Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Does not affect thermal conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat-conducting flame-retardant room temperature vulcanized silicone rubber and preparation method thereof

InactiveCN104592763AImprove processing performanceImprove system compatibilityFire retardantHeat conducting

The invention discloses heat-conducting flame-retardant room temperature vulcanized silicone rubber. The silicone rubber consists of the following components in parts by weight: 100 parts of alpha, omega-triethoxy polydimethylsiloxane, 400-1500 parts of an inorganic heat conducting filler, 0.5-5 parts of a filler treating agent, 1-10 parts of titanium dioxide prepared by a vapor phase method, 0.5-15 parts of a cross-linking agent, 0.1-5 parts of a flame-retardant agent, 0-10 parts of a catalyst and 0-5 parts of a silane coupling agent. The silicone rubber and the preparation method use the alpha, omega-triethoxy polydimethylsiloxane so as to improve the processing property and the storing property of a composition system. Compared with the prior art, through the use of the silicone rubber and the preparation method, the compatibility, the storing property and the extrudability of the filler and the silicon rubber are improved, the flame retardance in a UL94-V0 level is realized, and the situation that because a large amount of the inorganic flame-retardant filler is used, the heat-conducting property of the system is influenced is avoided; silicon dioxide prepared by a vapor phase method is added, the thixotropy of the composition is regulated, and besides the heat-conducting property is not influenced; the silicone rubber has good system compatibility, a good regulable heat-conducting property and a good flame-retardant property and can be suitable for a glue point asking for a high heat dissipation property and a high flame-retardant property.

Owner:TONSAN ADHESIVES INC

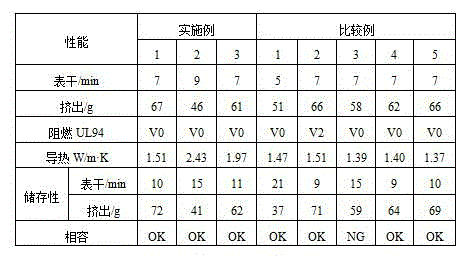

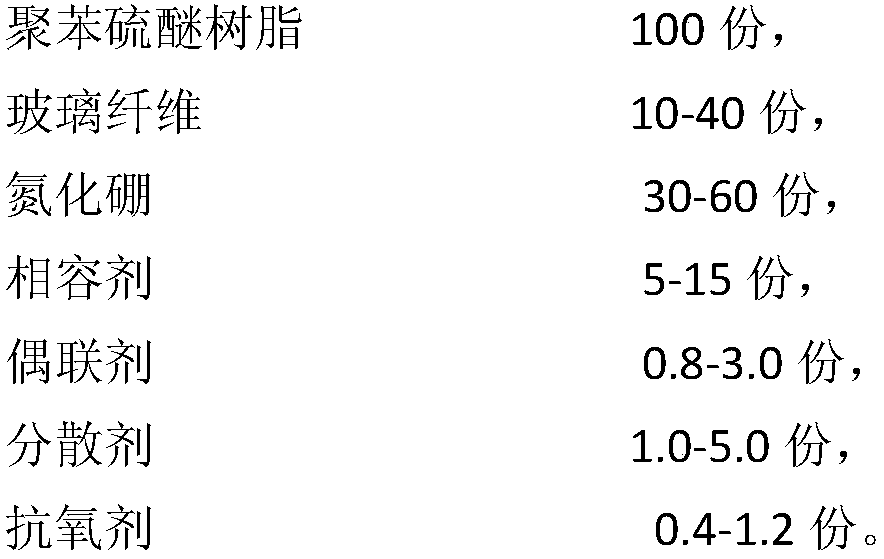

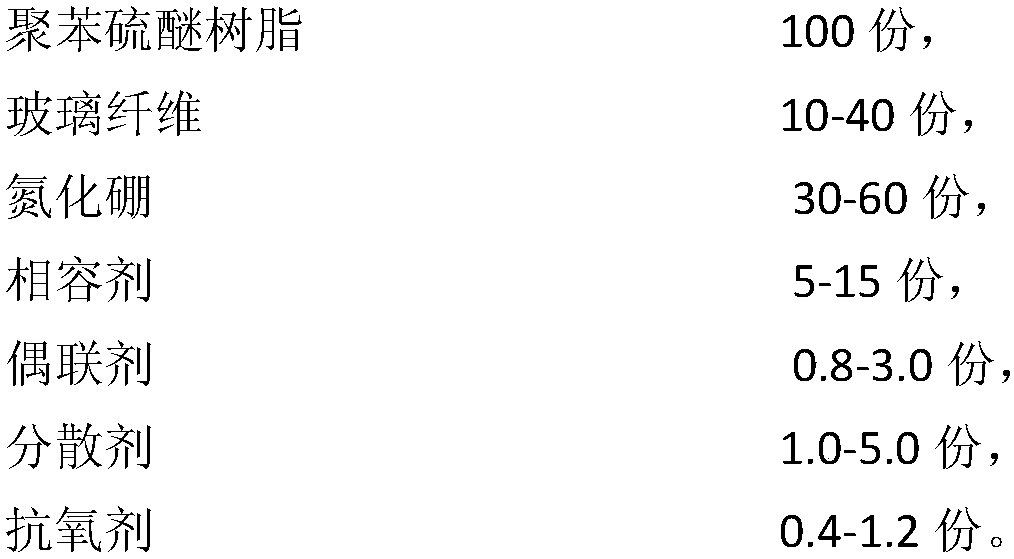

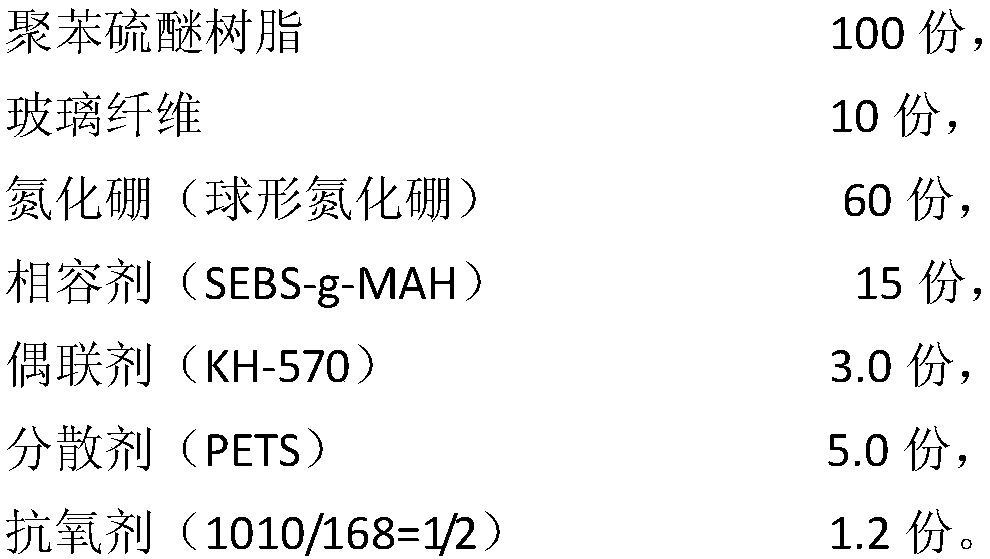

High-thermal-conductivity low-dielectric-loss polyphenylene sulfide composite and preparation method thereof

InactiveCN108165010AHigh thermal conductivityLow dielectric lossHeat-exchange elementsGlass fiberDielectric loss

The invention provides a high-thermal-conductivity low-dielectric-loss polyphenylene sulfide composite and a preparation method thereof. The composite comprises 100 parts of polyphenylene sulfide resin, 10 to 40 parts of glass fibers, 30 to 60 parts of boron nitride, 5 to 15 parts of a compatilizer, 0.8 to 3.0 parts of a coupling agent, 1.0 to 5.0 parts of a dispersant and 0.4 to 1.2 parts of an anti-oxidant. The preparation method comprises the following steps: mixing boron nitride with the coupling agent so as to obtain a first mixture, adding the dispersant into the first mixture and carrying out mixing so as to obtain a second mixture; and mixing the polyphenylene sulfide resin, the compatilizer and the anti-oxidant, adding the obtained mixture into a screw extruder from a main feed inlet, adding the second mixture into the screw extruder from a lateral feed inlet, adding the glass fibers into the screw extruder from a glass fiber feeding inlet, and carrying out extrusion granulation via the screw extruder so as to obtain the polyphenylene sulfide composite in the form of granules. The polyphenylene sulfide composite provided by the invention has the advantages of high heat conduction coefficient and low dielectric loss and is applicable to the field of electrocommunication.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Preparing method of large-size low-heat-conductivity-coefficient high-strength foam carbon

InactiveCN103910350ALow costLow thermal conductivityCarbon preparation/purificationThermal insulationAviation

The invention discloses a preparing method of large-size low-heat-conductivity-coefficient high-strength foam carbon. By adopting pitch with a high softening point as a raw material and adopting a spherical or one-dimensional structural material as a compound reinforcement, the foam carbon with a good integral structure and a uniform pore structure is prepared through a foaming process, wherein the diameter of the foam carbon is 200 mm, the height is 200 mm, the heat conductivity coefficient is 0.15 W / (m.k), the compression strength is higher than 30 MPa, the volume shrinkage rate at 1500 DEG C is lower than 3%, and the density is 0.3-0.8 g / cm<3>. The foam carbon is suitable to be used as a structural thermal insulation material, a heat preservation material and a wave absorption material, and can be widely used for the fields of spaceflight, aviation, navigation, energy-saving building, and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

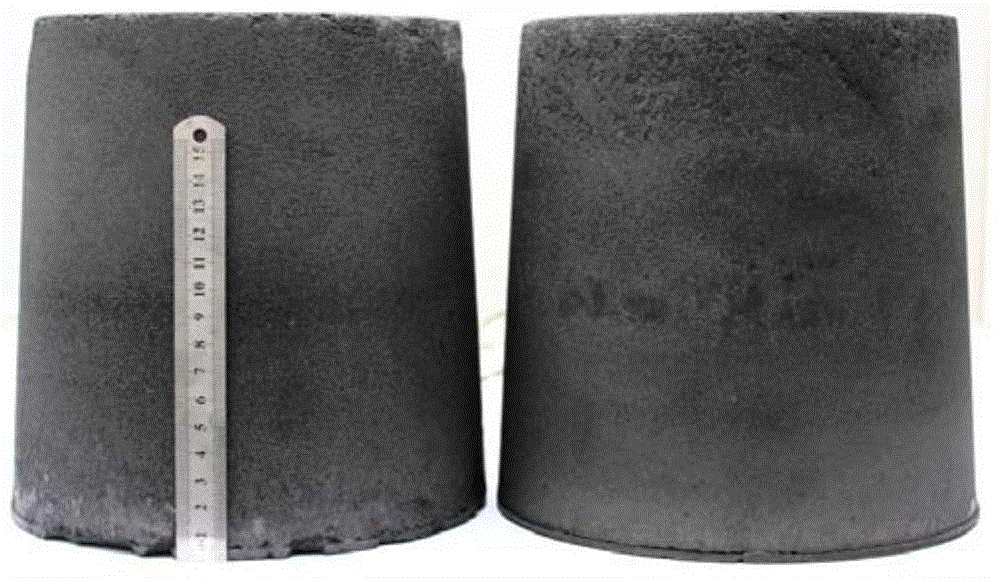

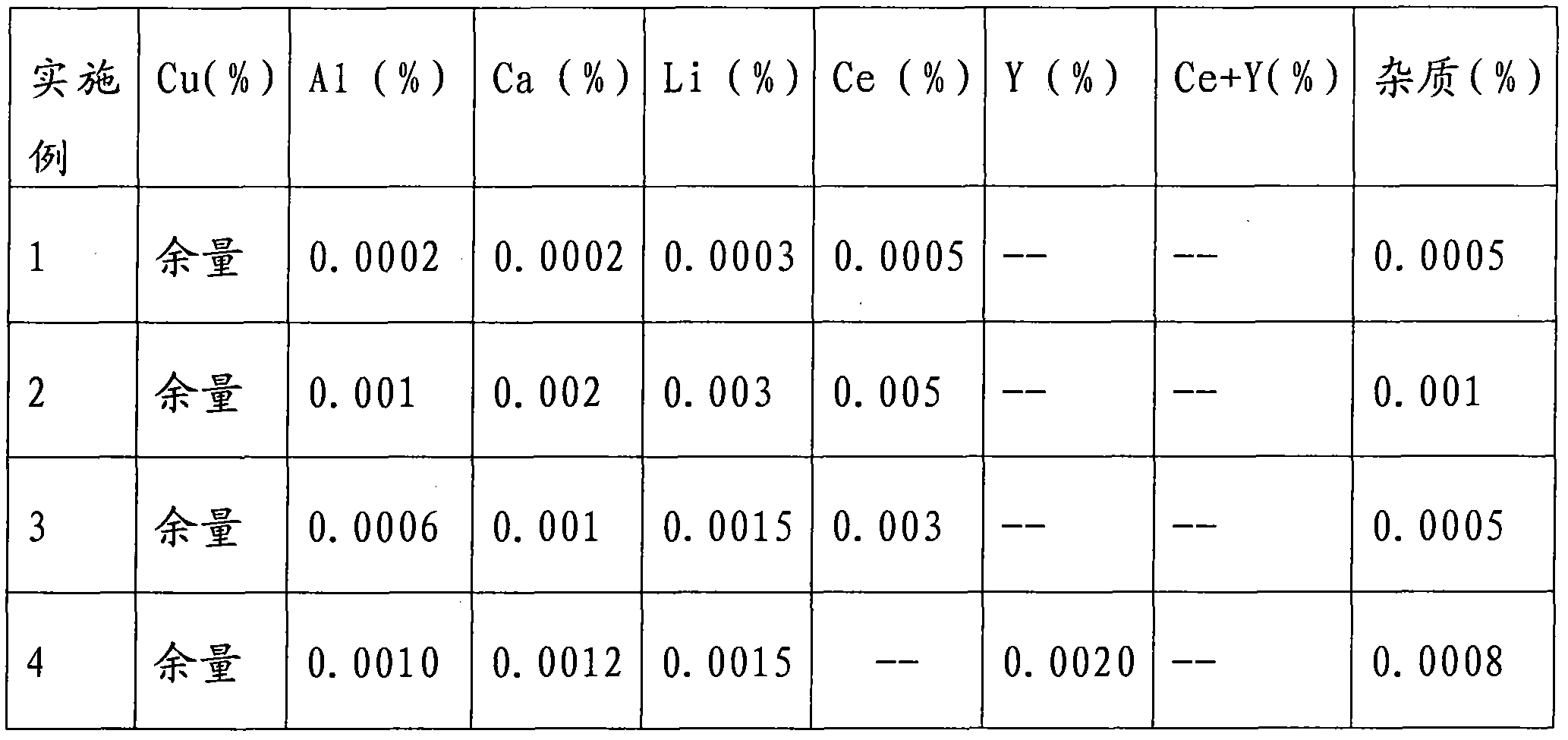

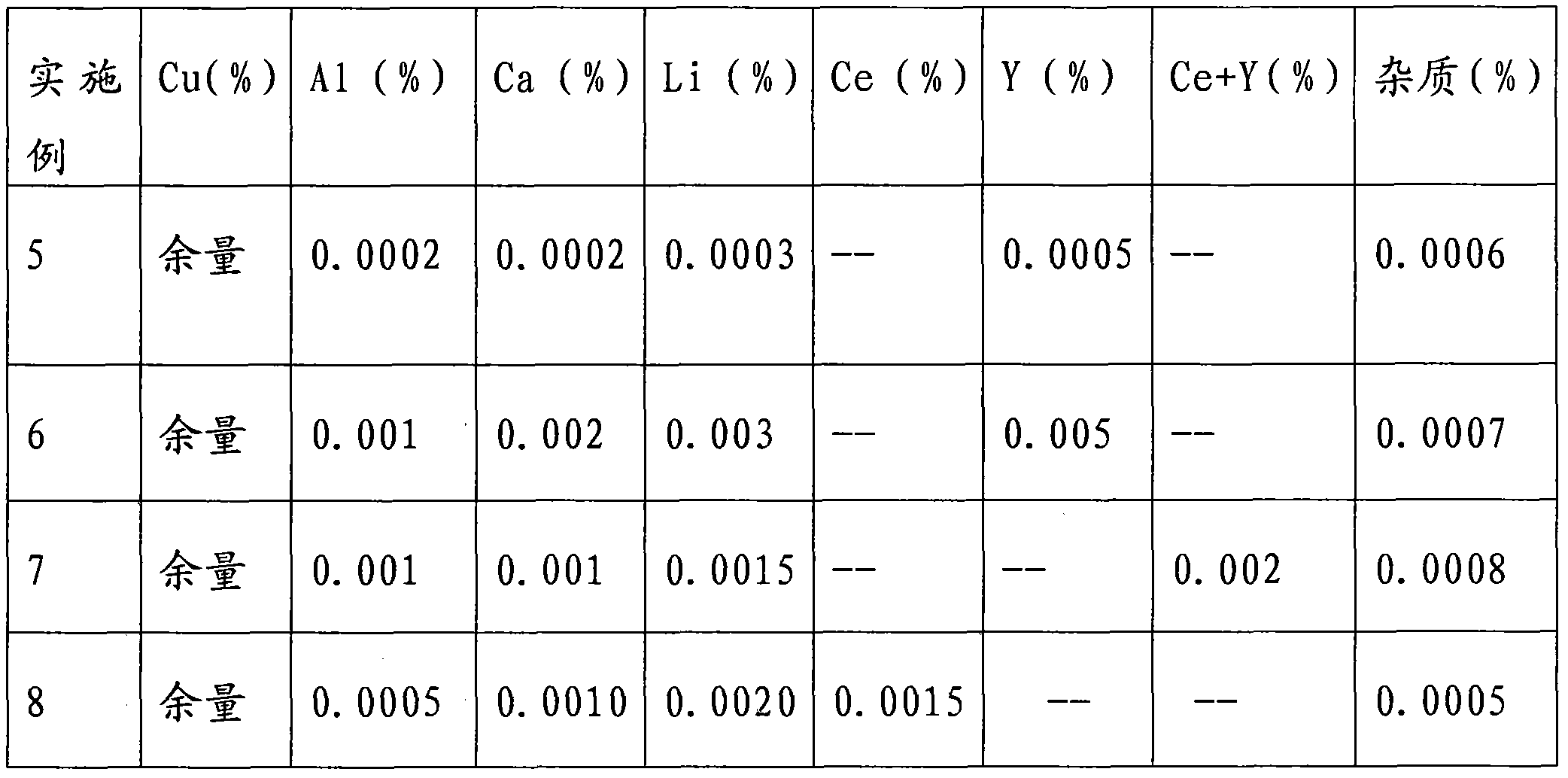

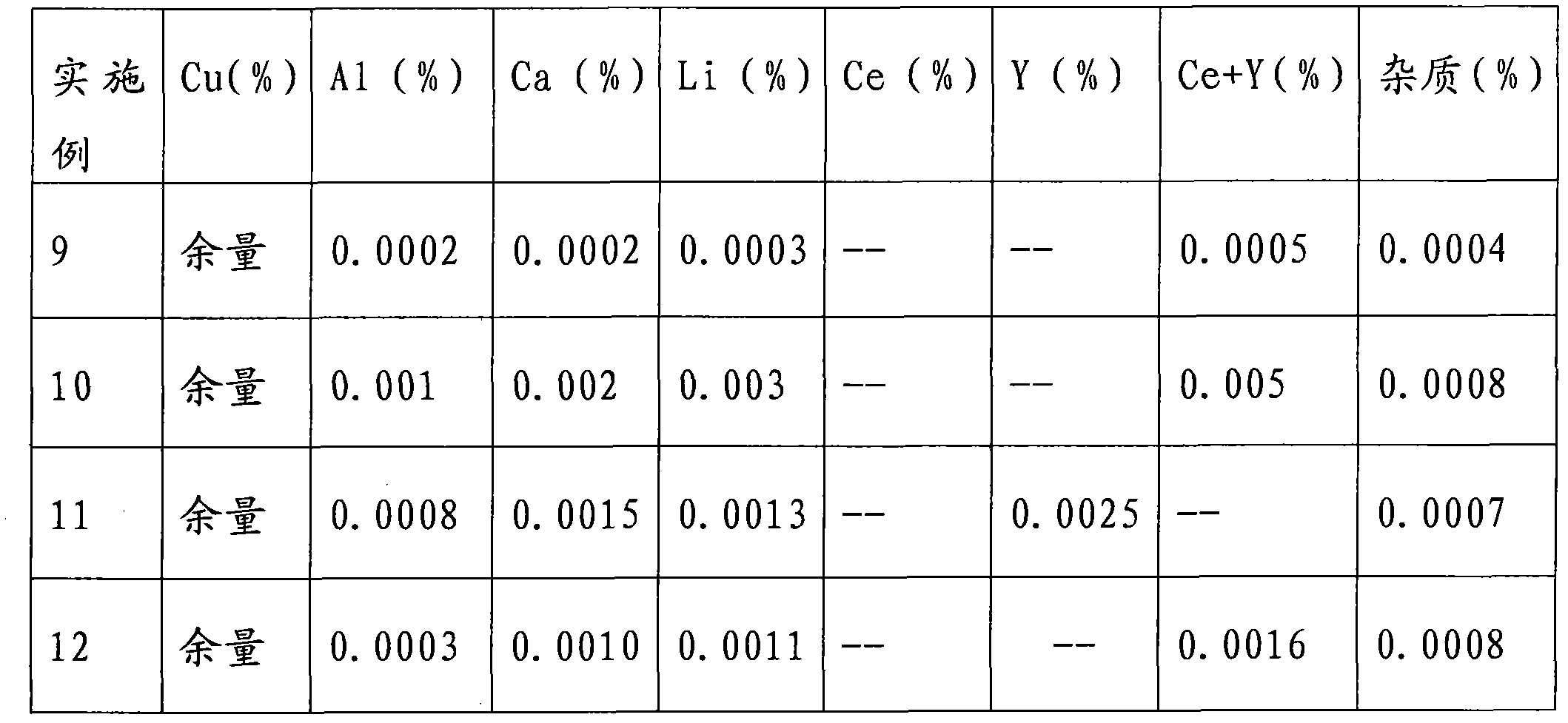

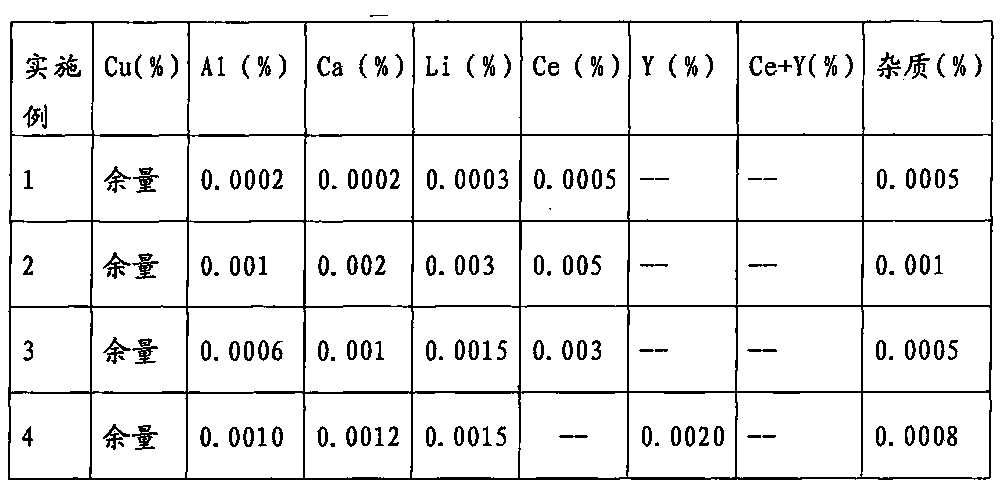

Bonding copper wire and preparation method thereof

InactiveCN101979689AImprove surface oxidation resistanceImprove performanceSingle bars/rods/wires/strips conductorsSolid-state devicesCopper wireCerium

The invention relates to a bonding copper wire and a preparation method thereof. The bonding copper wire comprises the following components in percentage by mass: 0.0003 percent to 0.003 percent of lithium, 0.0002 percent to 0.002 percent of calcium, 0.0002 percent to 0.001 percent of aluminium, 0.0005 percent to 0.005 percent of cerium and / or yttrium, 0.0001 percent to 0.001 percent of other inevitable impurity elements and the balance of copper. The preparation method of the bonding copper wire comprises the following steps of: preparing a middle alloy, preparing an alloy cast ingot, annealing uniformly, heat extrusion, stress relief annealing, drawing, final annealing, winding for multiple coils, packaging, and final protective packaging, wherein in a drawing process, middle stress relief annealing can be performed according to practical needs. The bonding copper wire has better inoxidizability while keeping better conduction and radiation properties; in the preparation process of the bonding copper wire, the uniform annealing is added and the middle stress relief annealing is performed, so that the mechanical property of the prepared bonding copper wire is better.

Owner:蔡元华

Copper nanofluid solar cooling liquid and preparation method thereof

InactiveCN103045181ASolve Oxidation ProblemsDoes not affect thermal conductivityHeat-exchange elementsPhosphatePropanediol

The invention provides a copper nanofluid solar cooling liquid and a preparation method thereof, and belongs to the field of synthesis technologies of inorganic materials. The copper nanofluid solar cooling liquid comprises deionized water, glycol and propylene glycol, nano-copper powder, vinylpyridine, azodiisobutyronitrile, acylamino compound, phosphates and benzotriazole. The preparation method comprises the following steps of: uniformly dispersing the nano-copper powder into alcoholic solution by rapid dispersing; polymerizing on the nanometer copper surface to obtain a monomolecular film; adding a dispersing agent; mixing the obtained alcoholic solution with phosphate aqueous solution; dispersing and mixing at a medium speed again; dispersing by an ultrasonic oscillating instrument; and then homogenizing through a fold-type reducer pipe, so as to obtain the copper nanofluid solar cooling liquid. The prepared copper nanofluid has the characteristics that the thermal conductivity is four times higher than that of the deionized water, the uniformity in dispersing is realized, the stability is excellent, the stability is remained after placing for 2400 hours at the normal state, the freezing point is low, no icing occurs at the temperature of -40 DEG C, the corrosion resistance is excellent, and the copper nanofluid is suitable for an anti-freezing liquid, and the material source is rich; the raw materials are directly sourced, low in price and easy to obtain; low requirement is brought to the running of the equipment; and the massive industrial production can be easily realized.

Owner:济南道生一新能源科技有限公司

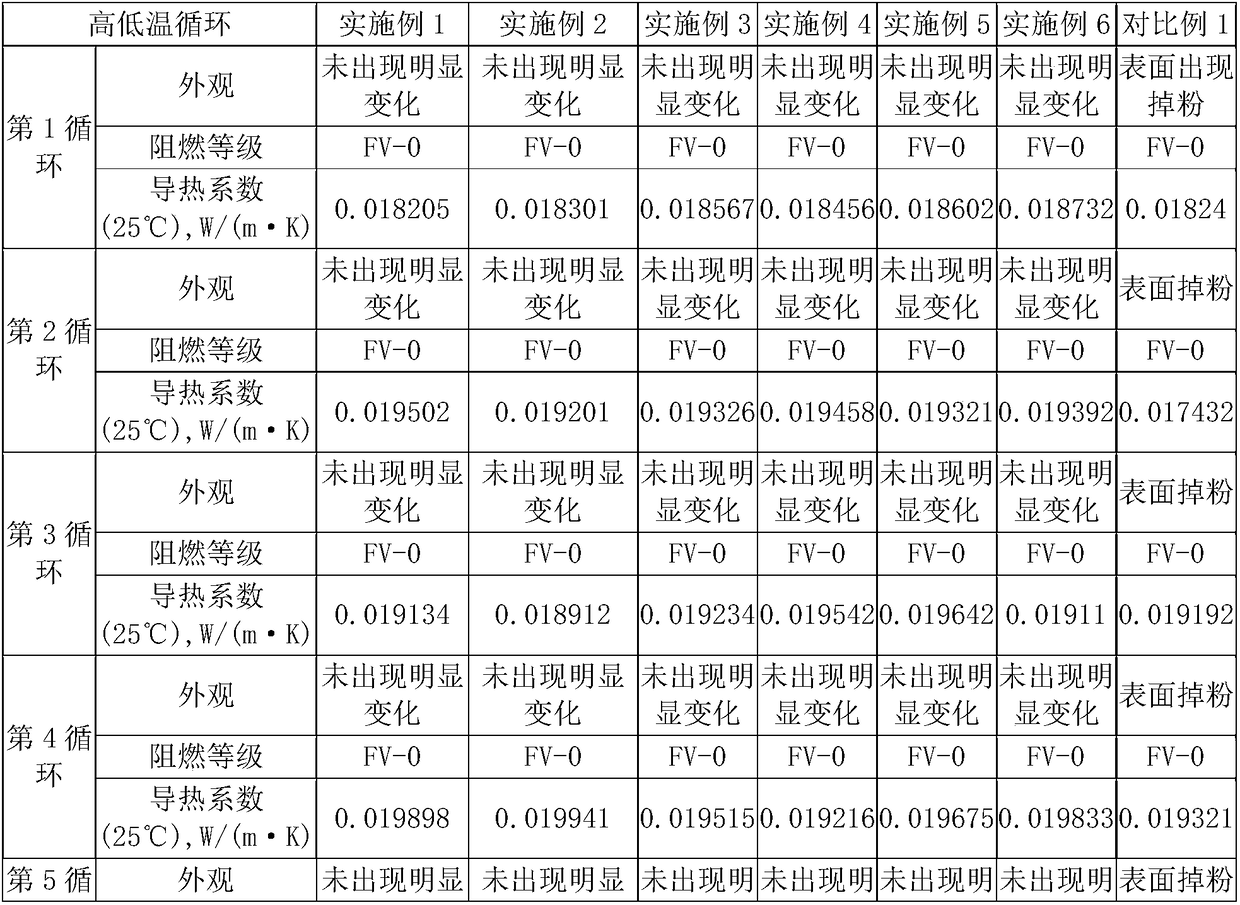

Aerogel heat insulation sheet

InactiveCN108587510ADoes not affect flame retardancyDoes not affect thermal conductivityNon-macromolecular adhesive additivesFilm/foil adhesivesGlass fiberAdhesive

The invention provides an aerogel heat insulation sheet which comprises an aerogel layer and a glue layer coating the outer surface of the aerogel layer; the glue layer covers the whole outer surfaceof the aerogel layer and is prepared from the following raw material components in part by weight: 0.03-1.5 parts of carbon powder, 0.5-5 parts of glass fiber powder, 0.2-5 parts of a flame retardantand 4-35 parts of a structural adhesive. The aerogel heat insulation sheet provided by the invention has the benefits that as the glue layer covers the whole outer surface of the aerogel layer, powderon the surface of an aerogel material is fixed in the glue layer, so that the problem of falling-off of the powder on the surface of the aerogel material is solved. Therefore, the aerogel heat insulation sheet can be applied to the automobile field, and is used as a heat insulation material for an automobile battery, and the problems of pollution and damage to an automobile product due to powderdrop of the aerogel material are effectively solved.

Owner:王宏宁 +3

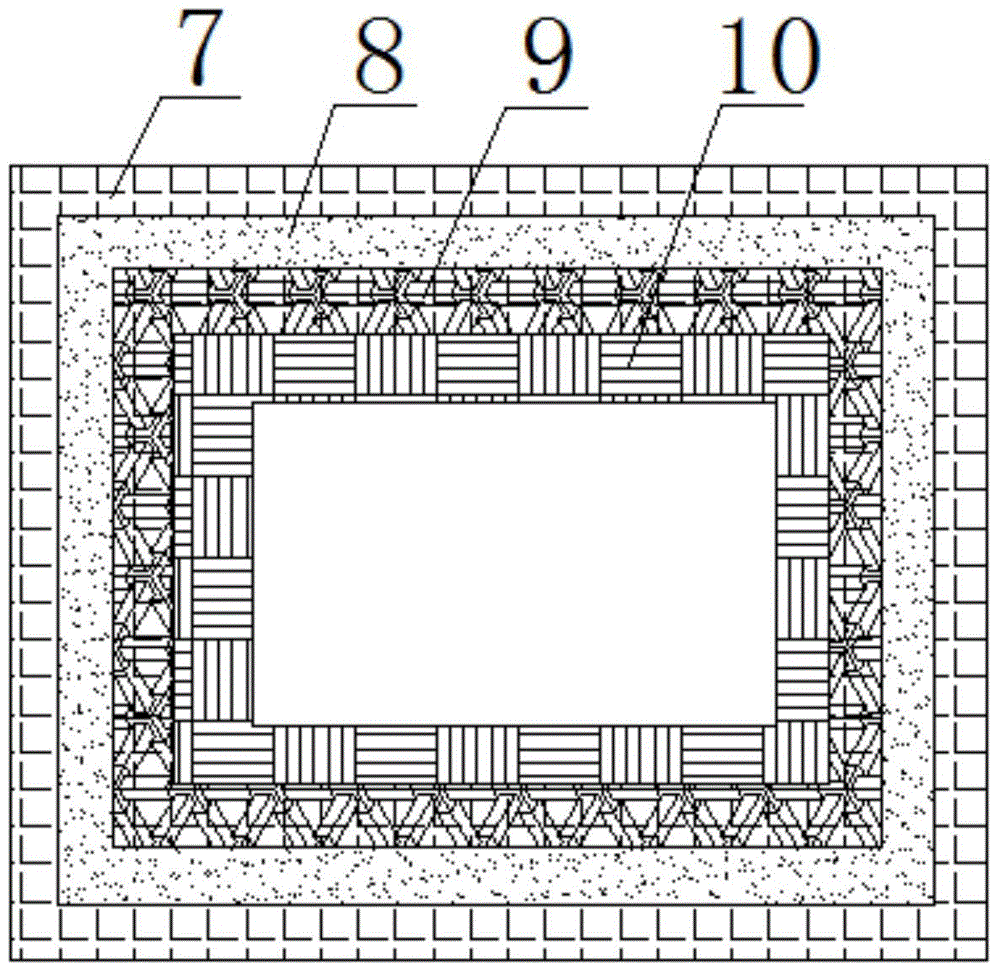

Waterproof heat preservation material for floors of a floor heating system

InactiveCN106977163AImprove technical effectImprove fire and water resistanceGlass fiberCalcium hydroxide

The invention discloses a waterproof heat preservation material for floors of a floor heating system. The heat preservation material is prepared from the raw materials of silicon dioxide, glass fiber, porous ceramisite, cement, graphite modified expanded polystyrene, a waterproof agent, calcium hydroxide, dimethyl siloxane and water according to the mass ratios of (20 to 30) to (30 to 40) to (40 to 45) to (35 to 45) to (20 to 30) to (15 to 18) to (3 to 8) to (5 to 10) to (140 to 150). The heat preservation material disclosed by the invention combines the advantages of raw materials of various heat preservation materials, and a novel heat preservation material which is good in comprehensive technical effect, high in fire and water prevention performance and good in heat preservation effect can be provided; the heat preservation material can be used in occasions such as roof heat preservation engineering and floor heating engineering or used for manufacturing a composite heat preservation plate.

Owner:SICHUAN YISEN THERMAL ENERGY SCI & TECHCO

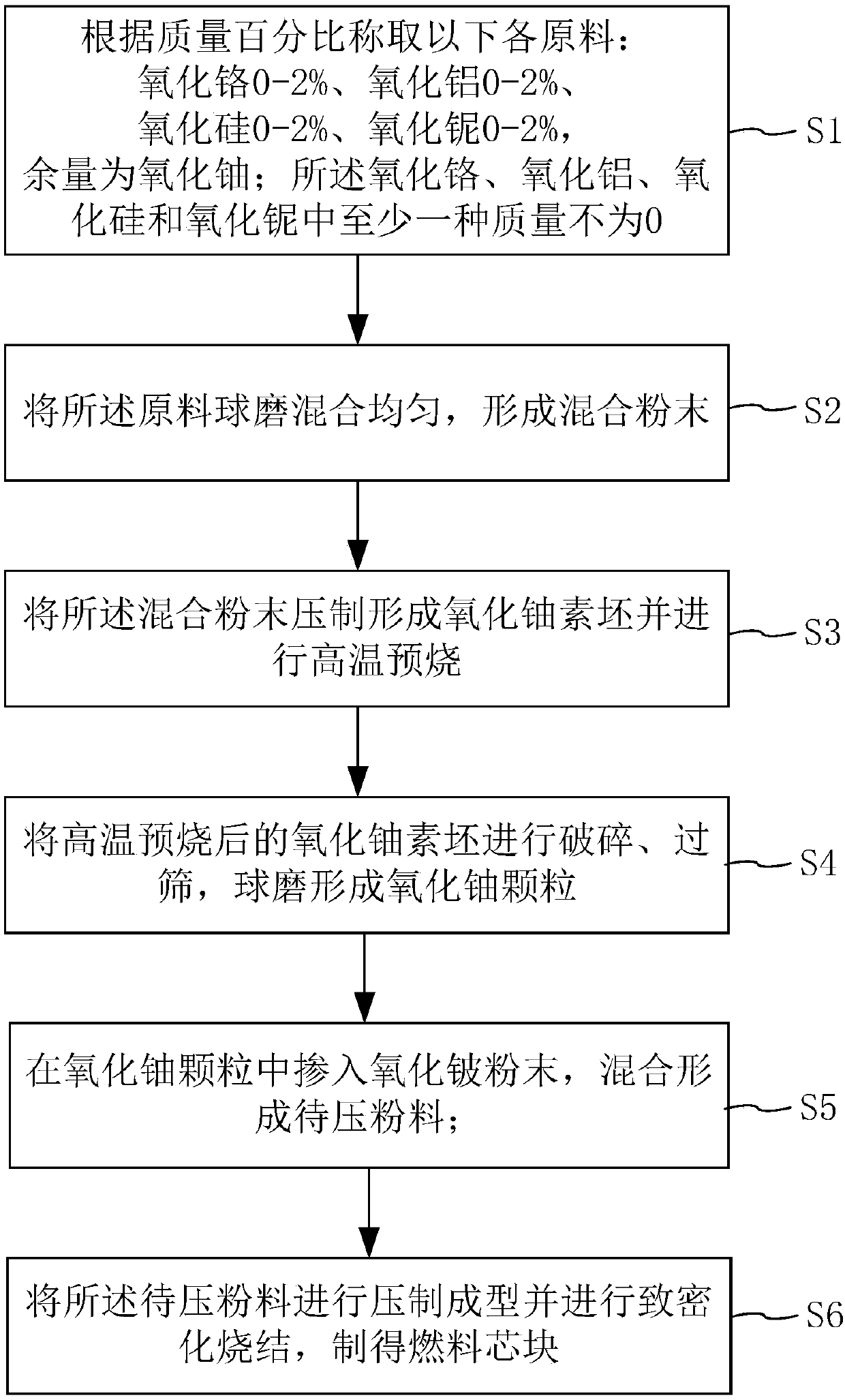

A fuel pellet and a manufacturing method thereof

InactiveCN108039210AReduce spreadDoes not affect thermal conductivityNuclear energy generationReactors manufactureChromium trioxideCompression molding

A fuel pellet and a manufacturing method thereof are disclosed. The method includes S1) weighing raw materials including 0-2% of chromium trioxide, 0-2% of alumina, 0-2% of silicon oxide and 0-2% of niobium pentoxide, with the balance being uranium dioxide; S2) ball milling and fully mixing the raw materials to form a powder mixture; S3) compressing the powder mixture to form a uranium dioxide blank, and subjecting the blank to high-temperature pre-sintering; S4) crushing the blank, sieving the crushed blank, and grinding the crushed blank into uranium dioxide particles; S5) adding beryllium oxide powder into the uranium dioxide particles, mixing the mixture to form powder to be compressed, with each uranium dioxide particle being covered with a cover layer formed from the beryllium oxidepowder; and S6) subjecting the powder to be compressed to compression molding and densification sintering to obtain the fuel pellet. A manner of two times of compound addition and two times of sintering is adopted, and therefore sintering aids form solid solution or are distributed in the uranium dioxide matrix, diffusion or solid solution formation of the sintering aids into the beryllium oxide is reduced, and on the premise that the sintering aids do not influence heat conductivity of the BeO phase, the pellet crystal grain size is effectively increased, and sintering activity is improved.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +2

Intangible needling type negative pressure injection manufacture method of fireproof insulation foam board

InactiveCN103537413ADoes not affect thermal conductivityImprove flame retardant performancePretreated surfacesCoatingsPolymer scienceLiquid state

The invention provides an intangible needling type negative pressure injection manufacture method of a fireproof insulation foam board and relates to a manufacture method of a fireproof insulation building material. The intangible needling type negative pressure injection manufacture method of the fireproof insulation foam board is simple in progress. The fireproof insulation foam board obtained by the manufacture method is low in heat conductivity coefficient and high in flame retardant property. The intangible needling type negative pressure injection manufacture method of the fireproof insulation foam board comprises the following steps of A, preparing a foam board and liquid-state or lacteal fireproof flame retardants; B, processing a plurality of through holes or pores in the surface of the foam board in an intangible needling mode; C, injecting the fireproof flame retardants into a sealed container, immersing the foam board in the fireproof flame retardants, and vacuuming the sealed container; D, taking the foam board out of the sealed container, performing slicking and rolling process on the surface of the foam board, and drying or airing the foam board; E, enabling the fireproof flame retardants to completely solidified in the foam board to obtain the fireproof insulation foam board.

Owner:中鑫泰新材料科技有限公司

Formula of graphite enamel glaze and production process of graphite enamel glaze

The invention discloses a graphite enamel glaze and a production process of the graphite enamel glaze. Si3N4 is added in the graphite enamel glaze, so that the expansion coefficient of the enamel can be adjusted and the adhesive force of the enamel and the graphite can be enhanced; Pr(No3)3.6H2O can enhance the dyeing power of the graphite enamel glaze; and enamel is enameled on the graphite product, so the graphite can be protected from being oxidized greatly, the service life of the graphite product is prolonged, strength of the graphite product is improved, the graphite product is easy to clean and the like, toxic substances penetrated into food are reduced, the application field of the graphite product is improved, and oneness of the appearance of the product is improved. The oxidation probability of the graphite can be reduced; the permeation probability of harmful substances in the graphite coating product can be reduced; the introduction of the graphite enamel glaze does not influence the advantages, such as the original thermal conductivity, the plasticity, high temperature resistance and the like, of the graphite; the enamel product is safe, non-toxic and easy to wash and clean and can be widely used as eating appliances and washing appliances in daily life; and under the specific condition, the glaze is enameled on the graphite body, the advantages and characteristics of high hardness, high temperature resistance, wear resistance, insulation effect and the like can be represented, so that the enamel product has wide application.

Owner:梁越闳

Copper bonding wire and preparation method thereof

The invention relates to a copper bonding wire and a preparation method thereof. The copper bonding wire comprises, by mass, 0.0003-0.003% of lithium, 0.0002-0.002% of calcium, 0.0002-0.001% of aluminum, 0.0005-0.005% of cerium or yttrium, 0.0001-0.001% of other inevitable impurity elements and the balance copper. The preparation method of the copper bonding wire comprises the steps of manufacturing of intermediate alloy, manufacturing of alloy ingots, homogenizing annealing, hot extrusion, stress relief annealing, drawing, final annealing, multiple winding subpackaging and final protective packaging, and intermediate stress relief annealing can further be conducted in the drawing process according to the actual demands. The copper bonding wire has better oxidation resistance while maintaining the good conducting and radiating properties, and the prepared copper bonding wire is better in mechanical performance due to the facts that homogenizing annealing is additionally conducted and the intermediate stress relief annealing technique can be conducted according to demands in the preparation process of the copper bonding wire.

Owner:上海铭沣科技股份有限公司

Overlapping graphite sheet

InactiveCN105517410AReduce sheddingGuaranteed functionCooling/ventilation/heating modificationsGraphite substrateMetallic materials

The invention discloses an overlapping graphite sheet including a graphite substrate. Four corners or edges at a side of the graphite substrate are provided with a metal frame. As heat conduction and dissipation properties of the graphite sheet is higher than metal materials, the arrangement of the metal frame at the four corners or edges at the side of the graphite substrate allows the heat to be dissipated in a more focused manner from the exposed graphite substrate, the dissipation from the metal frame is reduced, therefore the use function of surrounding objects is ensured without affecting the heat conduction and dissipation properties of the graphite sheet, and great convenience is brought to companies.

Owner:SUZHOU PADNIC THERMAL CONDUCTIVE MATERIAL

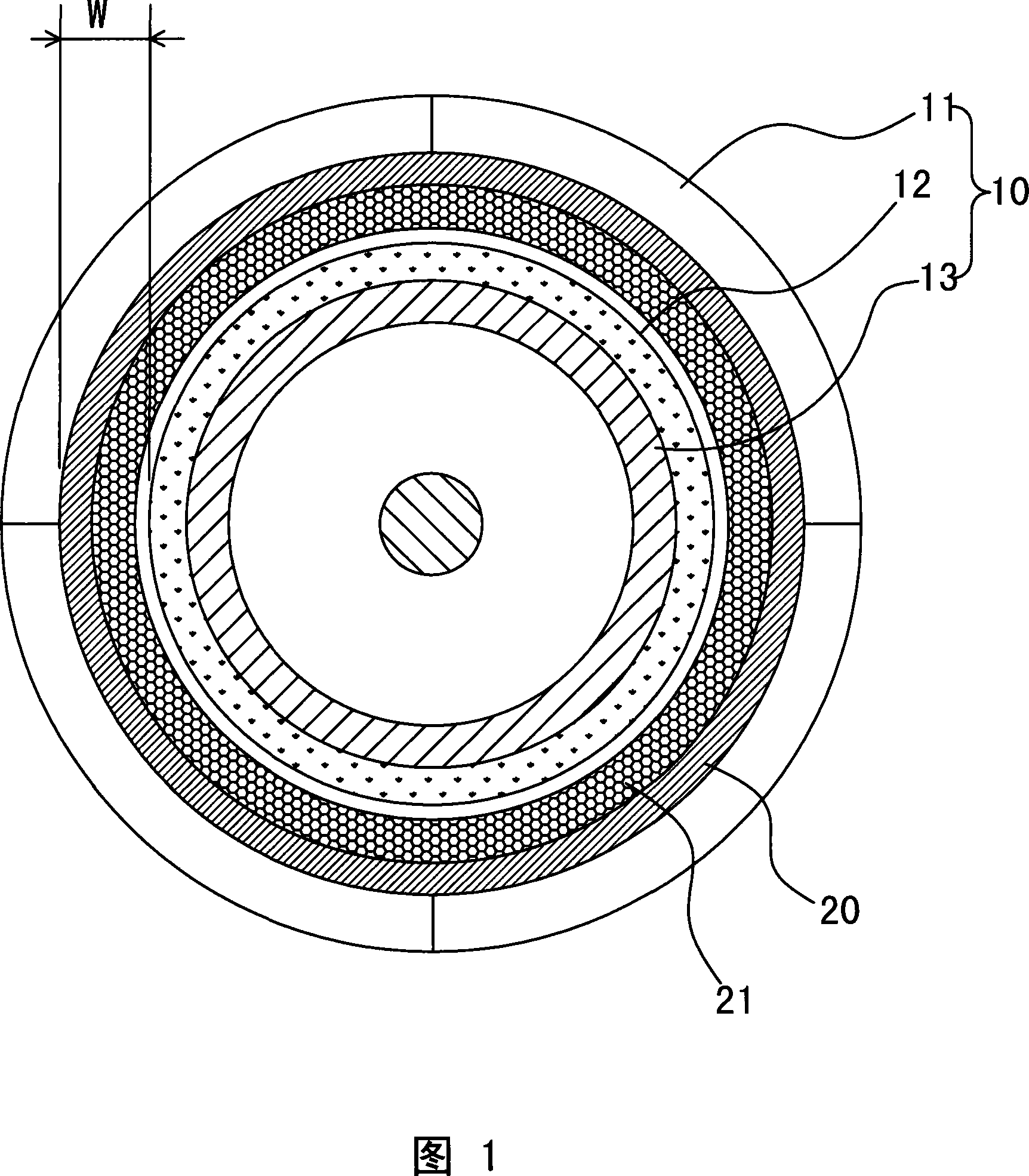

Heat pipe structure

InactiveCN101144695AEnough thicknessIncrease power generation capacityIndirect heat exchangersImpellerHeat conducting

The invention provides a heat pipe structure. The heat pipe comprises a pipe wall and a hollow pipe groove, and a capillarity organization is arranged on the inner side of the pipe wall. The invention is characterized in that the heat pipe wall presents a concavo convex buckling shape and forms a plurality of concave margin and flange parts; and the heat pipe can be provided with a generator, the heat pipe comprises an electrical output coil arranged on the outer side of the heat pipe wall and a magnetic iron ring arranged in the hollow pipe groove, a rotor and an impeller, therefore, the electrical output coil can be inserted on the concave margin part of the heat pipe wall, the capillarity organization can be inserted in a depressed space formed by the inner side of the concave margin part, thus the space of the electrical output coil and the magnetic iron ring can be smaller, thereby to effectively improving a power generation effect, and the capillarity organization can still have the enough thickness, and the heat conducting efficiency is not influenced.

Owner:SUZHOU FORCECON ELECTRIC

Novel heat-insulating polyester wadding and preparation method thereof

The invention relates to the technical field of polyester wadding, in particular to novel heat-insulating polyester wadding and a preparation method thereof. The novel heat-insulating polyester wadding comprises a matrix and a functional body, fiber flocculus taking high-crimp hollow polyester short fiber as a main body is adopted as the matrix, and a reagent serving as the functional body is sprayed into gaps in the surface and inside the flocculus matrix; the reagent is composed of, by weight, 4-7 parts of sodium alginate, 0.1-0.5 part of calcium chloride, 0.01-0.15 part of surfactant, 15-25parts of binder and 50-65 parts of diluent. The novel heat-insulating polyester wadding has excellent moisture absorptivity and heat insulativity and high fluffiness, is made through carding, glue spraying and special centrifugal process and is suitable for clothes, beddings and household supplies.

Owner:FUJIAN JINJIANG HENGFENG SPEWING WEAVING

Anti-corrosion temperature sensor

InactiveCN105043567AReduce corrosion resistanceDoes not affect thermal conductivityThermometer detailsThermometers using electric/magnetic elementsElectrochemical responseElectrical resistance and conductance

The invention provides an anti-corrosion temperature sensor, including a body and a plug which are mutually connected. The body is composed of a protection shell and a thermistor. The thermistor is positioned in the protection shell, and the plug is led out through a lead. The protection shell comprises a stainless steel layer, a graphite layer, an active metal layer and a heat-conducting insulation material layer from outside to inside, wherein the active metal layer refers to metal which is more active than stainless steel. With the adoption of the protection shell structure, the active metal layer is enabled to have a chemical or electrochemical reaction first as electrons of the stainless steel layer are conducted to a magnesium thin sheet layer due to corrosion, thereby reducing the corrosion resistance of the stainless steel layer, and meanwhile, the oxidized active metal layer cannot affect the thermal conductivity of the whole temperature sensor. The invention is simple and reasonable in structure.

Owner:WUHAN UNIV OF TECH

Epoxy composite material and production method thereof

The invention provides an epoxy composite material and a production method thereof. Raw materials of the epoxy composite material comprise an epoxy resin base material, inorganic filler, a curing agent and a fiber fabric; the inorganic filler is composed of two kinds of filler with different particle size, and a ratio of the average particle size of the two kinds of filler ranges from 1:0.37 to 1:0.45, wherein the average particle size of the filler with the larger particle size is equal to or larger than 10 [mu]m; on the basis of the volume of the fibber, in the two kinds of filler, a ratio of the amount of the filler with the larger particle size and the amount of the filler with the smaller particle size is as shown in the specification, wherein V is a volume percentage of the inorganicfiller in the epoxy composite material, and according to the epoxy composite material, by adding the fiber fabric, not only can the heat conduction performance and the insulation performance be freefrom effects, but also the mechanical performance, especially the anti-crack performance, of the epoxy composite material is effectively improved; and compared with a method where three kinds of filler with different particle size is adopted, the production method of the epoxy composite material has the advantages that by adopting the two kinds of inorganic filler with the different particle size,the production working procedure can be simplified, and operation is simple.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +3

Production method of graphite enameled product

The invention discloses a production method of a graphite enameled product. A graphite product is enameled, thus graphite can be greatly prevented from being oxidized, the service life and strength of the graphite product are enhanced, the graphite product is easy to clean, the toxic substances in the graphite product are prevented from penetrating into foods, the application field of the graphite product is broadened, and the single appearance of the product is improved, and the like. According to the invention, the oxidation of graphite and the penetration of harmful substances in the graphite coating product are lowered; the graphite product is enameled, which dose not influence the original thermal conductivity, plasticity and high temperature resistance of the graphite; by combining with the characteristics that an enameled product is safe and toxic and is easy to wash and clean, the graphite enameled product can be widely used as a food and drink vessel and a washing vessel which are used in daily life; and under the special conditions, the ceramic glaze is enameled on a graphite green body, so the enameled product exhibits good properties such as high hardness, high temperature resistance, wear resistance, good insulation and the like, thereby ensuring the wider application of the enameled product.

Owner:梁越闳

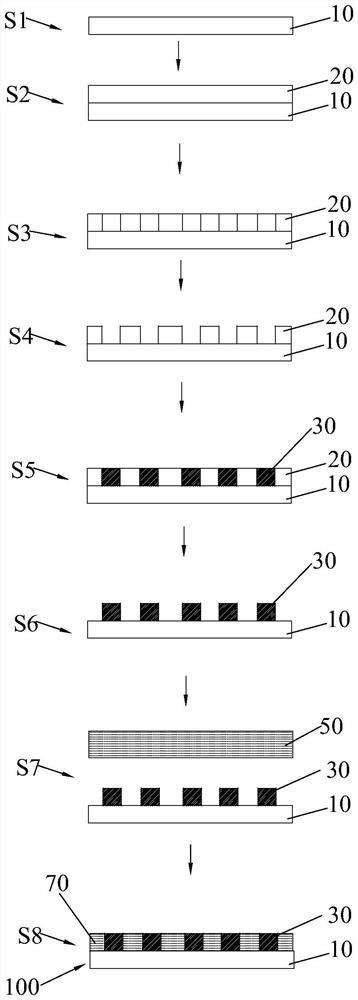

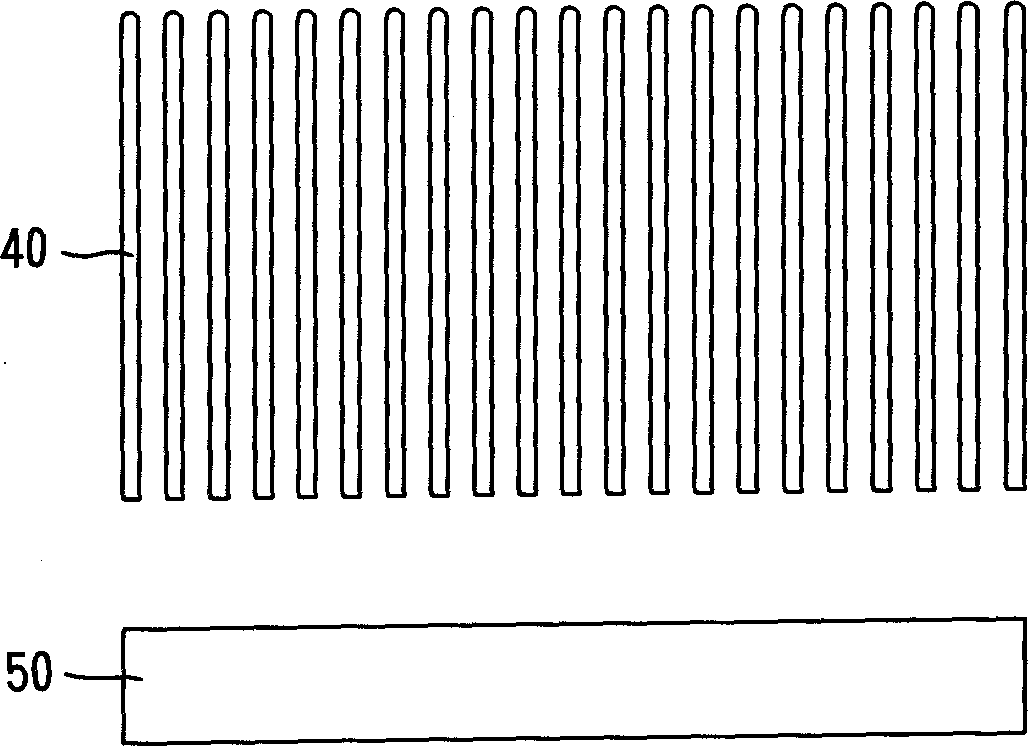

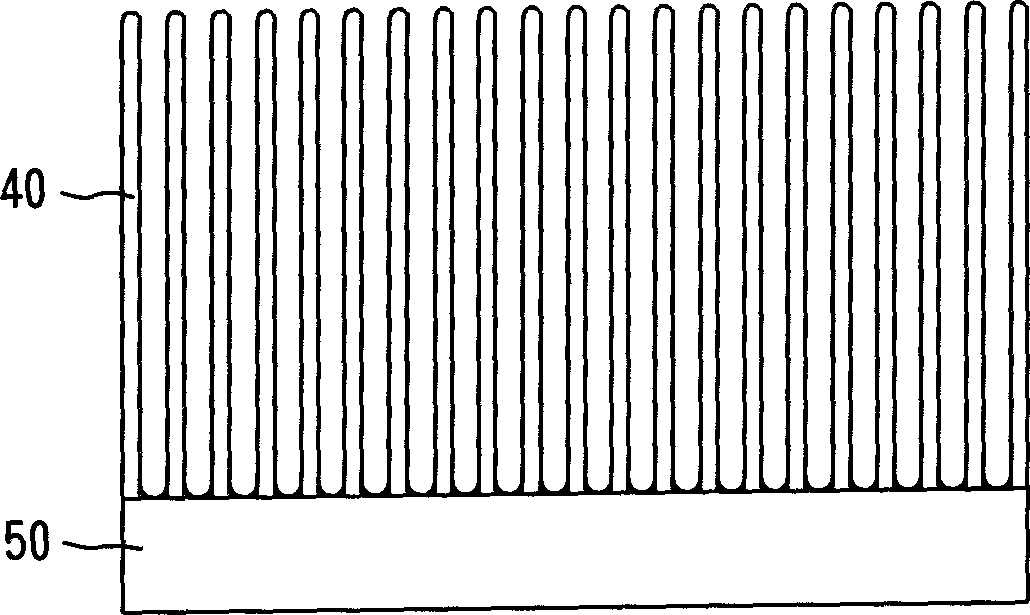

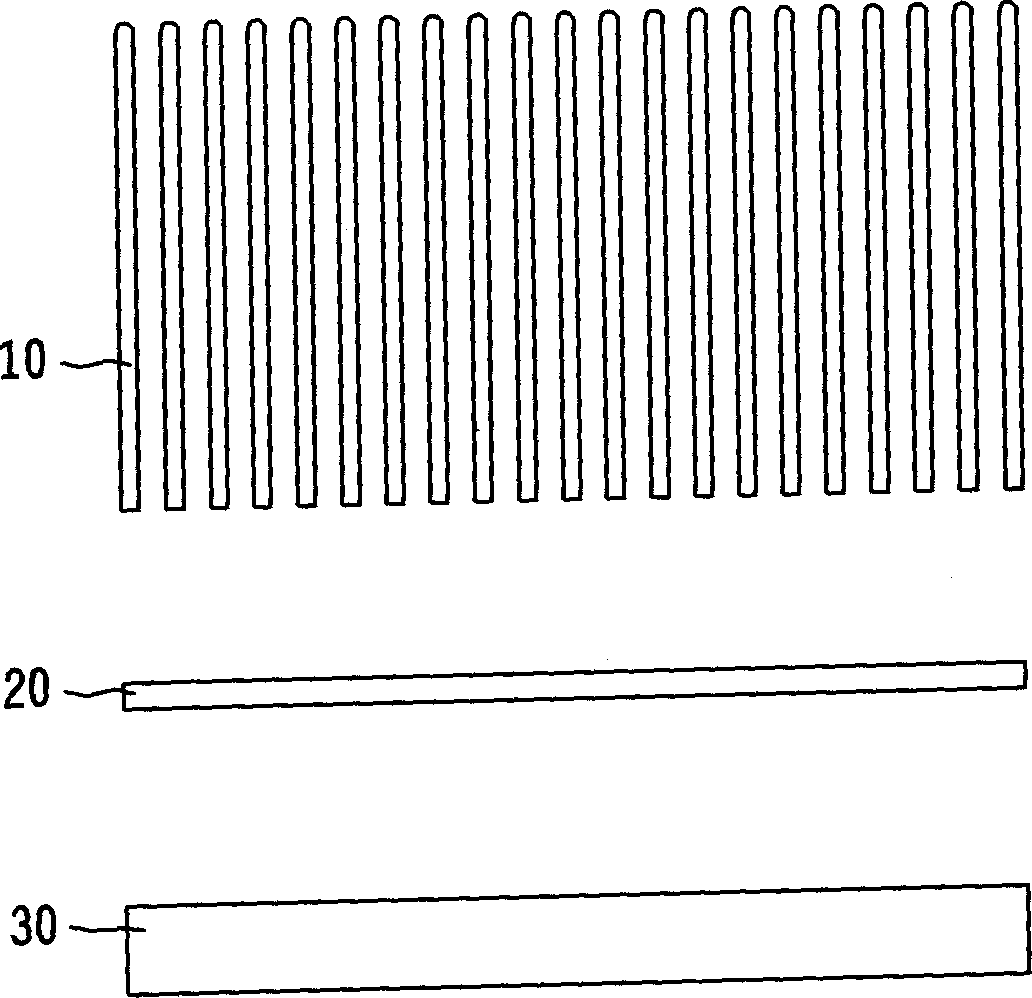

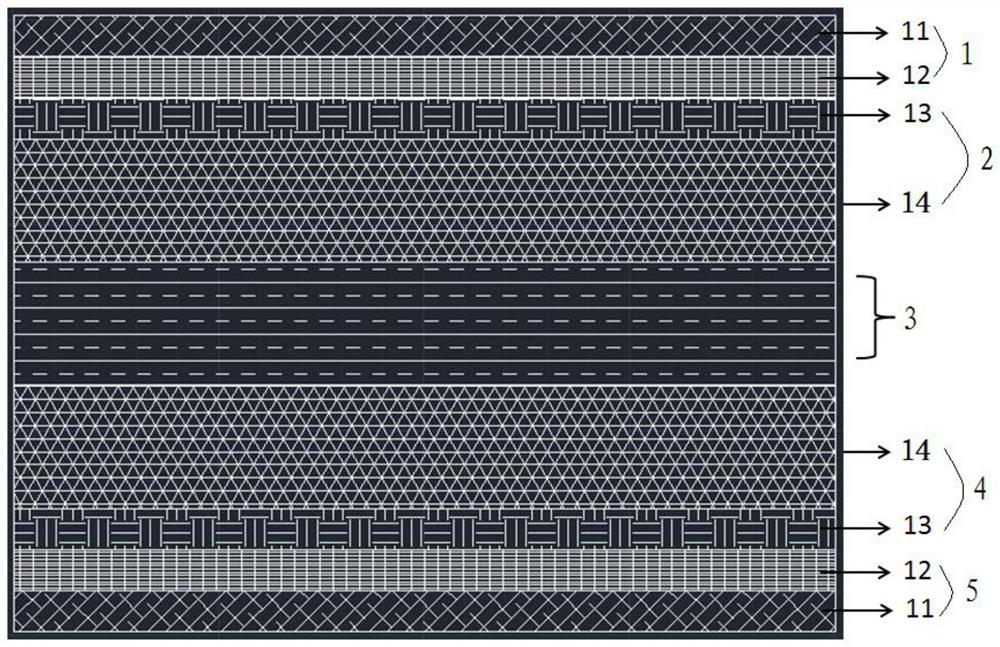

Copper foil graphite film and preparation method thereof

PendingCN114434894AImprove cooling effectImprove mechanical propertiesLamination ancillary operationsLaminationCopper foilGraphite

The invention discloses a copper foil graphite film and a preparation method thereof, and the preparation method comprises the following steps: (1) providing a copper foil substrate, and attaching a dry film to one side of the copper foil substrate; (2) performing an exposure process on the dry film; (3) performing a developing process, exposing the exposed part out of the copper foil substrate, and covering the unexposed part with the dry film; (4) depositing metal on the surface of the copper foil substrate exposed by the exposed part to form a copper column; (5) removing the dry film; and (6) laminating a semi-finished graphite film and one side, containing the copper columns, of the copper foil substrate to obtain the copper foil graphite film. According to the copper foil graphite film prepared by the method, the thermal conductivity in the thickness direction (namely the Z-axis direction) of the copper foil graphite film can be improved, the thermal conductivity in the horizontal direction (namely the X-axis direction and the Y-axis direction) is hardly influenced, and the copper foil graphite film has relatively good mechanical property, stability and bearing property.

Owner:江西鸿美新能源科技有限公司

Radiator

InactiveCN1467601ALow densityDoes not affect thermal conductivityDigital data processing detailsCopperMaterial quality

The invention discloses a radiator used for the radiation of a micro processor comprising radiating fins, binding mediator and substrate, wherein the radiating fins are sheet-like, and each radiating fin is spaced and pasted to the sheet-like binding mediator perpendicularly, while the substrate is also plate-like corresponding to the binding mediator whose material quality is aluminum based composite material, it is pasted to the binding mediator an a face-to-face manner. The radiator by the invention possesses both high thermoconductivity and light weight, and it does not influence the impact and vibration-testing for it.

Owner:INVENTEC CORP

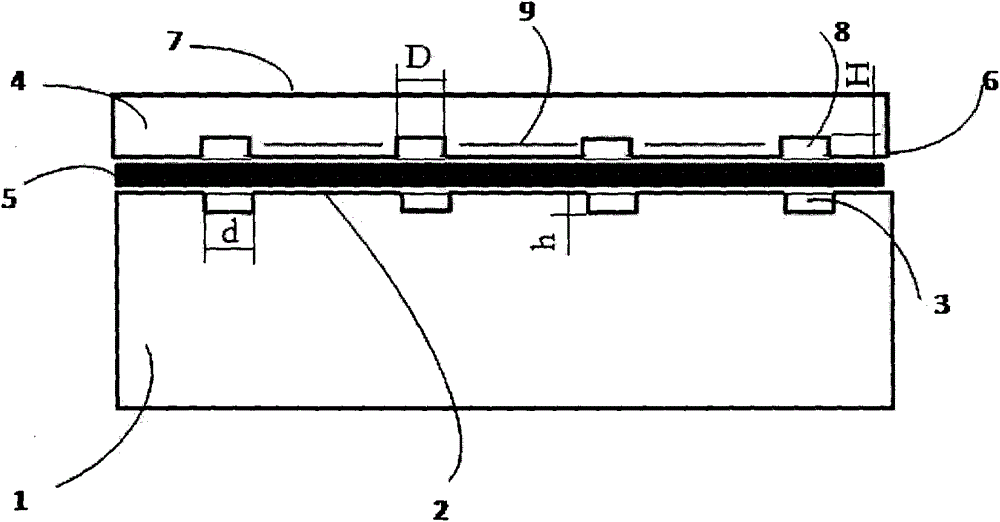

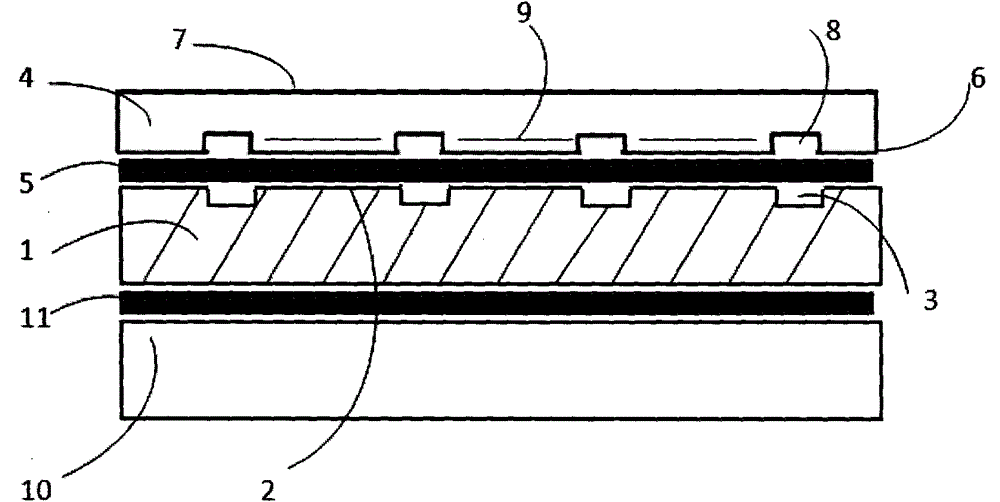

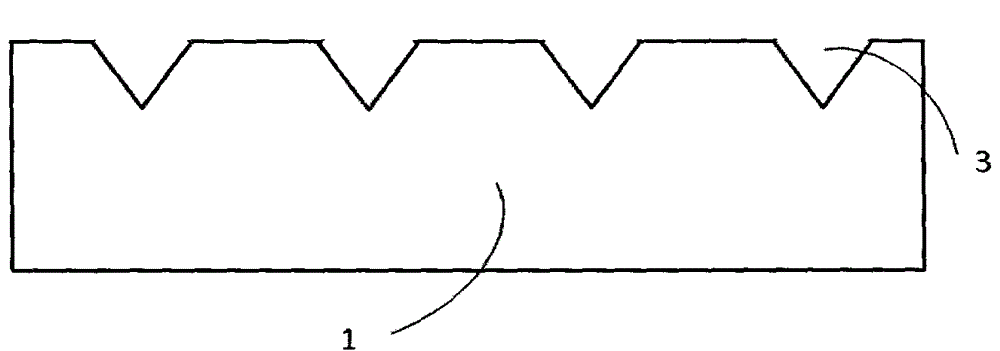

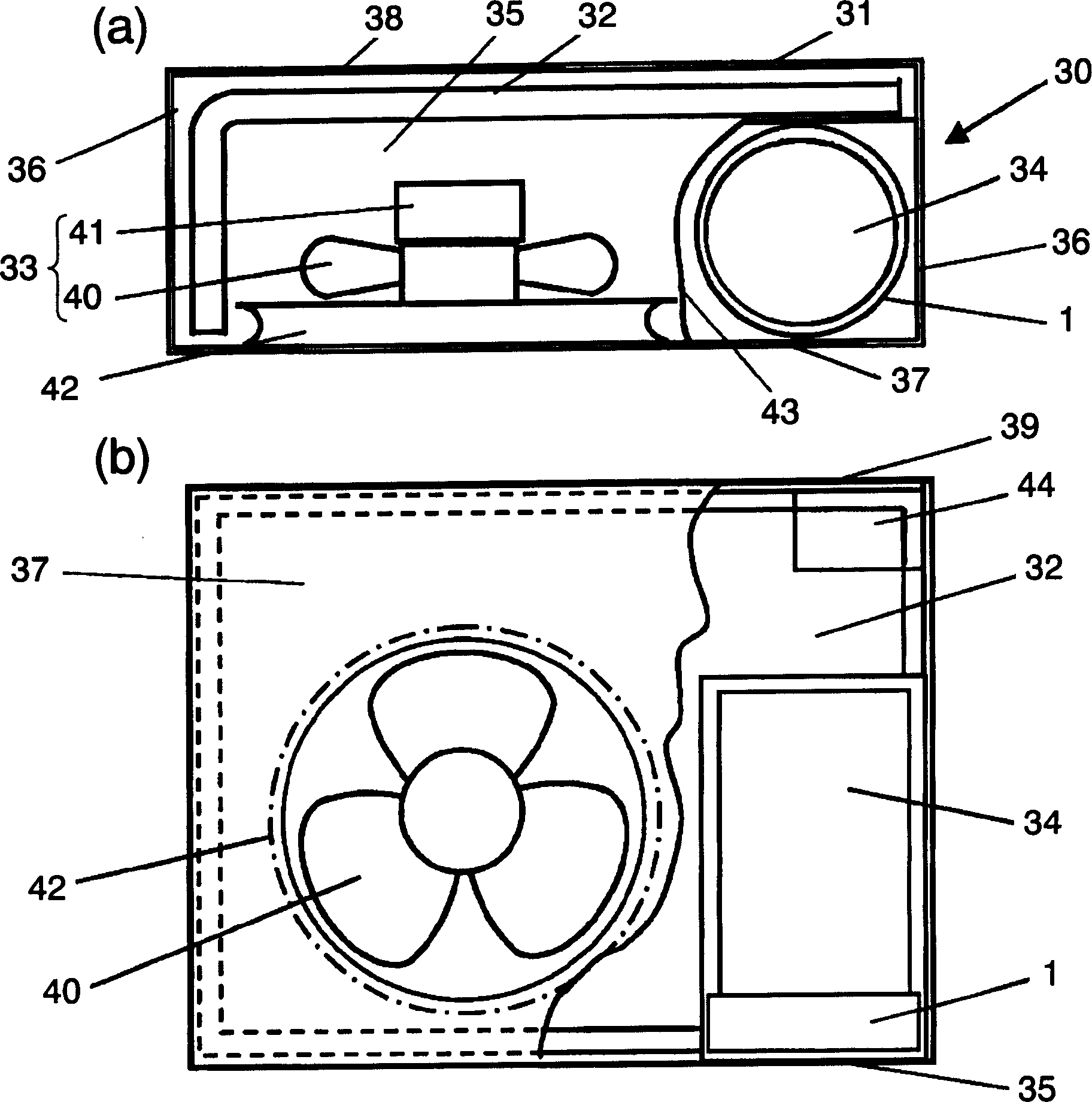

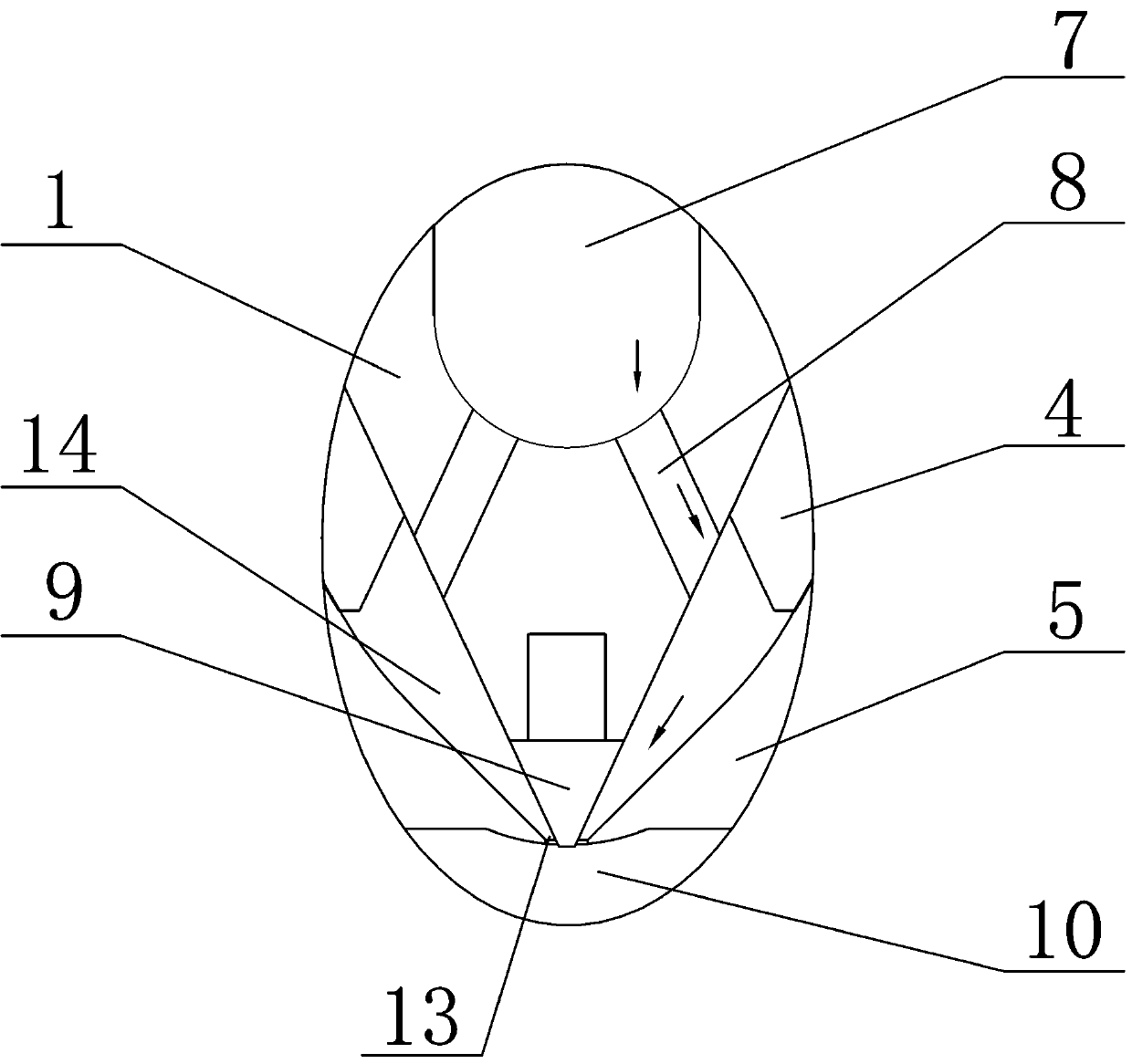

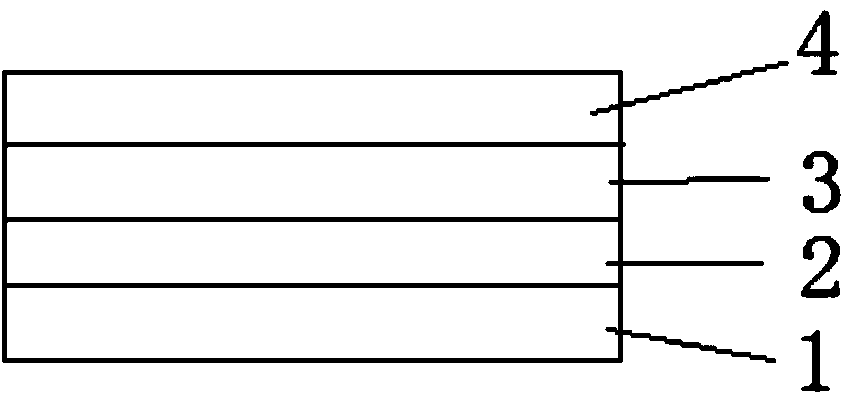

Stress-reducing laser chip structure and heat sink structure and preparation method thereof

ActiveCN103427330BReduce curvatureReduced stress stateLaser detailsSemiconductor lasersEngineeringHeat sink

A stress-reducing laser chip structure comprises a laser chip body (4), the laser chip body (4) is provided with a positive pole (6) and a negative pole (7) that is electrically connected to an external electrode, a plurality of light-emitting portions (9) is disposed on the positive pole (6), and a first groove (8) is disposed between the light-emitting portions (9). The laser chip structure further comprises a heat sink structure, the heat sink structure comprises a heat sink body (1), a front surface (2) of the heat sink body (1) is welded to the positive pole (6) of the laser chip body (4) by using a solder layer (5), a portion, corresponding to the first groove (8) of the laser chip body (4), of the heat sink body (1) is provided with a second groove (3), and the second groove (3) corresponds to the first groove (8) one by one. The laser chip structure has a low stress state and a low curvature, can implement low-stress or "stress-free" packaging without affecting a thermal conduction capability of a laser, and can ensure long-time working of the laser.

Owner:WUHU ANRUI LASER TECH CO LTD

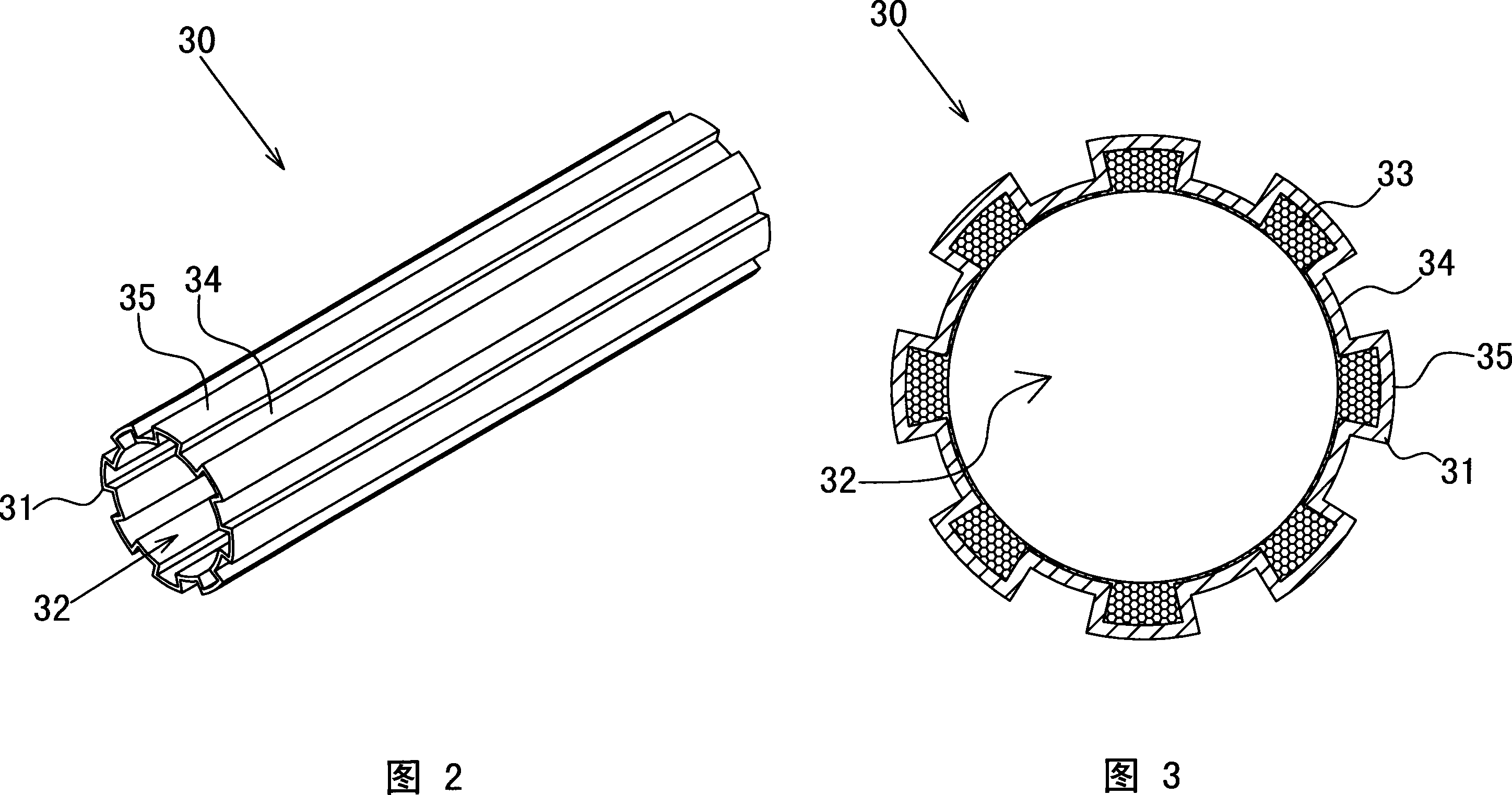

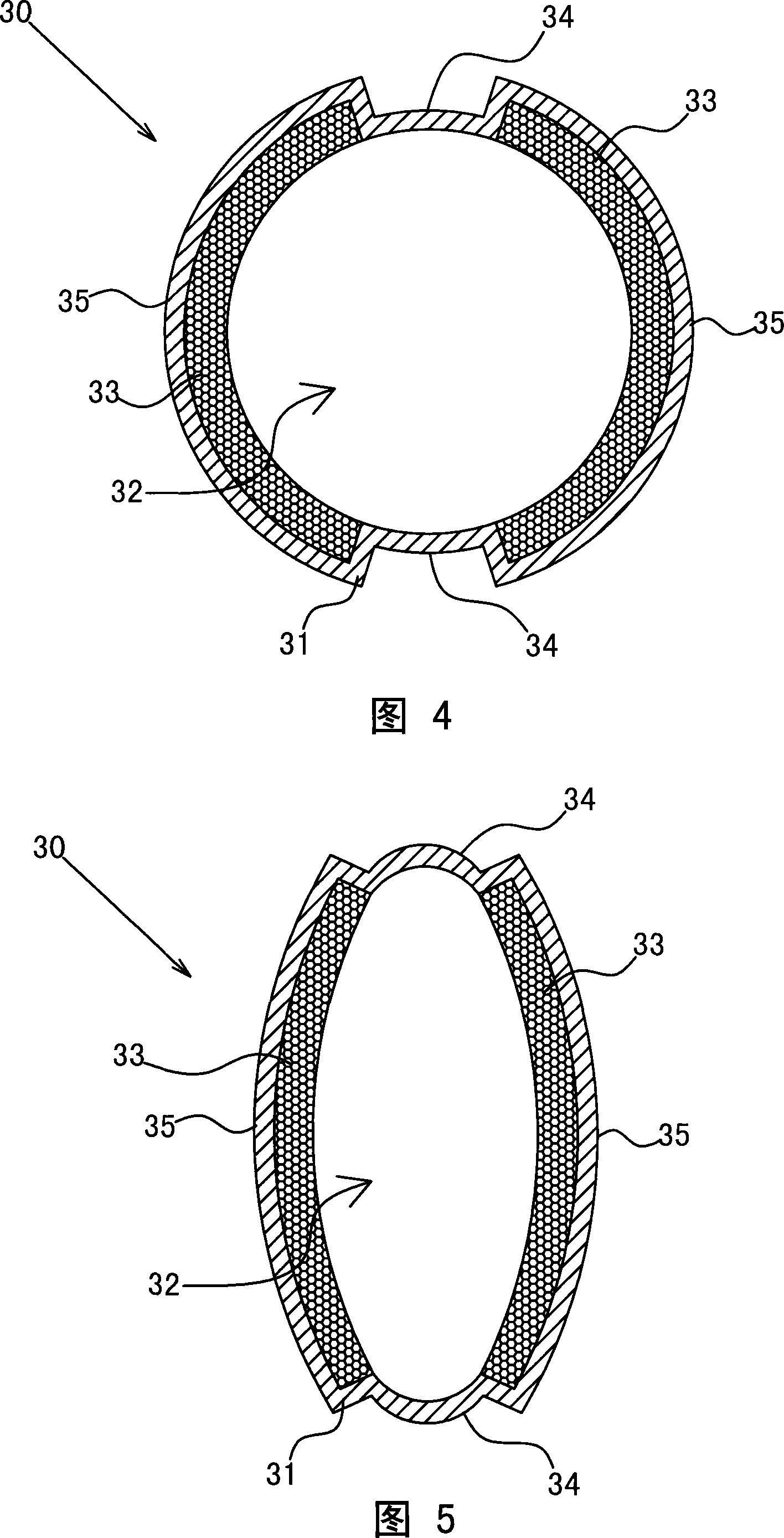

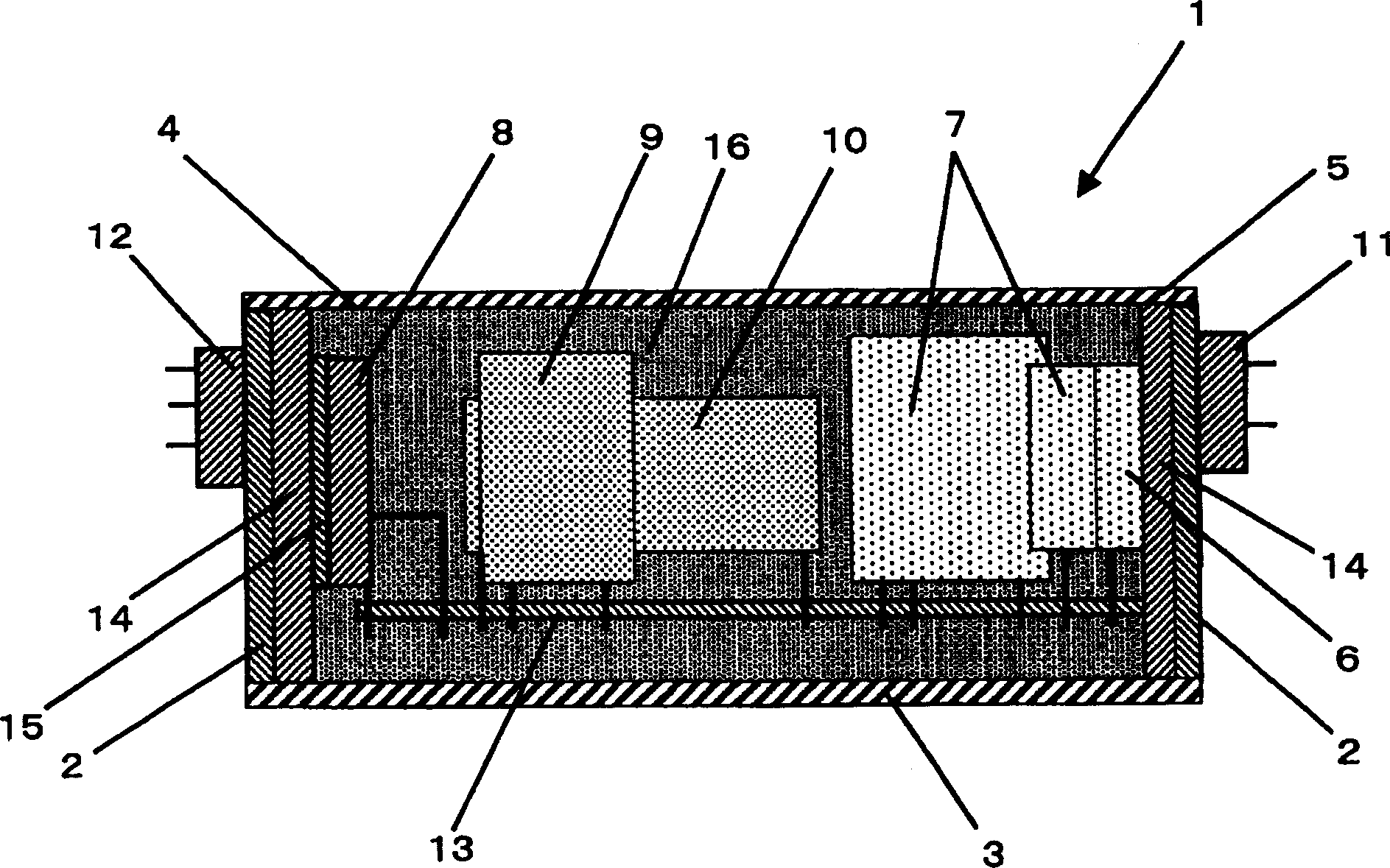

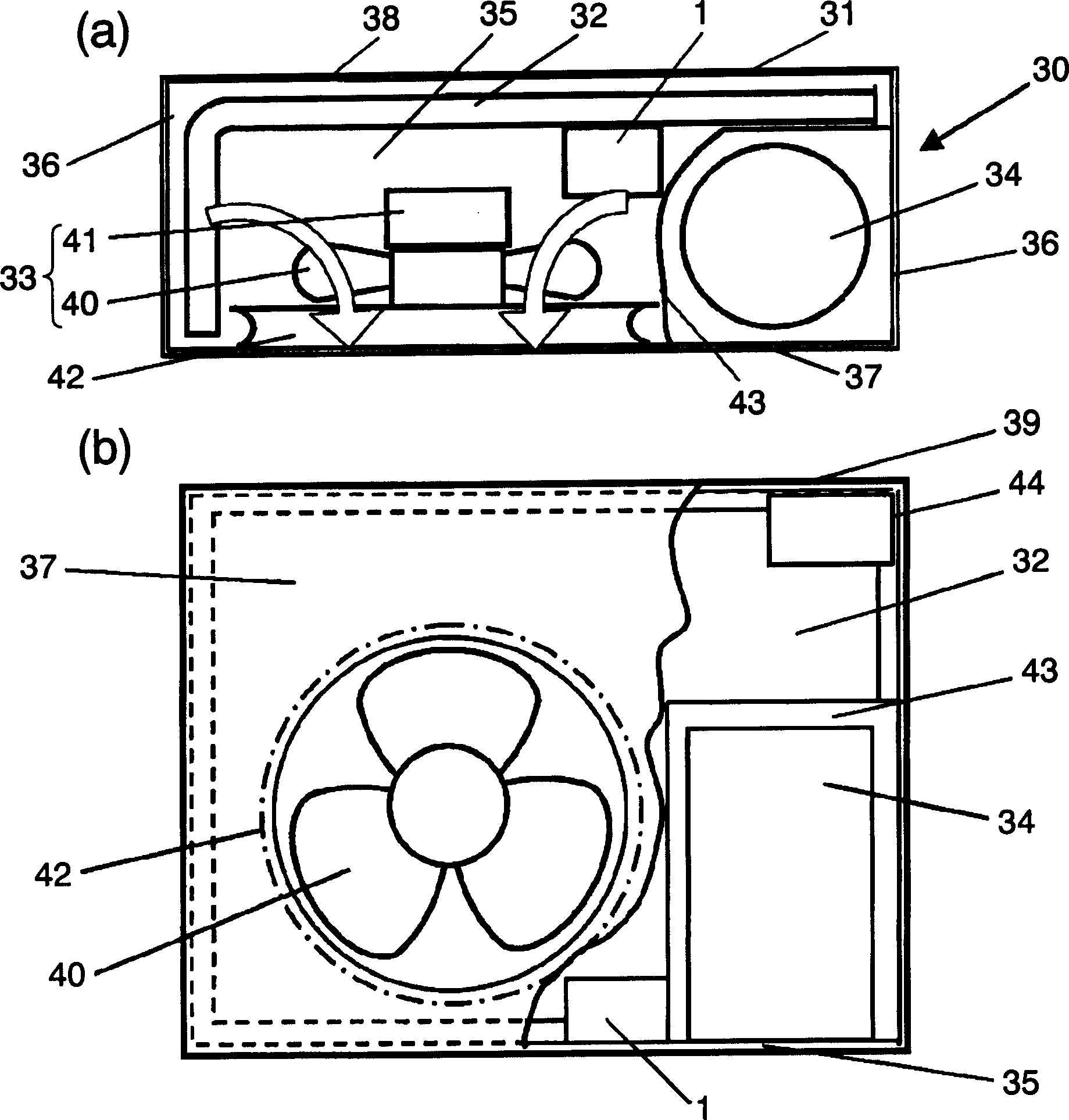

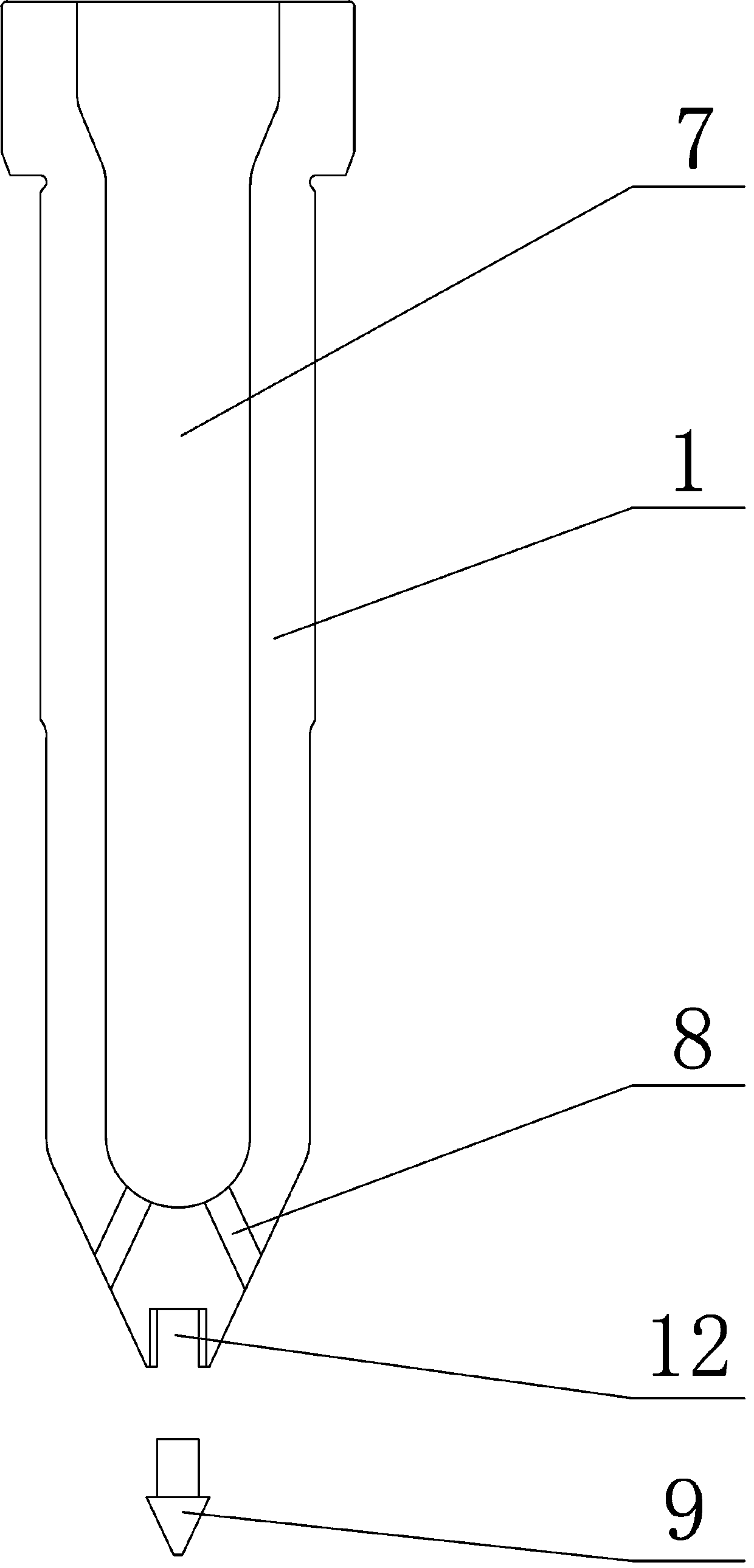

Outdoor machine for air conditioner

InactiveCN1576729AImprove cooling effectImprove reliabilitySpace heating and ventilation safety systemsLighting and heating apparatusAir conditioningControl circuit

To realize an outdoor unit for air conditioner enhanced in reliability of an inverter driving circuit part while improving the air conditioning performance with a small size. This outdoor unit comprises an outdoor unit body 30, an outdoor heat exchanger 32, an outdoor blower 33, a compressor 34 for compressing a refrigerant, and an electric module part body 1 having a circuit part arranged in a sealed casing, the circuit part comprising at least a converter circuit part for driving a motor part, an inverter circuit part, and a control circuit part. The electric module part body 1 is arranged on the bottom plate 35 of the outdoor unit body 30.

Owner:PANASONIC CORP

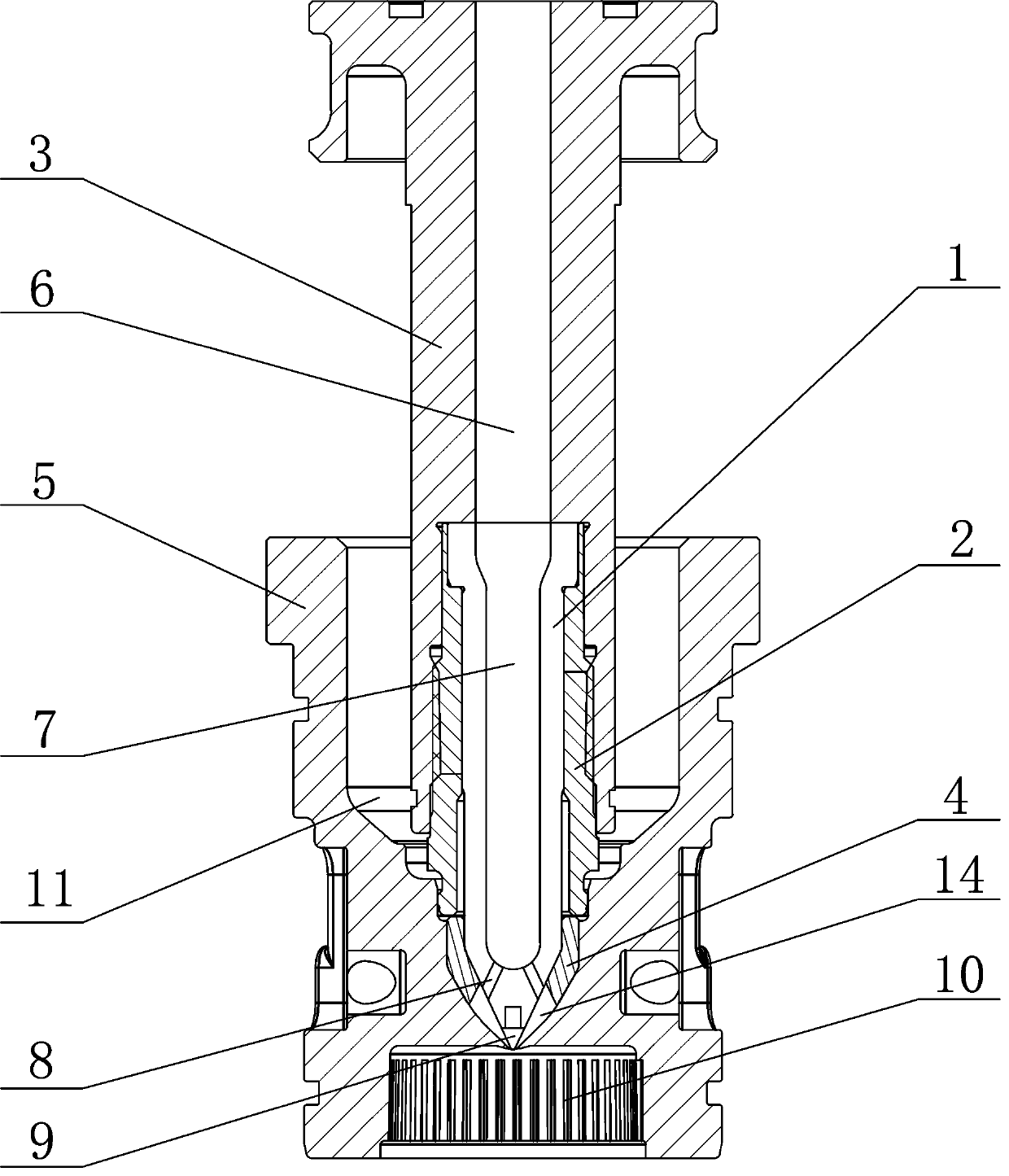

Wear-resistant degating structure and mounting process thereof

The invention discloses a wear-resistant degating structure. The wear-resistant degating structure comprises a gate mold core and a nozzle tip arranged in the gate mold core in a matched mode, whereina through degating channel is formed in the nozzle tip, a gap is formed between the gate mold core and the nozzle tip, and the gap communicates with the degating channel; a discharge port with stableflow is formed in the gap, and the gap gradually narrows towards the direction of the discharge port; and the end part of the nozzle tip is provided with a conical part, a wear-resistant tip is arranged on the conical part, generatrix of the wear-resistant tip is collinear with generatrix of the conical part, and the hardness of the wear-resistant tip and the hardness of the gate mold core are both greater than that of the nozzle tip. The wear-resistant tip is arranged at the end part of the nozzle tip, so that the hardness and the wear resistance of the end part of the nozzle tip are greatlyimproved on the premise of not influencing the overall heat conductivity of the nozzle tip, and the size of the discharge port is ensured, so that the flow of the discharge port is stable, the product quality is greatly improved and the service life of the degating structure is greatly prolonged.

Owner:CHENGDU LIANYU PRECISION MACHINERY

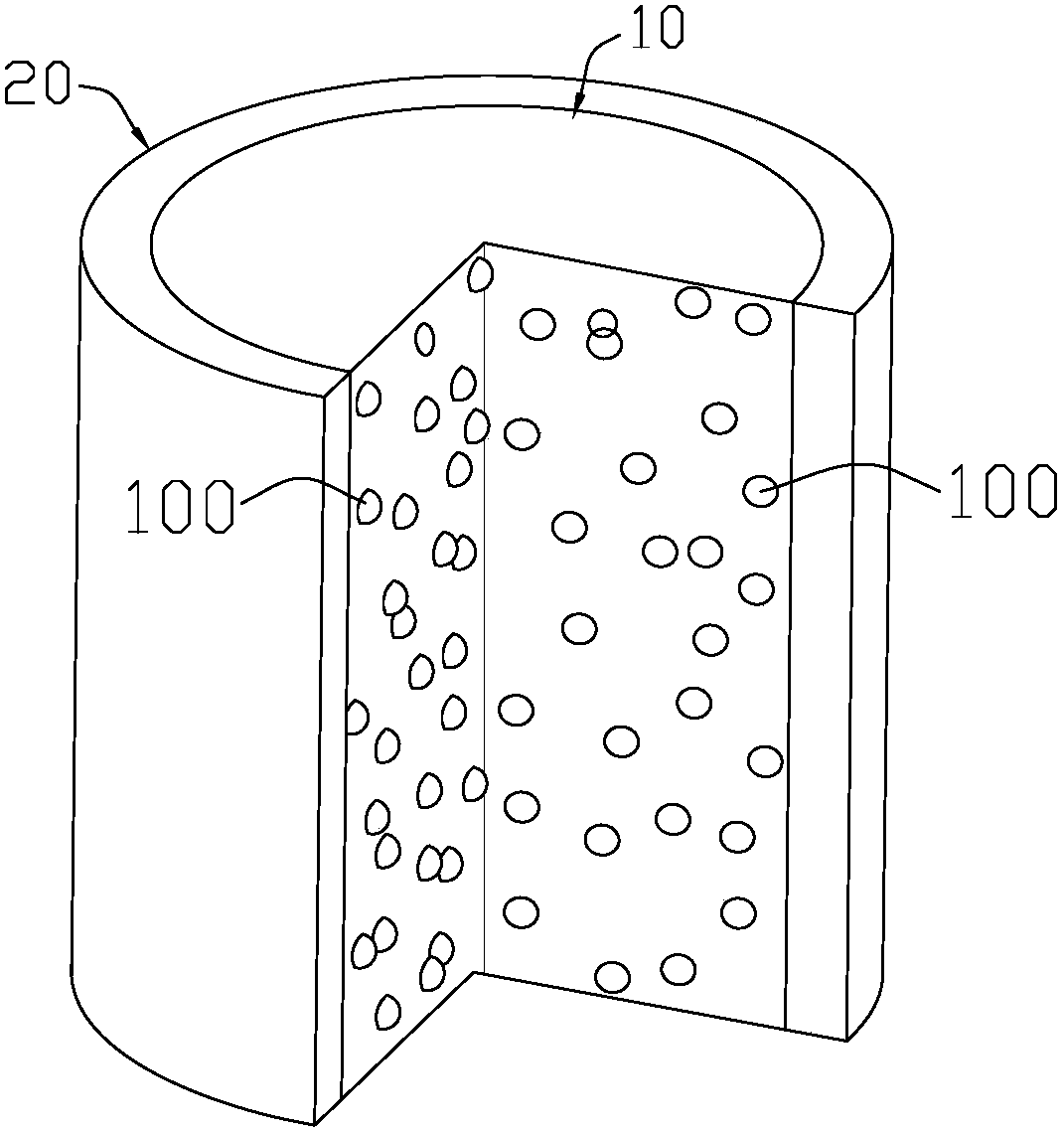

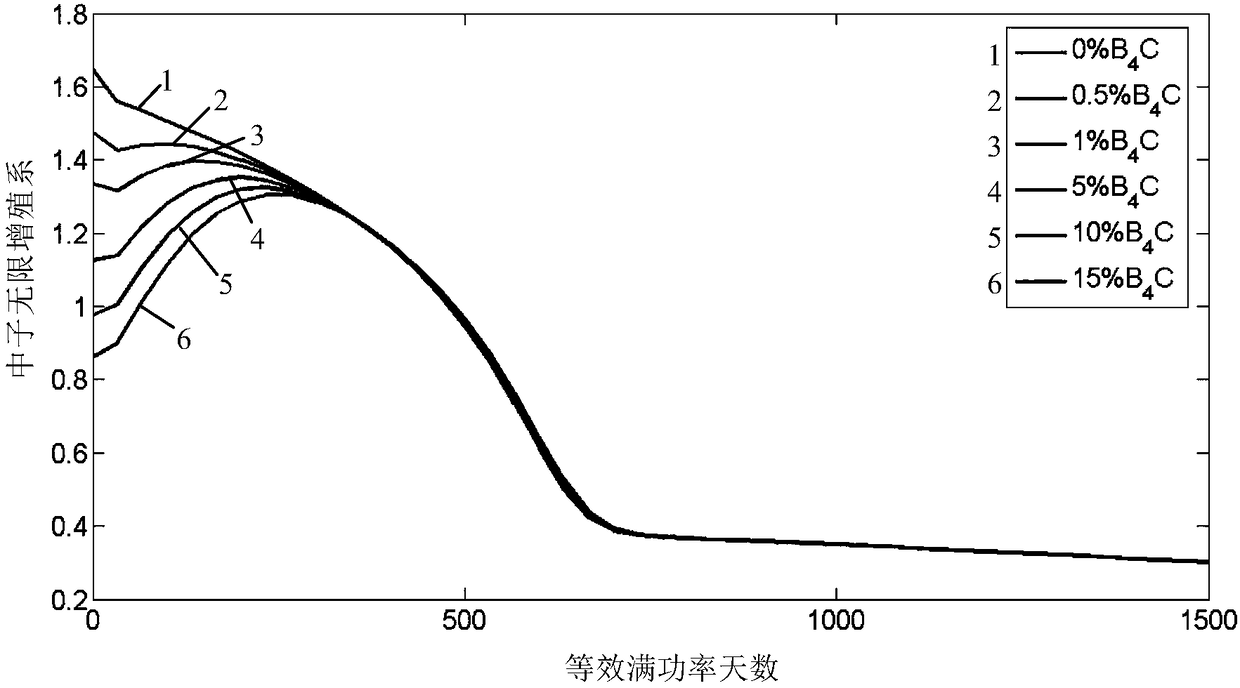

Boron carbide doped fuel pellet and production method thereof

InactiveCN108182979ADoes not affect melting pointDoes not affect thermal conductivityNuclear energy generationCeramic layered productsNeutron economyBoron carbide

The invention discloses a boron carbide doped fuel pellet and a production method thereof. The production method comprises the steps as follows: S1, raw materials of a first formula and a second formula are weighed respectively in percentage by mass; S2, the raw materials of the first formula and the second formula are mixed with ethanol respectively, then, polyethylenimine is added, the mixture is uniformly mixed through ball milling, and a first mixture and a second mixture are formed respectively; S3, 5%-20% of the first mixture is uniformly mixed in ethanol to form slurry, the slurry is sprayed on rolling TRISO particle surfaces, and to-be-pressed powder is formed after drying; S4, the second mixture is subjected to mold pressing to form a tube biscuit; S5, the to-be-pressed powder ispressed into a core biscuit in advance, the core biscuit is assembled in the tube biscuit, compact sintering is performed, and the boron carbide doped fuel pellet is obtained; or the to-be-pressed powder is put in the tube biscuit and subjected to mold pressing to form the core biscuit matched in the tube biscuit, compact sintering is performed, and the boron carbide doped fuel pellet is obtained.The neutron economy of the fuel pellet is improved.

Owner:GUANGDONG NUCLEAR POWER JOINT VENTURE +3

Thermally conductive adhesive tape

InactiveCN104031574ADoes not affect thermal conductivityImprove insulation performanceFilm/foil adhesivesPolyethylene terephthalatePackage design

The invention discloses a thermally conductive adhesive tape. The adhesive tape comprises a transparent PET (Polyethylene Terephthalate) film layer, wherein a graphite coating layer is formed on a side surface of the transparent PET film layer, the surface of the graphite coating layer is coated with an acrylic pressure-sensitive adhesive bonding layer, and a release film layer is adhered to the surface of the acrylic pressure-sensitive adhesive bonding layer. Due to the adoption of the structure, the thermally conductive adhesive tape disclosed by the invention has the following advantages that: 1, since adhesive tape is designed to be ultra-thin, the thermal conductivity of the graphite layer are not affected; 2, when the graphite layer is subjected to die cutting, the edge-packaged design can be adopted and thus the graphite film layer has good insulativity; and 3, the adhesive tape has good insulativity for the to-be-adhered objects, such as graphite film, mobile phone back shell, mobile phone motherboard, and stainless steel fins.

Owner:安徽格林开思茂光电科技股份有限公司

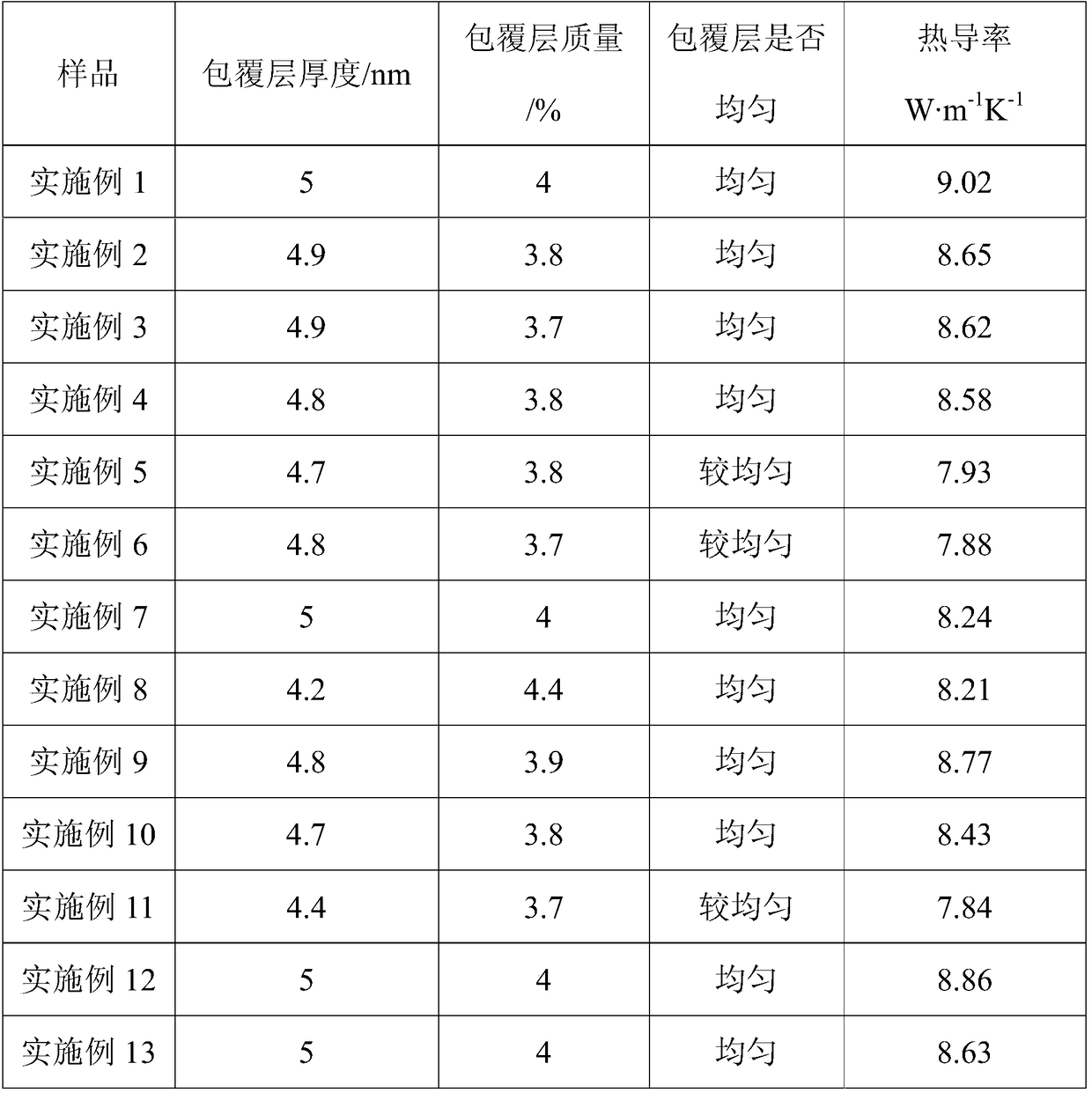

Modified hexagonal boron nitride as well as preparation method and application thereof

ActiveCN109161051ADoes not affect thermal conductivityReduce thicknessHeat-exchange elementsHexagonal boron nitridePolymer substrate

The invention provides modified hexagonal boron nitride as well as a preparation method and application thereof. The modified hexagonal boron nitride is prepared from polyethyleneimine as a coating layer, wherein t he thickness of the coating layer of the modified hexagonal boron nitride is 4-6nm. The modified hexagonal boron nitride provided by the invention has very good heat conductivity, and has good dispersibility in a polymer substrate.

Owner:SHENZHEN INST OF ADVANCED TECH

Production technique of solder tip

InactiveCN105563041ADoes not affect thermal conductivityImprove conductivitySoldering ironTinningMicrometer

The invention discloses a production technique of a solder tip. The production technique comprises the following steps: (1) manufacturing a copper mold blank, namely firstly straightening a copper material, cutting off the copper material after straightening is ended, and then lathing the head of the cut-off copper material on a lathe; (2) polishing and deoiling the copper mold blank in order to remove burrs from the lathed head; (3) preparing an iron plating solution and afterwards electroplating a layer of iron on the surface of the copper mold blank, wherein the thickness of the iron coating at a working part of the copper mold blank is 0.4mm to 0.5mm, and the thickness of the iron coating at a non-working part of the copper mold blank is 0.1mm to 0.15mm; (4) correcting the dimension of the copper mold blank on which the iron coatings are entirely plated, and polishing; (5) plating a layer of nickel coating on the surface of each iron coating, wherein the thickness of the nickel coating is 5 to 10 micrometers; (6) plating a layer of chromium coating on the surface of the non-working part of the nickel coating and plating a layer of tin coating on the working part of the nickel coating, wherein the chromium plating time is longer than or equal to 5min. The production technique of the solder tip has the advantages of improving the quality of the solder tip and prolonging the service life of the solder tip.

Owner:宁波市镇海城北电烙铁厂

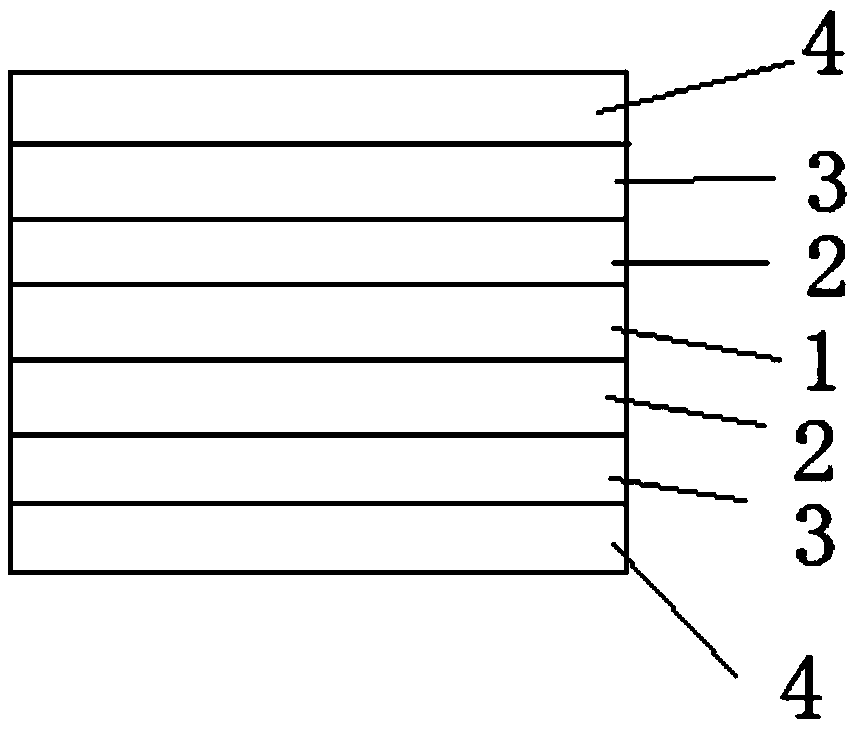

Multi-layer graphite heat conducting plate and preparation method thereof

InactiveCN109693427AImprove bending performanceDoes not affect thermal conductivityLamination ancillary operationsLaminationHeat conductingGraphite

The invention discloses a multi-layer graphite heat conducting plate and a preparation method thereof, wherein the preparation method comprises the following steps: selecting a plurality of high heatconducting graphite sheets according to the set thickness, and pasting the graphite sheets together to form a graphite heat conducting plate by a thin surface glue; and cutting the graphite heat conducting plate into a set shape, placing the graphite heat conducting plate in a deposition device, taking a macromolecular material as a deposition medium, carrying out CVD chemical vapor deposition, and generating an insulating macromolecular thin film on the surface of the graphite heat conducting plate, wherein the deposition thicknesses of the macromolecular thin films on the upper surface, thelower surface and all sides of the graphite heat conducting plate are the same. The invention has certain bending performance and high thermal conductivity, can be made into various shapes, and meetsuse of various types of environmental spaces.

Owner:GUANGDONG SUQUN NEW MATERIAL CO LTD

A kind of glued cotton

The present invention relates to the technical field of spray-bonded cotton, in particular to a spray-coated cotton, which includes a substrate and a functional agent. The surface of the sheet substrate and the internal space are sprayed with functional reagents; the weight components of the functional reagents are: 4-7 parts of sodium alginate, 0.1-0.5 parts of calcium chloride, 0.01-0.15 parts of surfactant, Adhesive 15-25 parts, thinner 50-65 parts. The product of the present invention has excellent moisture absorption and warmth retention properties and high fluffy properties, and is made by carding, glue spraying and special centrifugal process, and is suitable for clothing, bedding and household items.

Owner:FUJIAN JINJIANG HENGFENG SPEWING WEAVING

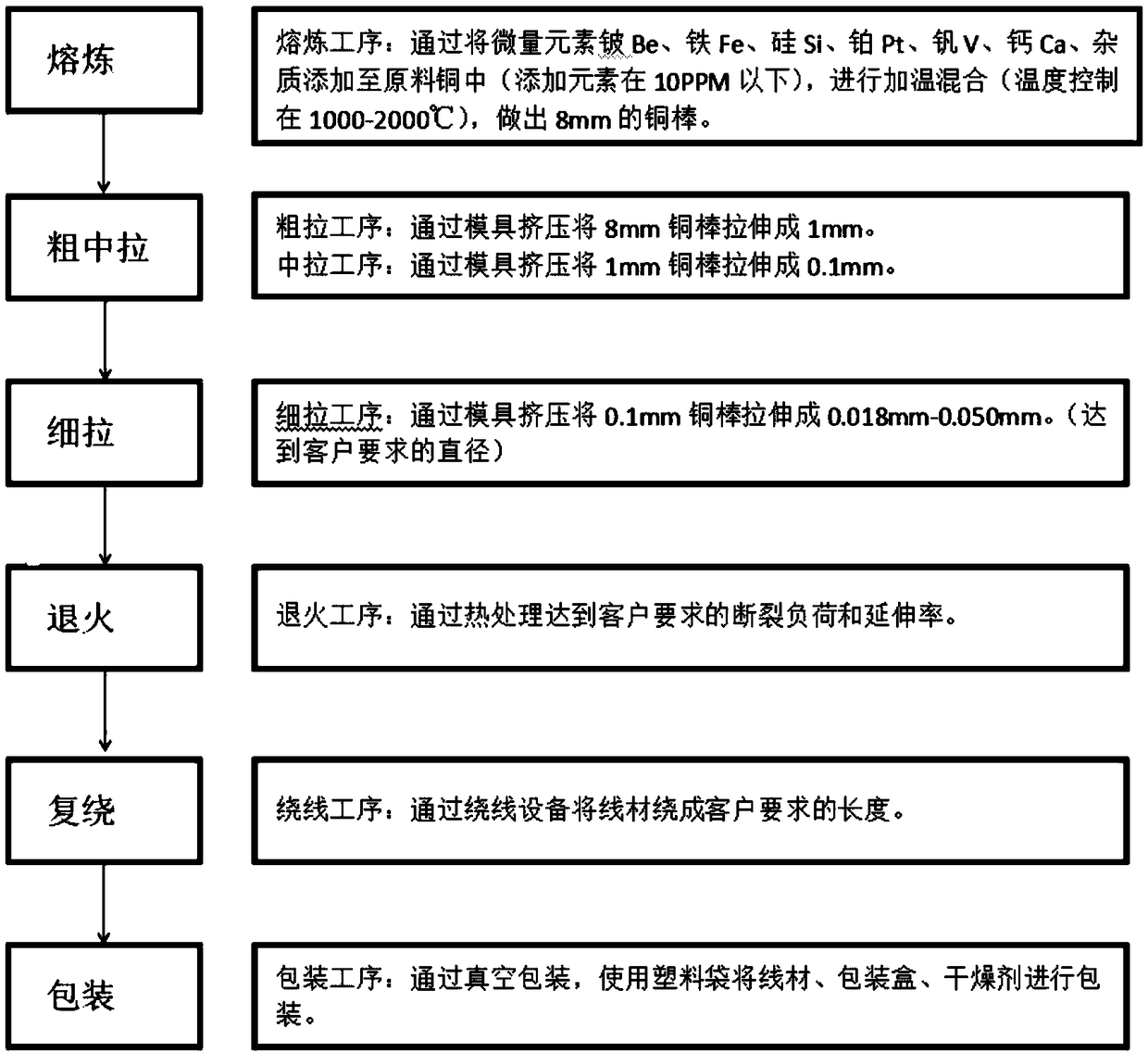

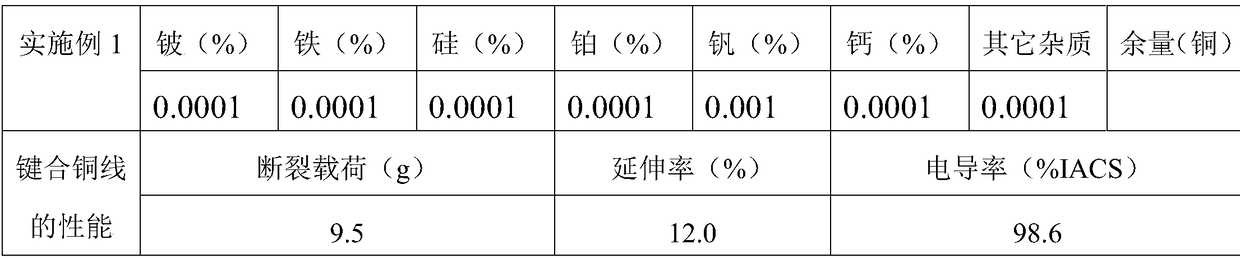

Bonded copper wire and preparation method thereof

The invention discloses a bonded copper wire. The bonded copper wire is prepared from the following components in percentage by mass: 0.0001%-0.0050% of beryllium, 0.0001-0.0010% of iron, 0.0001%-0.001% of silicon, 0.0001%-0.0010% of platinum, 0.001%-0.0050% of vanadium, 0.0001%-0.0050% of calcium, 0.0001%-0.01% of inevitable other impurity elements, and the balance of copper. A preparation methodfor the bonded copper wire comprises the following steps: (1) smelting; (2) rough-medium pulling; (3) fine pulling; (4) annealing; (5) re-winding; and (6) packaging. The preparation method can meet mechanical properties of a bonding material, and can provide the bonded copper wire with better surface oxidization resistance. Moreover, the preparation method is simple and convenient to operate, enables the processing material to obtain excellent mechanical properties, and meets practical using requirements.

Owner:上海万生合金材料有限公司

Heat-conducting composite material and plate

ActiveCN114133888ADoes not affect thermal conductivityWill not affect the heat storage functionNon-macromolecular adhesive additivesFilm/foil adhesivesCrack resistanceWood fibre

The invention discloses a heat-conducting composite material and a plate. The heat-conducting composite material comprises the following components in parts by weight: 100 parts of an adhesive, 10-3000 parts of a heat-conducting filler and 2-50 parts of a heat storage material, the heat-conducting filler comprises short wood fibers, a heat-conducting inorganic material and lignocellulose nanowhiskers. According to the heat-conducting composite material provided by the invention, the problem of cigarette burning resistance is well solved, and other side effects such as high water absorption and cracking resistance are not caused. The plate comprises the heat-conducting composite material, the surface of the plate can comprise a decorative layer, and the decorative layer does not affect the heat conduction, heat storage and heat dissipation functions of the heat-conducting composite material. In addition, the surface flatness of the sheet formed by mixing and pressing the heat-conducting, heat-dissipating and heat-storing layer is higher than that of a single plate, so that the surface of the decorative layer is more uniform, the heating process and the heat-dissipating and heat-transferring uniformity are improved, and the cigarette firing resistance is met.

Owner:JOMOO KITCHEN & BATHROOM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com