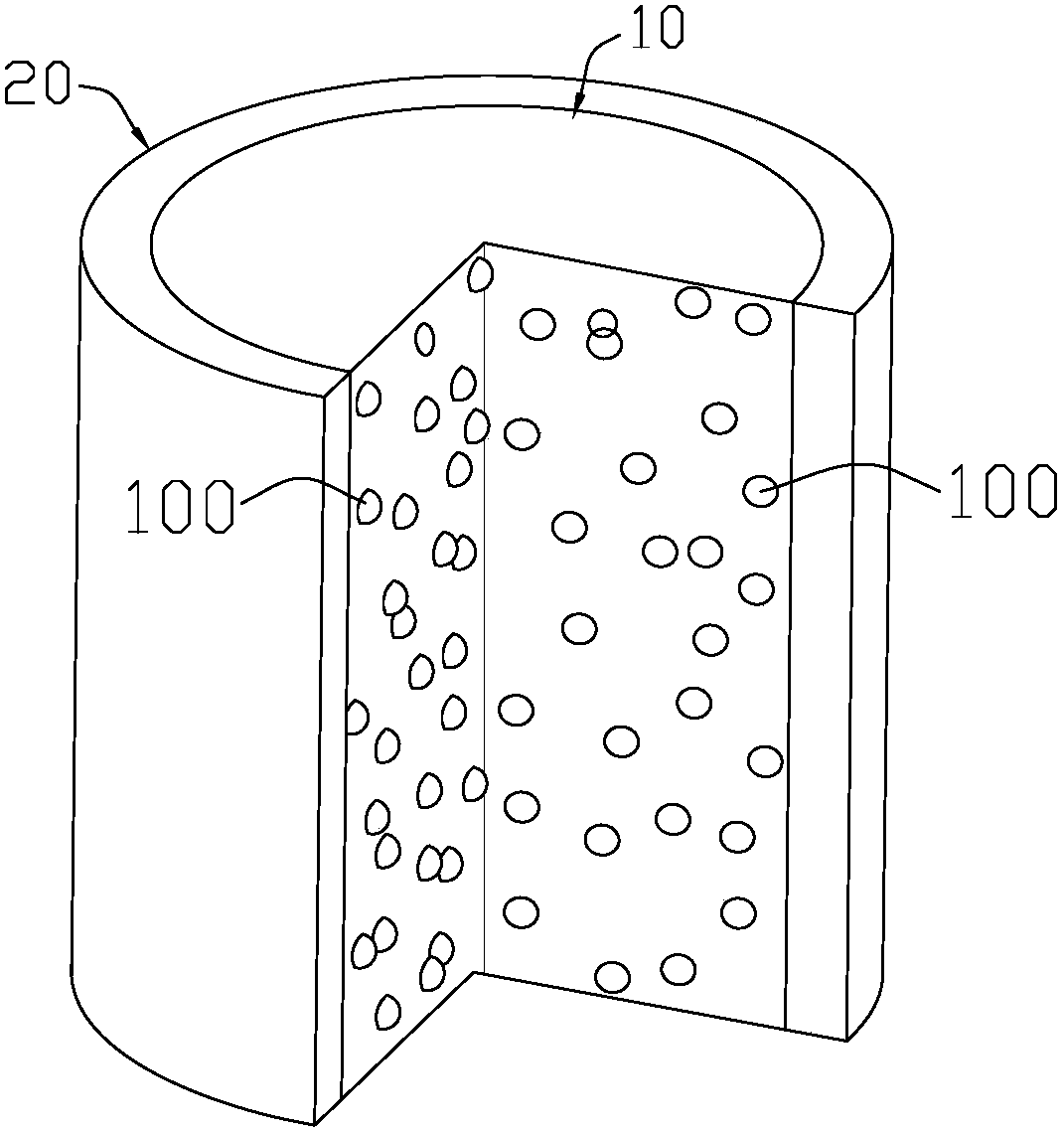

Boron carbide doped fuel pellet and production method thereof

A technology for fuel pellets and a manufacturing method, which is applied to chemical instruments and methods, reactor fuel materials, reactor fuel elements, etc., can solve the problems of easy volatilization, reduced high temperature stability of IMDP pellets, difficult and precise control of the content of combustible poisons, etc. Achieving the effect of broad industrial prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

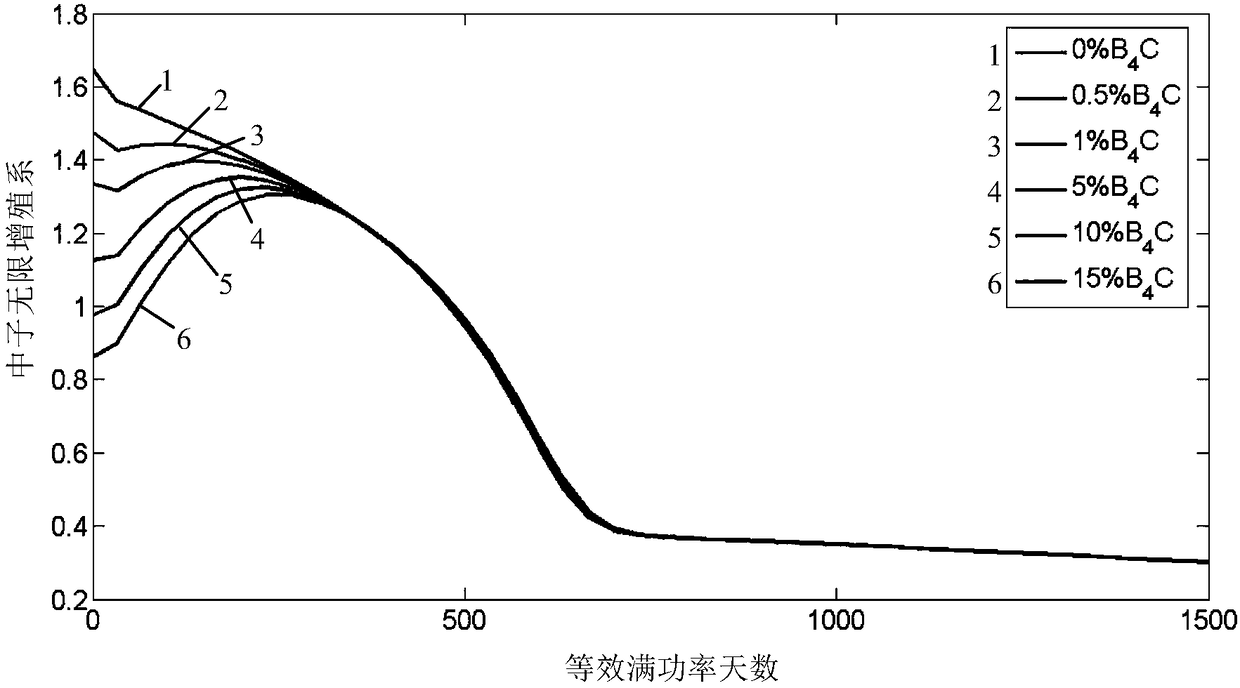

Embodiment 1

[0064] Weigh the following formula raw materials:

[0065] The first formula: Y with a particle size of 20nm 2 o 3 Powder 1.8wt.%, Al with a particle size of 10nm 2 o 3 Powder 3wt.%, SiO with particle size 10nm 2 Powder 1.2wt.%, particle size 0.5μm B 4 C powder 0.5wt.%; the rest is SiC powder with a particle size of 100nm.

[0066] The second formula: Y with a particle size of 20nm 2 o 3 Powder 1.8wt.%, Al with a particle size of 10nm 2 o 3 Powder 3wt.%, SiO with particle size 10nm 2 Powder 1.2wt.%; the remainder is SiC powder with a particle size of 100nm.

[0067] The raw material powders of the two formulations and ethanol with 2 times the mass were respectively placed in a nylon ball mill jar, polyethyleneimine (1wt.% of the raw material powder) was added, and ball milled on a planetary ball mill for 24 hours to form the first mixed material and the second mix.

[0068] Weigh 5-20wt.% of the first mixed material and mix it evenly in ethanol to form a slurry, sp...

Embodiment 2

[0072] The first formula: Y with a particle size of 20nm 2 o 3 Powder 3wt.%, Al with a particle size of 10nm 2 o 3 Powder 5wt.%, SiO with particle size 10nm 2 Powder 4wt.%, B with particle size 0.5μm 4 C powder 5wt.%; the remainder is SiC powder with a particle size of 100nm.

[0073] The second formula: Y with a particle size of 20nm 2 o 3 Powder 3wt.%, Al with a particle size of 10nm 2 o 3 Powder 5wt.%, SiO with particle size 10nm 2 Powder 4wt.%; the rest is SiC powder with a particle size of 100nm.

[0074] The raw material powders of the two formulations and ethanol with 2 times the mass were respectively placed in a nylon ball mill jar, polyethyleneimine (1wt.% of the raw material powder) was added, and ball milled on a planetary ball mill for 24 hours to form the first mixed material and the second mix.

[0075] Weigh 5-20wt.% of the first mixed material and mix it evenly in ethanol to form a slurry, spray the slurry on the surface of the rolling TRISO particl...

Embodiment 3

[0079] The first formula: Y with a particle size of 20nm 2 o 3 Powder 3.6wt.%, Al with a particle size of 10nm 2 o 3 Powder 6wt.%, SiO with particle size 10nm2 Powder 2.4wt.%, particle size 0.5μm B 4 C powder 15wt.%; the remainder is SiC powder with a particle size of 1 μm.

[0080] The second formula: Y with a particle size of 20nm 2 o 3 Powder 3.6wt.%, Al with a particle size of 10nm 2 o 3 Powder 6wt.%, SiO with particle size 10nm 2 Powder 2.4wt.%; the remainder is SiC powder with a particle size of 1 μm.

[0081] The raw material powders of the two formulations and ethanol with 2 times the mass were respectively placed in a nylon ball mill jar, polyethyleneimine (1wt.% of the raw material powder) was added, and ball milled on a planetary ball mill for 24 hours to form the first mixed material and the second mix.

[0082] Weigh 5-20wt.% of the first mixed material and mix it evenly in ethanol to form a slurry, spray the slurry on the surface of the rolling TRISO pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com