Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

186 results about "Uranium dioxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Uranium dioxide or uranium(IV) oxide (UO₂), also known as urania or uranous oxide, is an oxide of uranium, and is a black, radioactive, crystalline powder that naturally occurs in the mineral uraninite. It is used in nuclear fuel rods in nuclear reactors. A mixture of uranium and plutonium dioxides is used as MOX fuel. Prior to 1960, it was used as yellow and black color in ceramic glazes and glass.

Method for preparing metal reinforced uranium dioxide nuclear fuel pellet

ActiveCN107256726ALow densityHigh strengthNuclear energy generationReactor fuel susbtancesMicro cellTwo step

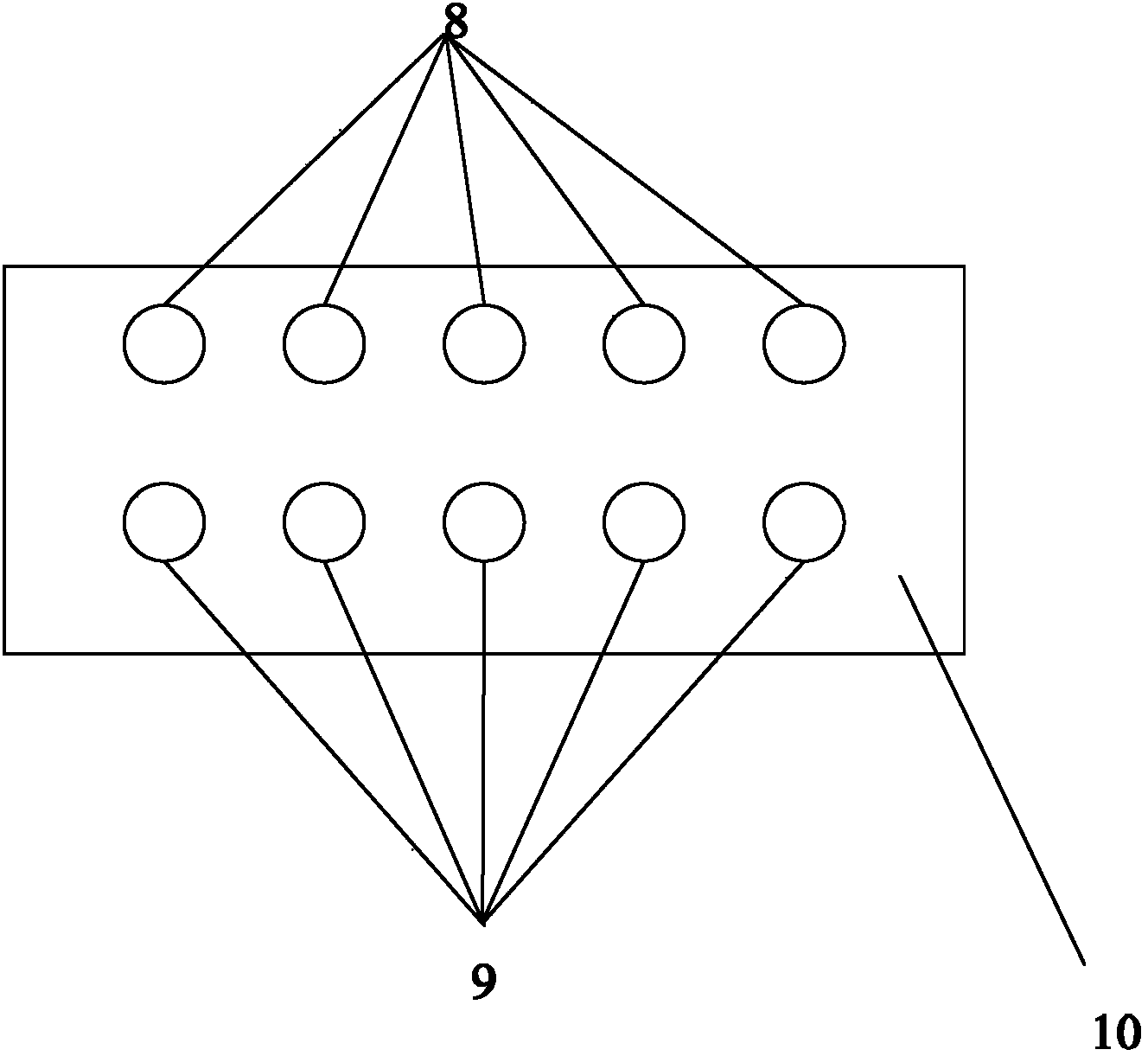

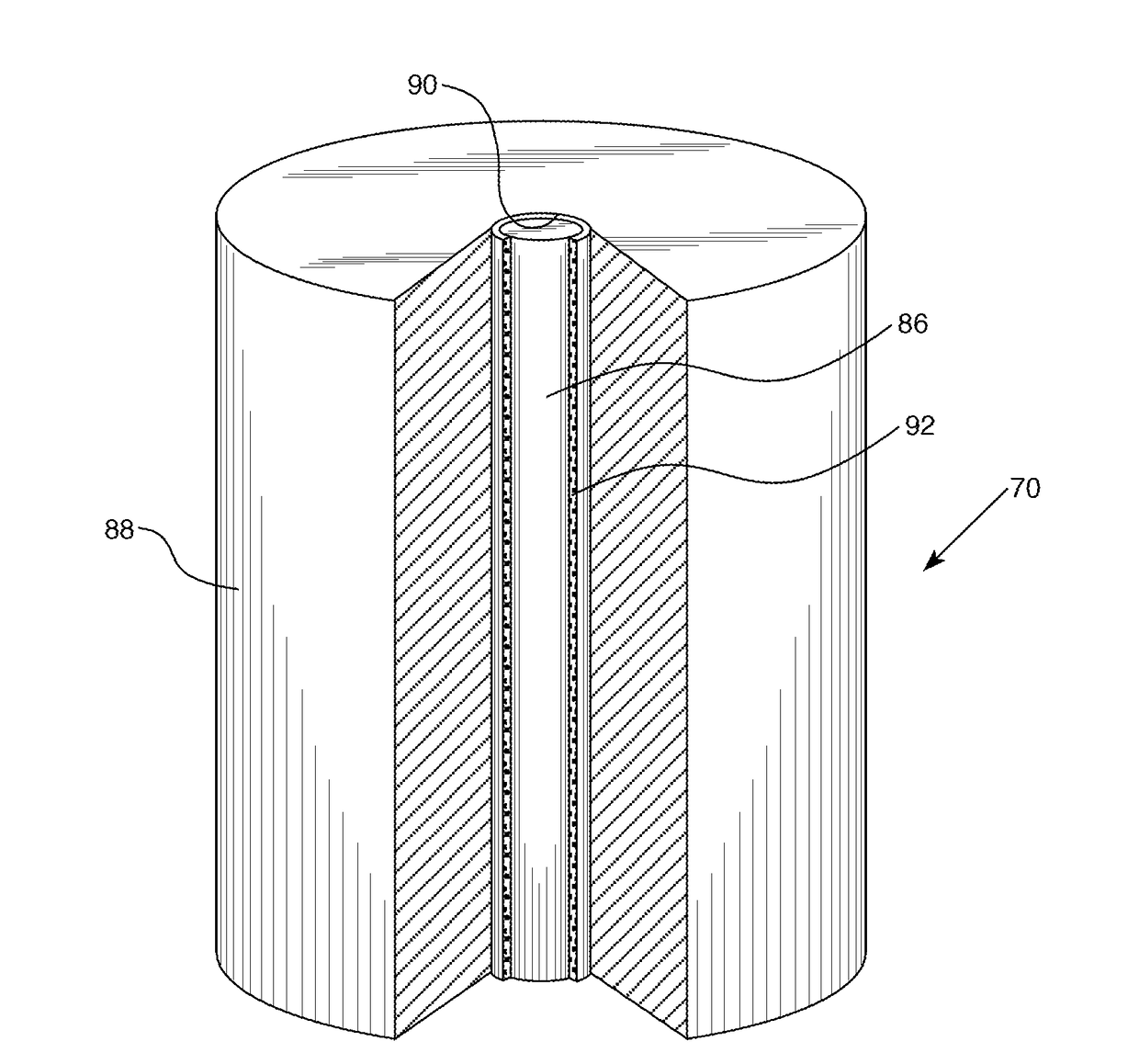

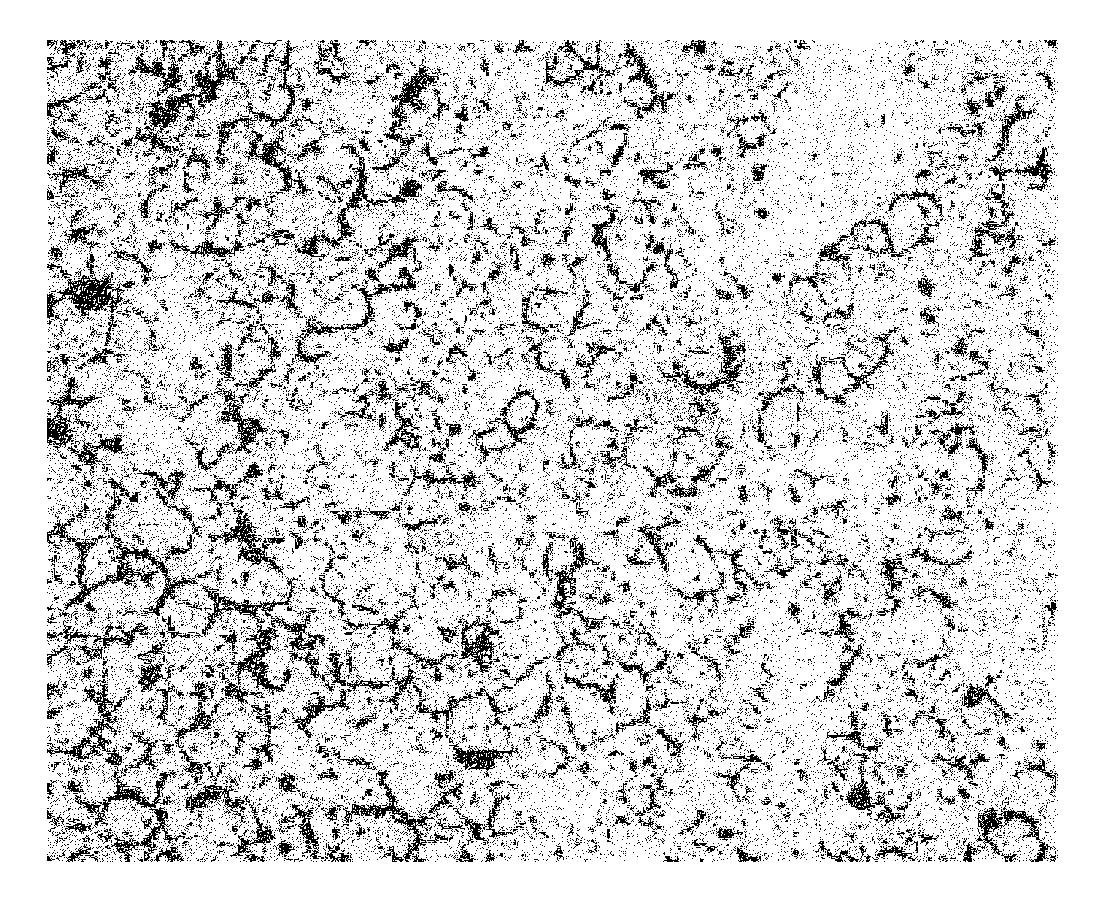

The invention discloses a method for preparing metal reinforced uranium dioxide nuclear fuel pellets. The method mainly comprises two steps: firstly, preparing core-shell structure granules, namely performing low-temperature rapid pre-sintering on UO2 powder by using a Spark Plasma Sintering SPS technique, pelletizing, balling to obtain UO2 pellets, performing physical mixing on the UO2 pellets with metal (one of Mo, Cr, W and the like) micro powder to coat surfaces of the UO2 pellets by the metal micro powder, thereby obtaining metal coated uranium dioxide core-shell structure granules; secondly, preparing a nuclear fuel pellets, namely performing high-temperature liquidation on the metal powder on the surfaces of the UO2 pellets, thereby forming a micro cell structure continuous phase similar to a cytomembrane structure around the UO2 pellets, and obtaining the special metal reinforced UO2 nuclear fuel pellets with a UO2 substrate.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS +1

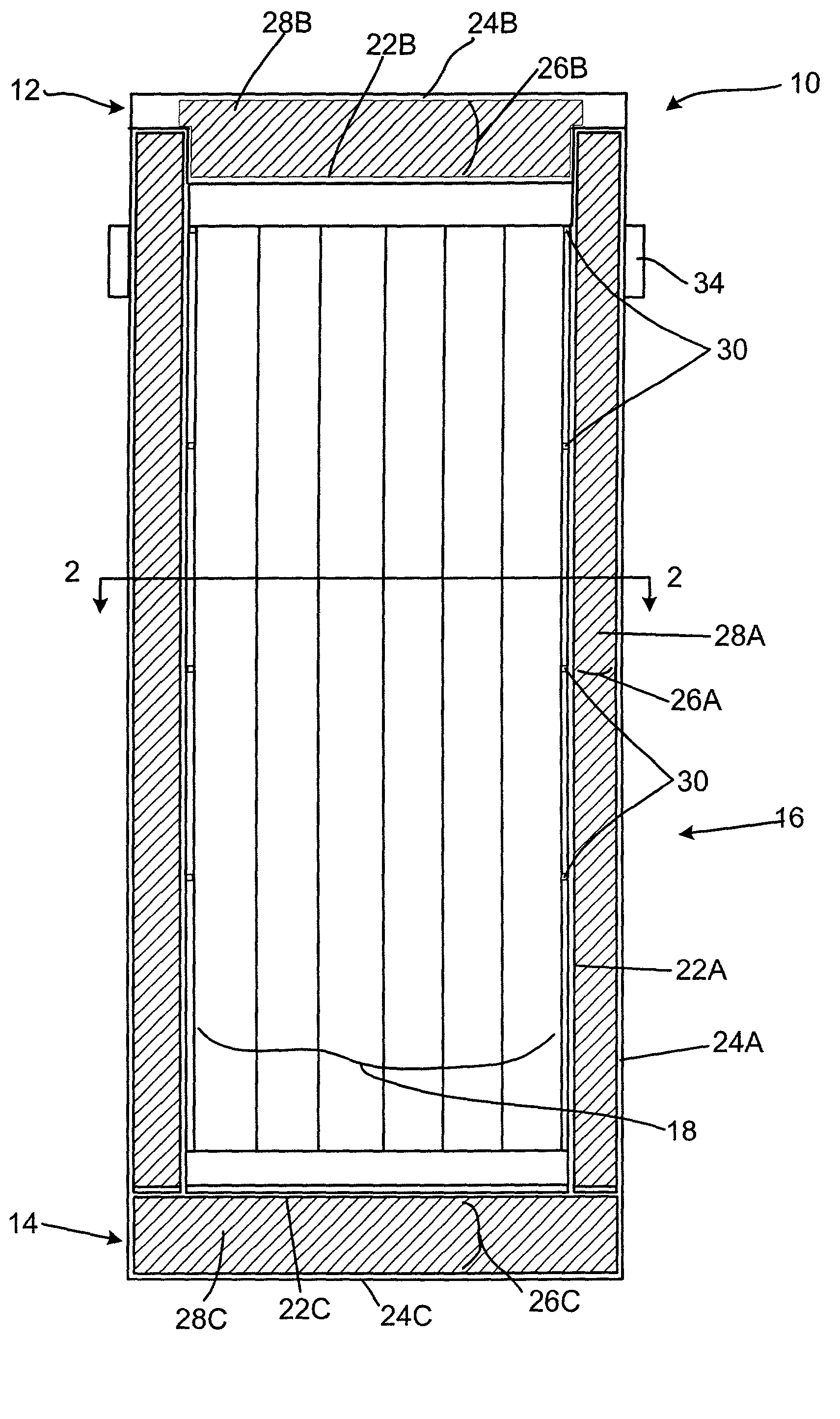

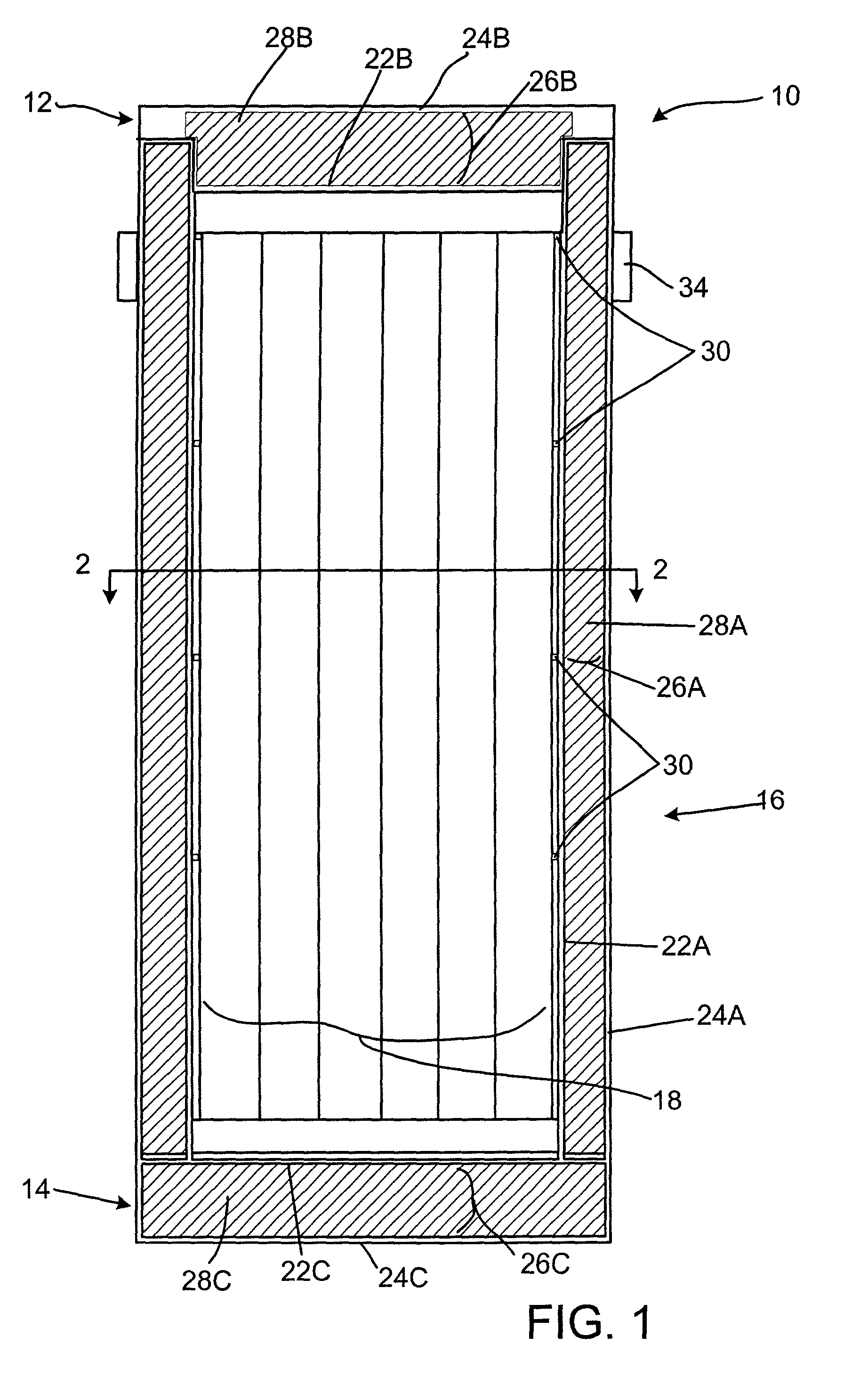

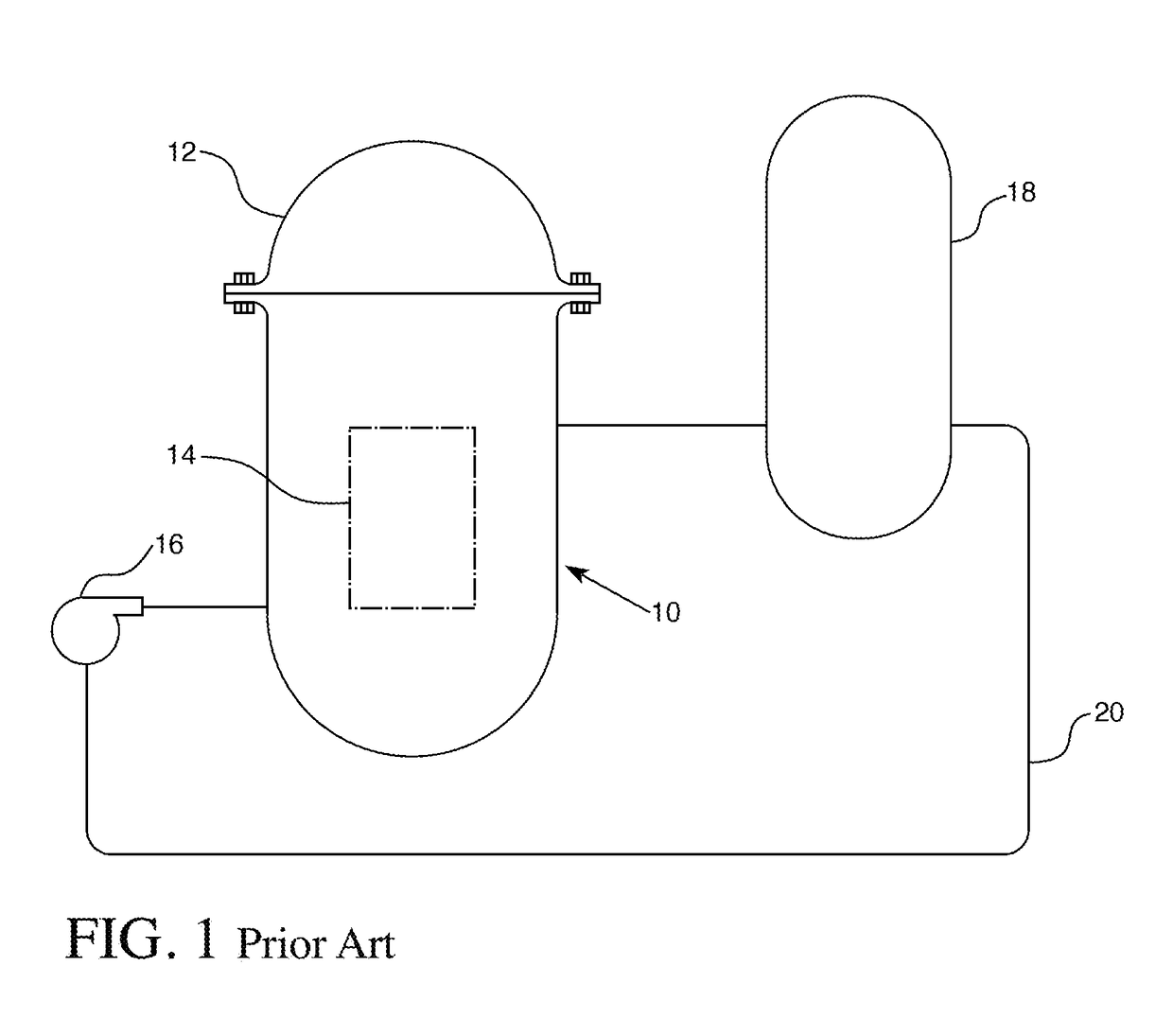

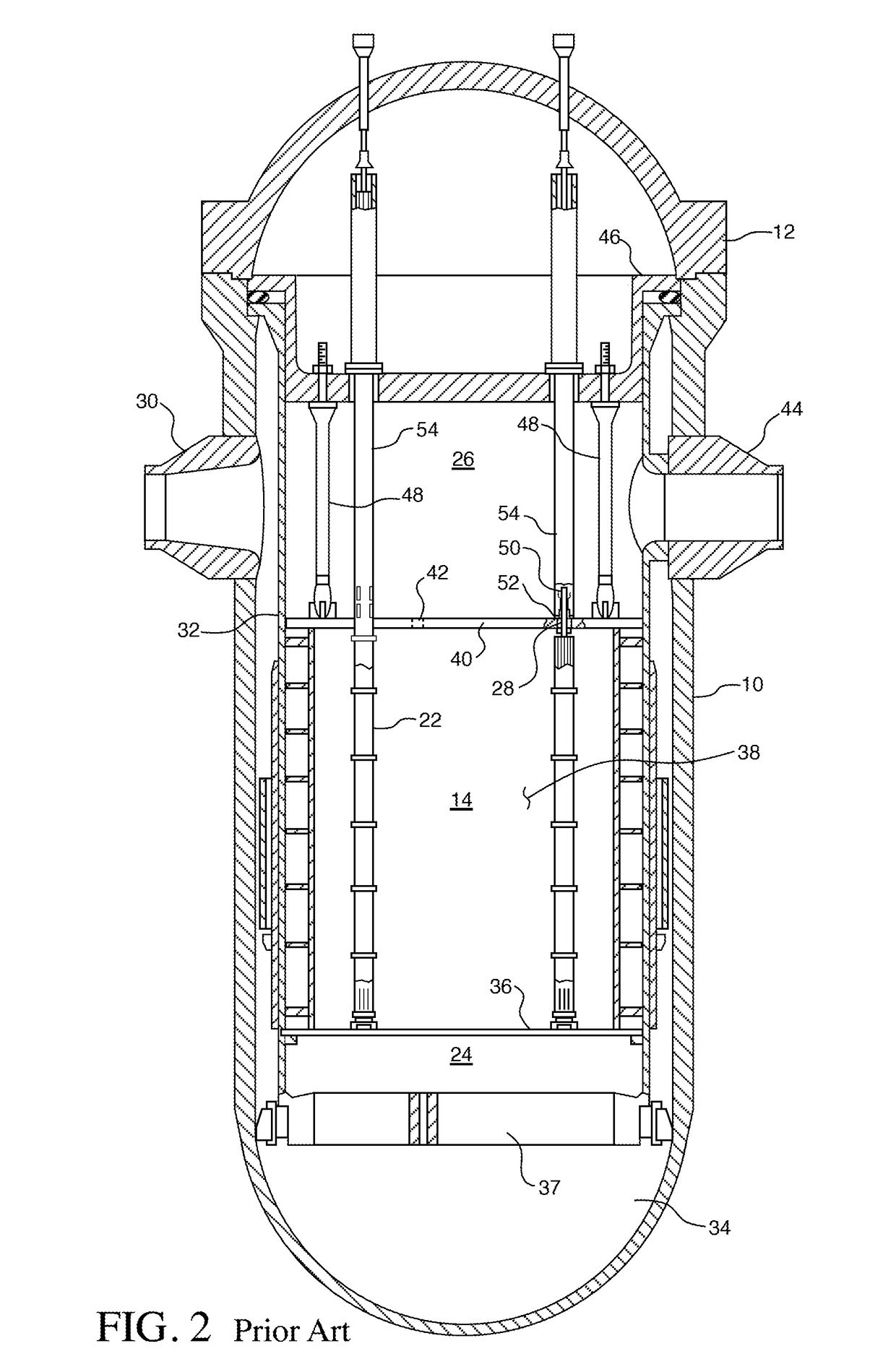

Radiation shielding materials and containers incorporating same

InactiveUS6960311B1Improve shielding effectMaximum flexibilityOther chemical processesTransuranic element compoundsMicrosphereUranium carbide

An improved radiation shielding material and storage systems for radioactive materials incorporating the same. The PYRolytic Uranium Compound (“PYRUC”) shielding material is preferably formed by heat and / or pressure treatment of a precursor material comprising microspheres of a uranium compound, such as uranium dioxide or uranium carbide, and a suitable binder. The PYRUC shielding material provides improved radiation shielding, thermal characteristic, cost and ease of use in comparison with other shielding materials. The shielding material can be used to form containment systems, container vessels, shielding structures, and containment storage areas, all of which can be used to house radioactive waste. The preferred shielding system is in the form of a container for storage, transportation, and disposal of radioactive waste. In addition, improved methods for preparing uranium dioxide and uranium carbide microspheres for use in the radiation shielding materials are also provided.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

Preparation by spray-drying of a flowable uranium dioxide powder obtained by dry process conversion of UF6

InactiveUS6656391B1Lower levelMaintain good propertiesNuclear energy generationUranium dioxideUranium hexafluorideViscosity

The invention relates to a process for preparing a castable powder of uranium dioxide UO2, for use in the manufacture of MOX fuel.This process comprises the following stages:1) to prepare an aqueous suspension of a powder of UO2 obtained by dry process from uranium hexafluoride, said suspension comprising 50 to 80% by weight of UO2 and at least one additive chosen among deflocculation agents, organic binders, hydrogen peroxide H2O2 and a powder of U3O8, in such a quantity that the viscosity of the suspension does not exceed 250 mPa.sec, and2) to atomise this suspension and dry it in a hot gas, at a temperature of 150 to 300° C., to obtain a castable powder of UO2 with an average particle size of 20 to 100 mum.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

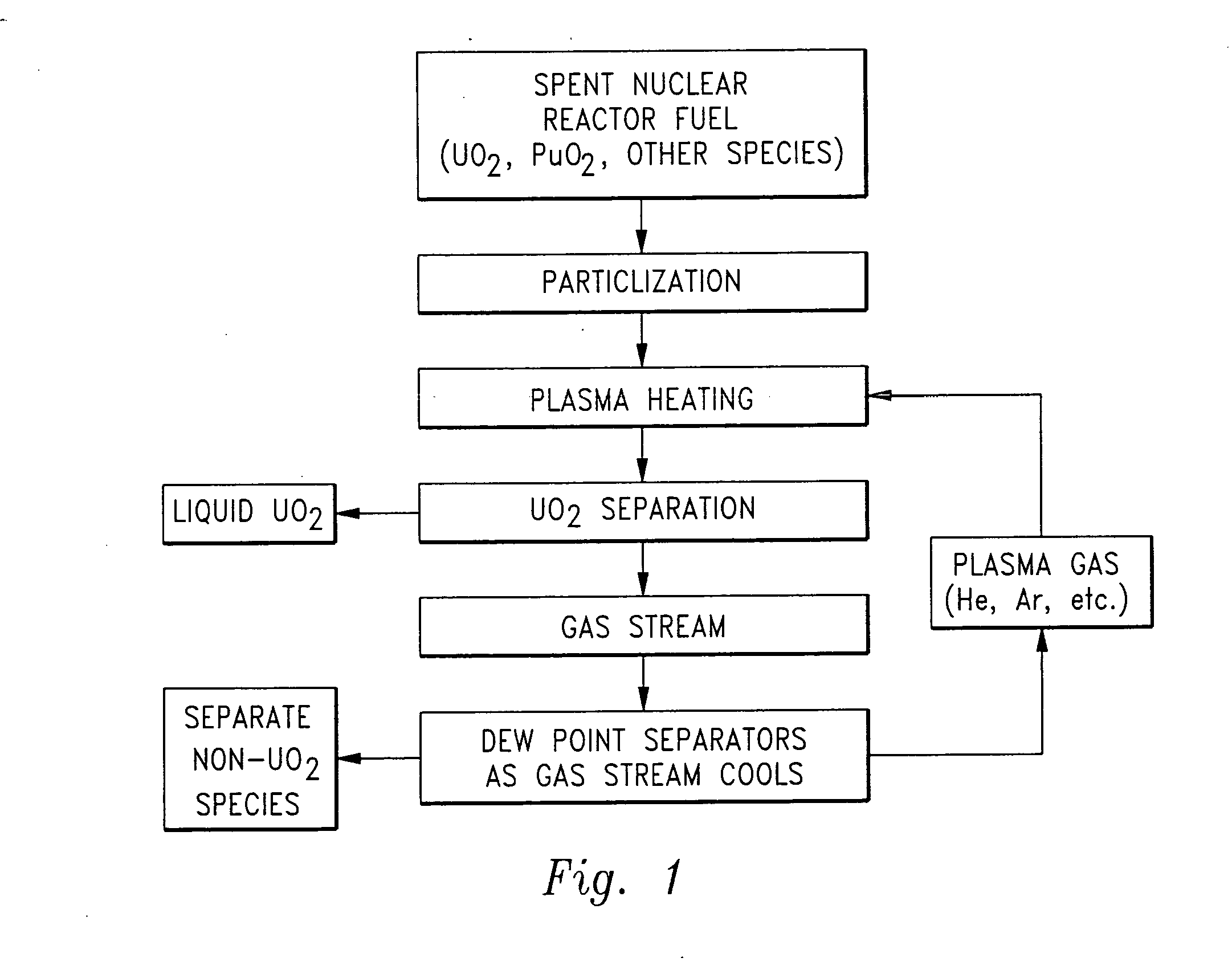

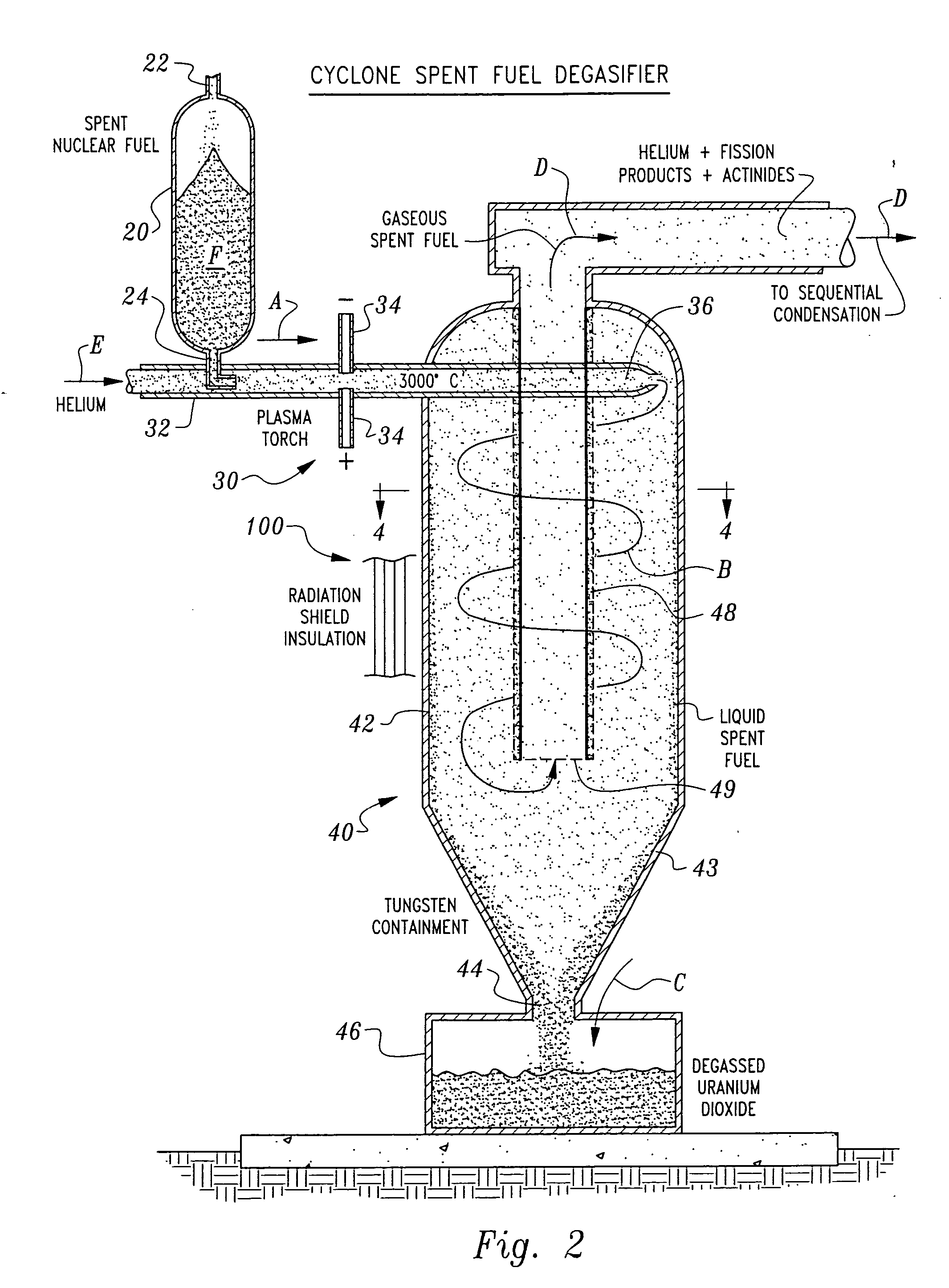

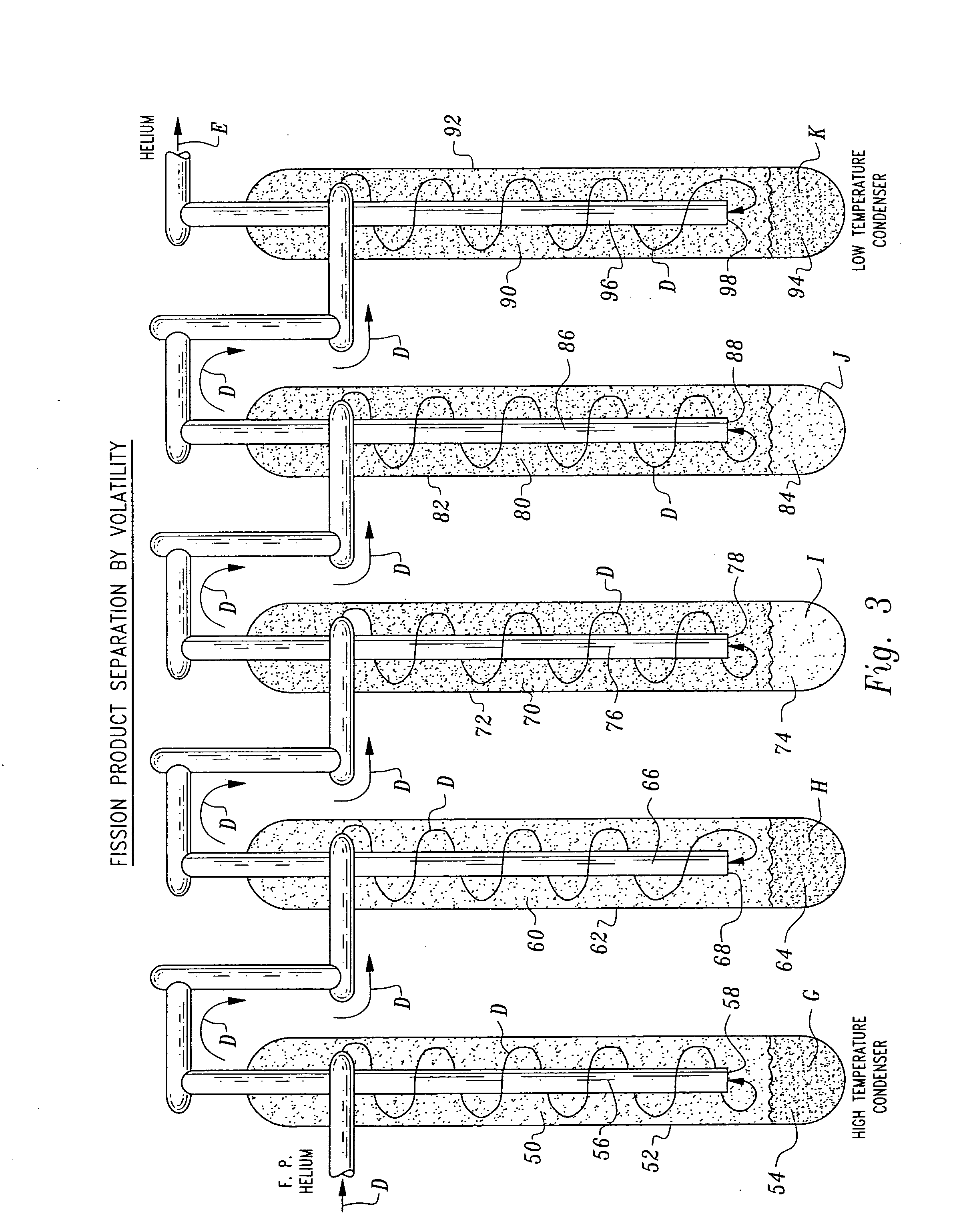

Non-aqueous method for separating chemical constituents in spent nuclear reactor fuel

InactiveUS20060233685A1Reduce riskIncrease ratingsNuclear energy generationPlutonium oxides/hydroxidesKryptonGas phase

Herein is a method of segregating chemical species contained in spent nuclear reactor fuel without employing conventional acid dissolution. Particularly, pellets of spent fuel are ground to talc sized particles. Heat is added. The preferred heating is by flow through a plasma arc producing micron sized liquid drops suspended in helium flow. The vapor pressure of the chemical species is significantly greater than uranium dioxide. the ultra volatile chemical species evolve from the drops into the helium flow. The gas phase is separated from the mist by a gas / liquid separator (demister). Heavy mist drops of UO2 impact the walls, coalesce and flow down to the separator drain, becoming legally transportable. Helium flow exhausts from the separator vertically. The gaseous chemical species will condense in sequentially cooler stages and separate from the helium down to the cryogenic temperatures of liquid radioactive xenon and krypton. Non-condensed helium is recycled.

Owner:JANES CLARENCE W

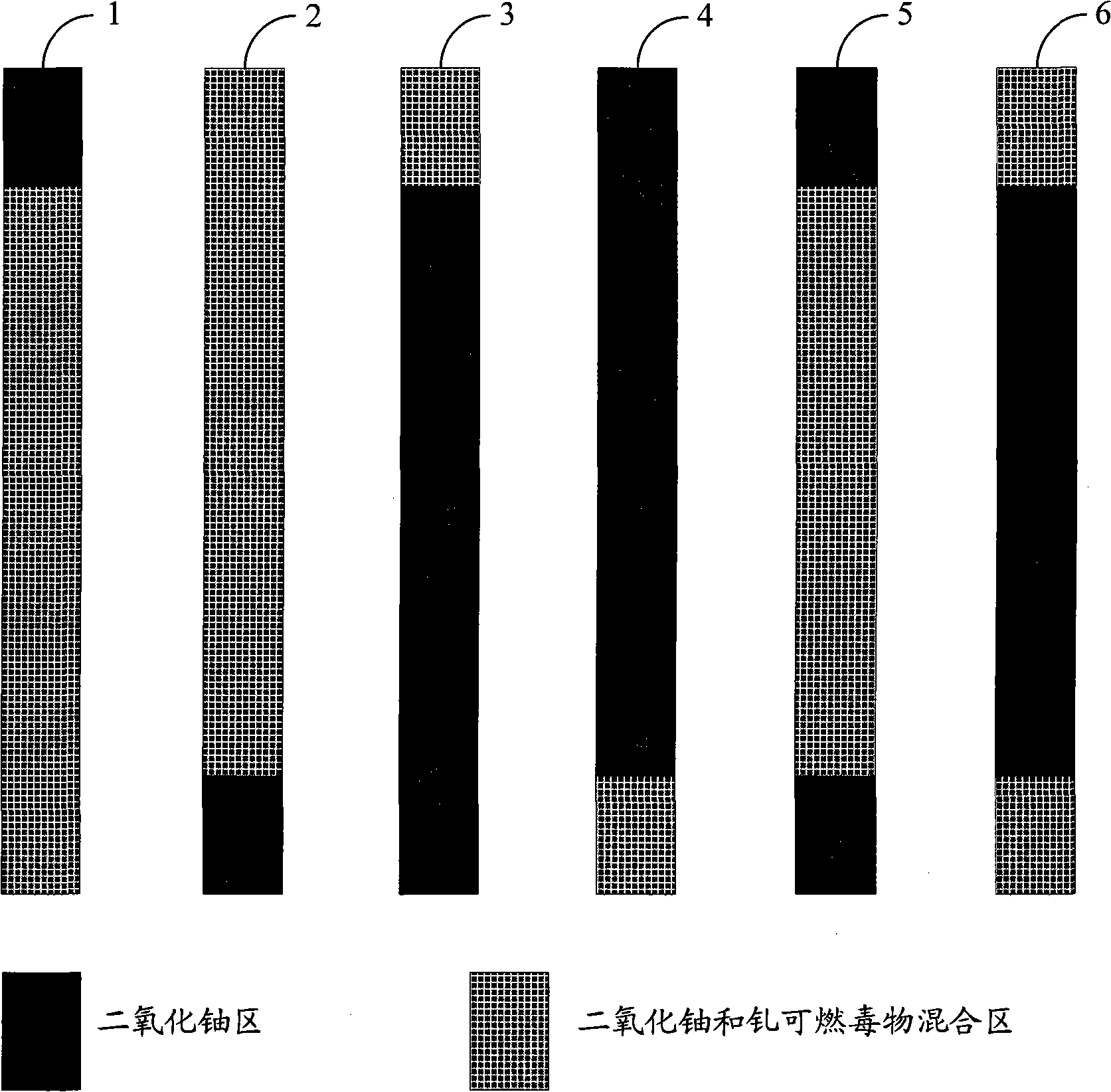

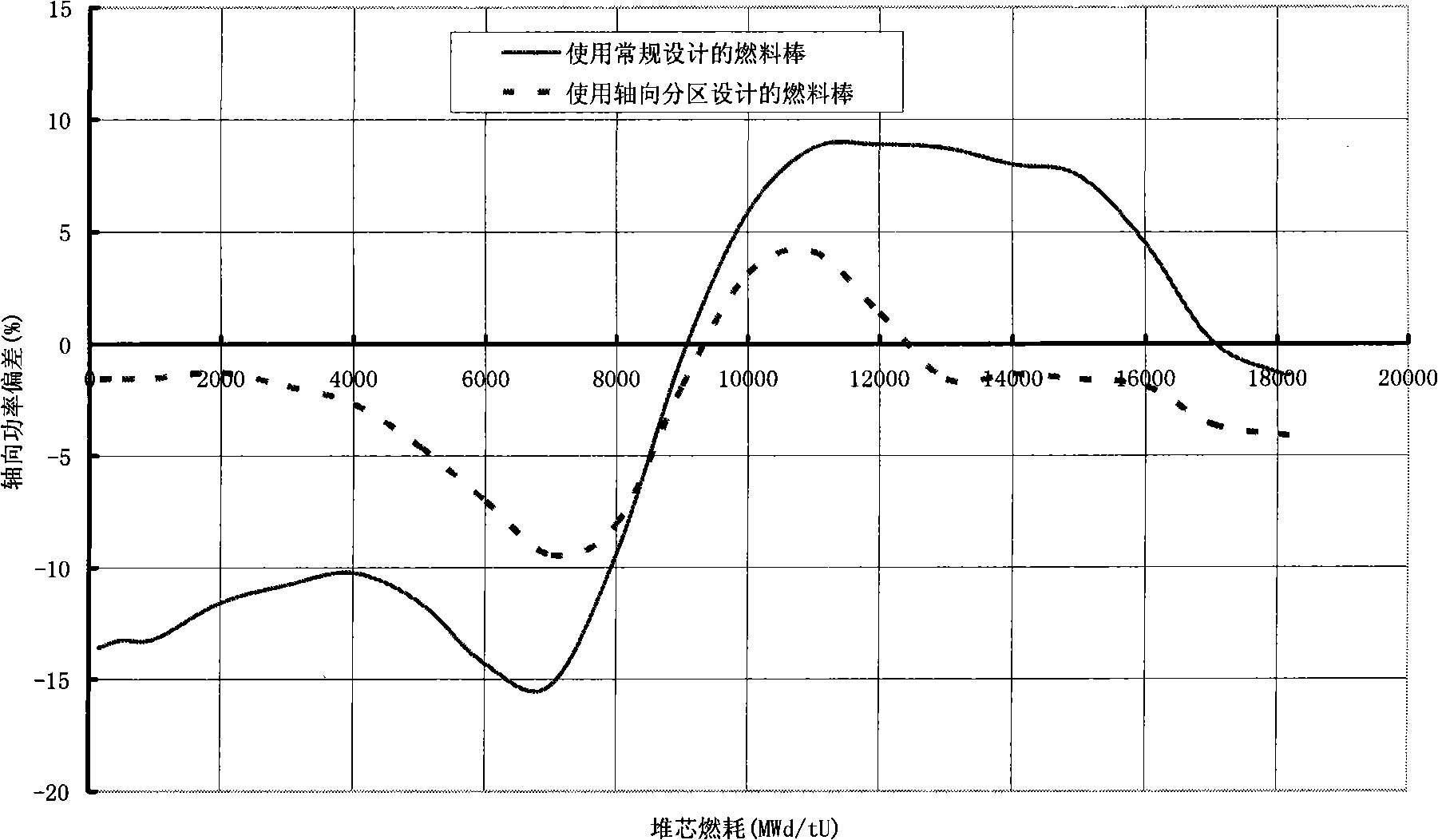

Nuclear fuel rod, nuclear fuel component and nuclear reactor core

ActiveCN101572127AGuaranteed uptimeImprove economyFuel elementsNuclear energy generationNuclear reactor coreNuclear reactor

The invention is applicable to the field of nuclear station fuel components and nuclear reactor cores, and provides a nuclear fuel rod, a nuclear fuel component and a nuclear reactor core. The nuclear fuel rod comprises two fuel pellets of different types in the axial direction thereof, i.e. a uranium dioxide fuel pellet and a gadolinium burnable poison fuel pellet; the nuclear fuel rod provided by the invention uses a type of fuel pellet as the main body, and the other type of fuel pellet is positioned at one end or two ends of the main fuel rod; the axial power error is improved, and the fuel utilization economy is improved, or the circulation length of the reactor core is prolonged through changing the neutron flux of the top end or the bottom end of the reactor core, so that the running performance of the reactor core is improved.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD

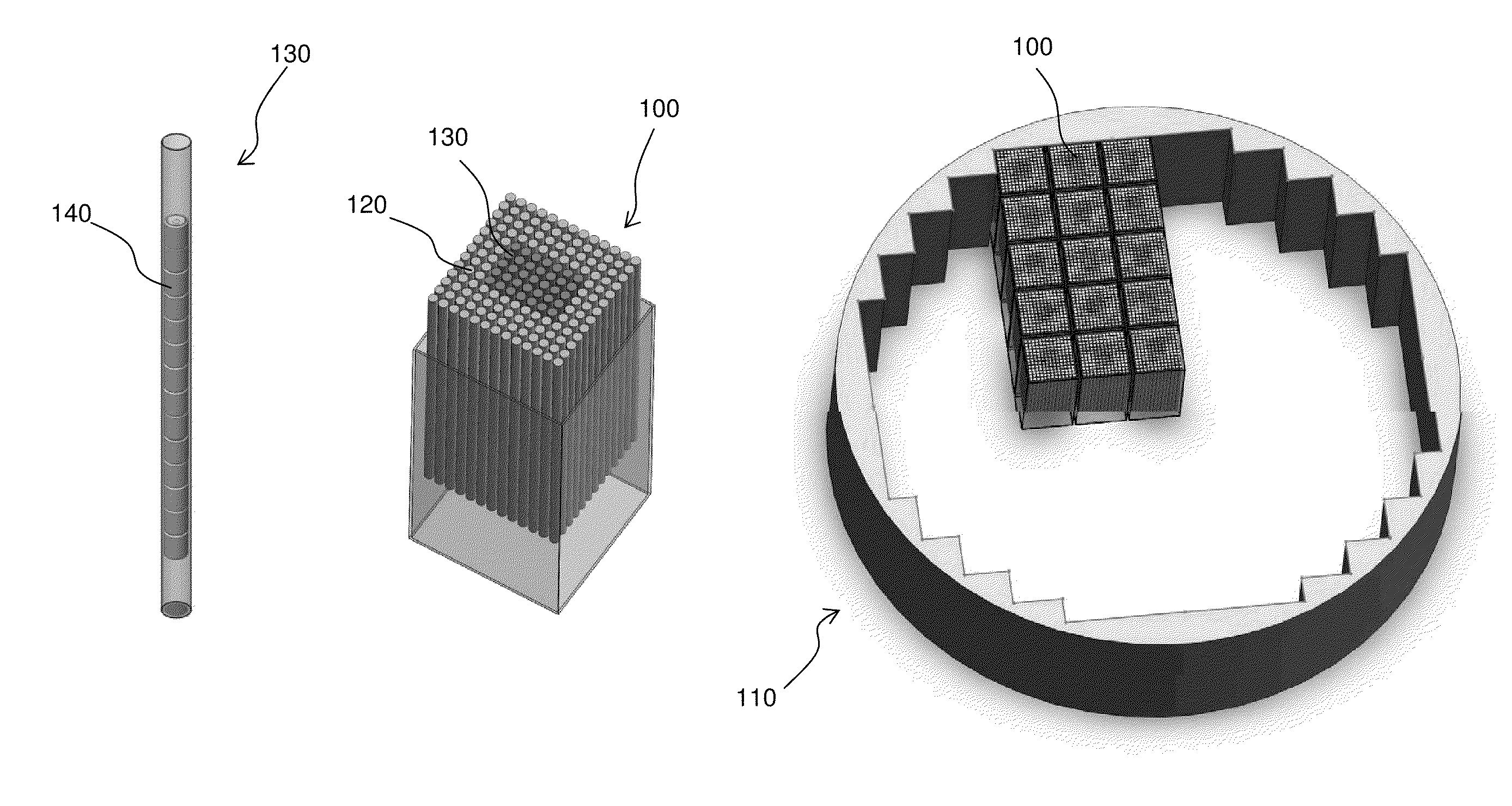

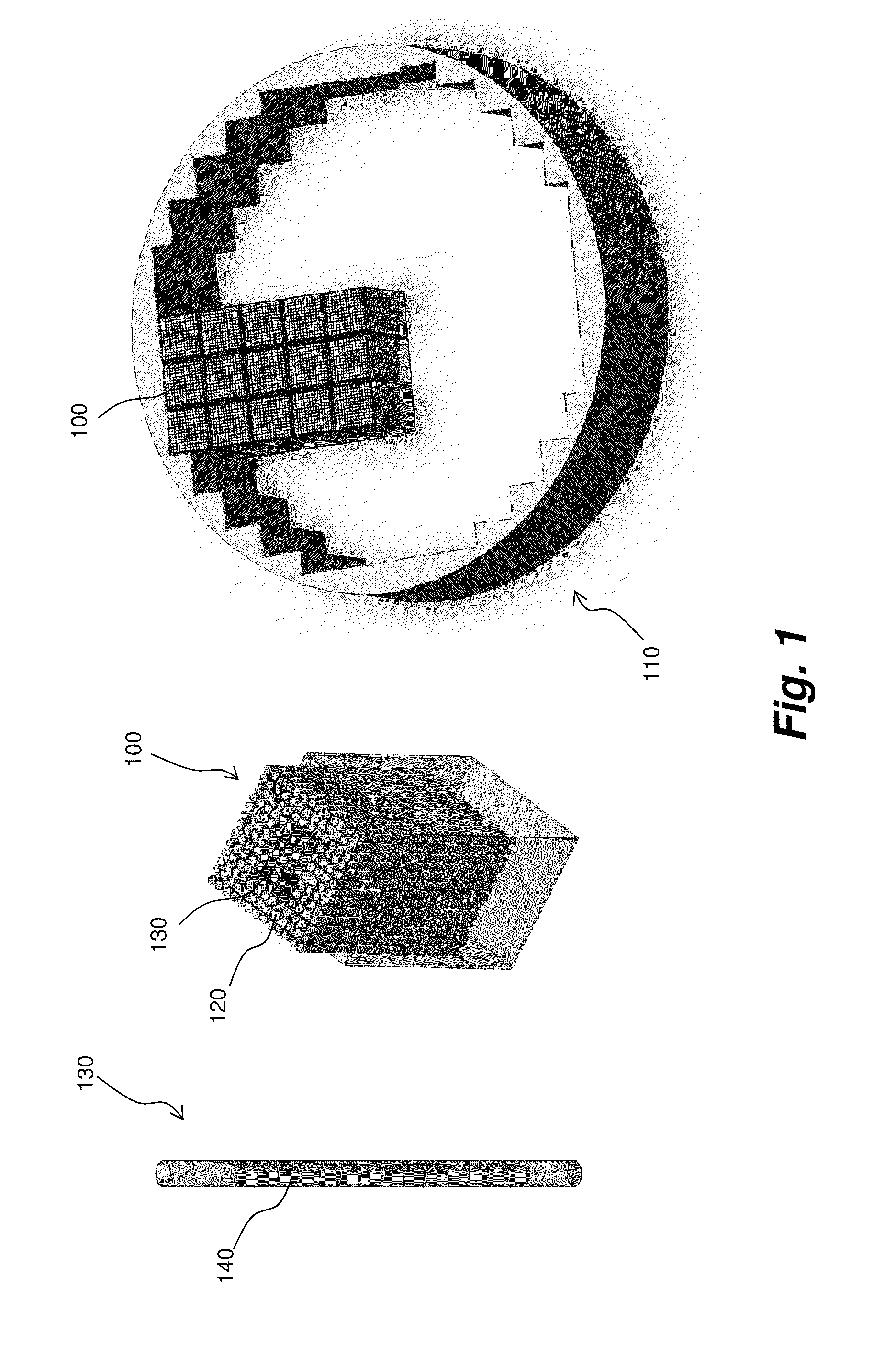

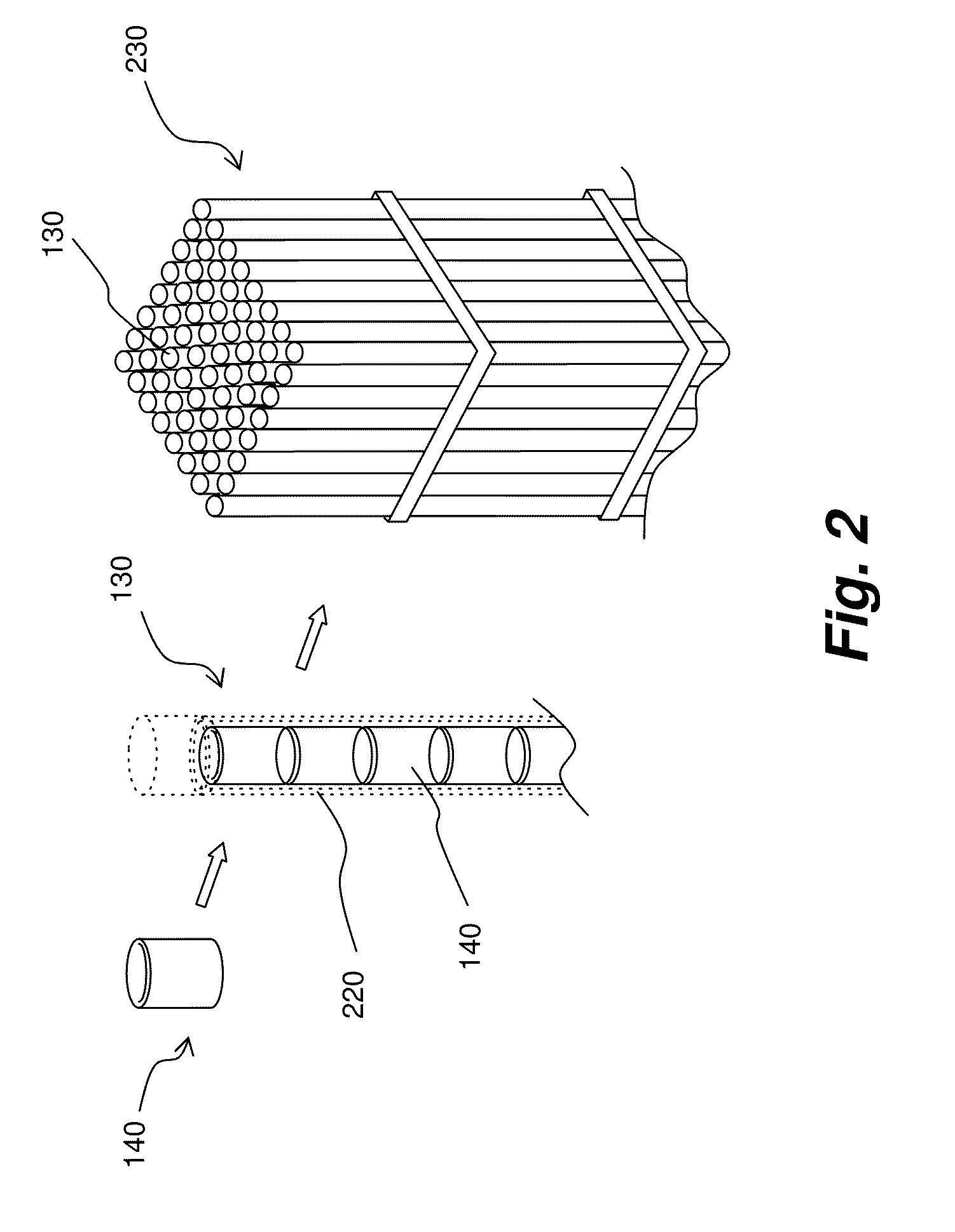

Nuclear fuel assembly and related methods for spent nuclear fuel reprocessing and management

InactiveUS20110317794A1Increase fuel consumptionLower the volumeFuel elementsConversion outside reactor/acceleratorsUranium dioxideNuclear fuel

Various embodiments of a nuclear fuel assembly and related methods for processing and managing spent nuclear fuel are disclosed. According to one exemplary embodiment, a nuclear fuel may include a plurality of first fuel rods having a plurality of first fuel elements and a plurality of second fuel rods having a plurality of second fuel elements. Each of the first fuel elements may include uranium dioxide fuel, and each of the second fuel elements may include a plurality of tristructural isotropic fuel particles embedded in a silicon carbide matrix. The plurality of first fuel rods and the plurality of second fuel rods are arranged in a fuel assembly.

Owner:UT BATTELLE LLC +1

Preparation method and application of uranium-based ternary carbide

ActiveCN107010960AHigh melting pointImprove thermal conductivityNuclear energy generationReactor fuel susbtancesFault toleranceNuclear power

The invention discloses a preparation method and application of uranium-based ternary carbide, and is used for overcoming the shortcomings of the uranium monocarbidc (UC) and uranium dioxide (UO2) nuclear fuels in the prior art on the aspects of melting point, heat conduction, irradiance resistance, and the like. The preparation method comprises the steps of processing mixing uranium carbide powder and transition metal carbide powder or mixing uranium dioxide powder and transition metal carbide powder and carbon powder, placing in a designed graphite jig, and allowing reactive sintering to obtain high-stability uranium-based ternary carbide. The uranium-based ternary carbide prepared by the preparation method of the invention has the characteristics of high melting point, high heat conductivity and good irradiation resistance, and can be used as an accident fault-tolerance nuclear fuel of a nuclear power station, or a nuclear fuel of a nuclear-powered rocket.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

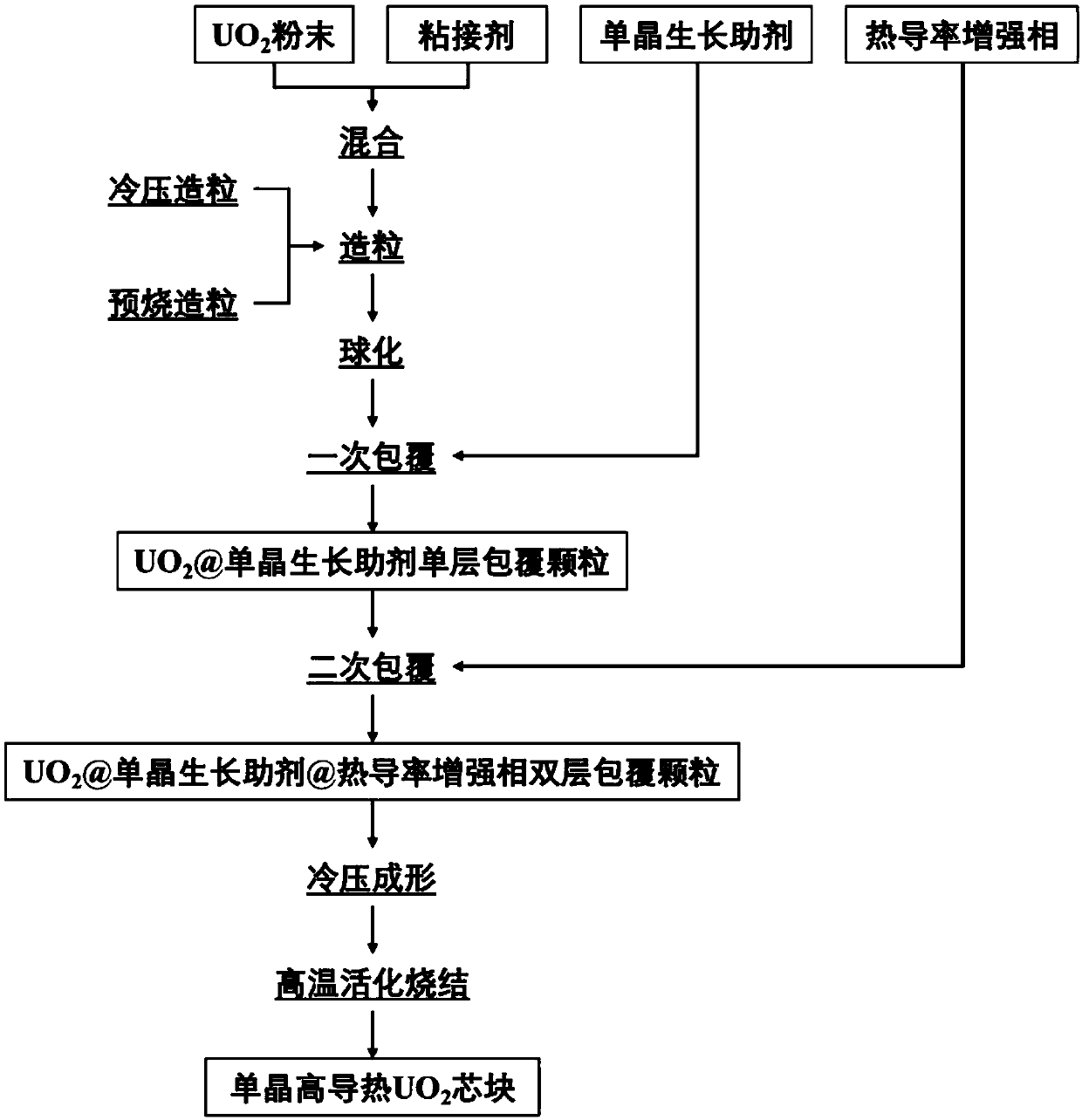

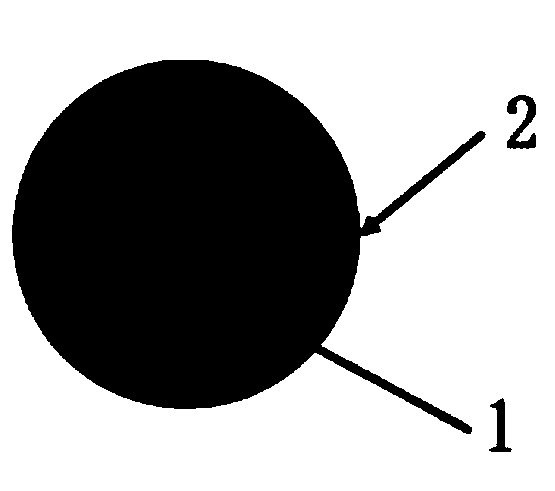

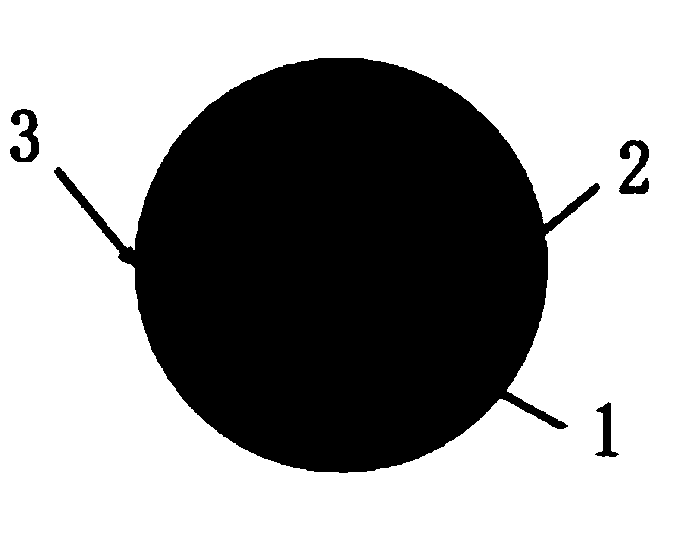

Preparation method of monocrystalline high-heat-conductivity uranium dioxide nuclear fuel core block

InactiveCN109671511AImprove thermal conductivityImprove securityNuclear energy generationReactors manufactureEconomic benefitsNetwork structure

The invention discloses a preparation method of a monocrystal high-heat-conductivity uranium dioxide nuclear fuel core block. The preparation method comprises the following steps: mixing and wrappinga monocrystal growth aid and a heat conductivity enhancing phase with UO2 particles, carrying out the high-temperature sintering in an active atmosphere, liquedifying the monocrystal growth aid, mutually diffusing the liquefied monocrystal growth aid and UO2 to form UO2 monocrystals, continuously distributing the heat conductivity enhancing phase on the periphery of each monocrystal UO2 particle,and forming the monocrystal high-heat-conductivity UO2 fuel core block with an inter-penetrating network structure with the monocrystal UO2 particles. The heat conductivity of the fuel core block is greatly improved, so that the operation safety of a reactor can be apparently improved, and the economic benefit of a nuclear station can be increased.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Preparation method of beryllium oxide modified uranium dioxide nuclear fuel

ActiveCN107221359AImprove high temperatureImprove stabilityNuclear energy generationReactor fuel susbtancesNetwork structureBeryllium oxide

The invention discloses a preparation method of a beryllium oxide modified uranium dioxide nuclear fuel. The preparation method comprises the following steps: extremely uniformly coating the surfaces of UO2 particles with BeO micro-powder through a spheroidizing and cladding technology, shaping the coated UO2 particles to make BeO extremely uniformly dispersed in a UO2 matrix, and carrying out high temperature sintering for a long time to locally melt the BeO in UO2 particle gaps and realize intercommunication in order to form a three-dimensional network structure and finally obtain the BeO modified UO2 nuclear fuel containing uniform distributed BeO and having a BeO and UO2 matrix formed interpenetrating network structure. The BeO enhancement phase of the three-dimensional network structure provides a rapid channel for heat conduction, so the heat conductivity of a BeO / UO2 composite core is maximally improved; and the UO2 matrix and the BeO of the three-dimensional network structure are interlaced, and can well support and constrain the BeO enhancement phase in a high temperature radiation environment, so the high temperature stability and the radiation resistance of the core are well guaranteed.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS +1

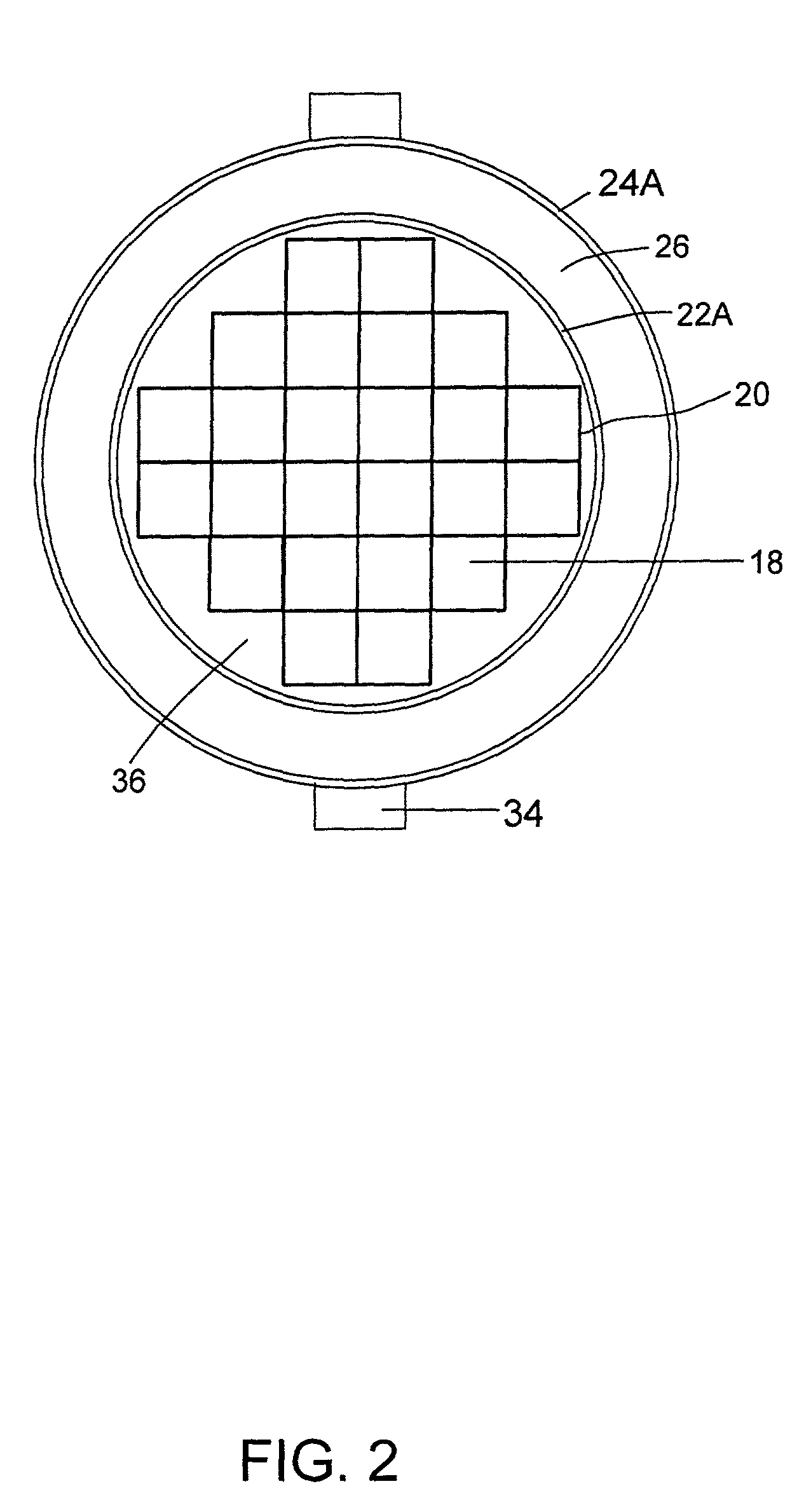

Two step dry UO2 production process utilizing a positive sealing valve means between steps

ActiveUS7824640B1Inhibition amountHigh densityTransuranic element compoundsNuclear energy generationTemperature controlNuclear grade

The present invention provides a two-step process for producing nuclear grade, active uranium dioxide (UO2) powder in which the first step comprises reacting uranium hexafluoride (UF6) with steam in a flame reactor to yield uranyl fluoride (UO2F2); and the second step comprises removing fluoride and reducing UO2F2 to uranium dioxide (UO2) in a kiln under a steam / hydrogen atmosphere. The two-step process, each step separated by a positive sealed valve means to prevent gas, particularly H2 flow back, tightly controls the exothermicity of the reaction, which allows for a very tight temperature control which controls the growth of the particles and results in UO2 powder that is active and of consistent morphology.

Owner:WESTINGHOUSE ELECTRIC CORP

Rapid preparation method of beryllium oxide-enhanced uranium dioxide nuclear fuel

ActiveCN107274936ALow densityReduce intensityNuclear energy generationReactor fuel susbtancesBeryllium oxideCore shell

The invention discloses a rapid preparation method of beryllium oxide-enhanced uranium dioxide nuclear fuel. The preparation method comprises preparing BeO-coated UO2(UO2 / BeO) core-shell structure particles through SPS low-temperature rapid pre-sintering granulation, spheroidization and coating processes, and carrying out SPS rapid sintering on the core-shell structure particles to obtain a UO2 / BeO composite nuclear fuel pellet. The preparation method is fast and efficient. The beryllium oxide-enhanced uranium dioxide nuclear fuel can solve the problem that the existing UO2 fuel pellet has low thermal conductivity.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS +1

Nanometer uranium dioxide and preparation method of composite material powder thereof

ActiveCN108298587ALow priceSimple manufacturing methodMaterial nanotechnologyNuclear energy generationNuclear powerCarbon nanotube

The invention discloses nanometer UO2 used for the preparation of a novel nuclear fuel pellet and a preparation method of compound powder thereof. According to the nanometer UO2 and compound powder thereof (including but not limited to nanometer UO2 powder, nanometer UO2 / SiC, nanometer UO2 / carbon nanotubes, nanometer UO2 / graphene, nanometer UO2 / nanometer diamond composite material powder) preparedand obtained by adopting a hydrothermal method or a precipitation method, the prepared and obtained powder can serve as a raw material for preparing the novel nuclear fuel pellet in a nuclear power station, and has the characteristics of high melting point, high heat conduction, good anti-radiation performance, high fission gas accommodating capacity and excellent mechanical property.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Method of preparing ceramic grade uranium dioxide ball

The invention discloses a method of preparing a ceramic grade uranium dioxide ball. The method sequentially comprises the following steps: carrying out ball milling on uranium oxide, wherein the particle size of the uranium oxide after ball milling is 0.1-0.3 micron; adding the uranium oxide into a polymer monomer, and uniformly stirring to obtain polymer slurry; producing slurry drops by virtue of the polymer slurry; adding the slurry drops into a dispersion column which contains heated carbon tetrachloride or liquid paraffin, and descending the slurry drops to obtain a green body ball in the dispersion column under the surface tension, wherein the temperature in the dispersion column is 80-90 DEG C; washing the green body ball by adopting an ethanol solution; drying the green body ball, and removing an organic matter on the surface of the green body ball to obtain a dry calcined ball; and carrying out reduction sintering on the dry calcined ball in a hydrogen atmosphere to obtain the ceramic grade UO2 ball. The method is simple in whole process, convenient in realization, small in introduced impurities, high in purity of the prepared UO2 ball and beneficial to popularizing and applying the UO2 ball in the field of nuclear technology.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Two step uo2 production process

This present invention provides a two-step process for producing nuclear grade, active uranium dioxide (UO2)powder in which the first step comprises reacting uranium hexafluoride (UF6) with steam in, for example, an integrated dry route (IDR)-type kiln or a flame reactor to yield uranyl fluoride (UO2F2); and the second step comprises removing fluoride and reducing UO2F2 to uranium dioxide (UO2) in a second kiln under a steam / hydrogen atmosphere. The two-step process tightly controls the exothermicity of the reaction, which allows for a very tight temperature control which controls the growth of the particles and results in UO2 powder that is active.

Owner:WESTINGHOUSE ELECTRIC CORP

Method for removing and recovering uranium in water and achieving synchronous electricity generation by utilizing microbial fuel cell

ActiveCN109942076AReduce consumptionCan be reused for a long timeSeawater treatmentBiochemical fuel cellsClean energySeawater

The method discloses a method for removing and recovering uranium in water and achieving synchronous electricity generation by utilizing a microbial fuel cell. The method comprises the steps that an array electrode of a ti-based titanium dioxide nanotube is taken as a negative electrode, a carbon material where microorganisms grow is taken as a positive electrode, hexavalent uranyl ions can obtainthe characteristic that electrons are subjected to reduction to obtain uranium dioxide, and the uranium dioxide is deposited on the surfaces of the electrodes, and the characteristic is utilized formaking hexavalent uranium subjected to reduction to obtain uranium dioxide gathering on the surfaces of the electrodes. After microbial electrochemical reduction and gathering are completed, the electrodes with enrichment of the uranium dioxide are taken from a solution, and efficient reduction removal of the uranium in waste water, underground water and seawater can be achieved. In the process ofreduction removal, chemical energy contained in organic matter in a positive electrode chamber and water containing the uranium in a negative electrode chamber can be converted into electric energy,and clean energy production is achieved. The method is wide in application range and can achieve efficient removal and recovery of the uranium in the waste water containing the uranium of different concentrations and carbonate of different concentrations, the underground water and the seawater and synchronous electricity generation.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Method for the Production of Nuclear Fuel Pellets

InactiveUS20070284766A1Easy to manufactureEasy to operateNuclear energy generationReactors manufactureUranium hexafluorideUranium dioxide

A process for manufacturing nuclear fuel pellets through sintering of a material containing uranium dioxide obtained from a powder from a power originating from a process for a conversion of uranium hexafluoride.

Owner:AREVA NP SAS

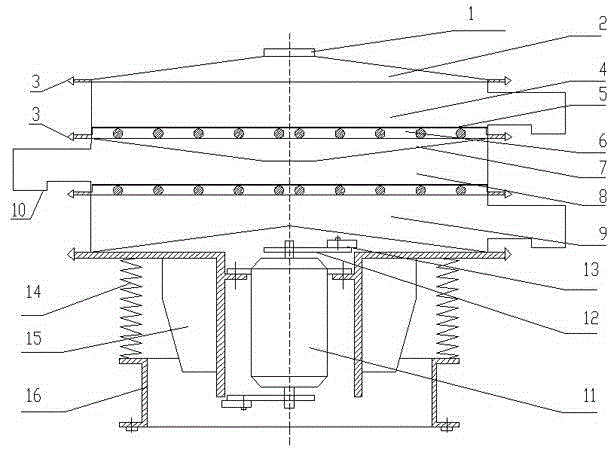

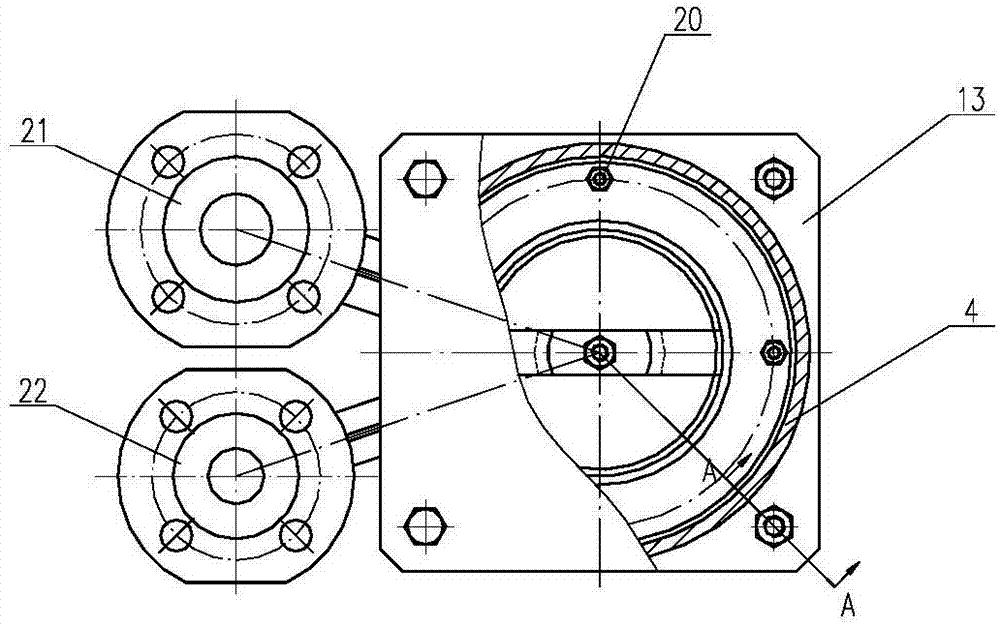

Rotary-vibrating and sieving device of nuclear fuel UO2 microspheres

ActiveCN104550013ASolve the problem of build-up on the screen surfaceIncrease productivitySievingScreeningMicrosphereEngineering

The invention discloses a rotary-vibrating and sieving device of nuclear fuel UO2 (uranium dioxide) microspheres. The rotary-vibrating and sieving device comprises a substrate on which an oscillating body is installed, wherein a lower sieve frame, a middle sieve frame and an upper sieve frame are respectively provided with a discharge hole; the outside of the oscillating body is provided with a spring connected with the substrate and the bottom of the lower sieve frame, an electrical rotating machine is installed in the oscillating body, and two output shafts of the electrical rotating machine are respectively provided with an oscillating arm on which an arc counterweight block is arranged. When the arc counterweight block is applied to the rotary-vibrating and sieving device and the same as the square counterweight block, amplitude and oscillation intensity are obviously promoted according to actual measurement, and spiral motion lines can be generated on the sieve by the materials, thus the problem that the materials are accumulated on the sieve is solved, the output rate of the single machine is greatly improved about 1.5kg / hour and by 5 times.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Preparation method of large-grained UO2 (uranium dioxide) fuel pellets with high heat conductivity

ActiveCN107871540AImprove high temperature stabilityImprove thermal conductivityNuclear energy generationReactor fuel susbtancesNetwork structureTemperature resistance

The invention discloses a preparation method of large-grained UO2 (uranium dioxide) fuel pellets with high heat conductivity. The surfaces of UO2-grain growth promoter compound spheres with good sphericity are uniformly coated with heat conductivity enhanced phase powder, coated particles are obtained and subjected to forming and sintering in a high-temperature atmosphere, so that UO2 grains growunder the action of the grain growth promoter, meanwhile, the heat conductivity enhanced phase coating the surfaces of the UO2 particles is intercommunicated after being liquefied at the high temperature, a three-dimensional network structure is formed, and the enhanced phase and a UO2 matrix form special UO2 fuel pellets with the three-dimensional network structure. The enhanced UO2 fuel palletsprepared with the method have the heat conductivity remarkably superior to that of pure UO2, besides, the size of UO2 grains is notably larger than that of conventional UO2 pellets, the high-temperature resistance and the irradiation stability are excellent, and the safety level of a reactor and a fuel system can be remarkably improved.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Preparation method of high-safety uranium dioxide nuclear fuel core block

ActiveCN108218456AImprove high temperatureImprove stabilityNuclear energy generationReactors manufactureCore shellGrain growth

The invention discloses a preparation method of a high-safety uranium dioxide nuclear fuel core block. The preparation method comprises the following steps: physically mixing crystallite grain growthauxiliaries, a reinforced phase and uranium dioxide particles, coating the surfaces of the uranium dioxide particles with the crystallite grain growth auxiliaries and the reinforced phase to obtain particles with core-shell structures; sintering the particles with the core-shell structures at a high temperature under micro-oxidation atmosphere, spreading the crystallite grain growth auxiliaries into the uranium dioxide particles and gaps among the particles, dissolving the uranium dioxide particles in the crystallite grain growth auxiliaries, crystallizing and growing, and forming a continuousthree-dimensional net-shaped structure, and dispersing and distributing the reinforcing phase into the crystallite grain growth auxiliaries, thereby obtaining the high-safety uranium dioxide nuclearfuel core block. Dimensions of the uranium dioxide particles are increased through the crystallite grain growth auxiliaries, so that the crystal boundary is reduced, and heat conductivity and stability of the UO2 fuel core block are greatly improved by cooperating with dispersive distribution of the reinforced phase, and therefore, operation economical efficiency and safety level of a reactor anda fuel system are remarkably improved.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

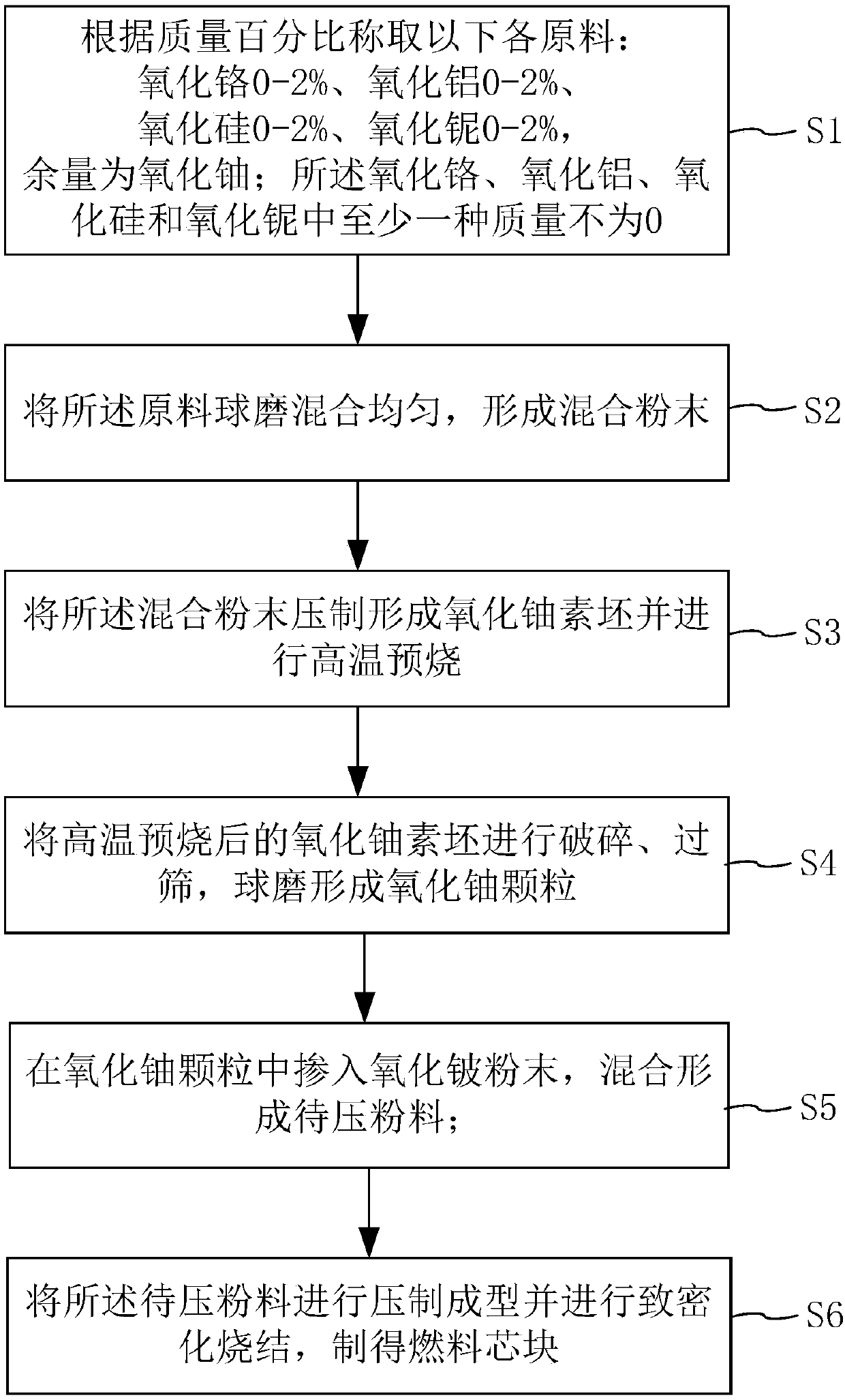

A fuel pellet and a manufacturing method thereof

InactiveCN108039210AReduce spreadDoes not affect thermal conductivityNuclear energy generationReactors manufactureChromium trioxideCompression molding

A fuel pellet and a manufacturing method thereof are disclosed. The method includes S1) weighing raw materials including 0-2% of chromium trioxide, 0-2% of alumina, 0-2% of silicon oxide and 0-2% of niobium pentoxide, with the balance being uranium dioxide; S2) ball milling and fully mixing the raw materials to form a powder mixture; S3) compressing the powder mixture to form a uranium dioxide blank, and subjecting the blank to high-temperature pre-sintering; S4) crushing the blank, sieving the crushed blank, and grinding the crushed blank into uranium dioxide particles; S5) adding beryllium oxide powder into the uranium dioxide particles, mixing the mixture to form powder to be compressed, with each uranium dioxide particle being covered with a cover layer formed from the beryllium oxidepowder; and S6) subjecting the powder to be compressed to compression molding and densification sintering to obtain the fuel pellet. A manner of two times of compound addition and two times of sintering is adopted, and therefore sintering aids form solid solution or are distributed in the uranium dioxide matrix, diffusion or solid solution formation of the sintering aids into the beryllium oxide is reduced, and on the premise that the sintering aids do not influence heat conductivity of the BeO phase, the pellet crystal grain size is effectively increased, and sintering activity is improved.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +2

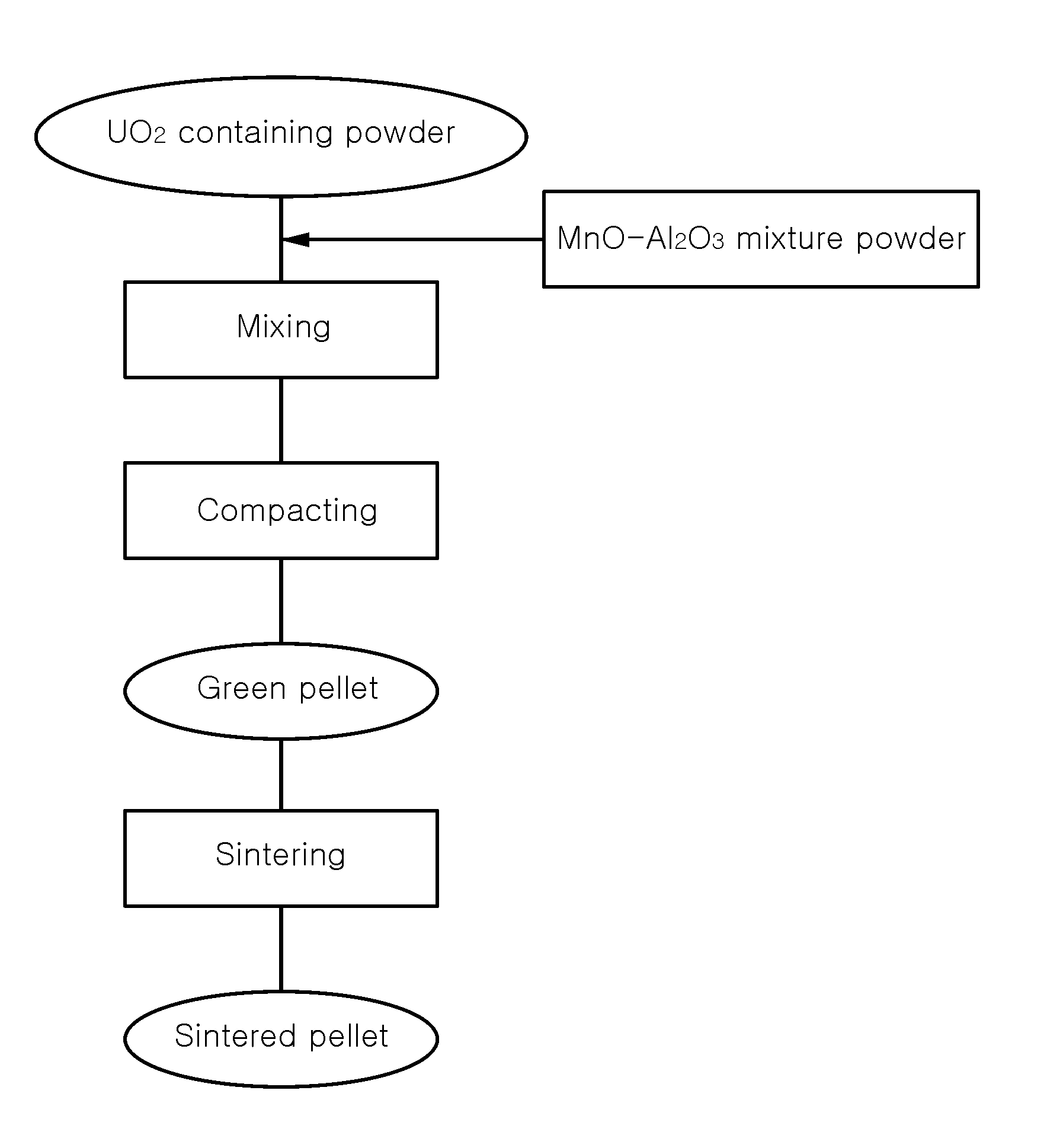

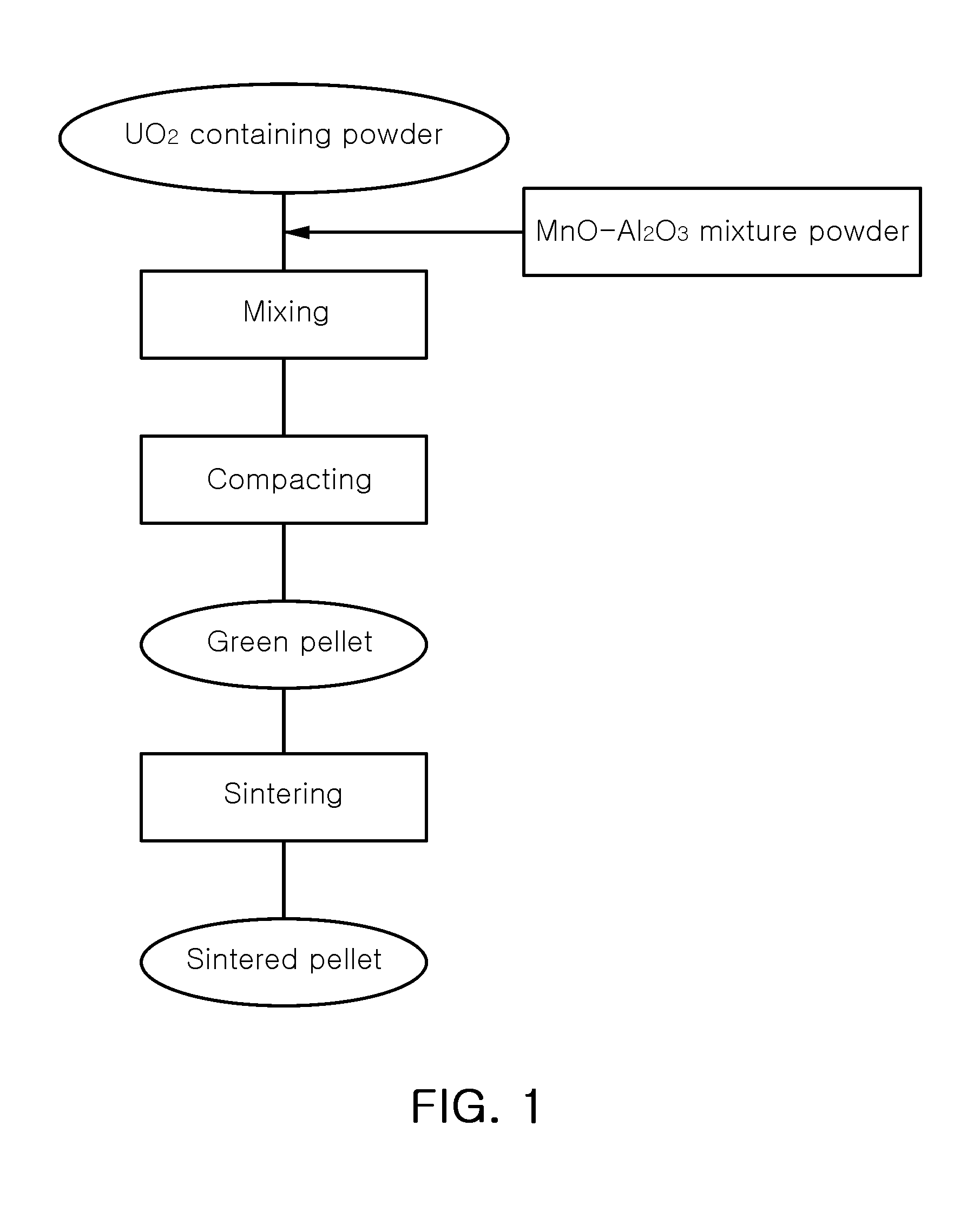

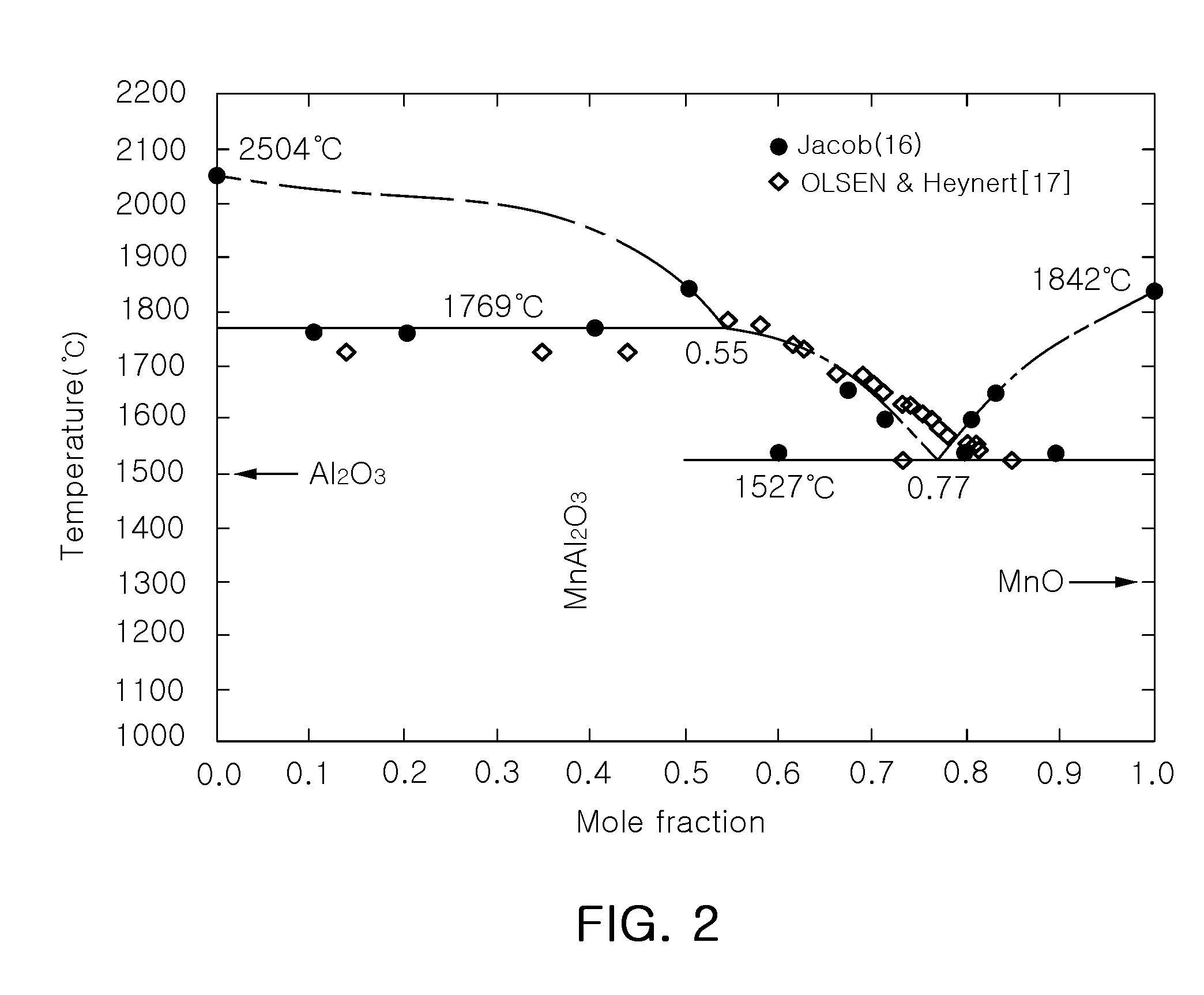

Uranium Dioxide Nuclear Fuel Containing Mn and Al as Additives and Method of Fabricating the Same

ActiveUS20130240805A1Large grainFast creep deformation rateFuel elementsNuclear energy generationUranium dioxideMaterials science

UO2 nuclear fuel pellets are fabricated by adding additive powder comprising Mn compound and Al compound into UO2 powder.

Owner:KOREA ATOMIC ENERGY RES INST +1

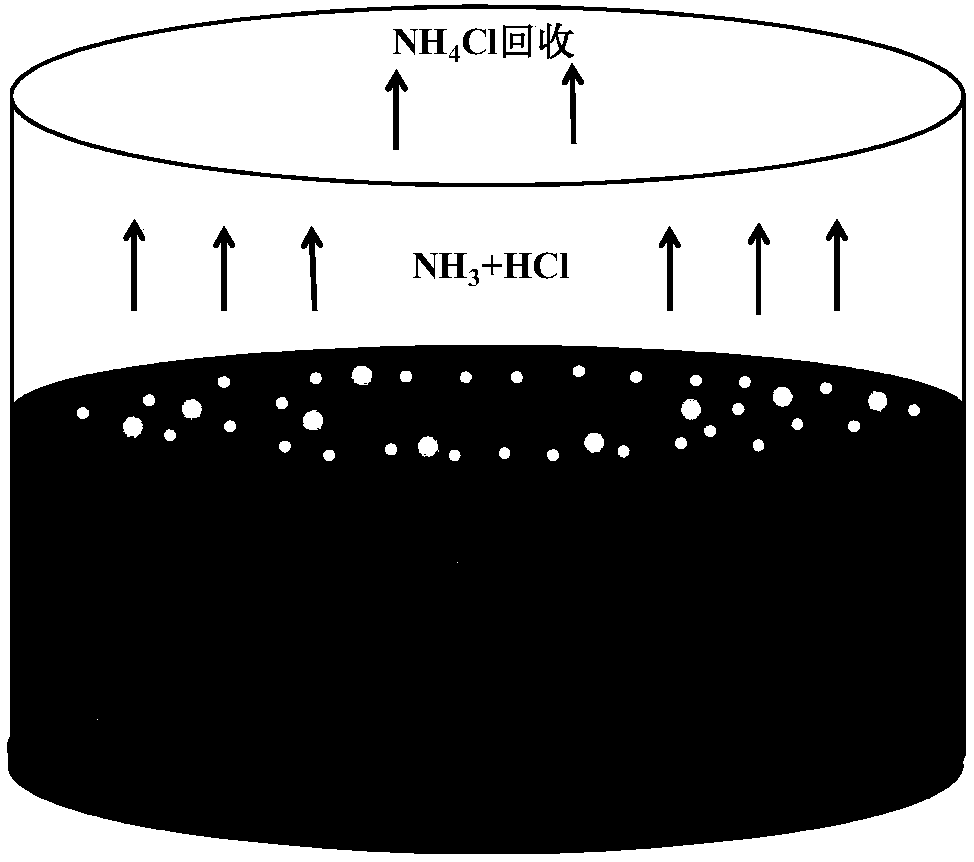

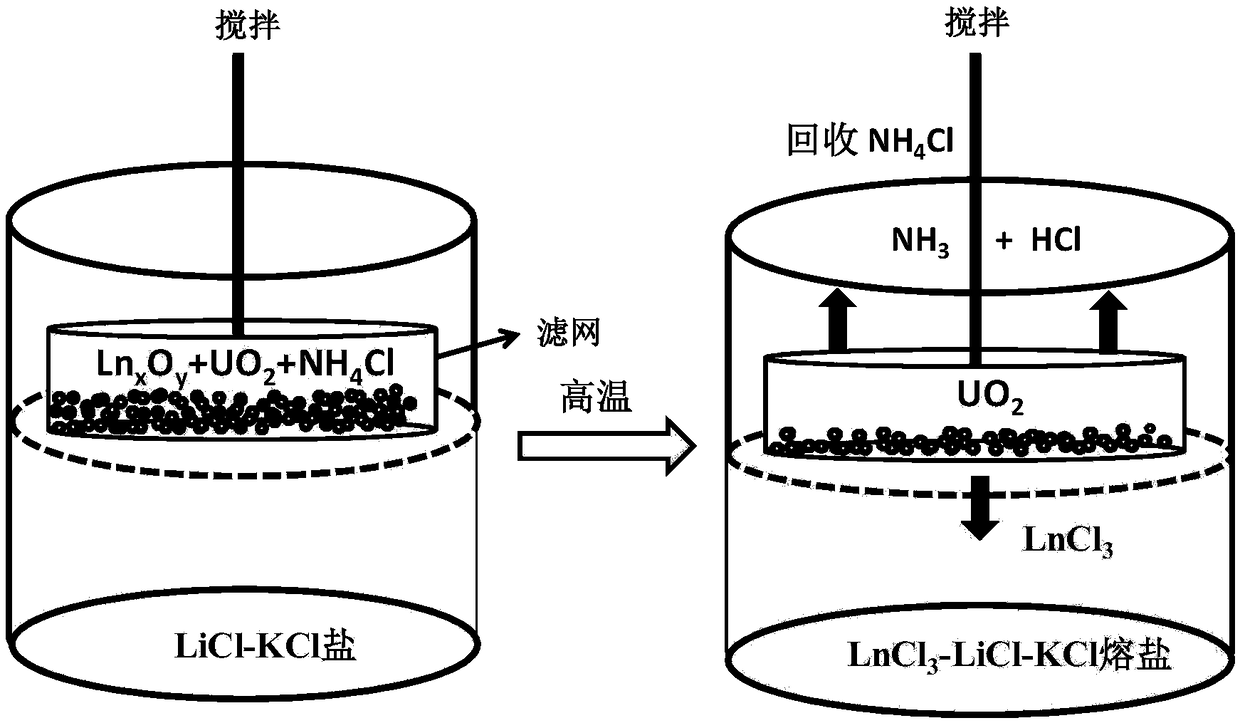

Application of ammonium chloride for separating uranium dioxide and lanthanide oxide

ActiveCN108364703ASolving insoluble puzzlesPracticalNuclear energy generationRecycling and recovery technologiesLanthanideMolten salt

The invention provides an application of ammonium chloride for separating uranium dioxide and lanthanide oxide, and provides a method for separating uranium dioxide and lanthanide oxide by using ammonium chloride. The method is characterized in that ammonium chloride is added in a reactant containing uranium dioxide and lanthanide oxide, the materials are contacted with chloride molten salt at thetemperature of 450-600 DEG C, the reactant and the chloride molten salt are controlled for isolating air, and the uranium dioxide and lanthanide oxide are separated. The application of the ammonium chloride in separation of dioxide solves the difficult dissolving problem of uranium dioxide in molten salt, and the reaction condition is controlled to separate the uranium dioxide and lanthanide oxide. The method can directly realize UO2 dissolution in a chloride molten salt system, and can be carried out in air during a dissolving process, other deposition is not formed, other impurity is not introduced, strongly corrosive gas is not employed, and a whole process has the advantages of simple operation, mild reaction condition, and strong practicality.

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACADEMY OF SCI

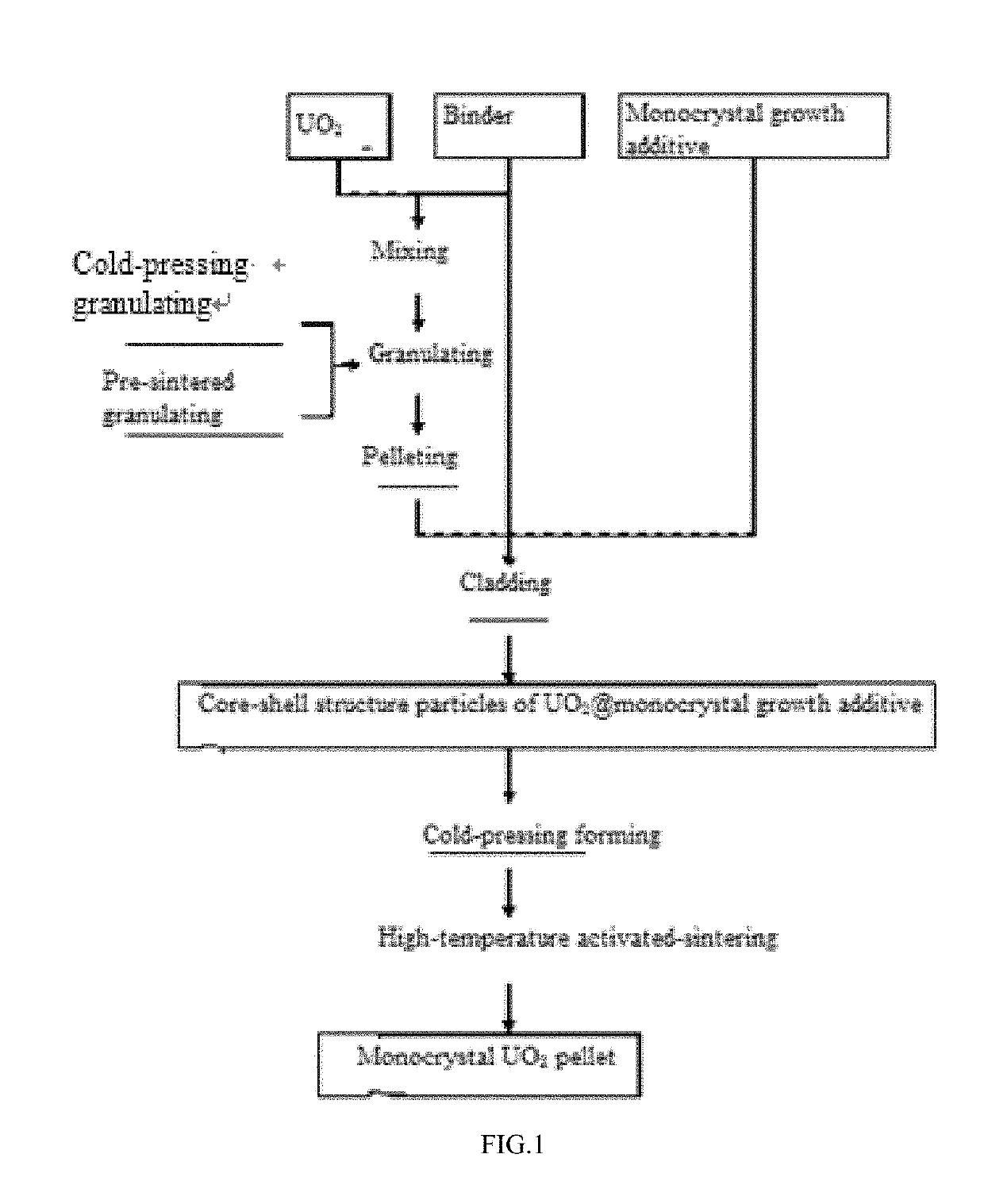

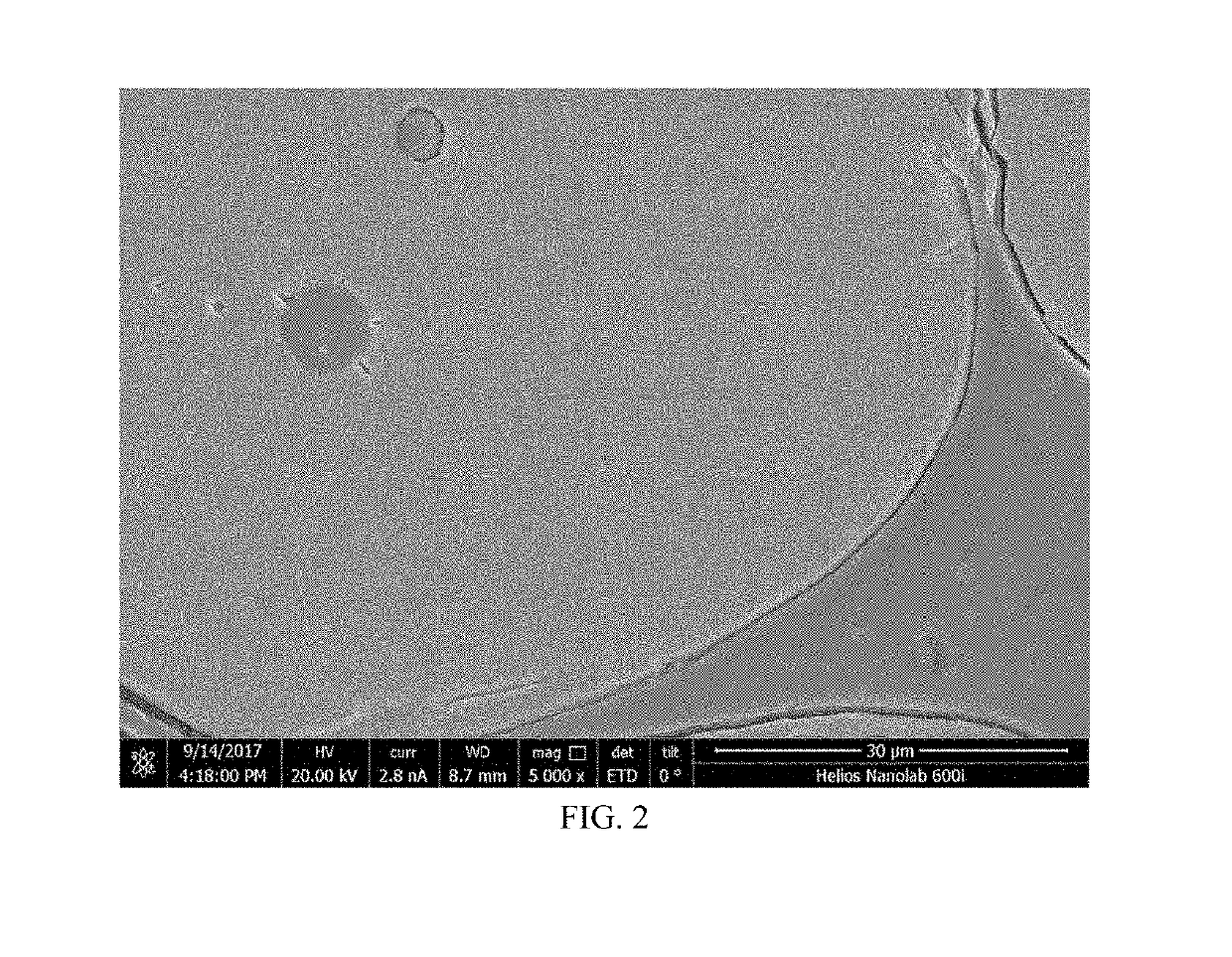

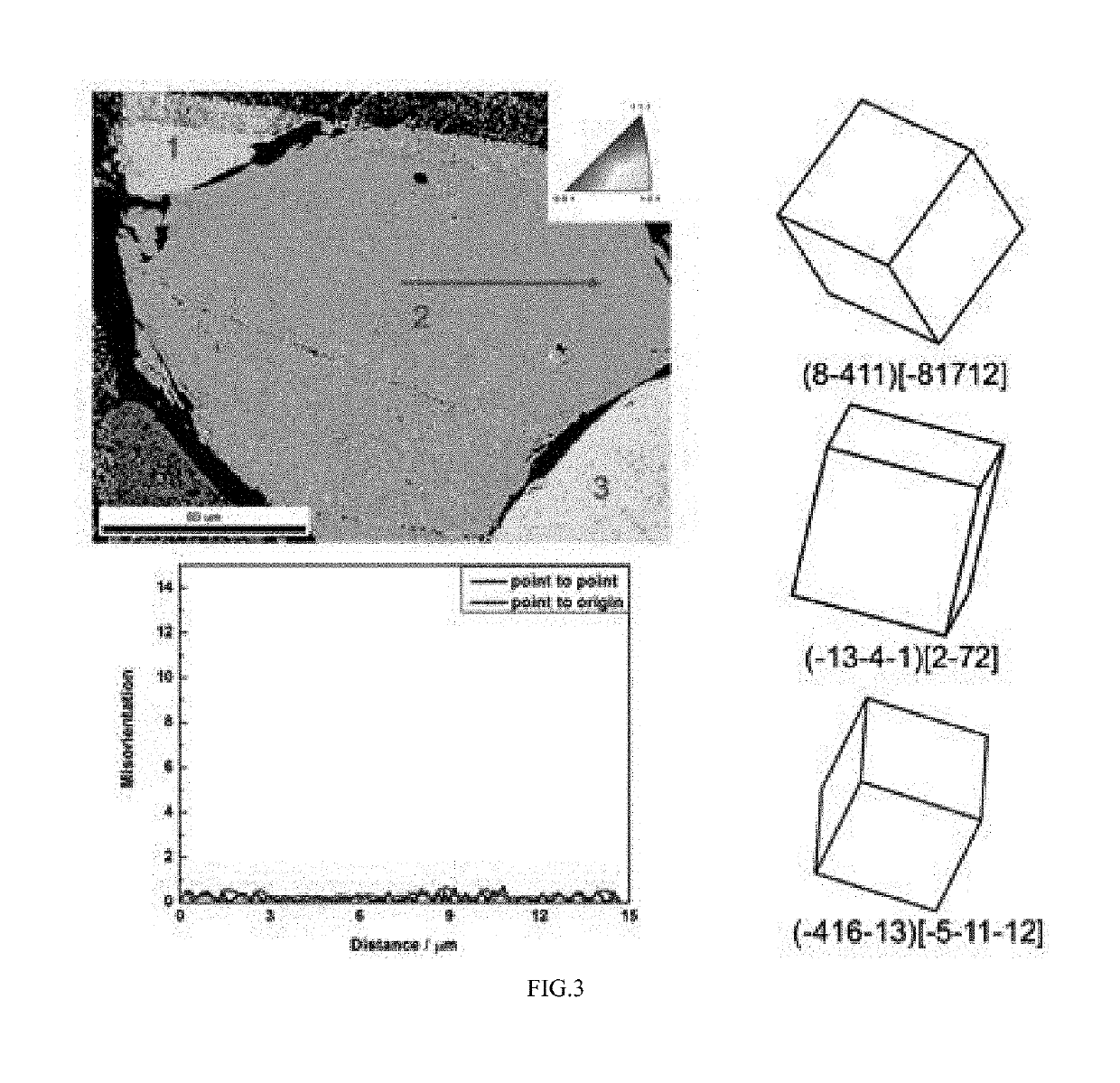

Preparation method of monocrystal uranium dioxide nuclear fuel pellets

ActiveUS20190127876A1Quick upgradeShort timeAfter-treatment apparatusPolycrystalline material growthSingle crystalCore shell

The application discloses a preparation method of monocrystal uranium dioxide nuclear fuel pellets, comprising: granulating and pelleting UO2 powder to obtain UO2 pellets; then coating surfaces of the UO2 pellets with monocrystal growth additive micro powder to form core-shell structure particles; and activated-sintering the core-shell structure particles at high temperature, liquefying the monocrystal growth additive on the surface of the core-shell structure particle at high temperature and then diffusing into UO2 pellets, dissolving the UO3 in the liquid monocrystal growth additive, and recrystallizing the UO2 to form the monocrystal UO2 nuclear fuel pellets.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS +1

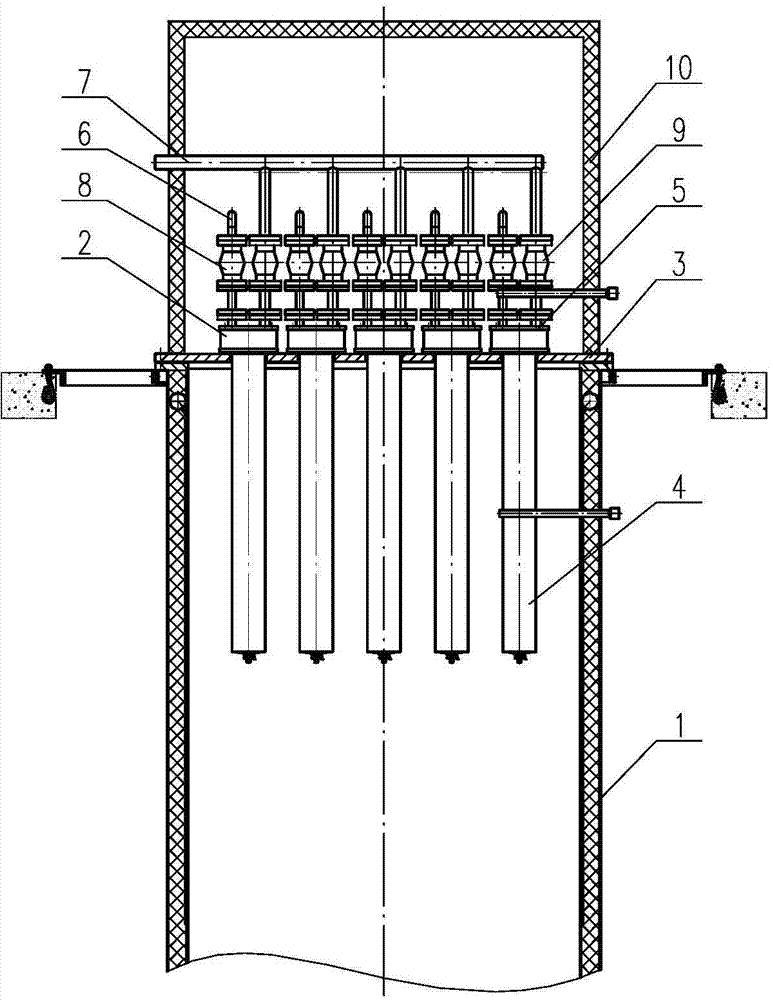

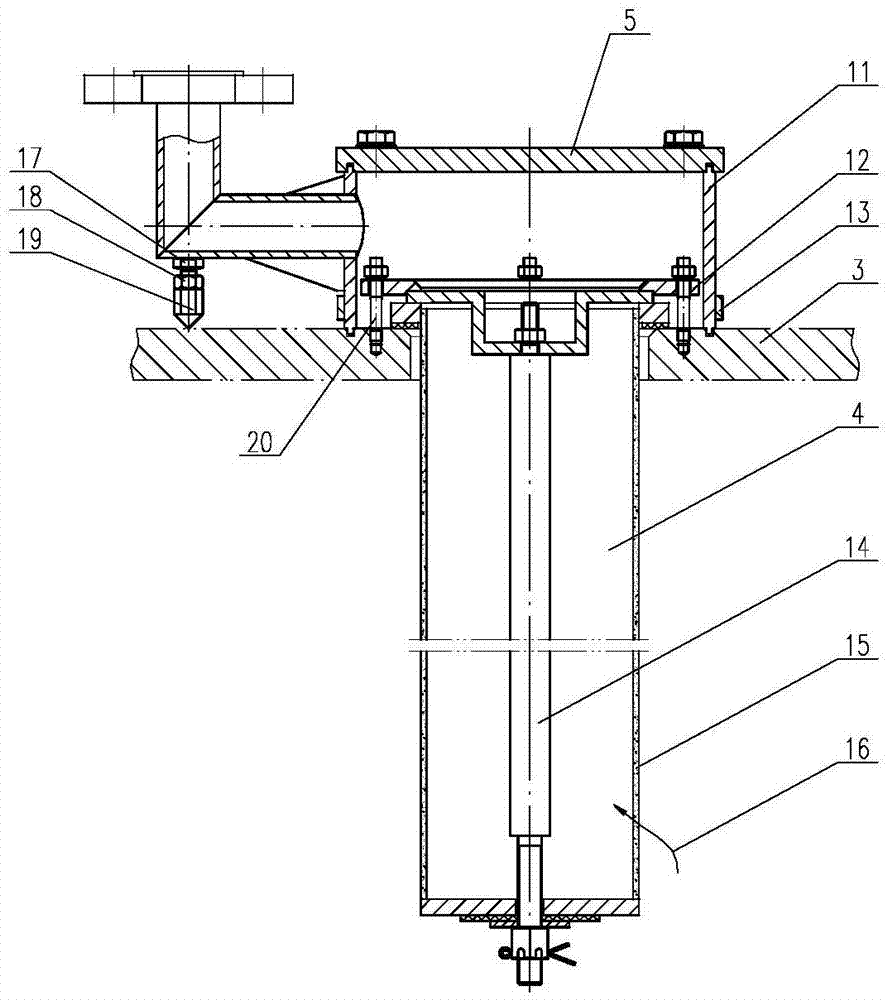

Uranium dioxide core aging tank, and system and method for aging, cleaning and drying

ActiveCN103366846ASolve health problemsSolve environmental problemsNuclear energy generationReactors manufactureEngineeringUranium dioxide

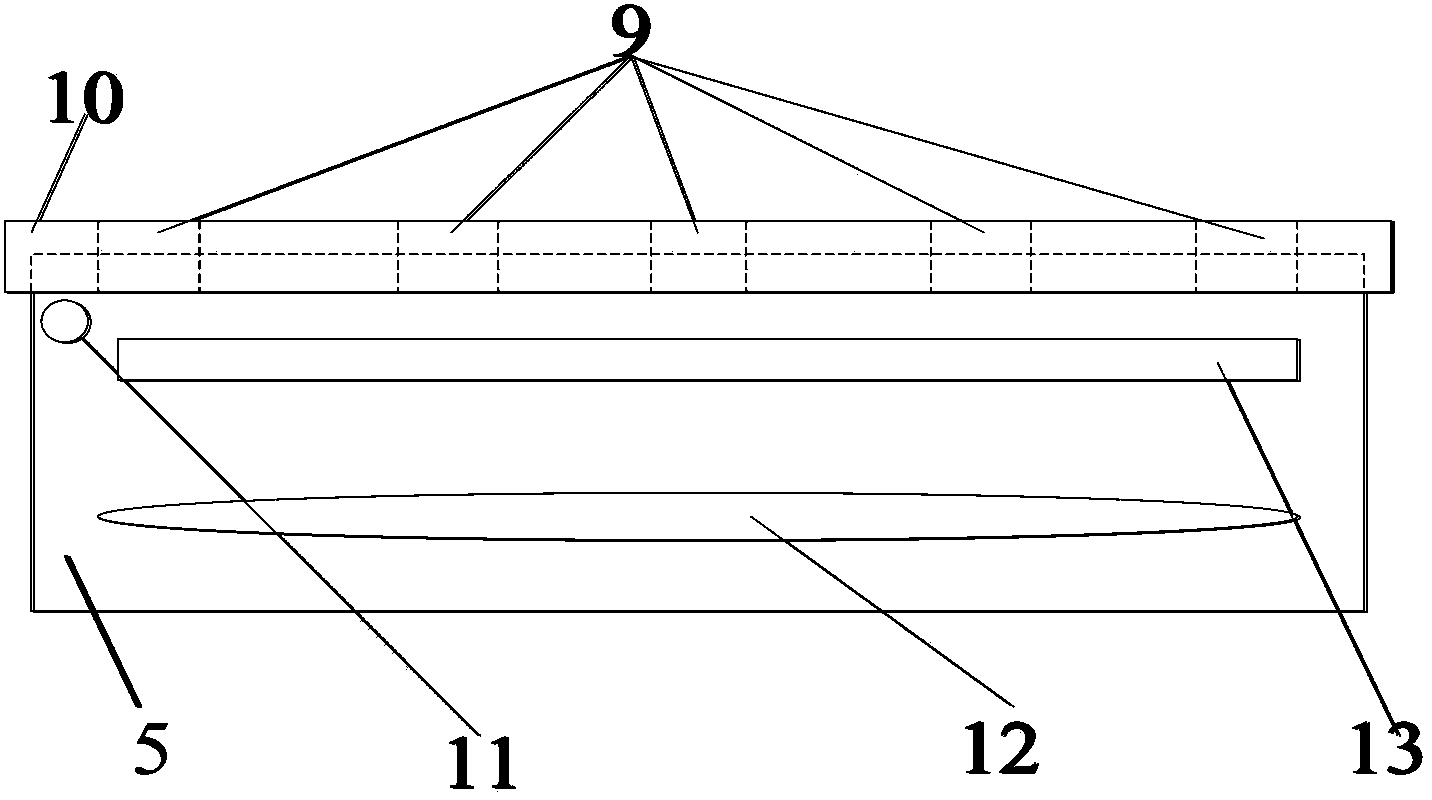

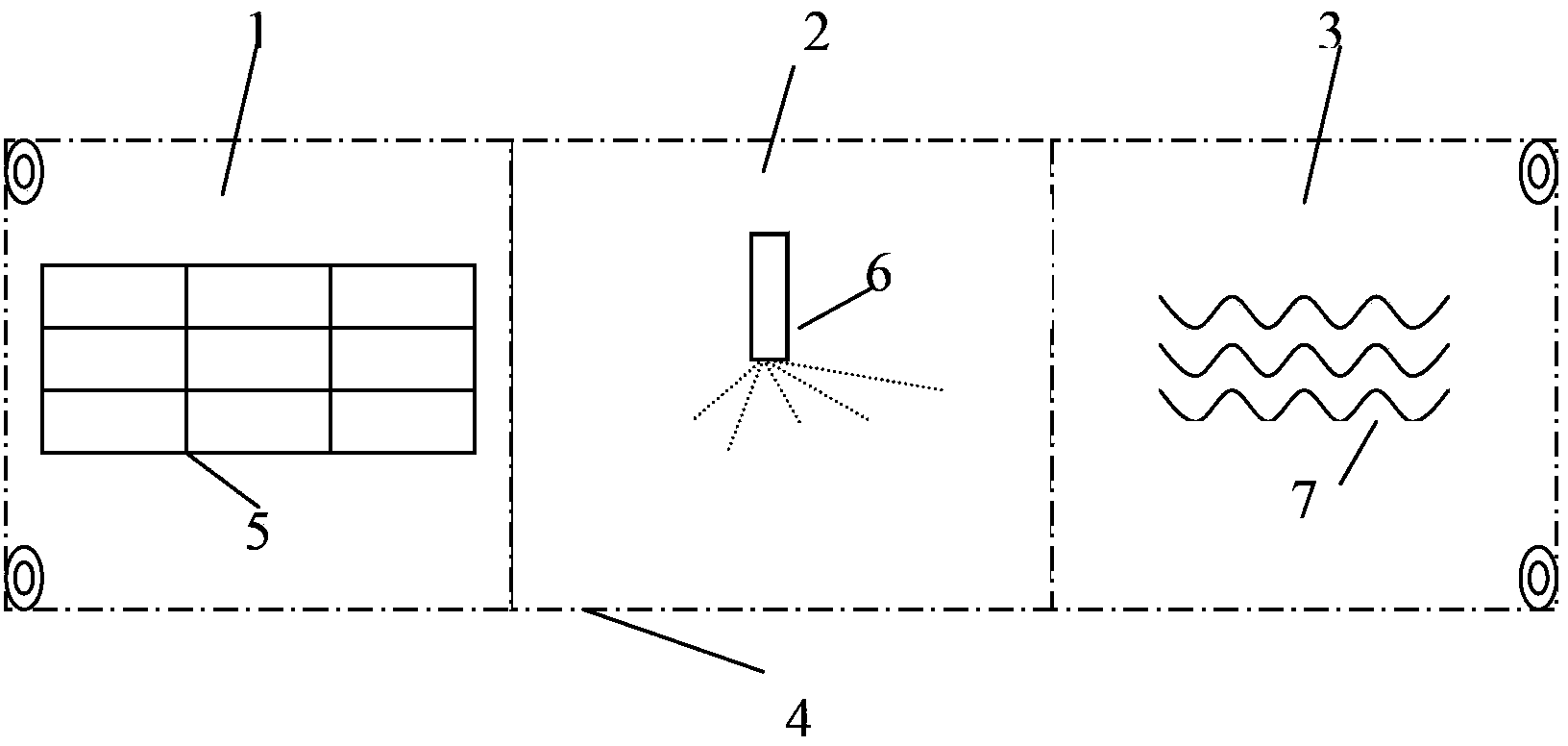

The invention discloses a uranium dioxide core aging tank. The aging tank is a cylindrical object with an opening on the surface, and the opening is sealed by a sealing cover; the surface of the aging tank is provided with a gas outlet, spray interfaces and heating device interfaces; the aging tank is provided with a vibration and / or stirring device. The invention discloses a system for aging, cleaning and drying uranium dioxide cores. The system includes aging tank modules each composed of the uranium dioxide core aging tank, an aging region module, a cleaning region module, a drying region module and a conveying module. At the same time, the invention also discloses a method for aging, cleaning and drying the uranium dioxide cores. The method comprises the steps: standing for aging the uranium dioxide cores by using the aging region module, conveying the aging tank modules to the cleaning region module by using the conveying module, cleaning the uranium dioxide cores by using the cleaning region module, conveying the aging tank modules to the drying region module by using the conveying module, and drying the uranium dioxide cores in the aging tank modules by using the drying region module.

Owner:TSINGHUA UNIV

Preparation method of MAX-phase-imitating accident fault-tolerant nuclear fuel pellet

ActiveCN106927832ALow costImprove processing stabilityFuel elementsNuclear energy generationNuclear reactorIrradiation

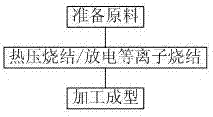

The invention discloses a preparation method of a MAX-phase-imitating accident fault-tolerant nuclear fuel (U3Si2C2) pellet. U3Si2C2 is obtained by carrying out reactive sintering on uranium dioxide, a silicon-containing phase, carbon powder, a bonding agent and a sintering aid at a high temperature. Compared with U3Si2C2 prepared through traditional electric arc melting, U3Si2C2 prepared through the method has the advantages of low cost and good process stability. The nuclear fuel combines the excellent irradiation resistance, thermal conductance and oxidation resistance of the MAX phase and can be applied to traditional water reactors and a new generation of nuclear reactors.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Annular nuclear fuel pellets with discrete burnable absorber pins

An annular nuclear fuel pellet in combination with an inserted discrete neutron absorber. The pellet / absorber may be compatible with existing or future nuclear fuel assembly designs. The concept involves the use of nuclear fuel (e.g., uranium dioxide or uranium silicide) formed into annular fuel pellets which can then have a discrete absorber material inserted into the center of the pin. Preferably, the discrete absorber is a non-parasitic absorber. The resulting pellet / absorber can then be stacked into a fuel rod which is arranged in a nuclear fuel assembly. Dimensioning of the annular pellet and absorber and selection of the absorber material and density can allow the concept to be tailored for various nuclear fuel applications.

Owner:WESTINGHOUSE ELECTRIC CORP

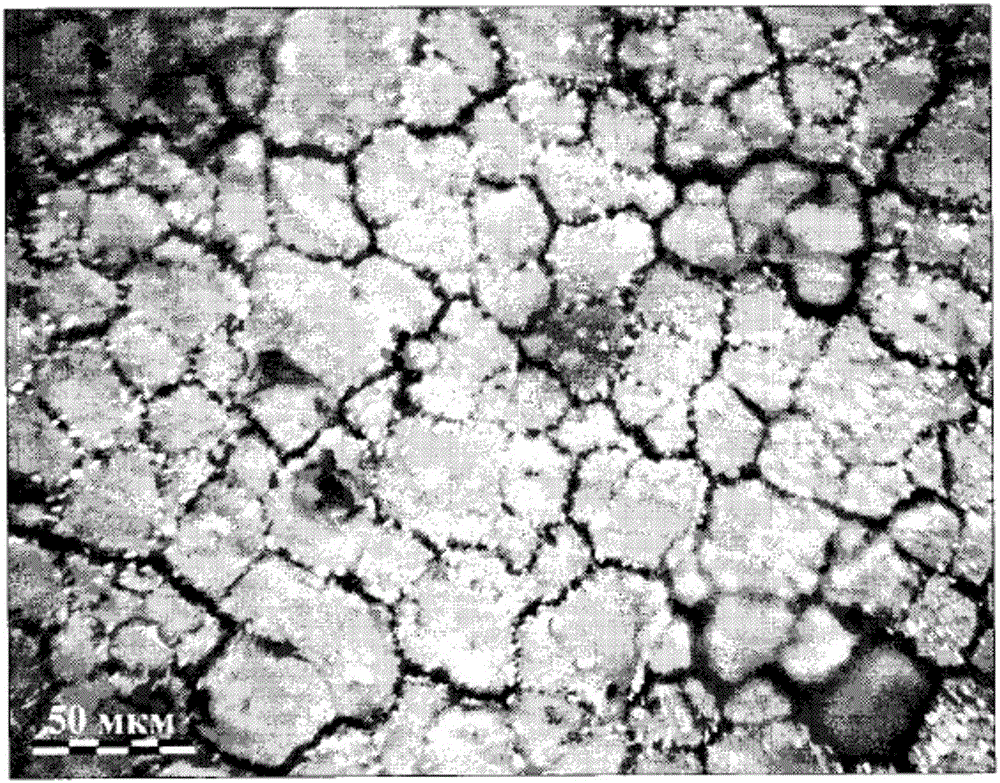

Nuclear fuel pellet having enhanced thermal conductivity, and preparation method thereof

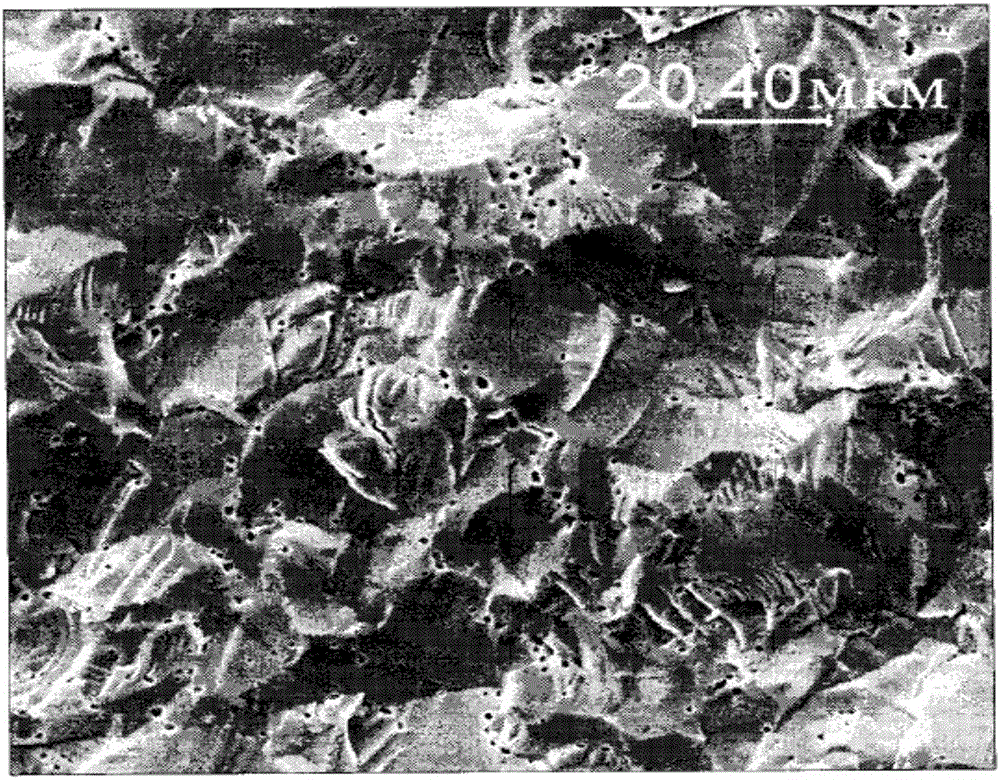

ActiveCN105706177AEasy to prepareLow costNuclear energy generationReactors manufactureMicro structureMaterials science

The invention relates to nuclear physics, and specifically to reactor fuel elements and units thereof, and particularly to the composition of solid ceramic fuel elements based on uranium dioxide, intended for and exhibiting characteristics for being used in variously-purposed nuclear reactors. The result consists in a more reliable, special structure and a simple composition of uranium dioxide without heterogeneous fuel pellet additives, approaching the characteristics of a monocrystal having enhanced, and specifically exceeding reference data, thermal conductivity as temperature increases, and a simple production method thereof. The result is achieved in that pores of between 1 and 5 microns in size are distributed along the perimeters of grains in the micro-structure of each metal cluster in a nuclear fuel pellet, and in that located within the grains are pores which are predominantly nano-sized. In addition, the metal clusters comprise between 0.01 and 1.0 percent by mass. The invention provides for a method of preparing a nuclear fuel pellet, including precipitating metal hydroxides, in two stages, having different pH levels. Uranium metal is melted at a temperature exceeding 1150 DEG C, sintering is carried out in an insignificant amount of liquid phase at a temperature ranging between 1600 and 2200 DEG C in a hydrogen medium until forming uranium dioxide, the structure of which includes metal clusters dispersed therein. An X-ray photon spectroscope is used for identifying the new structure of the UO2 pellet and the additional U-U chemical bond.

Owner:JOINT CO AKME ENG

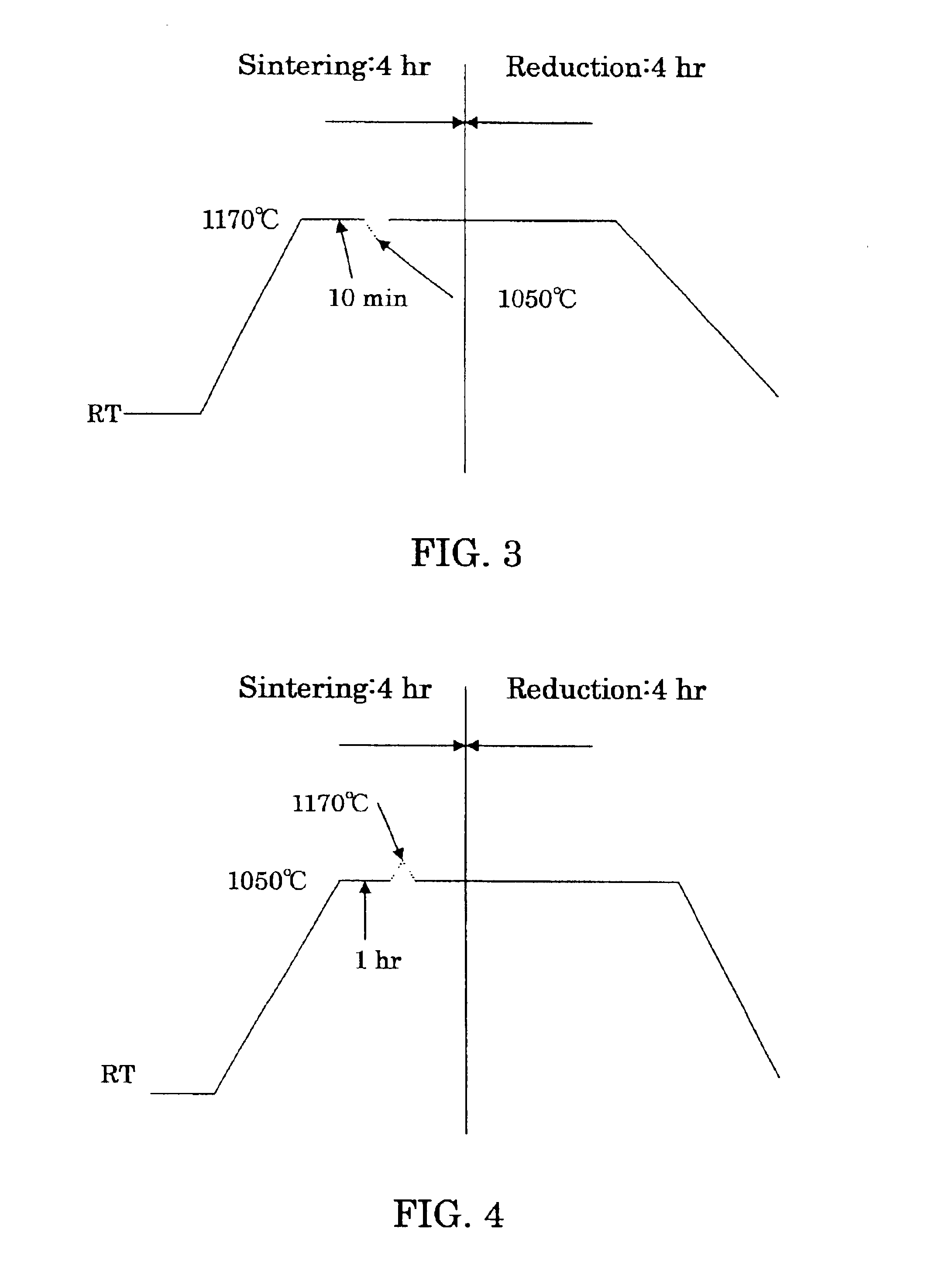

Method of fabricating sintered nuclear fuel compact

InactiveUS6878313B2Large particle sizeAppropriate useNuclear energy generationReactors manufacturePowder mixtureUranium oxide

To furnish stably a sintered nuclear fuel compact of uranium dioxide with a large grain diameter, a fabrication method therefor requires sintering a starting material at two stages in an oxidizing atmosphere and in a reducing atmosphere at relatively low temperatures. The starting material is either a powder mixture of uranium dioxide fresh material powder and triuranium octaoxide in a weight ratio of 75 / 25 ˜ 55 / 45 or pulverulent mixed uranium oxides yielding a final O / U ratio equal to that of the powder mixture. The sintering process in the oxidizing atmosphere involves at least one time period of a temperature rise to a higher temperature of 1200 to 1100° C. and at least one time period of a temperature drop to a lower temperature of up to 1080° C. A temperature difference between the higher and lower temperatures is preferred to be 50° C. or more.

Owner:NUCLEAR FUEL INDS

Revolving furnace tail gas filter device for manufacturing uranium dioxide from uranium hexafluoride

InactiveCN104707415AEffective decloggingAvoid breakingDispersed particle filtrationUranium dioxideUranyl fluorideProcess engineering

The invention belongs to a tail gas filter device, and in particular, relates to a revolving furnace tail gas filter device for manufacturing uranium dioxide from uranium hexafluoride. The device includes at least one tail gas filter unit; each tail gas filter unit includes a head and a filter tube; the filter tube of the tail gas filter unit is positioned inside a reaction chamber; the head of the tail gas filter unit is positioned at the outer side of the top end of the reaction chamber; the bottom end of the filter tube in the reaction chamber is sealed; the head is connected with a tail gas recovery tube, and moreover, the head is also connected with a reverse blowing connecting tube, and the other end of the reverse blowing connecting tube is connected with a reverse blowing pipeline. Adhesive uranyl fluoride UO2F2 particles can be separated from the outer wall of the filter tube, and blocking of the filter tube is effectively cleaned; through arrangement of a pull rod, root fracture of the filter pipe can be effectively avoided, and the service life of the filter tube is improved.

Owner:CHINA NUCLEAR POWER ENG CO LTD

Method for preparing a porous nuclear fuel based on at least one minor actinide

InactiveUS20120228788A1Easy to aimReduce porosityFuel elementsNuclear energy generationPowder mixtureUranium oxide

A method for manufacturing a porous fuel comprising uranium, optionally plutonium and at least one minor actinide is provided. The method may comprise the following successive steps: a) a step for compacting as pellets a mixture of powders comprising uranium oxide, optionally plutonium oxide and at least one oxide of a minor actinide, at least one portion of the uranium oxide being in the form of triuranium octaoxide U3O8, the other portion being in the form of uranium dioxide UO2; b) a step for reducing at least one portion of the triuranium octaoxide U3O8 into uranium dioxide UO2.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com