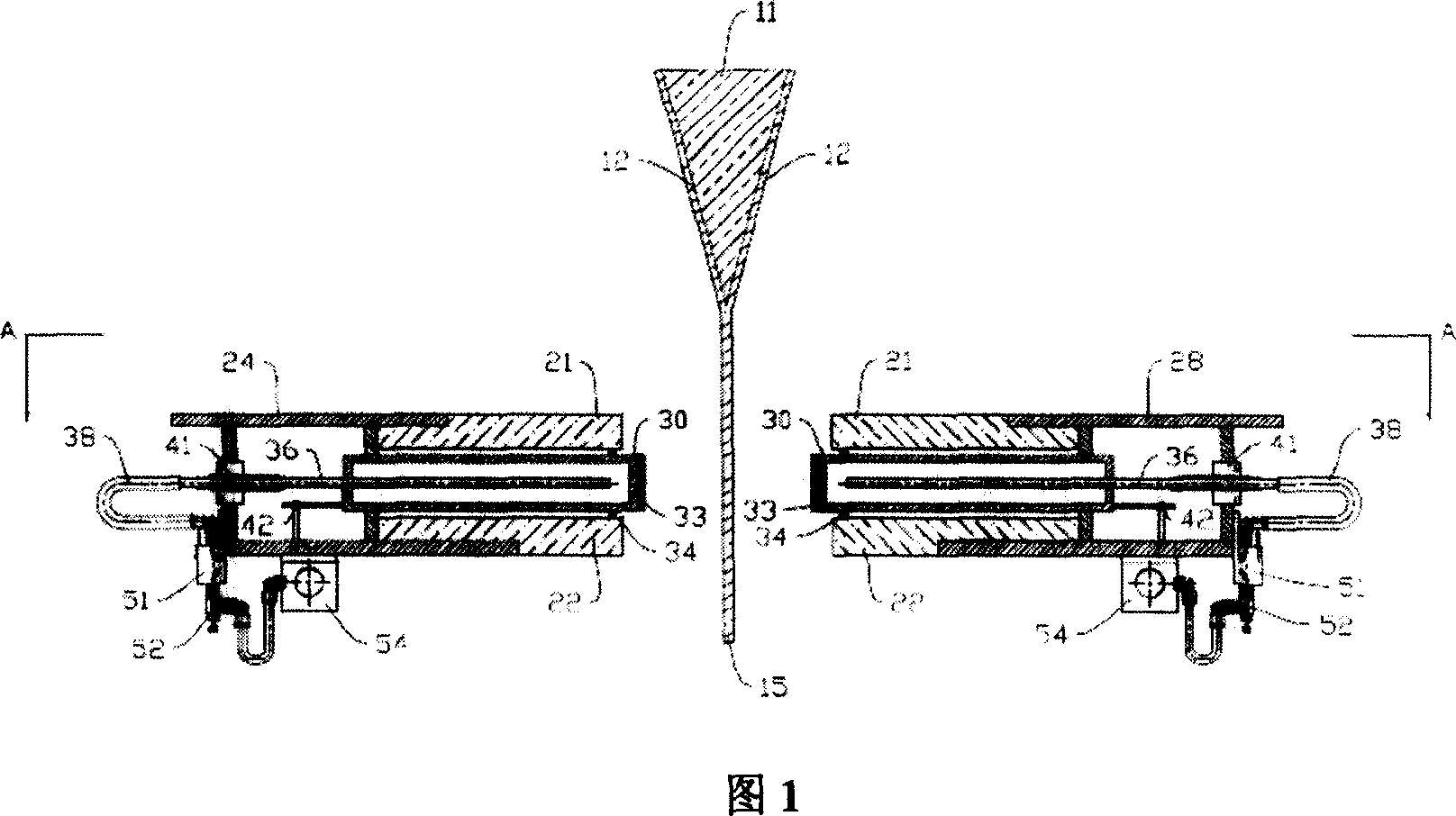

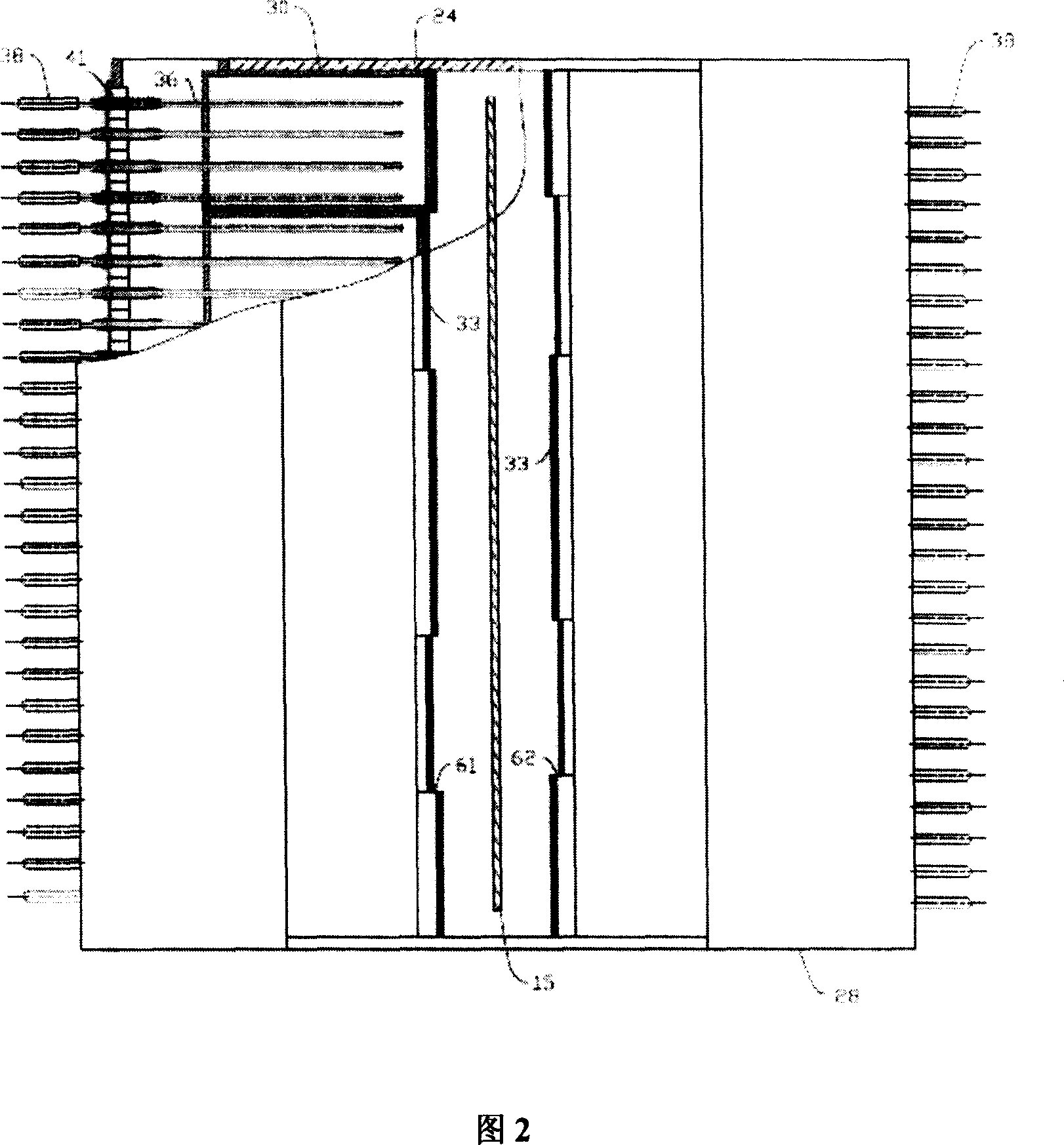

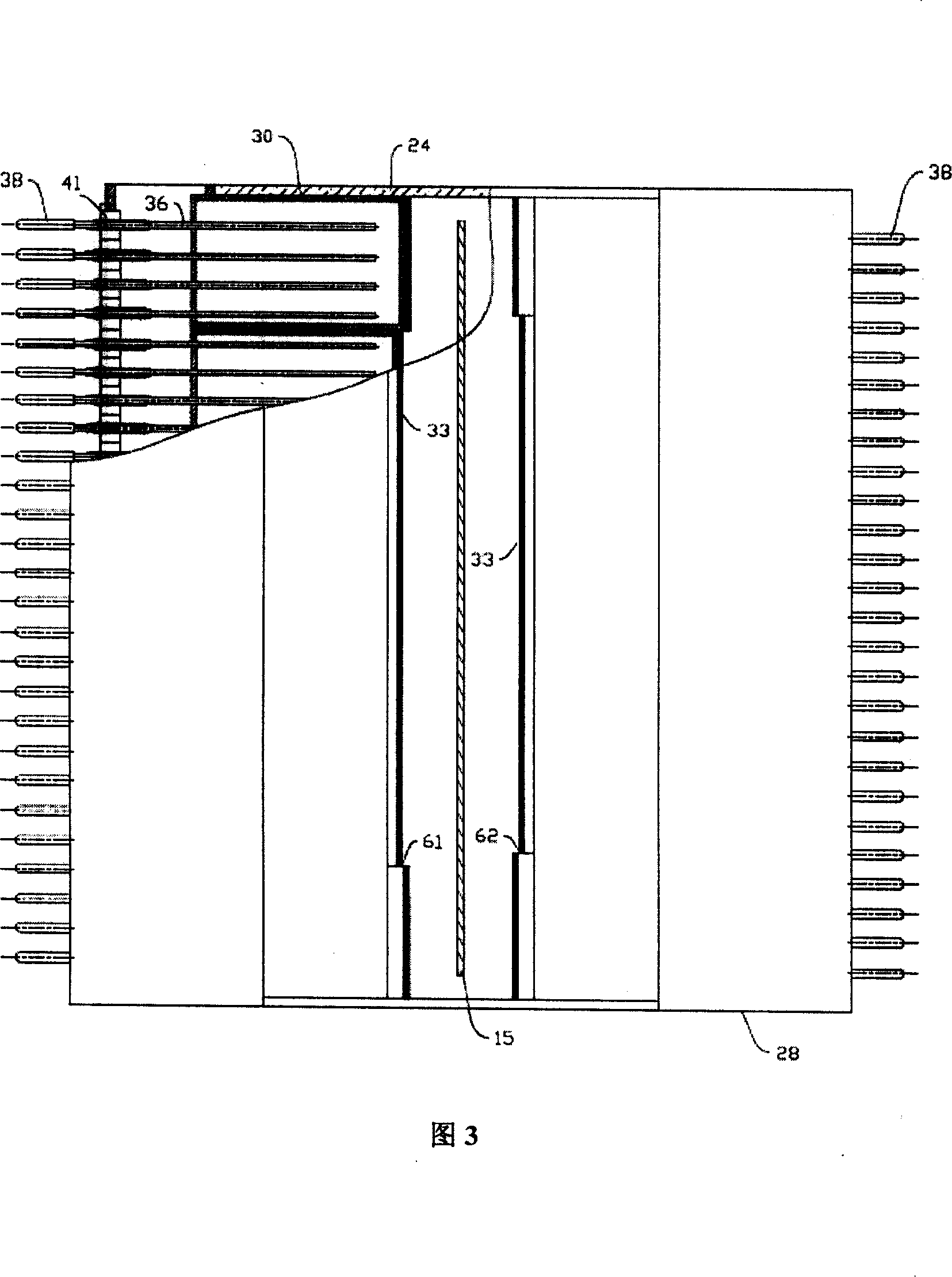

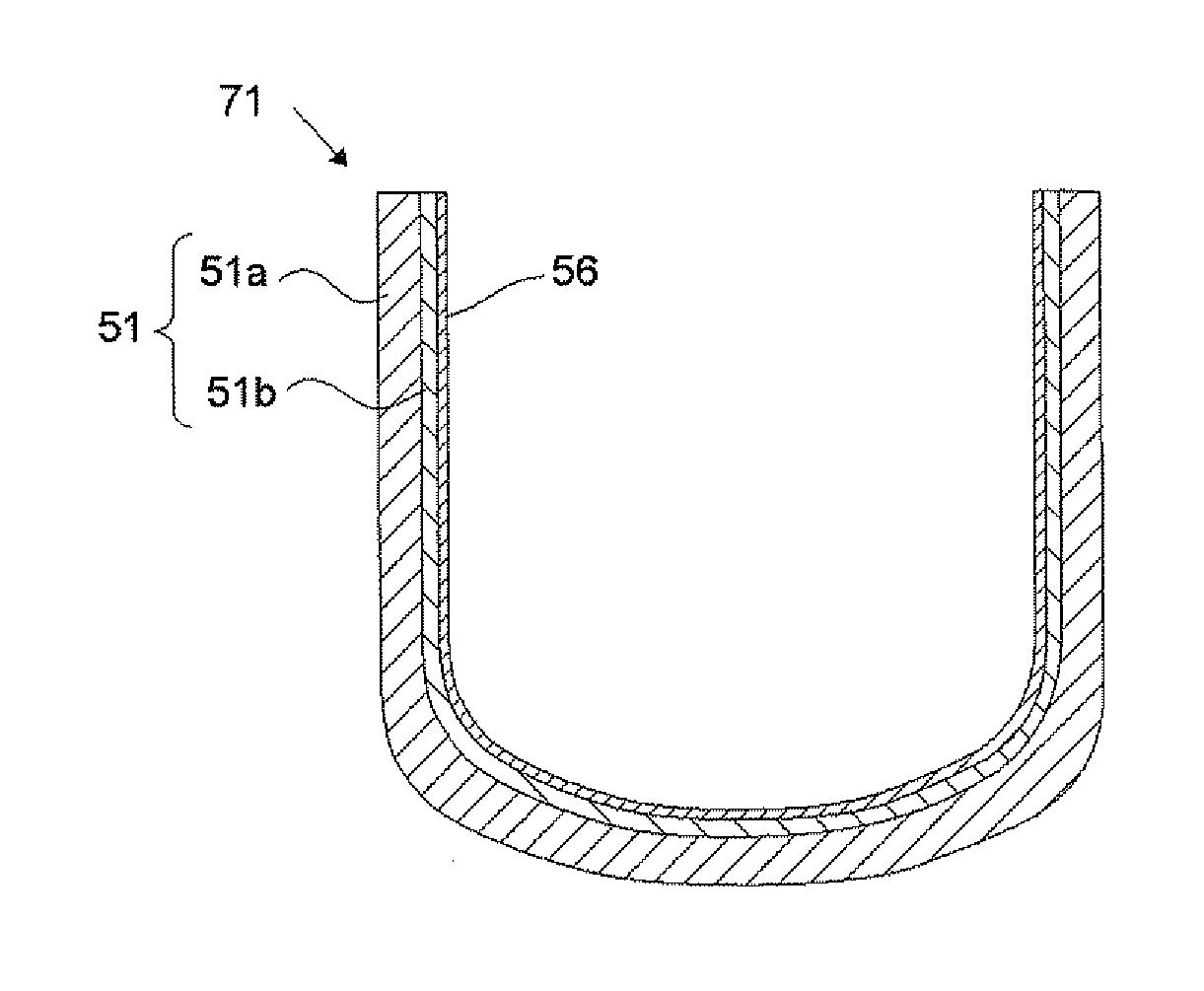

The invention discloses a temperature evening device and method in the glass moulding course, which comprises the following parts: moulding bulk to overflow fusing glass, heating moulding space with top heating element and lateral heating element, insulating part on the exterior of top heating element and lateral wall heating element, board-shaped temperature evening device on the periphery between overflow glass liquid moulding bulk and heating element, wherein the board-shaped temperature evening device gathers glass fusing heat to heat glass at face irradiation pattern, which makes glass flow obtain even temperature; the distance between board-shaped temperature evening device and fusing glass and relative position of back heating element are adjusted to control temperature of fusing glass temperature.

Owner:HENAN ANCAI HI-TECH +1

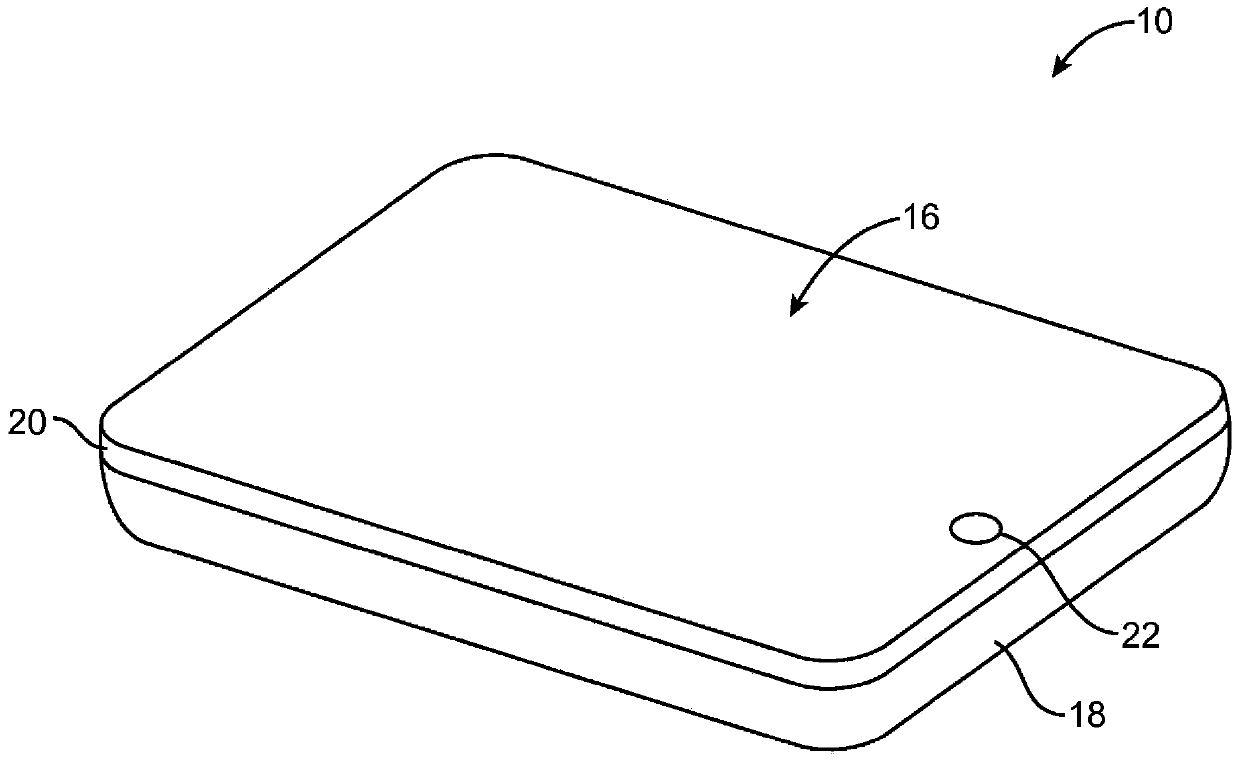

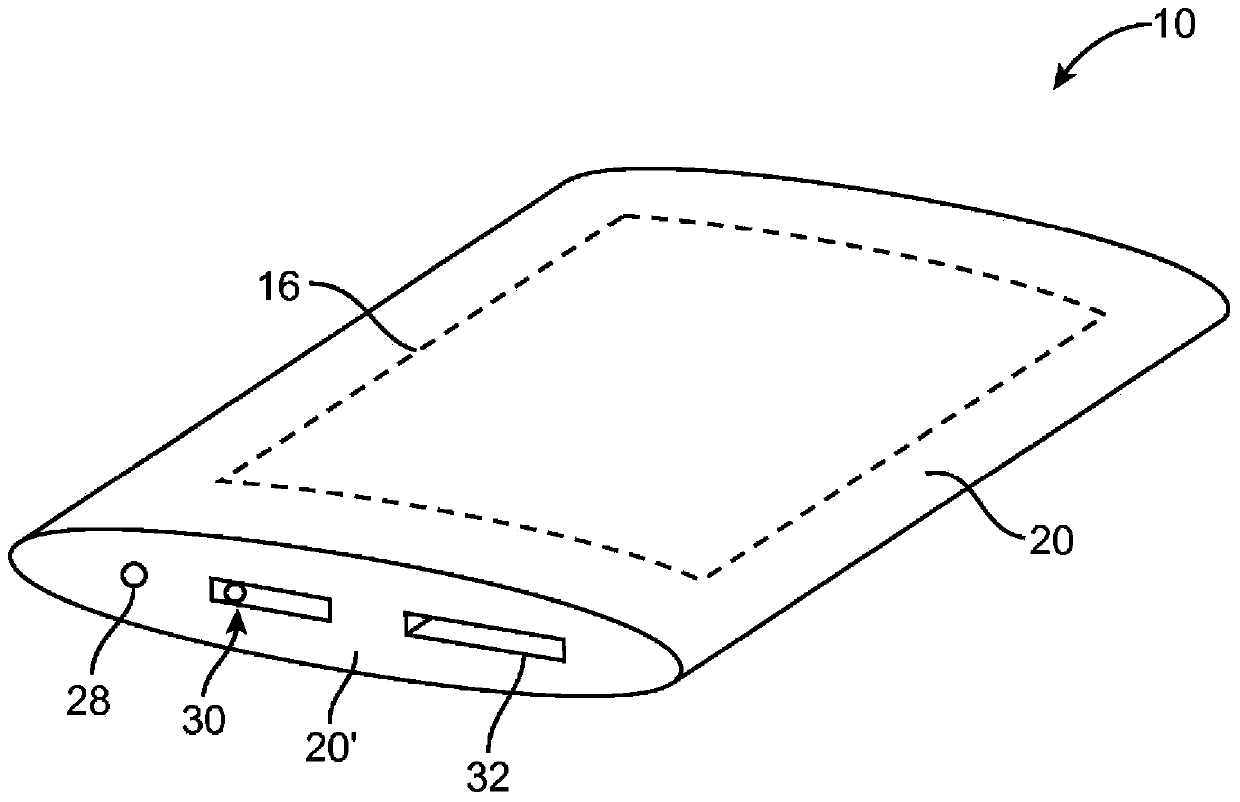

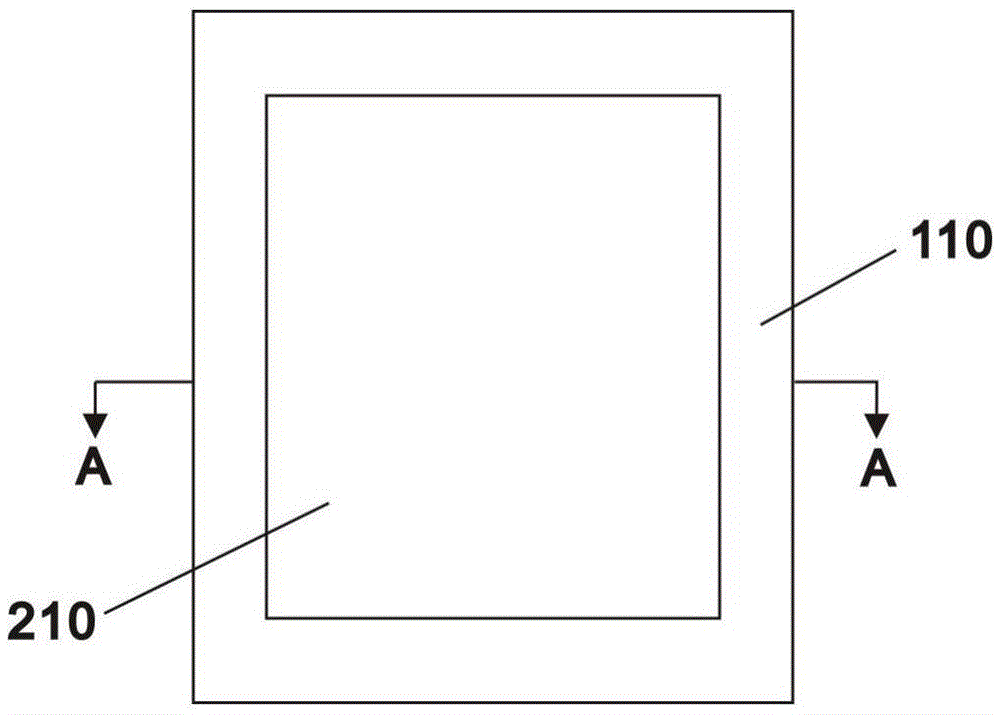

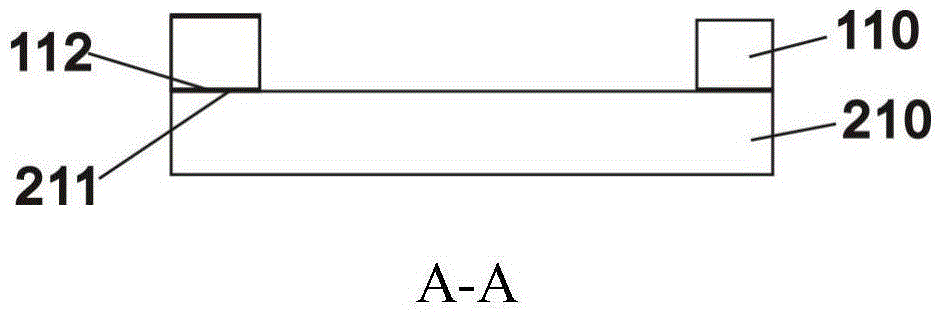

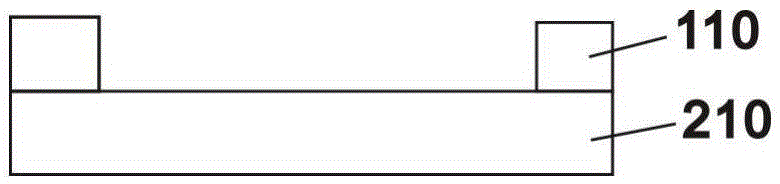

Fused glass device housings

An electronic device may have glass housing structures. The glass housing structures may be used to cover a display and other internal electronic device components. The glass housing structure may have multiple glass pieces that are joined using a glass fusing process. A peripheral glass member may be fused along the edge of a planar glass member to enhance the thickness of the edge. A rounded edge feature may be formed by machining the thickened edge. Raised fused glass features may surround openings in the planar glass member. Multiple planar glass members may be fused together to form a five-sided box in which electronic components may be mounted. Raised support structure ribs may be formed by fusing glass structures to a planar glass member. Opaque masking material and colored glass may be used to create portions of the glass housing structures that hide internal device components from view.

Owner:APPLE INC

Method of adhering sensor chips

The invention relates to a method of adhering sensor chips and in particular to a method of adhering sensor chips on metal membranes through a glass micro-fusion method. The method comprises the steps of: firstly preparing a metal pedestal and a sensor chip, wherein a sealing bottom used for forming a metal membrane is arranged on one end of the metal pedestal, and an end port is reserved on the other end of the metal pedestal, the sensor chip comprises a silicon chip, four foil gauges are integrated on the silicon chip, and the four foil gauges are connected to a Wheatstone bridge through metallization deposition; and then, processing the outer surface of the metal membrane to a rough surface; printing glass powder on the rough surface; putting the metal pedestal with the glass powder in a tubular furnace with temperature of 450-550 DEG C for heating, putting the sensor chip on the glass powder when the glass powder on the metal membrane is at a semi-fusion state, and continuing to heat to embed the sensor chip in the fused glass solution; and finally, stopping heating and naturally cooling the sensor chip.

Owner:无锡永阳电子科技有限公司

Rare earth doped gallium germanium bismuth lead luminous glass material and its preparation method and uses

InactiveCN1807310AWith integrationWith miniaturizationGlass furnace apparatusWaveguide lasersRare earth

The disclosed Ga-Ge-Bi-Pb fluorescent glass material doped with rare earth is prepared by: mixing and fusing the Ga2O3, Bi2O3, GeO2, lead-contained compound and rare earth compound to obtain the fused glass liquor; clearing and pouring the liquor into the mold to obtain the glass; putting the glass rapidly into a muffle furnace with temperature as the glass transformation temperature for heat preservation; finally, cooling to room temperature. This product can be manufactured into different shape, and has wide application as the gain medium.

Owner:SOUTH CHINA UNIV OF TECH

Incompletely-fused glass group and making method thereof

InactiveCN105565647AHave diversitySolve the flatnessGlass reforming apparatusFracture zoneFused glass

The invention provides an incompletely-fused glass group and a making method thereof. The incompletely-fused glass group comprises at least two pieces of glass, wherein the surface smoothness of the glass is less than 10 nanometers; the at least two pieces of glass are jointed together; a fused fracture zone is formed between every two pieces of glass. The making method comprises the following steps: cleaning the surfaces of the two pieces of glass; making the surfaces of the two pieces of the glass come into contact with each other; applying force to the glass group to make contact parts form Van der Waals force joint; heating the glass group in a backing way at the temperature of 240-600 DEG C for 0.5-48 hours; watching the glass group state of the fused fracture zone, namely, the incompletely-fused glass group, under a microscope. In the incompletely-fused glass group, no jointing medium is used, so that the diversity of glass can be met, and the machining quality of the glass is ensured.

Owner:XIAMEN BOENSI APPL MATERIAL SCI & TECH

Vitrification reagent for preparing glass melt piece for X fluorescence analysis and use method thereof

ActiveCN101509847AShorten the analysis cycleQuick analysisMaterial analysis using wave/particle radiationPreparing sample for investigationPlatinumVitrification

The invention provides a glass reagent for preparing glass fuse pieces used for metallurgical flux X-ray fluorescence analysis, consisting of anhydrous lithium tetraborate or mixture of anhydrous lithium tetraborate and lithium metaborate, and boric acid. A method for preparing the glass fuse pieces includes: firstly adding the anhydrous lithium tetraborate or the mixture of anhydrous lithium tetraborate and lithium metaborate in the metallurgical flux, then fusing at a high temperature for 12-15mins in a platinum yellow pot, preparing the glass fuse pieces after cooling; or fully mixing the boric acid with the anhydrous lithium tetraborate or the mixture of the anhydrous lithium tetraborate and lithium metaborate in advance, preparing the fast fused glass reagent and then mixing with the metallurgical flux, then fusing at the high temperature for 12-15mins in the platinum yellow pot, and preparing the glass fuse pieces after cooling. The glass reagent has accurate and stable analysis results, and greatly shortens the analysis period of the metallurgical fusing agent.

Owner:MAANSHAN IRON & STEEL CO LTD

Biological activity glass ceramics capable of cutting and its preparation method

The invention relates to silicate material field used in repair and substitution for bone and tooth. Wherein, mixing materials with weight share in alumina ball mill tank; putting into alumina crucible, hot smelting in silicomolybdic bar furnace; pouring fused glass into water for quenching, drying and smashing; remelting the glass powder to cast in graphite mould at 500-700Deg for one hour; cooling to room temperature and obtaining even glass parent body; heating to 800-110Deg for 4-24h to separate controlled glass ceramic contained fluorine bronze mica and fluorapatite. The product has bending strength and elastic modulus fit to mechanical property of bone and teeth of human body, and can generate strong chemical bond with human bone group. This invention is simple and convenient to operate.

Owner:CENT SOUTH UNIV

Preparation of oriented alloy material by original position deep supercooling process

A in-situ deep overcold process for preparing the oriented alloy material includes such steps as using HF induction heater and the combination of fused glass protection with cyclic overheat to make the Ni-Fe-Ga, Co-Ni-Ga, or Fe-Ga alloy in overcold state, heating the alloy to the soft point of quartz tube, and flowing the alloy from the first quartz tube to the second one whose bottom is in contact with molten Ga-In alloy.

Owner:SHANGHAI JIAO TONG UNIV

Glass substrate and a manufacturing method thereof

The present invention provides a glass substrate which enables to manufacture a FPD in keeping cost low and in efficient, and to provide an efficient manufacturing method of a glass substrate. The method for manufacturing a glass substrate by fusion process comprising the following steps; flowing fused glass into a fusion pipe, and gradually cooling and solidifying the fused glass by flowing downward from the fusion pipe, wherein forming an asperity on a surface of the glass substrate by fastening and pressing the glass toward a direction of thickness of the glass with a pair of transfer rollers during the glass is flowing down from the fusion pipe.

Owner:NIKON CORP

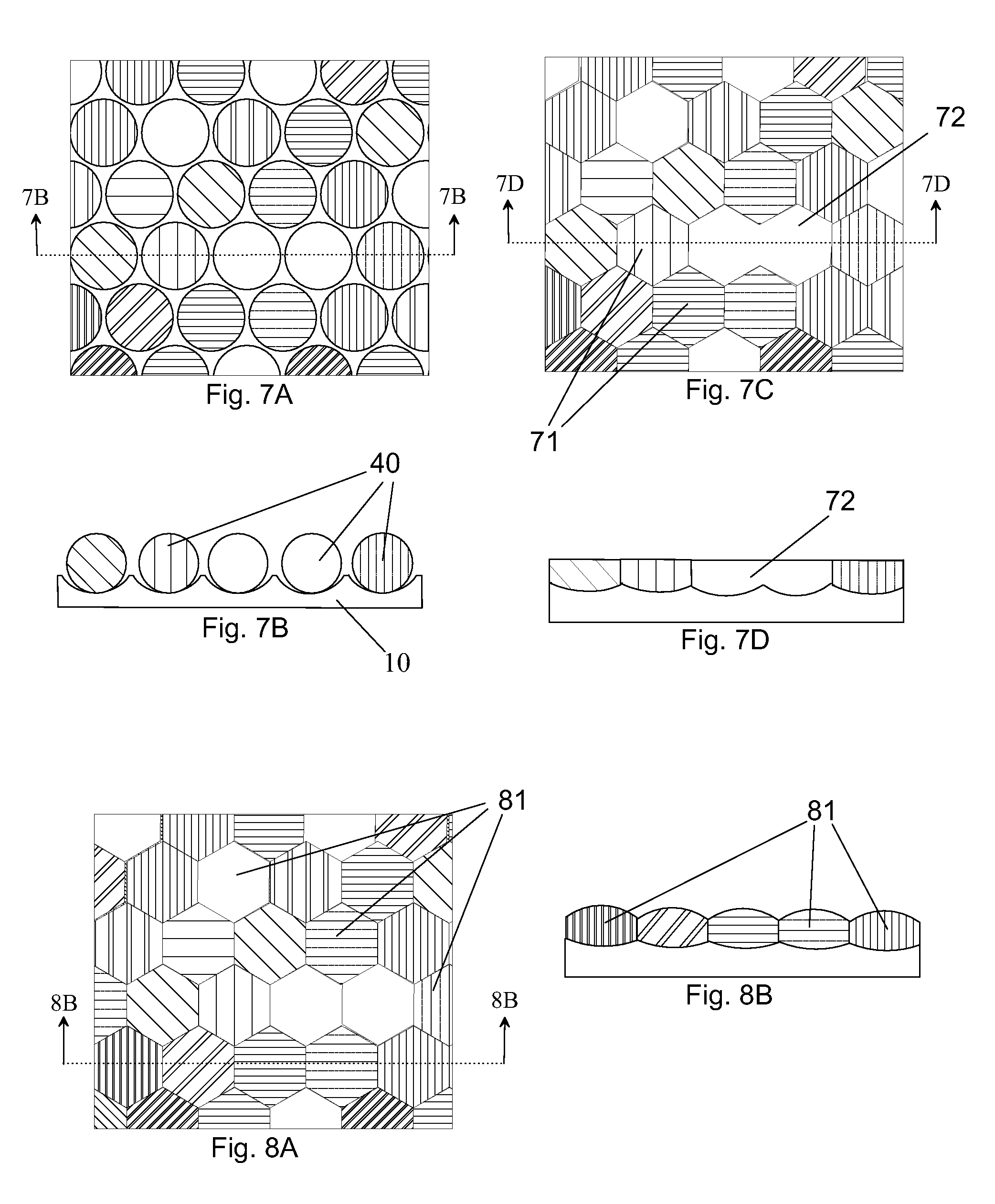

Preforms for Creating Decorative Fused Glass

InactiveUS20080115534A1Easy to createPredictable resultOrnamental structuresSpecial ornamental structuresFused glassEngineering

Coordinated preforms made of COE (coefficient of expansion) compatible glass are shaped for making predictable decorative patterns in fused glass. When color design preforms 40, 50, 60 are positioned using the indentations 11, 31 in base sheet preforms 10, 20, 30 they will deform into predictable mosaic patterns when the arrangement is fused together.

Owner:KERNAN MELVIN CRAIG

Glass fiber cotton felt used for sound insulation and heat insulation, and manufacturing method thereof

InactiveCN106868706AQuality improvementImprove uniformityGlass making apparatusNon-woven fabricsSound transmission classGlass fiber

Provided is a glass fiber cotton felt used for sound insulation and heat insulation. The glass fiber cotton felt used for sound insulation and heat insulation is characterized in that the glass fiber cotton felt is made by the following method: fusing glass blocks to clear glass melt through a kiln, through primary drawing and flame injection, obtaining glass wool, through spraying an adhesive, the glass wool bonding to form a felt, and finally curing through a curing oven. Average fiber diameter of the glass fiber cotton felt is 0.5-3.5 [mu]m, volume-weight is 6.5-20.5 kg / m<3>, gum content is 1-25%, 1000 Hz sound transmission loss is 5.2-11.4 dB, heat conductivity coefficient is 0.020-0.045 W / (m.K), and air permeability is 250-715 mm / s. The invention also discloses a manufacturing method for the glass fiber cotton felt used for sound insulation and heat insulation. The method comprises the following steps: (1) feeding in materials; (2) performing primary drawing; (3) performing secondary drawing; (3) collecting cotton and spraying adhesive; (5) curing and drying; (6) trimming and rolling cotton. Beneficial effects of the glass fiber cotton felt are that 1, the sound insulation and heat insulation performance are excellent; 2, quality is stable and cotton felt uniformity is good; 3, the cotton felt is light and high in strength.

Owner:宿迁空天新材料有限公司

Anodizing-assisted low-temperature glass brazing method

The invention discloses an anodizing-assisted low-temperature glass brazing method which aims at mainly solving the problem that in the process of using low-temperature glass brazing for brazing, spreading wetting is insufficient due to poor chemical compatibility of the brazing and base metal or low brazing temperatures and large fused glass brazing viscosity. The brazing method comprises the steps that firstly, low-temperature sealing ground glass is put into a mold to be smelted into a block, and a low-temperature glass block is obtained; secondly, the low-temperature sealing glass block is cut into slices, and base metal to be brazed is cut and molded; thirdly, a brazing piece is subjected to ultrasonic cleaning and grinding; fourthly, the brazing piece is subjected to anodizing and hole sealing treatment; fifthly, the slice-shaped low-temperature glass brazing is put at the to-be-connected position of the brazing piece; and sixthly, heating is conducted for melting brazing paste, heat preservation is carried out, and then the brazing piece is cooled along with a furnace. The slice-shaped low-temperature glass used in the method is low in sealing temperature and small in coefficient of linear expansion, an obtained brazing connector is free of macroscopic defects such as cracks and air holes and high in strength, and meanwhile an oxidation film formed through anodizing has a good protection effect on the base metal.

Owner:HARBIN INST OF TECH

Deep super-cooling method for preparing big bulk homogeneous difficult mixed dissolve Ni-Pb alloy

A process for preparing large-volume homogeneous Ni-Pb alloy difficult to mix and dissolve mutually by deep over-cold method features that the HF induction heater is used, and the fused glass cleaning and cyclic over-heat are combined to obtain deep over-cold which is equal to or higher than 250 deg.C. Its advantages are easy control, no need of vacuum environment, and less fire and loss of Pb.

Owner:SHANGHAI JIAO TONG UNIV

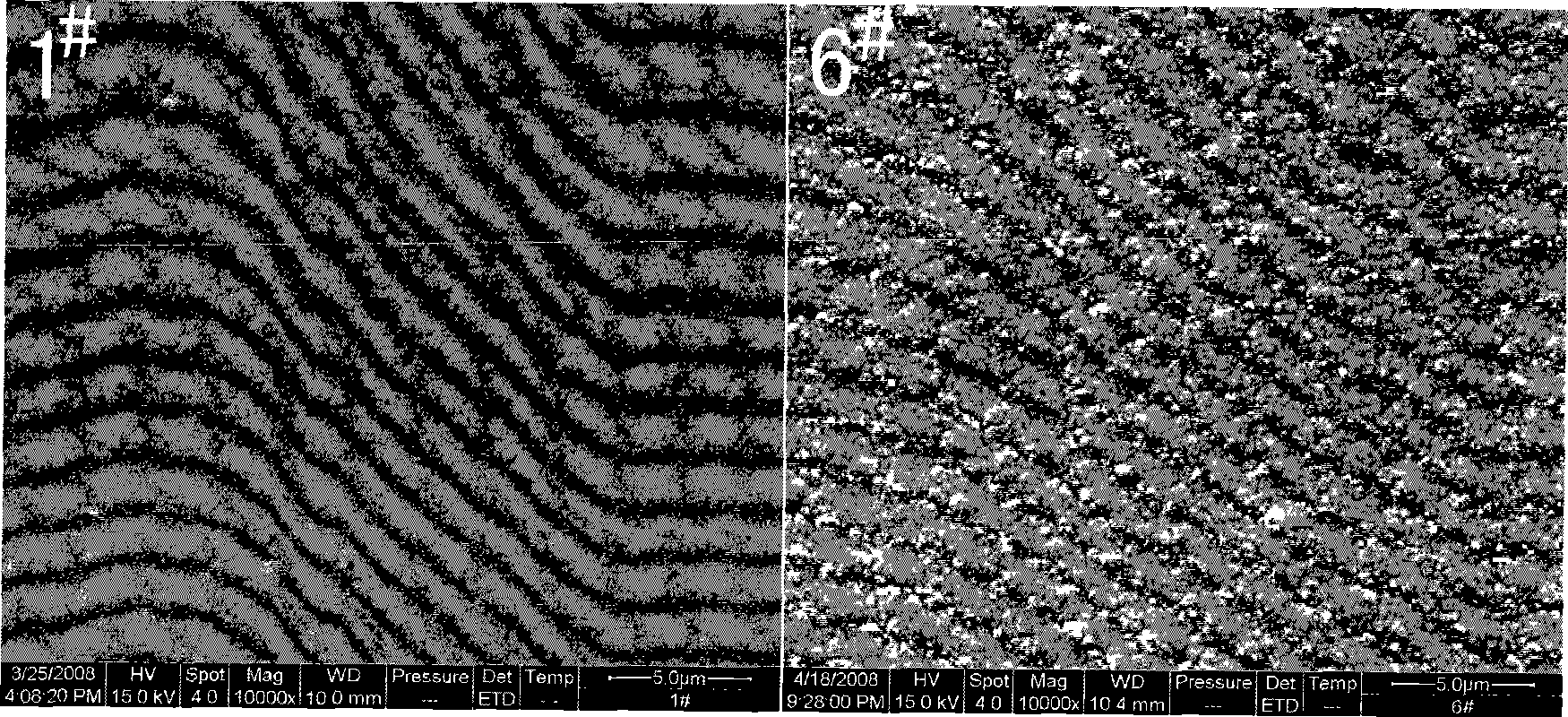

Ni-W-nano CeF3 composite coating for glass mould surface, electroplating method and electroplating solution

InactiveCN101462819ACompact structureIncreased microhardnessElectrolytic coatingsGlass pressing apparatusTungstateFrictional coefficient

The invention provides a Ni-W-nanometer CeF3 composite plating used on the surface of a glass die. The composite plate has a Ni-W basal body interlarded with nanometer CeF3 micro-particles. The invention also provides a method for electroplating the Ni-W-nanometer CeF3 composite plating onto the surface of the glass dire and the electrolyte thereof. Na tungstates and Ni sulphamates are taken as the main salts of the electrolyte; nanometer CeF3 powder is added to form the bath; and the Ni-W-nanometer CeF3 composite plating is obtained through controlling the content of the Na tungstates, the Ni sulphamates and the CeF3, the variety and content of codeposition promoters, the pH value and the current density, and stirring the bath. The composite plating has a simple process, little pollution, safety, low overall cost, high plating hardness, corrosion resistance, wear resistance and high temperature resistance, and good self lubrication performance. When the Ni-W-nanometer CeF3 composite plating is ground with fused glass, the Ni-W-nanometer CeF3 composite plating has a lower frictional coefficient, thereby bringing about good demoldability of the die.

Owner:TSINGHUA UNIV

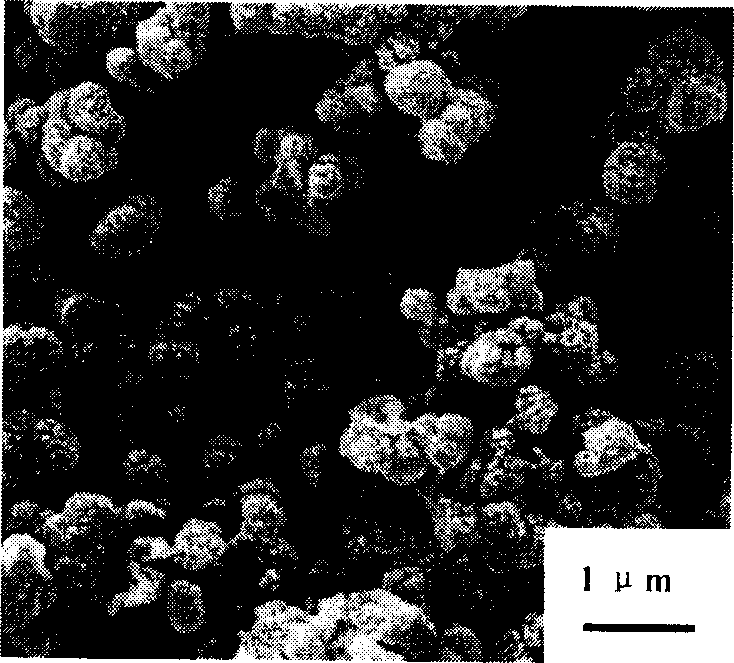

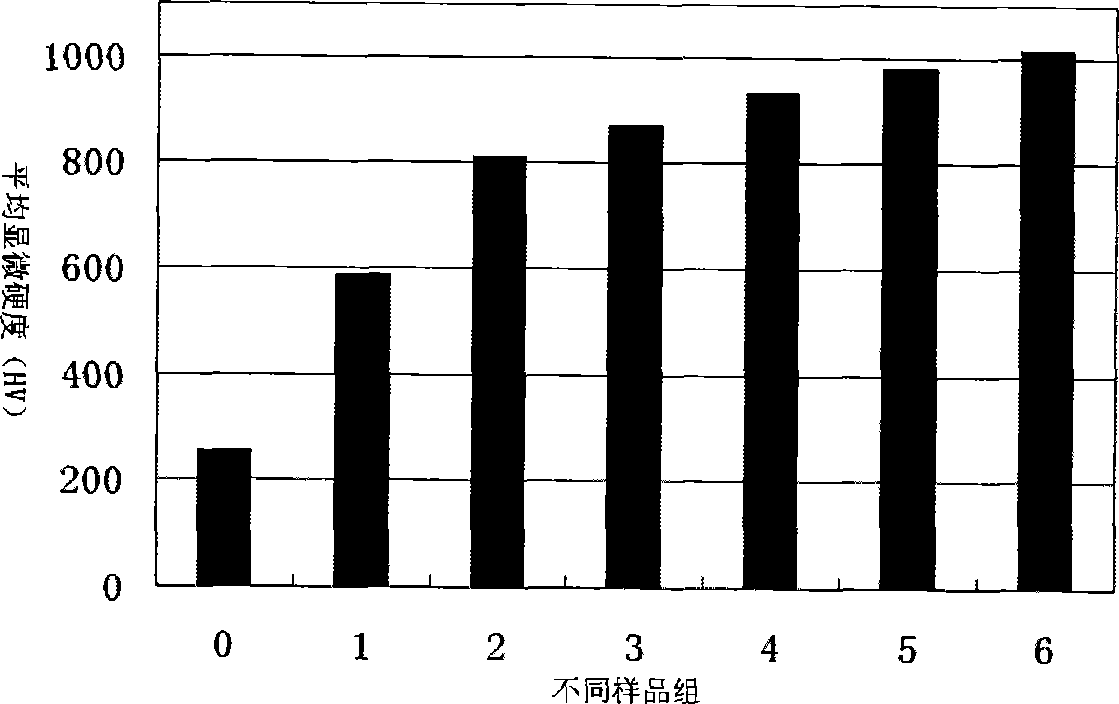

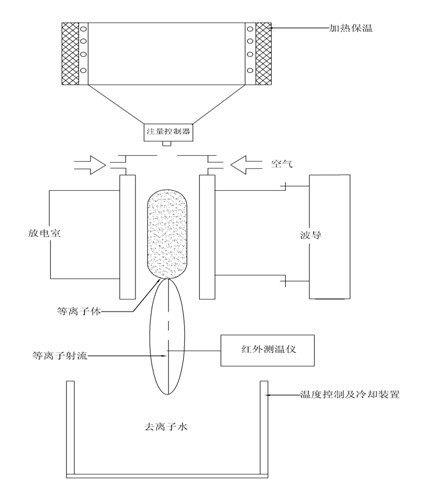

Process method for preparing ltcc amorphous glass porcelain powder with microwave plasma torch

The invention discloses a technological method for preparing LTCC amorphous glass ceramic powder with a microwave plasma torch. The technological method comprises the following steps: mixing raw materials of glass, ball milling, drying, and granulating into particles with diameters of 1-3mm, and sintering into ceramic balls at 650-850DEG C; and rapidly fusing the hot ceramic balls into glass droplets through the microwave plasma torch with the temperature of 3000-5000DEG C, falling into deionized water, chilling to obtain an amorphous glass ceramic material with the particle size of 15-500mum, carrying out wet ball milling, and drying to a product the LTCC amorphous glass ceramic powder. According to the invention, methods for fusing glass with platinum and ceramic crucibles in traditional technologies are abandoned, and the glass droplets are in a suspending state in the process of fusing with the microwave plasma torch and do not contact with any vessels, so the technological methodof the invention which has the advantages of guarantee of the glass purity, convenient operation, uniform glass chilling, obvious effect better than the traditional technologies, good product consistency, and good economy is in favor of the large scale production.

Owner:YUNNAN INFINE NEO MATERIAL

Production process of colorfully-painted and back-engraved crystal glass

InactiveCN103253057AGuaranteed persistenceLong storage timeDecorative surface effectsGlass shaping apparatusEngravingFused glass

The invention provides a production process of colorfully-painted and back-engraved crystal glass. The production process is realized by sequential steps of prefabricating a colorfully-painted pattern mould, mixing and agitating, drying material powder, granulating, heating and fusing, dropping materials into the mould, cooling and de-molding, annealing, carrying out cold machining and the like. According to the production process, a laser precision engraving machine is used for engraving patterns on a metal mould; then fused glass liquid is processed by the process of dropping the materials into the mould, cooling and de-molding, and annealing to obtain a semi-finished product; and then, the cold machining is carried out and manners of back engraving, circular engraving, floating engraving and the like are utilized to machine back loss of a product and fuzzy pattern details in a previous production process to enable to the patterns to be vivid. When paint is used for gradually coloring the product layer by layer, an outer layer needs to be colored under the precondition that the inner layer is completely dried. After the coloring is finished, the product is dried to guarantee the durability of colorfully-painted colors. Compared with an existing product, the product prepared by the production process disclosed by the invention has the characteristics of long preservation time, bright pattern colors and capability of vividly presenting three-dimensional patterns.

Owner:ARIAMOTION DALIAN

Crucible having a doped upper wall portion and method for making the same

ActiveUS7716948B2Difficult to controlEasy to processBy pulling from meltCeramic shaping apparatusFused glassSilicon dioxide

A fused glass crucible includes a collar of doped aluminum silica that defines uppermost and outermost surfaces of the crucible. The melt line that defines the surface of molten silicon in the crucible may be substantially at the lower end of the collar or slightly above it. Crystallization of the collar makes it hard and therefore supports the remaining uncrystallized portion of the crucible above the melt line. The melt line may also be below the lower end of the collar, especially if the melt is drawn down or poured early in the process. Because there is little or no overlap or because the overlap does not last long, the doped aluminum collar is not damaged by the heat of from the melt.

Owner:SHIN ETABU QUARTZ PRODS

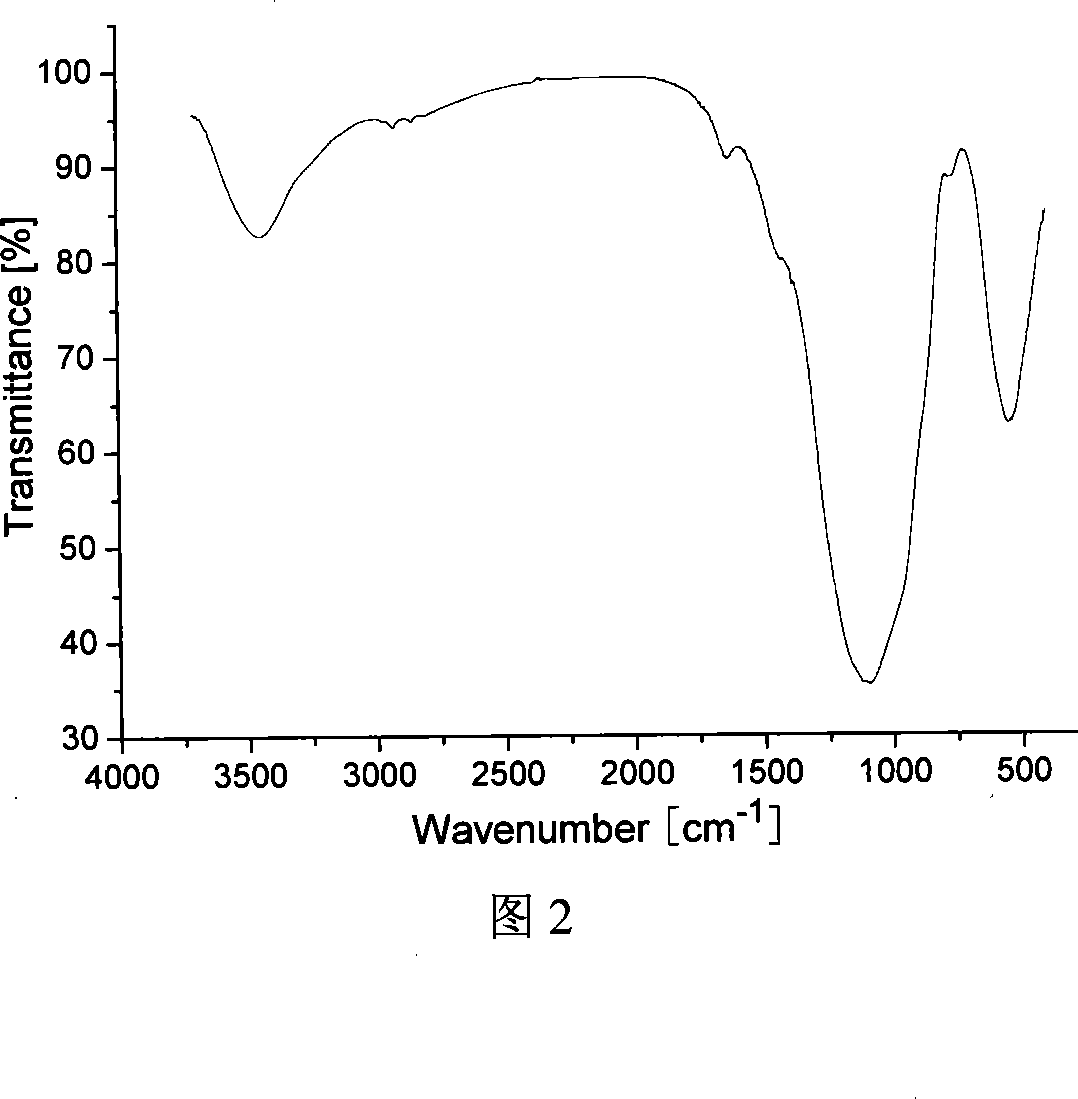

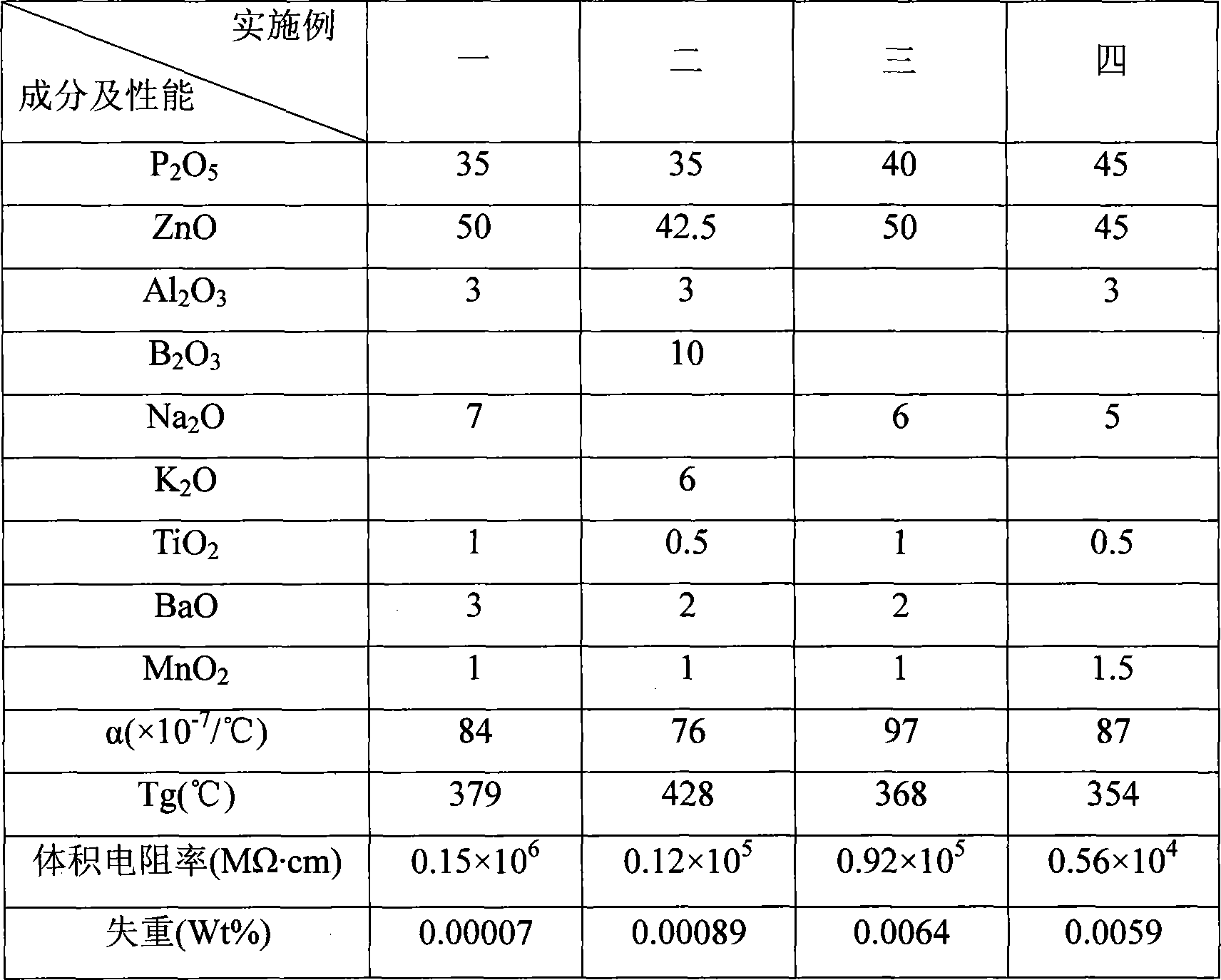

Electricity vacuum glass products lead-free seal glass and preparing method thereof

InactiveCN101058477AImprove performanceLow costGlass furnace apparatusGlass reforming apparatusElectricityElectrical resistance and conductance

The invention discloses a non-lead seal glass of electric vacuum glass product, which comprises the following parts: 30%-55% P2O5, 30%-55% ZnO, 0%-10% Al2O3, 0%-3. 5% MnO2, wherein the adding component is composed of 0%-10% Na2O, 0%-10% K2O, 0-20 mol% B2O3, 0-5mol%BaO and 0-1mol%Ti2O. The making course comprises the following steps: 1. blending each raw material completely; 2. loading in the quartz copple; insulating under 1050-1250 deg. c for 0. 5-2h; 3. cooling the fused glass liquid; solidifying; obtaining the sealing glass with bulking coefficient at 70-140X10-7 / deg. c and sealing temperature at 440-600 deg. c.

Owner:DONGHUA UNIV

Method for producing glass-ceramic from waste glass

The invention discloses a method for producing glass-ceramic from waste glass. The method comprises steps that: (1) waste glass is finely selected, washed and crushed, such that glass powder is prepared; (2) cobalt slag is crushed, such that cobalt slag powder is prepared; (3) the glass powder and the cobalt slag powder are mixed; a crystal nucleus agent and an auxiliary agent are added to the mixture, and the mixture is well mixed, such that a mixed raw material is obtained; (4) the mixed raw material is fused under a high temperature, such that a fused glass liquid is obtained; the fused glass liquid is clarified, homogenized, and molded; the molded glass is annealed, and is processed through heat treatment; the glass is nucleated and crystallized, such that the glass-ceramic is prepared. With the method provided by the invention, harmful effects of waste glass and cobalt slag to the environment can be reduced or eliminated, and wastes are turned into valuable natters. Cobalt slag serves as a main auxiliary material, and is added into waste glass with other auxiliary agents, such that high-grade glass-ceramic is produced. Therefore, great social and economic benefits are broughtin.

Owner:GEM CO LTD

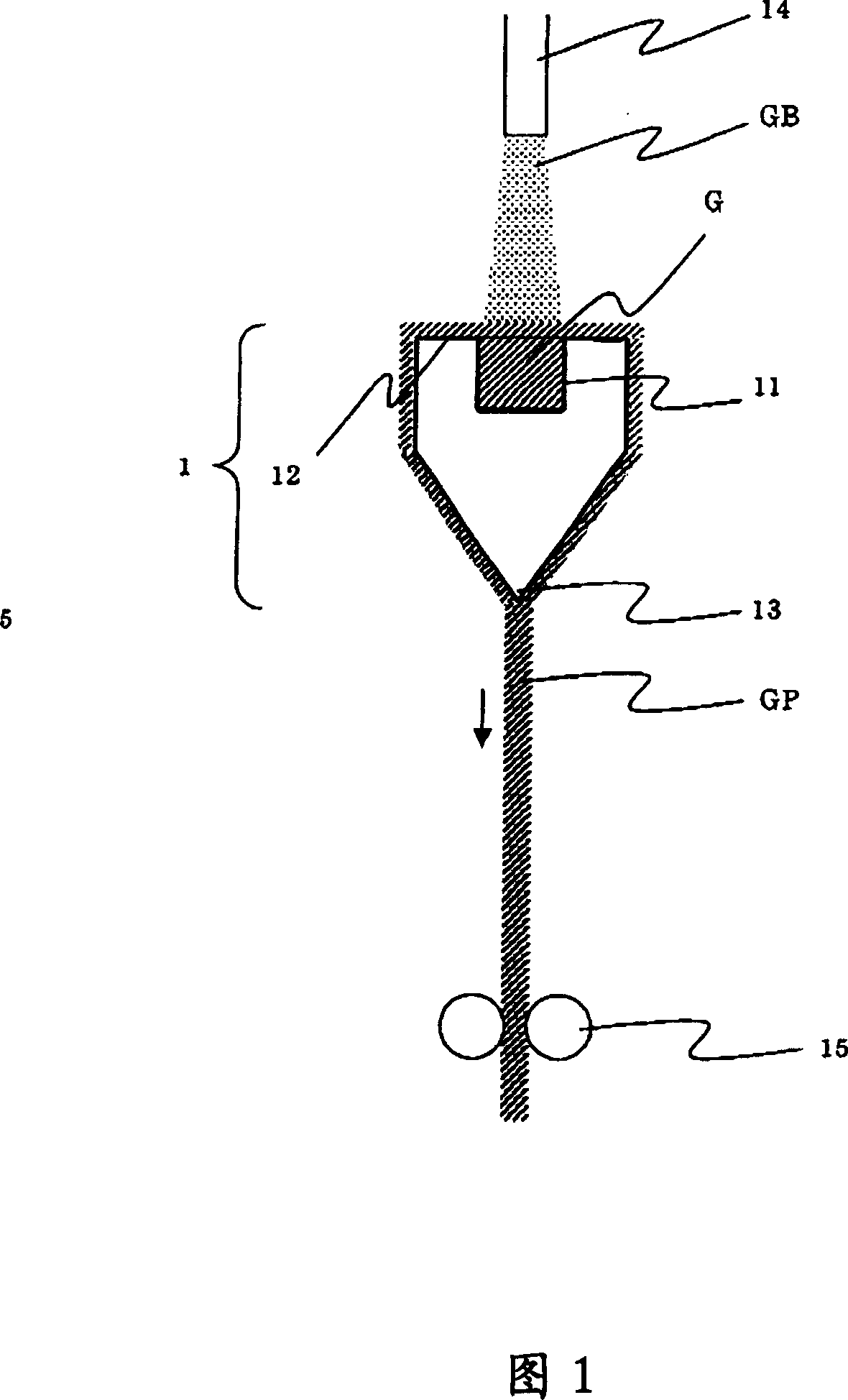

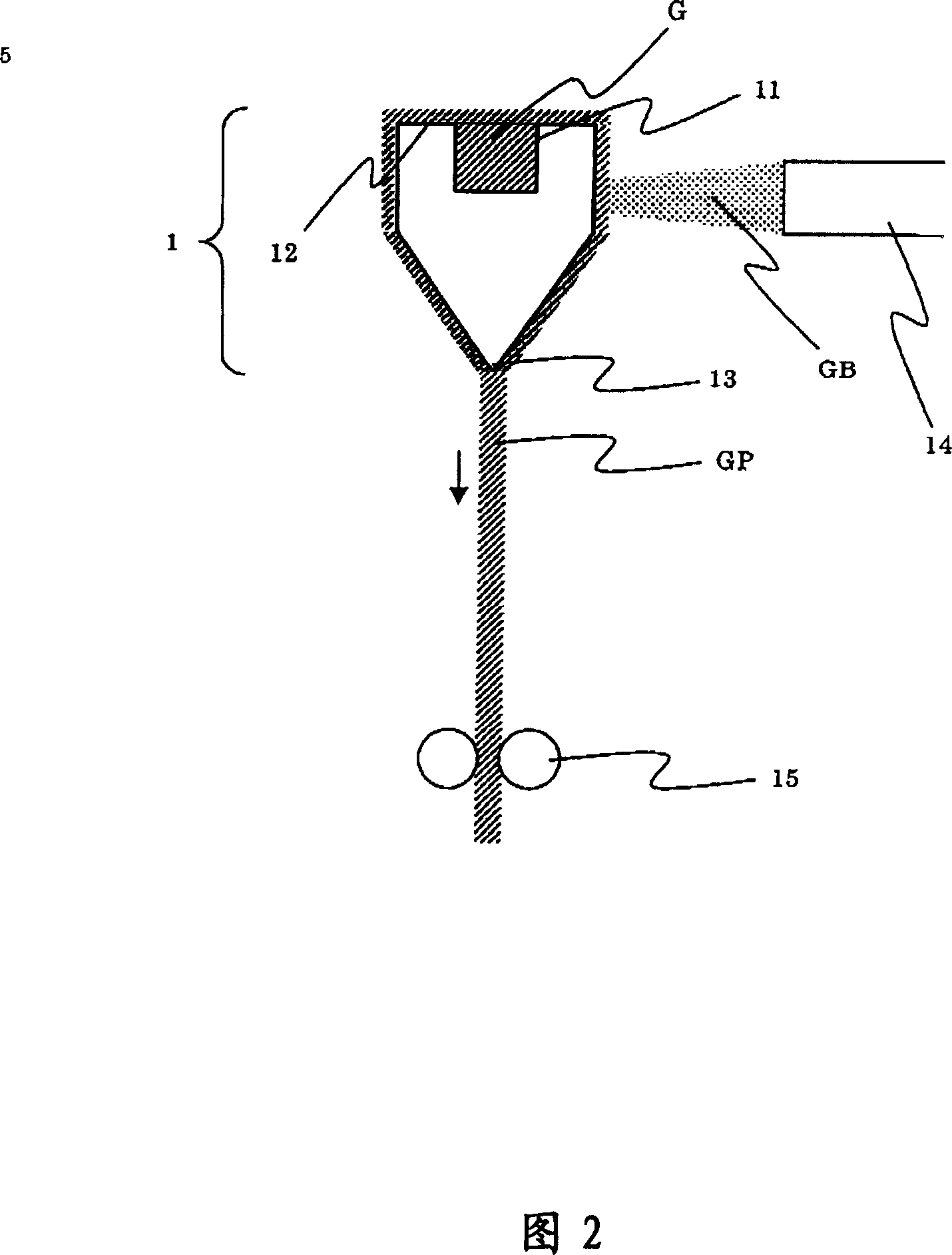

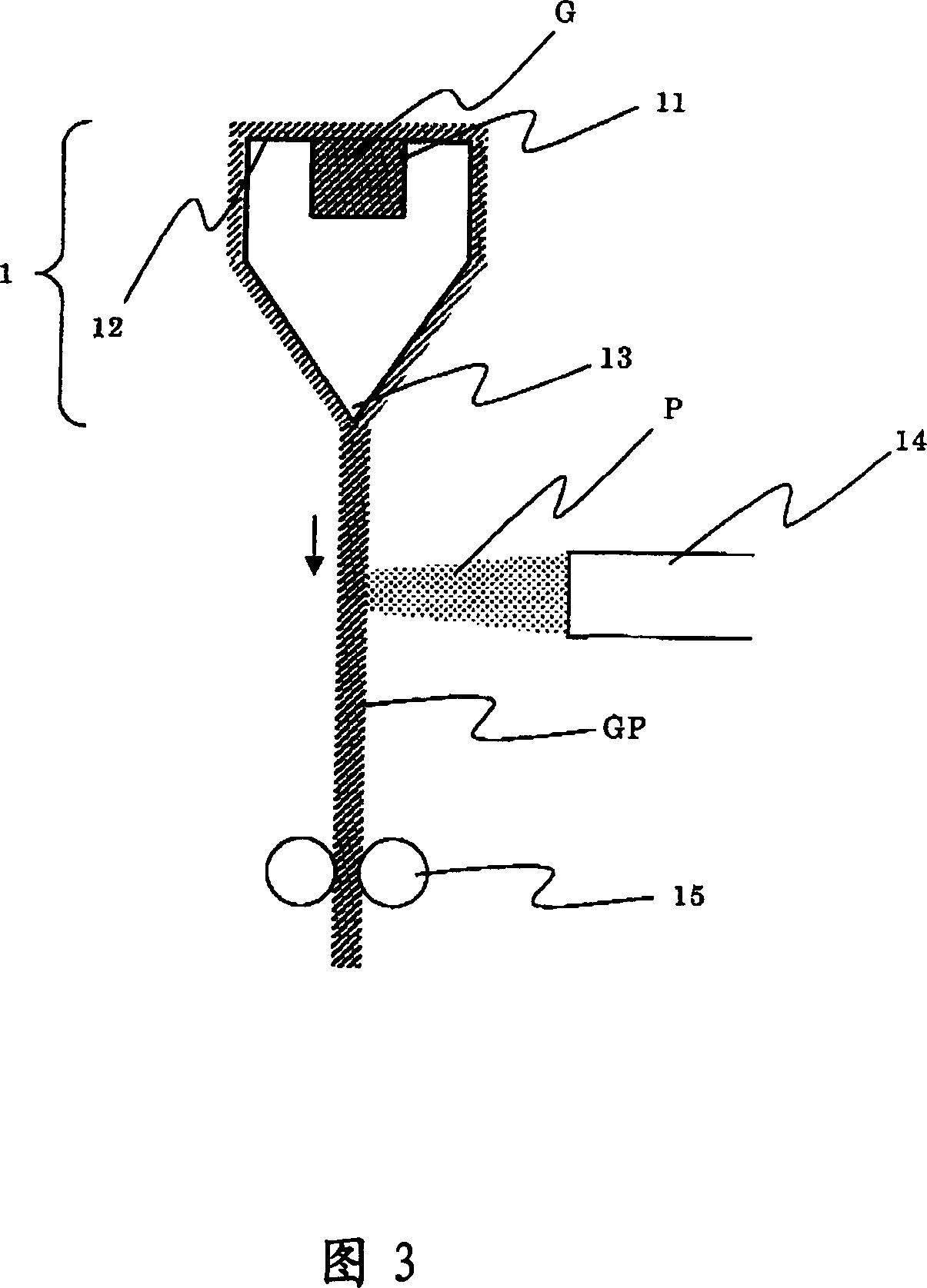

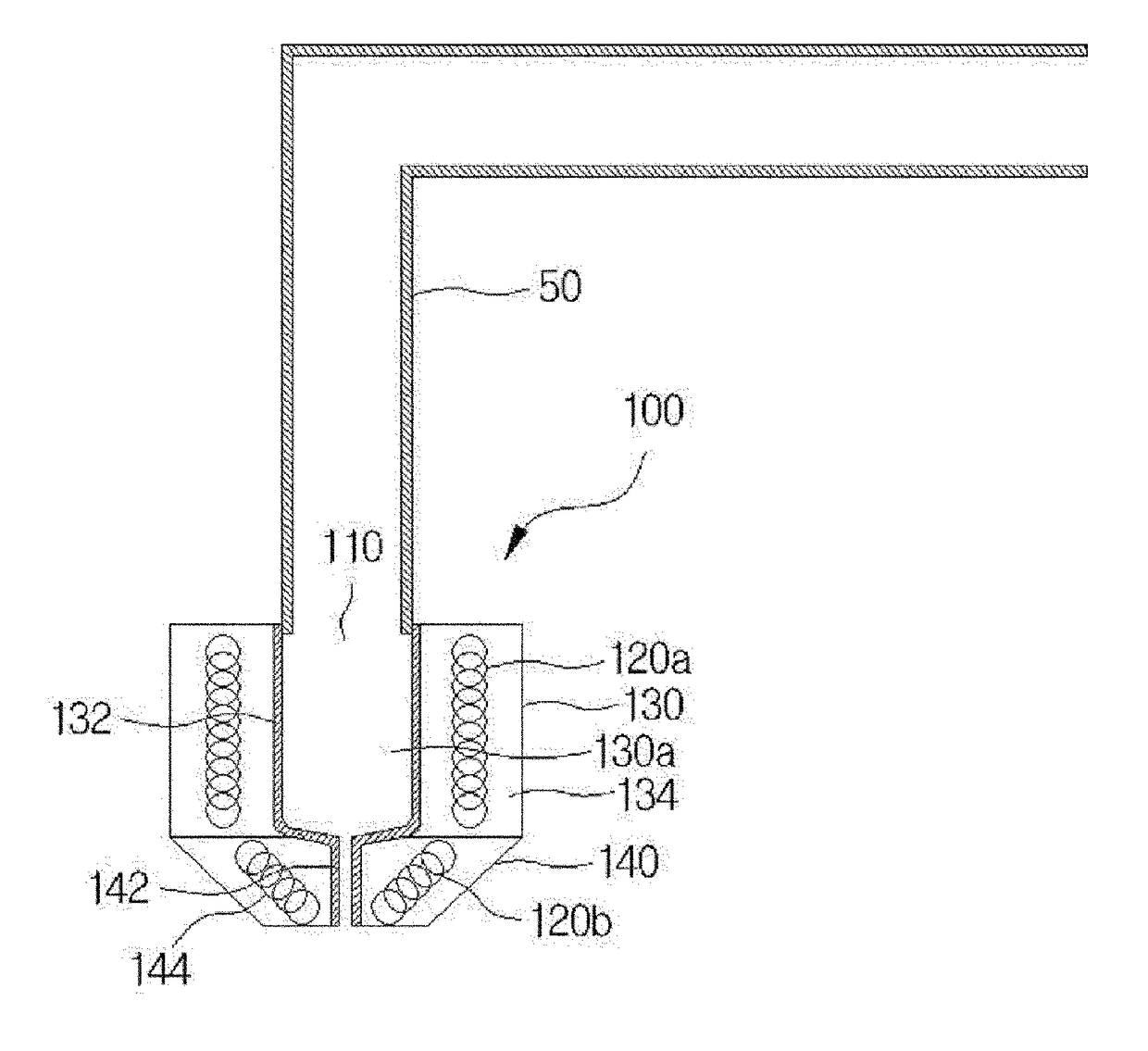

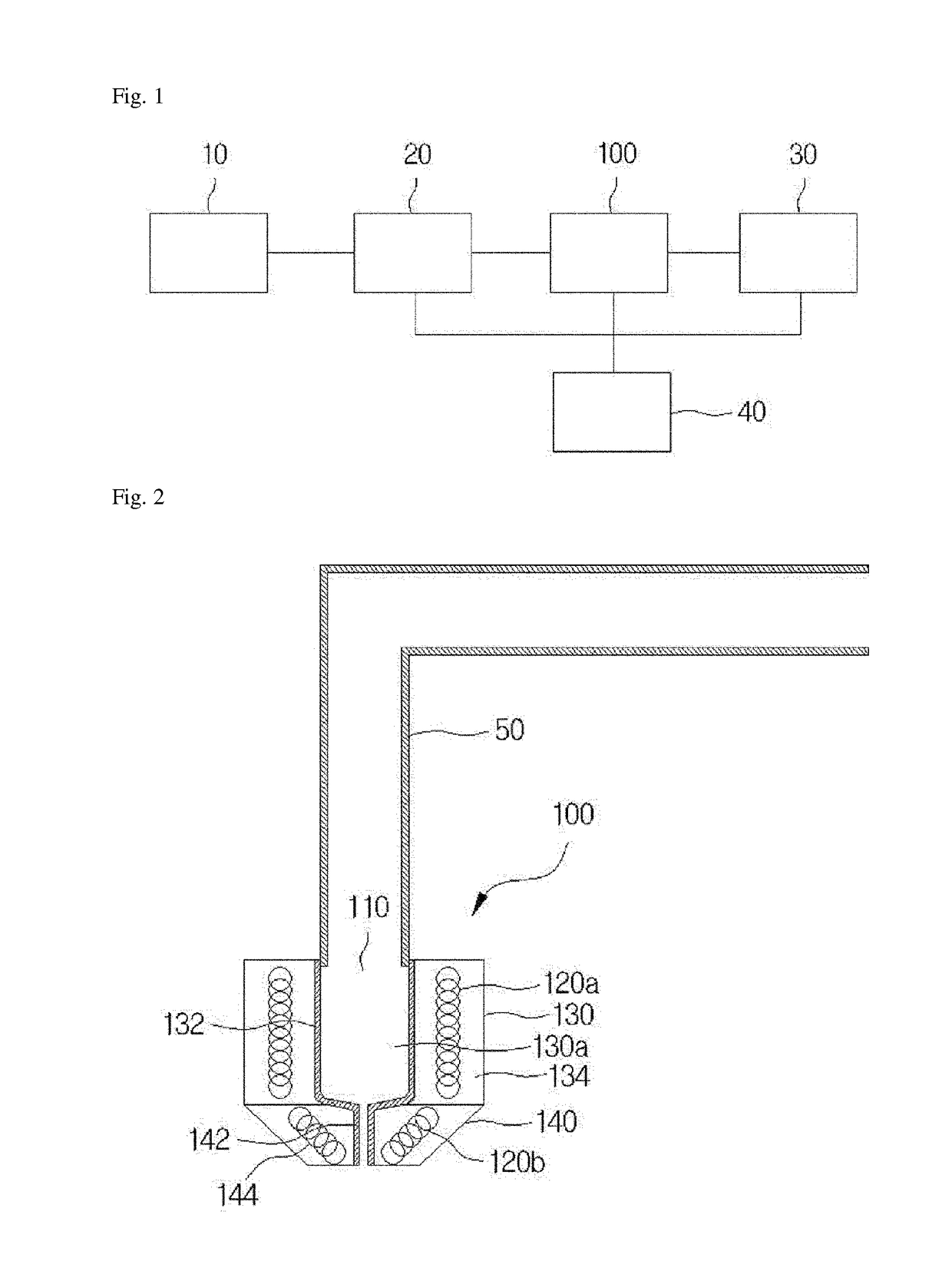

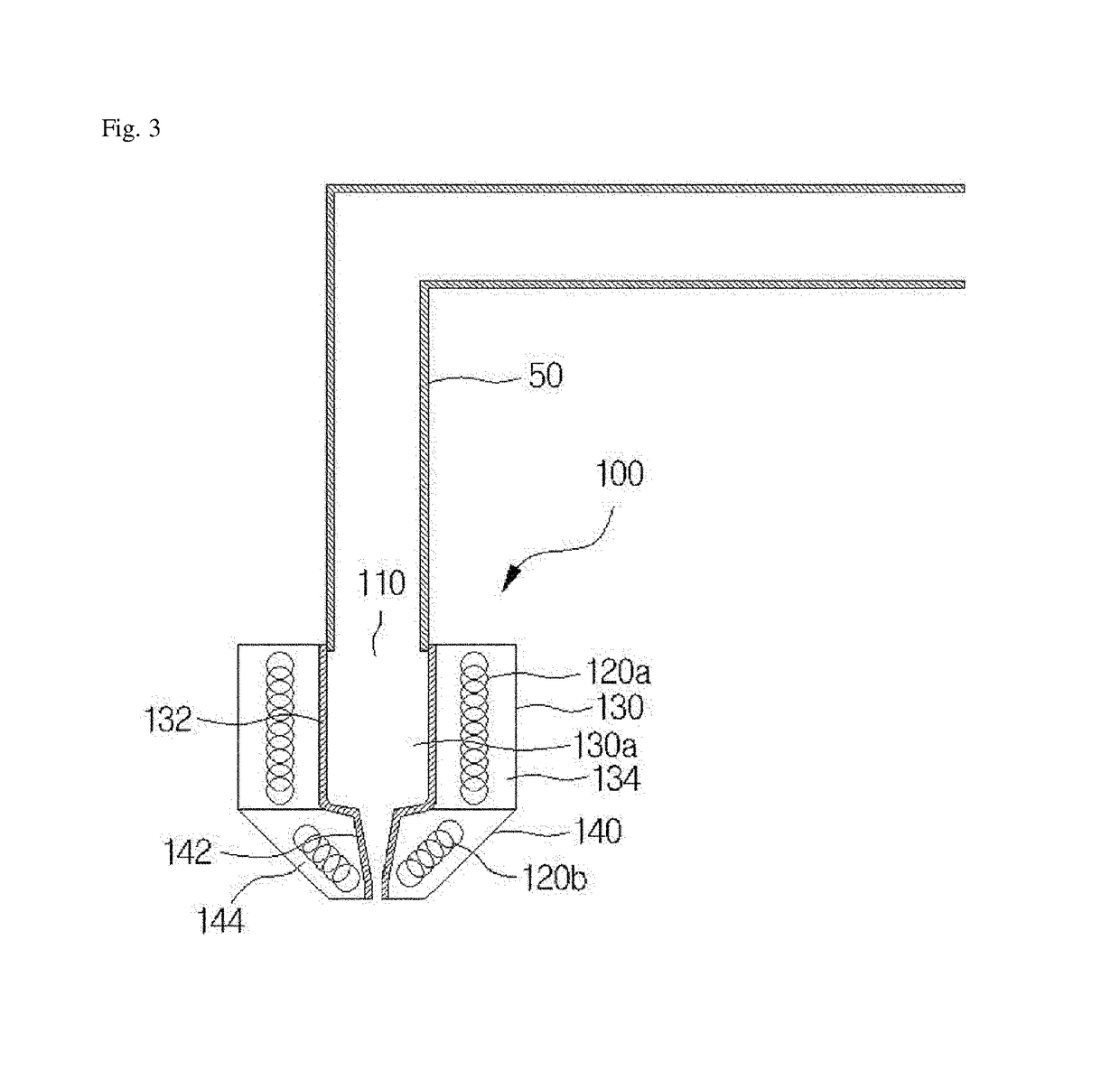

3D printer printhead, 3D printer using same, method for manufacturing molded product by using 3D printer, method for manufacturing artificial tooth by using 3D printer, and method for manufacturing machinable glass ceramic molded product by using 3D printer

InactiveUS20180009696A1Improve textureExcellent chemical durabilityAdditive manufacturing apparatusGlass furnace apparatusDiamond-like carbonAlloy

The present invention relates to a 3D printer printhead, a 3D printer using the same, a method for manufacturing a molded product by using the 3D printer, a method for manufacturing an artificial tooth by using the 3D printer, and a method for manufacturing a machinable glass ceramic molded product by using the 3D printer, the 3D printer printhead comprising: an inlet through which glass wire, which is a raw material, is introduced; a heating means for heating the glass wire introduced through the inlet; a melting furnace for providing a space in which the glass wire is fused; and a nozzle connected to the lower part of the melting furnace so as to temporarily store the fused glass or discharge a targeted amount of the fused glass, wherein the melting furnace includes an exterior frame made from a heat resistant material and an interior frame having a crucible shape, and the interior frame is made from platinum (Pt), a Pt alloy or graphite, which have a low contact angle, or a material having a surface coated with Pt or a diamond-like carbon (DLC) so as to prevent the fused glass from sticking thereto. According to the present invention, the molded product, the artificial tooth, and the machinable glass ceramic molded product can be manufactured with excellent mechanical properties, thermal durability, chemical durability and oxidation resistance and outstanding texture by using the glass wire as a raw material.

Owner:KOREA INST OF CERAMIC ENG & TECH

Deep super-cooling method for preparing directional difficult mixed dissolve Ni-Pb alloy

A process for preparing orientated Ni-Pb alloy difficult to mix and dissolve mutural by deep over-cold features that the HF induction heater isused, and the fused glass cleaning and cyclic over-heat are combined to obtain the over-cold (77-110 deg.K). Its advantages are easy control, no need of vacuum environment, and less loss of Pb.

Owner:SHANGHAI JIAO TONG UNIV

Front-surface silver paste for diamond wire-cut silicon wafer solar cell and preparation method of front-surface silver paste

InactiveCN108039224AReduce tensionImprove photoelectric conversion efficiencyNon-conductive material with dispersed conductive materialCable/conductor manufactureWater bathsSlurry

The invention discloses a front-surface silver paste for a diamond wire-cut silicon wafer solar cell and a preparation method of the front-surface silver paste. The silver paste contains the followingcomponents: spherical silver, an organic carrier, main body glass powder, additional glass powder and an aid. The preparation method comprises the following steps: preparing the organic carrier: weighing resin, a thixotropic agent and a solvent, and stirring for dissolving under a circulating water bath temperature maintenance condition at a constant temperature of 40-70 DEG C, so as to obtain the uniform and stable organic carrier; preparing the additional glass powder: weighing the raw materials, adequately premixing by virtue of a power mixing machine, adding the mixed powder into a platinum crucible, pouring fused glass liquid into deionized water, carrying out water quenching, and carrying out ball-milling, crushing, sieving, separation and drying on the glass powder after water quenching, so as to obtain the glass powder; and weighing spherical silver powder, the main body glass powder, the organic carrier and the aid, putting the raw materials into a slurry tank, stirring to form paste, uniformly stirring and mixing by virtue of a planetary homogenizer, and grinding and dispersing on the mixture by virtue of an EXAKT experimental three-roller machine until the diameter of the mixture is less than 6 microns, so as to finally obtain the silver paste.

Owner:JIANGSU HOYI TECH

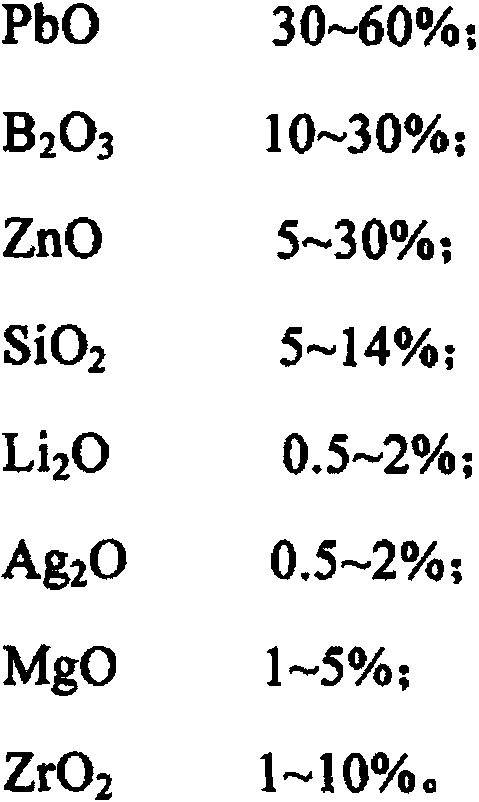

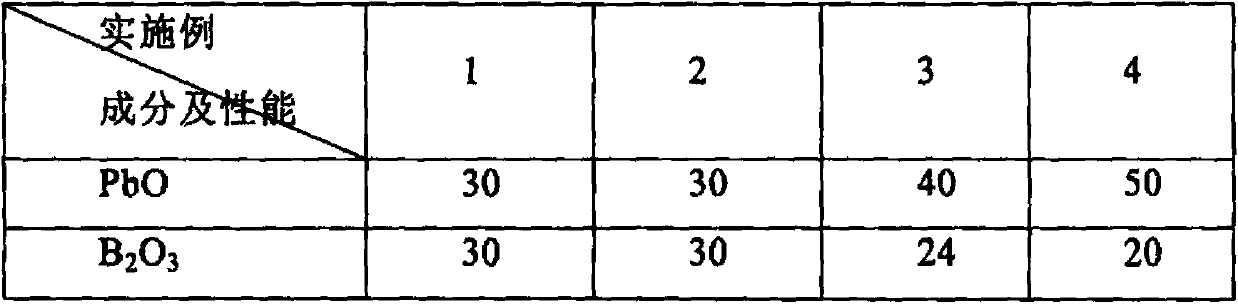

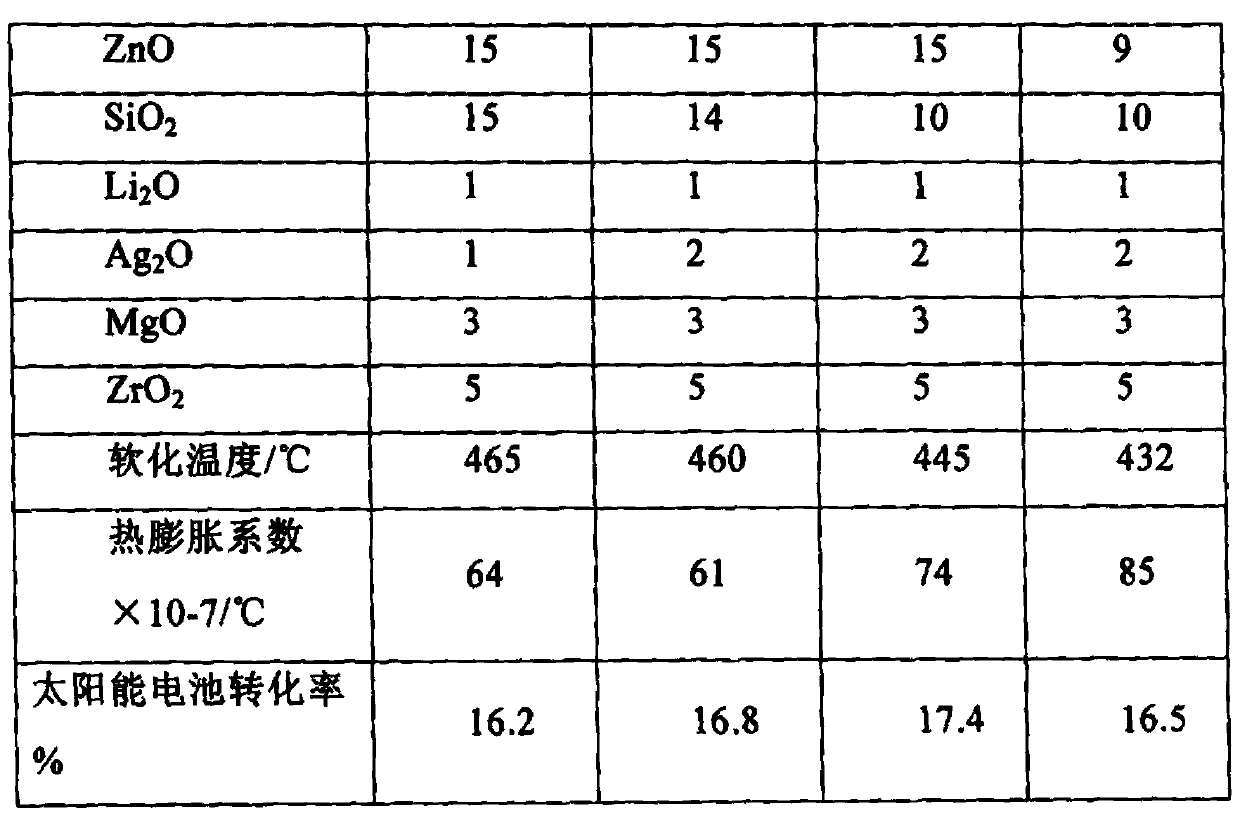

Low-melting glass powder of crystalline silicon solar energy battery front side silver paste and preparation method thereof

ActiveCN105084766AImprove photoelectric conversion efficiencyExtended service lifeFurnace temperatureSilicon solar cell

The invention provides a low-melting glass powder of crystalline silicon solar energy battery front side silver paste, and the powder is processed from the following substances in percentage by weight: 30-60% of PbO, 10-30% of B2O3, 5-30% of ZnO, 5-14% of SiO2, 0.5-2% of Li2O, 0.5-2% of Ag2O, 1-5% of MgO and 1-10% of ZrO. The preparation method comprises the following steps: 1. weighing materials, and uniformly mixing the materials in a ceramic mortar; 2. pouring the mixed powder into a corundum crucible, covering the crucible with a cover, and placing the crucible into a muffle furnace for fusion at an assigned furnace temperature; 3. carrying out water quenching of the fused glass liquid; 4. carrying out a drying; 5. milling and crushing the glass material after water quenching. The prepared glass powder has a suitable softening temperature, and has a good wetting capability for silver and silicon, simultaneously the glass contains silver oxide, and thereby better conveying and precipitating silver crystal grains in the sintering process, obtaining more contact points, improving the generation probability of tunnel effect, and reducing the contact resistor. Because the lead content is low, corrosion to silicon is reduced and possibility for breakdown of PN junction is effectively decreased, and thereby improving photoelectric conversion efficiency and life of solar energy battery in the prerequisite for guarantying the contact resistor.

Owner:上海太阳能工程技术研究中心有限公司

Fluorescence detection method of zirconia content in TFT glass

InactiveCN105651745AExpand the scope of detectionAccurate measurementPreparing sample for investigationFluorescence/phosphorescenceLithium metaborateFluorescence

The invention discloses a fluorescence detection method of the zirconia content in TFT glass. The method comprises: a, finely grinding a glass sample to obtain glass powder; b, mixing the glass powder obtained from the step a with a fusing agent and a releasing agent for fusion sample preparation to obtain a fused glass sheet, wherein the mass ratio of the glass powder to the fusing agent to the releasing agent is 1: (0.5-2): (0.01-0.1), and the fusing agent is a mixture of lithium tetraborate and lithium metaborate with the mass ratio being (1-5): 1; and c, performing fluorescence detection of the fused glass sheet obtained from the step b to obtain the zirconia content in the glass sample. According to the method, the zirconia content in glass can be quickly, accurately, and efficiently measured.

Owner:ZHENGZHOU XUFEI OPTOELECTRONICS TECH +1

Preparation method for ferromolybdenum sample melting glass body

ActiveCN102401756AAvoid difficultiesSo as not to damageMaterial analysis using wave/particle radiationPreparing sample for investigationLithiumFused glass

The present invention discloses a preparation method for a ferromolybdenum sample melting glass body. The preparation method comprises the following process steps: preparation of a sample, acid digestion of the sample, preparation of a melting glass body sample, and preparation of a glass body in a shaped crucible by the melting glass body sample. According to the method of the present invention, nitric acid is adopted to digest the ferromolybdenum sample; a treatment of low temperature drying is performed; regents of lithium tetraborate and ammonium iodide are added, the melting glass body is prepared at the high temperature of 1100 DEG C by high temperature melting. According to the present invention, a new melting sample preparing approach is provided for the ferromolybdenum synthesis by the X-ray spectrometry; the difficulties in the ferromolybdenum melting glass body preparation in the prior art are solved; the method of the present invention has characteristics of convenient operation, rapidness, easy control; with the method, the platinum crucible is not damaged, the service life and the use period of the platinum crucible are prolonged, the cost for repeatedly repairing the crucible is saved; the formed ferromolybdenum melting glass body is bright and transparent, meets the requirements of the detection by the XRF method, and has a strong application prospect.

Owner:ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com