Automatic stripping and sticking device for sponges with release paper

A technology of automatic peeling and release paper, applied in the field of sponge sticking, can solve the problems of inability to realize automatic matching of manipulators, reduce production efficiency, sponge deformation, etc., and achieve the effect of saving manpower, improving production efficiency, and reducing resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the application according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. . In the following description, different "one embodiment" or "embodiment" do not necessarily refer to the same embodiment. Furthermore, the particular features, structures, or characteristics of one or more embodiments may be combined in any suitable manner.

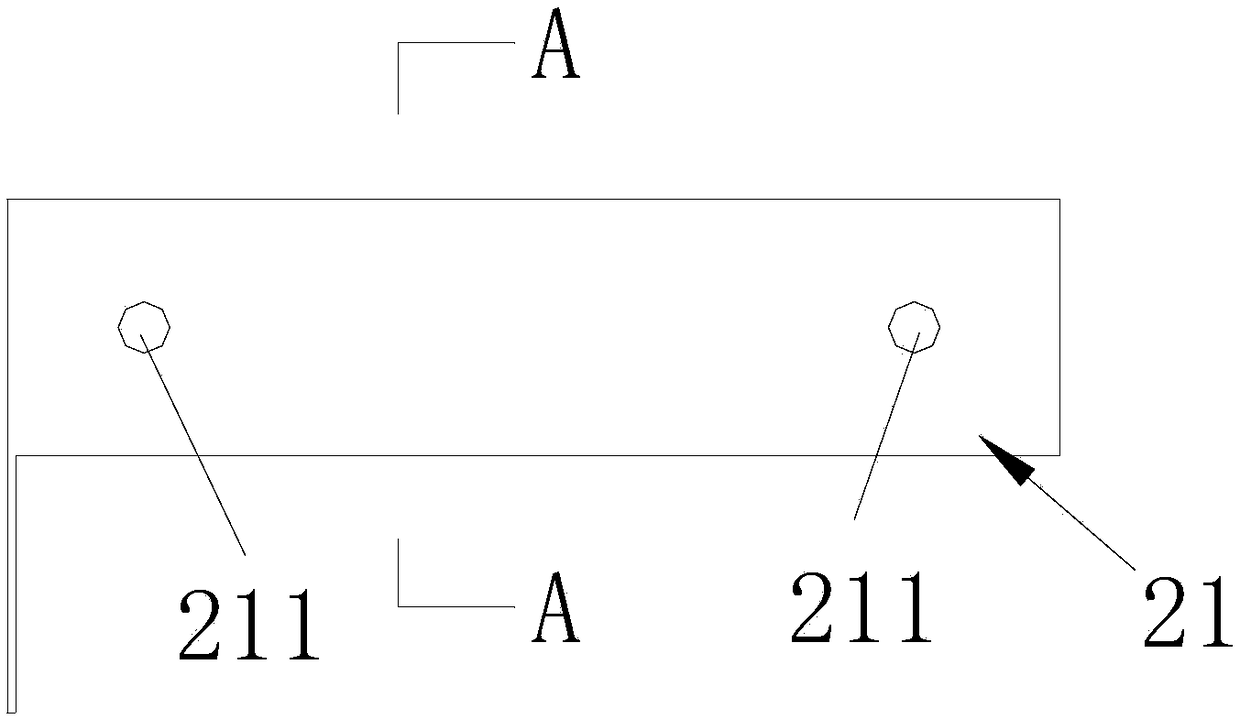

[0025] Such as Figure 1-4 As shown, the present embodiment provides a sponge release paper automatic peeling and pasting device, including a peeling module 1 for peeling off the release paper 101 on the sponge 100 and a sponge 100 pasted after peeling off the release paper 101 to the paste module 2 on the corresponding structure.

[0026] exist figure 1 A pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com