Titanium dioxide photocatalyst with coating layer coated on surface and preparation method thereof

A titanium dioxide and surface coating technology, applied in the field of catalysis, can solve problems such as emission restrictions, and achieve the effects of improving adsorption capacity, improving photocatalytic rate, and improving ultraviolet photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] Method 1 A method for preparing a titanium dioxide photocatalyst whose surface is coated with a metal fluoride coating layer, i.e. an alkali method, comprises the following steps:

[0027] 1) At room temperature, the precursor titanium dioxide is dispersed in an aqueous solution of a metal ion salt as a precipitant, TiO 2 The molar ratio to the metal ion is 100:2 to 100:40;

[0028] 2) Under vigorous stirring, add fluoride salt solution, TiO 2 The molar ratio to fluoride ion is 100:4~100:120;

[0029] 3) by adding a pH regulator, the pH value of the reaction solution is 8-11;

[0030] 4) React for 2 hours at 60°C to 100°C;

[0031] 5) After cooling to room temperature, the precipitate is filtered, washed with water, dried at 70° C. to 120° C., and ground into powder to obtain a titanium dioxide photocatalyst coated with a fluoride coating on the surface.

[0032] The above process is expressed as follows (where M n+ for metal ions):

[0033]

[0034] Method 2, ...

Embodiment 1

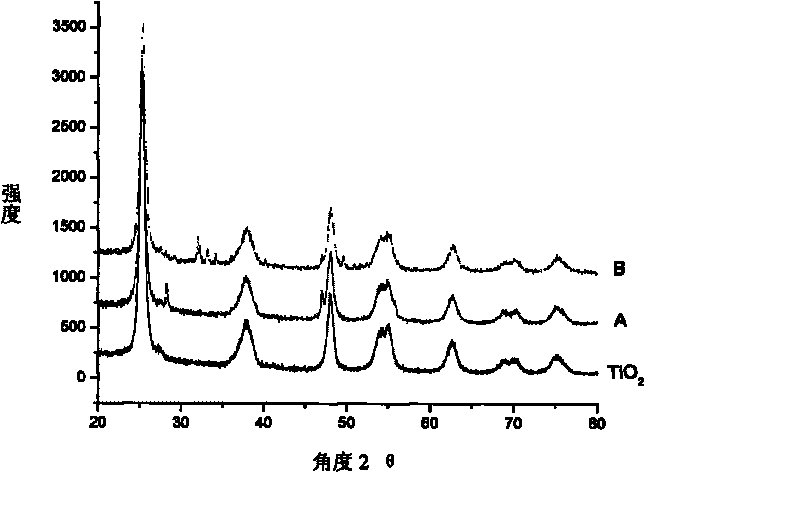

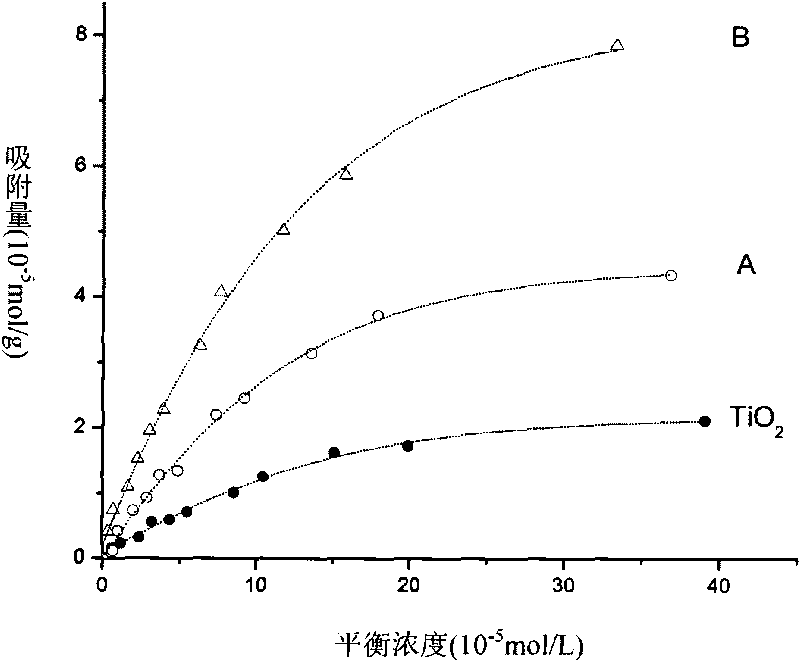

[0068] Take 1g of commercial anatase phase titanium oxide (AT), and disperse it in 100ml with a concentration of 6mM (mM is 10 -3 mol / L) of Ca(NO 3 ) 2 In aqueous solution (Solution S1), placed on a magnetic stirrer at room temperature to stir, slowly drop into 100mL of NH with a concentration of 12mM 4 F in water (Solution S2). By adding 20% dilute ammonia water, the pH value of the control system is about 10. After the dropwise addition was completed, the suspension was heated to 80° C. in a water bath and kept at this temperature for 2 hours. After cooling to room temperature naturally, the suspension was aged overnight. Gained precipitate was filtered, washed, and dried at 60°C to obtain calcium fluoride-coated titanium dioxide catalyst A (see Figure 1~4 middle line A). where TiO 2 The molar ratio of Ca and F elements is 100:4.8:9.6. Using the above photocatalytic activity evaluation method, after irradiating with ultraviolet light for 1 hour, the degradation ra...

Embodiment 2

[0070] Take 1g of commercial anatase phase titanium oxide and disperse it in 100ml of Ca(NO 3 ) 2 in aqueous solution. While boiling, slowly drop 100mL 3mM (NH 4 ) 2 HPO 4 with 1mM NH 4 A mixed solution of F. By adding 20% dilute ammonia water, the pH value of the control system is about 9. After the dropwise addition was completed, the suspension was aged at 80° C. for 1 hour. After naturally cooling to room temperature, the resulting precipitate was filtered, washed, and dried overnight at 60°C to obtain fluoroapatite-coated titanium dioxide catalyst B (see Figure 1~4 middle line B). where TiO 2 The molar ratio of Ca element, P element and F element is 100:4.0:2.4:0.8. Using the above photocatalytic activity evaluation method, the degradation rate of phenol was 48.70% after being irradiated with ultraviolet light for 1 hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com