An overheat protection device

An overheating protection and overheating technology, applied in the direction of heating/cooling contact switch, etc., can solve the problems of loose battery electrode connection, thermal runaway of power battery, and ineffective thermal control sheet, etc., to achieve reasonable layout and increase contact area , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

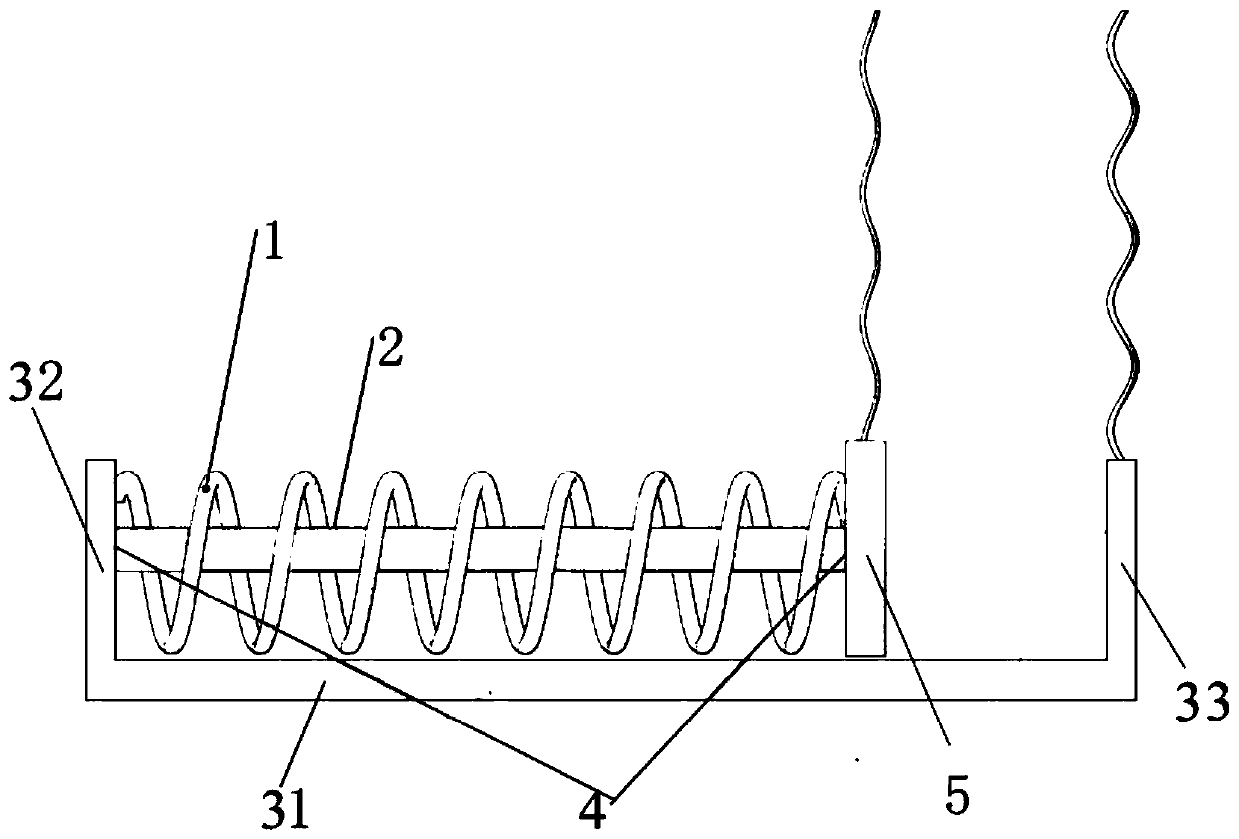

[0044] An overheating protection device, including a plastic element 2 and an elastic auxiliary assembly, the elastic auxiliary assembly includes a support and a spring 1 connected to the support at one end, and the plastic element 2 is connected between the support and the spring 1 so that the spring 1 is in energy storage state, and when overheated, it will be pulled and broken, so that the spring 1 releases energy. Both the spring 1 and the support are equipped with electrodes 5 for connecting with the alarm. The two electrodes 5 are in contact when the spring 1 releases energy, and the alarm is turned on. .

[0045] The material of the plastic element 2 can be selected from plastic materials with different melting temperatures according to the temperature requirements of its applied working conditions, such as polycaprolactone, polyvinyl chloride, polyethylene, polypropylene, nylon or polyoxymethylene, etc., and can also be blended, Filling, crosslinking, reinforcement, co...

Embodiment 2

[0055] An overheating protection device, including a plastic element 2 and an elastic auxiliary assembly, the elastic auxiliary assembly includes a support and a spring 1 connected to the support at one end, and the plastic element 2 is connected between the support and the spring 1 so that the spring 1 is in energy storage state, and when overheated, it will be pulled and broken, so that the spring 1 releases energy. Both the spring 1 and the support are equipped with electrodes 5 for connecting with the alarm. The two electrodes 5 are in contact when the spring 1 releases energy, and the alarm is turned on. .

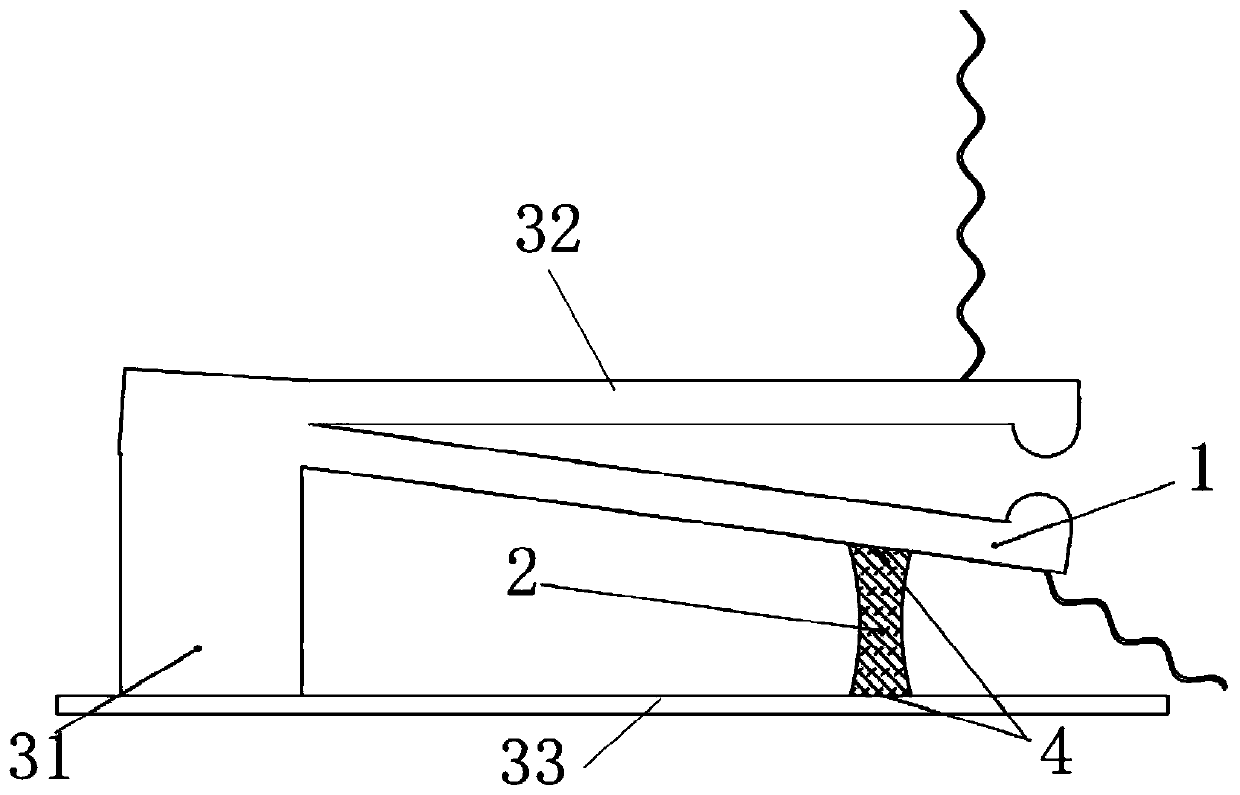

[0056] The support in this embodiment includes a support body in the shape of a "匚", the support body is composed of a connecting plate 31 and a first wing plate 32 and a second wing plate 33 arranged at both ends of the connecting plate 31, the spring 1 And the plastic element 2 is arranged in the semi-enclosed space surrounded by the support. Wherein, the spring 1 ...

Embodiment 3

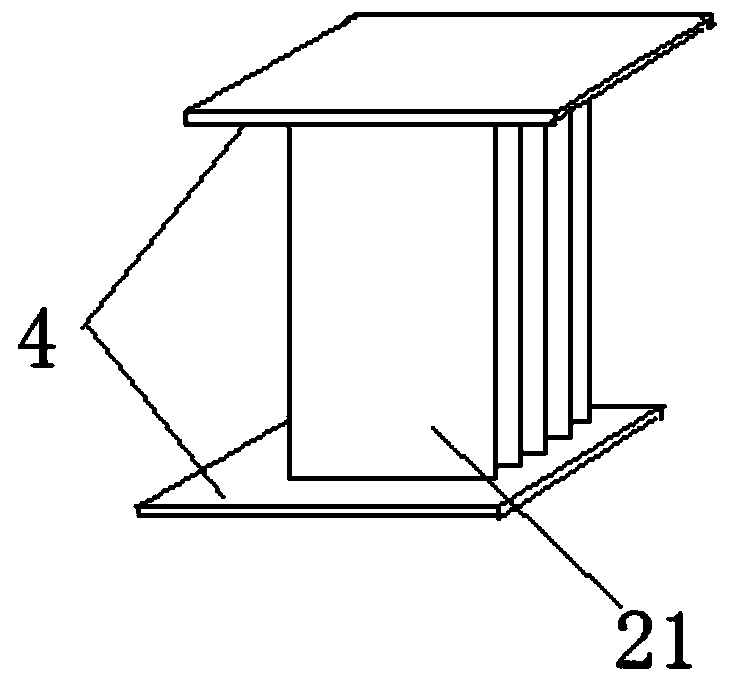

[0065] This embodiment is basically the same as Embodiment 2, except that the plastic element 2 in this embodiment is in the shape of a multi-layer film, including a plurality of parallel plastic films 21, and there is a gap between two adjacent plastic films 21. Such as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com