Method for preparing fluorapatite ceramic solidified body

A technology of ceramic solidification and fluoroapatite, which is used in the preparation of fluoroapatite ceramic solidified body and the field of ceramic solidification treatment, and can solve the problems of reduced stability of glass solidified body, poor thermodynamic stability, devitrification or crystallization, etc. , to achieve the effect of protecting human health and ecological environment, high chemical stability and thermal stability, and realizing resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

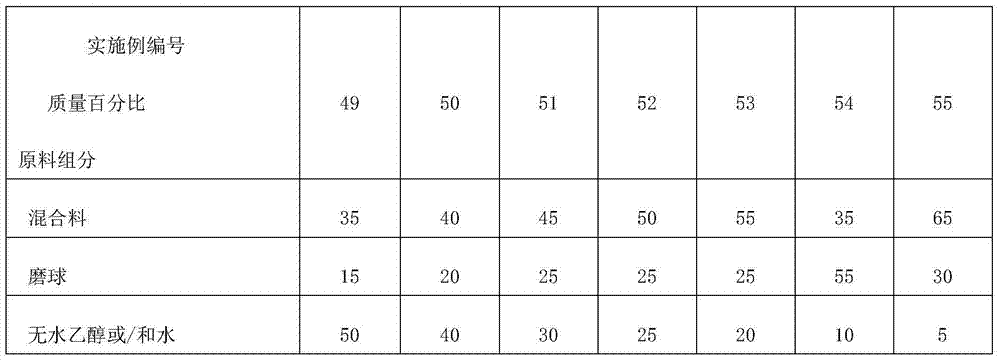

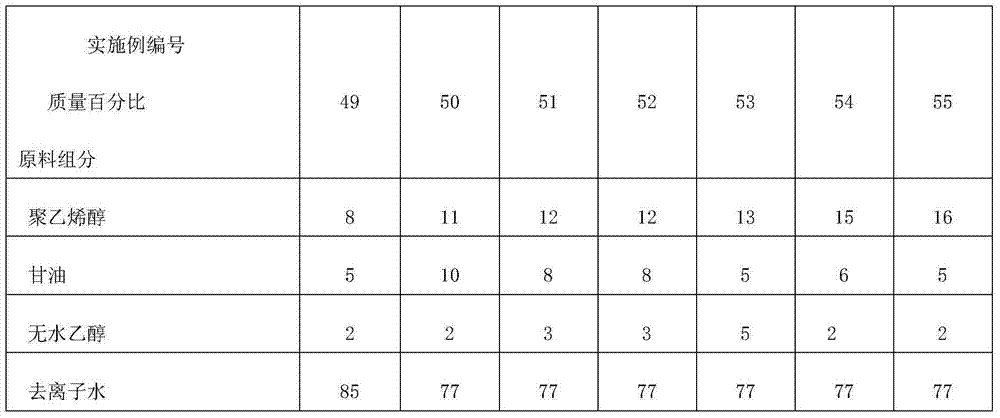

Embodiment 1

[0034] A preparation method of fluorapatite ceramic solidified body, the steps are: according to the mass percentage of 50.69% of calcium pyrophosphate, 20.62% of calcium fluoride, and 28.69% of samarium oxide, the raw materials of each component are weighed, and after mixing evenly, a mixture is obtained ; According to the mass percentages of 40% of the mixture, 20% of the grinding balls, 20% of absolute ethanol, and 20% of deionized water, the mixture, the grinding balls, and the absolute ethanol were added to the planetary ball mill for grinding for 3 hours, and then the grinding The subsequent ingredients are dried at 60°C for 4 hours to obtain dried powder; add polyvinyl alcohol sol with 5% of the dried powder mass to the dried powder, mix and granulate, and then successively After sieving with 15-mesh and 180-mesh sieves, the 15-mesh sieve and the 180-mesh sieve are the prepared granulated materials; the granulated materials are put into steel molds, and the pressure of 1...

Embodiment 2

[0036] A preparation method of fluorapatite ceramic solidified body, the steps are: according to the mass percentage of calcium pyrophosphate 39.88%, calcium fluoride 25.45%, and samarium oxide 34.67%, the raw materials of each component are weighed, and after mixing evenly, a mixture is obtained ; According to the mass percentage of 35% of the mixture, 15% of the grinding balls, and 50% of absolute ethanol, the mixture, the grinding balls, and the absolute ethanol were added to the planetary ball mill for grinding for 2 hours, and then the ingredients after grinding were ground at 40°C Dry at a temperature of 6 hours to obtain the dried powder; add polyvinyl alcohol sol with a mass of 3% of the dried powder to the dried powder, mix and granulate, and then successively use 12 mesh and 170 mesh After the sieve is screened, the 12-mesh sieve material and the 170-mesh sieve material are the prepared granulated material; the granulated material is put into a steel mold, and the pre...

Embodiment 3

[0038] A method for preparing a fluorapatite ceramic solidified body, the steps are: weighing the raw materials of each component according to the mass percentage of calcium pyrophosphate 75.12%, calcium fluoride 13.65%, and samarium oxide 11.23%, and mixing them uniformly to obtain a mixture ;According to the mass percentage of 65% of the mixture, 30% of the grinding balls, and 5% of deionized water, the mixture, the grinding balls, and the deionized water were added to the planetary ball mill for grinding for 5 hours, and then the ingredients after grinding were heated at 80°C Dry at a temperature of 3 hours to obtain the dried powder; add polyvinyl alcohol sol with a mass of 10% of the dried powder to the dried powder, mix and granulate, and then successively use 25 mesh and 270 mesh After the sieve is screened, the 25-mesh sieve material and the 270-mesh sieve material are the prepared granulated material; the granulated material is put into a steel mold, and the pressure o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com