Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Achieve paste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

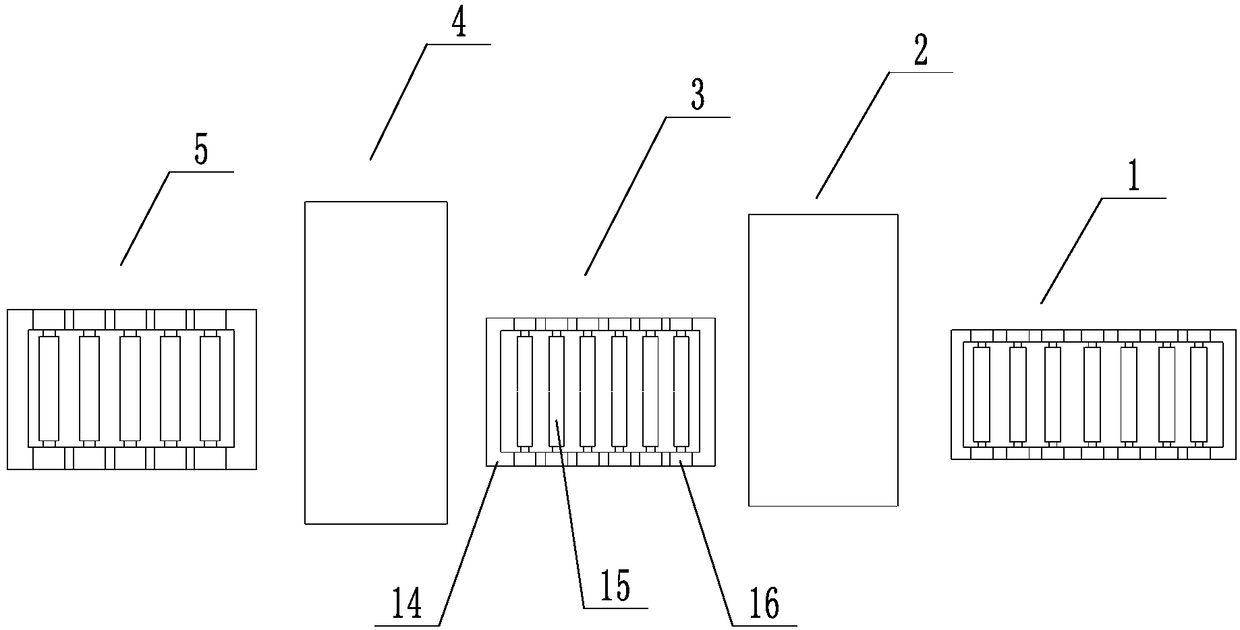

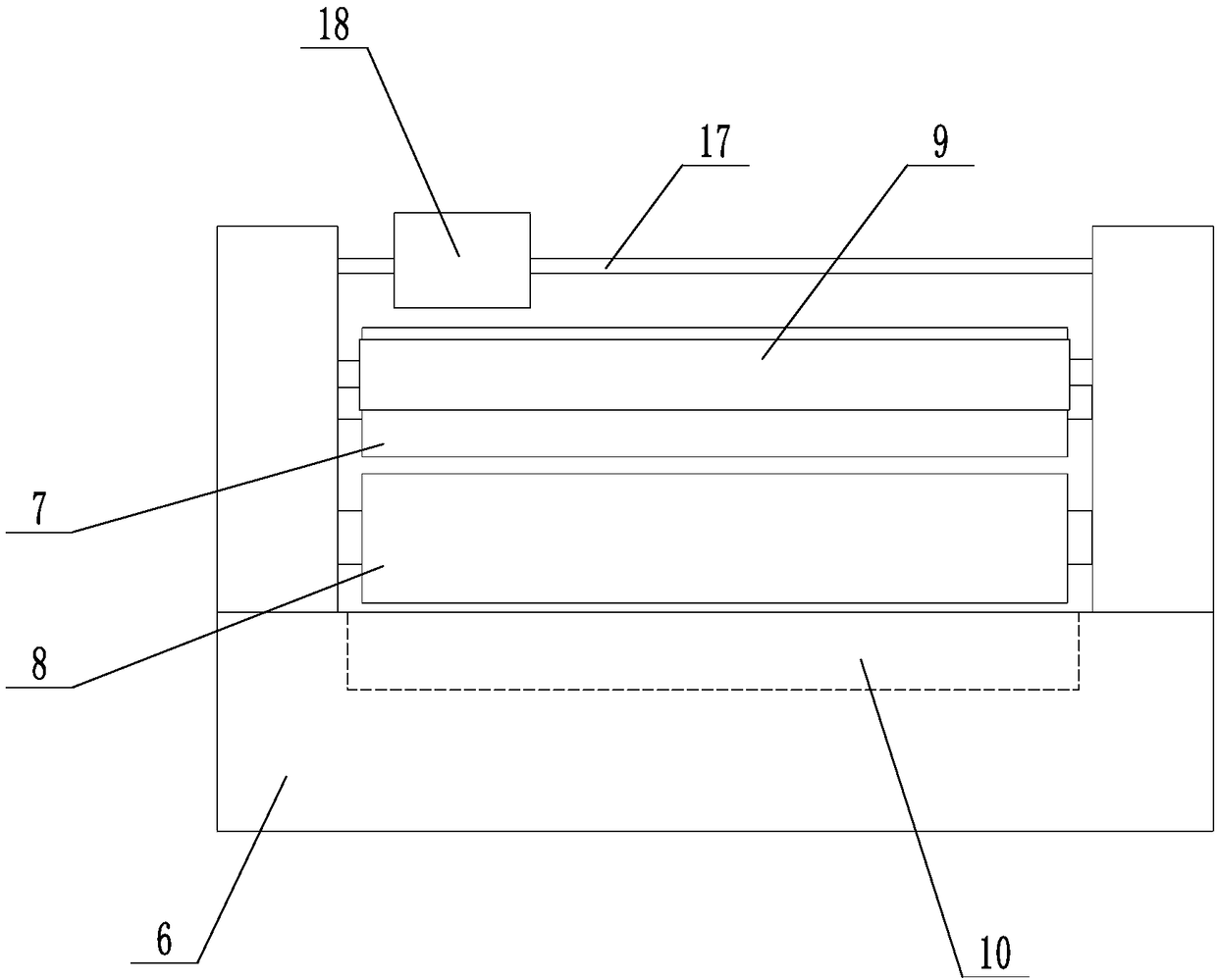

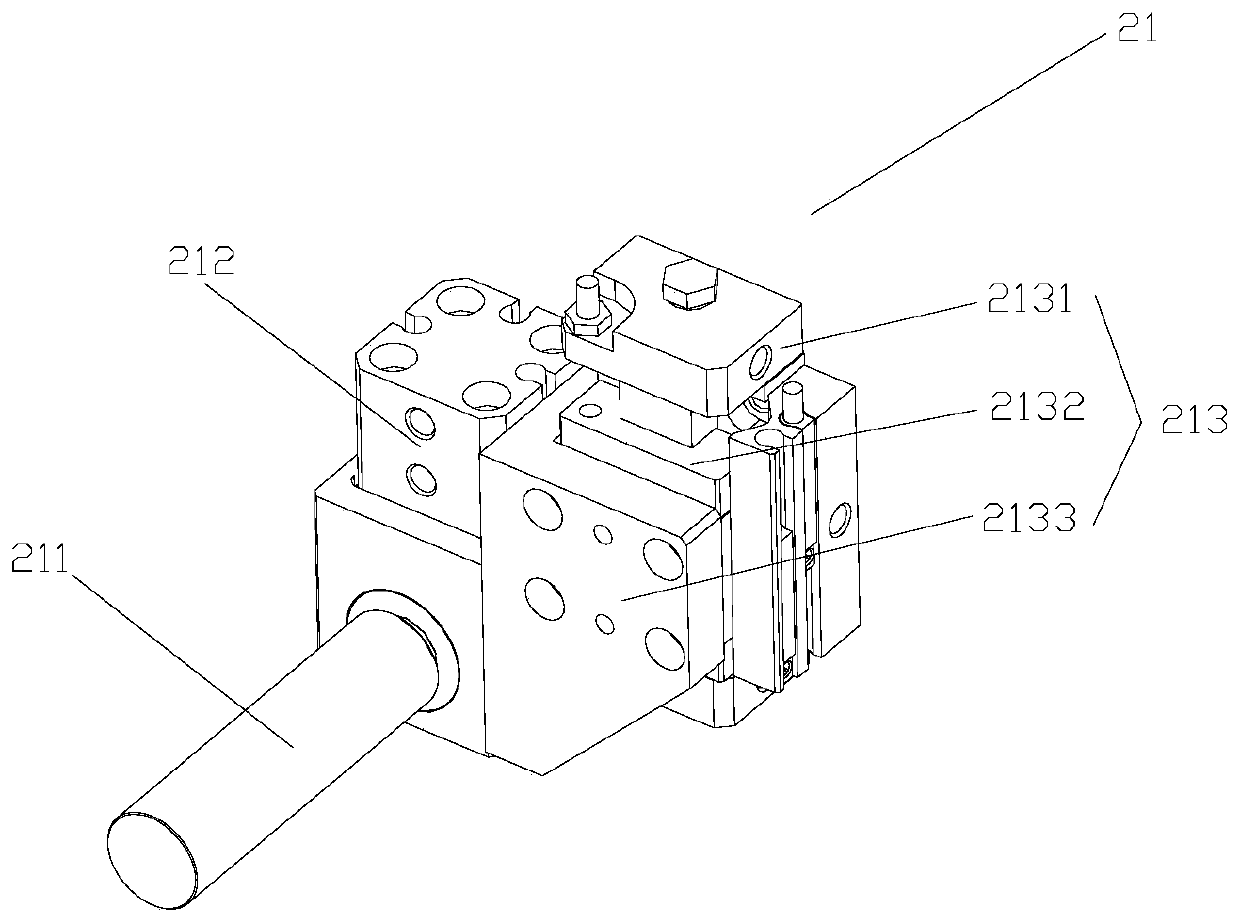

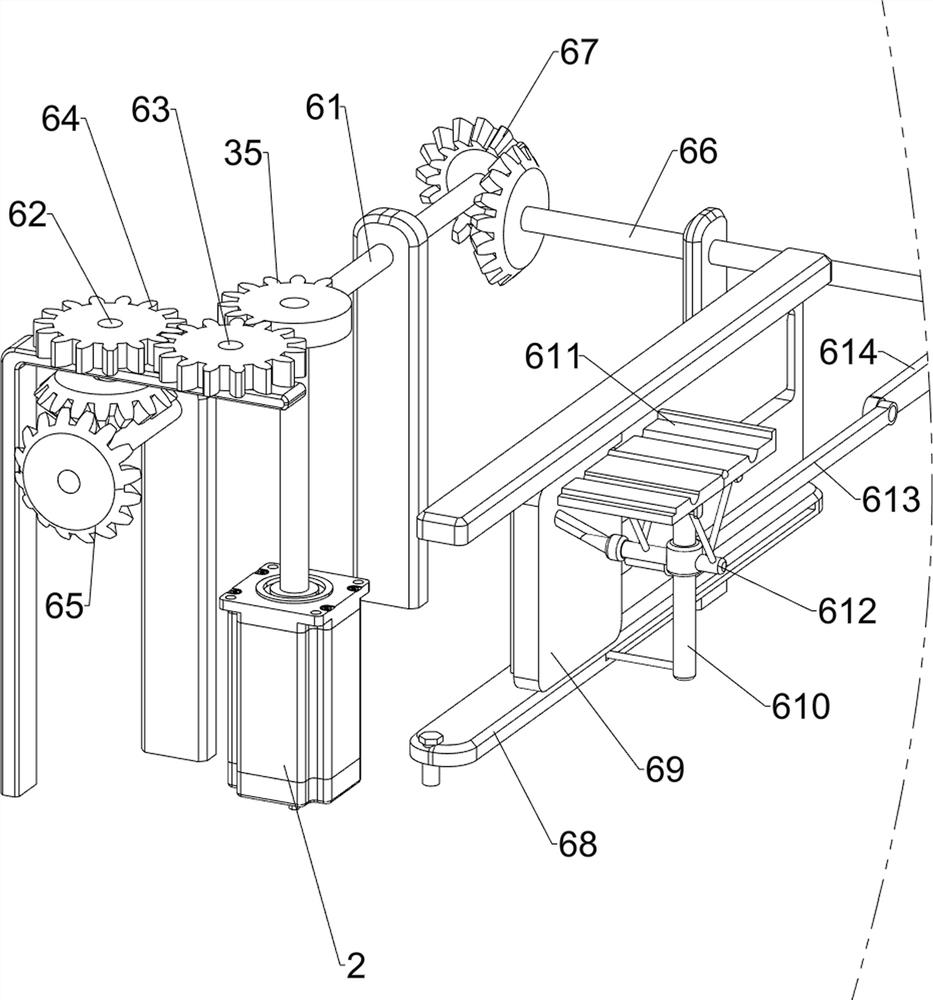

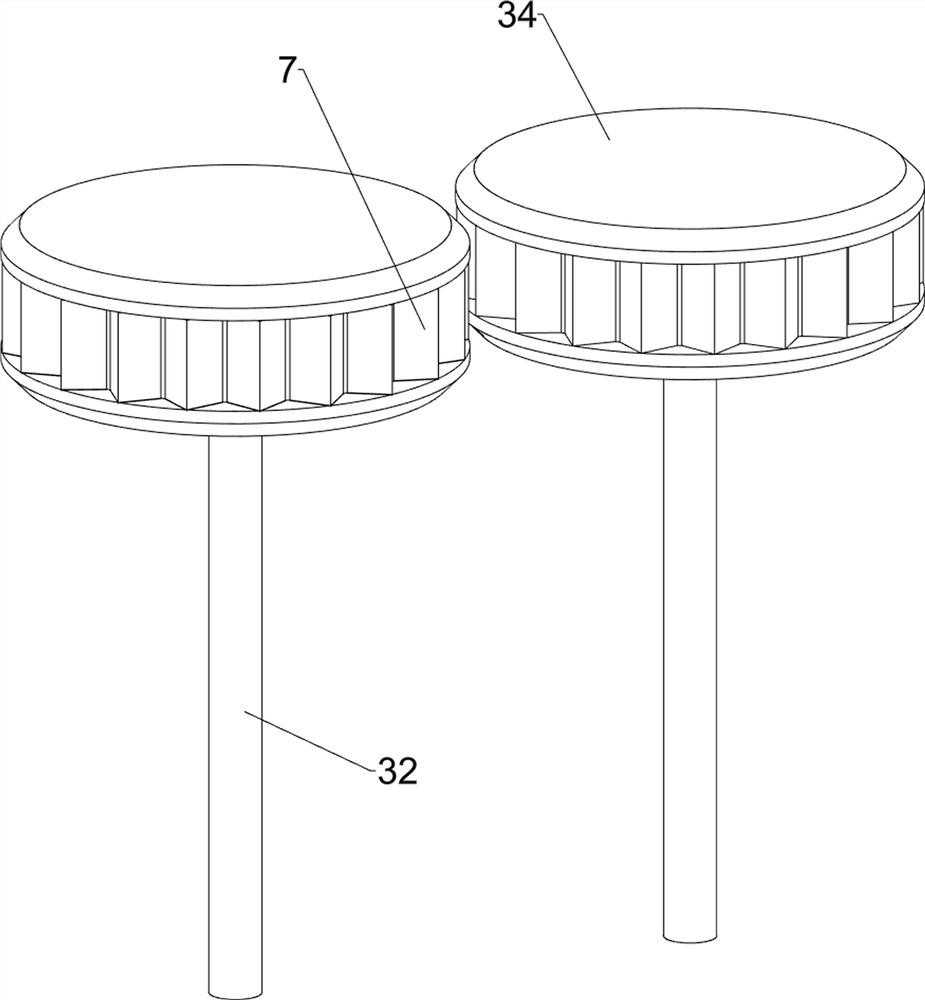

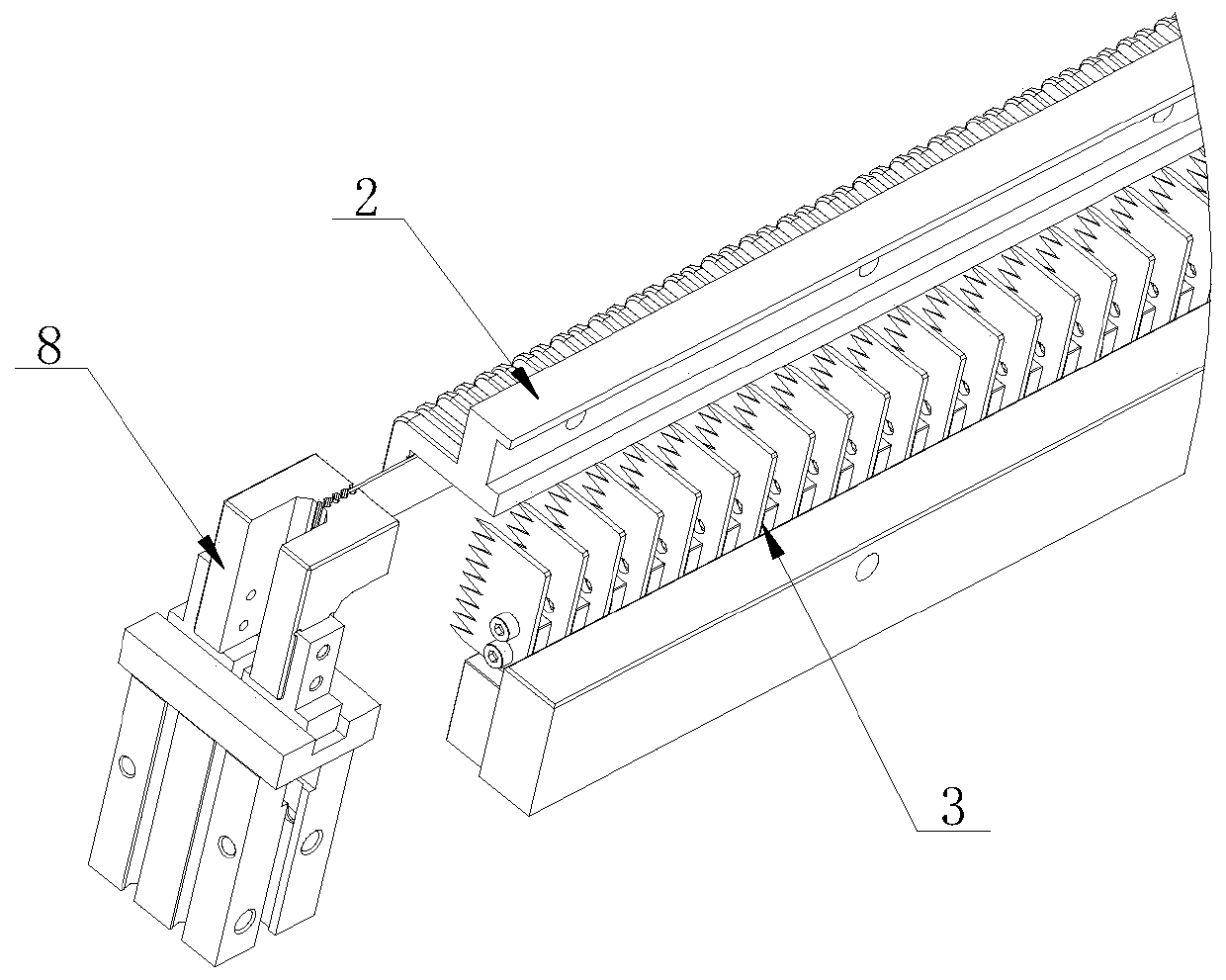

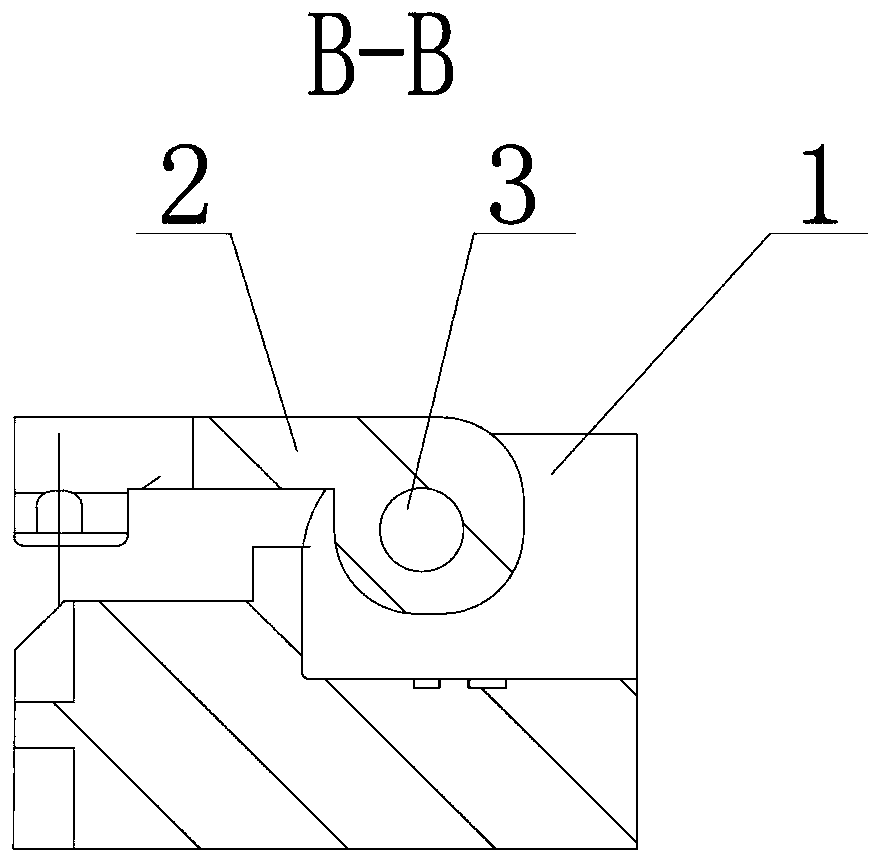

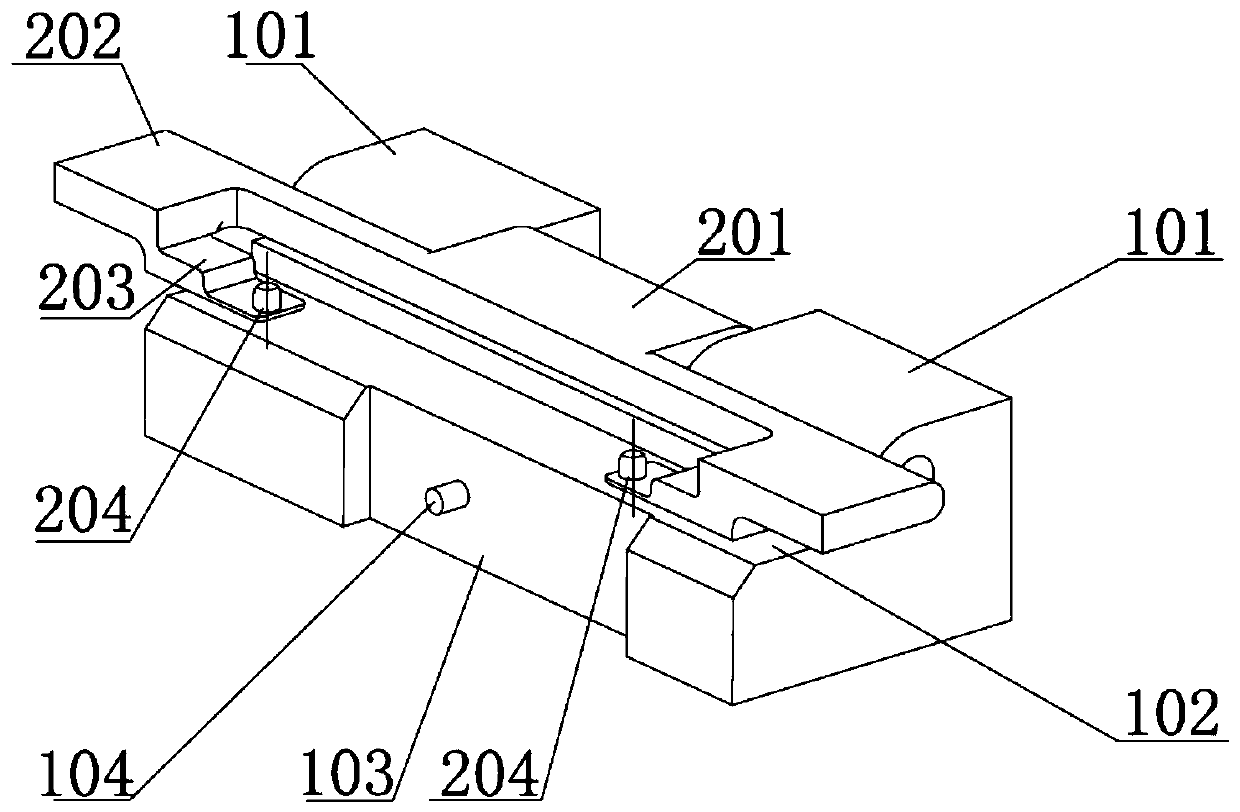

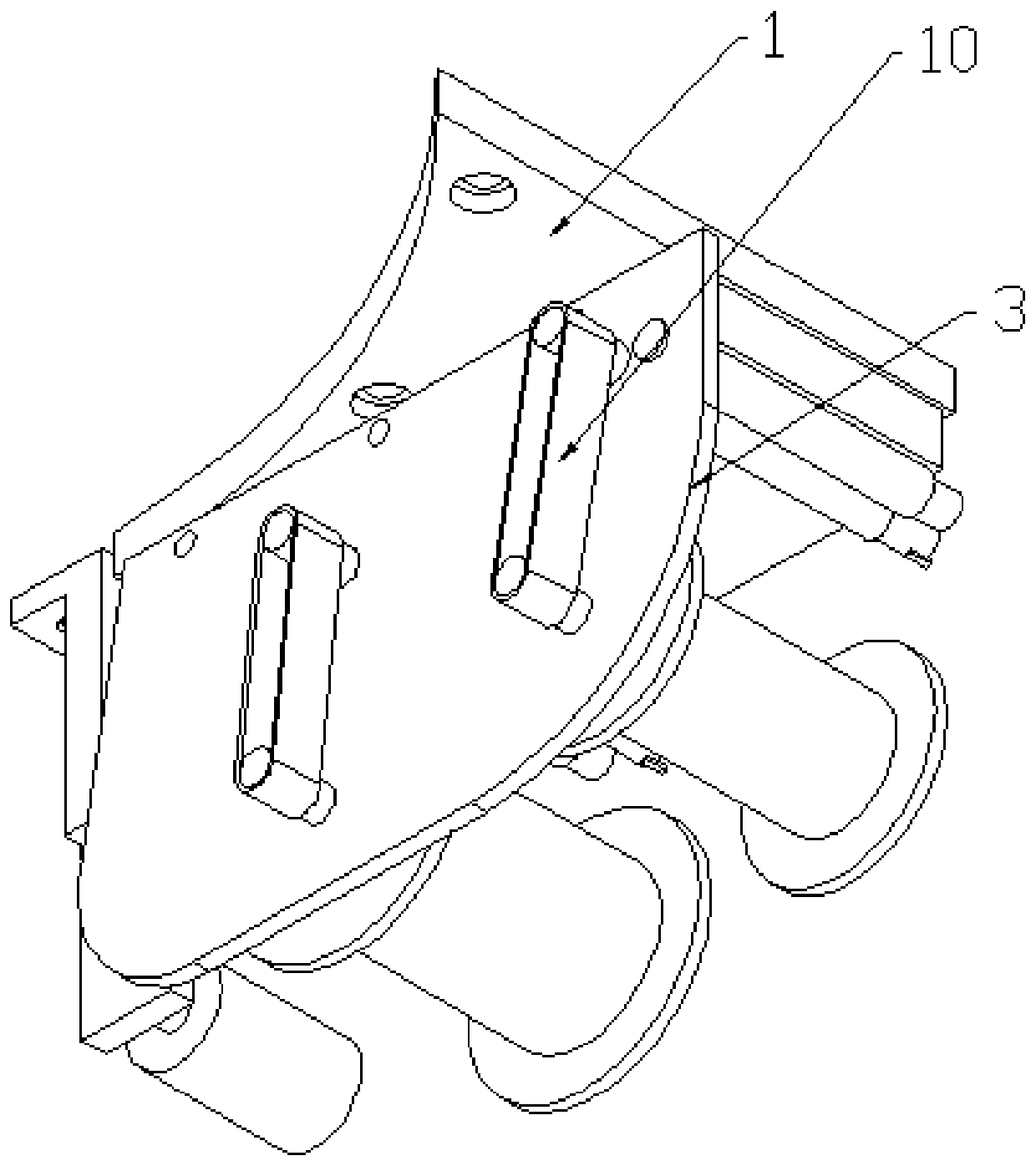

Equipment capable of automatically installing screws

InactiveCN103157987AImprove versatilityFlexible adjustmentMetal working apparatusMotor driveProgrammable logic controller

The invention discloses equipment capable of automatically installing screws. The equipment capable of automatically installing the screws comprises a screw feeder, a vacuum generator, a programmable logic controller (PLC), a touch screen and an alarm device, and further comprises a three-shaft platform and a motor-driven screwdriver feeding device. An electric control portion of the screw feeder, an electric control portion of the vacuum generator, an electric control portion of the touch screen, an electric control portion of the of alarm device, an electric control portion of the three-shaft platform and an electric control portion of the motor-driven screwdriver feeding device are all connected with the PLC. A crosswise-running guide rail, a lengthways-running guide rail and a height running guide rail are arranged on the three-shaft platform. The motor-driven screwdriver feeding device can rapidly run up and down with the height running guide rail, the height running guide rail can also rapidly run along the crosswise-running guide rail, and system equipment can rapidly run along the lengthways-running guide rail. The screw feeder is fixed on a base plate outer shell of the three-shaft platform. The gas circuit of the vacuum generator is connected with the motor-driven screwdriver feeding device. The touch screen can be controlled by hand and can be connected with the equipment. The alarm device is arranged on a front panel. The equipment capable of automatically installing screws can achieve automatic and vertical absorption of the screws and can be automatically in place to conduct screw vertical locking and check floating height according to setting of a program.

Owner:TIANJIN JINYA ELECTRONICS

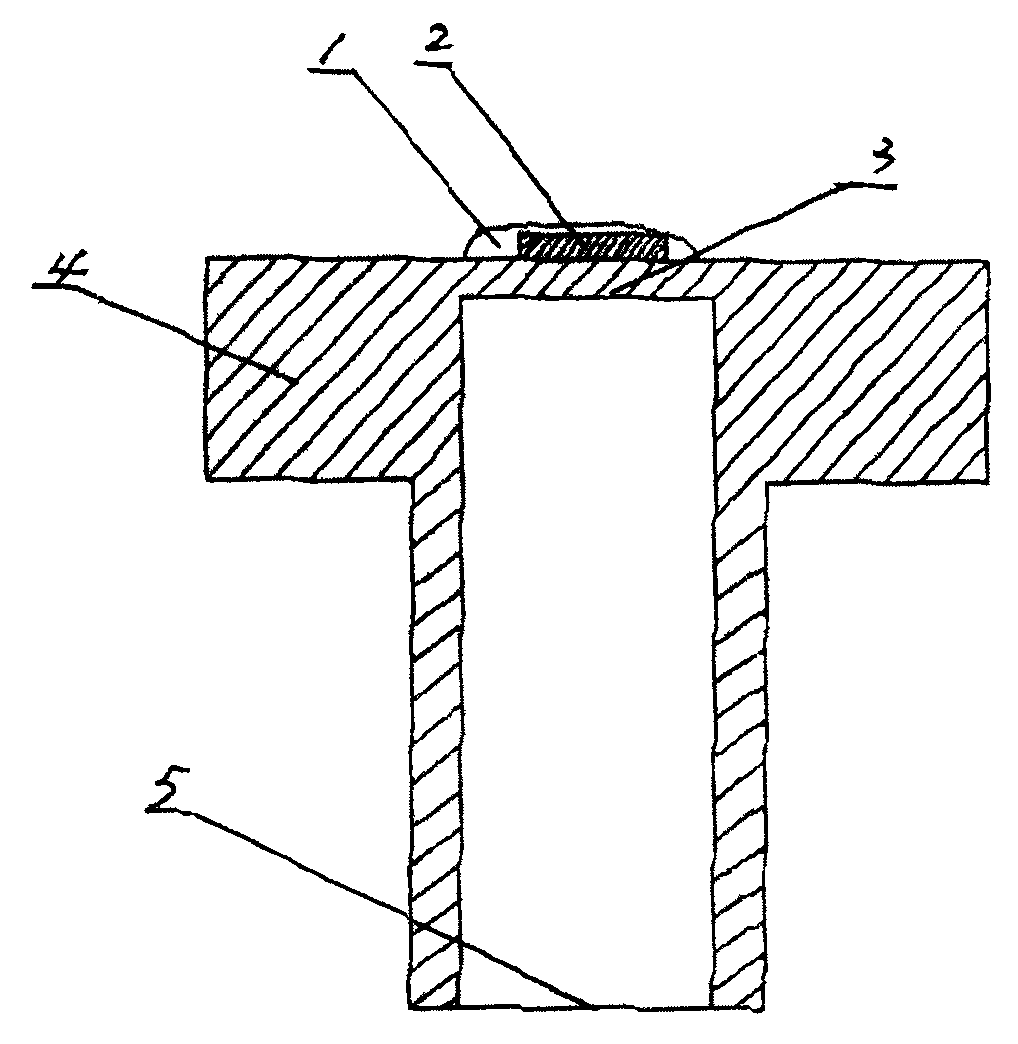

Method of adhering sensor chips

The invention relates to a method of adhering sensor chips and in particular to a method of adhering sensor chips on metal membranes through a glass micro-fusion method. The method comprises the steps of: firstly preparing a metal pedestal and a sensor chip, wherein a sealing bottom used for forming a metal membrane is arranged on one end of the metal pedestal, and an end port is reserved on the other end of the metal pedestal, the sensor chip comprises a silicon chip, four foil gauges are integrated on the silicon chip, and the four foil gauges are connected to a Wheatstone bridge through metallization deposition; and then, processing the outer surface of the metal membrane to a rough surface; printing glass powder on the rough surface; putting the metal pedestal with the glass powder in a tubular furnace with temperature of 450-550 DEG C for heating, putting the sensor chip on the glass powder when the glass powder on the metal membrane is at a semi-fusion state, and continuing to heat to embed the sensor chip in the fused glass solution; and finally, stopping heating and naturally cooling the sensor chip.

Owner:无锡永阳电子科技有限公司

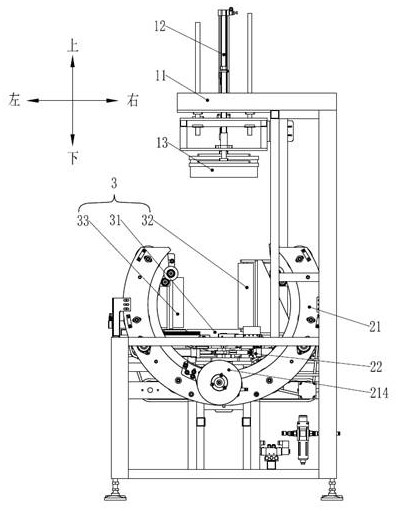

Adhesive tape sticking device

The invention discloses an adhesive tape sticking device, which comprises a rack, a carrier turntable instrument, an adhesive tape feeder, an adhesive tape sticking instrument, a component discharge instrument and a controller. Specifically, the adhesive tape feeder is used for adhesive tape feeding, the adhesive tape sticking instrument is disposed at the adhesive tape discharge end of the adhesive tape feeder, and a suction nozzle on the adhesive tape sticking instrument can suck an adhesive tape. The carrier turntable instrument is located on the rack, and can convey the carrier thereon to the place right below the suction nozzle so as to stick the adhesive tape by the suction nozzle. The component discharge instrument can send the carrier of an adhesive tape sticked product into a discharge flow channel for discharge. And the controller controls the work of each component. The adhesive tape sticking device provided by the invention realizes automatic peeling and sticking of adhesive tapes and automatic receiving of sticked products, achieves full automatic work, and has no need for manual operation. The adhesive tape sticking speed is fast, and the sticked adhesive tapes are accurate in positions and are firm. Manpower and space are saved, the production efficiency is improved, and production cost is reduced.

Owner:KUNSHAN FULIRUI ELECTRONICS TECH

Flexible dual-band planar microstrip antenna

InactiveCN103457030AEasy to bendHigh temperature resistantSimultaneous aerial operationsResonant antennasUltra-widebandSoftware engineering

Owner:EAST CHINA JIAOTONG UNIVERSITY

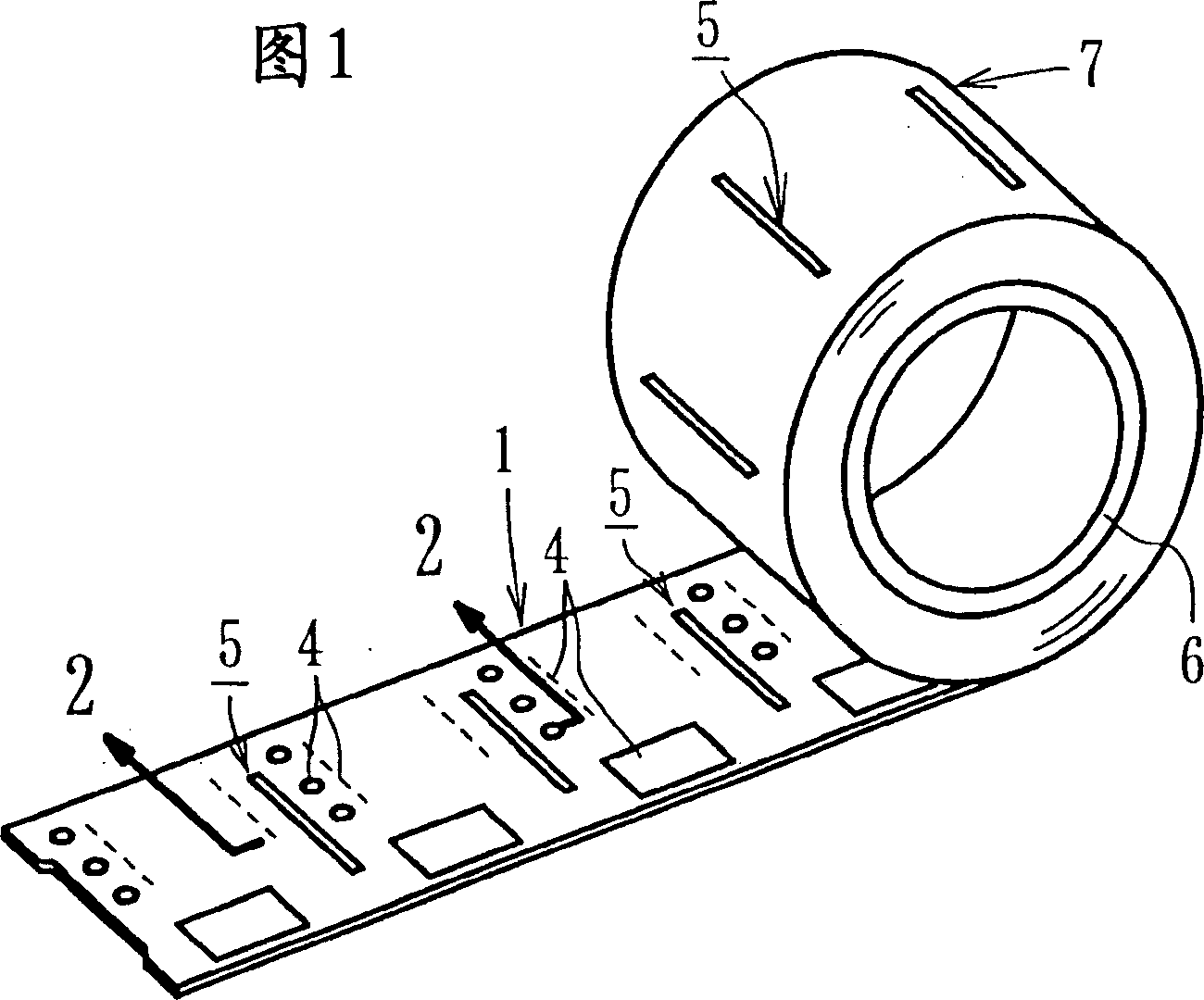

Label, Its ue and affixing method and appts.

InactiveCN1541382AInhibition of recrystallizationEasy to useStampsManual label dispensersBand shapeAdhesive

With respect to a release-paper-free label requiring the activation of adhesive layer, a label structure adapted to reduce peeling after sticking; a method of using the same; a method of label sticking for reducing the number of costly printers used at the time of simultaneous sticking operations at multiple locations; and an apparatus therefor. Adhesive (3) not having tackiness at ordinary temperatures is applied to the back of tape shaped label substrate (2), and multiple continuous printing of label marking (4) is carried out on the top of the label substrate, thereby forming a label tape. The label tape is rolled. The rolled tape is separated apart into individual labels (8). The adhesive of the labels (8) is heated so as to restore adherence, and plasticizer (9) is applied onto the adhesive. Then, sticking of the labels (8) is carried out. These means enable inhibiting the recrystallization of adhesive even if detachment at the edge occurs after label sticking, thereby maintaining adherence, so that peeling can be prevented.

Owner:HONDA MOTOR CO LTD +1

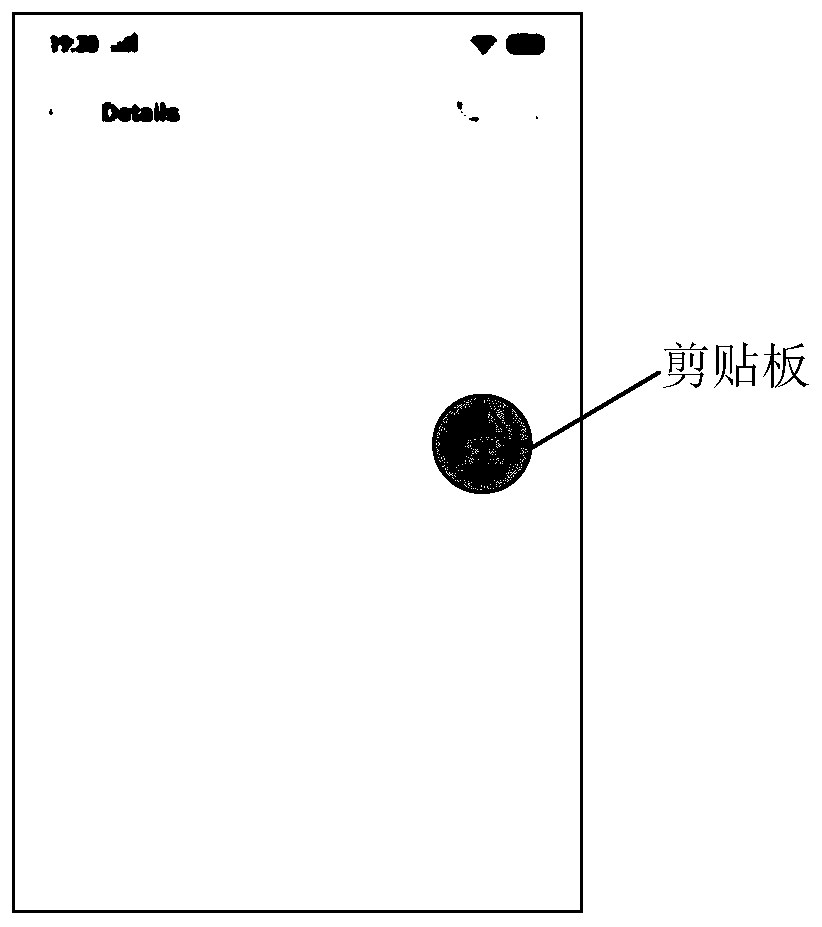

Copying method and device and terminal

InactiveCN110018915AAchieve acquisitionAchieve pasteInterprogram communicationInput/output processes for data processingDuplicate contentCopying

The invention provides a copying method, a copying device and a terminal, and relates to the technical field of communication. The copying method comprises the following steps: displaying a label listcomprising at least one copied label, wherein each copied label corresponds to a storage space; in response to a first operation of a user, determining copied content and a first copied label, and storing the copied content in a storage space corresponding to the first copied label; and in response to a second operation of the user, determining a second duplicated label for pasting, and pasting the duplicated content in the storage space corresponding to the second duplicated label to the target position. According to the embodiment of the invention, the determined one or more copied contentscan be stored in the storage space corresponding to the first copied label; t copy contents at multiple positions and multiple pages are obtained, a second copy label needing to be pasted is selectedin a first copy label when the copy contents need to be pasted, and the copy contents in a storage space corresponding to the second copy label is pasted to a target position, thereby realizing pasting of the multiple positions and the multiple pages.

Owner:VIVO MOBILE COMM CO LTD

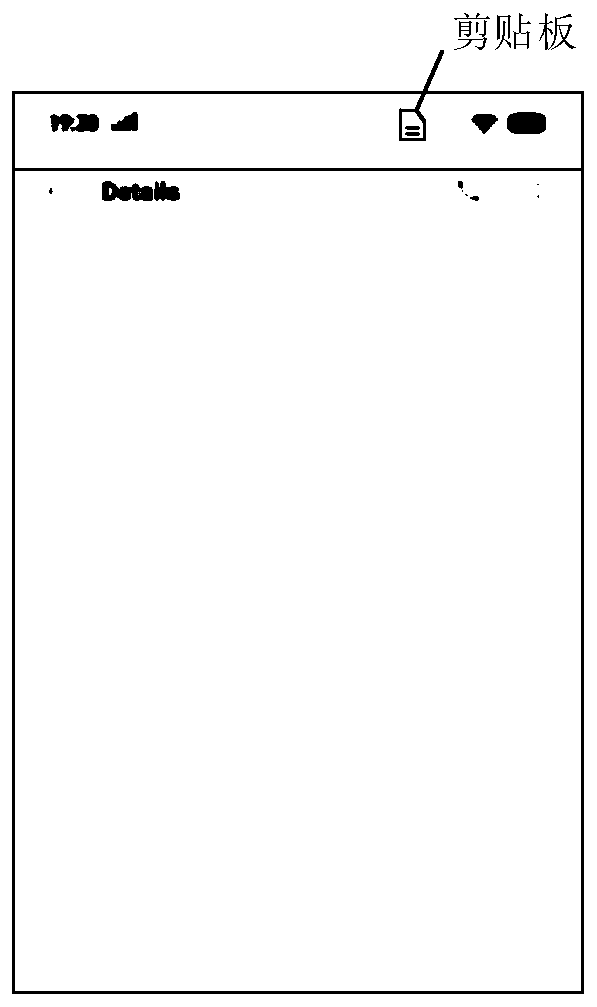

Information processing method and device, storage medium and electronic device

InactiveCN110489039AImprove pasting efficiencyImprove experienceInterprogram communicationInput/output processes for data processingInformation processingWorld Wide Web

The embodiment of the invention discloses an information processing method and device, a storage medium and an electronic device, and the method comprises the steps: receiving a copy operation for target information in a first display interface, and storing the target information to a clipboard in response to the copy operation; displaying a second display interface, and displaying the clipboard on the second display interface; wherein the second display interface comprises an information input box; and when it is detected that the clipboard is located in the information input box, displayingthe target information in the information input box. Therefore, by adopting the embodiment of the invention, a user only needs to move the clipboard into the information input box to paste the copiedcontent, the operation is simple and quick, and the information pasting efficiency is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Automatic wood board paper pasting equipment

The invention discloses automatic wood board paper pasting equipment. The automatic wood board paper pasting equipment comprises a first conveying table, a gluing device, a second conveying table, a press-fit device and a third conveying table, all of which are sequentially arranged in the wood board conveying direction. The gluing device comprises a first machine base. The first machine base is rotationally provided with a gluing roller. The gluing roller comprises a horizontally-arranged upper gluing roller body and a horizontally-arranged lower gluing roller body. The upper gluing roller body is driven through a first drive device, a glue scraping roller is arranged at the side portion of the upper gluing roller body, and a glue groove is formed below the upper gluing roller body. The press-fit device comprises a second machine base, the second machine base is rotationally and horizontally provided with an upper pressing roller and a lower pressing roller, the upper pressing rolleris driven through a second drive device, and the two ends of the upper pressing roller are provided with adjusting structures used for adjusting the distance between the upper pressing roller and thelower pressing roller. The automatic wood board paper pasting equipment has the beneficial effects that usage is convenient, and time and labor are saved.

Owner:台山市新英汉装饰材料有限公司

Online testing and labeling device for surface defect

The invention discloses an online and labeling device for a surface defect. The online testing and labeling device for the surface detect comprises a base plate, a winding bracket, an idler, a driving wheel bracket, a corner seat, a paper pressing wheel seat, an unwinding socket, a phototube, a paper pressing device, a labeling band, a stepper motor, a reducing motor, a reducing motor seat, a stepper motor seat and the like, wherein a signal receiving device used for receiving an operation signal transmitted from a testing host is arranged on the stepper motor; and the signal receiving device starts the stepper motor and drives each component of the labeling device to operate by receiving an operation command transmitted from the testing host, so that labeling operations can be finished accurately. The online testing and labeling deice for the surface defect has a small volume, light weight, and high labeling accuracy, and can be used for effectively preventing external noise and clutter interferences, and realizing continuous or discontinuous label paper labeling; therefore, the online testing and labeling device for the surface defect is particularly suitable to be used for labeling operations of online testing of the surface defect on a production line.

Owner:浙江双元科技股份有限公司

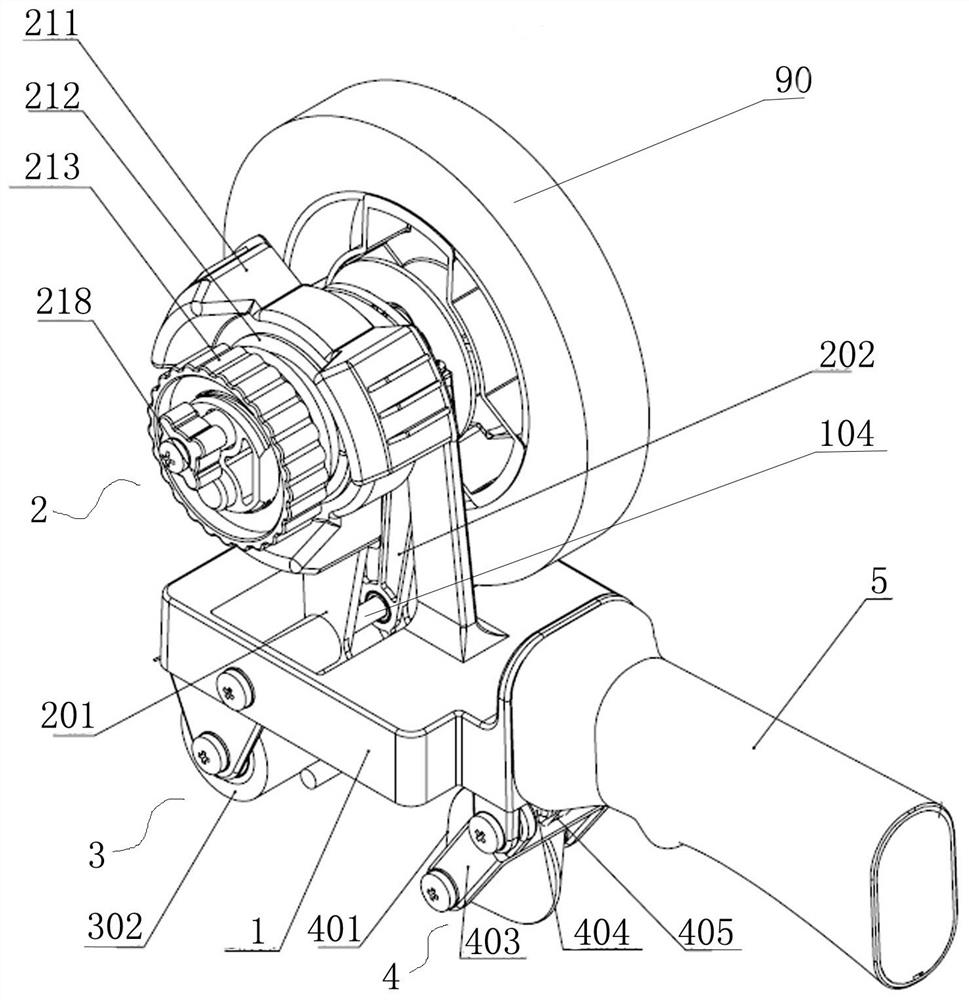

A sticking tool for masking tape

The invention discloses a sticking tool for a masking paper tape. The sticking tool comprises a main body bracket, a tape rotating device arranged above the main body bracket and a pressure roller device and a tool guiding device which are arranged under the main body bracket, wherein the pressure roller device includes a pressure roller shaft connected with the main body bracket and a pressure roller which sleeves the pressure roller shaft; the tape rotating device comprises a rotating column, an axial adjusting mechanism is axially arranged on the rotating column, and the axial adjusting mechanism enables the rotating column to move in the axial direction of the rotating column; a tape rotating wheel, a compression spring acting on the tape rotating wheel and a compression spring cover plate acting on the compression spring are sequentially arranged on the rotating column in the axial direction in a sleeving mode; and a tape guiding device connected by a rotating guide bracket is arranged under the tape rotating device in a matched mode, and a stop piece for stopping the tape is arranged under the tape guiding device. The sticking tool can realize quick sticking of the tape on both sides of a gap, the adjustment of the distance between the tape and the gap and the damping control of the rotary speed of the tape.

Owner:上海沣江科技有限公司

Plank paper-pasting equipment with automatic feed system

PendingCN108162094AAchieve pasteAvoid wastingLiquid surface applicatorsWood veneer joiningAdhesiveEngineering

The invention discloses plank paper-pasting equipment with an automatic feed system. The plank paper-pasting equipment includes a push device, a lifting platform, a first transport table, an adhesivespreading device, a second transport table, a press-fitting device and a third transport table which are sequentially arranged in the transport direction of a plank, and the adhesive spreading deviceincludes a first machine base; the first machine base is rotatably provided with an adhesive spreading roller, the adhesive spreading roller includes an upper adhesive spreading roller and a lower adhesive spreading roller which are horizontally arranged, the upper adhesive spreading roller is driven by a first driving device, and the side portion of the upper adhesive spreading roller is providedwith an adhesive-scraping roller; the lower portion of the upper adhesive spreading roller is provided with an adhesive groove, the pressing device includes a second machine frame which is rotatablyand horizontally provided with an upper pressing roller and a lower pressing roller, and the upper pressing roller is driven by a second driving device; and two ends of the upper pressing roller are separately provided with regulating structures for regulating the distance between the upper pressing roller and the lower pressing roller. The plank paper-pasting equipment with the automatic feed system has the advantages of convenient use, time and labor saving and the like.

Owner:台山市新英汉装饰材料有限公司

Automatic stripping and sticking device for sponges with release paper

ActiveCN108202890ARealize automatic strippingAchieve pasteArticle unpackingPulp and paper industryRelease liner

The invention discloses an automatic stripping and sticking device for the sponges with release paper. The automatic stripping and sticking device for the sponges with the release paper comprises a stripping module and a sticking module. The stripping module is used for stripping off the release paper on the sponges. The sticking module is used for sticking the sponges without the release paper tothe structures needing the sponges. The sticking module comprises an air blowing plate and an air intake pipe. The air blowing plate is arranged at the material outlet of the stripping module. The air intake pipe which is vertically arranged can move between the air blowing plate and the structures needing the sponges. The air blowing plate can blow air upwards so as to blow the sponges without the release paper upwards while the sponges move from the material outlet of the stripping module to the air blowing plate. With the automatic stripping and sticking device for the sponges with the release paper, it can be realized that the release paper on the sponges is automatically stripped off and the sponges are automatically stuck; and the production efficiency is improved, and manpower is saved.

Owner:CHANGSHA GREE HVAC EQUIP CO LTD +1

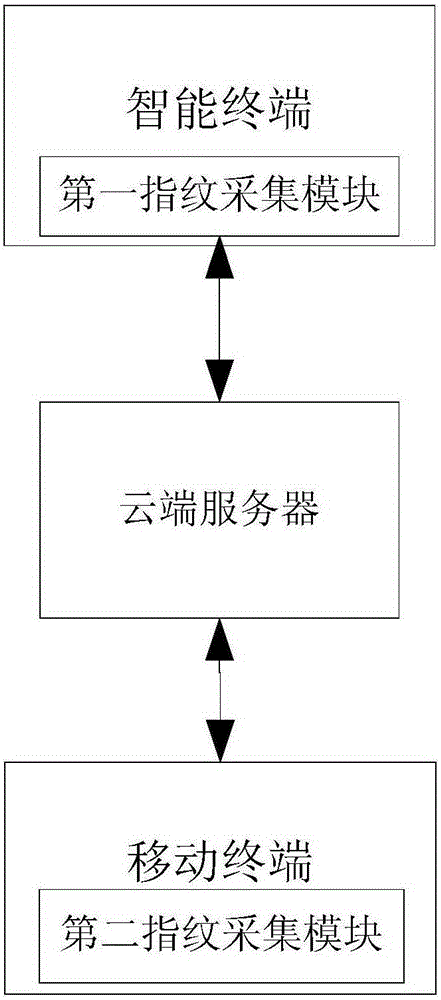

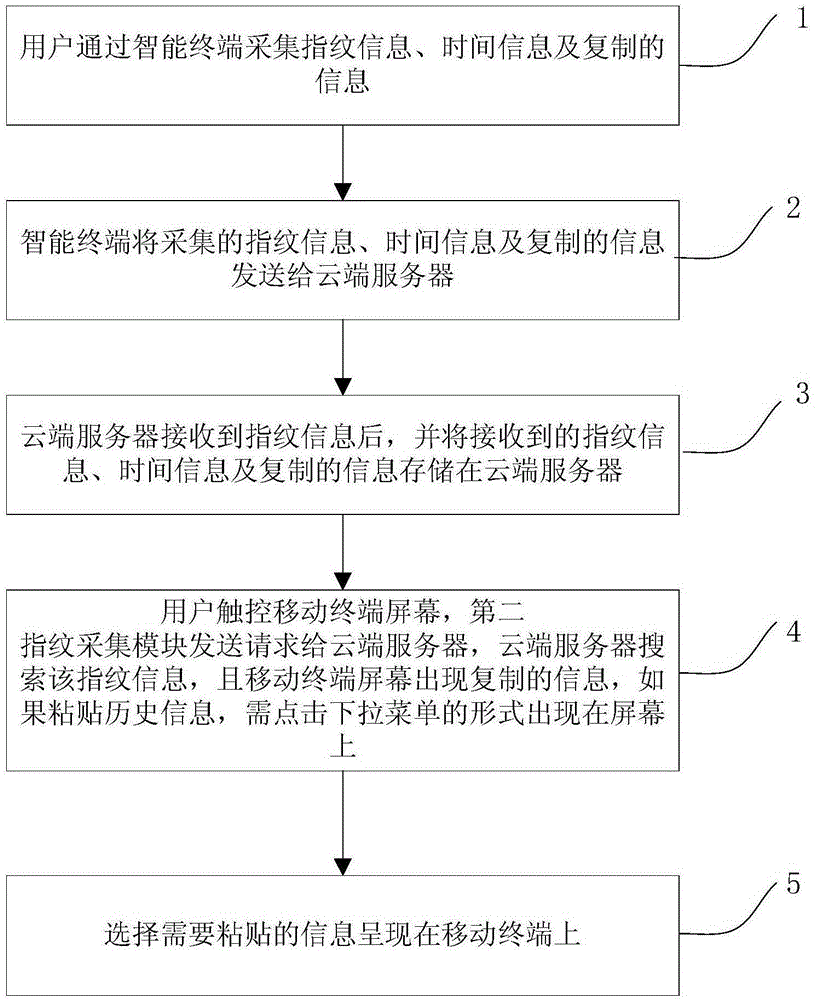

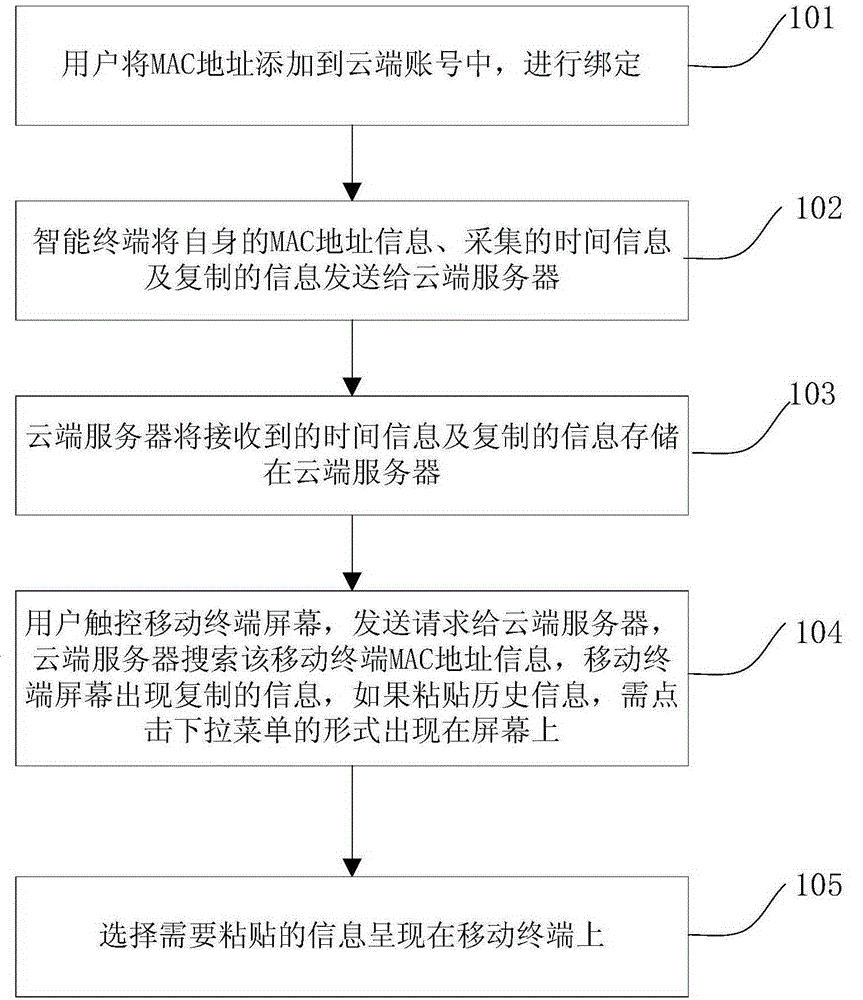

Transfer interaction system and method based on fingerprint identification information

InactiveCN106487862AAchieve replicationAchieve pasteTransmissionInteraction systemsTemporal information

The invention discloses a transfer interaction system and method based on fingerprint identification information. The system comprises an intelligent terminal with a first fingerprint acquisition module, and further comprises a cloud server and a mobile terminal with a second fingerprint acquisition module; the intelligent terminal with the first fingerprint acquisition module obtains copied information, fingerprint information and time information, and transmits the obtained fingerprint information, copied information and time information to the cloud server; and the cloud server receives the fingerprint information, the time information and the copied information, stores the received fingerprint information, time information and copied information, and sends the time information and the copied information. By means of the transfer interaction system and method based on fingerprint identification information disclosed by the invention, the rapid transfer problem of information data of electronic touch equipment in the prior art can be solved; the electronic touch equipment acquires fingerprint information through the fingerprint acquisition module; furthermore, all operations are connected to a time shaft; and all interaction equipment interfaces have interactive object identification capability.

Owner:NANJING IOT SENSOR TECH

Double-roller adhesive tape pasting mechanism

PendingCN110048169AAchieve pasteFinal product manufactureElectrolyte accumulators manufactureAdhesiveEngineering

The invention belongs to the technical field of lithium battery production, in particular to a double-roller adhesive tape pasting mechanism, which comprises an adhesive tape preparation table, an adhesive tape pulling assembly and an adhesive tape rolling assembly, wherein the adhesive tape pulling assembly comprises an adhesive tape pasting unit and a traction unit; the adhesive tape rolling assembly comprises an adhesive tape pasting unit and a rotation driving unit. The double-roller adhesive tape pasting mechanism is characterized in that the two ends of the traction unit are arranged above the adhesive tape preparation table and the adhesive tape pasting unit respectively, the adhesive tape pasting unit is slidably arranged on the traction unit, the traction unit drives the adhesivetape pasting unit to slide back and forth between the adhesive tape preparation table and the adhesive tape pasting unit, and one end of the rotation driving unit is connected with the adhesive tape pasting unit so as to drive the adhesive tape pasting unit to rotate or stop. The double-roller adhesive tape pasting mechanism is reasonable in structure, adhesive tapes with different lengths can bepasted by only adjusting the adhesive tape preparing length without replacing an adhesive tape preparation table or an adhesive tape pasting unit, and the pasting requirements and different adhesive tape pasting positions of the adhesive tapes with the different lengths are met.

Owner:东莞市联德企业管理有限公司

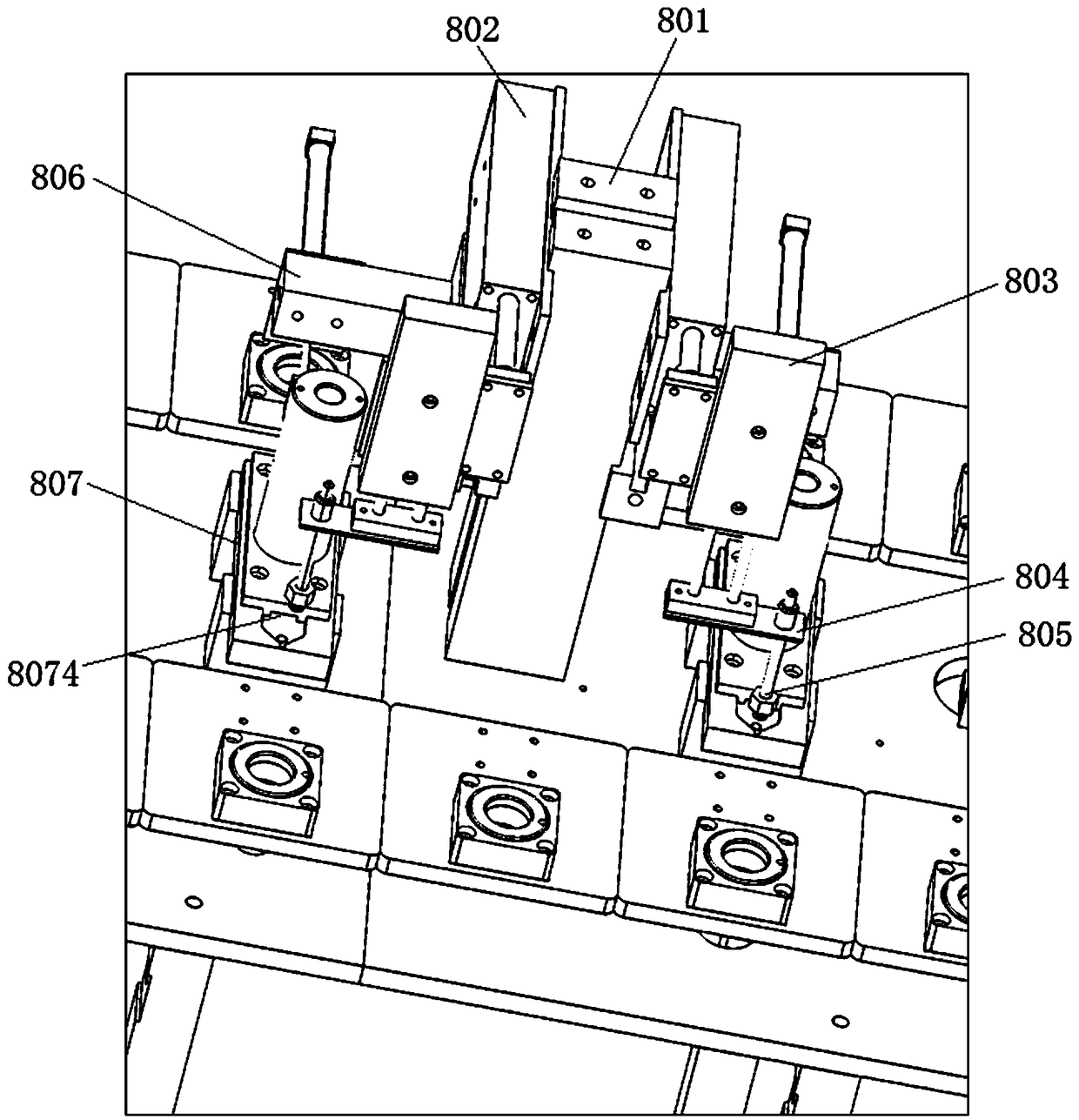

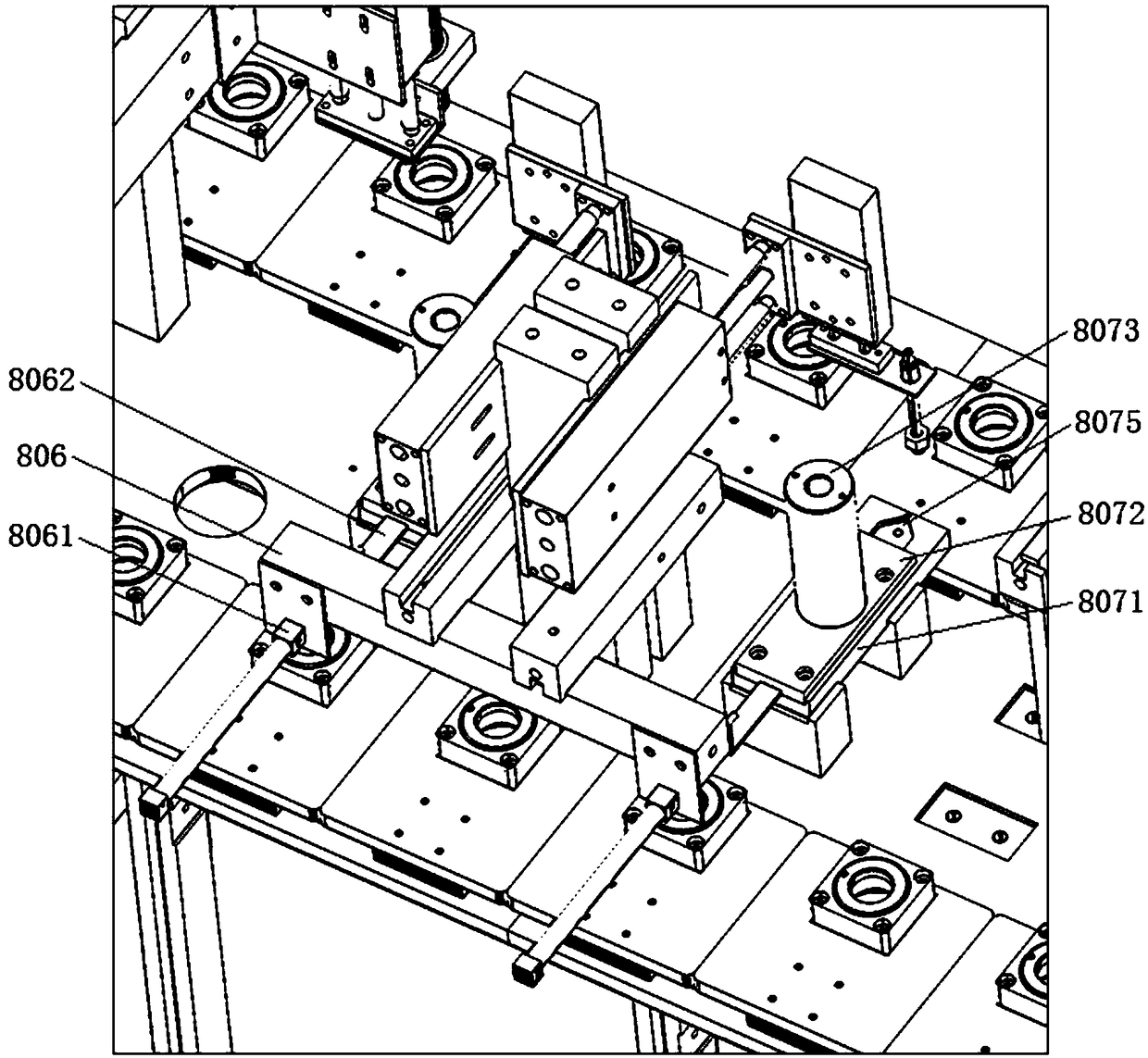

Loudspeaker magnet peeling assembly machine

ActiveCN109246578ARealize automatic separationAchieve crawlingElectrical transducersChinese charactersMagnetization

The invention proposes a loudspeaker magnet peeling assembly machine, and the assembly machine comprises a turnover platform which is provided with a circulating working procedure line of a structureshaped like the Chinese character Hui. The circulating working procedure line is provided with a plurality of bearing plates for a jig. The head of the turnover platform is provided with a lateral push assembly in the lateral direction of the circulating working procedure line, and is provided with a longitudinal push assembly in the longitudinal direction of the circulating working procedure line. The tail end of the turnover platform is provided with two gluing devices, one magnetization device and two detection devices in the direction of the working procedure. The assembly machine achievesthe automatic separation, grabbing and pasting of a magnetic piece, a magnetic core and a magnetic circuit assembly. The assembly machine can simulate the manual operation to rotate a support, improves the yield, improves the work efficiency, is low in rejection rate, and reduces the manpower cost of an enterprise.

Owner:南京闻新声学科技有限公司

Blood collection tube labeling device

ActiveCN112249459AAchieve extrusionReduce misposting rateLabelling short rigid containersLabelling machinesBlood collectionControl cell

The invention relates to the field of medical instruments, and particularly relates to a blood collection tube labeling device. The blood collection tube labeling device comprises a plurality of labeling units, a control unit and an input unit, wherein the control unit controls the corresponding labeling units to work according to labeling content input by the input unit; each labeling unit comprises a containing chamber used for transversely containing blood collection tubes and a labeling machine used for making labels out, wherein the blood collection tubes placed in the single containing chamber are the same in color; each containing chamber communicates with a conveying channel used for conveying the corresponding blood collection tube to a label outlet of the corresponding labeling machine; the bottom of each containing chamber is rotationally connected with a transversely-arranged conveying disc; a first motor used for driving the corresponding conveying disc to rotate is arranged at the bottom of each containing chamber; a plurality of arc-shaped grooves are formed in the edge of each conveying disc and evenly distributed around the circumference of the center line of the corresponding conveying disc; and each labeling unit further comprises an extrusion mechanism used for pasting the labels coming out of the label outlet of the corresponding labeling machine to the corresponding blood collection tubes. According to the scheme, the situation that the labels are pasted to the blood collection tubes in other colors by mistake is avoided.

Owner:THE FIRST AFFILIATED HOSPITAL OF ARMY MEDICAL UNIV

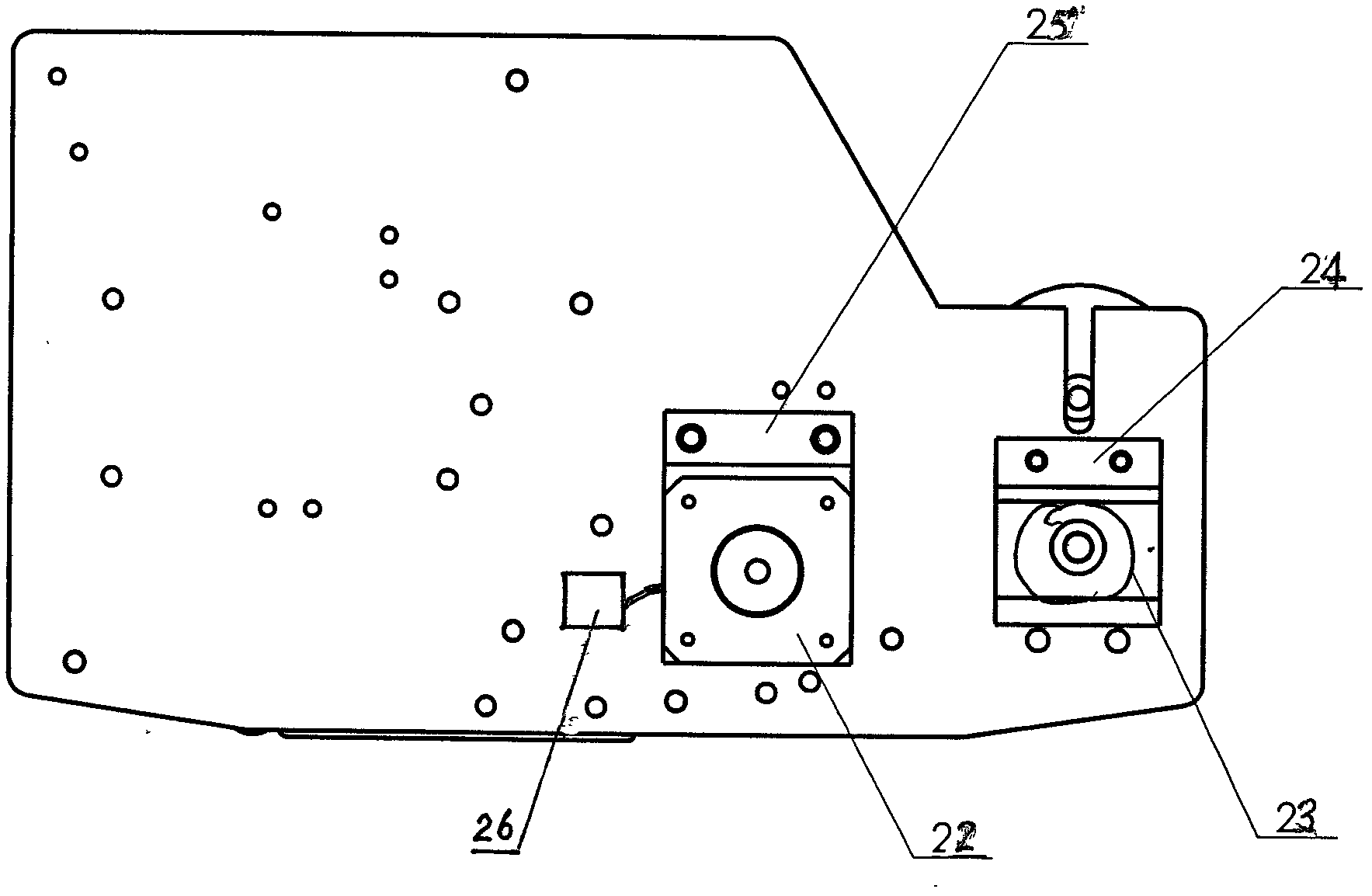

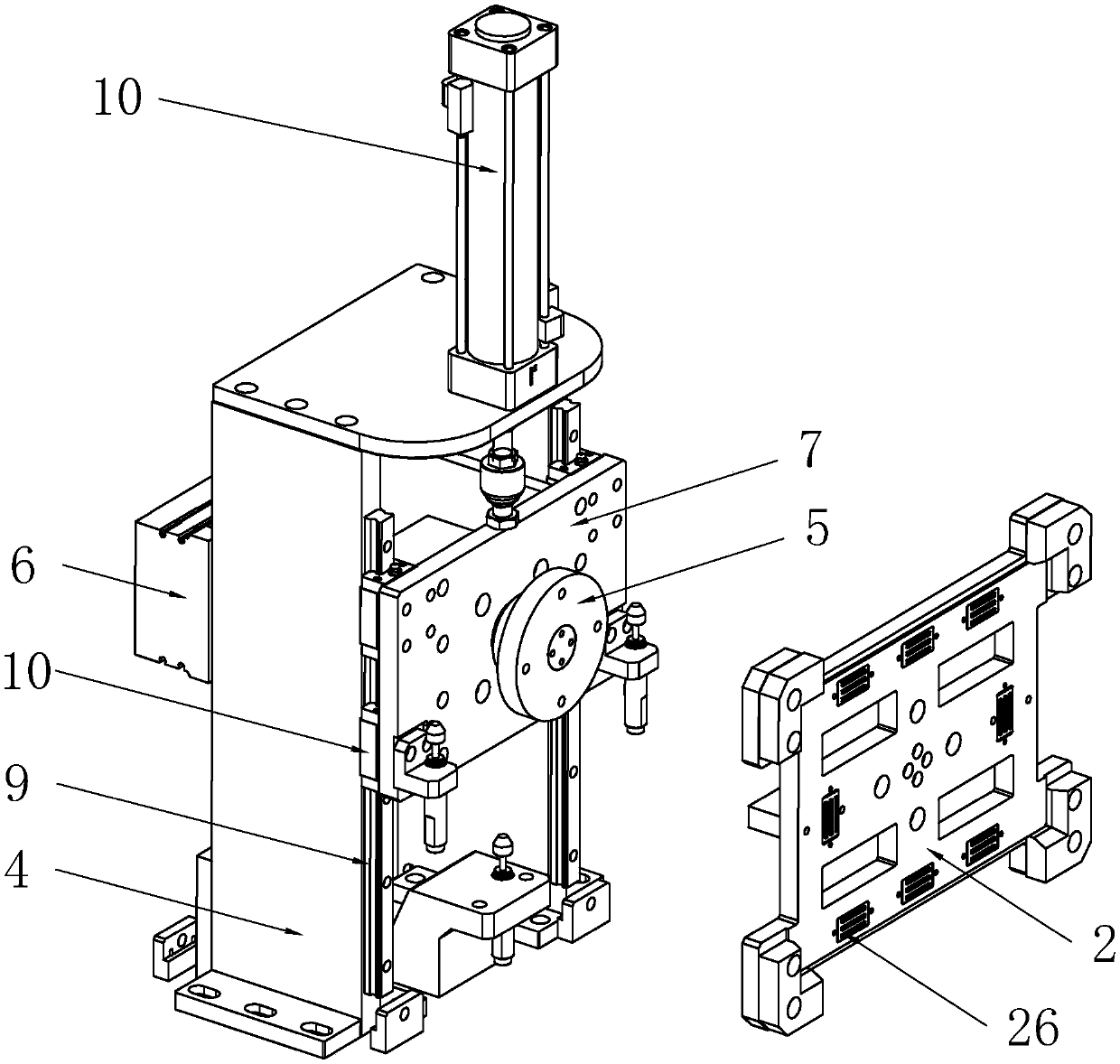

An integrated PCB board automatic access system

ActiveCN109219340AAchieve pasteRealize the assemblyElectrical componentsCantileverIntegrated production

The invention discloses an integrated PCB automatic access system, comprising a main box, wherein a table panel is arranged through the inside of the main box, a synchronous belt is arranged at the upper end of the table panel, a feeding device is arranged at one end of the synchronous belt, and a receiving device is arranged at the other end of the synchronous belt. The invention relates to the integrated PCB board automatic access system, There are three sets of automatic devices on the machine: a PCB board automatic feeding device, a PCB intelligent access station, a PCB board automatic receiving device. At that same time, the anti-static sponge pad can be adhered, and the positioning thimble can be assembled at the same time; the combined and integrated production line is carried out;a cantilever XY-axis structure is employed and a Z-axis is provided with a CCD detection function, so the manual assembling time is saved. The SMT process of PCB board is automated by machine, whichcan quickly assemble, can improve the assembling efficiency and product quality, and has certain practicability, thus bringing better application prospects.

Owner:湖南卓芯智能科技有限公司

Linear sticking reinforcing process for PET (Polyethylene Terephthalate) film of flexible circuit board

ActiveCN103079351AImprove work efficiencyAchieve pastePrinted circuit manufacturePolyethylene terephthalatePolyethylene terephthalate glycol

The invention discloses a linear sticking reinforcing process for a PET (Polyethylene Terephthalate) film of a flexible circuit board. The linear sticking reinforcing process comprises the following steps of: transversely sticking all reinforcing films to the PET film according to mirror image positions of positions to be stuck of the reinforcing films in a product; vertically punching the PET film provided with the reinforcing films; sticking the entire PET film provided with the reinforcing films to the flexible circuit board; and separating the reinforcing films from the PET film. Compared with the conventional sticking reinforcing method, the linear sticking reinforcing process for the PET film of the flexible circuit board is a process with the highest working efficiency. The sticking reinforcing quality requirement is met, and the working efficiency is increased greatly.

Owner:DALIAN JIXING ELECTRONICS

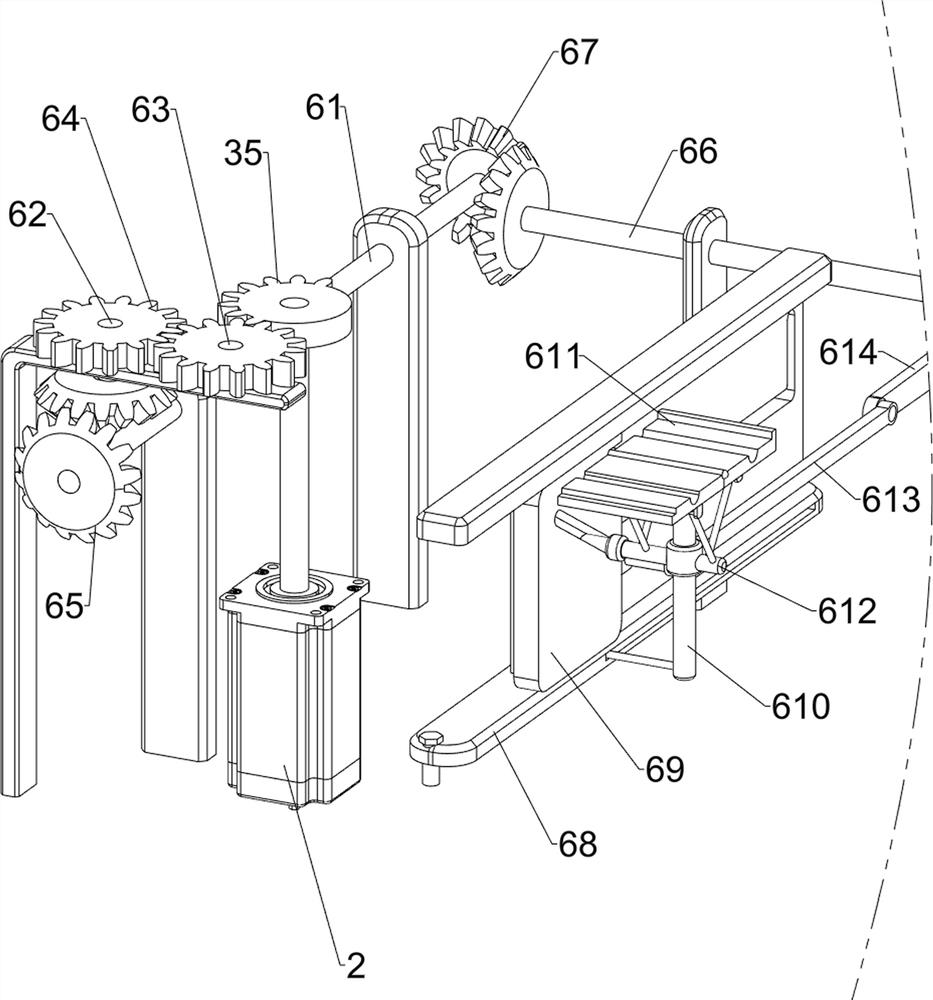

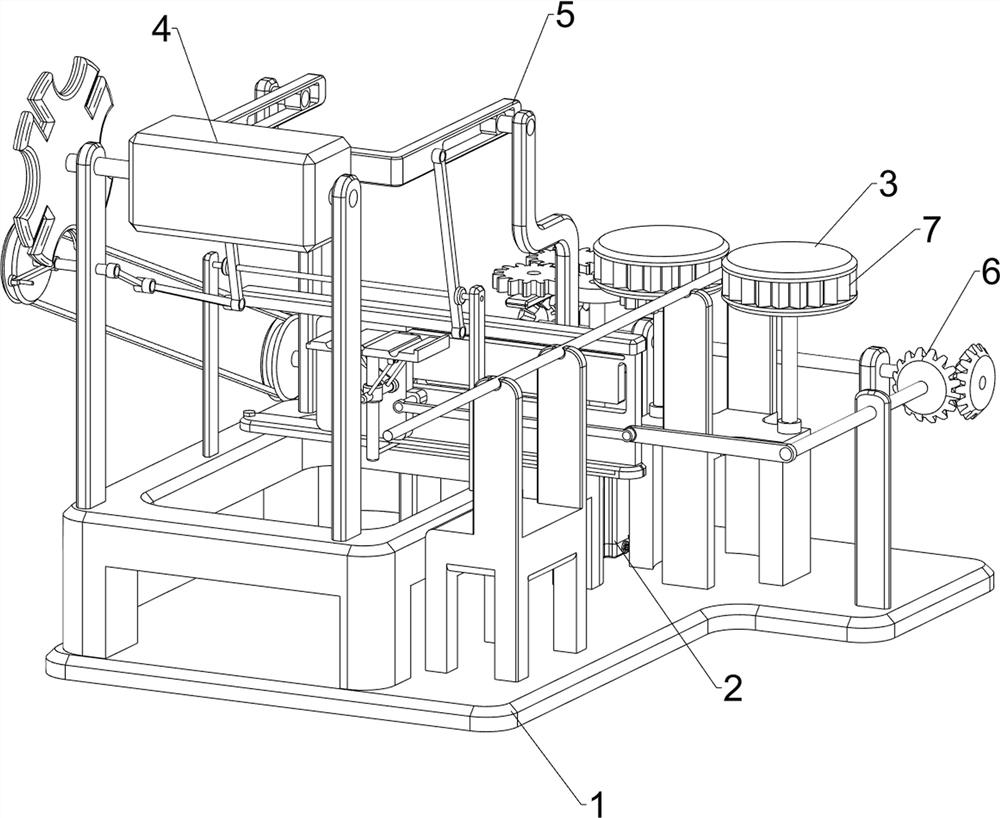

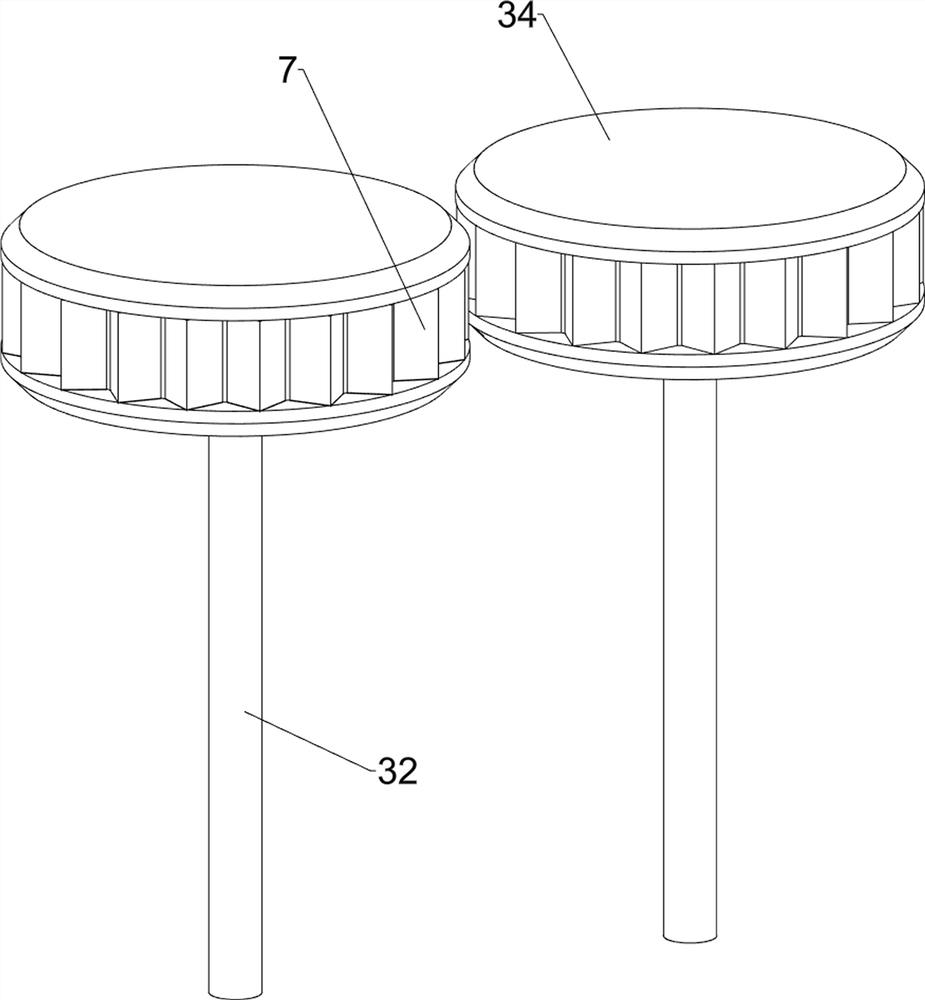

Ladder-pasting type network cable identifying equipment for network engineering

ActiveCN112357272AHigh speedReduce inconvenienceFilament handlingLabelling machinesControl engineeringStructural engineering

The invention relates to equipment for identifying a network cable, in particular to a ladder-pasting type network cable identifying equipment for network engineering. The invention provides the ladder pasting type network cable identifying equipment for the network engineering, which can realize automatic pasting, save manpower and improve the working efficiency. The ladder pasting type identification network cable equipment for network engineering comprises a bottom plate and a servo motor, a conveying mechanism, a turnover mechanism, a feeding mechanism and a labeling mechanism, wherein theservo motor is mounted in the middle of the front side of the bottom plate; the conveying mechanism is arranged at the left part of the front side of the bottom plate. the turnover mechanism is arranged on the rear side of the bottom plate; the feeding mechanism is arranged at the middle part of the bottom plate, and the feeding mechanism is matched with the turnover mechanism; and the labeling mechanism is arranged in the middle of the bottom plate, and the labeling mechanism is matched with the feeding mechanism. When the equipment is used, the network cable needing to be identified can beautomatically transported through the conveying mechanism, and the network cable does not need to be manually held by hand, so that the identification of the network cable becomes more convenient, andthe inconvenience of manual operation is reduced.

Owner:山东明高智能化科技有限公司

Process for sticking adhesive tape on wire rods

PendingCN111232738AReduce manpower requirementsImprove efficiencyArticle deliveryWire rodAdhesive disc

The invention discloses a process for sticking adhesive tape on wire rods. The process comprises an adhesive tape straightening device, a transfer plate, a cutter group and shaping clamps, wherein theadhesive tape straightening device comprises an adhesive disc, a roller and a fixing clamp; the transfer plate comprises a base plate and an ear plate; vertical rectangular notches are formed in theear plate at equal intervals; the cutter group comprises cutters which are horizontally arranged at equal intervals; and each shaping clamp comprises symmetrical clamping plates and an air cylinder. According to the process, the adhesive tape is vertically stuck on the inner side of the ear plate of the transfer plate after being straightened, then the cutter group is matched with the transfer plate, and the cutters extend into the rectangular notches to cut off the adhesive tape; the wire rods are vertically arranged at equal intervals and matched with the rectangular notches of the ear plate, during the relative movement, the cut adhesive tape is stuck on the surfaces of the wire rods and separated from the transfer plate, then the part with the adhesive tape of each wire rod moves between the symmetrical clamping plates of the corresponding shaping clamp, and the air cylinders are started to drive the clamping plates to clamp the adhesive tape on the surfaces of the wire rods; and thus the adhesive tape sticking work of the plurality of wire rods can be completed at one time, the speed and the efficiency are high, the labor requirement of adhesive tape sticking is reduced, the adhesive tape sticking efficiency is improved, and the production cost is greatly reduced.

Owner:东莞市鑫华翼自动化科技有限公司

Trademark paste tooling

The invention relates to a device for pasting a label, in particular to a trademark pasting tool. The tool comprises a mounting base and a glue sheet fixing piece, wherein the glue sheet fixing pieceis located above the mounting base, and the mounting base is rotationally connected with the glue sheet fixing piece; the glue sheet fixing piece comprises a base connecting piece and a rotating connecting plate, the base connecting piece is fixed on one side face of the rotating connecting plate, the base connecting piece is rotationally connected with the mounting base, a U-shaped groove is formed in the other side of the corresponding rotating connecting plate, two pressing plates are arranged in the U-shaped groove, the pressing plates are fixedly connected with the inner walls of the twoopposite sides of the U-shaped groove correspondingly, one ends of the pressing plates are fixedly connected with the rotating connecting plate, and the other ends of the pressing plates are free ends; and the free ends of the pressing plates are provided with glue sheet fixing bulges, the depth of the U-shaped groove is not smaller than the width of a glue sheet, and the two ends of the glue sheet are placed in the glue sheet fixing bulges correspondingly. According to the tool, the precision of a trademark pasting position is high, only by replacing part of parts, pasting of trademarks of different sizes and models can be realized, and the tool is simple to machine and is few in material consumption.

Owner:QINGDAO COLETTE PHOTOELECTRIC TECH

An integrated pcb board automatic entry and exit system

ActiveCN109219340BAchieve pasteRealize the assemblyElectrical componentsProcess engineeringMechanical engineering

The invention discloses an integrated PCB automatic access system, comprising a main box, wherein a table panel is arranged through the inside of the main box, a synchronous belt is arranged at the upper end of the table panel, a feeding device is arranged at one end of the synchronous belt, and a receiving device is arranged at the other end of the synchronous belt. The invention relates to the integrated PCB board automatic access system, There are three sets of automatic devices on the machine: a PCB board automatic feeding device, a PCB intelligent access station, a PCB board automatic receiving device. At that same time, the anti-static sponge pad can be adhered, and the positioning thimble can be assembled at the same time; the combined and integrated production line is carried out;a cantilever XY-axis structure is employed and a Z-axis is provided with a CCD detection function, so the manual assembling time is saved. The SMT process of PCB board is automated by machine, whichcan quickly assemble, can improve the assembling efficiency and product quality, and has certain practicability, thus bringing better application prospects.

Owner:湖南卓芯智能科技有限公司

An automatic adhesive edge banding machine

InactiveCN106739177BAchieve pasteNo tilting phenomenonDispersed particle filtrationPaper/cardboard articlesEngineeringMachining process

The invention discloses an automatic gluing edge sealing machine which comprises a machine frame. A workpiece placing mechanism and a side plate coiling and placing mechanism are arranged on the machine frame. The workpiece placing mechanism comprises a workpiece fixing seat which is arranged vertically and faces the front. A workpiece jig is movably arranged on the workpiece fixing seat. A side plate clamping mechanism is arranged on the front side of the workpiece placing mechanism. The side plate clamping mechanism comprises a side plate clamping head and a clamping head driving device used for driving the side plate clamping head to slide. The side plate clamping head is located below the workpiece jig. A gluing mechanism is arranged on one side of the workpiece placing mechanism. A side plate shearing mechanism is arranged beside the gluing mechanism. The whole machining process is fast and safe, manual operation is not needed, and the machining efficiency is greatly improved; and in addition, gluing is even, the phenomenon that glue inclines towards one side is avoided, gluing is firmer, and the appearance is more attractive.

Owner:珠海清菱净化科技有限公司

OCR double-component thermosetting silica gel dry laminating process and device

PendingCN114589076AAchieve pasteAvoid wastingLiquid surface applicatorsSpraying apparatusThermodynamicsAdhesive belt

A sliding rail drives a sliding plate to move, a pressing wheel adheres a high-temperature adhesive tape to the periphery of a product, an electric sliding rail pushes the sliding plate to move one side, then the pressing wheel adheres the adhesive tape to one side of the product, the electric sliding rail is driven to move to the initial position, a motor drives the sliding plate to rotate by 90 degrees, and the adhesive tape is attached to the other side of the product. And the electric sliding rail continues to drive the sliding plate to move, so that adhesive tape pasting on the other side is achieved, and adhesive tape pasting on the periphery of the product is achieved through multiple times of edge changing adhesive tape pasting. The water conveying pump pumps water after heat exchange into the collecting pipe, the water is heated through the heating threaded ring and discharged, heat waste is avoided through heat exchange, and meanwhile, the heating threaded ring is used for heating, so that the situation that glue cannot be cleaned thoroughly due to insufficient temperature is avoided. The heated water flow flushes down glue under the action of high pressure, and meanwhile, the glue is flushed down by cooperating with high-temperature water flow, so that glue adsorption is reduced, and low-temperature solidification is avoided.

Owner:深圳市中欣科技有限公司

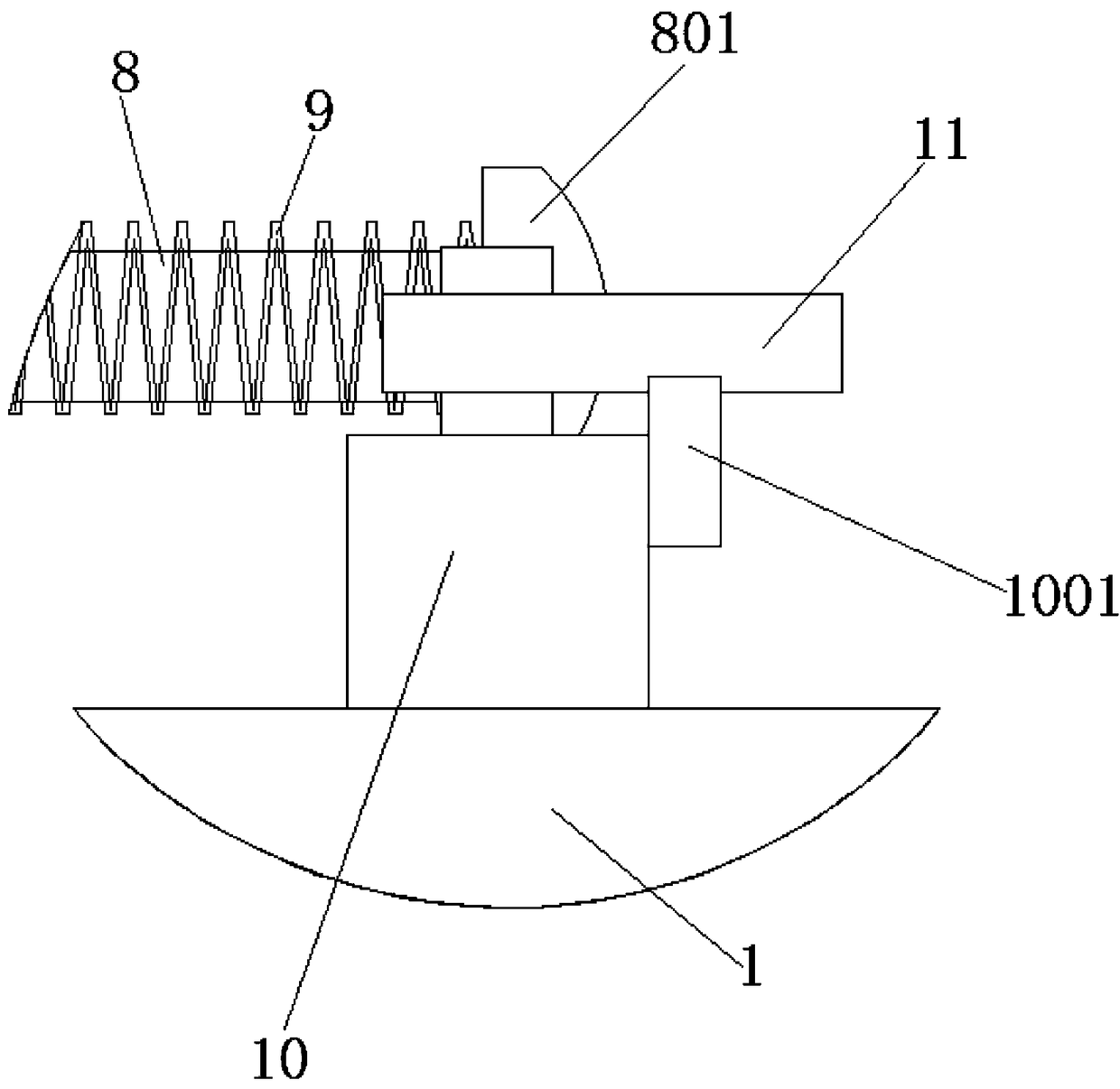

Multi-station lifting opening tape winding machine

ActiveCN113602553AQuality improvementRealize automatic tape wrappingFinal product manufactureWeb rotation wrappingWinding machineAdhesive belt

The invention discloses a multi-station lifting opening tape winding machine. A tape winding machine body is sequentially provided with a plurality of tape winding modules in the direction from feeding to discharging, a pressing module is arranged above the tape winding modules, the tape winding machine body is used for conveying and placing products, the products are arranged on the tape winding modules in a penetrating mode, the pressing module is used for fixing the products to the tape winding machine body, each tape winding module comprises a winding unit and a clamping and cutting unit, the clamping and cutting unit is arranged in the winding unit, the winding unit is provided with an adhesive tape roll, the clamping and cutting unit faces the adhesive tape roll, the winding unit is used for driving the adhesive tape roll to move around the clamping and cutting unit, and the clamping and cutting unit is used for clamping the adhesive tape at one end of the adhesive tape roll and cutting the adhesive tape after the product is wound with the adhesive tape. According to the multi-station lifting opening tape winding machine, the adhesive tape can be automatically wound on the surface of the product, and the adhesive tape can be automatically cut off after tape winding is completed so that automatic tape winding is achieved, and compared with manual operation, the production efficiency is improved, and the tape winding quality is further improved.

Owner:GUANGDONG VOCATIONAL & TECHNICAL COLLEGE

rotary cam mechanism

Owner:GUANGZHOU CHILI AUTOMATION EQUIP

Multifunctional handheld box sealing device

PendingCN113942700AAchieve pasteImprove work efficiencyWrapper twisting/gatheringArticle deliveryAdhesive beltEngineering

The invention discloses a multifunctional handheld box sealing device which comprises a holding assembly, a material carrying assembly, an adjustable adhesive pressing assembly and an adjusting assembly. The material carrying assembly is arranged on a base and is used for placing an adhesive tape roll; the adjustable adhesive pressing assembly comprises a pair of adhesive pressing roller sets which extend out of the holding assembly from the interior of a containing space and can rotate close to each other or away from each other; and each adhesive pressing roller set comprises a transmission shaft arranged in the containing space, an adhesive guide frame which is arranged at one end of the transmission shaft and is positioned outside the holding assembly, and a roller which is rotatably mounted on the inner side surface of the adhesive guide frame. Adhesive tape can be pasted on a plane, non-plane adhesive tape pasting (determined according to actual needs, especially at the right-angle position of a box) can also be achieved through adjustment, and the working efficiency can be improved.

Owner:祝进平

A ladder-type labeling network cable equipment for network engineering

ActiveCN112357272BHigh speedReduce inconvenienceFilament handlingLabelling machinesControl engineeringIdentification device

Owner:山东明高智能化科技有限公司

Adhesive tape replacing device

ActiveCN113184608AAchieve pasteImprove pasting efficiencyCleaning using toolsArticle deliveryAdhesive beltStructural engineering

The invention provides an adhesive tape replacing device which is used for replacing an adhesive tape adhered to a heating bottom plate of a series welding machine. The adhesive tape replacing device comprises a handle, a mounting part, a shovel head and an adhesive tape bearing shaft, wherein the mounting part is connected to the first end of the handle, and the mounting part comprises a cross beam connected to the end part of the first end of the handle and two mounting plates which are respectively positioned at the end parts of the cross beam and are arranged in parallel; the two ends of the shovel head are detachably connected with the top ends of the mounting plates respectively; and the two ends of the adhesive tape bearing shaft are detachably connected with the mounting plates respectively, and the adhesive tape bearing shaft is located between the shovel head and the handle and is used for bearing an adhesive tape roll. According to the adhesive tape replacing device, manual adhesive tape pasting operation can be replaced, the pasting efficiency is improved, and high practicability is achieved.

Owner:JA XINGTAI SOLAR CO LTD

Labeling machine and trash can with intelligent labeling function

InactiveCN111422453AAchieve pasteAchieve recyclingLabelling machinesLabelling machineElectric machinery

The invention belongs to the technical field of labeling devices, and discloses a labeling machine and a trash can with an intelligent labeling function. The labeling machine aims to solve the problemthat a labeling machine has difficulty in automatically separating labels and waste paper in the prior art. The labeling machine comprises a top plate, and a first side plate and a second side platewhich are arranged on the two sides of the top plate in parallel. A label raw material bucket, a waste paper recovery bucket, a rotary cylinder assembly and a thermal printing mechanism are arranged between the first side plate and the second side plate. The rotary cylinder assembly comprises a first rotary cylinder and a second rotary cylinder. The label raw material bucket, the waste paper recovery bucket, the first rotary cylinder and the second rotary cylinder all can rotate. A first motor assembly for driving the waste paper recovery bucket to rotate is arranged on the first side plate. Acorner is arranged on the thermal printing mechanism. Raw material paper in the label raw material bucket passes through the thermal printing mechanism and is then separated into the labels and the waste paper by the corner of the thermal printing mechanism, and the waste paper passes through the second rotary cylinder and is then recovered through the waste paper recovery bucket. The trash can comprises the labeling machine.

Owner:光植科技(厦门)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com