Preparing method of large-size low-heat-conductivity-coefficient high-strength foam carbon

A technology of low thermal conductivity and foam carbon, which is applied in the preparation/purification of carbon, etc., can solve the problems of foam carbon impact strength, low tensile strength, difficulty in controlling the overall structure of foam carbon, and difficulty in controlling the uniformity of foam carbon, etc., to achieve The effect of good overall structure, low cost and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

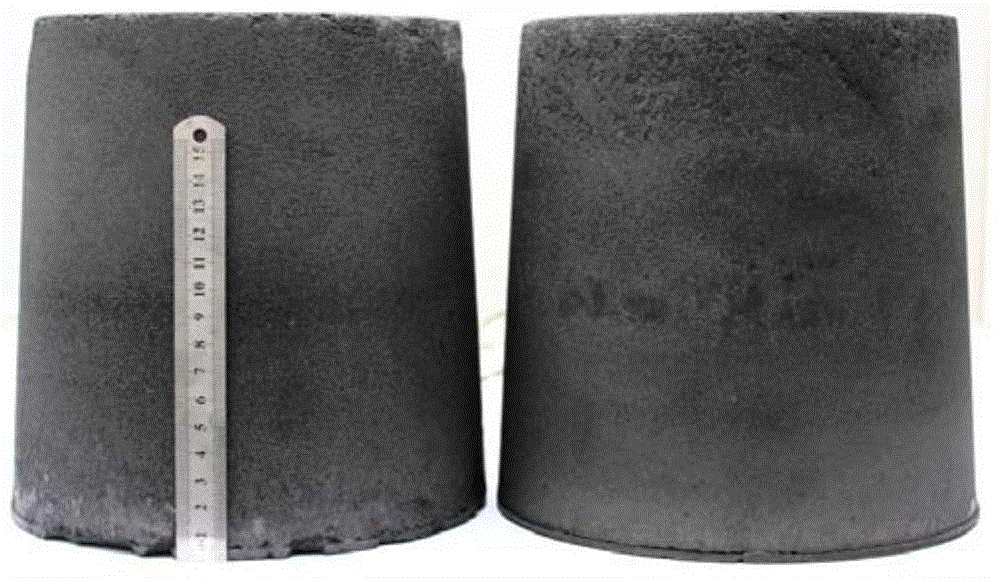

Embodiment 1

[0030] Mechanically mix 2000g of coal-based high softening point pitch with an average particle size of 5 microns, 200g of uncarbonized mesocarbon microspheres and 50g of activated carbon fibers, then place them in a 10L glass container, and then add 3L of ethanol for stirring mix. The above mixture was dried at 100°C, and placed in a 6L high-temperature and high-pressure reactor (inner diameter: 200mm) after drying. Put the high temperature and high pressure reactor into the initial pressure of 3MPa, then raise the temperature to 290°C at a rate of 3°C / min, and keep the temperature constant for 2h. Raise the temperature to 600°C at a rate of 0.2°C / min, and keep the temperature constant for 2h. At 600°C, quickly release the pressure to 1 atmosphere, and then continue to raise the temperature to 1000°C at a rate of 5°C / min for carbonization, and then foam carbon is obtained. The final foamed carbon has a diameter of 200mm, a height of 200mm, a thermal conductivity of 0.09W / (m...

Embodiment 2

[0032] The weight of the uncarbonized material of the mesophase carbon microspheres in [Example 1] was increased from 200g to 500g, and all other preparation conditions remained unchanged. The diameter of the prepared foam carbon is 200mm, the height is 200mm, the thermal conductivity is 0.101W / (m.k), the compressive strength is 31MPa, the volume shrinkage rate at 1500°C is 2.1%, and the density is 0.72g / cm 3 .

Embodiment 3

[0034] The initial pressure passed into the high-temperature and high-pressure reactor in [Example 1] is increased from 3MPa to 4.5MPa, and all other conditions remain unchanged. The diameter of the prepared foam carbon is 200mm, the height is 200mm, the thermal conductivity is 0.091W / (m.k), the compressive strength is 26MPa, the volume shrinkage rate at 1500°C is 2.2%, and the density is 0.69g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com