Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35 results about "Minor actinide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The minor actinides are the actinide elements in used nuclear fuel other than uranium and plutonium, which are termed the major actinides. The minor actinides include neptunium (element 93), americium (element 95), curium (element 96), berkelium (element 97), californium (element 98), einsteinium (element 99), and fermium (element 100). The most important isotopes in spent nuclear fuel are neptunium-237, americium-241, americium-243, curium-242 through -248, and californium-249 through -252.

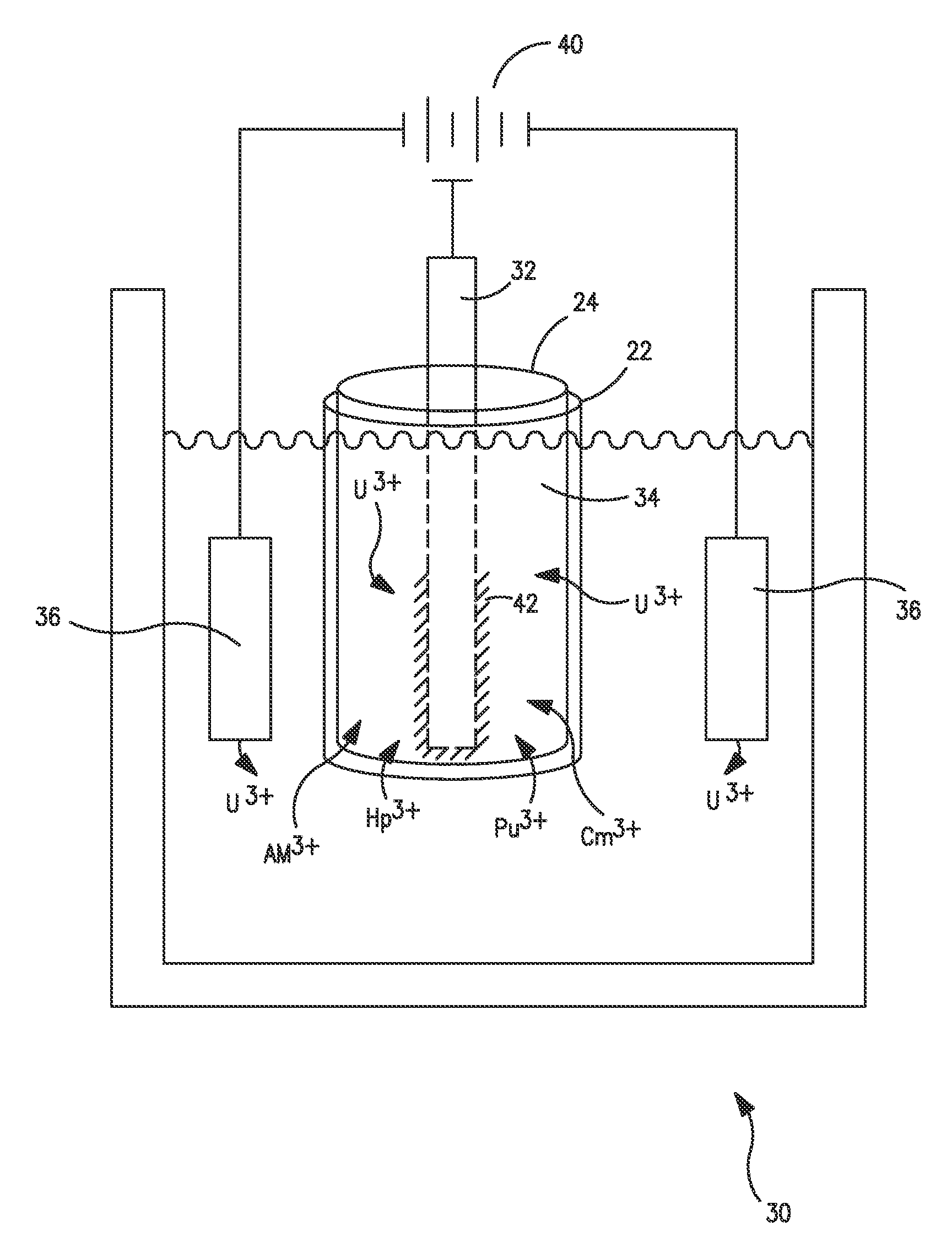

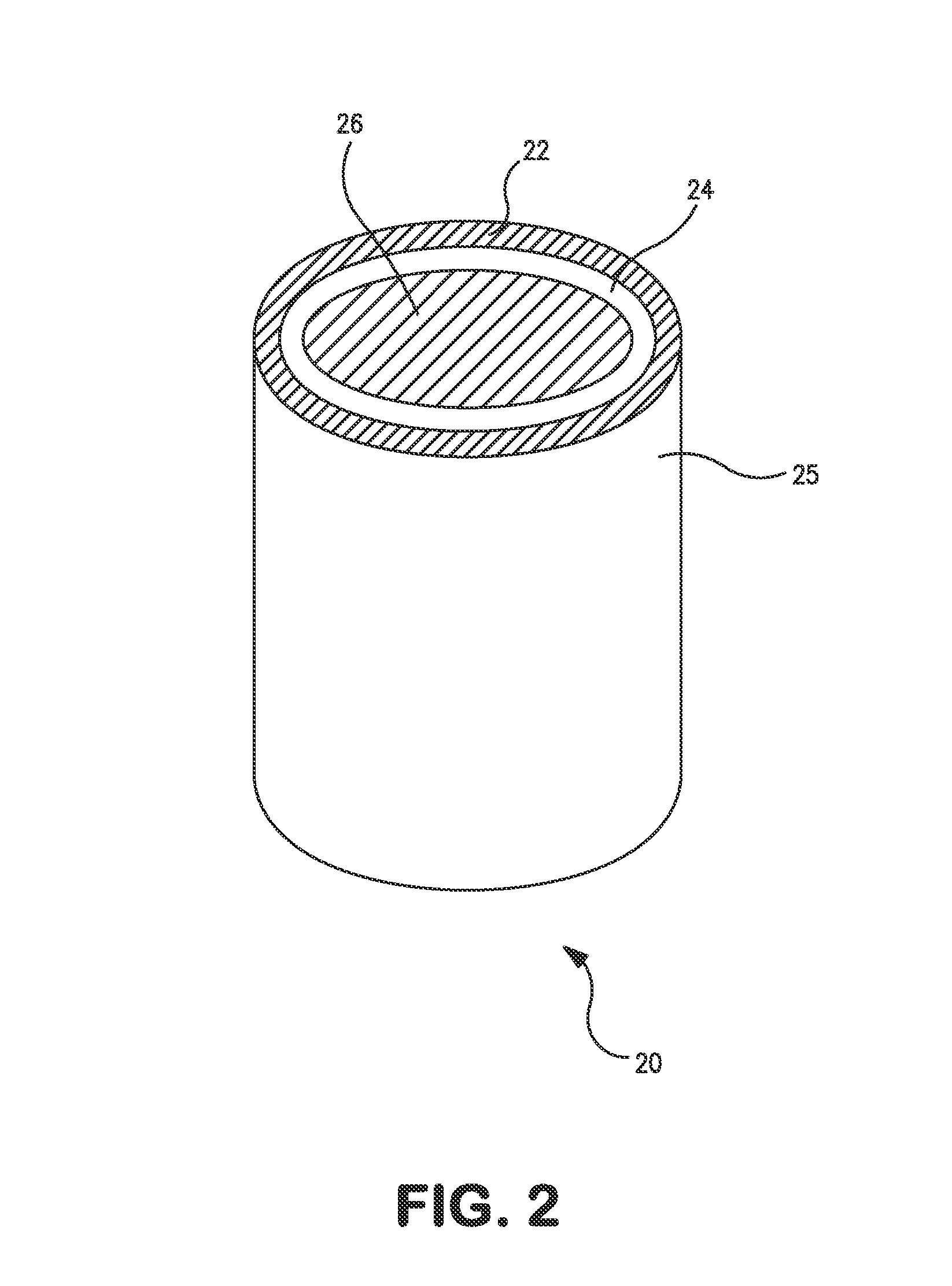

Porous membrane electrochemical cell for uranium and transuranic recovery from molten salt electrolyte

InactiveUS7799185B1Eliminate the problemDiffusion slowCellsIsotope separationMaterials scienceUranium

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

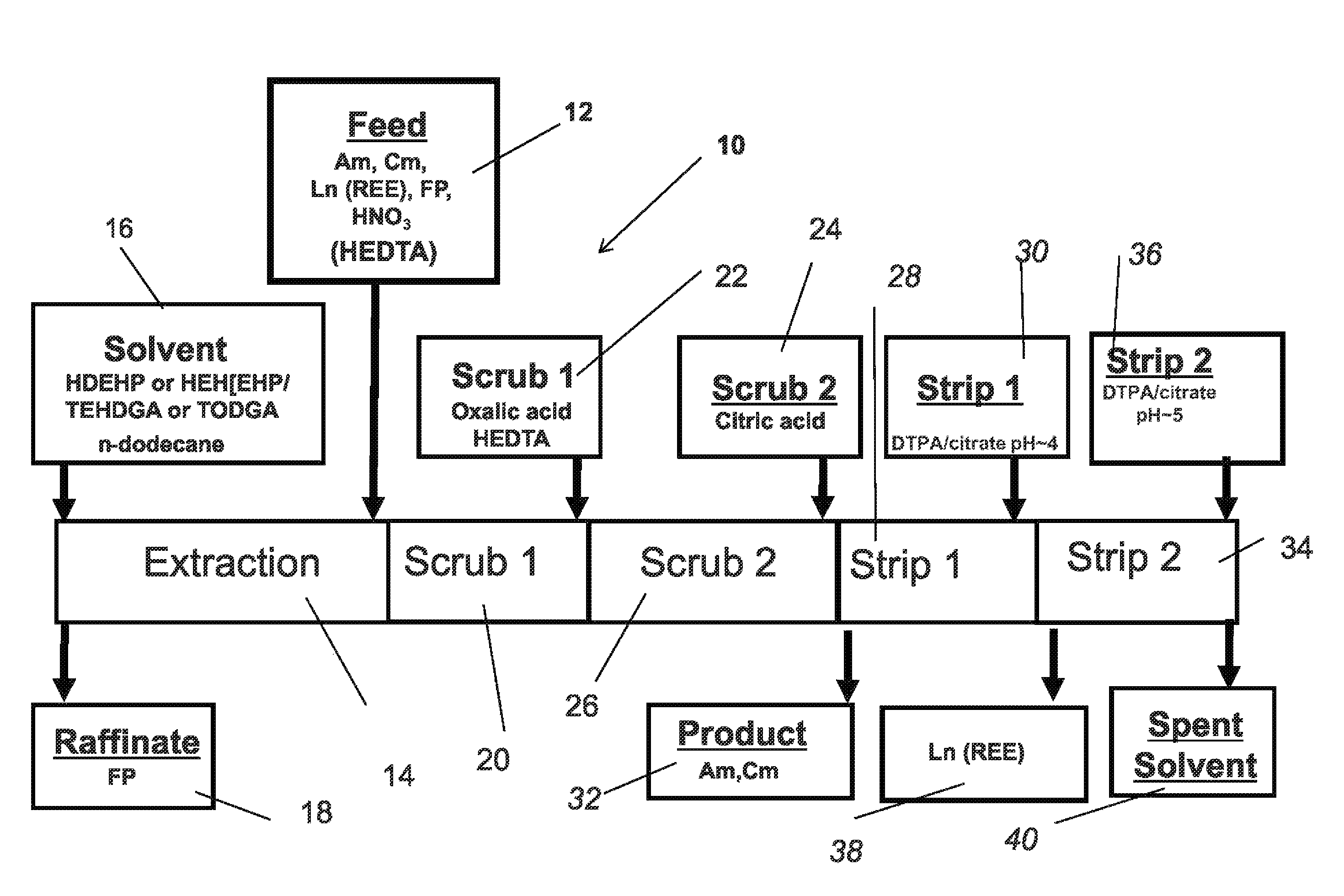

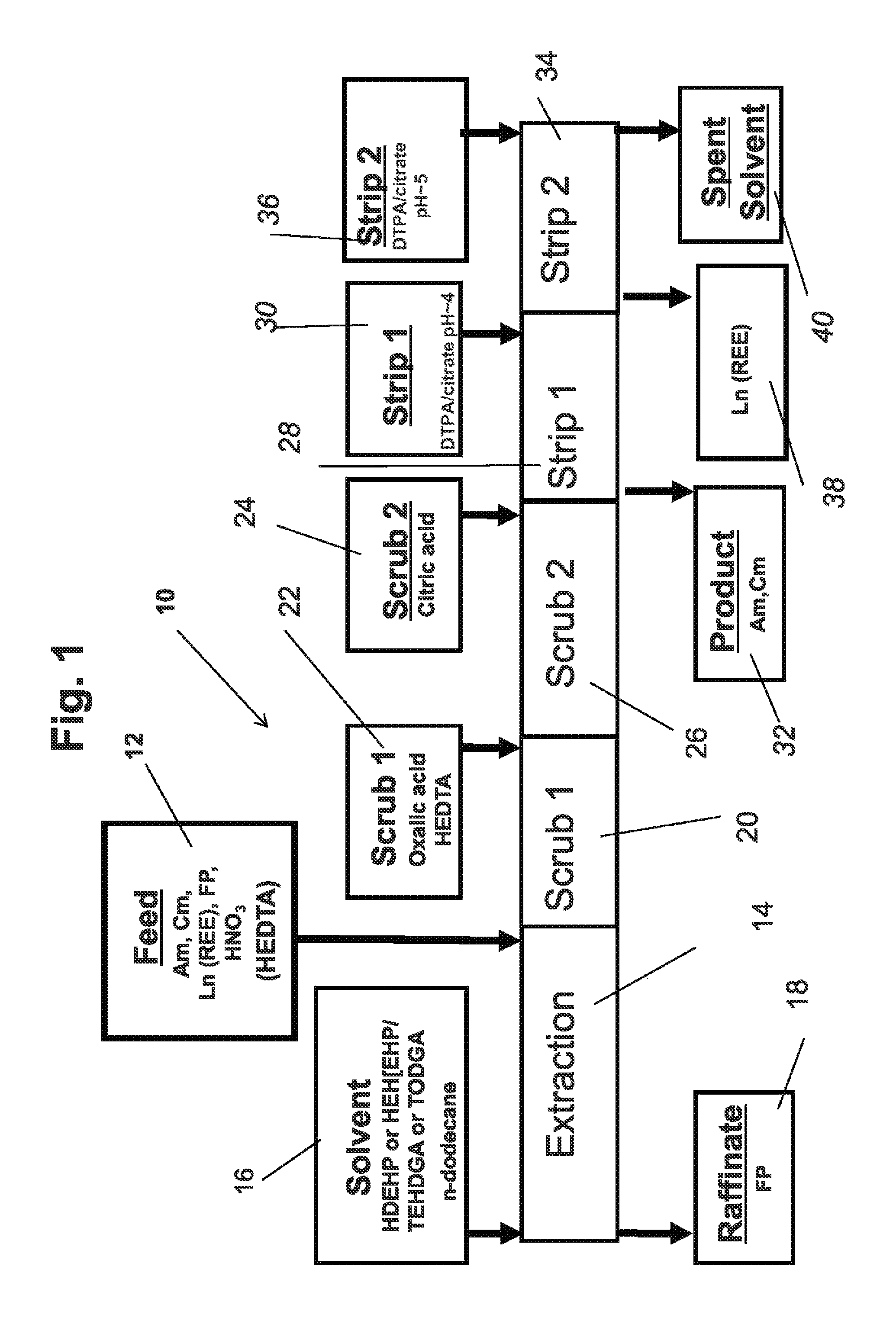

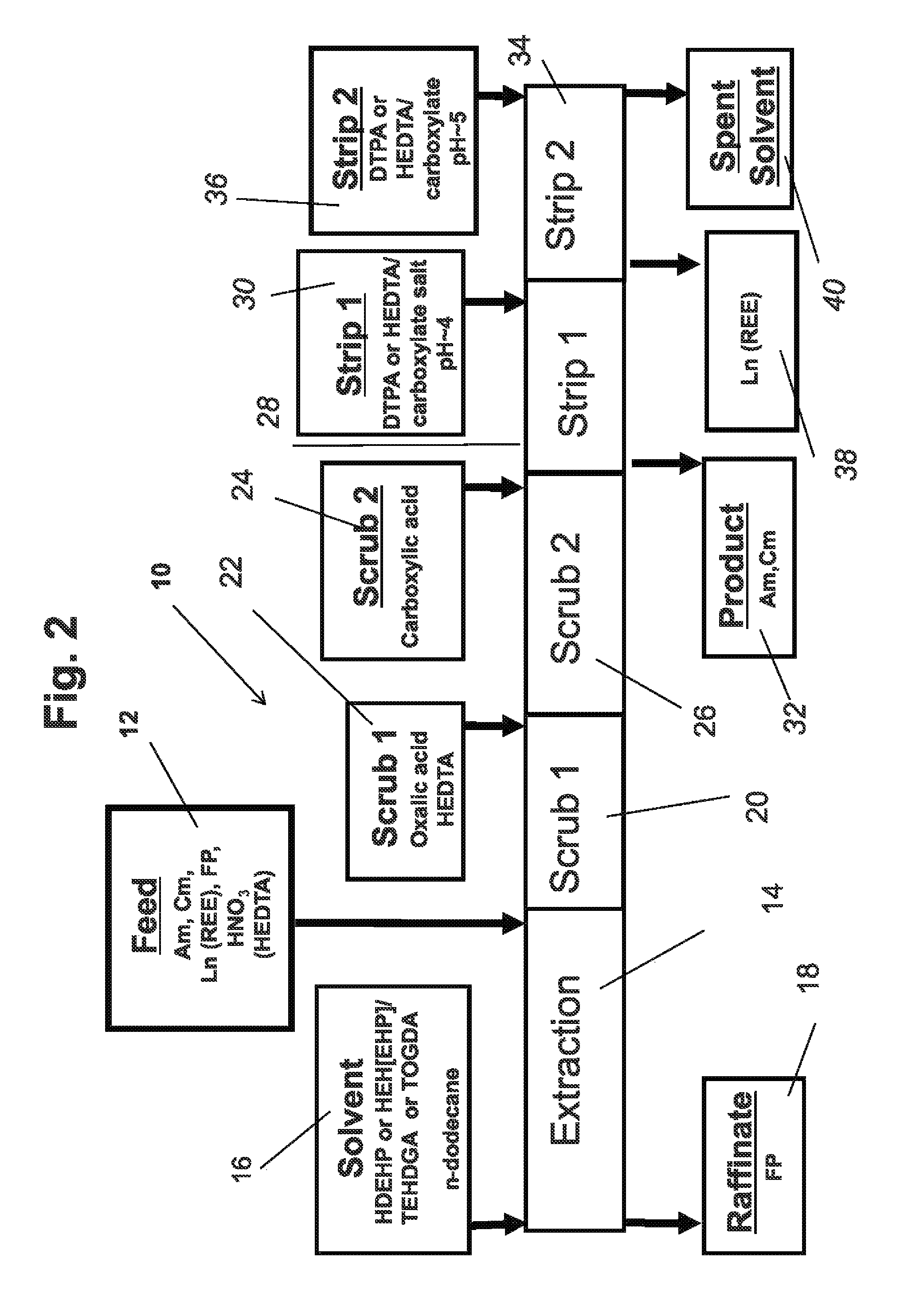

Actinide and lanthanide separation process (ALSEP)

InactiveUS8354085B1Permit separationSolvent extractionTransuranic element compoundsRare-earth elementLanthanide

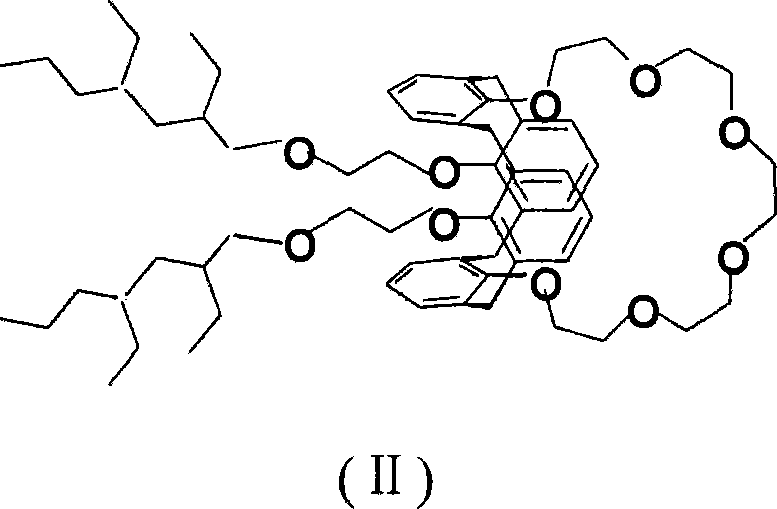

The process of the invention is the separation of minor actinides from lanthanides in a fluid mixture comprising, fission products, lanthanides, minor actinides, rare earth elements, nitric acid and water by addition of an organic chelating aid to the fluid; extracting the fluid with a solvent comprising a first extractant, a second extractant and an organic diluent to form an organic extractant stream and an aqueous raffinate. Scrubbing the organic stream with a dicarboxylic acid and a chelating agent to form a scrubber discharge. The scrubber discharge is stripped with a simple buffering agent and a second chelating agent in the pH range of 2.5 to 6.1 to produce actinide and lanthanide streams and spent organic diluents. The first extractant is selected from bis(2-ethylhexyl)hydrogen phosphate (HDEHP) and mono(2-ethylhexyl)2-ethylhexyl phosphonate (HEH(EHP)) and the second extractant is selected from N,N,N,N-tetra-2-ethylhexyl diglycol amide (TEHDGA) and N,N,N′,N′-tetraoctyl-3-oxapentanediamide (TODGA).

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

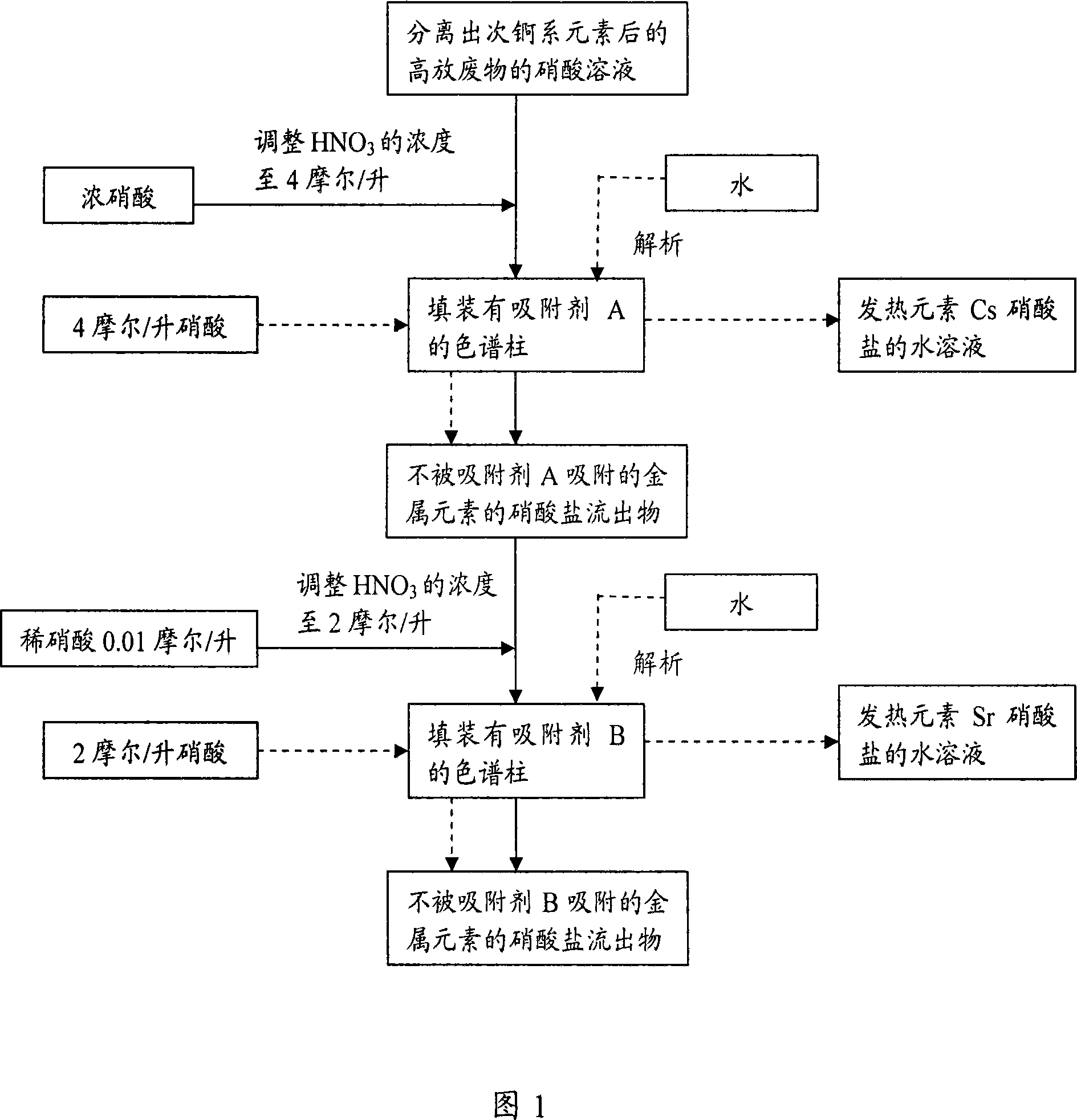

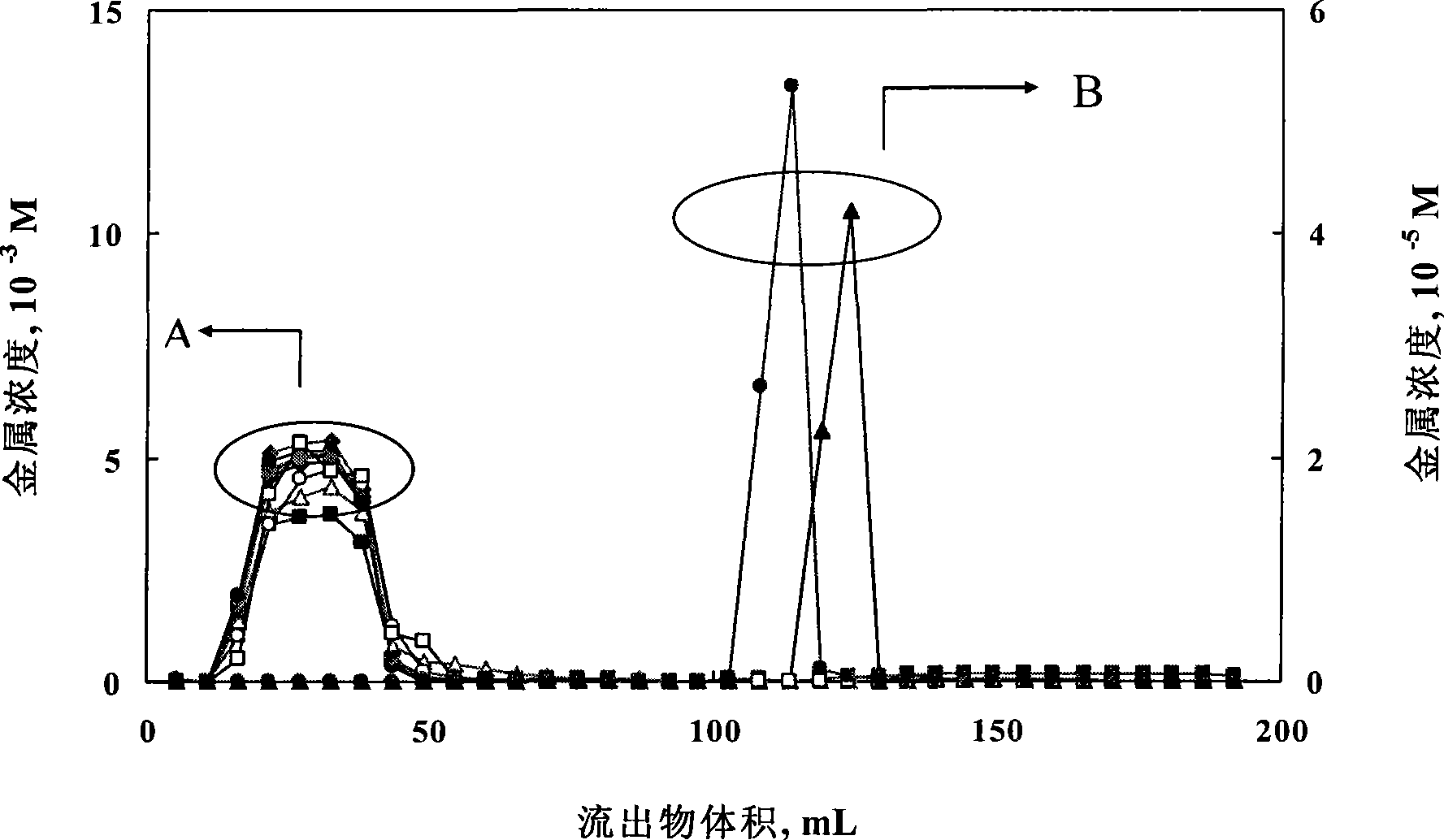

Method for separating heating element Cs and Sr from high radioactive waste

InactiveCN101143273AHigh selectivityEasy to separateIon-exchange process apparatusOther chemical processesNitrateSorbent

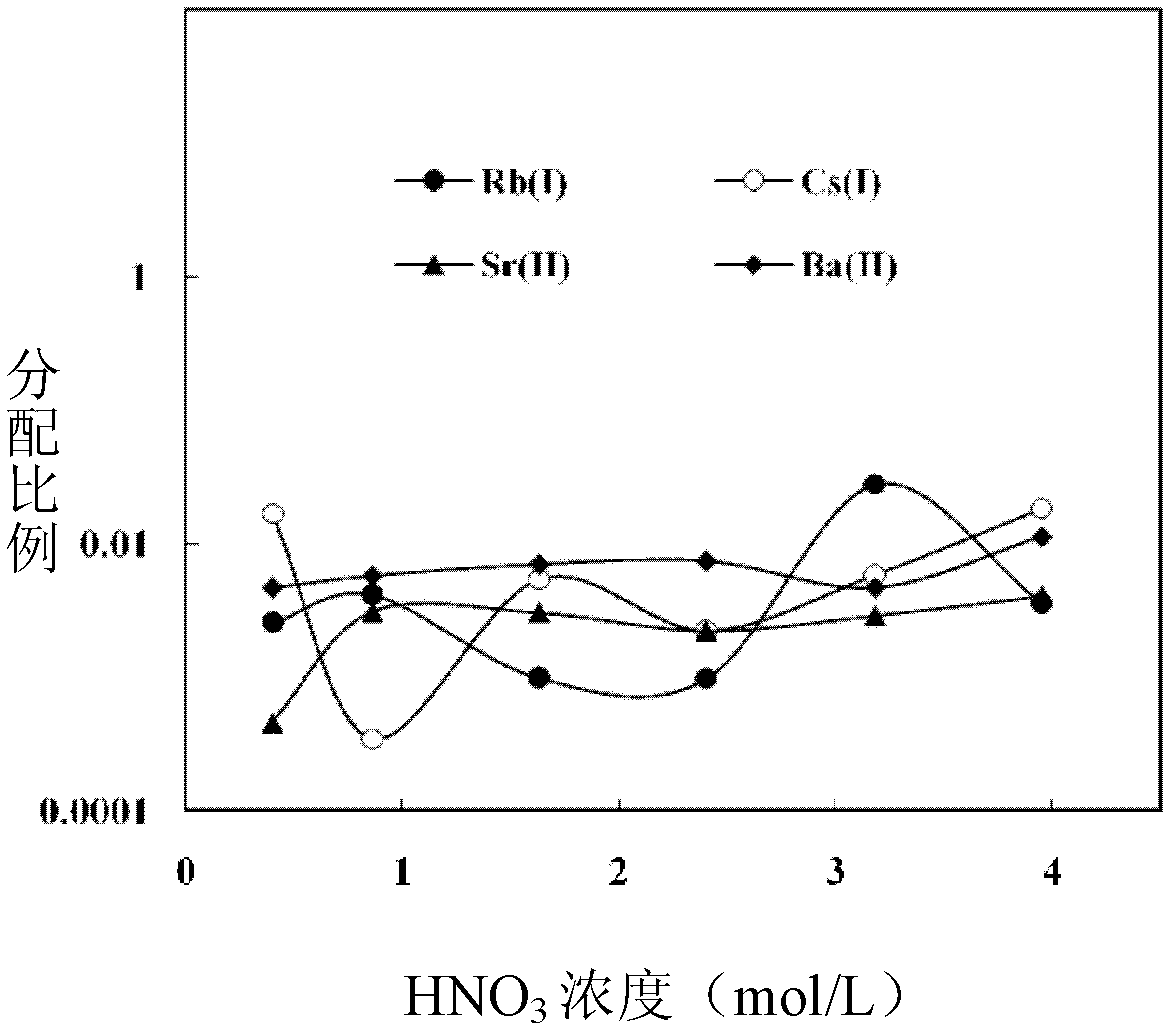

The invention discloses a method of separating heating elements Cs and Sr from high level radioactive waste. The method contains the following steps: (1) concentrated nitric acid is added into the nitrate solution of high level radioactive waste that the secondary actinide is separated; the concentration of the nitric acid is adjusted to 3.5-4.4 mol / L; (2) the nitrate solution of high level radioactive waste that the nitric acid concentration is adjusted passes by a chromatographic column filled with adsorbent A, and the heating element Cs is absorbed by the chromatographic column filled with adsorbent A; (3) after the nitrate solution of high level radioactive waste that the nitric acid concentration is adjusted flowing out of the chromatographic column filled with adsorbent A, water is added and the concentration of the nitric acid is adjusted to 1.5-2.5 mol / L; and when the solution passes by the a chromatographic column filled with adsorbent B, the heating element Sr is absorbed by the chromatographic column filled with adsorbent B. The method is simple with high efficiency. The concentration of the nitric acid is similar when the two chromatographic column adsorptions are separated, which is convenient to be adjusted.

Owner:ZHEJIANG UNIV

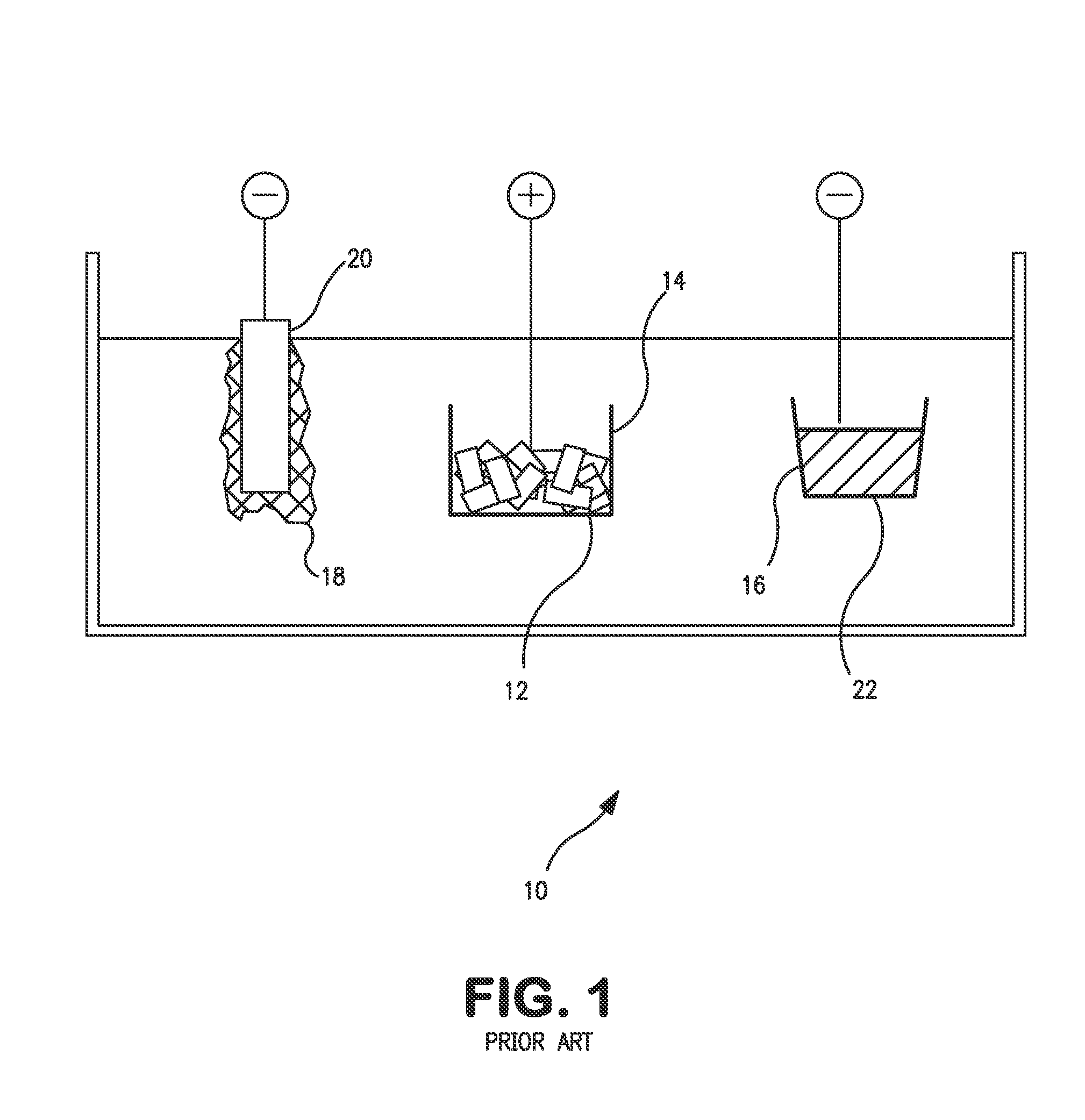

Porous membrane electrochemical cell for uranium and transuranic recovery from molten salt electrolyte

InactiveUS7267754B1Eliminate the problemDiffusion slowPhotography auxillary processesMaterials scienceUranium

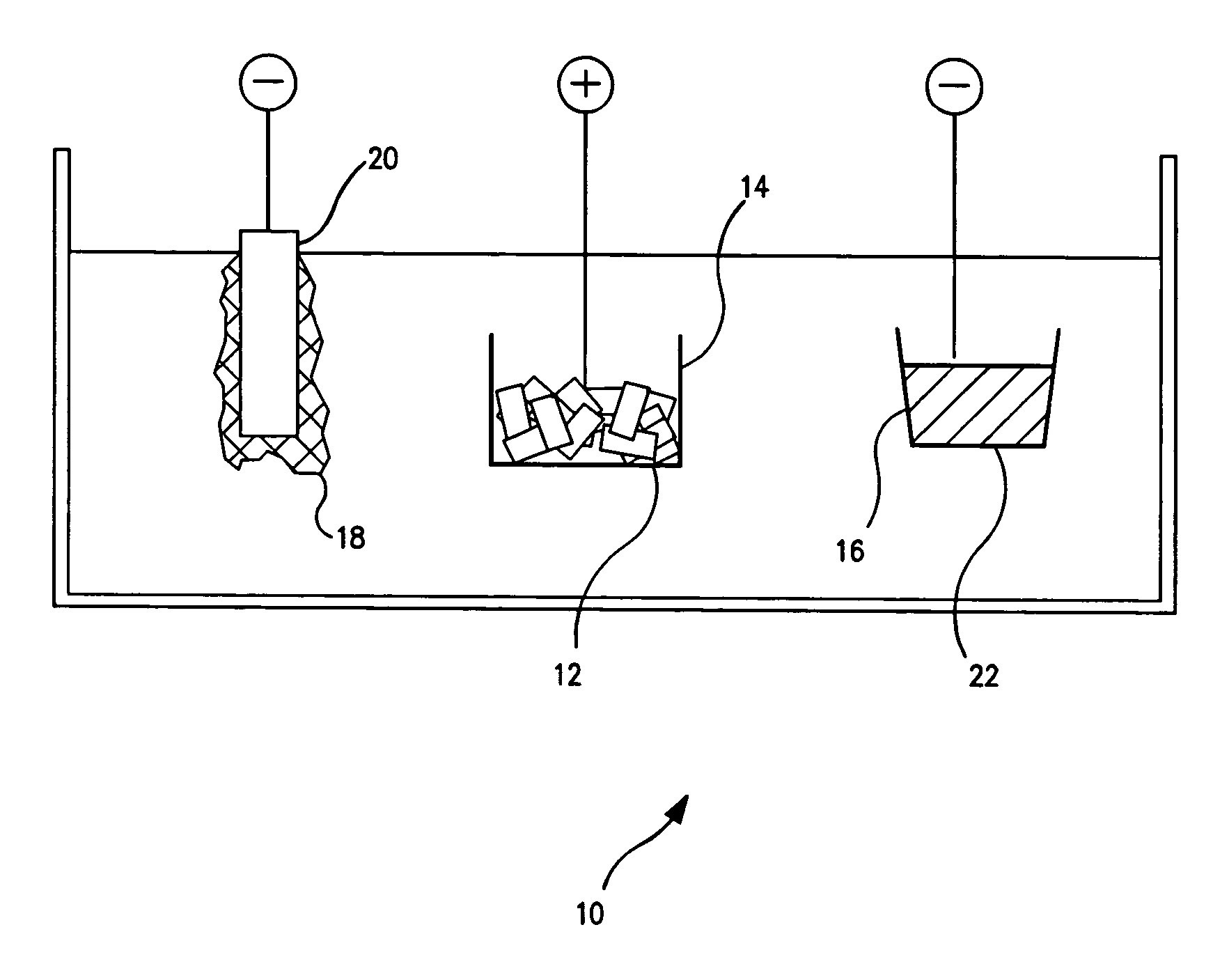

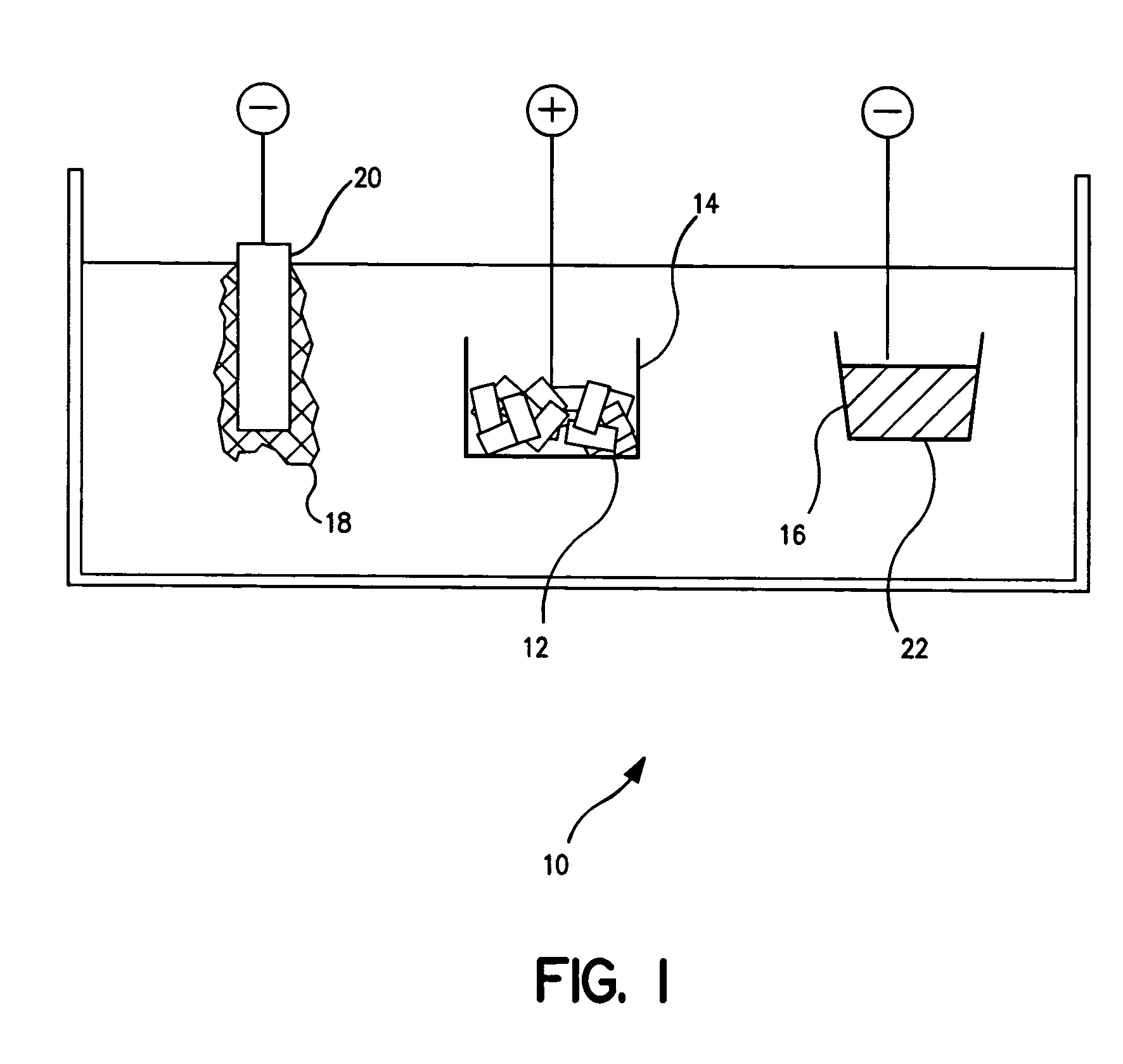

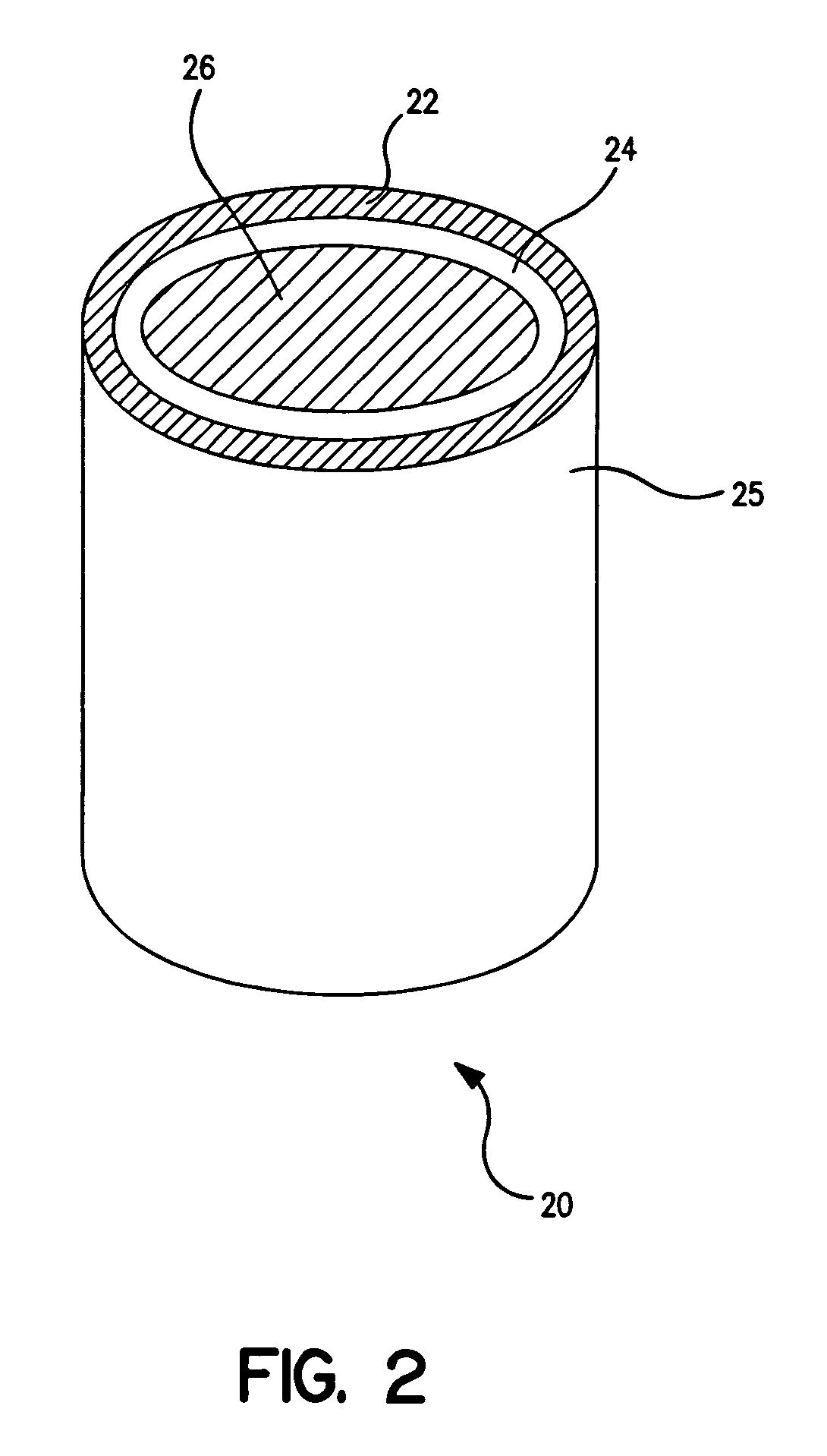

An improved process and device for the recovery of the minor actinides and the transuranic elements (TRU's) from a molten salt electrolyte. The process involves placing the device, an electrically non-conducting barrier between an anode salt and a cathode salt. The porous barrier allows uranium to diffuse between the anode and cathode, yet slows the diffusion of uranium ions so as to cause depletion of uranium ions in the catholyte. This allows for the eventual preferential deposition of transuranics present in spent nuclear fuel such as Np, Pu, Am, Cm. The device also comprises an uranium oxidation anode. The oxidation anode is solid uranium metal in the form of spent nuclear fuel. The spent fuel is placed in a ferric metal anode basket which serves as the electrical lead or contact between the molten electrolyte and the anodic uranium metal.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

Method for MA/RE mutual separation in high-level waste

InactiveCN101483079AImprove adsorption capacityCompletely separated from each otherIon-exchange process apparatusIon-exchanger regenerationRare-earth elementNitrate

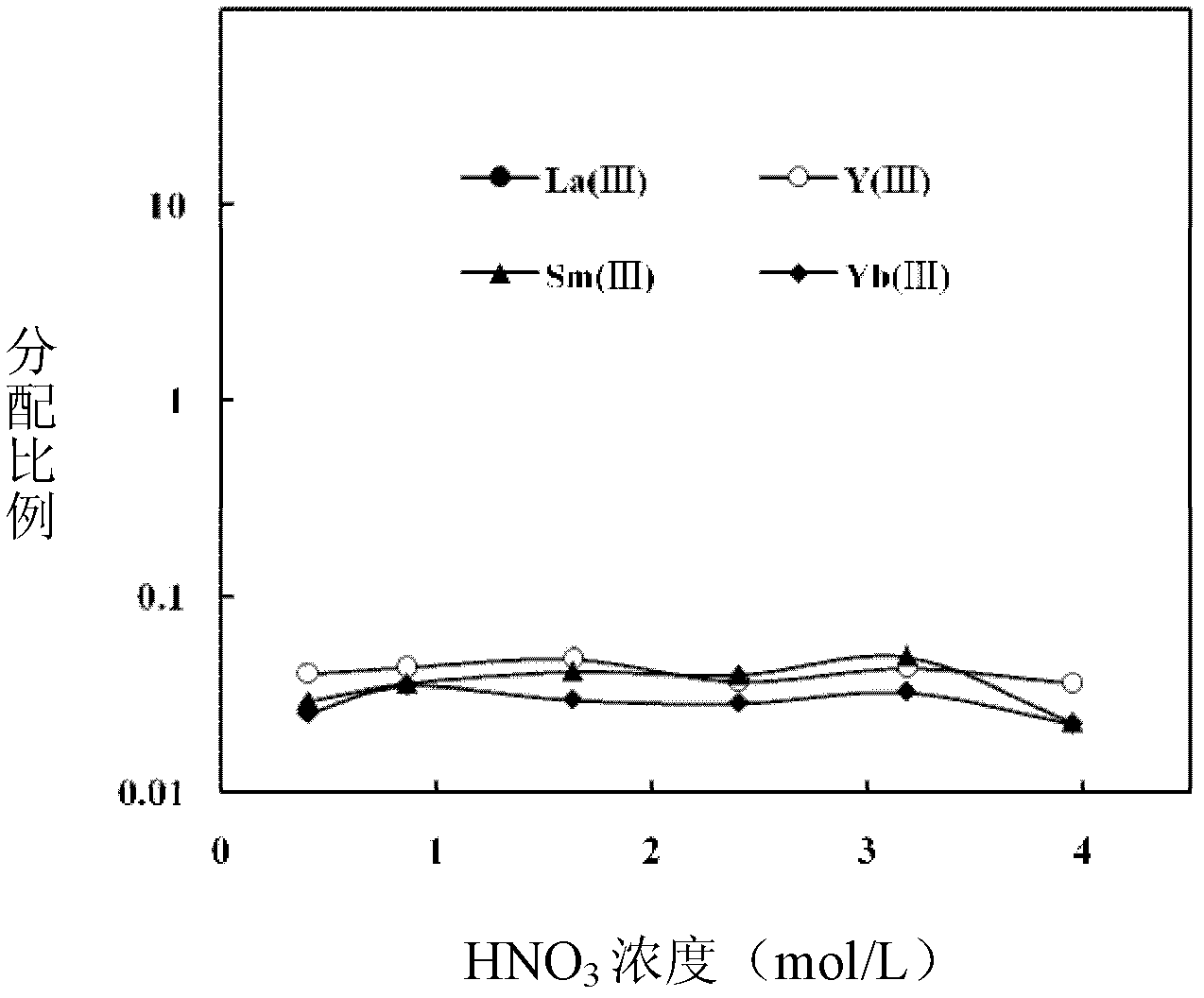

The present invention discloses a method for performing MA / RE mutual separation to high-level waste, including: adjusting the nitrate concentration of the nitrate solution containing hypo-actinide element MA and rare-earth element RE; (2) the nitrates solution with adjusted nitrate concentration flowing through a chromatographic column filled with adsorbing substance; (3) using the eluent A to elute the chromatographic column to leach out the nitrates of rare-earth element, wherein, the eluate A is an aqueous solution containing NaNO3 and HNO3; (4) leaching the chromatographic column using the de-ionized water to leaching out the nitrate containing hypo-actinide element. The inventions has features of good separation effect, strong selection adsorbability of the adsorbing substance, capability of comparative thoroughly MA / RE mutual separation in the high-level waste, thoroughly security, economy and high efficiency.

Owner:ZHEJIANG UNIV

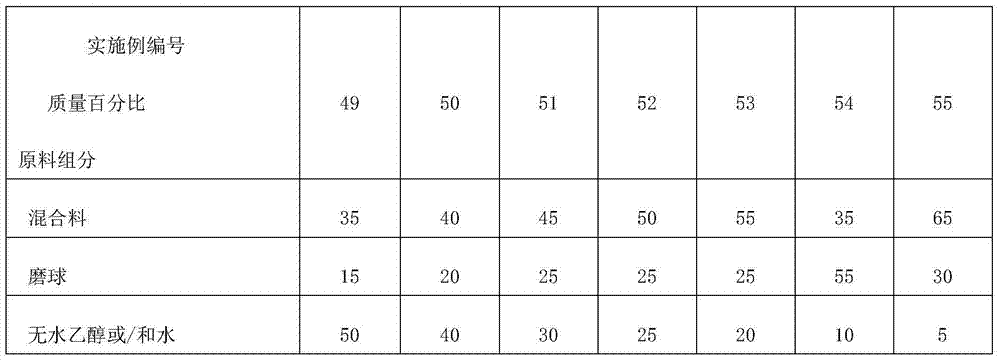

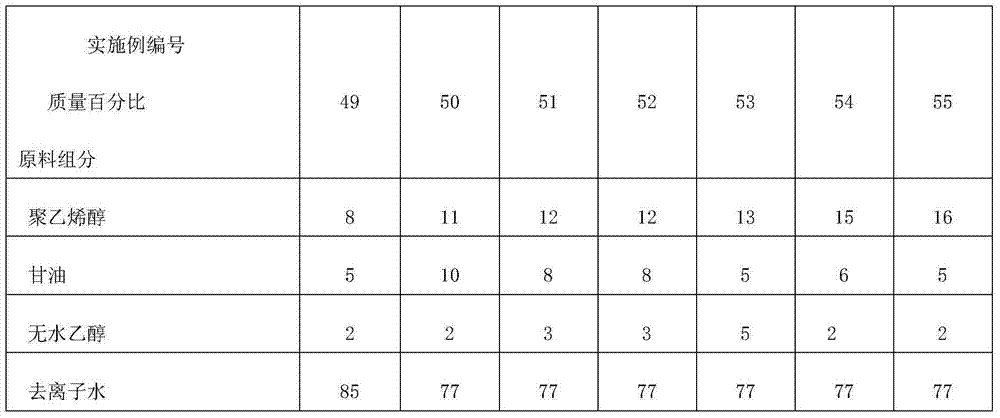

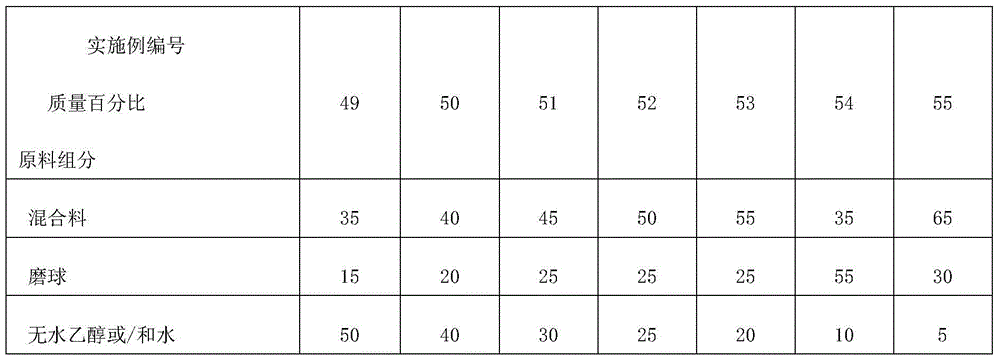

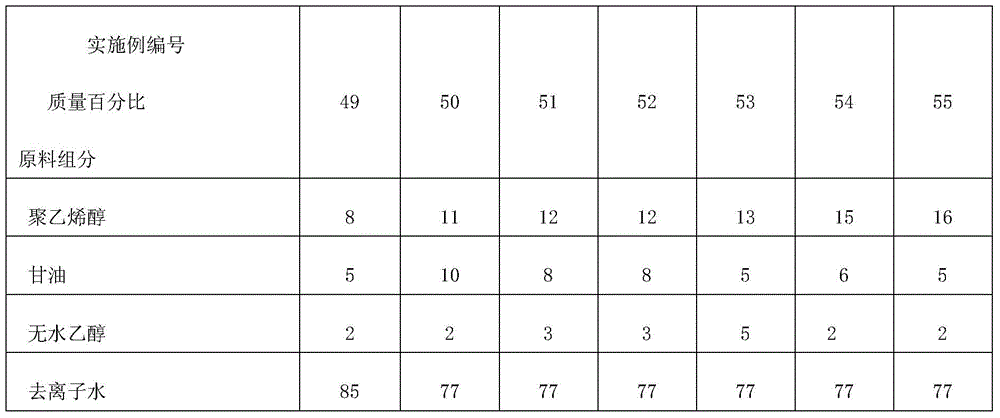

Method for preparing fluorapatite ceramic solidified body

The present invention discloses a method for preparing a fluorapatite ceramic solidified body. The method is characterized by comprising the steps of: taking and mixing 23-76 wt.% of calcium pyrophosphate, 8-26 wt.% of calcium fluoride, 0. 02-52wt.% of samarium oxide (europium oxide, gadolinium oxide), 0-15 wt.% of sodium carbonate, 0-16 wt.% of silica to obtain a mixture; grinding, drying, granulating, molding, discharging rubber and conducting vacuum hot pressing sintering on the mixture to obtain a fluorapatite ceramic solidified body. The method not only utilizes the phosphorus in high-level radioactive waste in a recycling way, but also can address the problem of low solubility of phosphorus and minor actinides nuclide in glass solidified body. The fluorapatite ceramic cured body prepared by the invention has excellent preparation geological stability, irradiation stability, mechanical stability, chemical stability and thermal stability, and can be used as a ceramic solidified body for safe treatment of minor actinides high-level radioactive waste with high toxicity, long half-life period and strong radioactivity.

Owner:SOUTHWEAT UNIV OF SCI & TECH

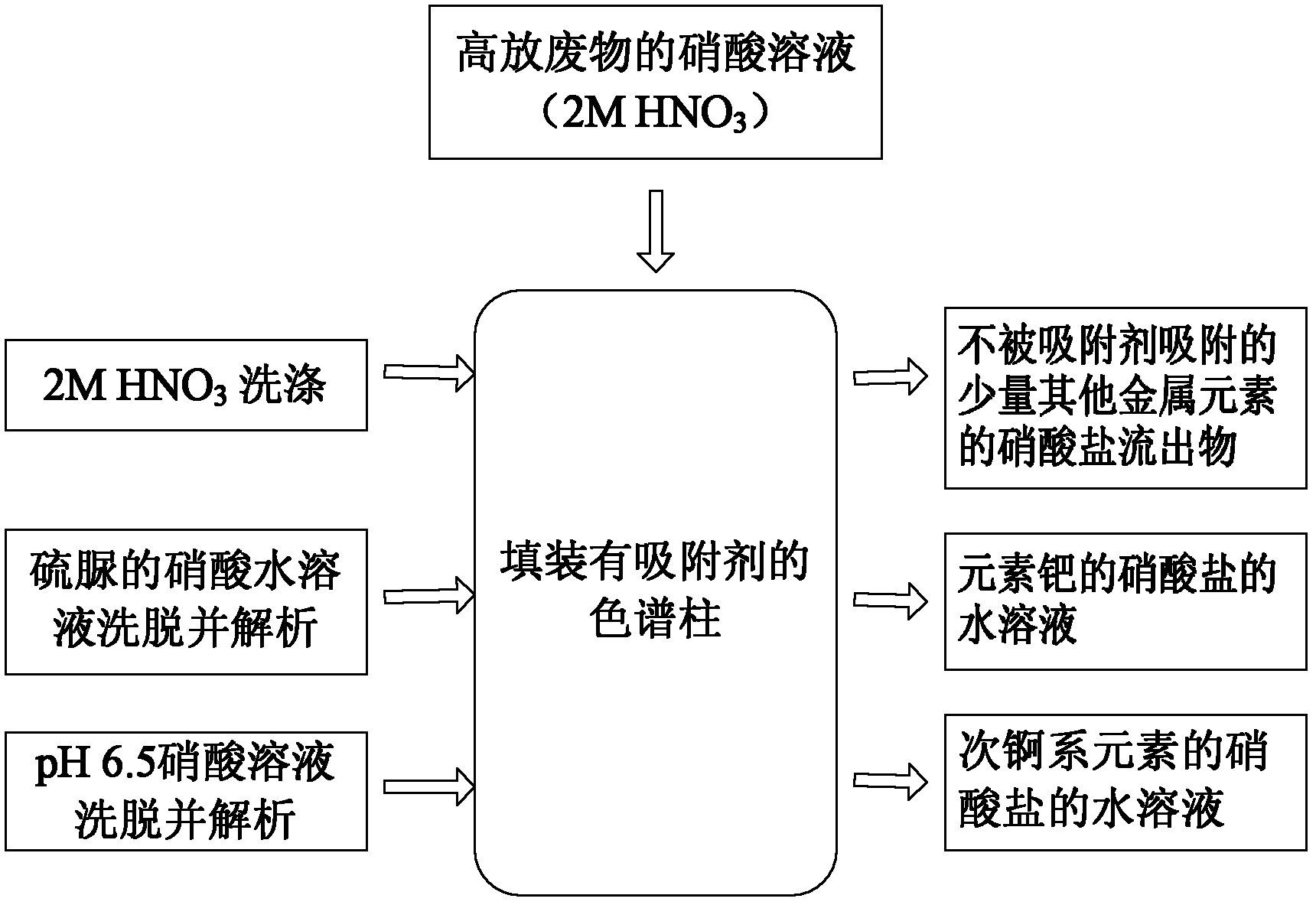

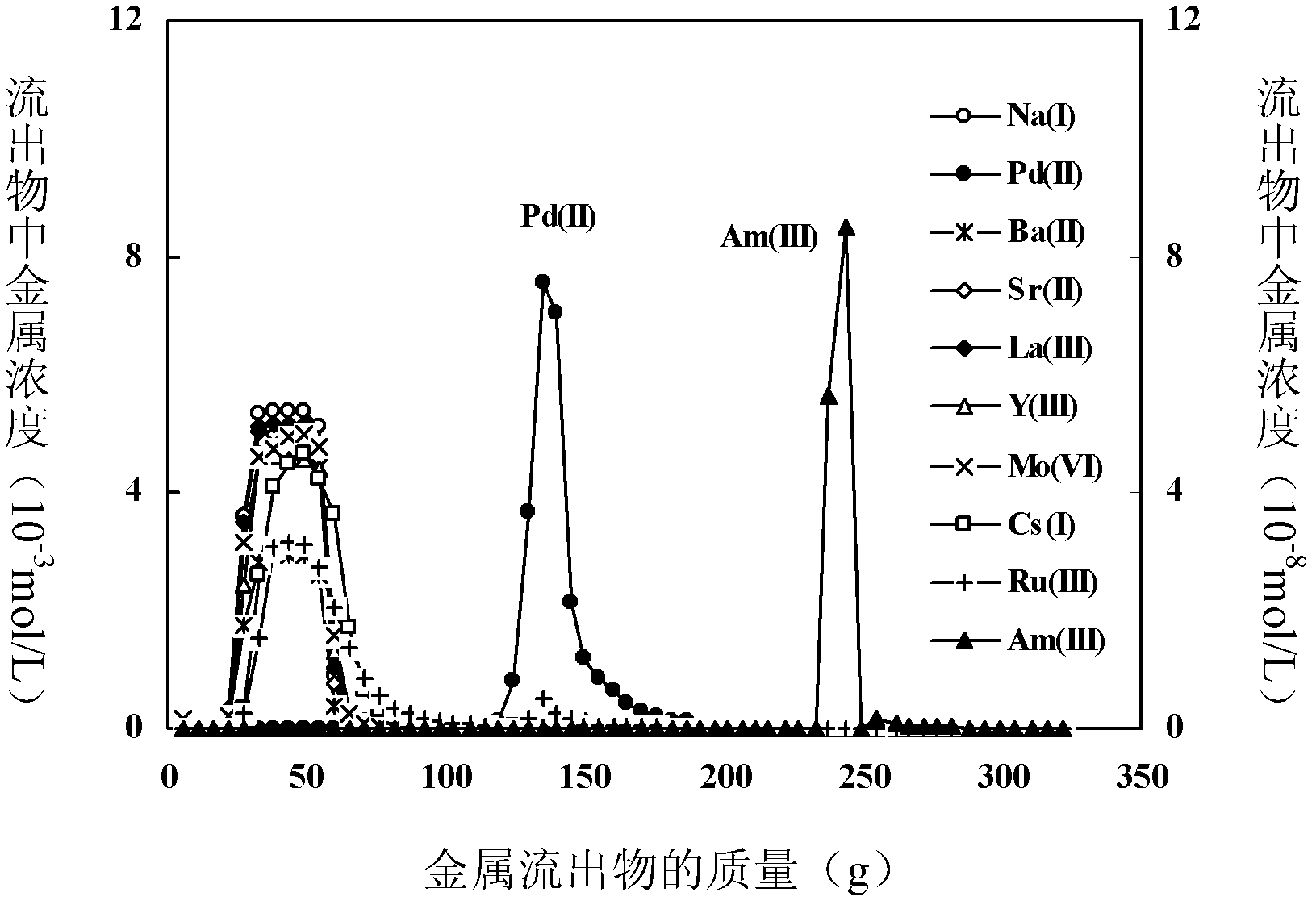

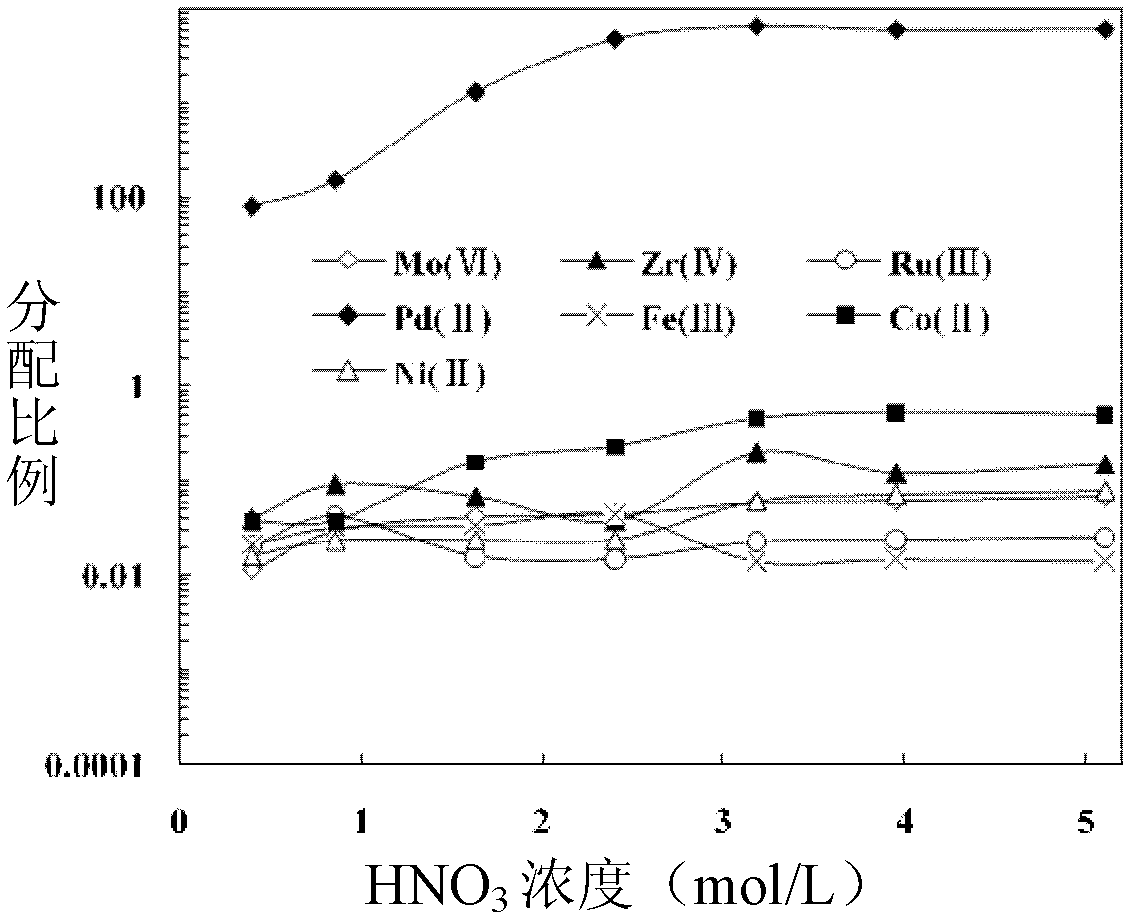

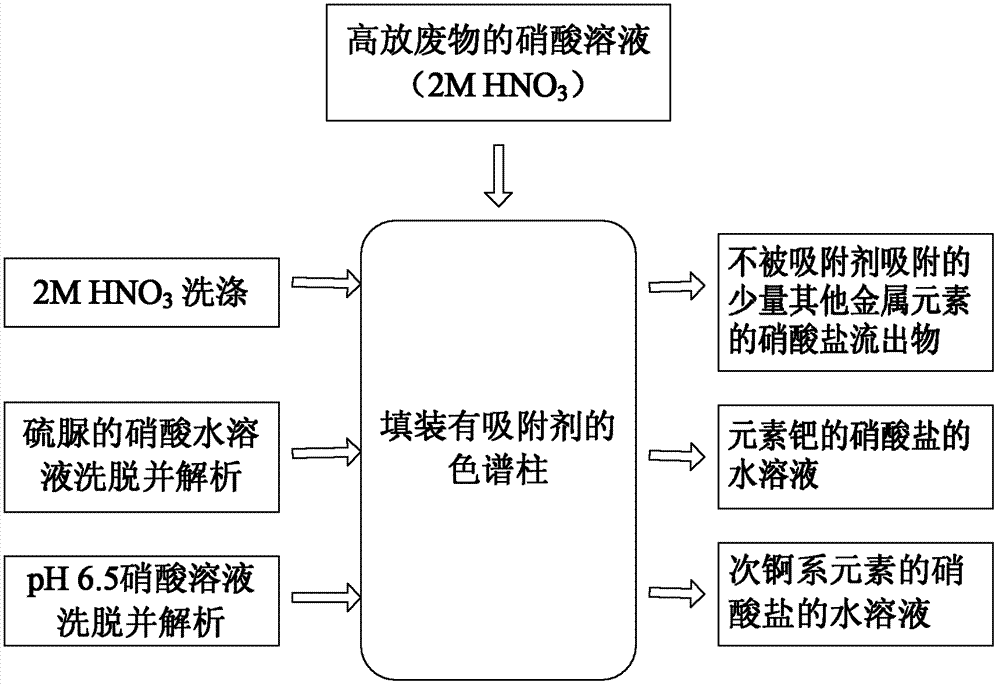

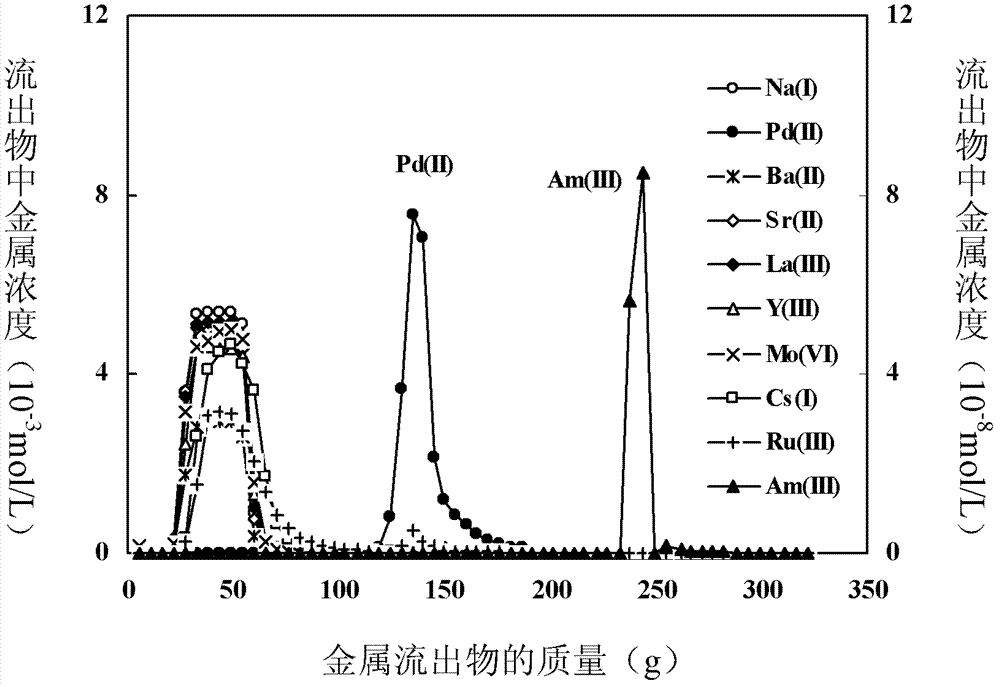

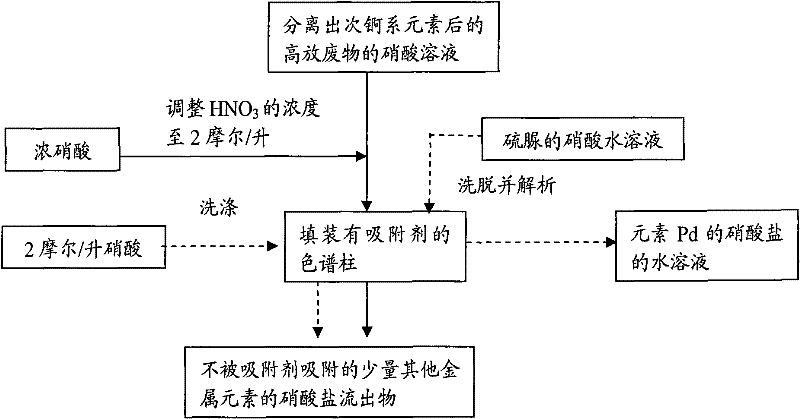

Method for separating element palladium and sub-actinide elements from high-level waste

InactiveCN102614683AHigh selectivityEasy to separateOther chemical processesSolid sorbent liquid separationHydrogenNitrate

The invention discloses a method for separating element palladium from high-level waste, which includes the steps: adding concentrated nitric acid into nitrate solution of the high-level waste to adjust the nitric acid concentration to be 2mol / L; and allowing the high-level waste nitrate solution with the nitric acid concentration adjusted to pass through a chromatographic column filled with adsorbent to enable element palladium and sub-actinide elements to be adsorbed by the chromatographic column filled with the adsorbent; using nitric acid aqueous solution of thiourea to elute the chromatographic column with the adsorbed element palladium and sub-actinide elements, and eluting the element palladium out in a nitrate form, wherein the thiourea concentration of the nitric acid aqueous solution of thiourea is 0.2mol / L, and the nitric acid concentration is 0.1mol / L; and after the element palladium is eluted out in a nitrate form, using saltpeter solution with the pH (potential of hydrogen) being 6.5 to elute the chromatographic column with the adsorbed sub-actinide elements and eluting the sub-actinide elements out in a nitrate form. The method is simple, efficient, high in selectivity of the chromatographic column and effective in separation.

Owner:ZHEJIANG UNIV

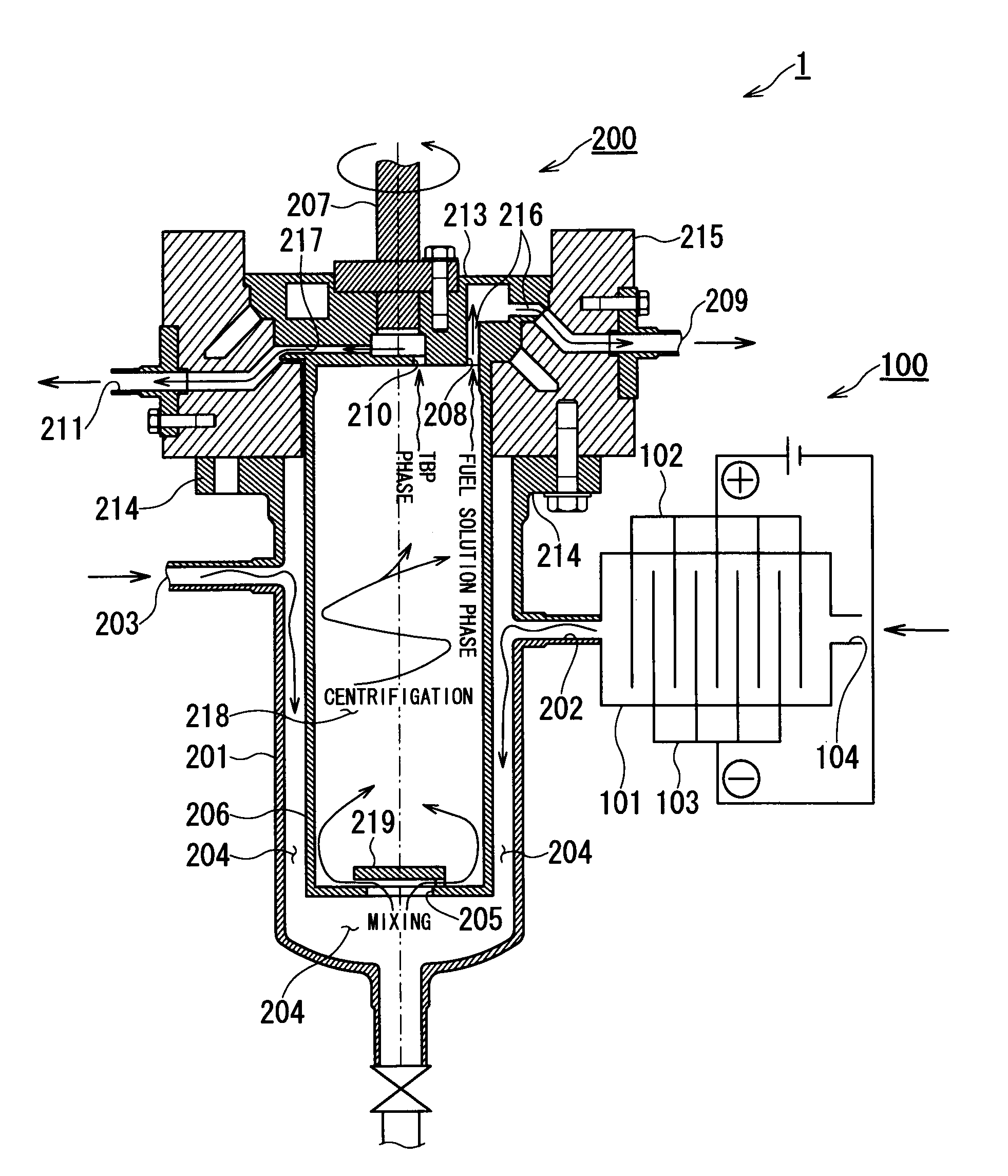

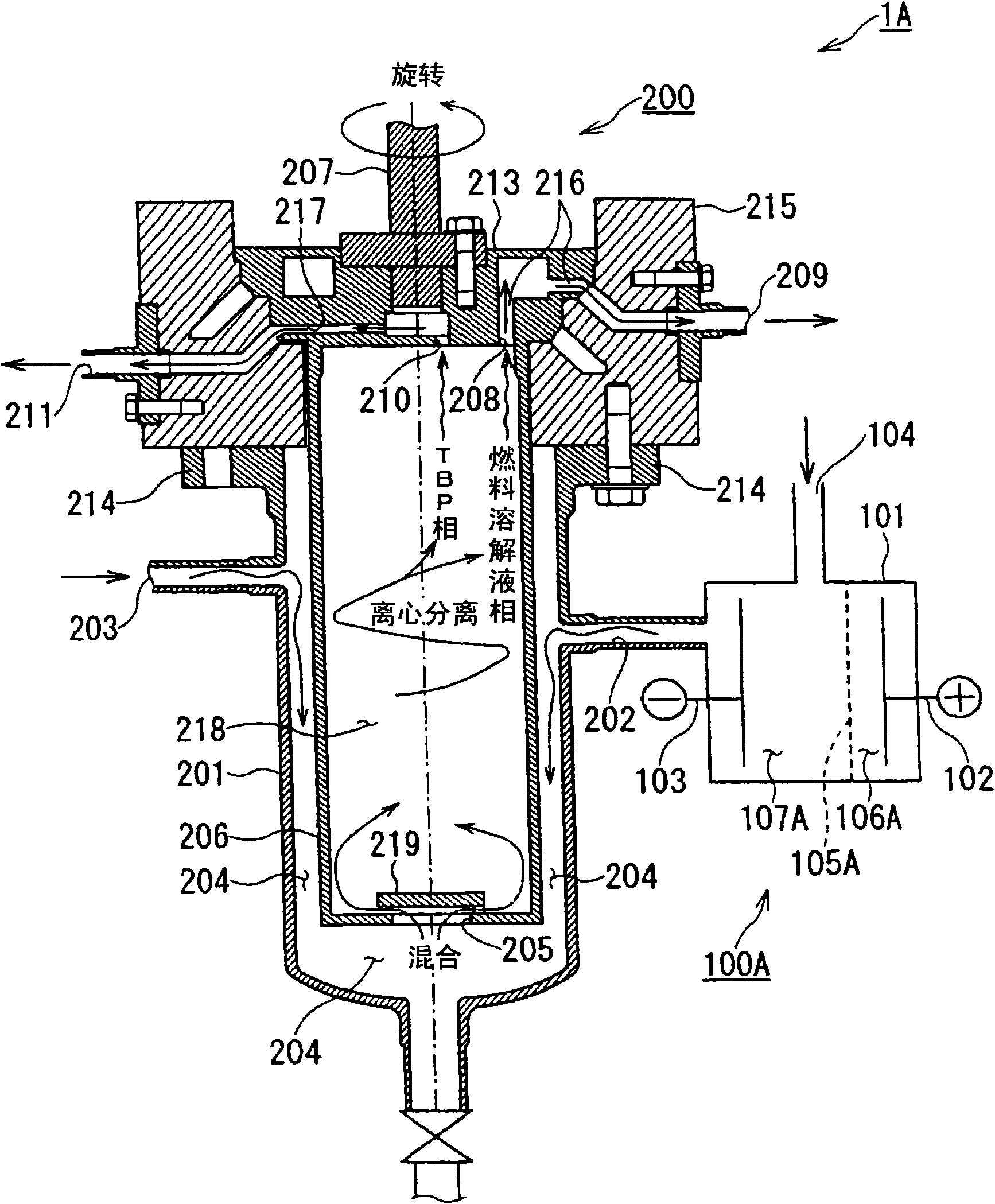

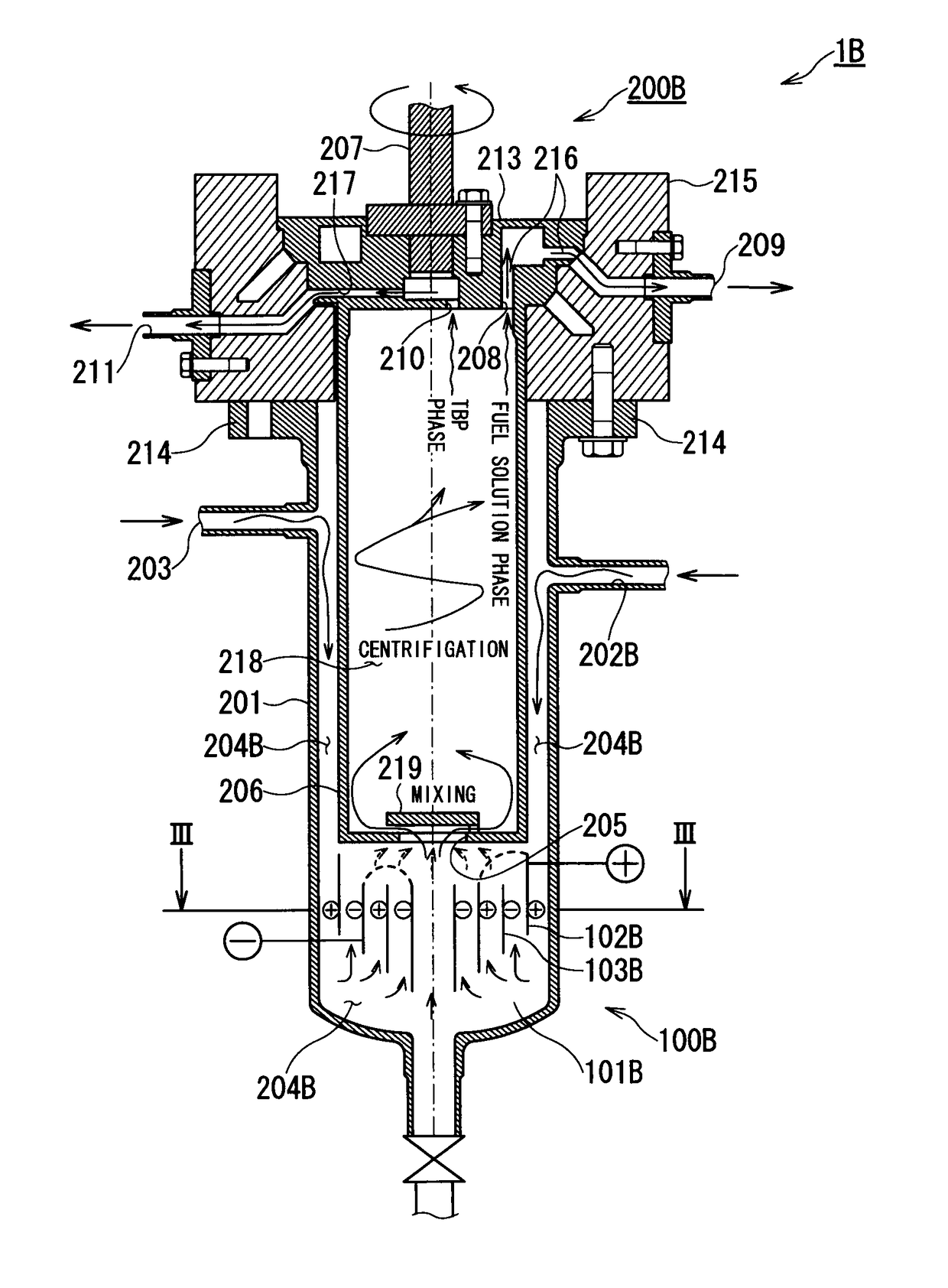

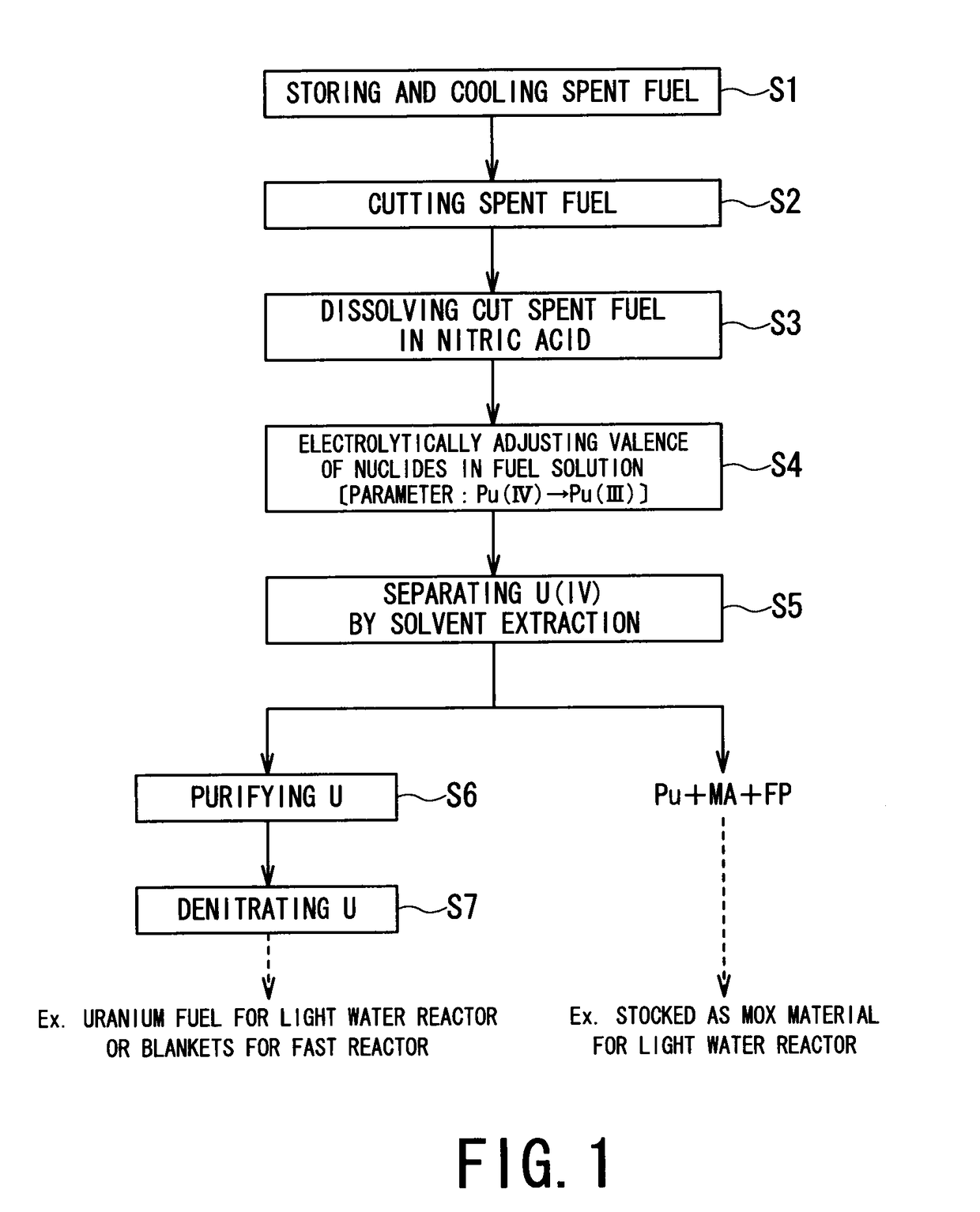

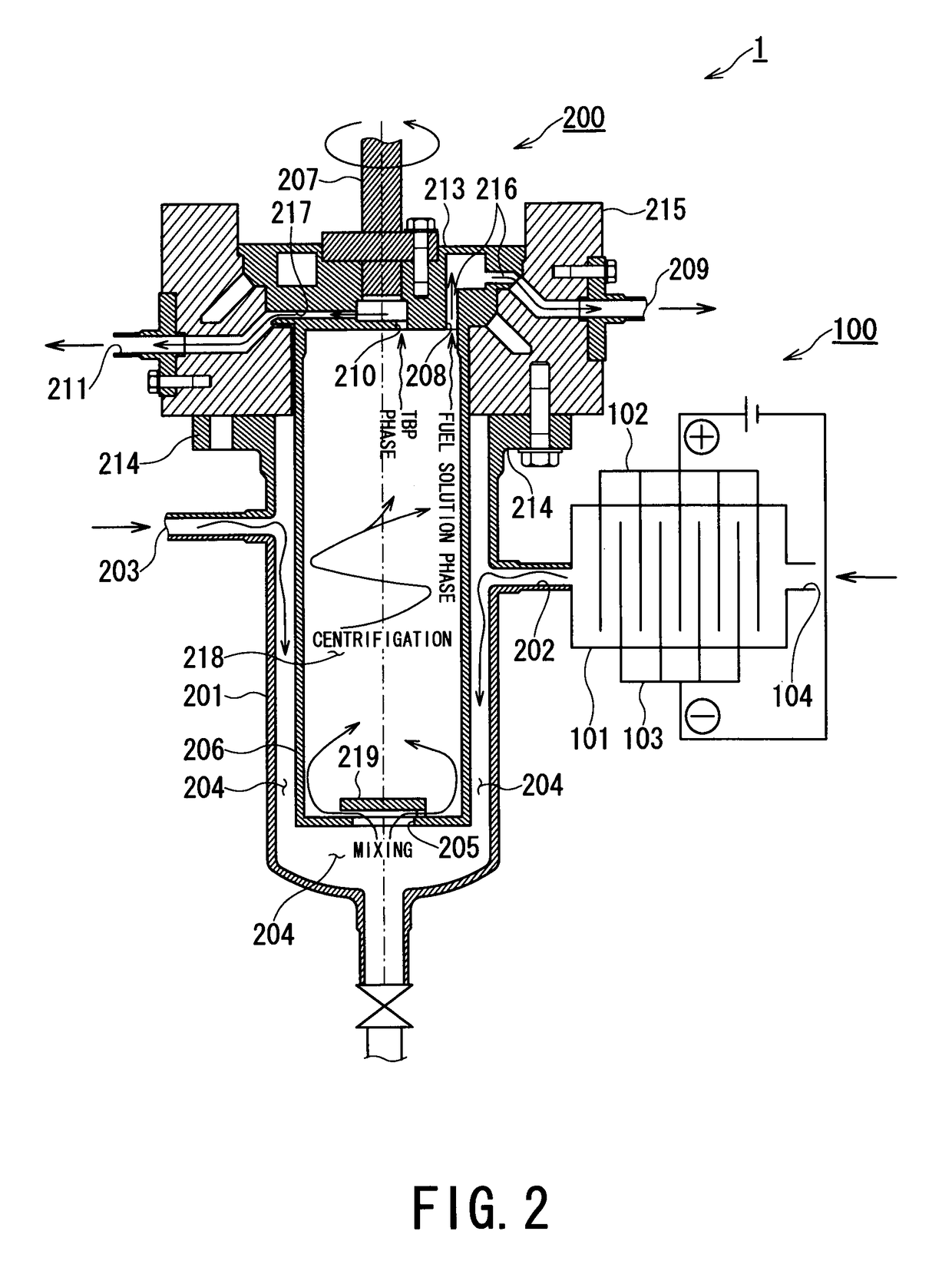

Method for reprocessing spent nuclear fuel and centrifugal extractor therefor

ActiveUS20100038249A1Isolation difficultRecovery difficultPhotography auxillary processesElectrolysis componentsElectrolysisEngineering

A spent nuclear fuel is reprocessed by dissolving a spent nuclear fuel in an aqueous nitric acid solution and separating and recovering nuclides contained in the resulting fuel solution by solvent extraction. A spent nuclear fuel reprocessing method includes: an electrolytic valence adjustment step in which nuclides contained in the fuel solution is electrolytically reduced without removing fission products or minor actinides until valence of plutonium is at a level at which solvent extraction efficiency is low by using the valence of plutonium contained in the fuel solution as a parameter; and a nuclide separation step in which, by using an extraction solvent which extracts uranium contained in the fuel solution, uranium is distributed from the fuel solution subjected to the electrolytic valence adjustment step to the extraction solvent.

Owner:KK TOSHIBA

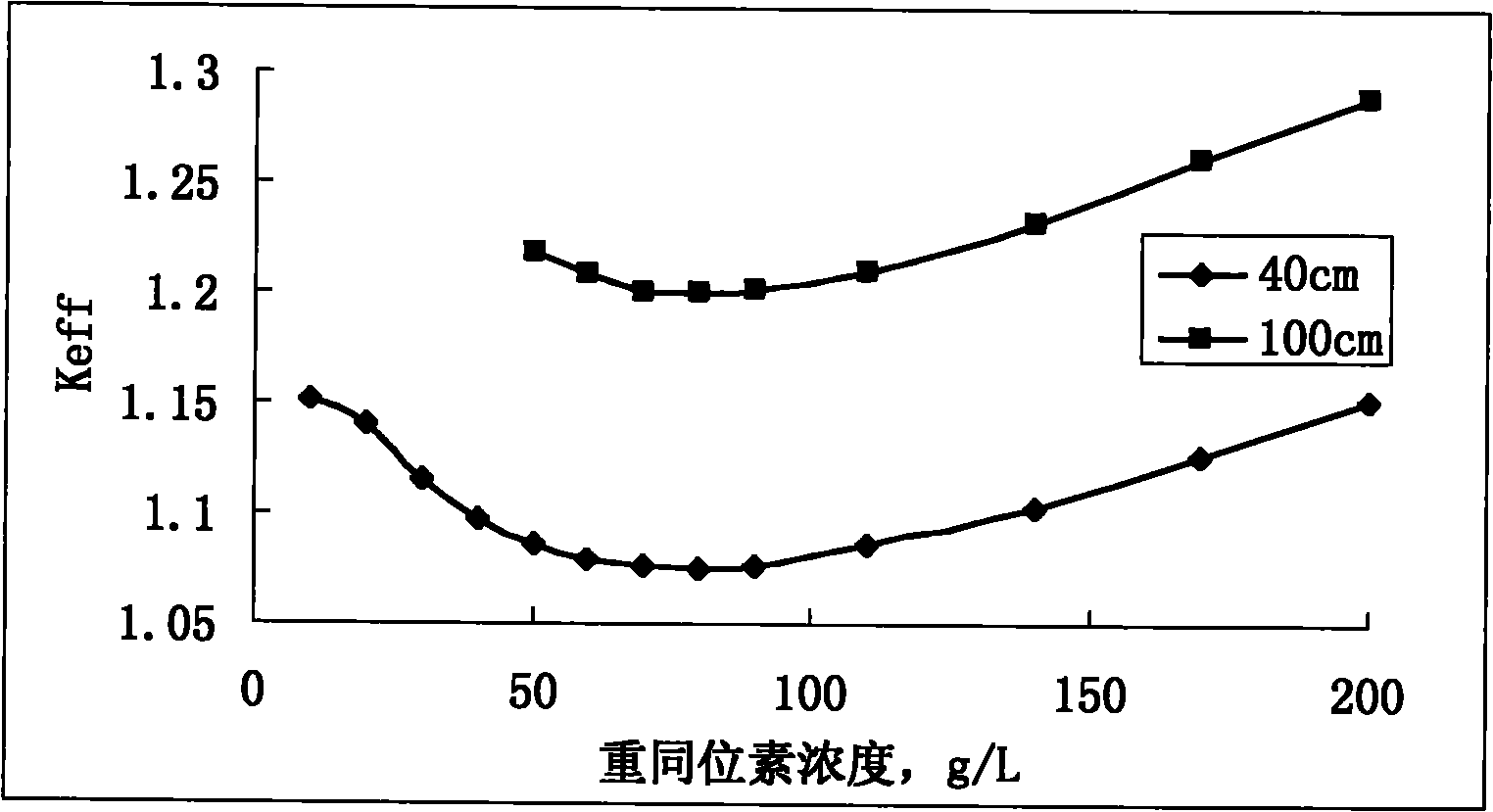

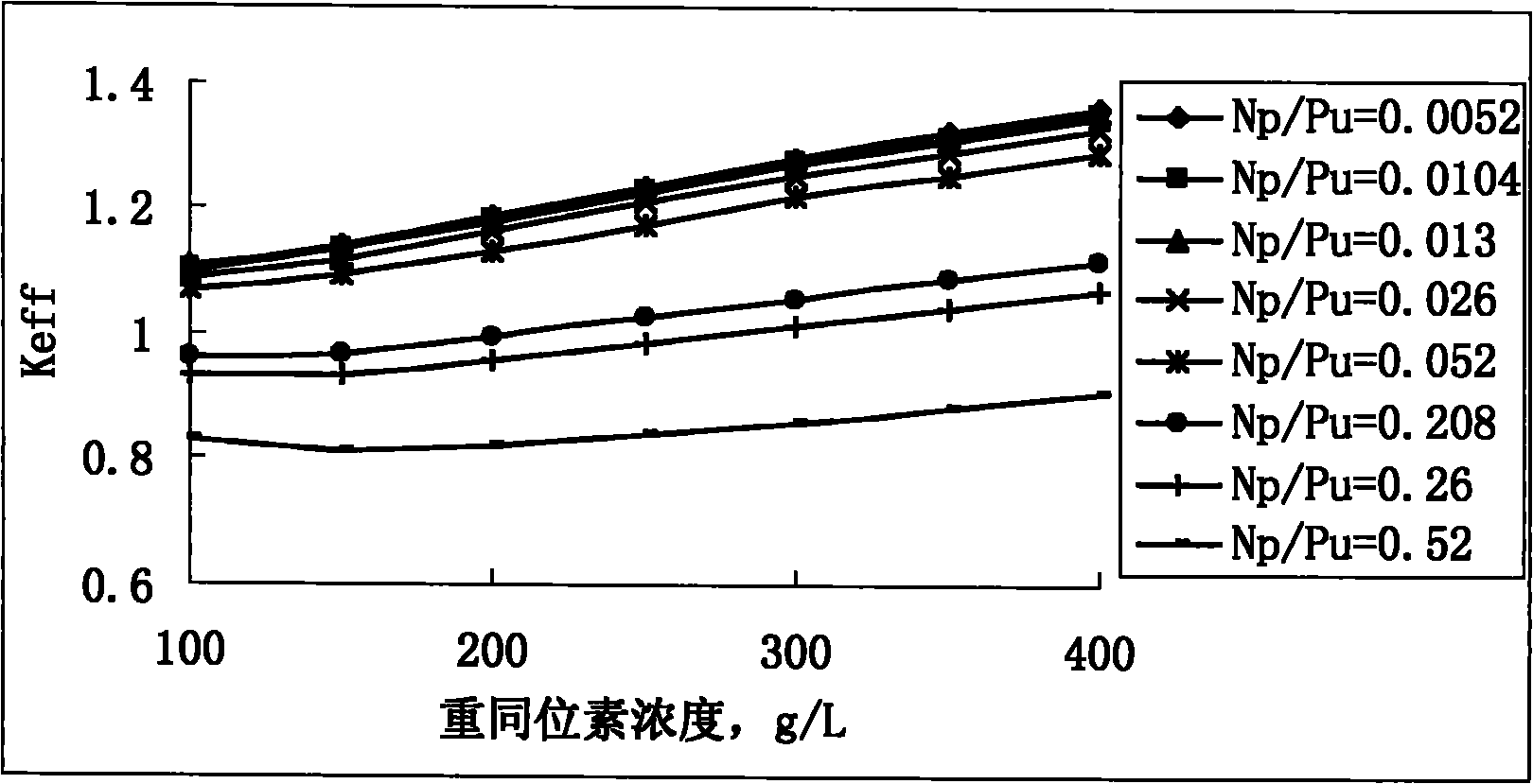

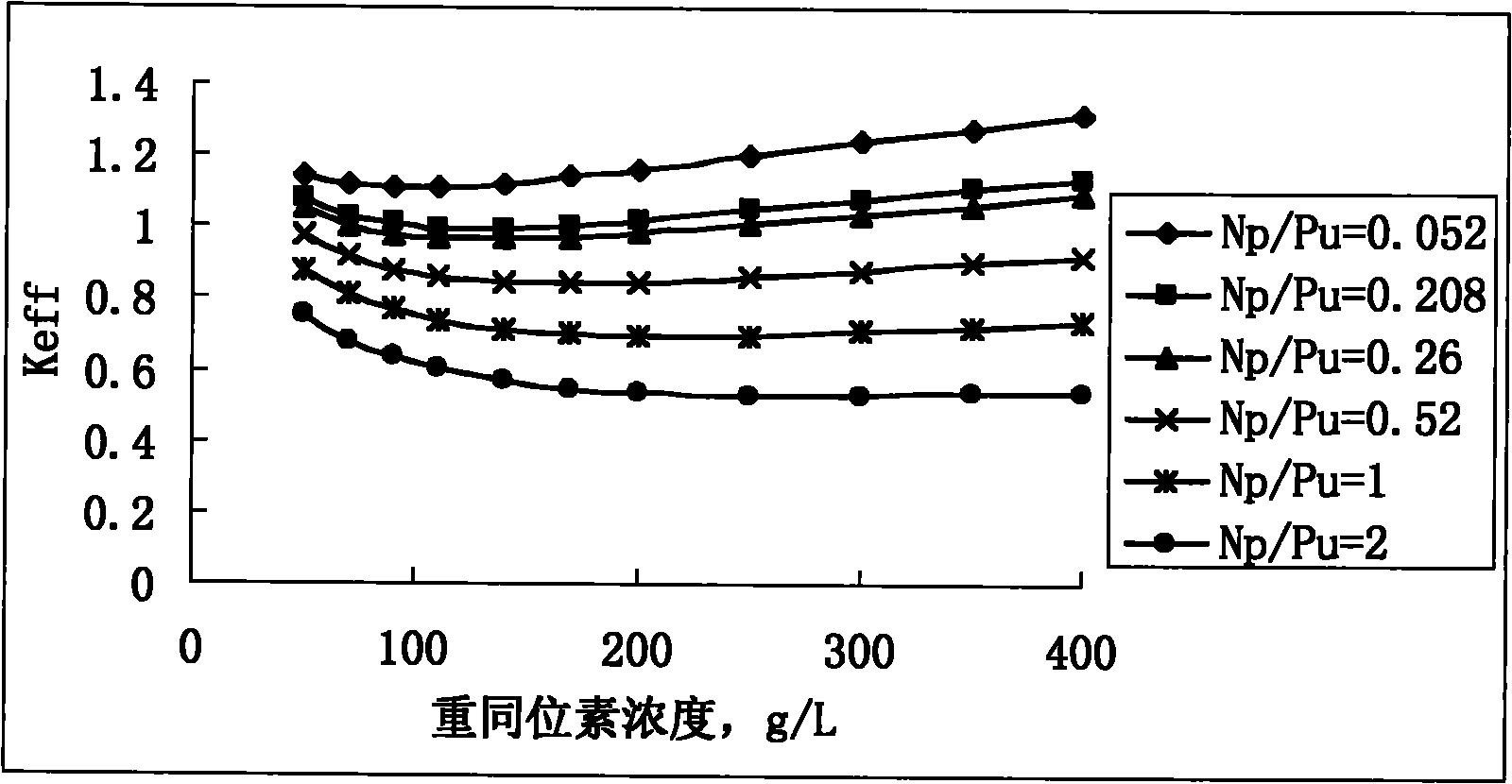

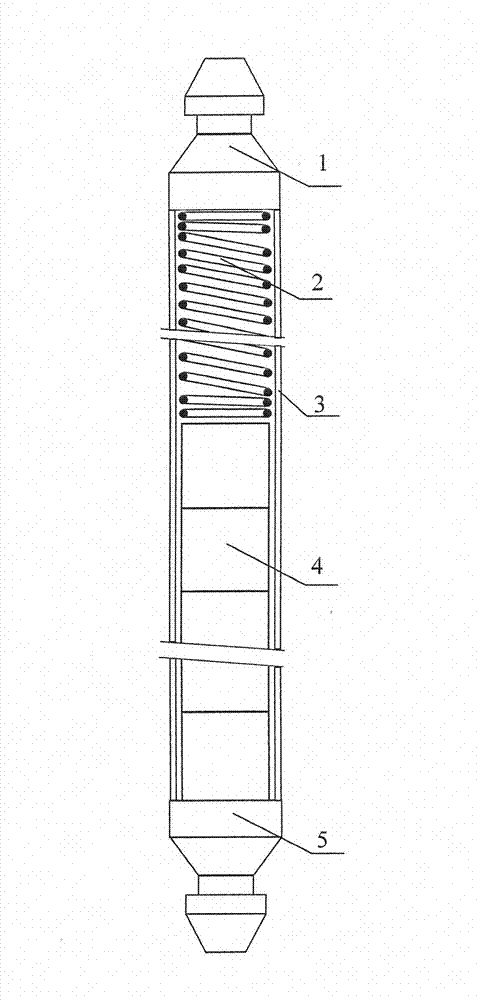

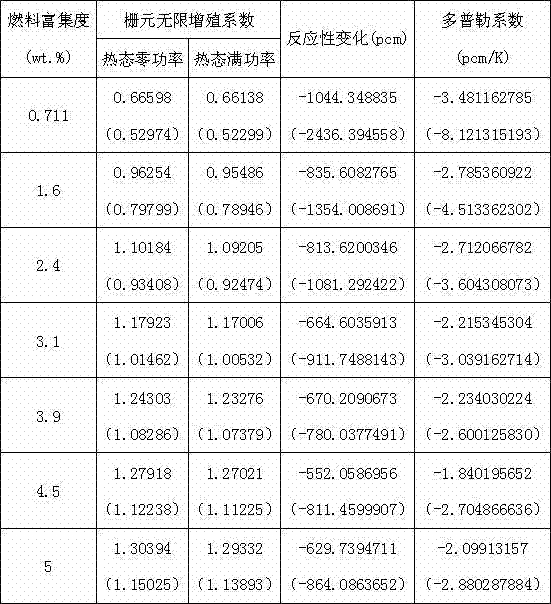

Reactor core design method for improving reactivity and transmutation effect of homogeneous spent fuel solution transmutation reactor

ActiveCN102376376AGet moreImprove core reactivityNuclear energy generationReactors manufactureChemistryMinor actinide

The invention discloses a reactor core design method for improving the reactivity and the transmutation effect of a homogeneous spent fuel solution transmutation reactor, which comprises the following steps: according to the component proportion of a plutonium isotope to a minor actinide in spent fuel, preparing reactor core spent fuel solution; determining the radius dimension of a reactor core, the arrangement material and the thickness of a reflecting layer, the heavy isotope concentration and the heavy isotope nuclide proportion; and calculating the critical performances of the reactor core under various reactor core parameters, wherein 100cm is selected to serve as the radius dimension of the reactor core; the height of the solution is 200cm, and light water of which the thickness is 10cm is adopted in the radial direction of the reactor core is used as the reflecting layer; 200g / L is selected to serve as the heavy isotope concentration; the ratio of 237Np / Pu is 0.26-0.52; and the light water is selected to serve as a moderator of the reactor core. The method disclosed by the invention can improve the reactivity of the reactor core, and is beneficial to burning more plutonium and obtaining more transmutation products.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

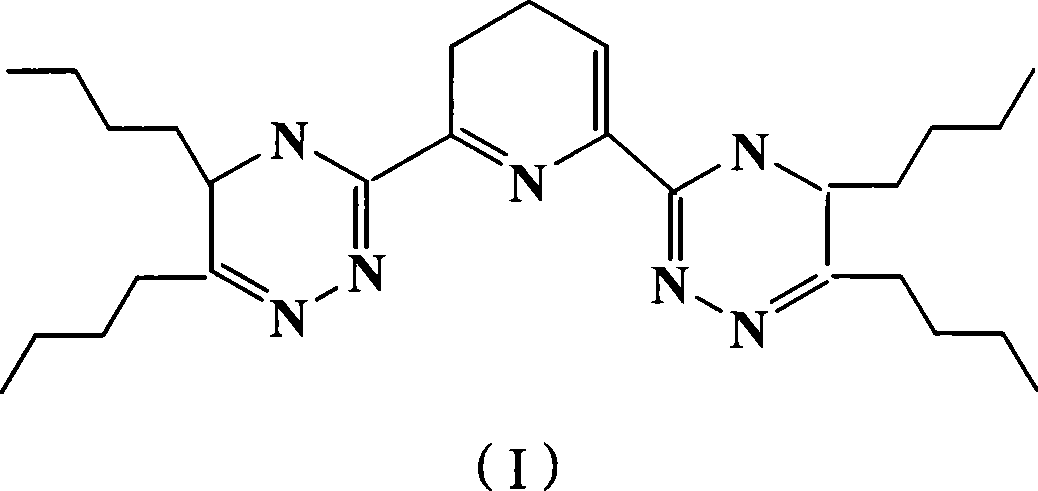

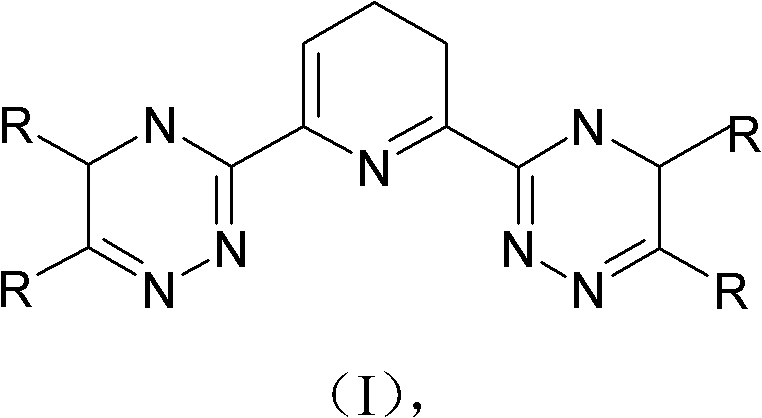

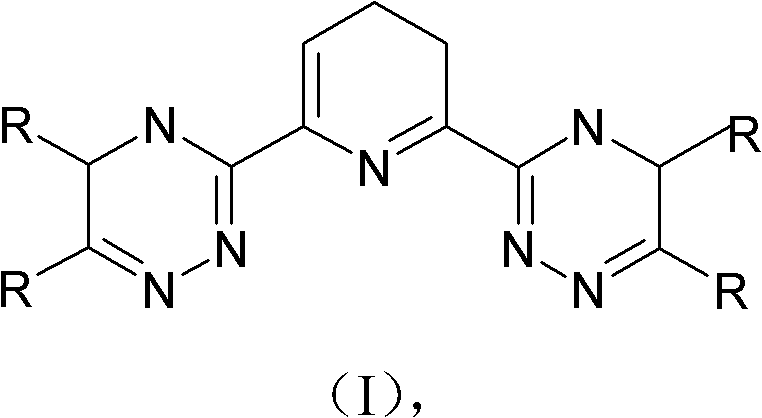

Method for extracting and separating element palladium from high-level waste

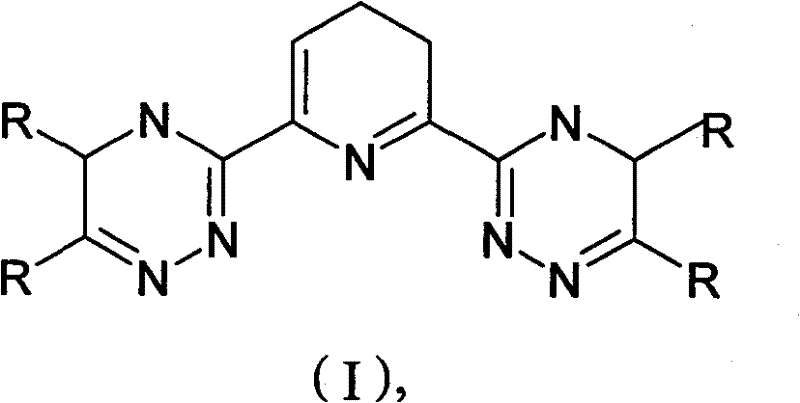

InactiveCN102629494AHigh selectivityEasy to separateLiquid solutions solvent extractionRadioactive decontaminationAlkaneOil phase

The invention discloses a method for extracting and separating element palladium from high-level waste. The method comprises the following steps of: adding concentrated nitric acid into nitrate solution of the high-level waste, from which minor actinide elements have been separated, to adjust the concentration of nitric acid to be 0.42-5.11 mol / L to obtain solution A; mixing 2,6-bi (5,6-dinonyl-1,2,4-triazine-3-yl) pyridine, R-OH and alkanes of C6-C12 to obtain solution B, wherein R is alkyl groups of C6-C12, and the volume fraction of R-OH is 30-100 percent in terms of the total volume of the R-OH and alkanes of C6-C12; mixing the solution A and the solution B, oscillating and then demixing to obtain an oil phase and a water phase; separating the oil phase from the water phase to obtain palladium nitrate-containing oil phase and the nitrate solution of the high-level waste from which the element palladium is separated respectively. The method for extracting and separating element palladium from high-level waste provided by the invention has the advantages of high selectivity, high separation capacity and suitability for large-scale industrial application.

Owner:ZHEJIANG UNIV

Method for reprocessing spent nuclear fuel and centrifugal extractor therefor

InactiveCN101650980AEnhanced inhibitory effectLiquid separation by electricityNuclear energy generationEngineeringSolvent

The invention provides a method for reprocessing a spent nuclear fuel which can reprocess highly purified uranium without arranged with a step of separating Pu from solely from a spent nuclear fuel, and solely separated reprocessing of the reprocessed Pu is more difficult and has an excellent repression effect to nuclear proliferation. In a method for reprocessing a spent nuclear fuel by dissolving a spent nuclear fuel in an aqueous nitric acid solution and separating and recovering nuclides contained in the resulting fuel solution by solvent extraction comprising an electrolytic valence adjustment step by using the valence of plutonium contained in the fuel solution as a parameter until the valence of plutonium becomes 3 in which nuclides contained in the fuel solution is electrolyticallyreduced without removing fission products or minor actinides; a nuclide separation step in which, by using an extraction solvent which extracts uranium contained in the fuel solution, uranium is distributed from the fuel solution subjected to the electrolytic valence adjustment step to the extraction solvent.

Owner:KK TOSHIBA

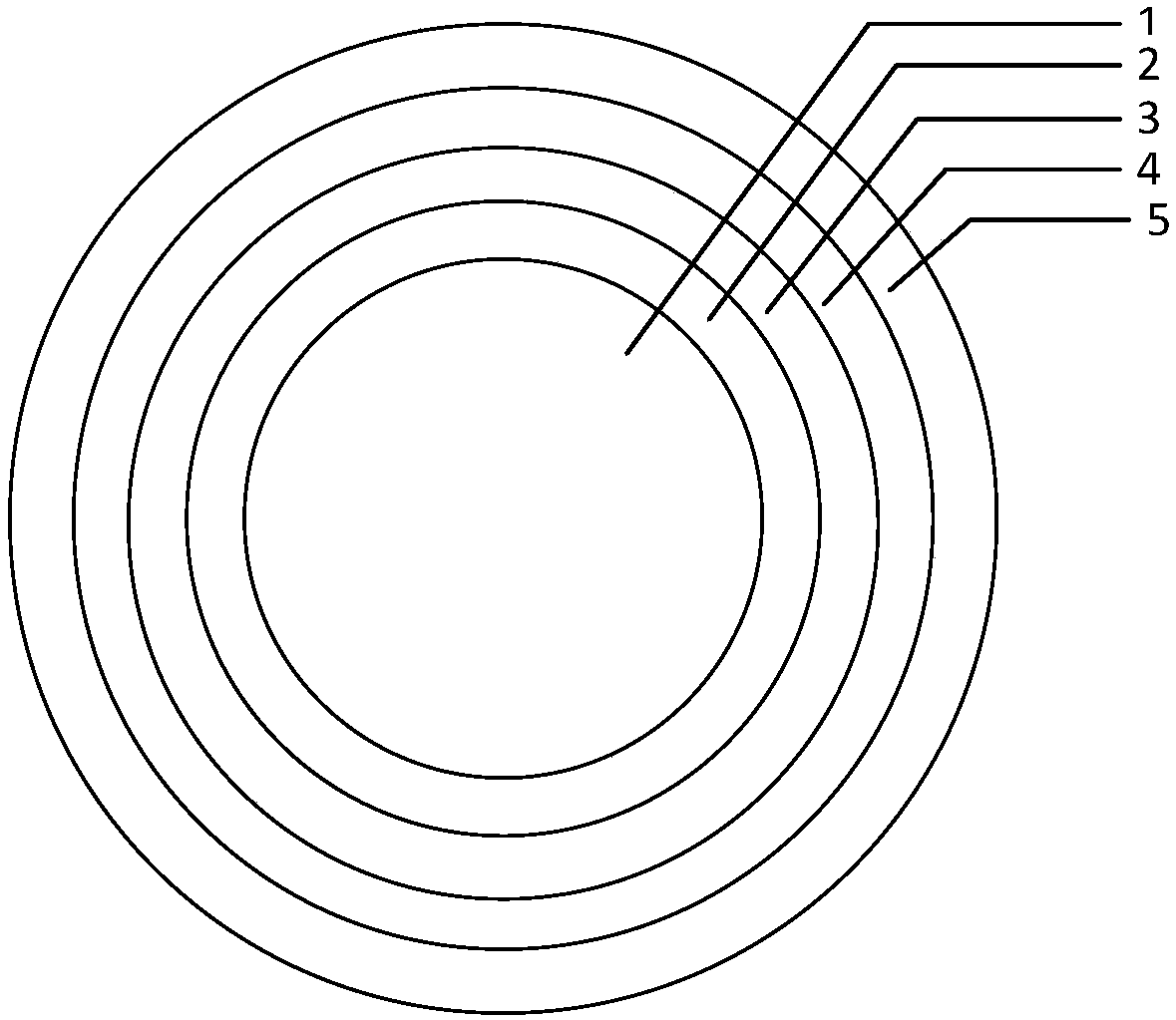

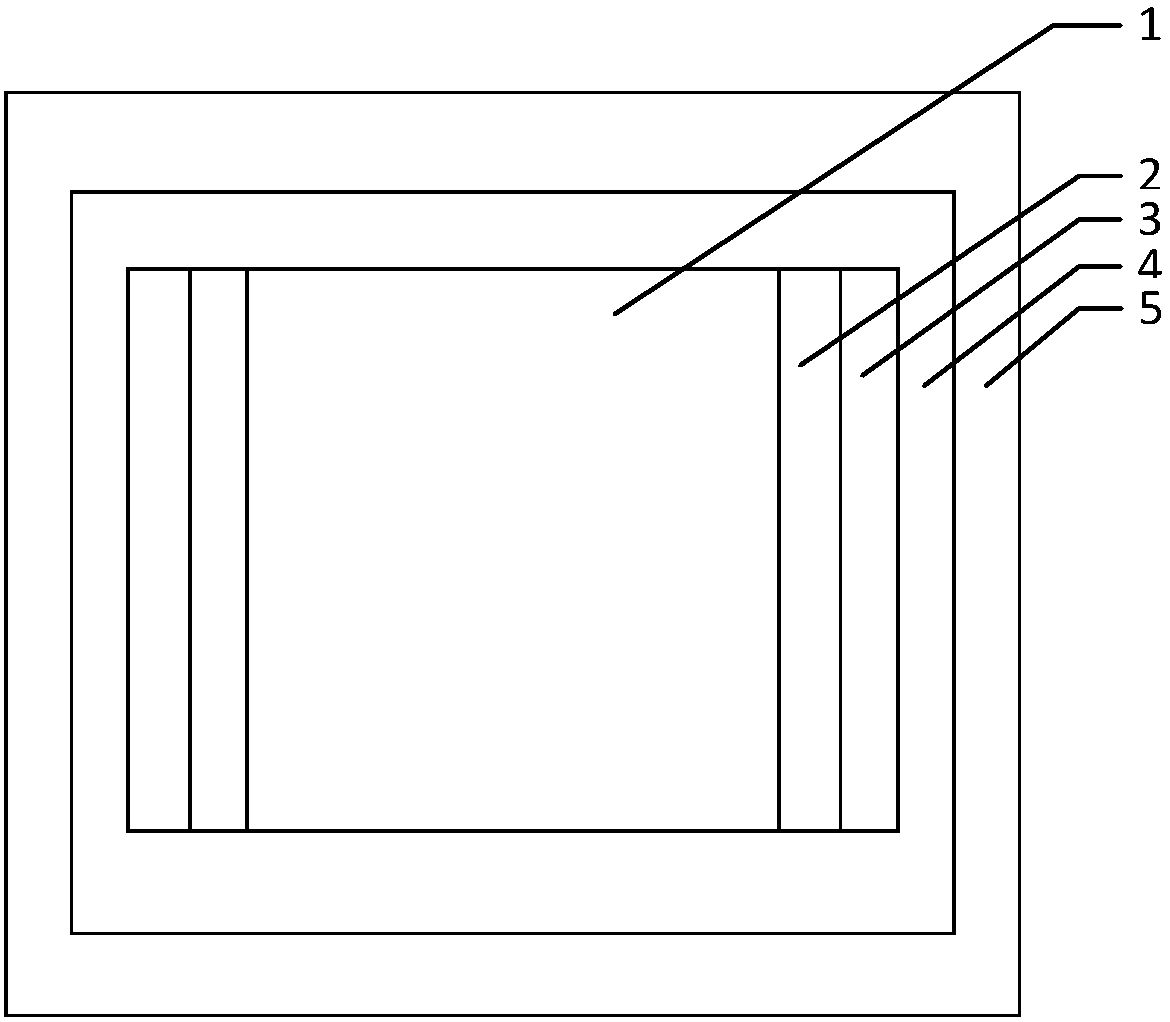

MOX fuel rod, MOX fuel assembly and method for flattening axial power

InactiveCN108550405AAxial power reductionAxial power up toFuel elementsNuclear energy generationCombustionNuclear engineering

The invention relates to an MOX fuel rod, an MOX fuel assembly and a method of flattening the axial power. The MOX fuel rod includes a doped fuel, the doped fuel is distributed in the axially middle part of the MOX fuel rod, and the doped fuel is a fuel doped with a long-lived minor actinide. The fuel in the axially middle part of the MOX fuel rod is the doped fuel, and the long-lived minor actinide in the doped fuel is transmuted in a neutron field to form a short-lived or stable nuclide, so the cost and the difficulty of final treatment of a spent fuel are reduced, and the treatment problemof the long-lived minor actinide in the spent fuel solved; and the transmutation of the long-lived minor actinide in the doped fuel, absorbing neutrons in the neutron field, is used to reduce the fission reaction rate of the doped fuel in order to reduce the original axial power and fuel consumption in the MOX fuel rod and the power and fuel consumption at a high combustion position, so the purposes of flattening the axial power of the MOX fuel rod, enhancing the reactor core safety and improving the fuel utilization rate are achieved.

Owner:SUN YAT SEN UNIV

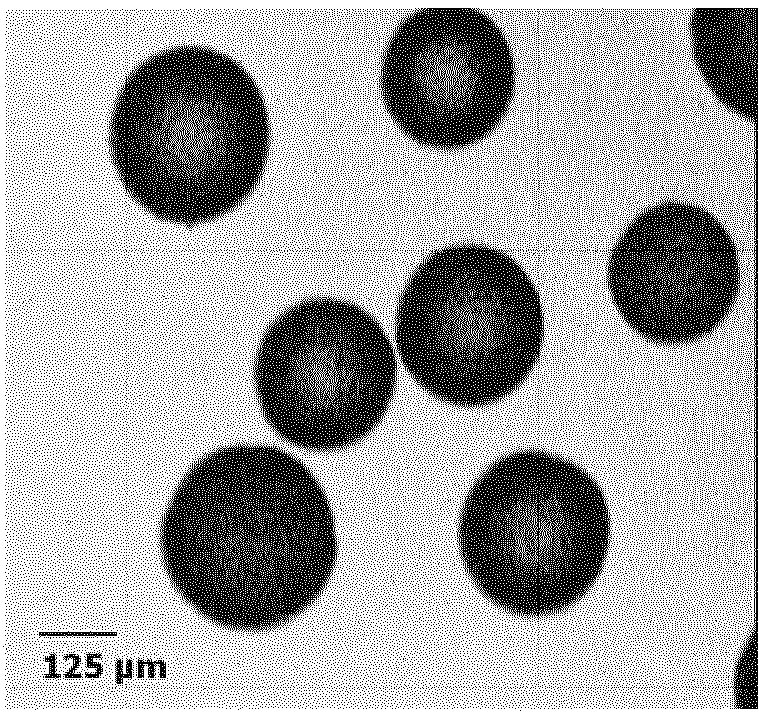

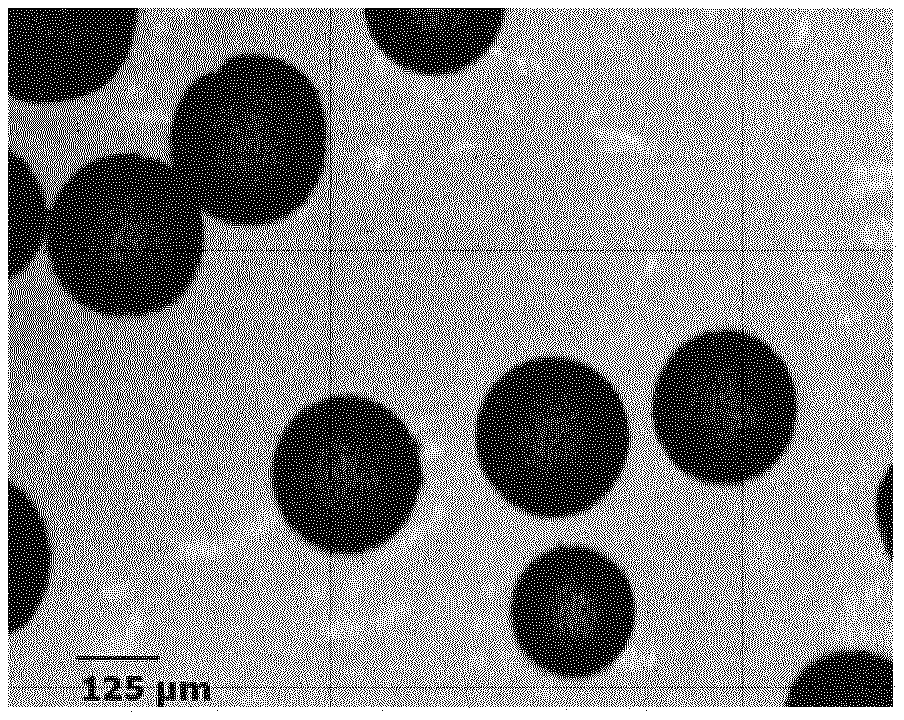

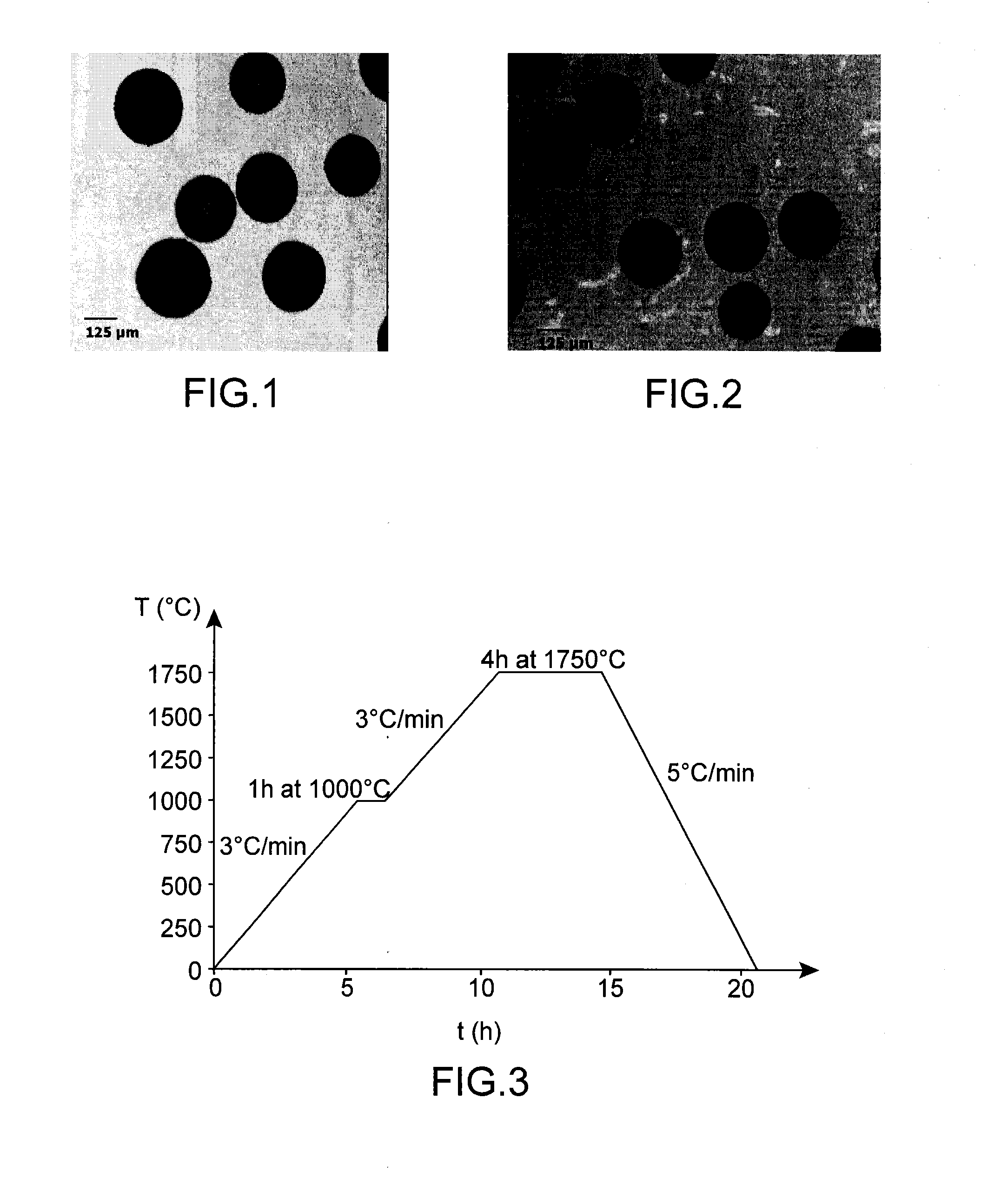

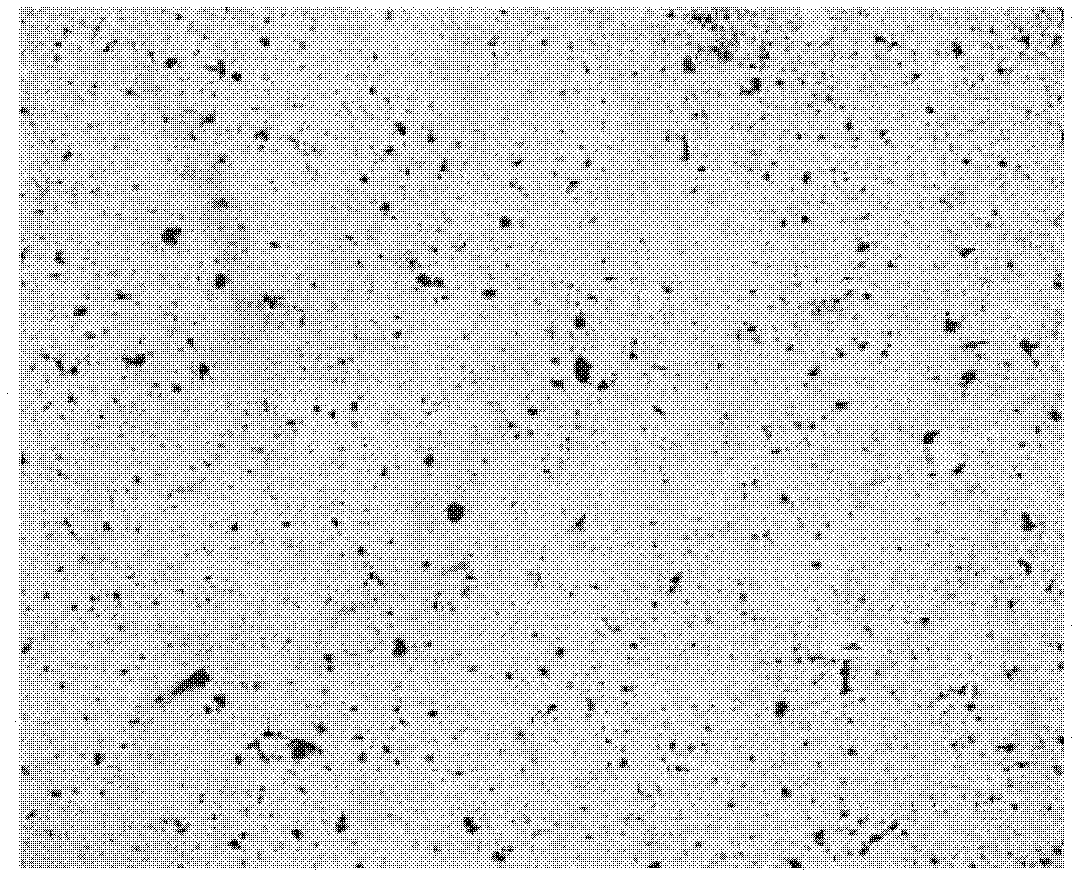

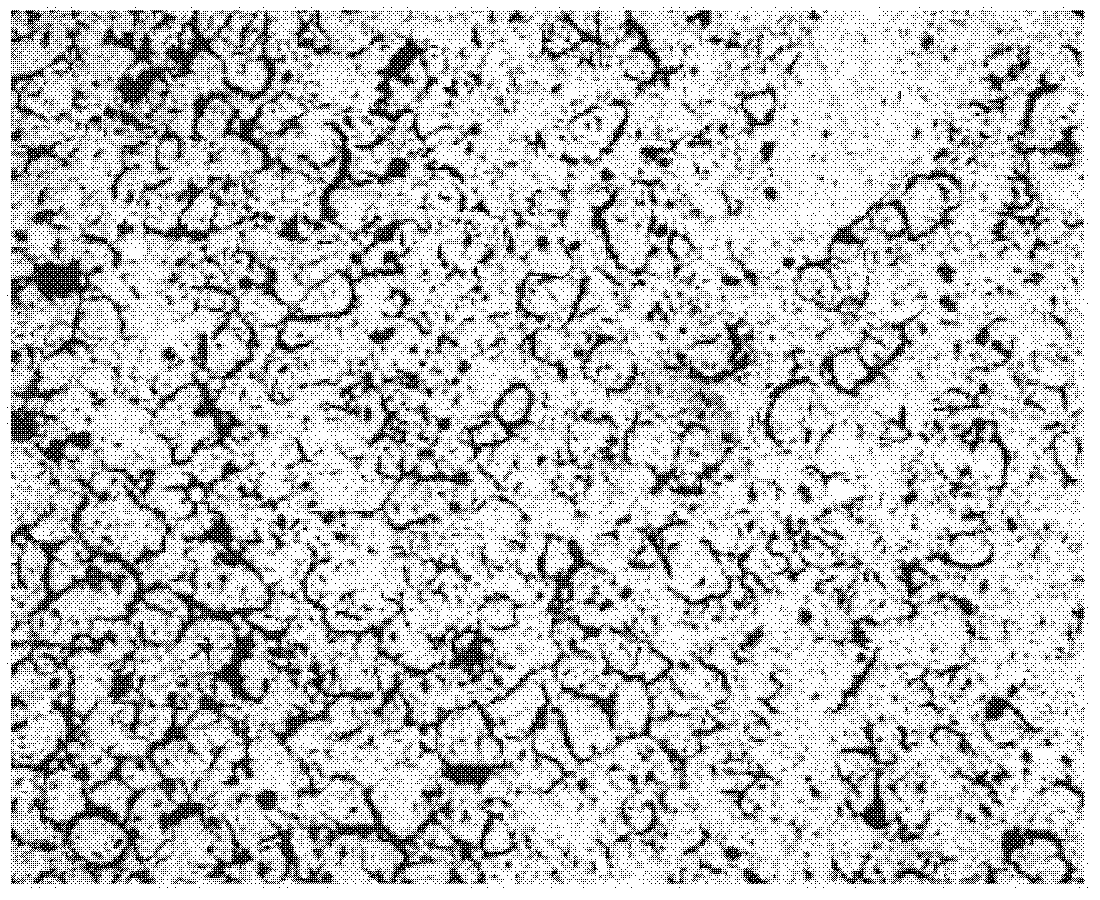

Method for preparing a porous nuclear fuel based on at least one minor actinide

InactiveUS20120228788A1Easy to aimReduce porosityFuel elementsNuclear energy generationPowder mixtureUranium oxide

A method for manufacturing a porous fuel comprising uranium, optionally plutonium and at least one minor actinide is provided. The method may comprise the following successive steps: a) a step for compacting as pellets a mixture of powders comprising uranium oxide, optionally plutonium oxide and at least one oxide of a minor actinide, at least one portion of the uranium oxide being in the form of triuranium octaoxide U3O8, the other portion being in the form of uranium dioxide UO2; b) a step for reducing at least one portion of the triuranium octaoxide U3O8 into uranium dioxide UO2.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Nuclear fuel element doped with technetium-99

InactiveCN102831939ADoppler coefficient enhancementReduce outputNuclear energy generationReactor fuel susbtancesTechnetium-99Engineering

The invention relates to a nuclear fuel element doped with technetium-99, which is characterized in that fuel pellets are overlapped to be placed into a zirconium quaternary alloy cladding pipe, after being compressed by a compression spring, two end ports of the cladding pipe are sealed and fixed by an end plug, and the nuclear fuel element is characterized in that each fuel pellet is a mixture of tachnetiuim-99 and uranium dioxide, wherein a ratio of the nuclear density of the technetium-99 and the sum of the nuclear density of technetium-99 and uranium-238 in the uranium dioxide is 10 percent to 90 percent. The resonance characteristic of the technetium-99 is utilized, and the technetium-99 is used for partially substituting the uranium-238 in the enriched uranium fuel, so that three purpose for enhancing the Doppler coefficient, reducing minor actinides nuclide so as to really reduce the minor actinides, guaranteeing the prompt negative temperature coefficient and transforming the nuclear waste technetium-99, and the safety of a reactor can be enhanced.

Owner:NANHUA UNIV

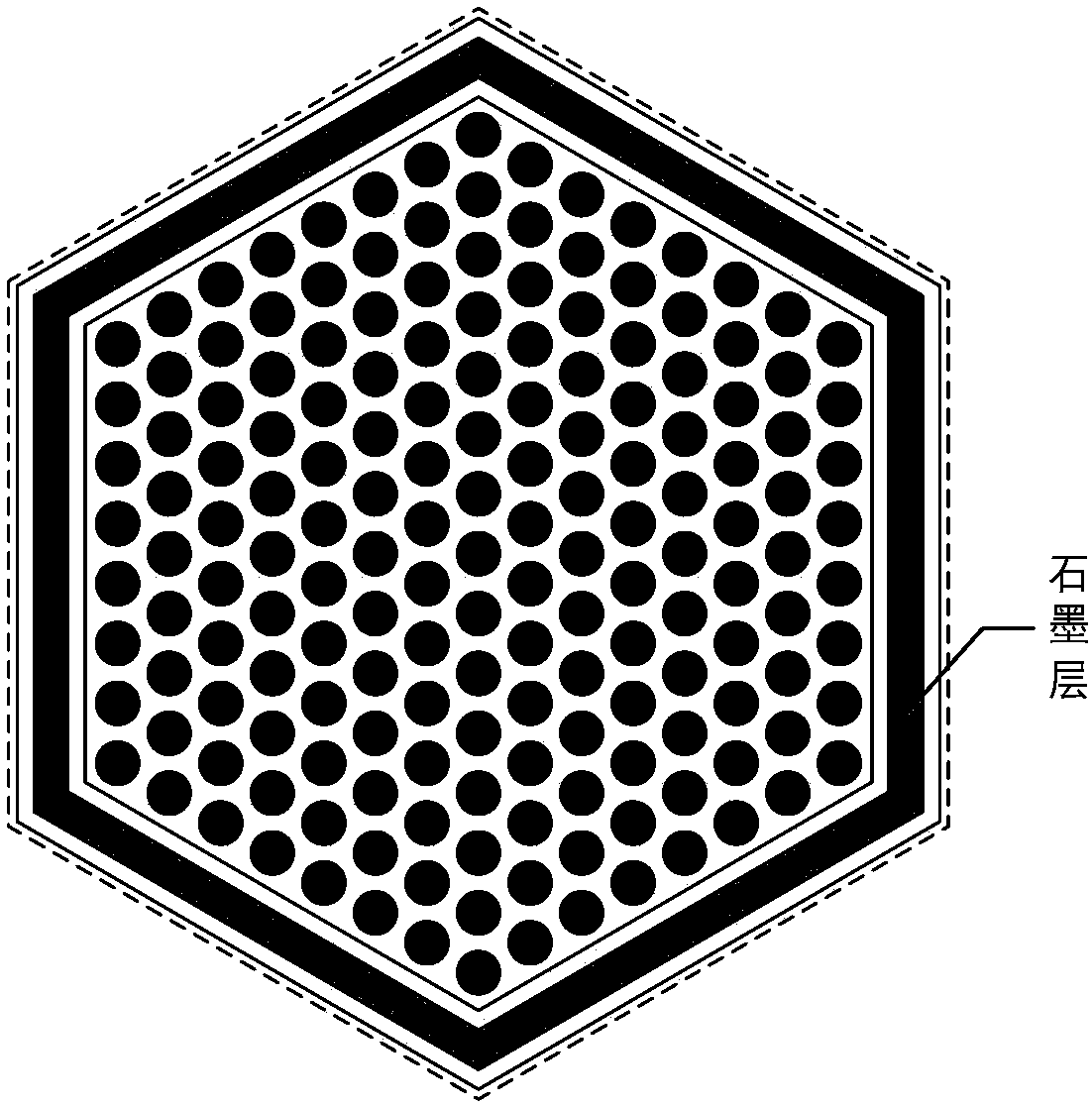

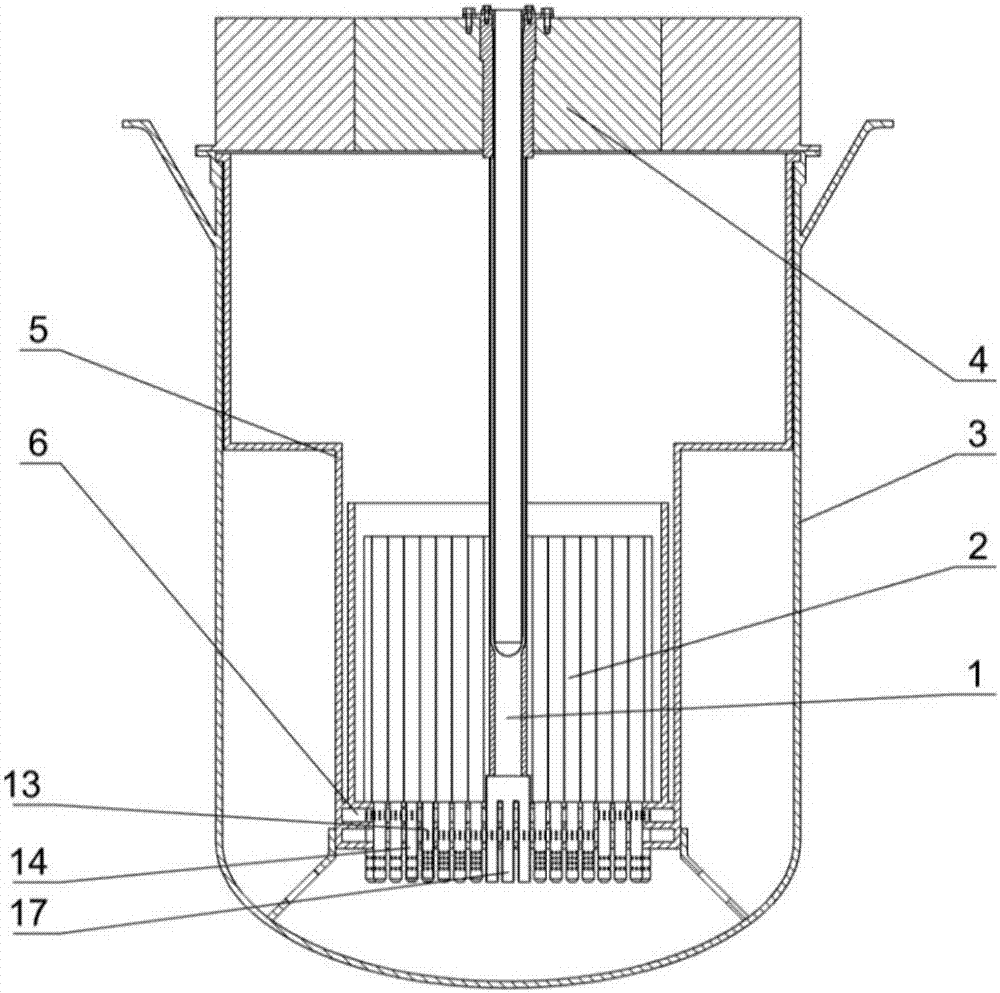

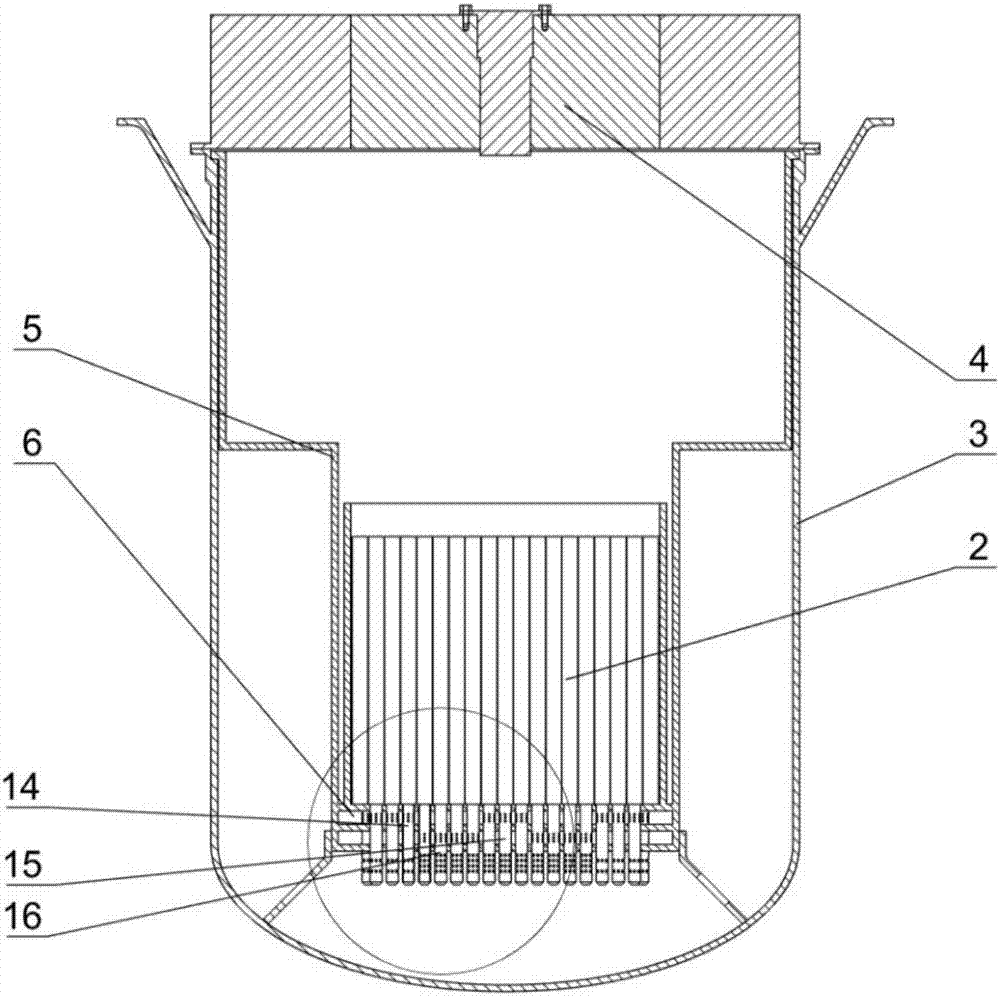

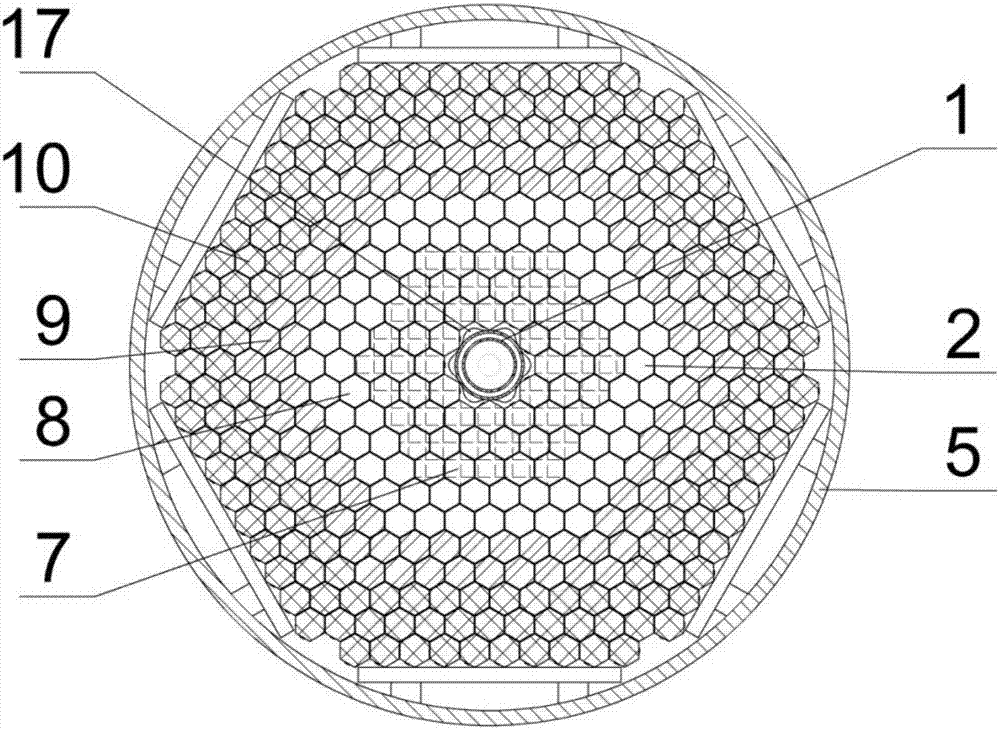

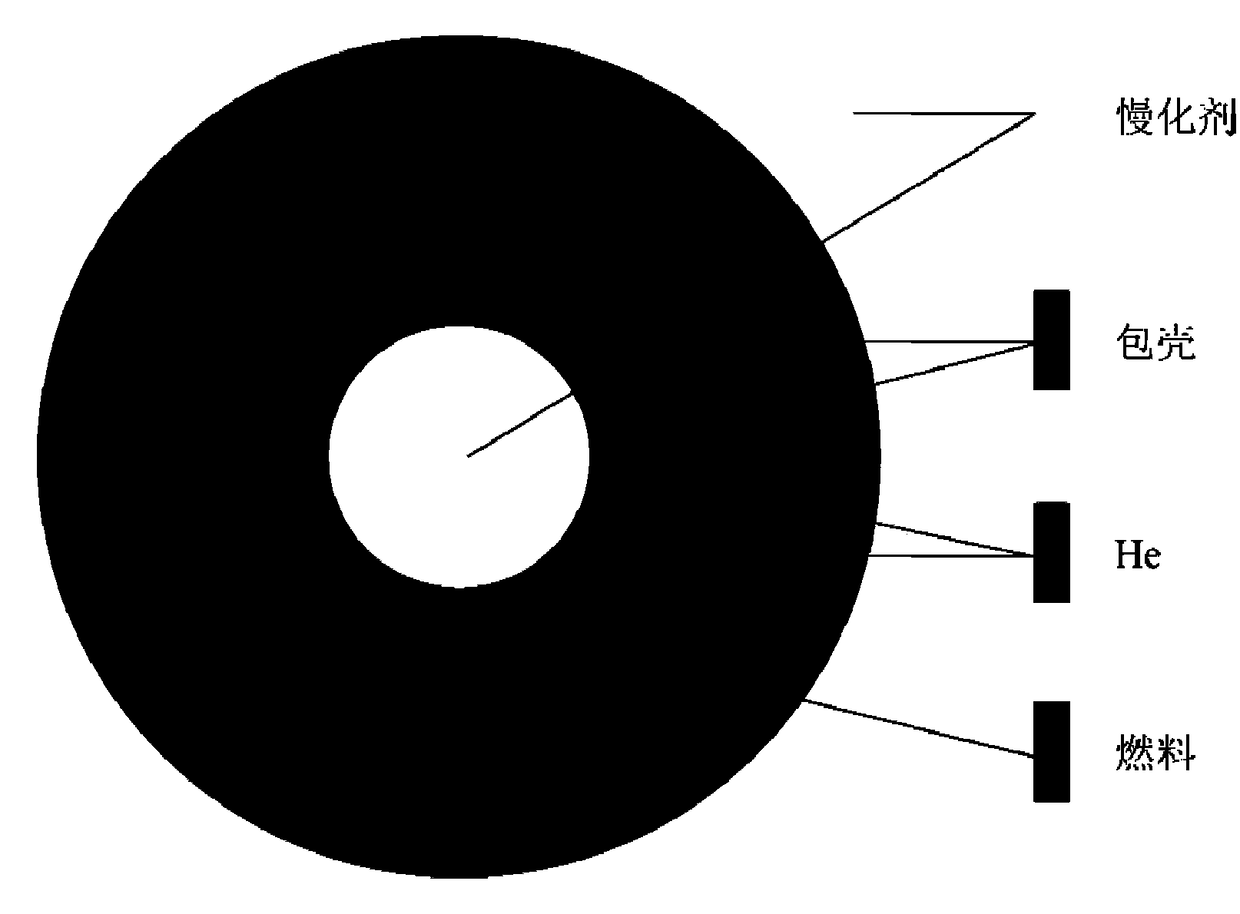

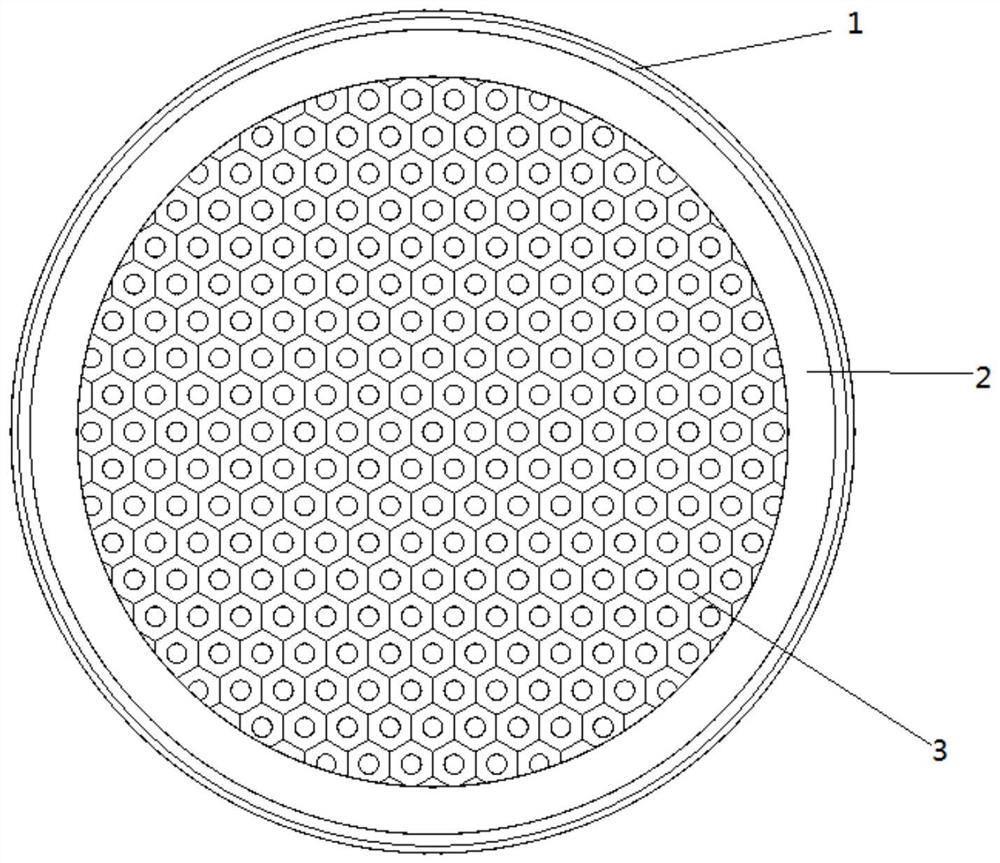

Fast heating mixed energy spectrum critical reactor core capable of simultaneously transmutating minor actinide and long-lived fission product

PendingCN108470589AEfficient use ofIncrease transmutation rateNuclear energy generationShieldingHigh energyBoron carbide

The invention discloses a fast heating mixed energy spectrum critical reactor core capable of simultaneously transmutating minor actinide and a long-lived fission product, a minor actinide transmutation area, a fissionable fuel breeding area, a long-lived fission product transmutation area, a reflection layer area and a shielding layer area are sequentially arranged from the center of the reactorcore to the outside, and the minor actinide transmutation area takes a mixture of MOX and MA as the fuels; the fissionable fuel breeding area takes MOX as the fuel; the long-lived fission product transmutation area takes a mixture of UO2 and LLFP as the fuels, and a graphite moderated layer is increased in a wall of a fuel component and a jacketing of a fuel rod; and a reflection layer and a shielding layer comprise graphite, boron carbide and a structural material. The high-energy neutron in the reactor core transmutates MA in the minor actinide transmutation area, the nuclear fuel breeds inthe fissionable fuel breeding area, the nuclear fuel is moderated into the low-energy neutron by the graphite layer in the wall of the fuel component and the jacketing of the fuel rod when entering the long-lived fission product transmutation area, the LLFP is effectively transmutated, the minor actinide and the long-lived fission product are transmutated while the use ratio of the neutron and theyield are increased.

Owner:UNIV OF SCI & TECH OF CHINA

Multi-mode operation compact nuclear reactor

ActiveCN106875983ASimple structureSave time and costIntegral reactorsNuclear energy generationPu elementMinor actinide

The invention discloses a multi-mode operation compact nuclear reactor, and belongs to the technical field of nuclear reactor design. For reactor critical and sub critical operation, the sub critical transmutation and critical yield functional switching is completed through spallation target introduction and moving-out and reactor core layout change; the sub critical degree regulation is completed. Beryllium softening neutrons are added in a long-service-life fission product transmutation region in the reactor core for reaching the requirements of long-service-life fission product high transmutation requirements; meanwhile, uranium 238 is added in the minor actinide element transmutation region for compensating the reaction performance reduction due to minor actinide element and plutonium combustion consumption. In the sub critical and critical switching process, through the matching of the spallation target, an assembly pipe pin of the reactor core and a layered grid plate connected box, the reactor general flowing is matched; the operation parameter consistency of the critical and sub critical systems can be maintained. The multi-mode operation compact nuclear reactor is based on the reactor layout change and multilayer flow rate distribution technology, and realizes the reactor multi-mode operation; the reactor universality is good; high engineering significance is realized.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Doped fuel-clad combination for transmutation

InactiveCN109036592ALow costReduce difficultyOptical rangefindersNuclear energy generationEngineeringShort life

The invention relates to a doped fuel-clad combination for transmutation. The doped fuel-clad combination for transmutation comprises a doped fuel and a clad, the clad is coated on the outside of thedoped fuel, and the doped fuel is a fuel doped with long-life minor actinides nuclide. The long-life minor actinides nuclide in the doped fuel is converted into short-life or stable nuclide in a neutron field, so that the cost and difficulty of final treatment of spent fuel, and long-life minor actinides nuclide processing problem can be solved. The clad is used to ensure the safety of the fuel inthe event of an accident and to counteract the negative reactivity caused by the transmutation. The combination can also achieve the effect of increasing the length of the fuel life of a reactor by doping the long-life minor actinides nuclide with lower concentration in the accident-tolerant fuel.

Owner:SUN YAT SEN UNIV

Method for preparing a porous nuclear fuel

The invention relates to a method for producing a porous fuel including uranium, optionally plutonium, and optionally at least one minor actinide, which includes the following series of steps: a) a step of compacting a mixture including a first type of agglomerate including uranium oxide in the form of uranium dioxide UO2, optionally plutonium oxide, and optionally at least one minor-actinide oxide, and a second type of agglomerate including uranium oxide in the form of triuranium octaoxide U3O8, optionally plutonium oxide, and optionally at least one minor-actinide oxide; b) a step of reducing the compacted mixture in a reducing medium so as to reduce all or part of the triuranium octaoxide U3O8 into uranium dioxide UO2, the second type of agglomerate being prepared prior to the compacting step by a series of specific operations.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

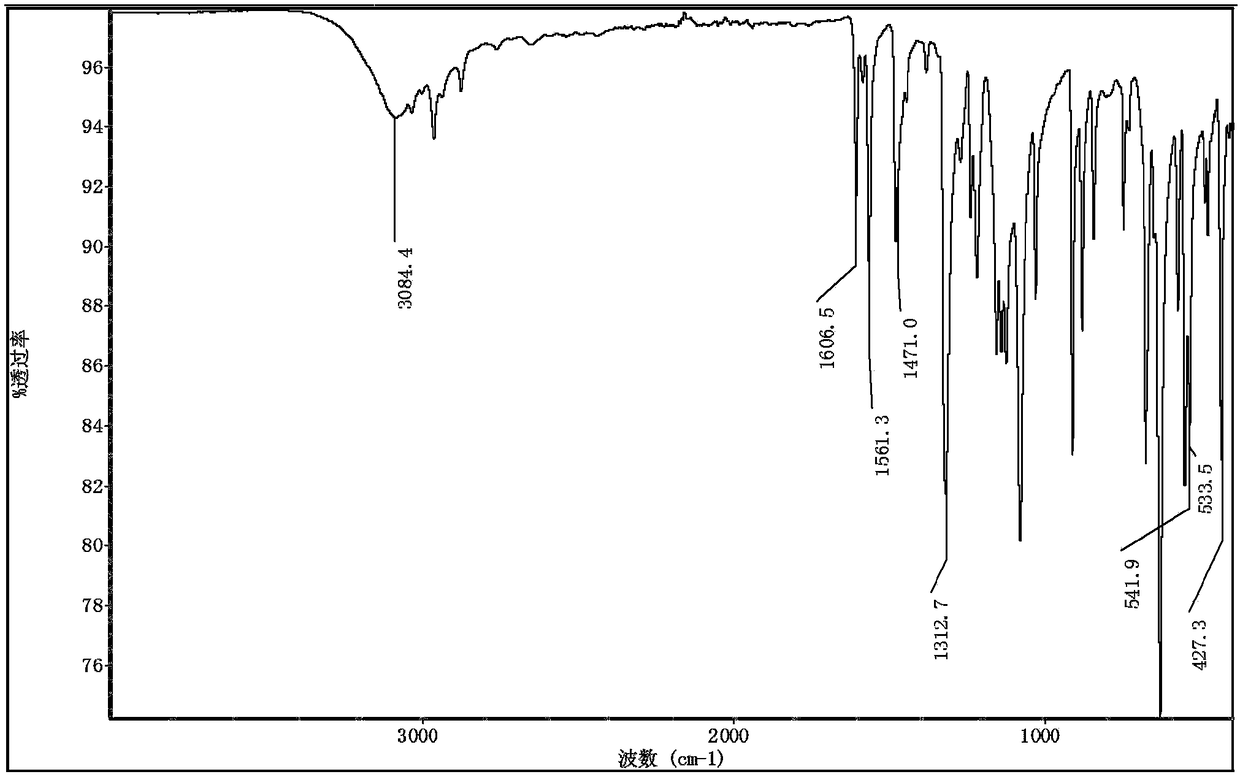

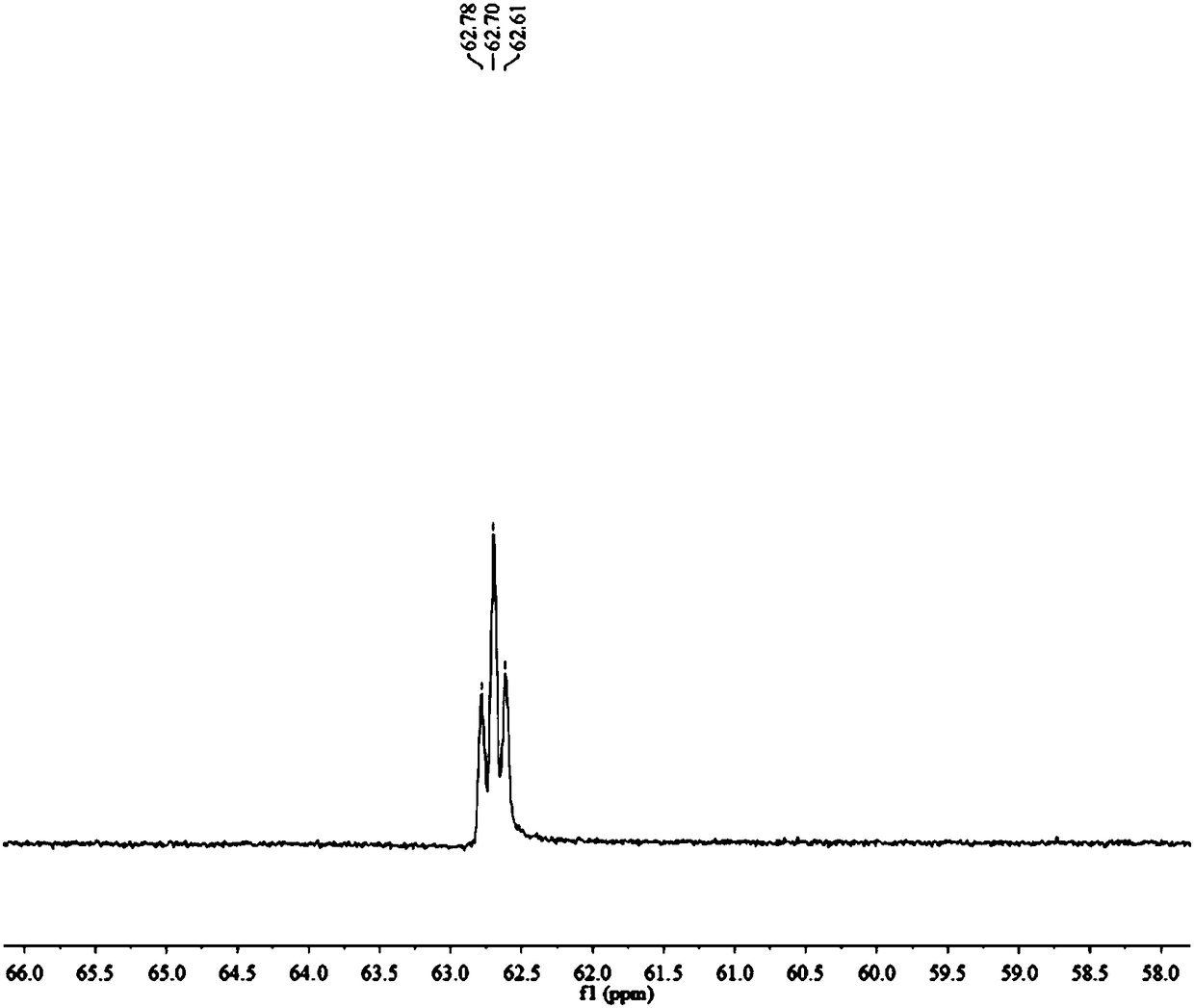

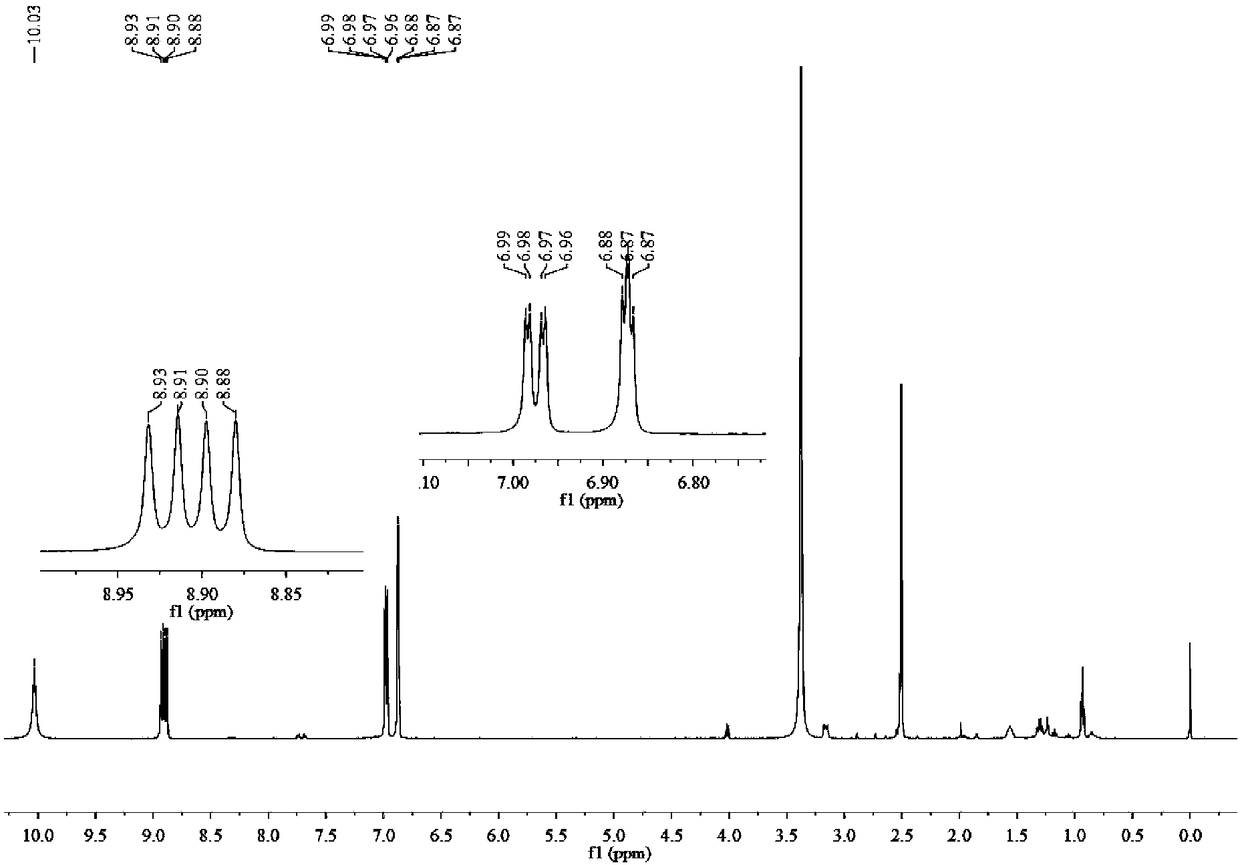

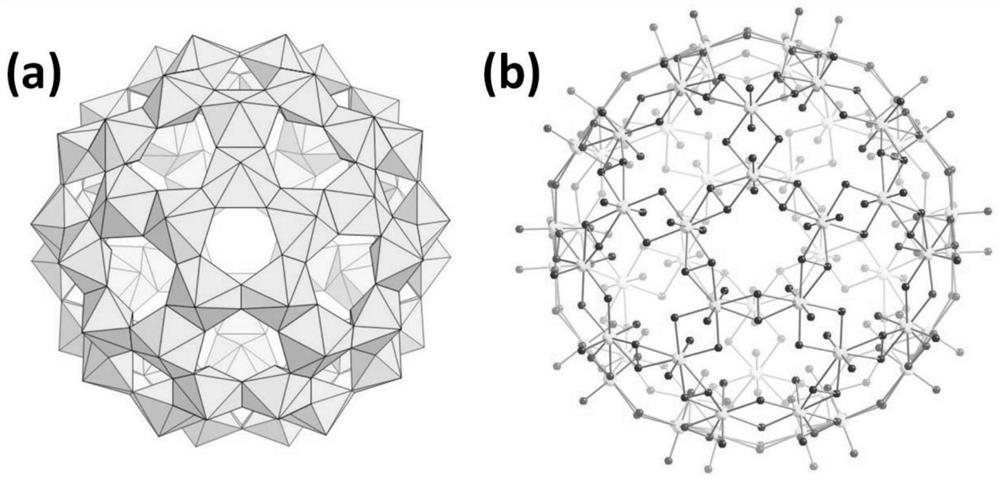

Solid-phase extraction agent for selectively separating trivalent minor actinides and trivalent lanthanides, and preparation method and application of same

ActiveCN108517406AAchieve separationEasy separationGroup 5/15 element organic compoundsProcess efficiency improvementMesoporous materialSolid phase extraction

The invention discloses a solid-phase extraction agent for selectively separating trivalent minor actinides and trivalent lanthanides, and a preparation method and an application of same, wherein thesolid-phase extraction agent includes a magnetic mesoporous material and a dithiophosphinic acid compound which is grafted thereto through a coupling agent; the dithiophosphinic acid compound is bis(2-trifluoromethyl-4-hydroxy)phenyldithiophosphinic acid and is represented as the structural formula (1). The preparation method includes steps of: 1) connecting the coupling agent to the magnetic mesoporous material; 2) under an alkaline catalyst, grafting the bis(2-trifluoromethyl-4-hydroxy)phenyldithiophosphinic acid on the magnetic mesoporous material through the coupling agent. The solid-phaseextraction agent can selectively separate the trivalent minor actinides and trivalent lanthanides, is environment-friendly in separation process, and has simple operation.

Owner:NAT UNIV OF DEFENSE TECH

Method for preparing a porous nuclear fuel

InactiveUS20140197557A1Reduce the risk of contaminationNuclear energy generationReactors manufactureUranium oxideUranium dioxide

A method for producing a porous fuel including uranium, optionally plutonium, and optionally at least one minor actinide, the method including: a) compacting a mixture including a first type of agglomerate including uranium oxide in a form of uranium dioxide UO2, optionally plutonium oxide, and optionally at least one minor actinide oxide, and a second type of agglomerate including uranium oxide in a form of triuranium octaoxide U3O8, optionally plutonium oxide, and optionally at least one minor actinide oxide; b) reducing the compacted mixture in a reducing medium, to reduce all or part of the triuranium octaoxide U3O8 into uranium dioxide UO2, the second type of agglomerate being prepared prior to the compacting by a series of specific operations.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

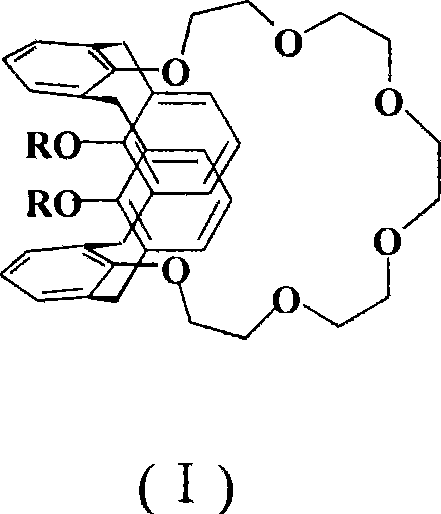

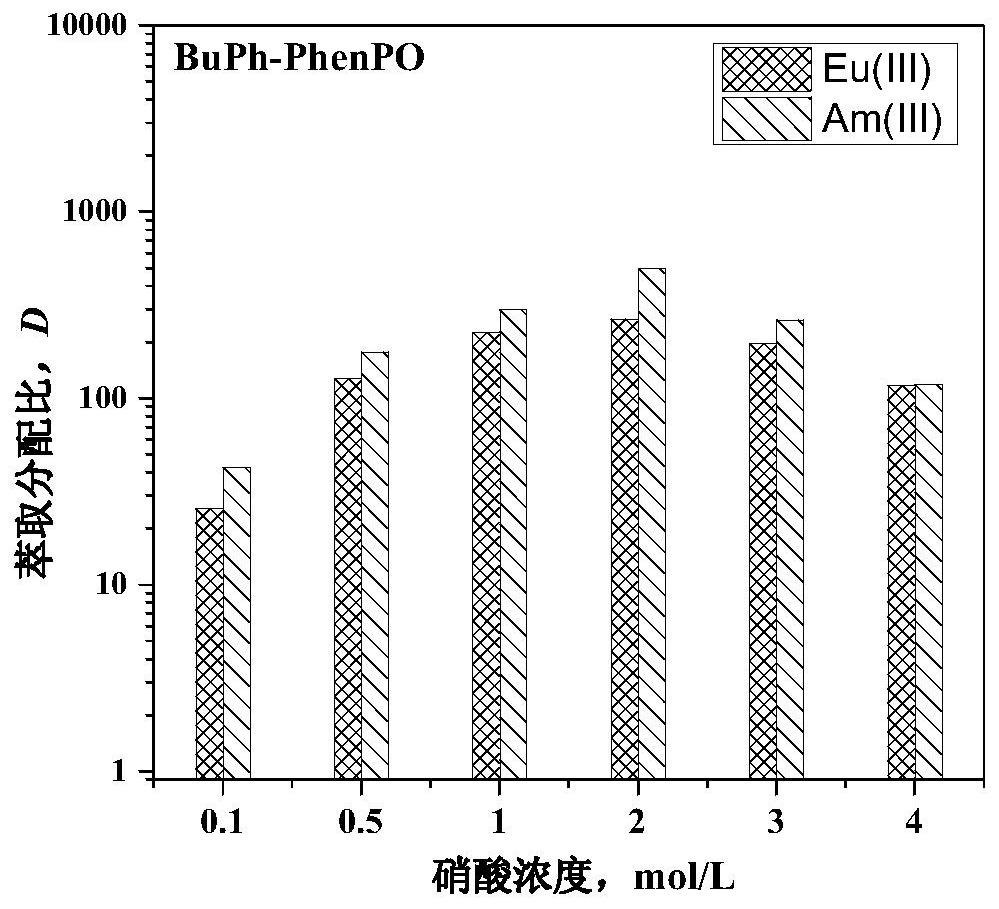

Method for extracting and separating trivalent lanthanide and/ or actinide ions by using phenanthroline phosphorus oxide

The invention relates to the technical field of nuclear fuel circulation and waste liquid treatment, and particularly relates to a method for extracting and separating trivalent lanthanide and / or actinide ions by using phenanthroline phosphorus oxide. The method comprises the following steps: taking phenanthroline phosphorus oxide shown in a formula (1) as an extracting agent, mixing the phenanthroline phosphorus oxide with an organic solvent to form an organic phase, and extracting the trivalent lanthanide and / or actinide ions from a water phase, wherein the water phase is an acidic solution containing the trivalent lanthanide and / or actinide ions, R1 is phenyl or substituted phenyl, and R2 is phenyl, C1-C10 straight-chain alkyl or branched-chain alkyl. By the method, minor actinide elements and lanthanide elements can be efficiently extracted and separated from a strong nitric acid aqueous solution, the highest extraction rate can reach 99.9%, and the method has good application prospect in the field of co-separation of the trivalent lanthanide and actinide ions in radioactive waste liquid, particularly high-level radioactive waste liquid, in the nuclear industry. Formula (I)sees the description.

Owner:ZHEJIANG UNIV

Method for preparing a porous nuclear fuel containing at least one minor actinide

InactiveCN102483960ANuclear energy generationRecycling and recovery technologiesUranium oxidePowder mixture

The invention relates to a method for manufacturing a porous fuel including uranium, optionally plutonium, and at least one minor actinide, including the following consecutive steps: a) a step of compacting, into pellets, a mixture of powders including uranium oxide, optionally plutonium oxide, and at least one minor actinide oxide, at least a portion of the uranium oxide being in the form of triuranium octaoxide (U3O8), the other portion being in the form of uranium dioxide (UO2); and b) a step of reducing at least one portion of the triuranium octaoxide (U3O8) into uranium dioxide (UO2).

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Super-uranium fuel and preparation method and transmutation method thereof

ActiveCN111627569ALarge capture cross sectionGuaranteed Intrinsic SecurityNuclear energy generationConversion in nuclear reactorEngineeringMolten salt reactor

The invention discloses a super-uranium fuel as well as a preparation method and a transmutation method thereof. The super-uranium fuel comprises a base salt and villiaumite of a super-uranium element, the super-uranium element comprises a plutonium element (Pu) and a minor actinide element (MA), and the content of the minor actinide element is not lower than 50%. The transmutation method of the super-uranium fuel comprises the steps that the super-uranium fuel serves as fuel of a liquid molten salt reactor, and the liquid molten salt reactor is operated. The preparation of the super-uranium fuel is simple and feasible, the transmutation method of the super-uranium fuel realizes better negative temperature feedback, and the inherent safety of the liquid molten salt reactor is ensured.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

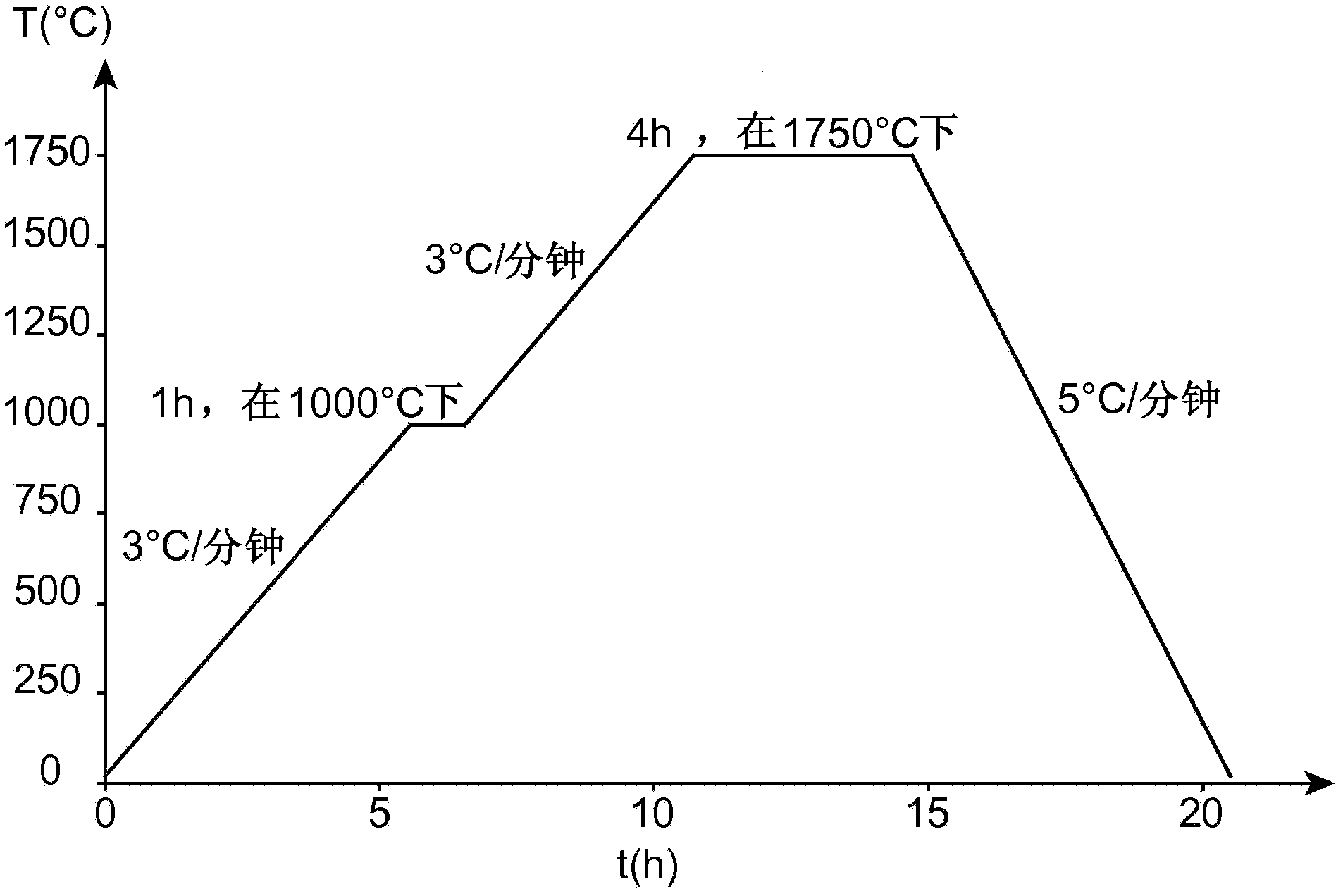

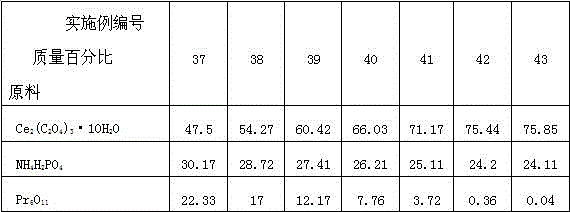

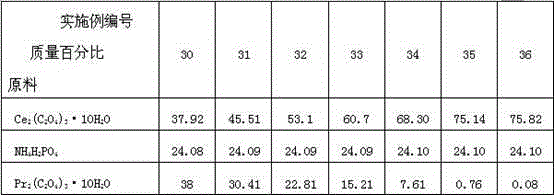

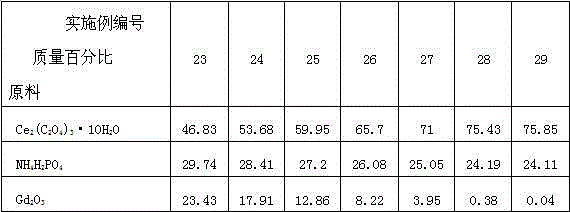

Preparation method of kularite ceramic solidifying body

InactiveCN103408304BGood chemical stabilityImprove mechanical stabilityRadioactive decontaminationRadiation stabilityHalf-life

The invention discloses a preparation method of a kularite ceramic solidifying body. The preparation method is characterized in that Ce2(C2O4)3.10H2O, An2 (C2O4)3.10H2O / oxide of An (An=Gd, Pr and Eu) and NH4H2PO4 are taken as raw materials; the high-quality kularite ceramic solidifying body is prepared according to formulation designing and the steps such as fine grinding, drying, granulating, forming, adhesive removing and vacuum hot-pressing sintering at a lower temperature. The kularite ceramic solidifying body prepared according to the preparation method is high in heat stability, mechanical stability, chemical stability and anti-radiation stability, is applicable to the safe solidification treatment of high-level waste, particularly applicable to the safe solidification treatment of high-level minor actinides waste which is high in radioactivity and toxicity, and long in half life period, and also applicable to the engineering application of high-level waste ceramic solidification treatment needing remote operation.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Method for reprocessing spent nuclear fuel and centrifugal extractor therefor

ActiveUS9666315B2Isolation difficultRecovery difficultWater/sewage treatment by centrifugal separationNuclear fuel reprocessingElectrolysisEngineering

A spent nuclear fuel is reprocessed by dissolving a spent nuclear fuel in an aqueous nitric acid solution and separating and recovering nuclides contained in the resulting fuel solution by solvent extraction. A spent nuclear fuel reprocessing method includes: an electrolytic valence adjustment step in which nuclides contained in the fuel solution is electrolytically reduced without removing fission products or minor actinides until valence of plutonium is at a level at which solvent extraction efficiency is low by using the valence of plutonium contained in the fuel solution as a parameter; and a nuclide separation step in which, by using an extraction solvent which extracts uranium contained in the fuel solution, uranium is distributed from the fuel solution subjected to the electrolytic valence adjustment step to the extraction solvent.

Owner:KK TOSHIBA

Method for separating element palladium and sub-actinide elements from high-level waste

InactiveCN102614683BHigh selectivityEasy to separateOther chemical processesSolid sorbent liquid separationHydrogenNitrate

The invention discloses a method for separating element palladium from high-level waste, which includes the steps: adding concentrated nitric acid into nitrate solution of the high-level waste to adjust the nitric acid concentration to be 2mol / L; and allowing the high-level waste nitrate solution with the nitric acid concentration adjusted to pass through a chromatographic column filled with adsorbent to enable element palladium and sub-actinide elements to be adsorbed by the chromatographic column filled with the adsorbent; using nitric acid aqueous solution of thiourea to elute the chromatographic column with the adsorbed element palladium and sub-actinide elements, and eluting the element palladium out in a nitrate form, wherein the thiourea concentration of the nitric acid aqueous solution of thiourea is 0.2mol / L, and the nitric acid concentration is 0.1mol / L; and after the element palladium is eluted out in a nitrate form, using saltpeter solution with the pH (potential of hydrogen) being 6.5 to elute the chromatographic column with the adsorbed sub-actinide elements and eluting the sub-actinide elements out in a nitrate form. The method is simple, efficient, high in selectivity of the chromatographic column and effective in separation.

Owner:ZHEJIANG UNIV

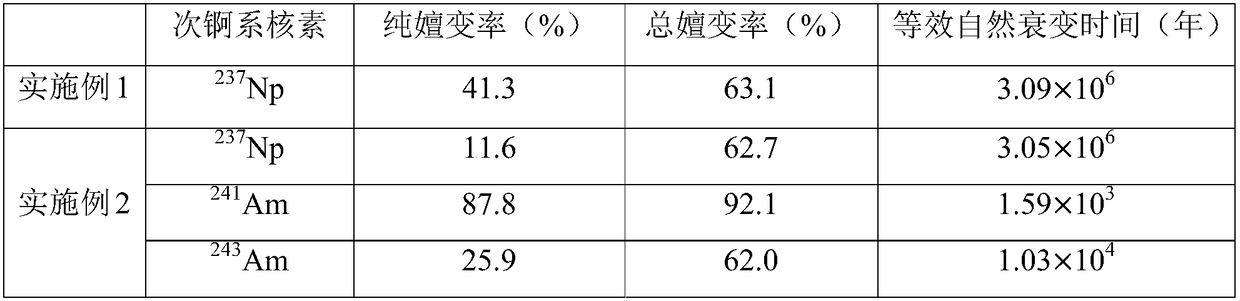

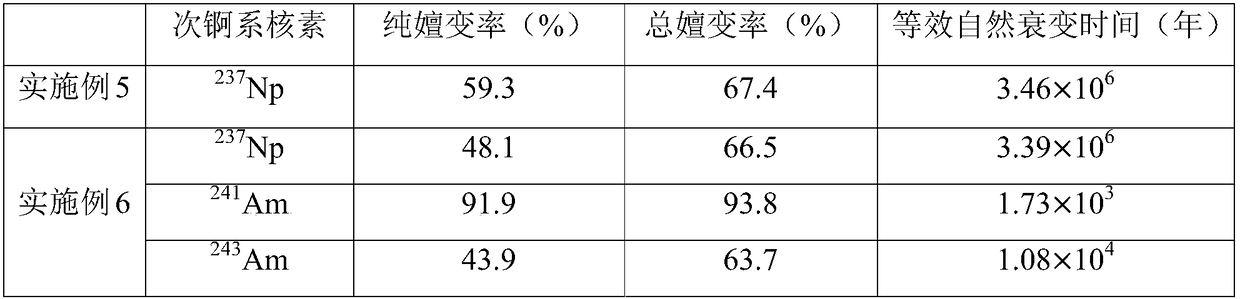

Solution stack for burning plutonium and transmutation of neptunium-237 or americium-241

The invention discloses a solution reactor used for the plutonium combustion and the neptunium-237 or the americium-241 transmutation. The solution reactor adopts plutonium or plutonium and americium in the spent fuel of the nuclear power plant as the fuel, and adopts neptunium-237 or americium-241 as the target. By adopting the solution reactor, the minor actinides which have long half life and high toxicity and can not be stored for a long time, such as the neptunium-237 or the americium-241, can be changed into nuclides with short half life and low toxicity through transmutation. Because the solution reactor adopts the spent fuel and can generate electricity at the low temperature, the cost-effectiveness and the security are high; the neutron provided by the plutonium combustion can extract plutonium-238 from the neptunium-237 solution target as the isotope battery, thereby the inexpensive energy is provided; the americium-242m extracted from the americium-241 solution target can be widely applied to the aerospace industry and the medical industry.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

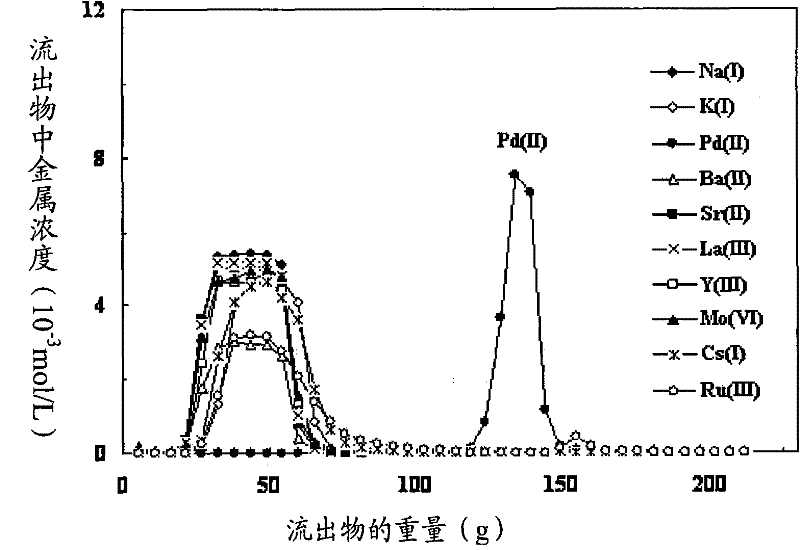

Method for separating element Pd from high-level radioactive waste

InactiveCN101690853BHigh selectivityEasy to separateOther chemical processesSolid sorbent liquid separationNitrateAcid water

The invention discloses a method for separating an element Pd from the high-level radioactive waste, which comprises the following steps: (1) adding concentrated nitric acid in nitrate solution of the high-level radioactive waste which separates minor actinides for adjusting the concentration of the nitric acid to 1.7-2.3 mol / L; (2) leading the nitrate solution of the high-level radioactive wasteafter the adjustment of the concentration of the nitric acid to pass through a column filled with an absorbent, and leading the element Pd to be absorbed by the column filled with the absorbent; and (3) using nitric acid water solution of thiourea to elute the column filled with the element Pd, and eluting out the element Pd in the form of nitrate, wherein the concentration of the thiourea in thenitric acid water solution of the thiourea is 0.1-0.3 mol / L, and the concentration of the nitric acid is 0.05-0.15 mol / L. The method is simple and high-efficient, the selectivity of the column is high, and the separation effect is good.

Owner:ZHEJIANG UNIV

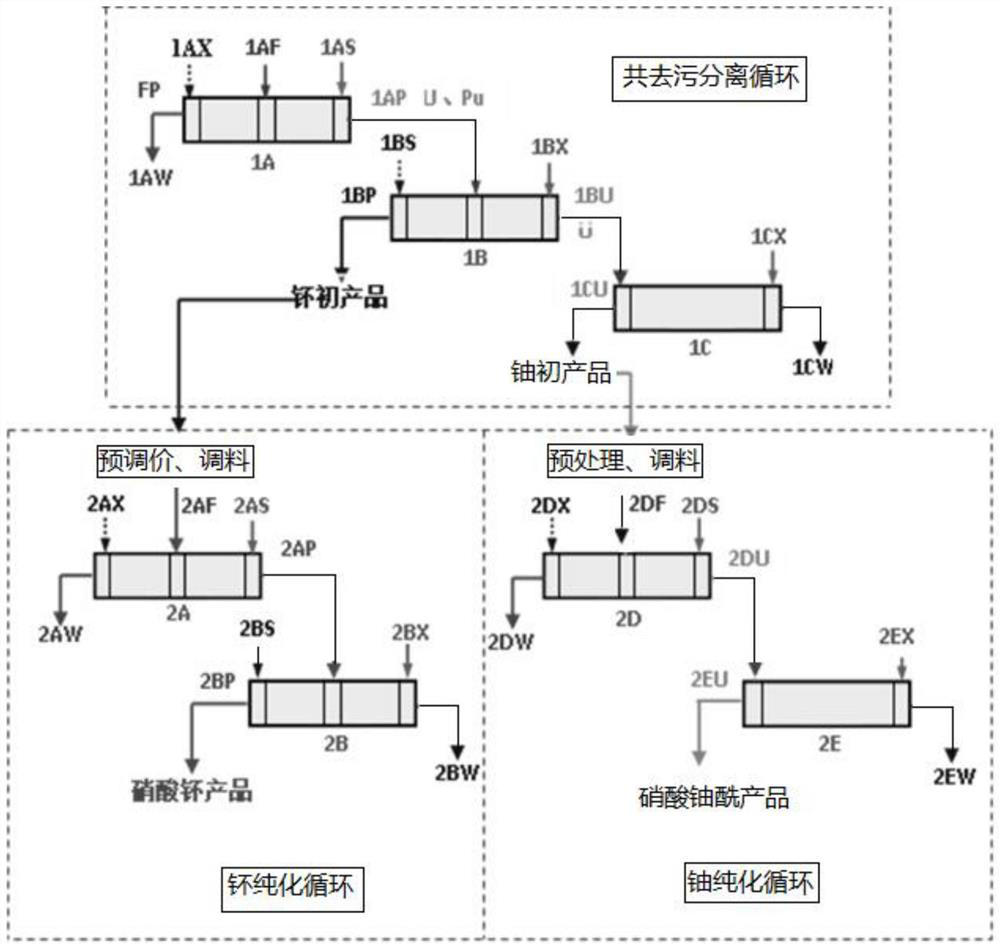

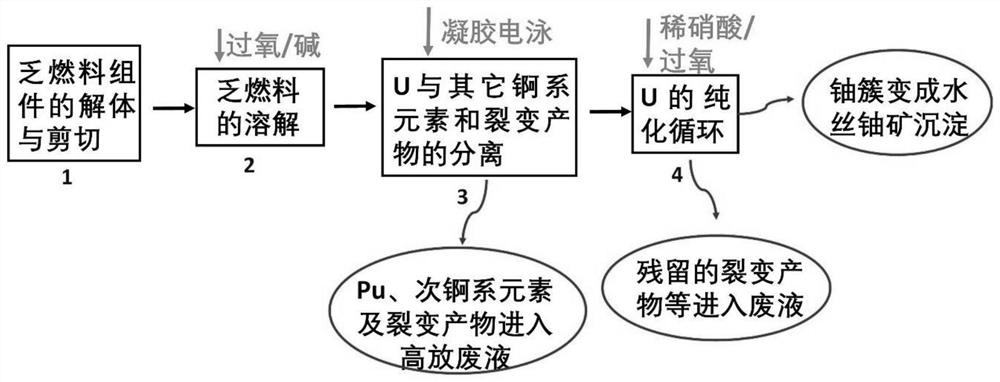

Spent fuel post-processing method based on uranium cluster compound

PendingCN114678149ARisk of nuclear proliferation noNo problems such as radiation decompositionNuclear energy generationRecycling and recovery technologiesFuel reprocessingUranium mine

The invention belongs to the technical field of spent fuel post-treatment, and particularly relates to a spent fuel post-treatment method based on a uranium cluster compound, which comprises the following steps: S1, disassembling and shearing a spent fuel assembly into small fuel rods; s2, dissolving the spent fuel by using hydrogen peroxide and an alkaline solution, and filtering to obtain a precipitate and a filtrate; s3, treating the filtrate obtained in the step S2 by utilizing gel electrophoresis, and separating to obtain a uranium cluster compound and a solution containing Pu, minor actinides and fission products; and S4, dilute nitric acid and hydrogen peroxide are added into the uranium cluster compound obtained in the step S3, uranium peroxide clusters are converted into hematite sediment, filtering is carried out, sediment is obtained, and separation of the uranium element is achieved. The spent fuel post-treatment process based on the uranium cluster compound has the advantages of being simple in process, small in corrosivity and the like, the risk of nuclear diffusion does not exist, and compared with a PUREX process, the spent fuel post-treatment process based on the uranium cluster compound has better economic benefits.

Owner:XI AN JIAOTONG UNIV

A kind of preparation method of fluorapatite ceramic solidified body

The present invention discloses a method for preparing a fluorapatite ceramic solidified body. The method is characterized by comprising the steps of: taking and mixing 23-76 wt.% of calcium pyrophosphate, 8-26 wt.% of calcium fluoride, 0. 02-52wt.% of samarium oxide (europium oxide, gadolinium oxide), 0-15 wt.% of sodium carbonate, 0-16 wt.% of silica to obtain a mixture; grinding, drying, granulating, molding, discharging rubber and conducting vacuum hot pressing sintering on the mixture to obtain a fluorapatite ceramic solidified body. The method not only utilizes the phosphorus in high-level radioactive waste in a recycling way, but also can address the problem of low solubility of phosphorus and minor actinides nuclide in glass solidified body. The fluorapatite ceramic cured body prepared by the invention has excellent preparation geological stability, irradiation stability, mechanical stability, chemical stability and thermal stability, and can be used as a ceramic solidified body for safe treatment of minor actinides high-level radioactive waste with high toxicity, long half-life period and strong radioactivity.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com