Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

119 results about "Calcium fluorophosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluorapatite, often with the alternate spelling of fluoroapatite, is a phosphate mineral with the formula Ca5(PO4)3F (calcium fluorophosphate).

Polyether-ether-ketone composite material containing fluorapatite and titanium dioxide and preparation method thereof

InactiveCN101879332AReinforcement and toughnessEnhanced mechanical compatibilityProsthesisCalcium fluorophosphateMechanical property

The invention discloses a polyether-ether-ketone composite material containing fluorapatite and titanium dioxide and a preparation method thereof, belonging to the technical field of biomedical composite materials. The composite material is a bone restoration material prepared from a polyether-ether-ketone composite material with enhanced fluorapatite and titanium dioxide and is prepared by blending fluorapatite, titanium dioxide and polyether-ether-ketone in a fusion way, wherein the fluorapatite and the titanium dioxide are respectively 10-30 percent of the total weight of the composite material, and the balance is the components of the polyether-ether-ketone. The composite material prepared from the fluorapatite, the titanium dioxide and the polyether-ether-ketone in the invention realizes good strength and toughness and consistent elastic modulus with a human bone, has bone-substitute material with bioactivity, and can overcome the defect that the traditional metal and ceramic bone-substitute material has the mechanical property which is not matched with the human bone.

Owner:PEKING UNIV

In-situ covering method for heavy metal in nano agustite immobilized sediment

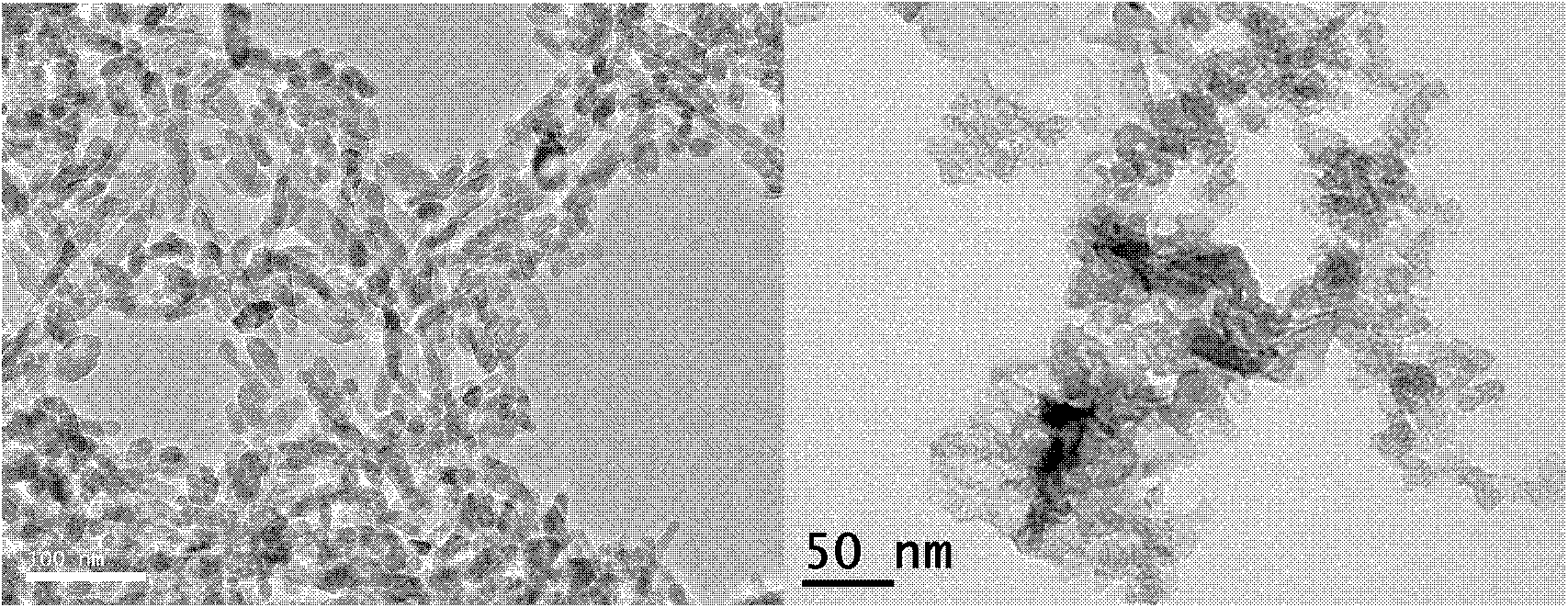

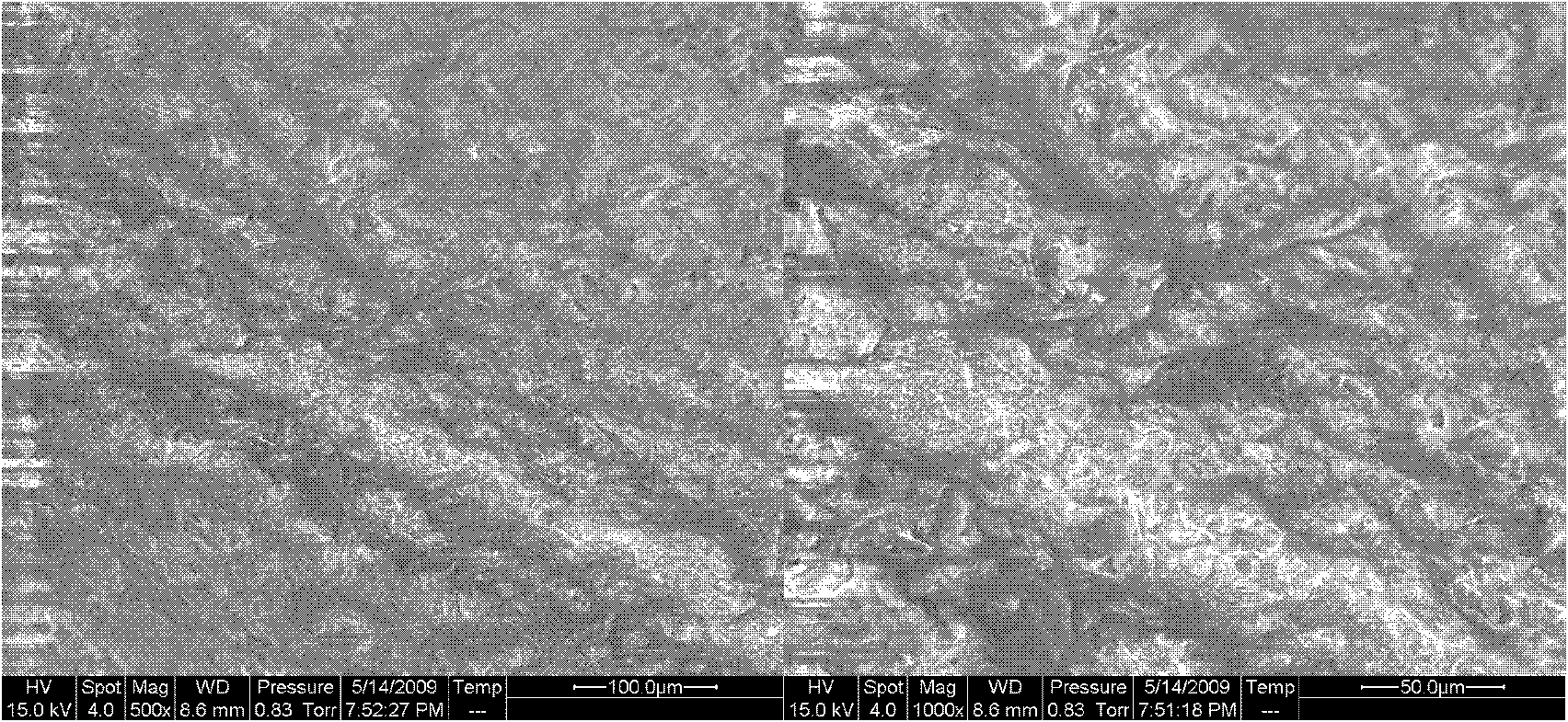

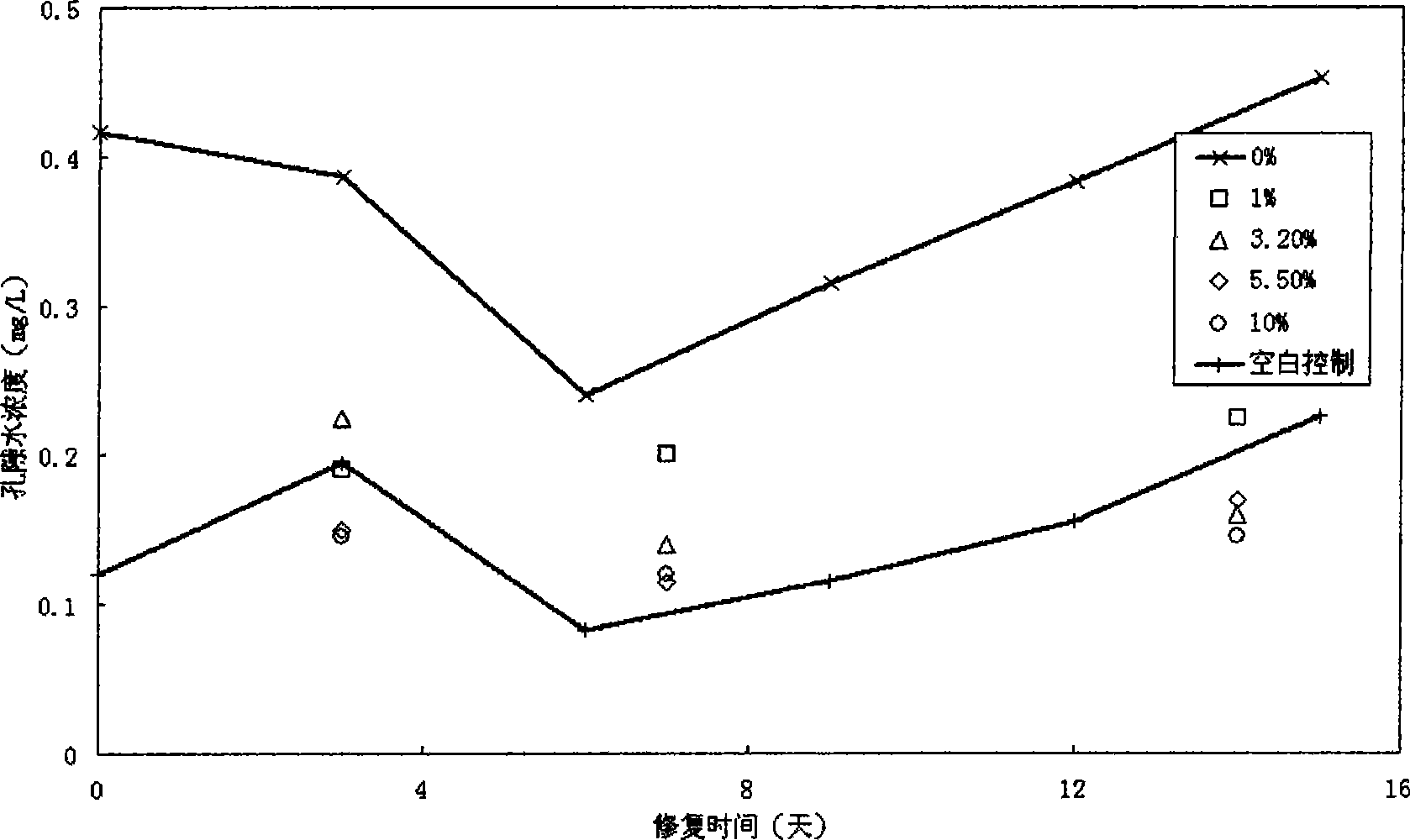

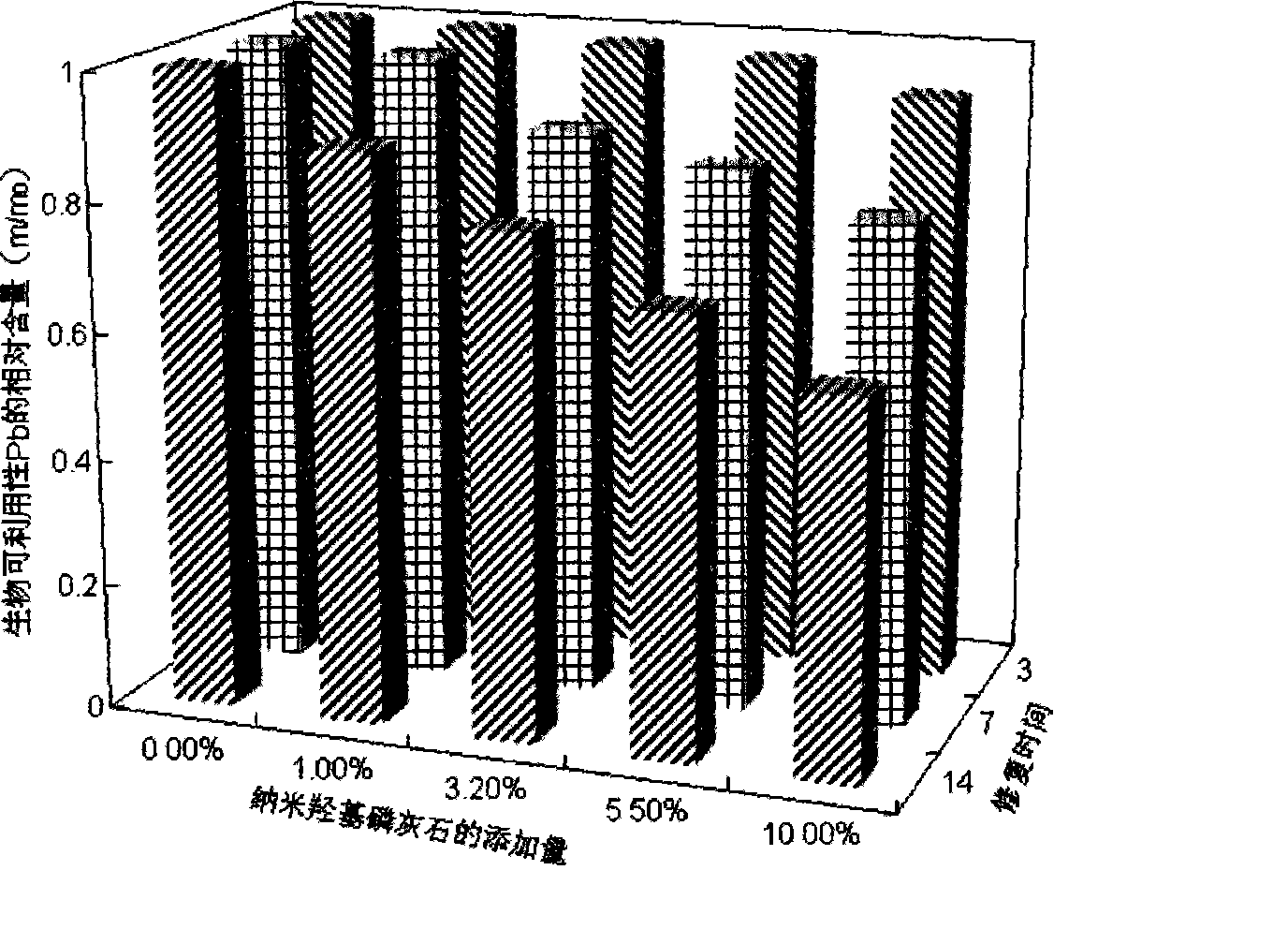

InactiveCN101412572AAvoid enteringFixed toSludge treatmentWater/sewage treatmentHydroxylapatiteWater quality

The invention discloses an in-situ covering method for heavy metal in nano phosphorite fixed sediment, which comprises the following steps: preparing nano hydroxylapatite; preparing an in-situ fixing material, that is, adopting one or more than one material of the nano hydroxylapatite, nano fluorapatite or nano chlorapatite; and carrying out in-situ covering for polluted rivers or lakes. The method also comprises the step of using an in-situ covering material mixed by one or mixture of more than one of unpolluted sediment, earth or soil, wherein specific usage amount of the in-situ covering material is 10 to 490 centimeters of covering thickness. The total covering thickness of the in-situ fixing material and the in-situ covering material is between 0.05 and 500 centimeters. The in-situ covering method is used for restoring the sediments polluted by organic substances in the rivers or the lakes, can effectively prevent pollutants such as the heavy metal in the sediments from entering water body, has remarkable function of improving water quality, has the functions of fixing the heavy metal in the sediments, reducing biological effectiveness, and the like, and has the advantages of good effect, no secondary pollution, and wide application range.

Owner:NANKAI UNIV

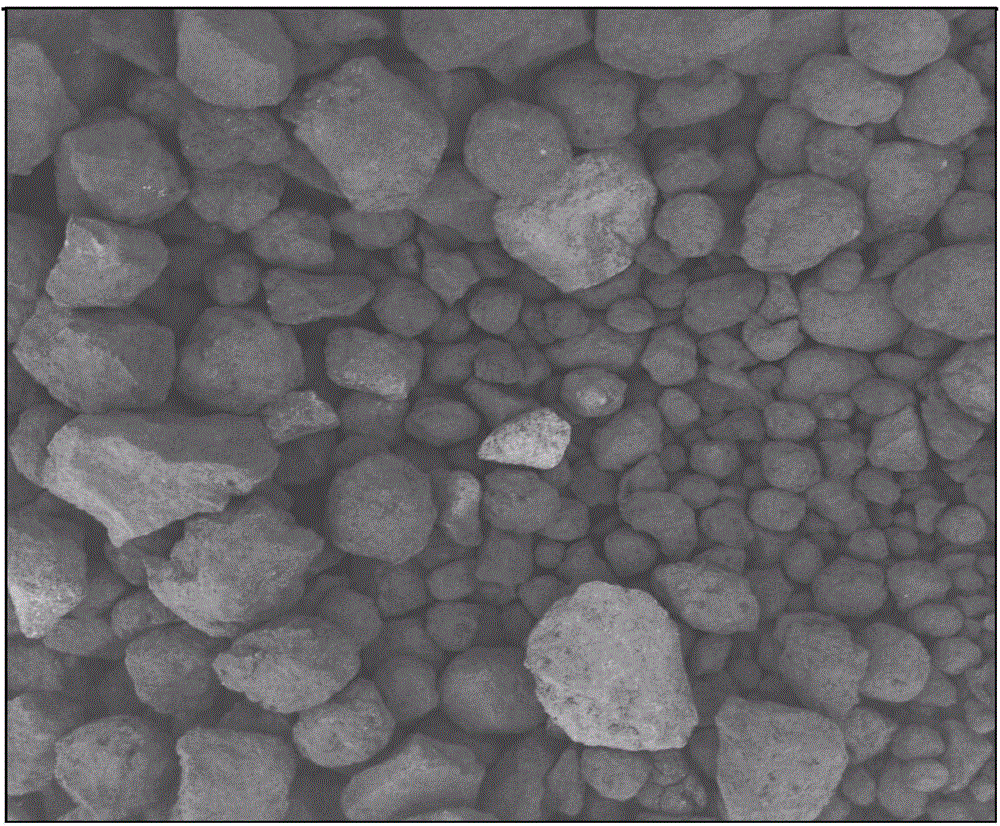

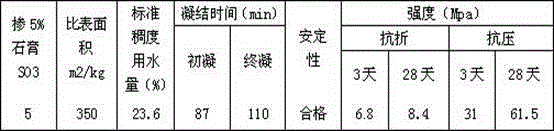

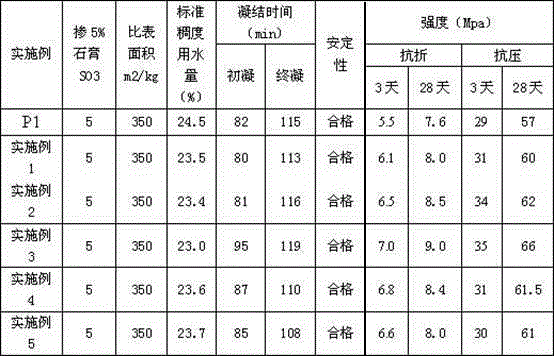

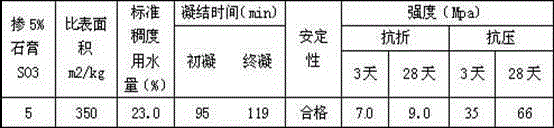

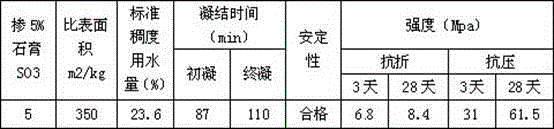

Particulate Portland cement clinker and preparation method thereof

PendingCN104944813AImprove sintering conditionLow free calcium oxideParticulatesCalcium fluorophosphate

The invention discloses particulate Portland cement clinker and a preparation method thereof. A control agent is directly mixed in raw materials in proportion as a raw material component and the materials are calcined by adopting a novel dry-process kiln. The clinker obtained after calcination contains plenty of clinker particles with appearances like fine pearls, wherein the percent of the particulate cement clinker with apparent particle size being 0.1-3.0mm in all the cement clinker exceeds 50%. The control agent is selected from natural gypsum, anhydrite, fluorapatite, copper slag, steel slag, zinc slag, nickel slag, phosphorus slag, flyash or a composite thereof. The mixing amount of the control agent is 0.1-5% compared with that of the cement raw materials. Compared with ordinary Portland cement, the mineral structure of the cement clinker, which is provided by the invention, has the effects of low energy consumption, low carbon content, high strength, and the like.

Owner:JIAHUA SPECIAL CEMENT

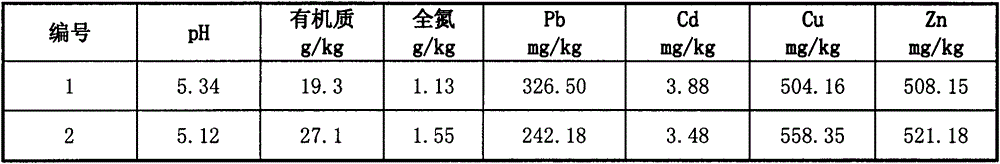

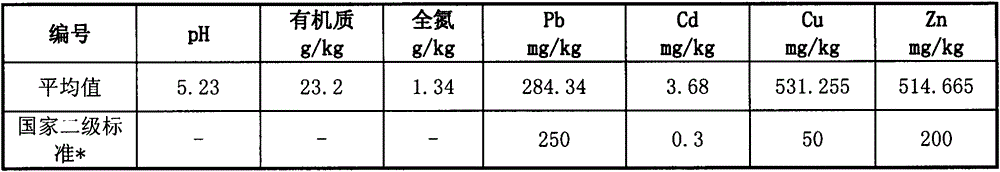

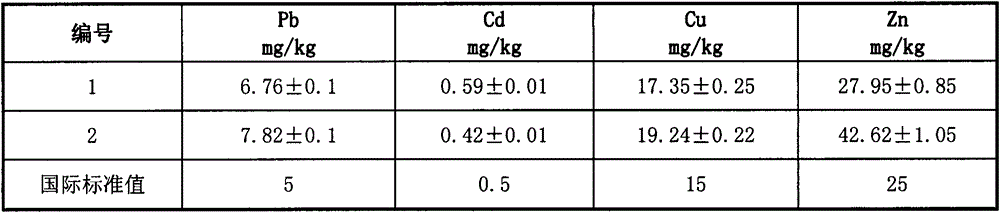

Heavy metal passivating agent, farmland purifying method and use thereof

InactiveCN103952156AGood removal effectContaminated soil reclamationOrganic fertilisersSulfateCalcium fluorophosphate

The present invention provides a heavy metal passivating agent, and a farmland purifying method and a use thereof. The raw materials comprise, by weight, 40-50% of high calcium fly ash, 20-25% of plant ash, 4-8% of gypsum, 5-10% of fluorapatite, 8-15% of vermiculite, 0.5-5% of ferric sulfate, and 0.5-5% of magnesium sulfate. The purifying method comprises: (1) crushing soil lumps; (2) adding the heavy metal passivating agent; (3) plowing the soil; (4) adding water to age; and (5) balancing. According to the present invention, the heavy metal in the farmland soil is well removed.

Owner:黎虹

Tooth Bleaching Agent

The invention relates to “tooth-bleaching agent” compositions and to their applications in whitening teeth. The dental bleaching agent of the present invention comprises apatite, especially preferably in particle sizes in the nano range, likewise especially preferably in the form of fluorapatite. The tooth-bleaching agent can have a desensitising action and a positive action in respect of the remineralisation of the tooth surface.

Owner:S & C POLYMER SILICON & COMPOSITE SPEZIALITATION

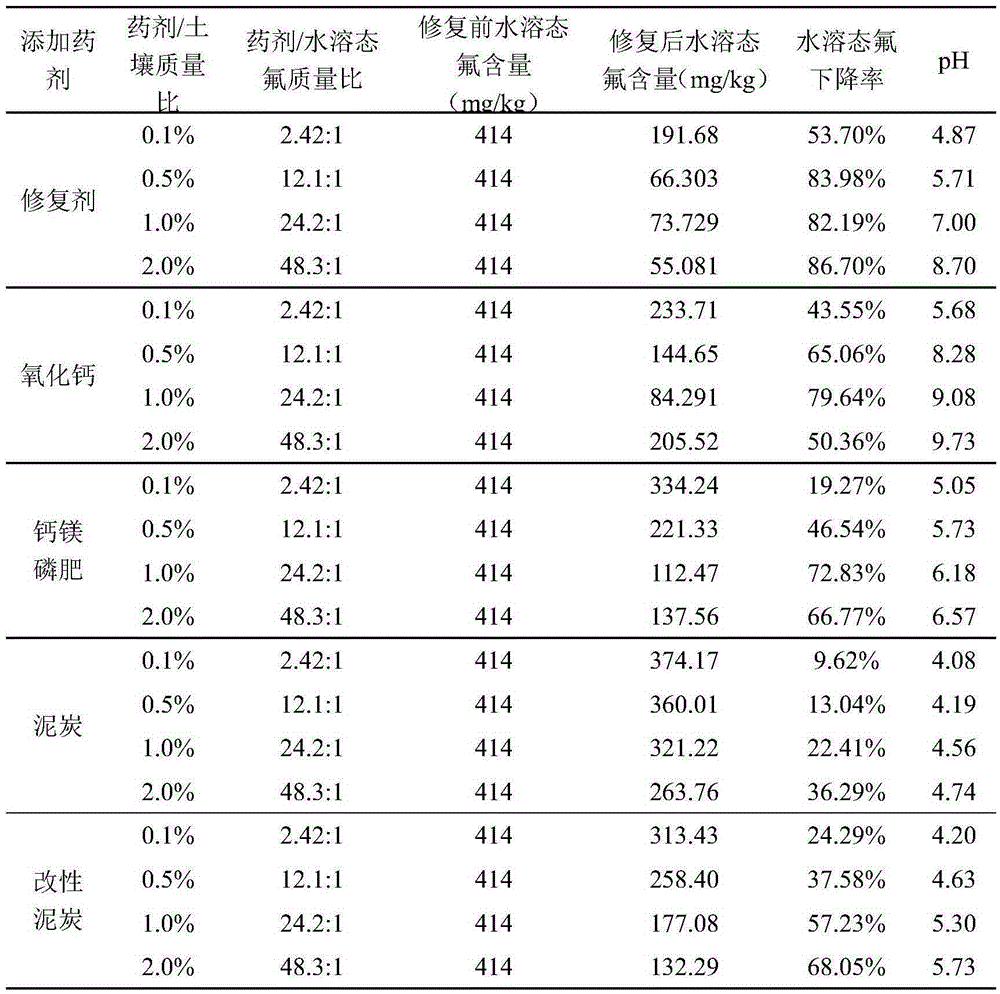

Repair agent for fluorine polluted soil and repair method for fluorine polluted soil

ActiveCN105419804AReduced activityHarm reductionContaminated soil reclamationOrganic fertilisersCalcium fluorophosphateCalcium magnesium phosphate

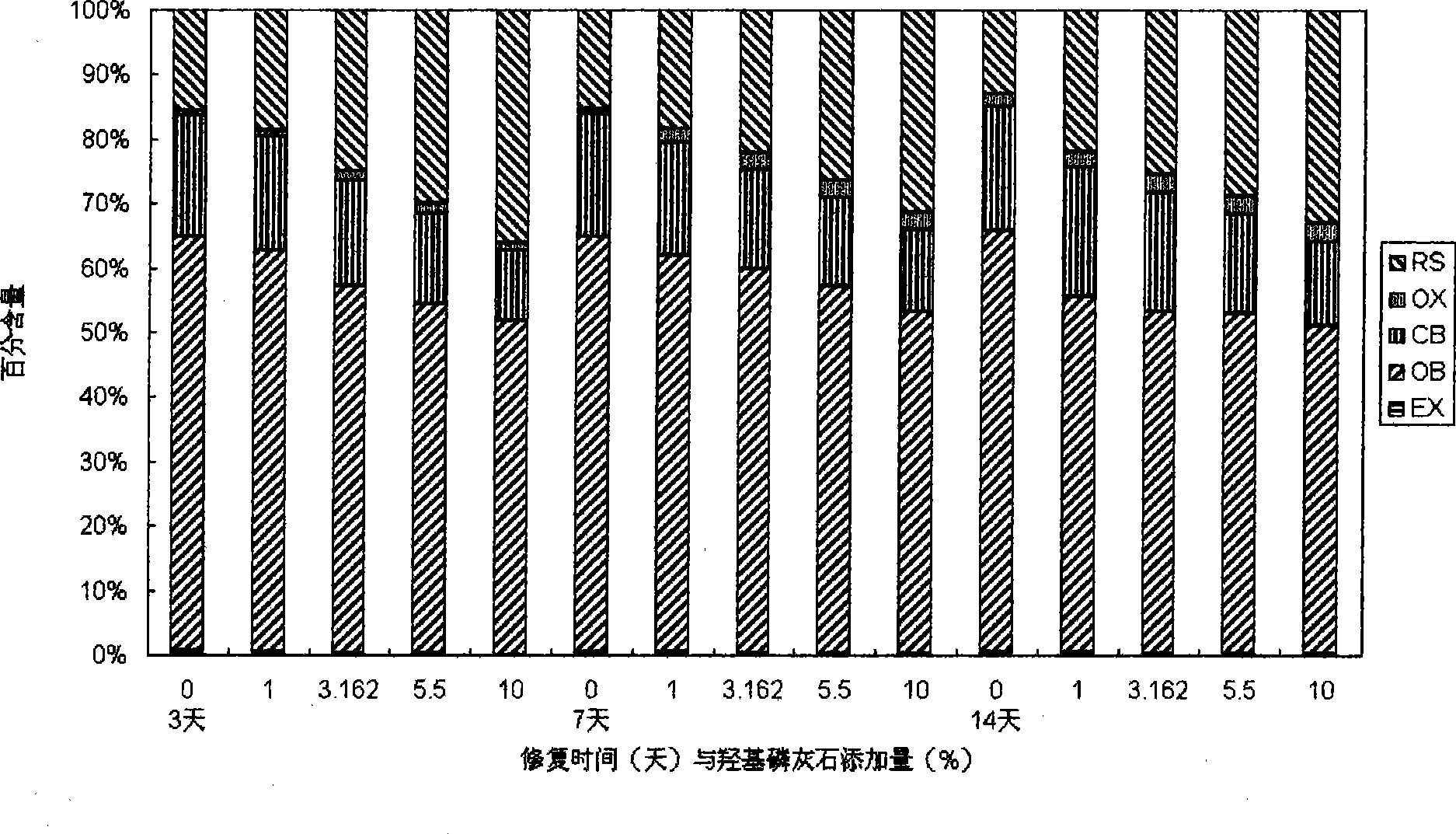

The present invention discloses a repair agent for fluorine polluted soil and a repair method for the fluorine polluted soil. The repair agent for the fluorine polluted soil comprises modified peat, calcium magnesium phosphate, and at least one of calcium carbonate, calcium oxide or calcium hydroxide; the repair method for the fluorine polluted soil comprises the following steps: analyzing bulk density of the fluorine polluted soil and the content of water soluble fluorine in the soil; and adding the repair agent for the fluorine polluted soil into the fluorine polluted soil, wherein the repair agent is as described above. The water soluble fluorine in the soil can be converted into calcium fluorophosphate and other insoluble materials by the calcium and phosphorus in the repair agent; the content of the water soluble fluorine in the soil can be further reduced by adsorption of the modified peat; the fluorine polluted soil can be repaired by using various low-cost raw materials after a simple process; activity of fluorine in the soil can be effectively reduced, thereby reducing harm of fluorine.

Owner:GUANGZHOU HUANFA ENVIRONMENTAL ENG CO LTD

Titanium dioxide photocatalyst with coating layer coated on surface and preparation method thereof

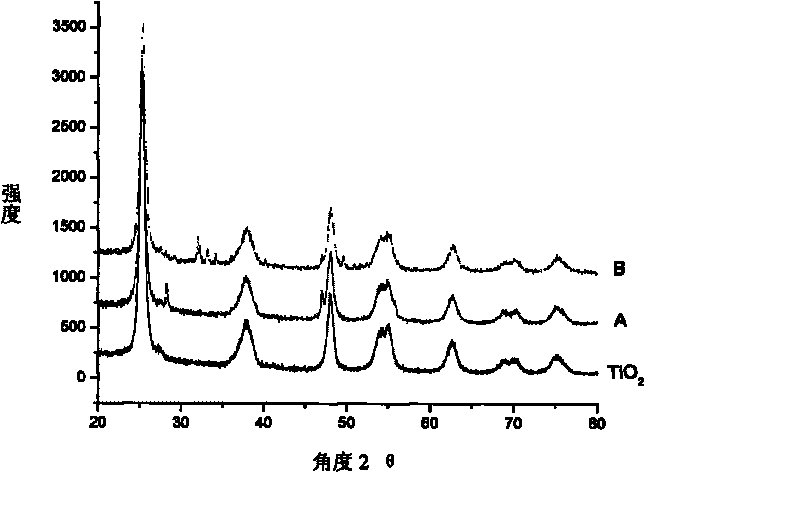

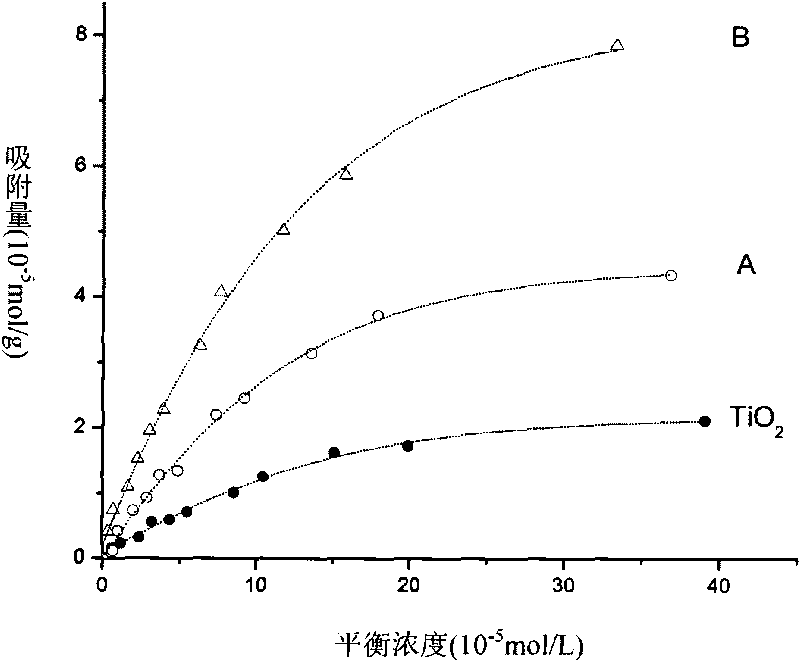

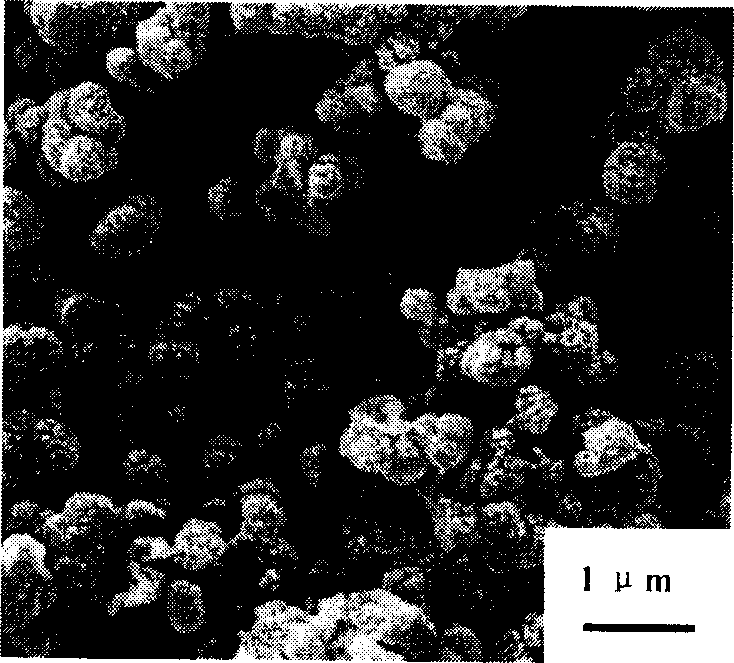

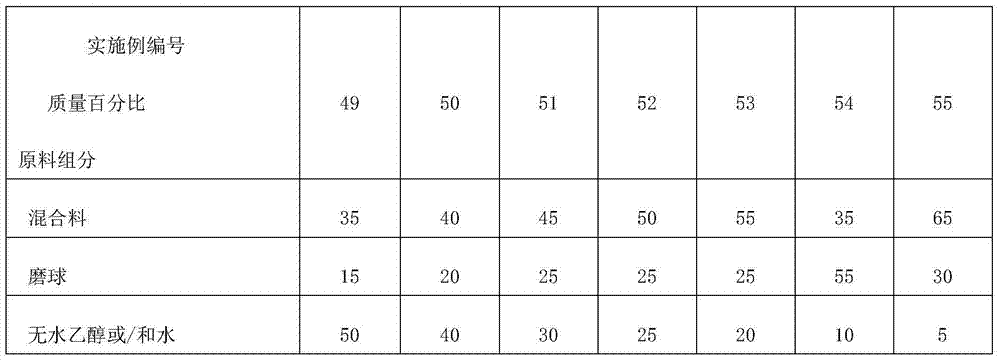

InactiveCN101733133ALow costImprove adsorption capacityWater/sewage treatment by irradiationWater contaminantsPhosphateUltraviolet lights

The invention provides a titanium dioxide photocatalyst with a coating layer coated on a surface, which comprises a titanium dioxide powder particle, wherein a fluoride coating layer, a fluoride-phosphate coating layer or a fluorapatite coating layer is arranged outside the titanium dioxide powder particle. Compared with an ordinary titanium dioxide powder particle, the photocatalytic speed is markedly increased. The invention also provides a preparation method of the titanium dioxide photocatalyst with the coating layer coated on the surface, which comprises the following steps of: depositing titanium dioxide as a precursor and a metal fluoride, a fluoride-phosphate mixture or fluorapatite as a coating material on the surface of the titanium dioxide powder particle by using a wet chemical method and preparing a product under the condition of not changing the crystal structure, the crystal phase composition and the average particle diameter of the titanium dioxide as the precursor. The titanium dioxide photocatalyst has low cost of the used raw materials, simple equipment and easy operation; compared with the pure titanium dioxide, the ultraviolet light catalytic activity of the obtained product is markedly improved, and meanwhile, the adsorption capacity for an organic pollutant is also enhanced.

Owner:ZHEJIANG UNIV

Anti-skid matte ceramic tile

The invention relates to an anti-skid matte ceramic tile. A microporous forming agent is introduced to overglaze of the ceramic tile. Micropores in the glaze layer on the surface of the ceramic tile are formed in a firing process. The microporous forming agent is composed of one or more of fluorite, cryolite and fluorapatite. The ceramic tile is composed of a blank, bottom glaze and surface glazeattached to two faces, separately, and the microporous forming agent introduced into the glaze. The bottom glaze is prepared from the following components: quartz, albite, potash feldspar, calcined talc, zirconium silicate, kaolin, calcined kaolin, aluminum oxide and a matte opacified melt block. The surface glaze is prepared from the following components: calcined zinc oxide, albite, potash feldspar, kaolin, calcined talc, calcined kaolin, dolomite, wollastonite, a matte transparent melt, a bright and transparent melt and the microporous forming agent.

Owner:JIANGXI HEMEI CERAMICS +4

Biological activity glass ceramics capable of cutting and its preparation method

The invention relates to silicate material field used in repair and substitution for bone and tooth. Wherein, mixing materials with weight share in alumina ball mill tank; putting into alumina crucible, hot smelting in silicomolybdic bar furnace; pouring fused glass into water for quenching, drying and smashing; remelting the glass powder to cast in graphite mould at 500-700Deg for one hour; cooling to room temperature and obtaining even glass parent body; heating to 800-110Deg for 4-24h to separate controlled glass ceramic contained fluorine bronze mica and fluorapatite. The product has bending strength and elastic modulus fit to mechanical property of bone and teeth of human body, and can generate strong chemical bond with human bone group. This invention is simple and convenient to operate.

Owner:CENT SOUTH UNIV

Method for preparing fluorapatite ceramic solidified body

The present invention discloses a method for preparing a fluorapatite ceramic solidified body. The method is characterized by comprising the steps of: taking and mixing 23-76 wt.% of calcium pyrophosphate, 8-26 wt.% of calcium fluoride, 0. 02-52wt.% of samarium oxide (europium oxide, gadolinium oxide), 0-15 wt.% of sodium carbonate, 0-16 wt.% of silica to obtain a mixture; grinding, drying, granulating, molding, discharging rubber and conducting vacuum hot pressing sintering on the mixture to obtain a fluorapatite ceramic solidified body. The method not only utilizes the phosphorus in high-level radioactive waste in a recycling way, but also can address the problem of low solubility of phosphorus and minor actinides nuclide in glass solidified body. The fluorapatite ceramic cured body prepared by the invention has excellent preparation geological stability, irradiation stability, mechanical stability, chemical stability and thermal stability, and can be used as a ceramic solidified body for safe treatment of minor actinides high-level radioactive waste with high toxicity, long half-life period and strong radioactivity.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Composite material for dental prosthesis and preparation method of composite material

InactiveCN105232340AHigh mechanical strengthHigh strengthImpression capsDentistry preparationsBiocompatibilitySILICONE DIOXIDE

The invention discloses a composite material for dental prosthesis and a preparation method of the composite material. The composite material is prepared from the following components in parts by weight: 20-40 parts of polyethylene, 25-40 parts of xanthan gum, 20-25 parts of hydroxy calcium phosphate, 2-8 parts of chitosan, 1-6 parts of tributyl citrate, 4-8 parts of a phase transfer agent, 2-6 parts of divinyl tetramine, 25-35 parts of 2-methyl-2-propenoic acid 2-(phosphonooxy) ethyl ester, 4-8 parts of silver lactate, 7-20 parts of titanium dioxide, 10-15 parts of silicon dioxide, 3-8 parts of an antioxidant, 4-8 parts of hydroxyanisole, 1-13 parts of calcium fluophosphate, 8-23 parts of ethanol and 25-45 parts of double distilled water. The tooth filling material disclosed by the invention is good in mechanical strength, high in intensity and good in biocompatibility, and the safety of the material to human bodies is improved. The preparation method disclosed by the invention is simple and easy to implement, and is suitable for industrial production.

Owner:SUZHOU COSMETIC MATERIALS

Making method of fluor apatite

InactiveCN1475436AGood response densityImpression capsDentistry preparationsCalcium hydroxideLithium

A process for preparing the fluorapatite (FAP) includes proportionally mixing calcium fluoride with hydroxyapatite, adding excipient, die pressing and sintering. It has high biological compatibility,so using it as biomedical material for curing teeth, etc.

Owner:文国琴

High-heat-conduction ceramic substrate material and preparing method thereof

The invention discloses a high-heat-conduction ceramic substrate material. The high-heat-conduction ceramic substrate material is prepared from, by weight, 82 parts to 90 parts of aluminum oxide powder, 7 parts to 18 parts of silicon carbide, 6 parts to 15 parts of mullite, 4 parts to 14 parts of bentonite, 3 parts to 8 parts of carbon fibers, 5 parts to 16 parts of fluorapatite, 3 parts to 13 parts of vanadium nitride, 4 parts to 10 parts of yttrium oxide, 11 parts to 20 parts of binding agents and 35 parts to 48 parts of solvents. The invention further discloses a preparing method of the high-heat-conduction ceramic substrate material. The heat conductivity coefficient of the ceramic substrate material prepared with the preparing method is larger than 1.8 W / m.K, the coefficient of thermal expansion is 5.23*10<-6> / K to 6.08*10<-6> / K and is close to the coefficient of thermal expansion of wafer silicon, and the matching degree is good; in addition, the breaking strength of the prepared ceramic substrate material is larger than or equal to 0.7 Mpa, and good comprehensive performance is shown.

Owner:SUZHOU KUANWEN ELECTRONICS SCI & TECH

Polyetheretherketone composite material and bone repairing body as well as preparation method and application thereof

InactiveCN102643514ARandom combinationSimple processProsthesisBarium titanateBiocompatibility Testing

The invention discloses a fluorapatite / barium titanate / polyetheretherketone composite material as well as a preparation method and application of the composite material. The preparation method comprises the following step of: carrying out melt blending and extrusion granulating on fluorapatite, barium titanate and polyetheretherketone, wherein the use amount of fluorapatite is 10-30wt%, the use amount of barium titanate is 10-40wt%, and the use amount of polyetheretherketone is 50-60wt%. The invention also discloses a bone repairing body and a preparation method of the bone repairing body. The composite material has excellent biological activity and biocompatibility, and better mechanical compatibility with bone tissue, and can stimulate bone growth, accelerate bone healing and reduce the healing time of the material is implanted to the bone. The preparation method is simple and feasible in process. The bone repairing body has excellent biocompatibility, biological activity, bone mechanical compatibility and microorganism resistance, thereby shortening the bone healing time, and is high in strength, good in fatigue resistance and corrosion resistance and long in service life, thereby meeting the clinical bone repairing requirements.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for preparing porous fluorapatite ceramic adsorbing radioactive nuclide

ActiveCN106045495AGood chemical stabilityReduce solubilityRadioactive decontaminationCeramicwareEcological environmentPolyethylene glycol

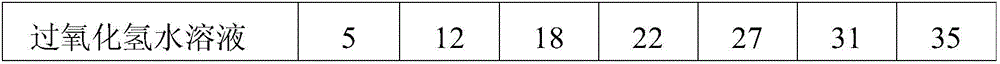

A method for preparing porous fluorapatite ceramic adsorbing radioactive nuclide is characterized by including: using the materials in percent by weight: 50-80% of calcium pyrophosphate, 4-26% of calcium fluoride and 16-45% of calcium carbonate, and mixing, ball-milling, drying, press-forming, calcining, grinding, and screening to obtain fluorapatite powder; mixing the fluorapatite powder with polyethylene glycol solution, methyl cellulose solution and hydrogen peroxide solution, and performing microwave assisted pore-forming, drying and the like to obtain a porous fluorapatite ceramic blank; preparing porous fluorapatite ceramic adsorbing material via normal pressure sintering. The porous fluorapatite ceramic adsorbing material prepared herein has the advantages of high radiation stability, good thermal stability, high mechanical and chemical stability and the like, also has high specific surface energy and nuclide adsorbing capacity and may be used as an efficient adsorbing material for radioactive nuclide in high-radioactive waste liquid, thus effectively protecting human health and ecological environment.

Owner:SOUTHWEAT UNIV OF SCI & TECH

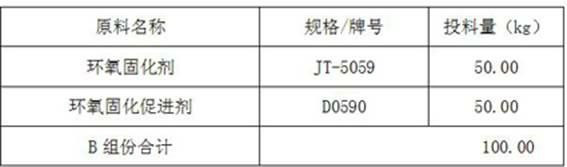

Solvent-free coumarone modified epoxy heavy-duty anticorrosive coating

The invention discloses a solvent-free coumarone modified epoxy heavy-duty anticorrosive coating and a preparation method thereof. The coating comprises a base coat and a finish coat and is characterized in that the base coat comprises a component A and a component B, the finish coat comprises a component C and the component B, the components A and C respectively contain an organophosphorus flame retardant agent, a mixed solvent of dimethylbenzene and PMA (propylene glycol monomethyl acetate), liquid coumarone resins, a barium zinc stabilizer, a dispersing agent with a superhigh molecular weight, a reaction type epoxy toughening agent, solid coumarone resins, epoxy resins, fumed silica, a flatting agent, a defoaming agent and a flavour agent, wherein the component A also contains barite powder, calcium fluophosphate powder and mica powder, the component C also contains high titanium powder and a tinting pigment, and the component B contains an epoxy curing agent and an epoxy curing accelerator. According to the invention, the cost of the prepared product is low, and the prepared product has good physical, mechanical and anticorrosive properties.

Owner:SUZHOU JIREN HIGH TECH MATERIAL CO LTD

Method for preparing fluorapatite/hydroxyapatite sosoloid nano-powder

The present invention discloses a preparation method of fluorapatite / hydroxylapatite solid solution nanometer powder. The method takes calcium compound and part esterification phosphate or organic phosphate alcohol solution as the base and then adds fluoride compounds and organic amine so as to synthesize the fluorapatite / hydroxylapatite solid solution nanometer powder by the method of sol combustion self-spreading. The present invention solves the problems that the fluorapatite / hydroxylapatite solid solution nanometer powder is hard to prepare, and the fluorine content and the existence state of the fluorine are difficult to control, etc. The preparation method provided by the present invention has the advantages of simple operation, low cost and being easy for industrialization.

Owner:ZHEJIANG UNIV

Method for preparing fluorapatite crystal whisker in-situ reinforced porous tricalcium phosphate biological ceramics

The invention relates to a method for preparing fluorapatite crystal whisker in-situ reinforced porous beta-tricalcium phosphate biological ceramics, and belongs to the technical field of the preparation of biological ceramics. The method is characterized by comprising the following steps of: weighing beta-tricalcium phosphate, bioglass and ammonium fluoride (or fluorine salts such as sodium fluoride and the like) serving as raw materials in a mass ratio of (65-85):(10-30):(0.25-1.5), and performing solid-phase reaction at a high temperature to prepare high-strength fluorapatite crystal whisker in-situ reinforced tricalcium phosphate porous biological ceramics. The method has the advantages that toughness is enhanced by introducing fluorapatite crystal whiskers and the strength of a substrate is enhanced, and the biological ceramics are mainly used for the field of the repair of bone tissue engineering at bearing positions or other positions.

Owner:CHINA NAT ACAD NANOTECH & ENG

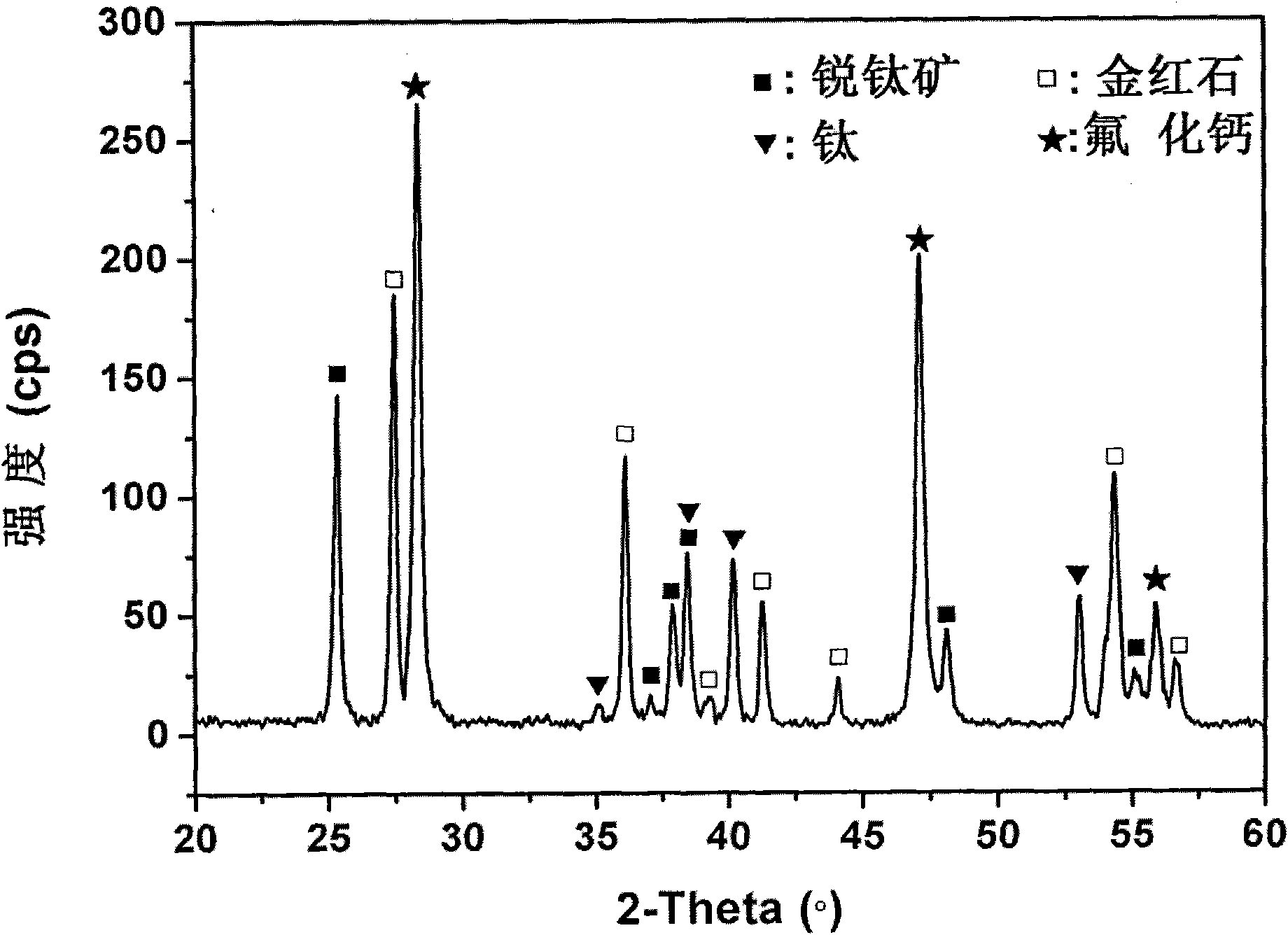

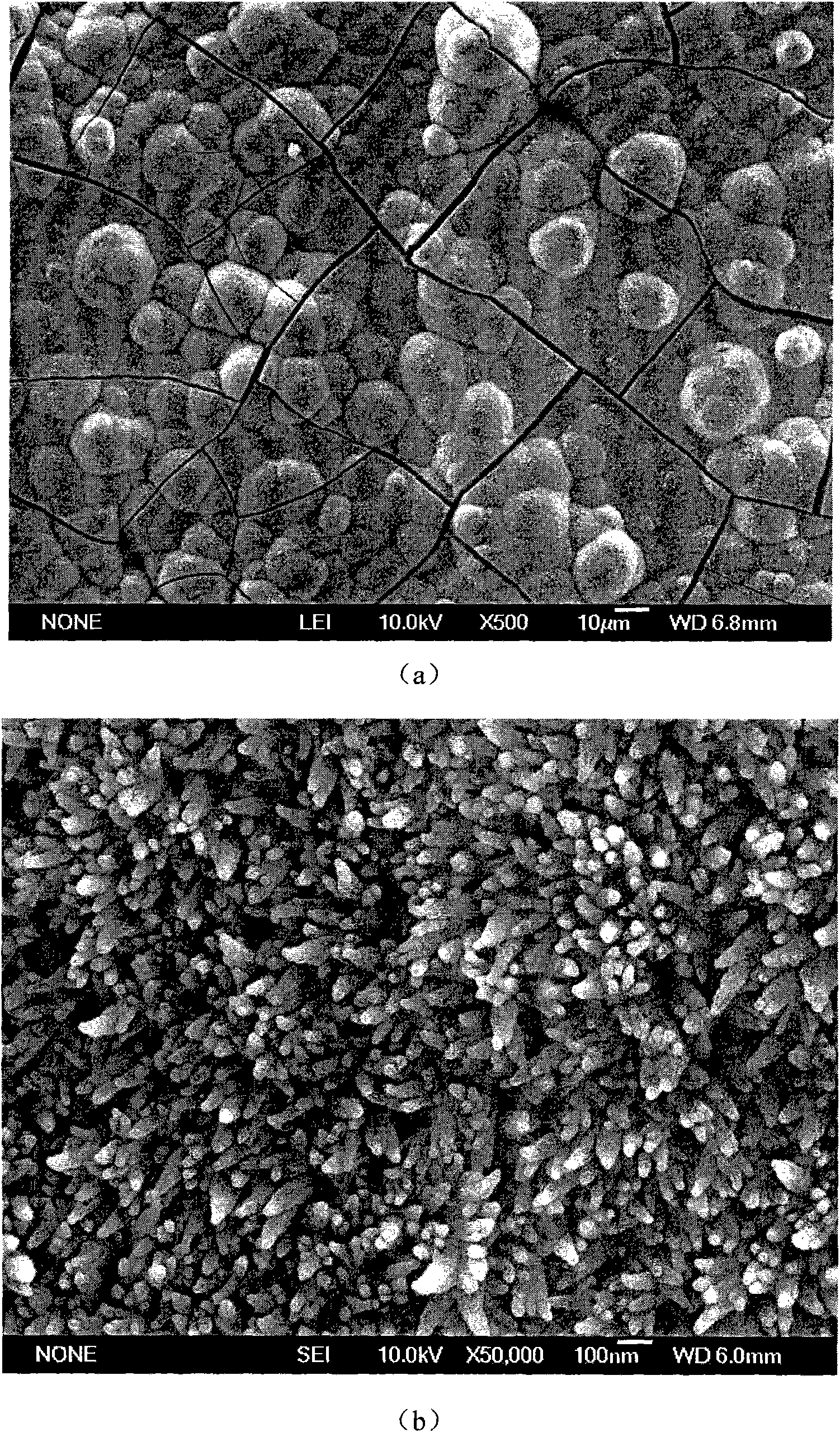

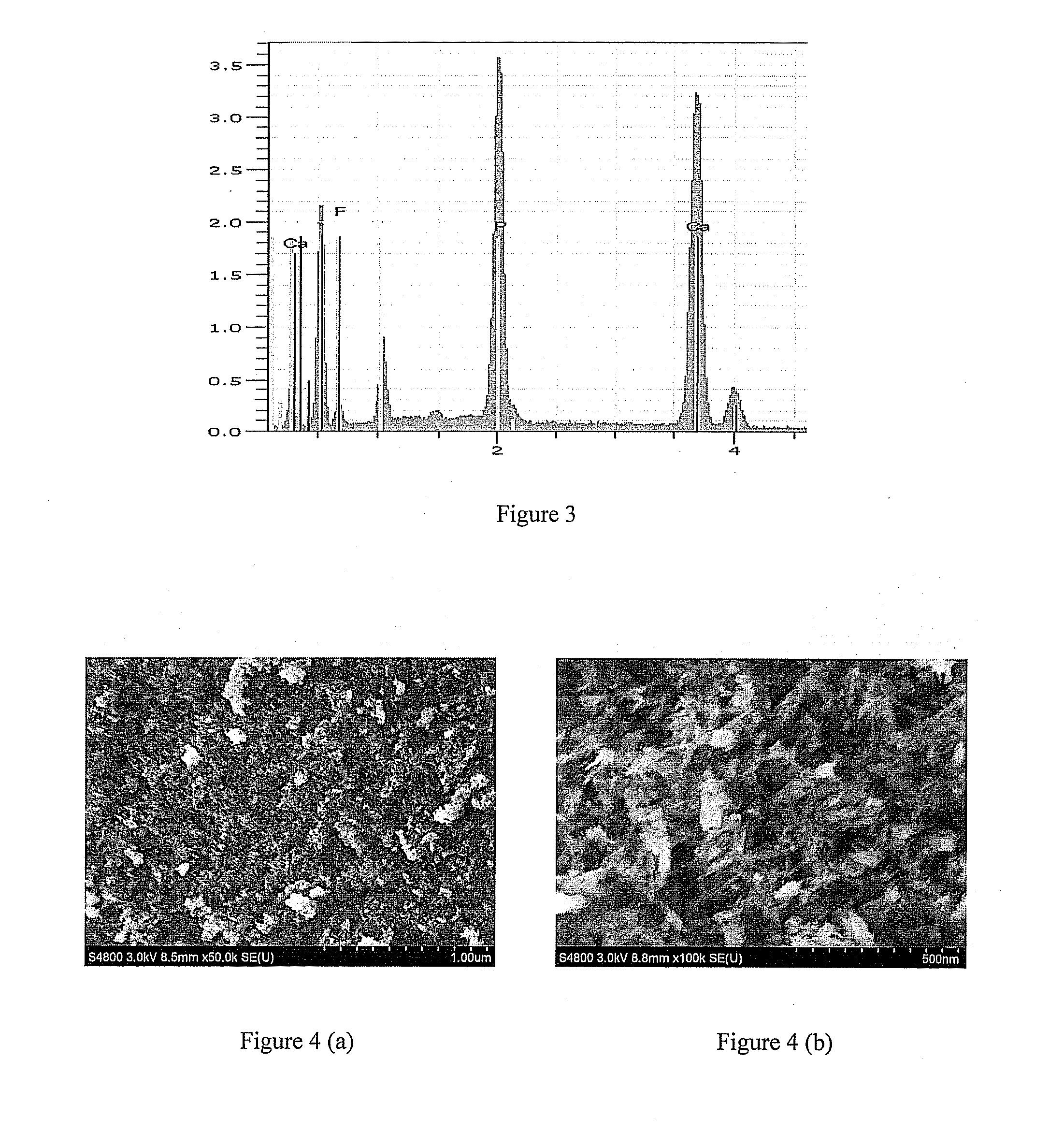

Method for preparing calcium fluoride coating on surface of titanium and alloy thereof and application thereof

ActiveCN101914799ATightly boundHigh bonding strengthSurface reaction electrolytic coatingPlasma electrolytic oxidationMicro arc oxidation

The invention belongs to the technical field of nano materials, and in particular relates to a method for preparing a calcium fluoride coating on the surface of titanium and alloy thereof. In the method, the nano calcium fluoride coating is directly generated in situ on the surface of the titanium or the titanium alloy by one step method in electrolyte containing calcium ions and fluorine ions through micro-arc oxidation. The nano calcium fluoride coating prepared by the method has the nano crystal structure, is closely combined with a matrix, has the phase mainly comprising calcium fluoride and titanium oxide, can induce fluorapatite to deposit on the surface thereof after the calcium fluoride coating is soaked in simulated body fluid for less than 14 days, has good bioactivity and can be applied to the fields such as biomedical materials and the like.

Owner:上海双申医疗器械股份有限公司

Method for separating rare-earth element and fluorapatite, calcium chloraphosphate and calcium phosphate

InactiveCN1928131AImprove dephosphorization rateEasy dischargeProcess efficiency improvementCalcium phosphate productCalcium biphosphate

The process of separating RE elements from calcium fluorophosphate, calcium chlorophosphate and calcium phosphate is to wash mineral with the mixed solution of hydrochloric acid and citric acid to leach out calcium fluorophosphate, calcium chlorophosphate and calcium phosphate while limiting the leaching of RE elements and other matters. The solution containing calcium fluorophosphate, calcium chlorophosphate and calcium phosphate is alkalized to produce precipitate and recover calcium fluorophosphate, calcium chlorophosphate and calcium phosphate product; and the small amount of RE elements are recovered with P204 or P507 extractant. The said process has calcium fluorophosphate, calcium chlorophosphate and calcium phosphate leaching rate not lower than 95 wt%, RE element leaching rate not higher than 10 wt% and total RE element yield not lower than 97 wt%.

Owner:NORTHEASTERN UNIV

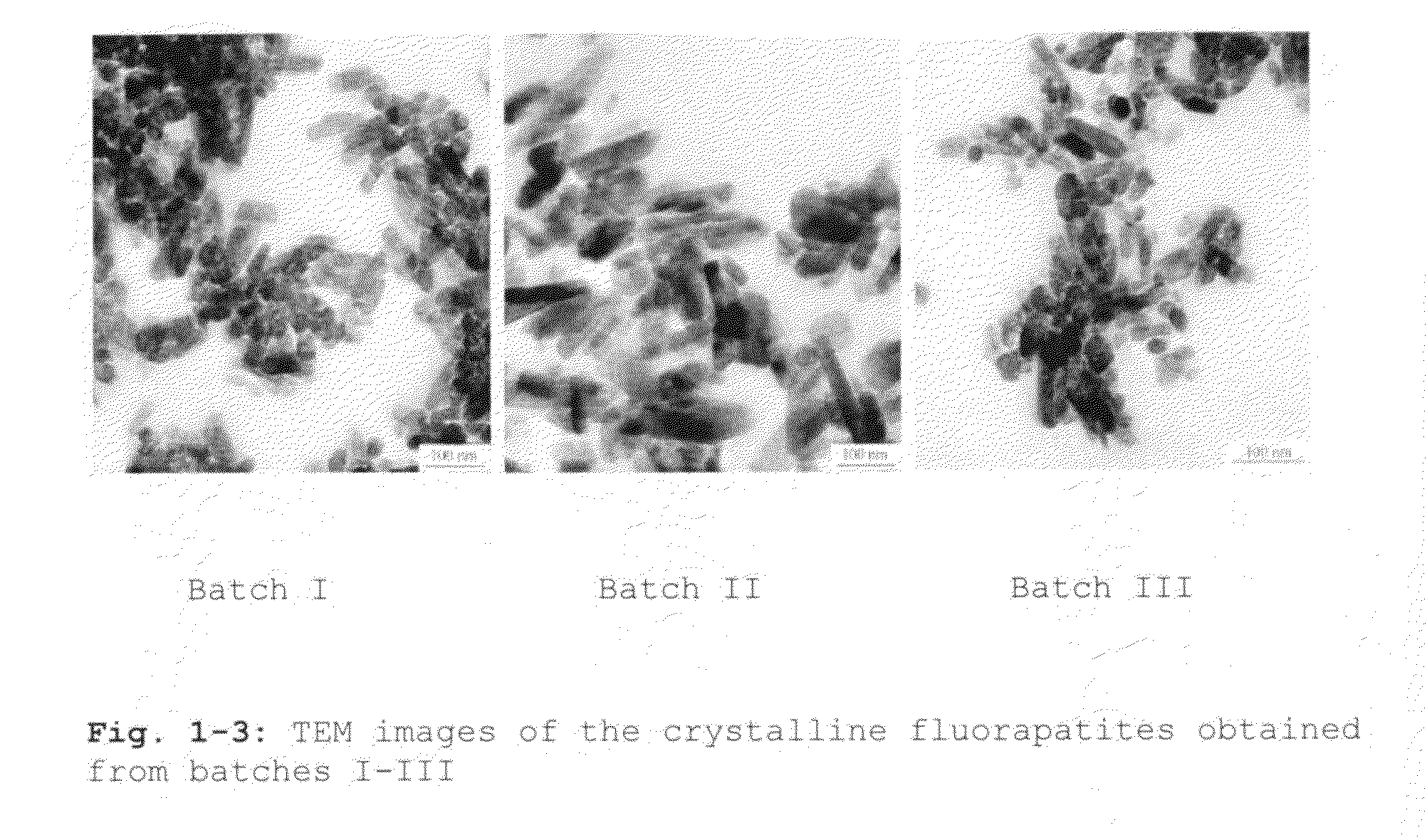

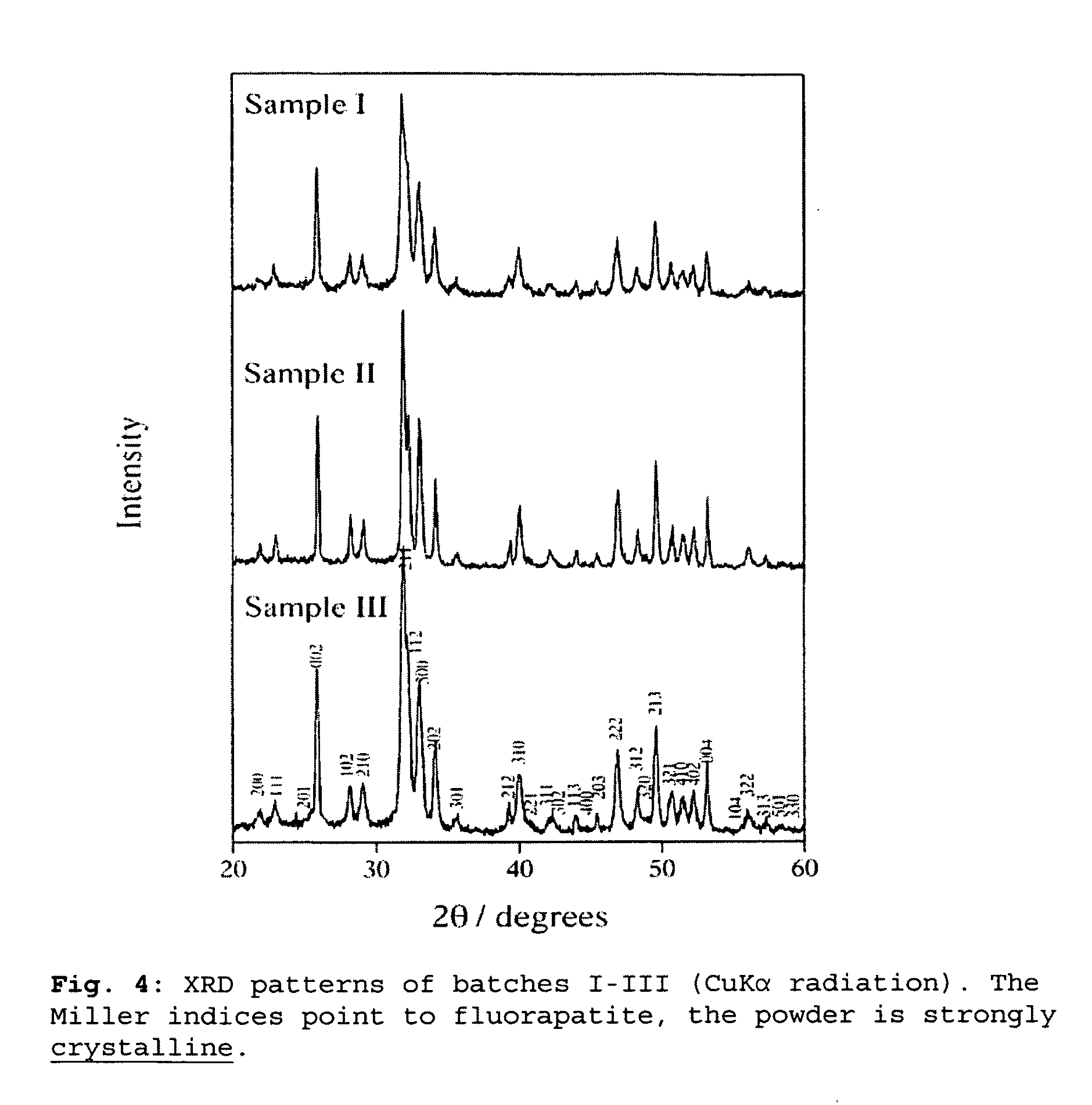

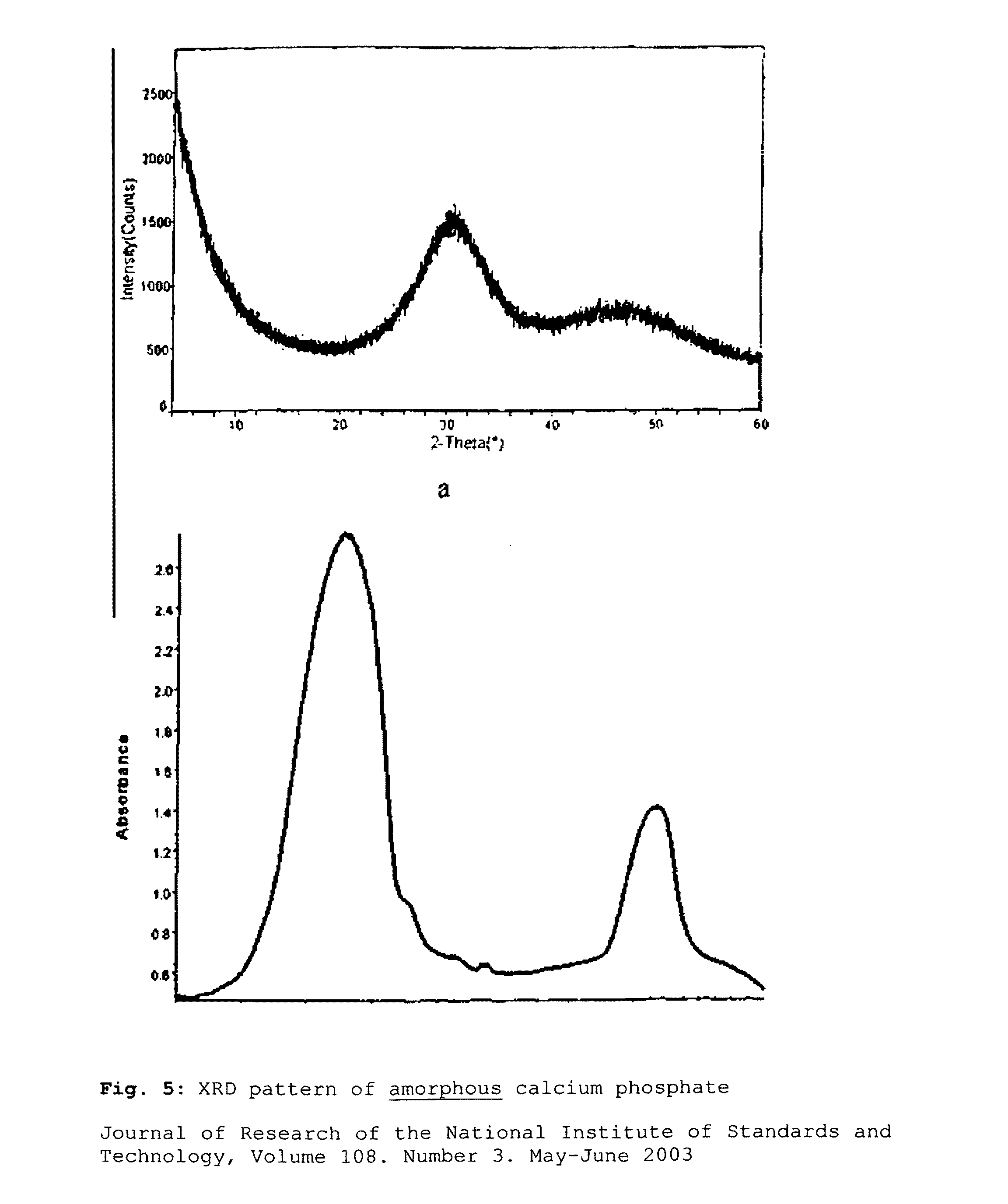

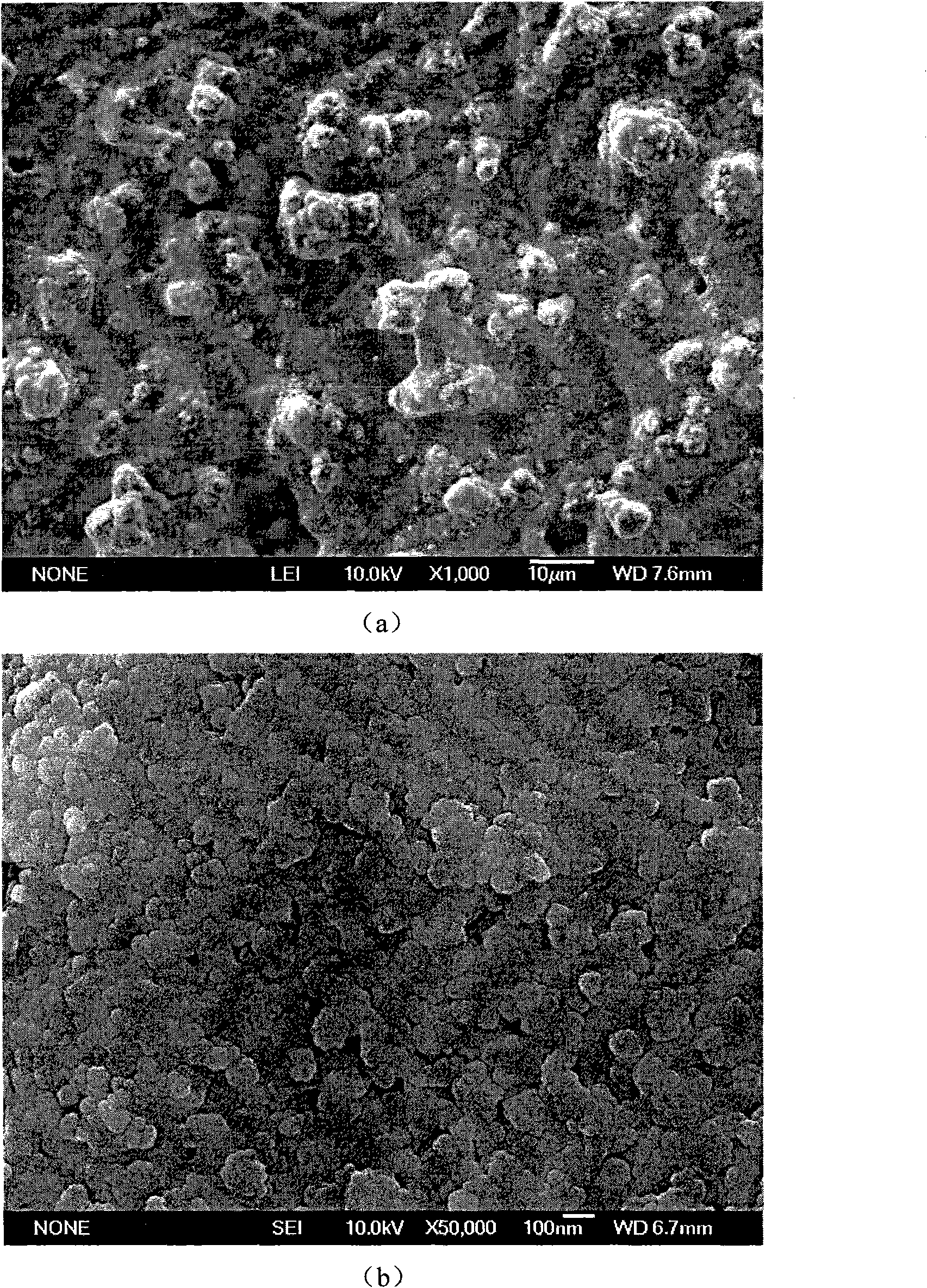

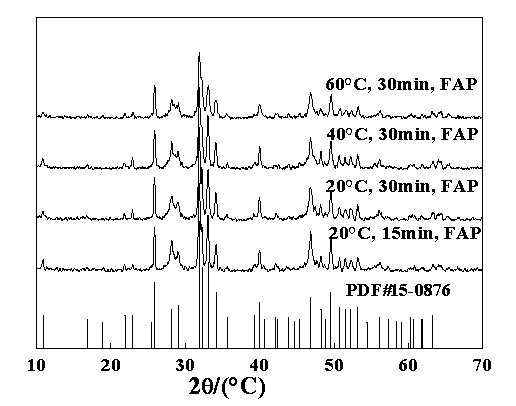

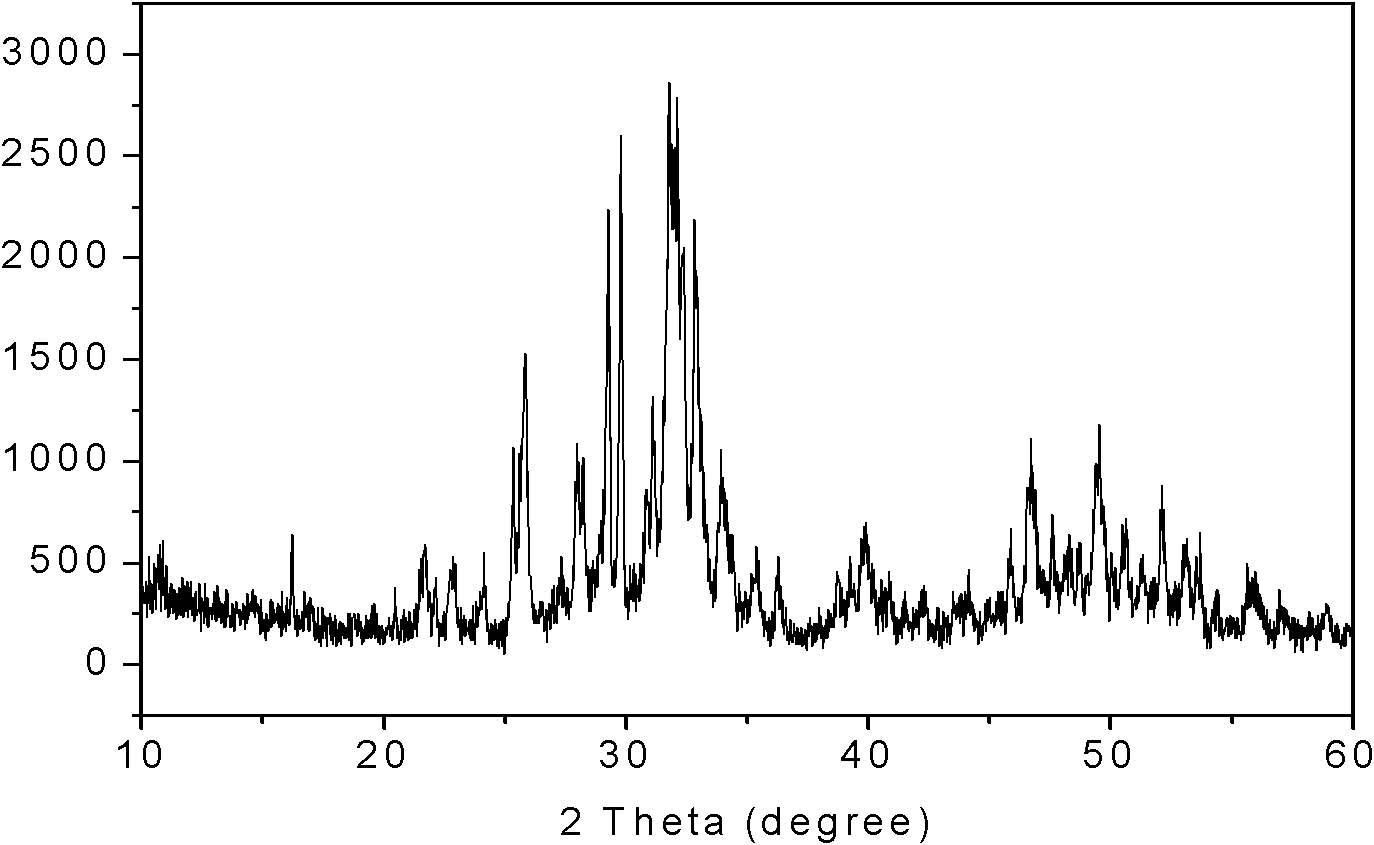

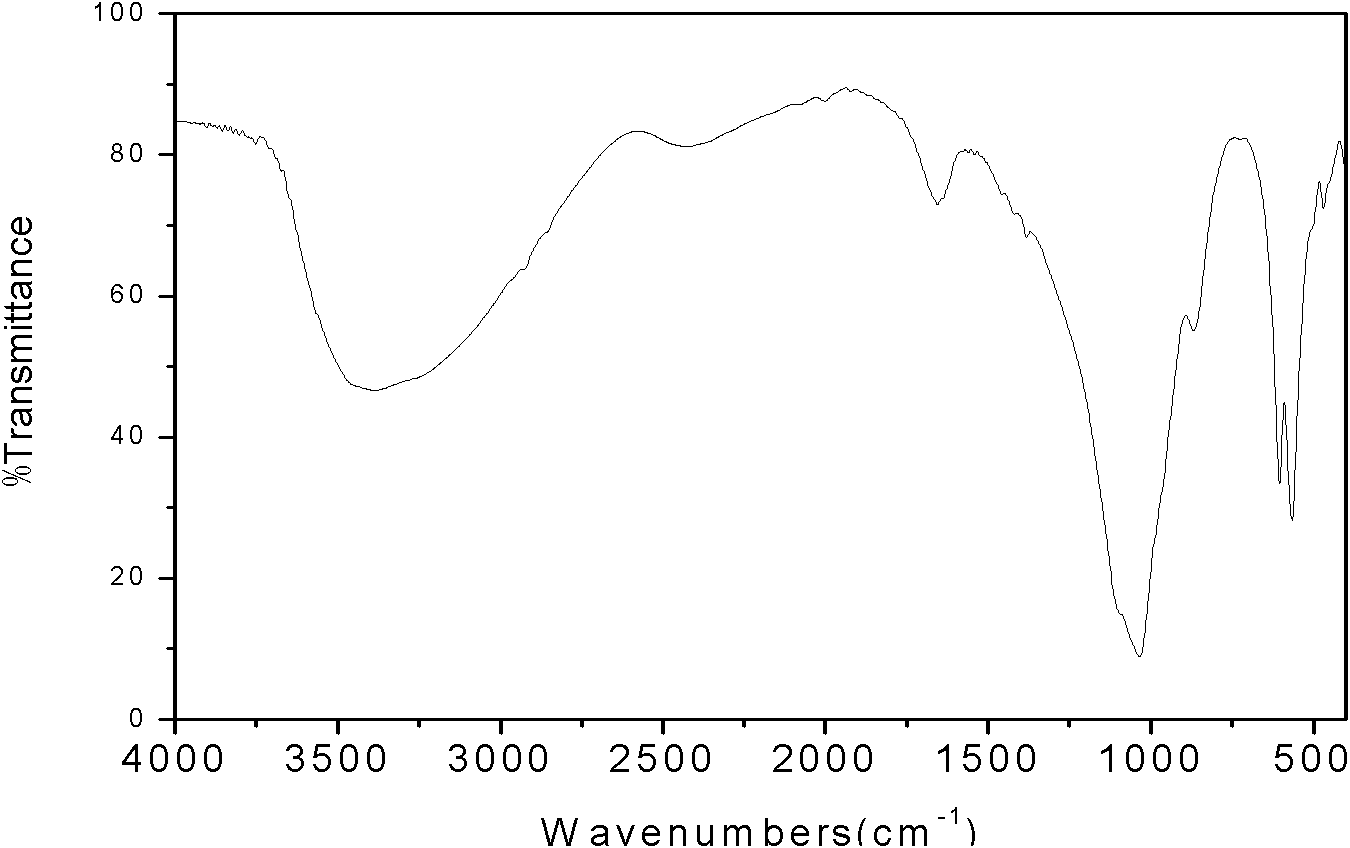

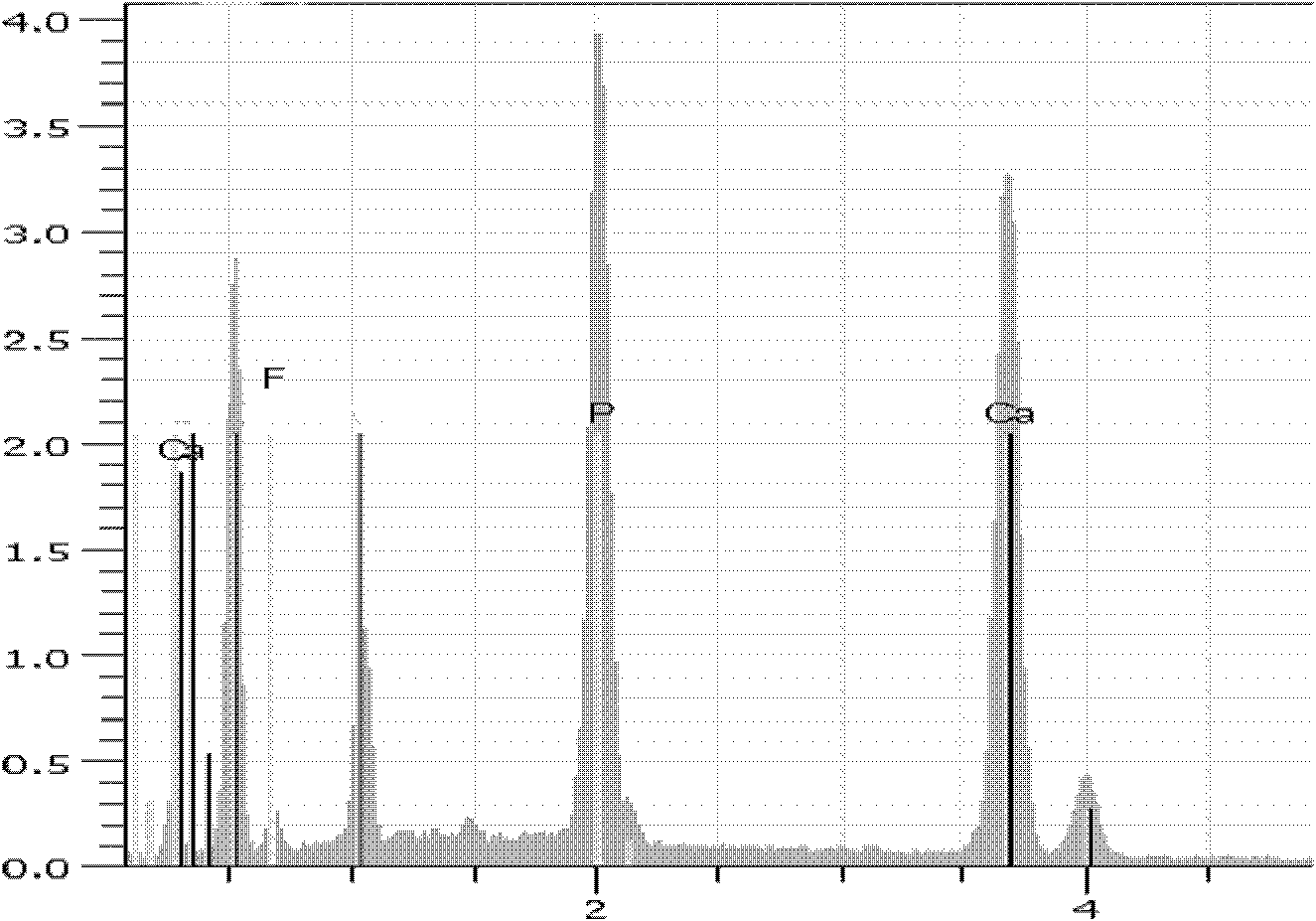

Microwave-assisted synthesis method of nano fluorapatite powder

InactiveCN103569991AEfficient synthesisNanotechnologyPhosphorus compoundsCalcium nitrate tetrahydrateAtherion elymus

The invention relates to a microwave-assisted synthesis method of nano fluorapatite powder. The microwave-assisted synthesis method of the nano fluorapatite powder is characterized by comprising the following steps: dissolving 4.723g of calcium nitrate tetrahydrate into 50ml of water to prepare a calcium ion solution with the concentration of 0.4mol / L; dissolving 1.585g of diammonium hydrogen phosphate and 0.333g of ammonium fluoride into 50ml of water to prepare a mixed solution of phosphate with the concentration of 0.24mol / L and fluorine ion with the concentration of 0.18mol / L, pouring the calcium ion solution, and the mixed solution of phosphate and fluorine ion into a three-necked flask, carrying out microwave synthesis for 30 minutes under the conditions of condensation refluxing and strong magnetic stirring, and carrying out centrifugal separation, washing, drying and grinding on products, thus the nano fluorapatite powder is obtained, wherein pH of a reaction system is natural pH of the mixed solution and a reaction temperature is 60 DEG C. The nano fluorapatite powder prepared by adopting the microwave-assisted synthesis method of the nano fluorapatite powder has high crystallinity and high purity. The microwave-assisted synthesis method of the nano fluorapatite powder is simple and feasible and low in cost, pH does not need to be regulated in a reaction process, reaction rate is high, low-temperature synthesis can be realized, and industrialization can be easily realized.

Owner:UNIV OF JINAN

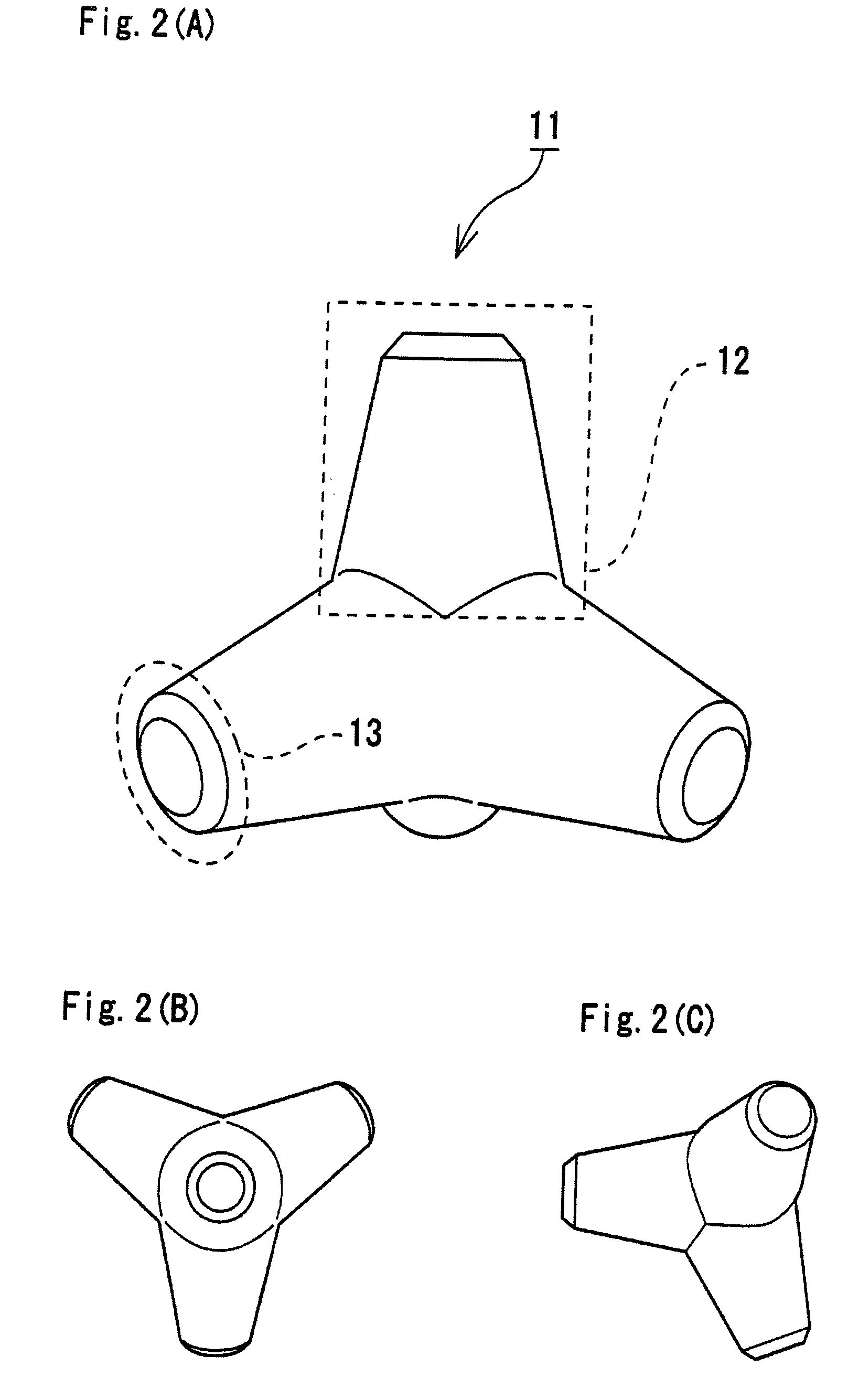

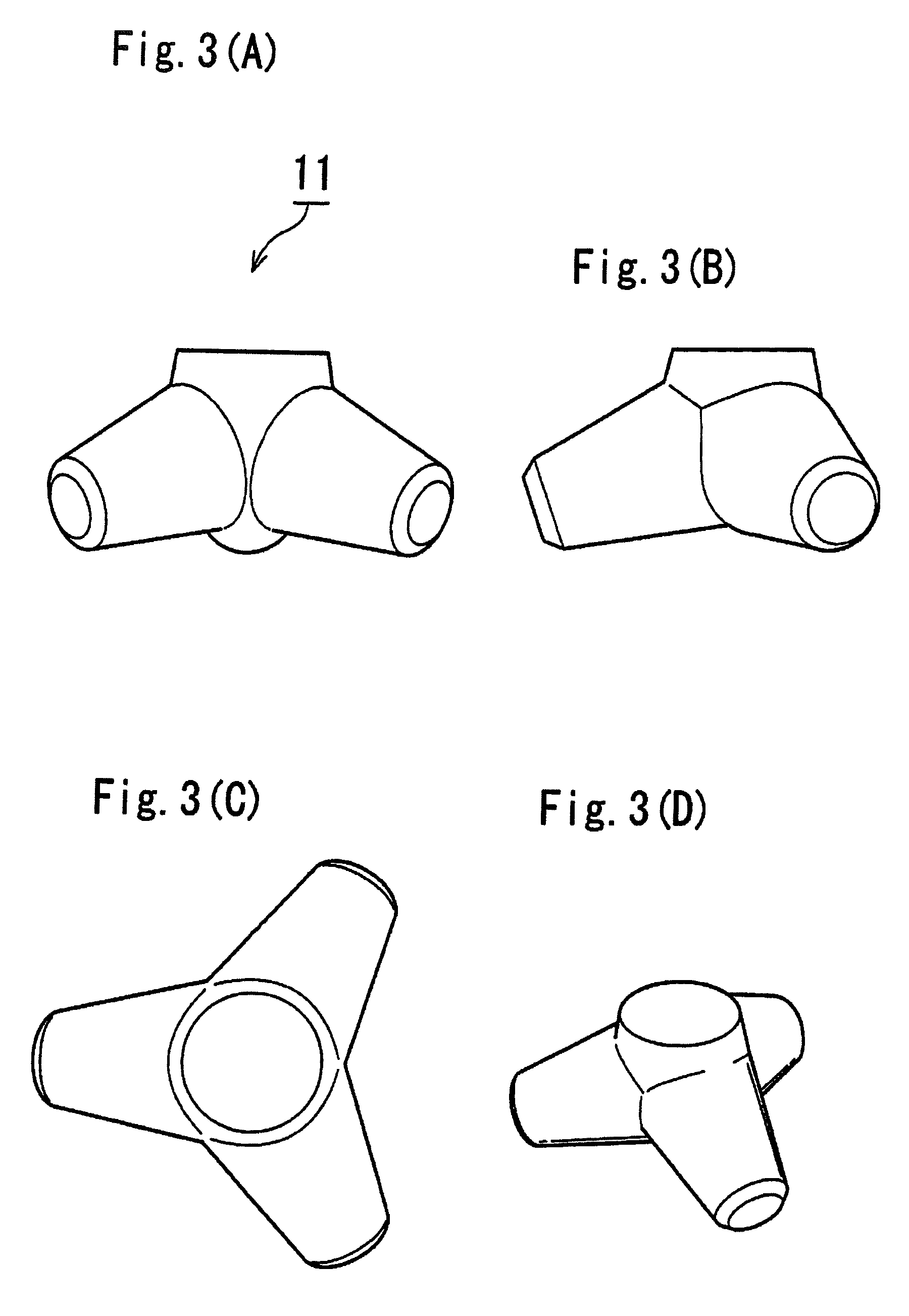

Bone Defect Filler, Release-Controlled Carrier, And Their Production Methods

InactiveUS20100003301A1AbsorbabilityControl releaseAntibacterial agentsSkeletal disorderCalcium fluorophosphateDrug release

A bone filling material having controlled release of a pharmaceutical agent such as a growth factor, and a drug release controlling carrier having controlled release of a pharmaceutical agent is provided by inactivating a functional group which can strongly bind to the pharmaceutical agent of the bone filling material with a blocking agent. The bone filling material and the drug release controlling carrier of the present invention comprises: a calcium-based material such as hydroxyapatite, carbonate apatite, fluorapatite, chlorapatite, β-TCP, and α-TCP; a blocking agent of the calcium-based material such as serine and dextran; and a pharmaceutical agent.

Owner:THE UNIV OF TOKYO +1

Agent for protection of tooth surfaces, in conjunction with conventional bleaching methods, by biomimetic deposition of fluorapatite

ActiveUS20120195941A1Reducing and eliminating undesired side effect of bleachingImprove stabilityBiocideCosmetic preparationsHydrogen phosphateOrganic solvent

An agent for protection of tooth surfaces, in conjunction with conventional bleaching methods, by biomimetic deposition of fluorapatite, containingA at least one preformulated 50-1000 μm thick gel film A, containingA1 at least one gel former,A2 water or a mixture of water and an organic solvent,A3 phosphate or hydrogen phosphate ions,A4 optionally fluoride,A5 optionally at least one amino acid,A6 optionally one carboxylic acid or a buffer system for a pH value from 4 to 7.B at least one 50 μm to 5 mm thick gel film B, containingB1 at least one gel former,B2 water,B3 calcium ions Ca2±.

Owner:HERAEUS KULZER

Ceramic material used for mouth rehabilitation and preparation method thereof

InactiveCN105906334AImprove the lack of brittleness and brittlenessImprove clinical successImpression capsDentistry preparationsNano al2o3Rare earth

The invention discloses a ceramic material used for mouth rehabilitation. The ceramic material is prepared from the following components in parts by weight: zirconia, nanometer aluminum oxide, niobium pentoxide, rare earth oxide, rectorite, molybdenum boride, aluminium borate, calcium-magnesium silicate whisker and fluorapatite. The invention also discloses a preparation method of the ceramic material used for the mouth rehabilitation. The Vickers hardness of the ceramic material used for the mouth rehabilitation exceeds 21.4GPa, the bending strength of the ceramic material exceeds 963.2MPa, and the breaking tenacity of the ceramic material is higher than 16.3MPa.m1 / 2. The defect of the traditional ceramic material that the traditional ceramic material is likely to be subjected to brittle failure since the traditional ceramic material is crisp is eliminated, a clinic success rate is improved, and the ceramic material can be used as a mouth rehabilitation material and has a wide application prospect.

Owner:王泽陆

High-pressure molding facing sand and preparation method thereof

InactiveCN104525834AImprove breathabilityGood dispersionFoundry mouldsFoundry coresSodium BentoniteUltra fine

High-pressure molding facing sand is prepared from the following raw materials in parts by weight: 30-40 parts of fly ash, 8-10 parts of polymeric hydroxy aluminum column bentonite, 7-9 parts of aluminum nitride, 16-18 parts of an ultra-fine silicon powder, 4-5 parts of fluorapatite, 70-90 parts of quartz sand, 5-6 parts of alpha-starch, 130-160 parts of clay, a proper amount of water, and 20-30 parts of an auxiliary agent. With adopting the clay for sintering granulation, the molding sand has good air permeability and good dispersion, and can be recycled; through addition of aluminum nitride and the ultra-fine silicon powder, the heat resistance of clay particles is increased; through the use of quartz sand particles, the fluidity and the air permeability of the molding sand are increased, and bonding of the clay particles is prevented; and the molding sand is applicable to the high-pressure molding facing sand, the surface of a casting piece does not easily produce pores, and heat dissipation is fast.

Owner:FANCHANG COUNTY HENGXIN AUTO PARTS

Agent for protection of tooth surfaces, in conjunction with conventional bleaching methods, by biomimetic deposition of fluorapatite

An agent for protection of tooth surfaces, in conjunction with conventional bleaching methods, by biomimetic deposition of fluorapatite, containingA at least one preformulated 50-1000 μm thick gel film A, containingA1 at least one gel former,A2 water or a mixture of water and an organic solvent,A3 phosphate or hydrogen phosphate ions,A4 optionally fluoride,A5 optionally at least one amino acid,A6 optionally one carboxylic acid or a buffer system for a pH value from 4 to 7.B at least one 50 μm to 5 mm thick gel film B, containingB1 at least one gel former,B2 water,B3 calcium ions Ca2+.

Owner:HERAEUS KULZER

Composition for treating dental caries and method for preparing fluorapatite by using same

InactiveCN101856310AGood chemical stabilityAchieve direct regenerationImpression capsDentistry preparationsSolubilitySludge

The invention discloses a composition for treating dental caries, and belongs to the field of biological materials for dental repair. Tetracalcium phosphate, ammonium fluoride and aqueous solution of phosphoric acid are blended to form sludge, the sludge is filled to surfaces of teeth with deep caries and small holes and is cured for 1 to 3 days under the condition of the physiological environment of human bodies to form fluorapatite, so that the coloboma of carious enamel and particularly the large coloboma of the enamel (the deep caries) are repaired. The synthetic fluorapatite and the enamel have the similar chemical components, so the repair materials can be combined with natural enamel directly. The synthetic fluorapatite has a stoichiometric apatite structure, has the high chemical stability (low dissolubility) under the condition of physiological body fluid of the human bodies and releases fluorine slowly under the condition of acidity (during the existence of bacteria), and thus the materials can repair the deep caries and have the effect of caries prevention.

Owner:PEKING UNIV

Low-temperature calcining technology for cement clinker

InactiveCN104944814ADelete broken linkReduce energy consumptionClinker productionCalcium fluorophosphateCoal

The invention discloses a low-temperature calcining technology for a cement clinker. According to the low-temperature calcining technology for the cement clinker, a control agent is used as a material component and doped in a raw material according to a certain ratio, and subjected to raw material preparation in a measuring scale; the control agent in the low-temperature calcining technology for the cement clinker disclosed by the invention is an additive needing to be added to form a small-particle clinker, and has the main functions of improving the liquid-phase surface tension of the clinker and controlling the dimensions of the clinker; the control agent is selected from natural gypsum, hard gypsum, fluorapatite, copper slag, steel slag, zinc slag, nickel slag, phosphorus slag, coal ash or the combinations thereof. The cement clinker prepared by the low-temperature calcining technology for the cement clinker provided by the invention has the beneficial effects of high quality, high yield, low consumption, low emission and the like.

Owner:JIAHUA SPECIAL CEMENT

Fluorapatite alkyd rust-inhibiting paint

InactiveCN101182400ANon-toxicImprove performanceAnti-corrosive paintsPolyester coatingsNational standardTitanium

The invention provides an antirust paint of calcium fluophosphate alkyd. The composition has the following weight percentages: 38 weight percent to 58 weight percent of alkyd resin, 35 weight percent to 55 weight percent of rust-proof powder of calcium fluophosphate, 1 weight percent to 3 weight percent of dispersing agent, 1 weight percent to 10 weight percent of anti-settling agent, 1 weight percent to 2 weight percent of dried material and 1 weight percent to 8 weight percent of mixed solvent. The invention has the following advantages: the antirust powder of white composite silicon and titanium of excellent performance and reasonable price is used for replacing lead red and has no poisonous damage to people and the biological environment; other colors, fillers and auxiliary agents are skillfully used for getting the unique white color. At the same time, the paint has strong steel compatibility and strong corrosion-delaying performance of anode; the salt-resistant dipping time can reach above 600 hours (the national standard salt-resistant dipping time of alkyd and epoxy lead red is 24 hours to 96 hours); the neutrality-resistant and salt fog resistant time is more than 200 hours; the coating quantity in unit area is only 30 percent to 40 percent of the lead red.

Owner:武汉市大汉科技发展有限公司

Method for producing fluorapatite and its application

ActiveUS20120128566A1Good chemical stabilityReduce solubilityImpression capsPhosphorus halides/oxyhalidesSolubilityPhosphoric acid

A method for producing fluorapatite and its application are disclosed in the present invention, which relates to the field of biomaterials for dental reparation. The present invention comprises steps of mixing tetracalcium phosphate, calcium hydrogen phosphate, and sodium fluoride to form a mixture and adding the mixture into water, or mixing tetracalcium phosphate and ammonium fluoride to form a mixture and then adding the mixture into a phosphoric acid / water solution, blending the above two sets of materials respectively to form cement-like substances; and solidifying the cement-like substances at a temperatures of 35° C. to 38° C. and a moisture of 100% for 1-3 days to produce fluorapatite. The synthesized fluorapatite has a similar chemical composition with tooth enamel, thus, the fluorapatite produced by the invention can be combined with the natural enamel directly, so as to repair enamel defects caused by caries, especially severe enamel defects (deep caries). The synthesized fluorapatite has a stoichiometric amount of apatite structure, and has high chemical stability (low solubility) in a physiological condition of human body fluid. In acidic conditions (when bacteria exist) the fluorapatite releases fluorine ion slowly, so it further has an ability to prevent dental caries.

Owner:PEKING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com