Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

81results about How to "Improve fire and water resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Self-insulation wall material

InactiveCN102795818AWith thermal insulationImprove fire and water resistanceClimate change adaptationPassive housesFiberThermal insulation

The invention discloses a self-insulation wall material. The self-insulation wall material comprising the following components in proportion: 30-90 parts by weight of high-performance cement or high-efficiency concrete admixture, 5-40 parts by weight of aggregate, 0.1-5 parts by weight of air entraining agent, 0-8 parts by weight of expanding agent, 0-2 parts by weight of waterproof agent, and 0-20 parts by weight of anti-crack fiber. The self-insulation wall material disclosed by the invention has thermal insulation and insulating performance similar to that of the organic insulation material, the strength of a material which can be used as a building enclosure, as well as the comprehensive performances of uniform and single material, convenience in construction, good durability, good fireproof and waterproof performance, resistance to deformation, and non-crack and non-leakage; and the invention provides an appropriate self-insulation material for saving more than 50% and 65% of building energy.

Owner:万俊松

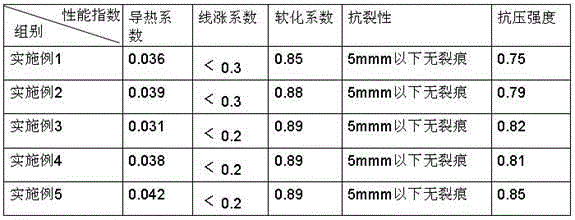

Crack-resistant thermal insulation mortar

The invention discloses crack-resistant thermal insulation mortar which consists of the following raw materials in parts by weight: 35-45 parts of common Portland cement, 20-30 parts of Mullite sand, 5-10 parts of diatomite, 4-8 parts of desulfurized fly ash, 3-6 parts of talcum powder, 40-50 parts of glass beads, 3-5 parts of micro-calcium silicate, 2-3 parts of polypropylene fiber, 1-2 parts of polyester fiber, 2-3 parts of polyvinyl acetate homopolymerization rubber powder, 0.4-0.8 part of hydroxyethyl cellulose ether, 3-5 parts of sodium polyacrylate, 2-3 parts of calcium lignosulphonate, 0.3-0.5 part of naphthalene water reducer and 4-6 parts of thermal insulation particles. The thermal insulation mortar is excellent in performance, can overcome the common problems such as cracking and flakes, is high in bonding strength and high in adhesive force, has excellent performances such as high thermal insulation property, weather resistance, high fire and water resistance and freezing resistance and is wide and readily available in raw material source, low in production cost, convenient in construction and wide in application prospect.

Owner:青岛米品品服装有限公司

Hydrolyzed animal blood meal cement foaming agent and its application in lightweight cement preparation

Belonging to the technical field of cement preparation, the invention specifically relates to a cement foaming agent with animal blood meal as a raw material and its application in lightweight cement preparation. The cement foaming agent is prepared by the steps of: in an alkaline solution, adding animal blood meal about 3%-5% of the weight of the alkaline solution, stirring the mixture for 4-8h and conducting hydrolyzation; then adjusting the reaction system to neutral, and stopping hydrolyzation, then removing waste residue by centrifugation or filtering, thus obtaining a foaming agent stock solution; adjusting the pH of the foaming agent stock solution to 8-9, adding a chelating agent, a stabilizing agent and a surfactant for stirring, thus obtaining a hydrolyzed animal blood meal cement foaming agent. The cement foaming agent prepared in the invention has table performance, high foam expansion rate, as well as low bleeding rate, and can generate foams with an average diameter of 0.5mm-3mm and independent pores. Lightweight cement products prepared by the cement foaming agent of the invention have low density, enclosed pores, different densities, low thermal conductivity, low sound absorption rate as well as good fire resistance and waterproofness, and are free of condition restriction and easy to implement.

Owner:JILIN UNIV

Board product and method for the preparation of the same

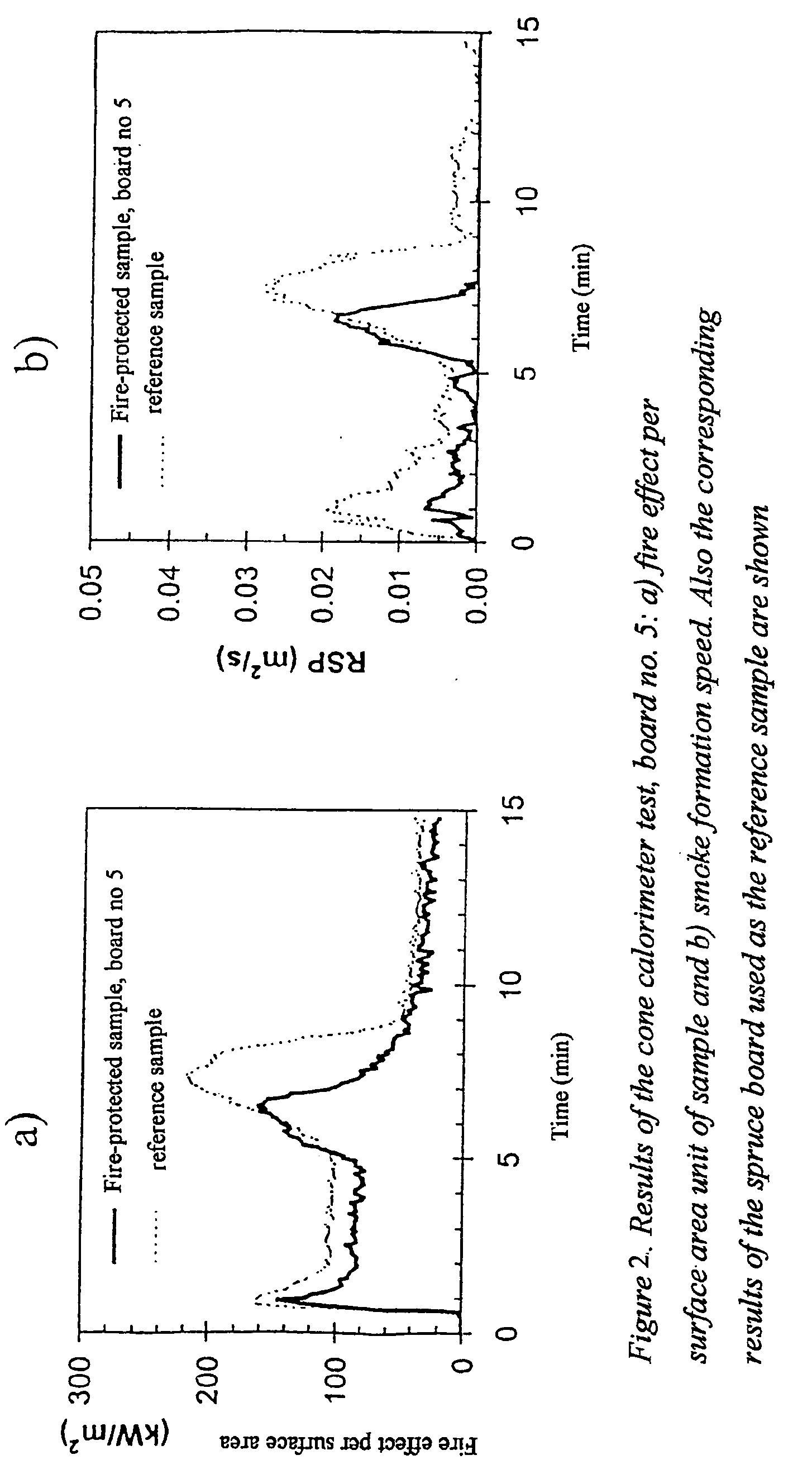

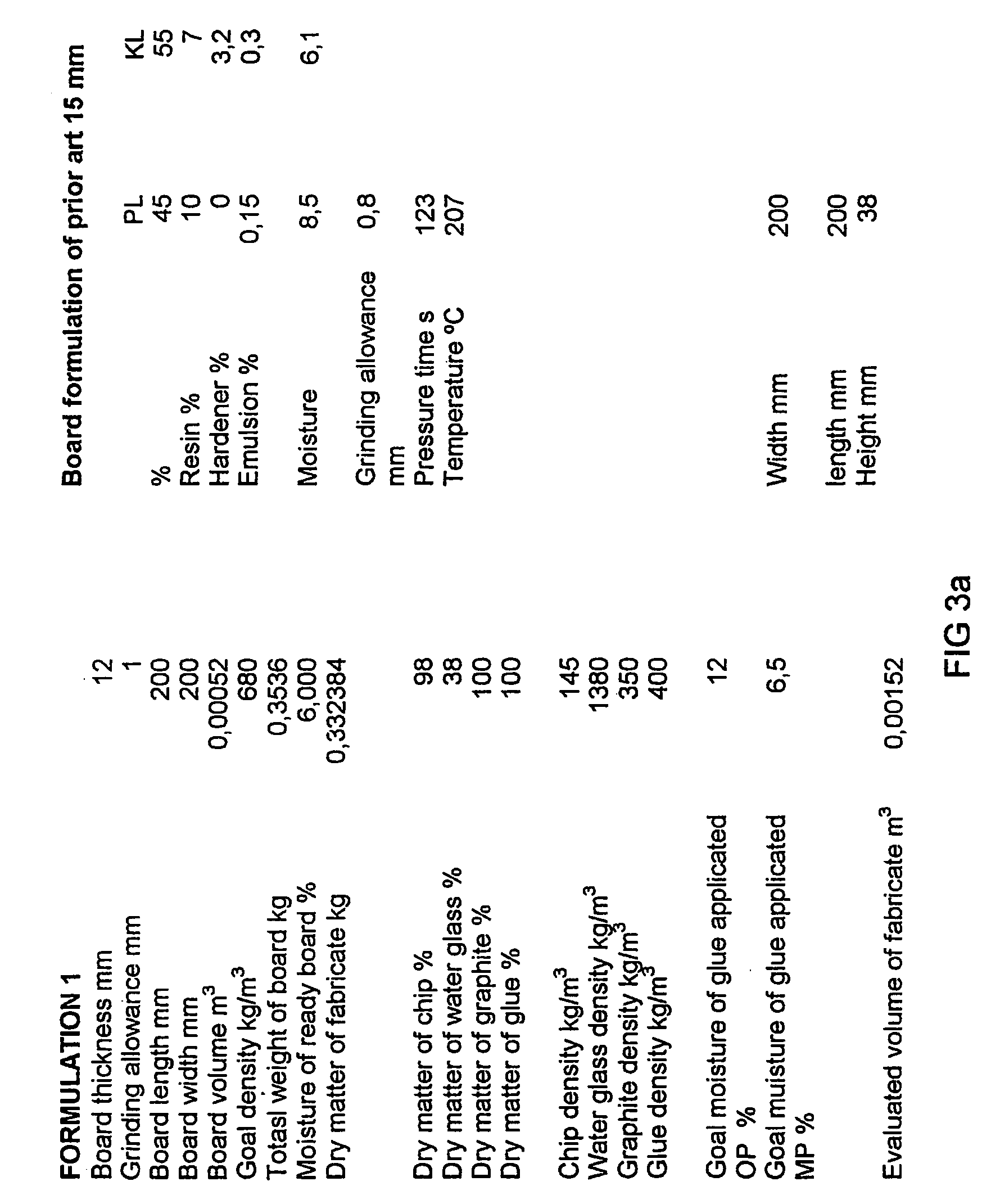

InactiveUS20050053778A1Improve fire and water resistanceImprove rigidityFibreboardNon-woven fabricsRefractoryGraphite

The invention is concerned with a board product that consists of wood material, a binding agent that keeps it together and additives. The binding agent is water glass and the product furthermore contains graphite that works as a fire resistant material and as a substance, which increases the water resistance. The invention is furthermore concerned with a method of preparing a board, wherein the wood material and graphite are mixed well together. Wall paper glue is added to this mixture if such glue is used, after which the mixture is again mixed and dry water glass is added after which the mixture is again mixed. Water is added to get the desired rigidity of the mixture, with which it can be regulated and then the mixture is poured into a form and compressed to desired density.

Owner:HUKKANEN JARMO

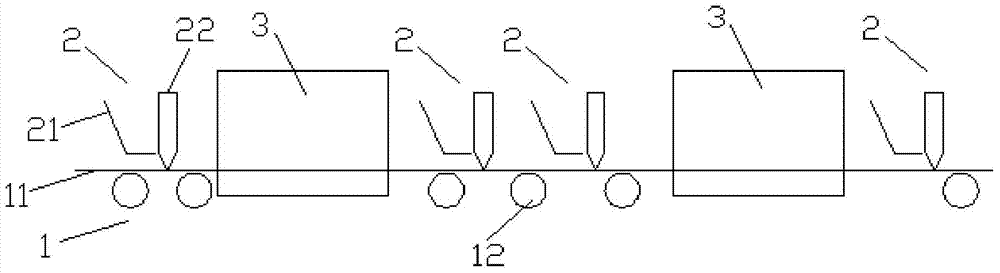

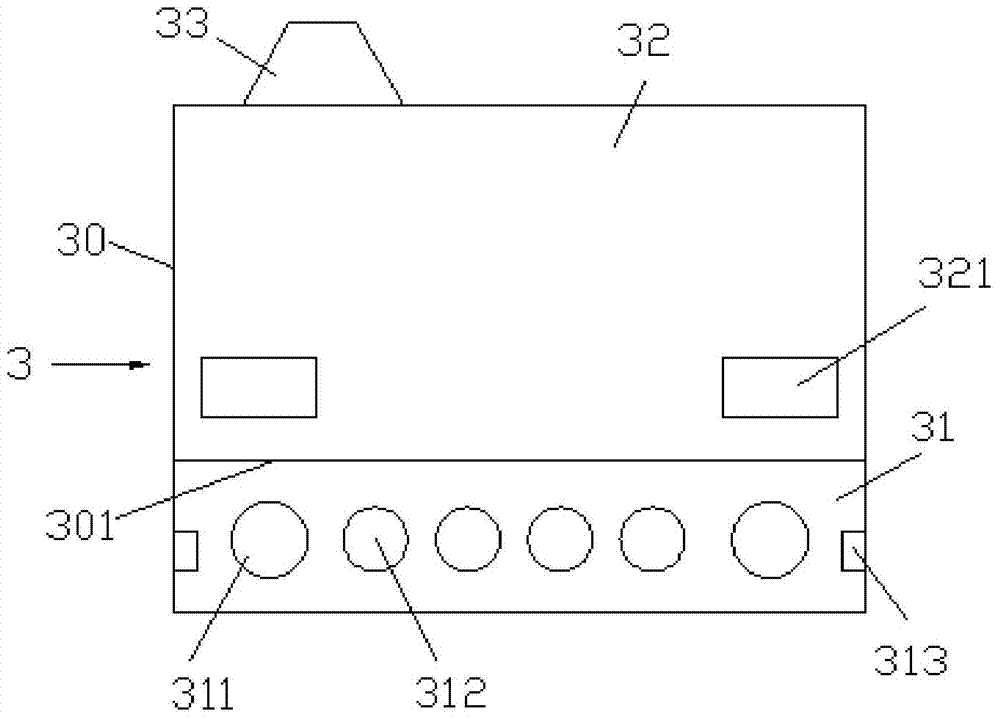

Coating process of fabric flame-retardant coating layer

ActiveCN104120571ASolve the upper limit of flame retardant and waterproof performanceImprove fire and water resistanceLiquid surface applicatorsCoatingsDry glueChemistry

The invention discloses a coating process of a fabric flame-retardant coating layer. A flame-retardant coating layer is coated on one or all of the upper surface and the lower surface of a fabric, primer coating, middle glue coating and surface glue coating are sequentially performed on a coating layer coating device, and total middle glue is coated in a twice mode. During coating, the middle glue accounting for 2 / 3 of total dried glue is added during the first-time coating, and the middle glue accounting for 1 / 3 of total dried glue is added during the second-time coating. The total middle glue is coated in a twice mode, so that the glue quantity of adhesive tapes in the fabric can be effectively increased, the upper limit problem of the flame-retardant water-proof performance is effectively solved, and the flame-retardant water-proof performance can be improved by a high level.

Owner:ZHEJIANG SHENGFA TEXTILE PRINTING & DYEING

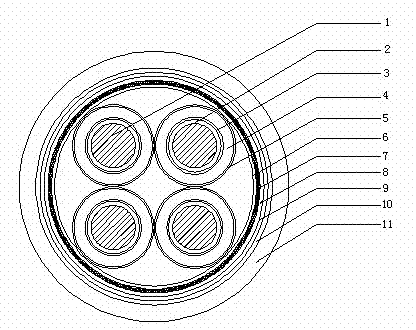

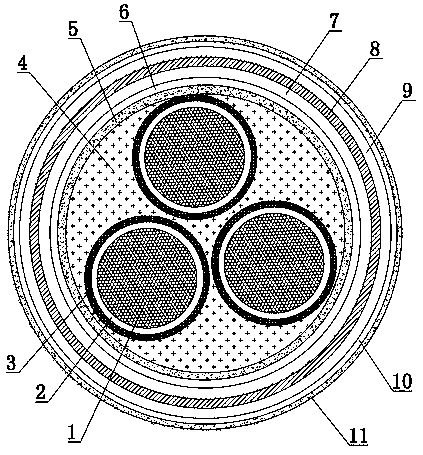

Environment-friendly safe waterproof fireproof cable

InactiveCN102789835AGood electrical and mechanical propertiesWon't happenNon-insulated conductorsFlexible cablesElectricityGreen environment

The invention relates to an environment-friendly safe waterproof fireproof cable which comprises an inner core of the cable and an outer layer of the cable. The cable is characterized in that the inner core of the cable comprises a conductive wire core, a fireproof layer and insulation shielding layers, wherein the fireproof layer is lapped on the conductive wire core, and the three insulation shielding layers formed in a coextrusion way are arranged outside the fireproof layer; and the outer layers of the cable comprises a semi-conductive waterproof belt, an inner lining layer, a copper wire-copper belt combined shielding layer, a semi-conductive waterproof buffering belt, a piece of aluminium foil and a expansion type halogen-free flame retardant protecting layer in sequence from inside to outside. The cable has the advantages that as the structure is adopted, fireproof, waterproof and safe and reliable effects can be realized, phenomena of spreading burning and harmful gas (such as halogen hydride) generating can not be generated, water can not enter the inside of the cable, a shielding system with a short circuit protection function can be arranged, and the design requirements of the green environment-friendly safe cable can be met. The cable is good in flexibility, can be bent frequently, can be laid flexibly, is good in insulation effect, is good in waterproof performance, avoids accidental electricity leakage, can not influence the reduction of the electrical performance, and is particularly suitable for certain occasions with relatively high fireproof requirements in coastal areas with relatively high humidity.

Owner:SHANGHAI SPECIAL CABLE +1

Insulation mortar and preparation method thereof

InactiveCN107162634AImprove crack resistanceHigh bonding strengthCeramicwareFiberCarboxymethyl cellulose

The invention discloses an insulation mortar and a preparation method thereof, which belong to the technical field of the cement mortar. The insulation mortar comprises the following components: 100-150 parts of ordinary portland cement, 50-80 parts of vitreous bead, 50-70 parts of pregelatinized starch, 20-50 parts of coated expanded perlite, 20-30 parts of diatomite, 10-20 parts of modified attapulgite, 10-15 parts of rubber particles, 10-15 parts of plant composite fiber, 2-8 parts of soluble glass, 2-6 parts of carboxymethyl cellulose, 2-6 parts of fireproof particles, 1-6 parts of active admixture, 0.2-1.2 parts of a water repellent, 0.2-0.6 parts of a physical foaming agent, and 100-200 parts of water. The preparation method comprises the following steps: 1) preparing the coated expanded perlite; 2) preparing the straw-coated particles; 3) preparing a slurry; and 4) preparing the finished product. The insulation mortar has the advantages of excellent crack resistance, high bonding intensity and strong adhesive force.

Owner:合肥市晨雷思建筑材料科技有限公司

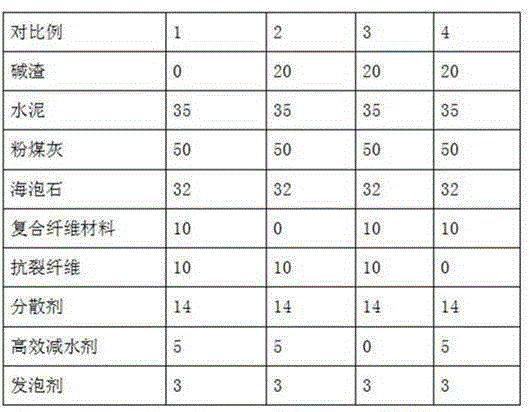

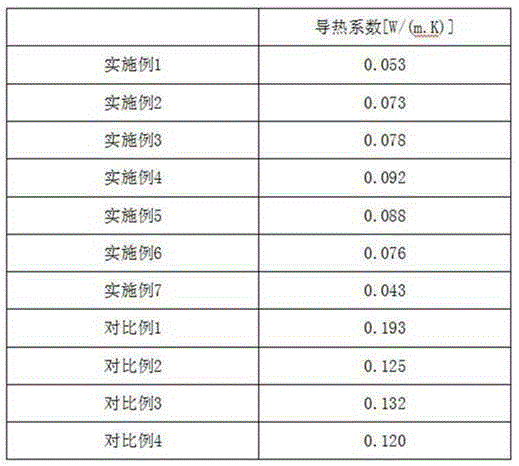

Compound silicate external wall insulation material

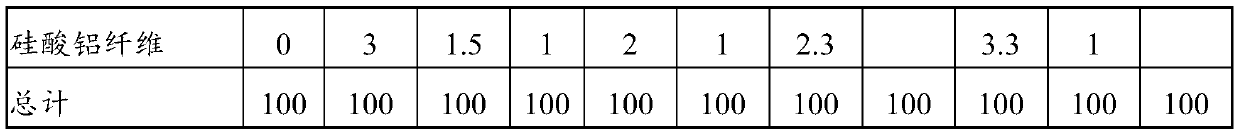

PendingCN105315002AImprove fire and water resistanceImprove adsorption capacityCeramicwareFiberFoaming agent

The invention relates to a compound silicate external wall insulation material. The compound silicate external wall insulation material is prepared from, by weight, 15-20 parts of caustic sludge, 30-50 parts of cement, 50-55 parts of coal ash, 31-36 parts of sepiolite, 10-14 parts of composition fiber materials, 6-10 parts of anti-cracking fiber, 10-14 parts of a dispersing agent, 3-5 parts of a high efficiency slushing agent and 1-5 parts of a foaming agent. The compound silicate external wall insulation material meets the requirement for environment protection, does not contain asbestos or perlite, is small in density, good in heat insulation performance, good in anti-cracking performance, capable of utilizing caustic sludge, environmentally friendly, low in cost, and good in fireproof and waterproof performance.

Owner:WENDENG LANDAO ARCHITECTURAL ENG CO LTD

Environment-friendly thermal insulation mortar

The invention discloses an environment-friendly thermal insulation mortar comprising the following components in parts by weight: 40-65 parts of Portland cement, 10-20 parts of thermal insulation aggregate, 5-10 parts of reinforced fibers, 5-10 parts of redispersible latex powder, 10-20 parts of filler, 1-5 parts of light calcined magnesia and 5-10 parts of kieselguhr. The environment-friendly thermal insulation mortar has excellent cracking resistance, high bonding strength, strong adhesive force and good thermal insulation heat insulation property, weather resistance, fire and water resistance and freezing resistance. By utilizing the environment-friendly thermal insulation mortar, such common problems of the thermal insulation mortar as cracking and flaking are overcome. The thermal insulation mortar is good in volume stability, generates volume microdilatancy during setting and hardening, does not crack or hollow and is strong in water resistance and ageing resistance and long in service life. The environment-friendly thermal insulation mortar is non-toxic, odorless, non-radioactive and harmless to a human body. By utilizing the environment-friendly thermal insulation mortar, the environment can not be polluted, energy is saved, the environment is protected, and electromagnetic radiation is absorbed.

Owner:QINGDAO WINCHANCE TECH

Waterproof heat preservation material for floors of a floor heating system

InactiveCN106977163AImprove technical effectImprove fire and water resistanceGlass fiberCalcium hydroxide

The invention discloses a waterproof heat preservation material for floors of a floor heating system. The heat preservation material is prepared from the raw materials of silicon dioxide, glass fiber, porous ceramisite, cement, graphite modified expanded polystyrene, a waterproof agent, calcium hydroxide, dimethyl siloxane and water according to the mass ratios of (20 to 30) to (30 to 40) to (40 to 45) to (35 to 45) to (20 to 30) to (15 to 18) to (3 to 8) to (5 to 10) to (140 to 150). The heat preservation material disclosed by the invention combines the advantages of raw materials of various heat preservation materials, and a novel heat preservation material which is good in comprehensive technical effect, high in fire and water prevention performance and good in heat preservation effect can be provided; the heat preservation material can be used in occasions such as roof heat preservation engineering and floor heating engineering or used for manufacturing a composite heat preservation plate.

Owner:SICHUAN YISEN THERMAL ENERGY SCI & TECHCO

Fireproof and waterproof composite board

InactiveCN101134326ASimple structureSimple processWood veneer joiningWood layered productsGlass fiberAdhesive

The fireproof and waterproof composite board with magnesia layer consists of one glass fiber reinforced magnesia board and one woody base board combined together with resin glue, foamed glue, universal glue or powerful glue, and the woody base board may be veneer, multilayer board, shaving board or artificial board. The fireproof and waterproof composite board is produced through painting adhesive between the glass fiber reinforced magnesia board and the woody base board and pressing to combine. It has simple structure, simple production process, high fireproof and waterproof performance, high strength and environment friendship.

Owner:王伯华

Fireproof and waterproof wallpaper and preparation method thereof

InactiveCN106835854AImprove waterproof performanceHigh speed stirringFireproof paintsCovering/liningsFiberSilanes

The invention discloses fireproof and waterproof wallpaper. The fireproof and waterproof wallpaper is prepared from a base material layer, a waterproof layer and a fireproof layer, wherein the periphery of the base material layer is coated with the waterproof layer; the periphery, which is far away from the base material layer, of the waterproof layer is coated with the fireproof layer; the fireproof layer is prepared from the following raw materials: epoxy acrylate, vinyl acetate homopolymer emulsion, pure acrylic emulsion, styrene-acetate copolymerization emulsion, silica sol, nano zinc borate, nano magnesium hydroxide, sepiolite, expanded vermiculite, expanded perlite, wood fiber, a modification additive, talcum powder, aluminum triphosphate, nano barium sulfate, fluorosilicon oil, sodium hexametaphosphate, dimethylbenzene, propylene glycol, an organic silicon defoamer, hydroxyethyl cellulose, a polyurethane thickener, a silane coupler KH-560, nonylphenol polyoxyethylene ether and deionized water. The invention also provides a preparation method of the fireproof and waterproof wallpaper. The fireproof and waterproof wallpaper prepared and obtained through the preparation method has excellent fire resistance and excellent water resistance.

Owner:安徽易有墙纸有限公司

High-strength vertical-fiber waterproof rock wool plate and production method thereof

InactiveCN105239680AImprove insulation effectImprove fire and water resistanceHeat proofingBuilding insulationsFiberHigh intensity

The invention discloses a high-strength vertical-fiber waterproof rock wool plate and a production method thereof. The high-strength vertical-fiber waterproof rock wool plate has both sides to which inorganic fireproof waterproof films are combined. The inorganic fireproof waterproof films are combined to the vertical-fiber rock wool plate through quick instant glue. The inorganic fireproof films are fiberglass mats the surface of each of which is infiltrated with an inorganic silicon nano-material waterproof layer. By using the automatic line production manner, overcome are the defects that at present, existing various combined rock wool plates are generally high in production cost, a binding process is complex, steam-curing maintenance is required, thermal solidifying is required, a processing cycle is long and large-scale continuous production is unable to be achieved.

Owner:JINCHANG WANLONG IND

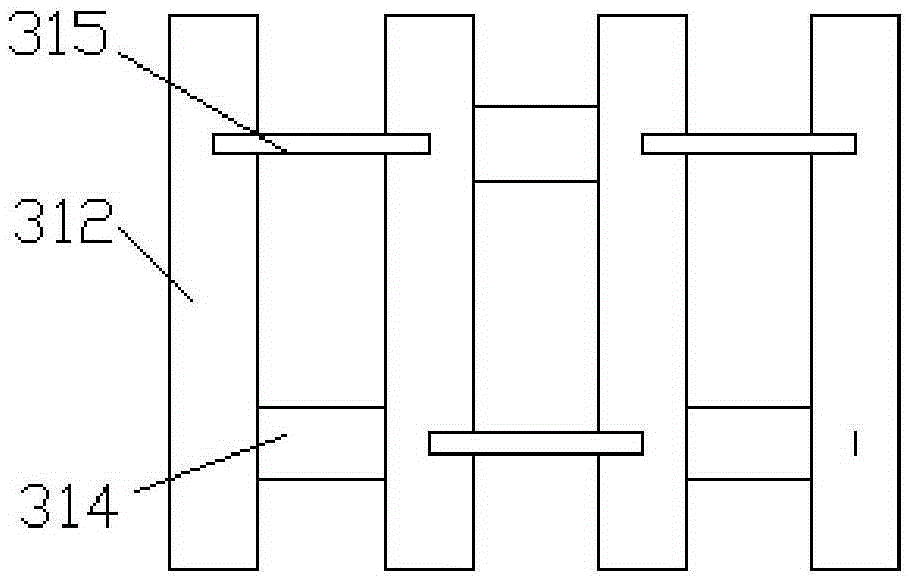

Water-blocking medium-voltage power cable employing aluminum-scandium alloy conductors

ActiveCN105719769ALow costGood flame retardant and waterproof effectConductive materialPower cables with screens/conductive layersAluminiumScandium

The invention discloses a water-blocking medium-voltage power cable employing aluminum-scandium alloy conductors. A wire core of the cable comprises three power wire cores, wherein each power wire core is formed by sequentially arranging a power wire core conductor shielding layer, a power wire core insulating layer and a power wire core metal shielding layer outside a power wire core conductor; a water-blocking tape lapping layer, an aluminum-plastic tape longitudinal wrapping layer, a galvanized steel strip armor layer and a polyvinyl chloride sheath are sequentially arranged outside the three power wire cores; and the space between the three power wire cores and the water-blocking tape lapping layer is filled with a water-blocking filling strip. The aluminum-scandium alloy conductors are adopted as the power wire core conductors, so that, on one hand, a plurality of disadvantages when pure aluminum is adopted as the wire and cable conductors are avoided, and the water-blocking medium-voltage power cable has the advantages of creep resistance, high flexibility, high ductility, low resilience, connection stability, good water-blocking property and the like; and on the other hand, the cost of the cable is also reduced by 50%.

Owner:ANHUI LINGYU CABLE TECH

Cement foaming agent

The invention discloses a cement foaming agent which comprises the following raw materials in parts by weight: 1-1.9 parts of rosin, 0.5-1 part of bone glue, 0.2-0.5 part of sodium hydroxide, 0.2-0.5 part of lauryl sodium sulfate, 3-5 parts of glutinous rice starch and 90-95 parts of water. The rosin is first level rosin, the bone glue is high quality bone glue, and the cement foaming agent also comprises 0.5-1 part of a silicone resin polyether emulsion as a foam stabilizer. The cement foaming agent is high in foaming rate, good in cement compatibility and stable in foam, is light in weight, high in strength, small in dosage and low in cost, is good in fireproof and waterproof properties, free of radioactivity and wide in application, and has energy-saving and environmental-friendly effects; the raw materials are easily available, and the preparation process is simple and easy to implement.

Owner:舒浪平 +1

Heat insulation mortar and preparation method thereof

The invention discloses a heat insulation mortar and a preparation method thereof, and relates-the technical field of cement mortars. The heat insulation mortar comprises 100-150 parts of ordinary Portland cement, 50-80 parts of glazed hollow beads, 50-70 parts of pre-gelatinized starch, 20-50 parts of coated expanded perlite, 20-30 parts of diatomaceous earth, 10-20 parts of modified attapulgite,10-15 parts of rubber particles, 10-15 parts of plant composite fiber, 2-8 parts of water glass, 2-6 parts of carboxymethylcellulose, 2-6 parts of refractory particles, 1-6 parts of an active admixture, 0.2-1.2 parts of a water repellent, 0.2-0.6 part of a physical foaming agent and 100-200 parts of water. The preparation method comprises the following steps: (1) preparing the coated expanded perlite; (2) preparing straw coated particles; (3) preparing a slurry; and (4) preparing the finished product. The heat insulation mortar has the advantages of excellent crack resistance, high bonding strength and strong adhesion.

Owner:张建

Calcium sulfate antistatic floor base material

ActiveCN105753450AHigh strengthImprove fire and water resistanceCeramic materials productionCeramicwareZinc borateSulfate

The invention belongs to the field of floors, and discloses a calcium sulfate antistatic floor base material.The calcium sulfate antistatic floor base material is prepared from calcium sulfate, paper fibers, zeolite powder, perlite, sepiolite, lignocelluloses, coal ash, peanut shells, soya bean meal, brucite fibers, polypropylene fibers, carboxymethylcellulose, kieselguhr, zinc borate and water.The floor made from the base material is good in antistatic performance, has good inflaming retarding and water preventing performance and mechanical performance, and is environmentally friendly, free of pollution, wide in application prospect and capable of being used instead of wooden floors in part of occasions.

Owner:山东汇联活动地板有限公司

Cable

InactiveCN104091641AImprove fire and water resistanceInsulated cablesPolyether coatingsElastomerPolyolefin

The invention provides a cable. The cable comprises a core, filler and a covering layer which are coaxially arranged from inside to outside in sequence, wherein the covering layer comprises the following components in parts by weight: 60-70 parts of polyolefin elastomer, 20-30 parts of magnesium hydroxide powder, 30-40 parts of aluminium hydroxide powder, 1-2 parts of magnesium oxide powder, 1-2 parts of fumed silica, 0.2-1 part of coupling agent, 5-7 parts of plasticizer and 1-3 parts of cross-linking agent; and the inner layer of the covering layer is coated with a water repellent flame retardant coating. The cable can reach the flame retardant grade UL94-V0, has excellent fire resistance and water resistance, can be widely applied to various fields and has good market prospect.

Owner:广州粤道智能科技发展有限公司

Fireproof coating for surface of steel structure and application thereof

The invention provides a fireproof coating for the surface of a steel structure, wherein the fireproof coating comprises, by weight, 12-25 parts of a fluorosilicone emulsion, 20-35 parts of a siliconeacrylic emulsion, 2-8 parts of a flame retardant, 2-12 parts of a carbon forming agent, 15-25 parts of a foaming agent, 3-8 parts of white oil, 8-15 parts of a filler, 3-10 parts of an antirust agent, 0.5-1.5 parts of an auxiliary agent, 0.1-0.5 part of a bacteriostatic agent, 0.1-0.5 part of a pH regulator and 1-3 parts of refractory fibers. Compared with the traditional epoxy fireproof coating,the fireproof coating disclosed by the invention is more suitable for steel structure coating construction needing both fire prevention and corrosion prevention, has excellent adhesive force, cracking resistance and weather resistance, and does not crack or fall off in a high-low temperature alternating environment.

Owner:铁科金化检测中心有限公司 +3

Thermal insulation wallboard and method for producing the same

InactiveUS20160375663A1Light weightSimple structureLamination ancillary operationsLayered product treatmentThermal insulationInterface layer

A thermal insulation wallboard including a thermal insulation board, a first hardened resin layer, a first alkali-resistant glass cloth, a second hardened resin layer, a third hardened resin layer, a second alkali-resistant glass cloth, a fourth hardened resin layer and waterproof interface layers. The first hardened resin layer is arranged on one side of the thermal insulation board. The first alkali-resistant glass cloth is arranged on the external part of the first hardened resin layer. The second hardened resin layer is arranged on the external part of the first alkali-resistant glass cloth. The third hardened resin layer is arranged on the other side of the thermal insulation board. The second alkali-resistant glass cloth is arranged on the external part of the third hardened resin layer. The fourth hardened resin layer is arranged on the external part of the second alkali-resistant glass cloth.

Owner:NANJING JINGYEDA NEW BUILDING MATERIALS

Anti-explosion cable structure

InactiveCN103606403ASimple structureStrong explosion-proofClimate change adaptationInsulated cablesElectrical conductorMica

The invention discloses an anti-explosion cable structure which comprises a cable conductor core. A mica fireproof layer is arranged outside the cable conductor core, a waterproof layer is arranged outside the mica fireproof layer, a first anti-explosion layer is arranged outside the waterproof layer, an anti-flaming layer is arranged outside the first anti-explosion layer, a second anti-explosion layer is arranged outside the anti-flaming layer, and an outer protective sleeve layer is arranged outside the second anti-explosion layer. In this way, the anti-explosion cable structure is simple and reasonable in structure, has the good fireproof and waterproof performance, and is good in anti-explosion performance.

Owner:WUXI GREAT TECH

Powdery external wall insulation material and preparation and construction methods thereof

The invention discloses a powdery external wall insulation material. The powdery external wall insulation material with excellent crack resistance can overcome common defects of cracking, peeling and the like of the external wall insulation material, is high in bonding strength and adhesion and has good properties such as thermal insulation, weather resistance, fireproof and waterproof performance, frost resistance and the like; thermal mortar has good volume stability, produces volume micro-expansion during setting and hardening, avoids cracking or hollowing and is high in water resistance, anti-aging and long in service life; the thermal mortar is non-toxic, odorless, energy-saving and environmentally friendly and is free of radioactivity, harmless to a human body and free of environmental pollution; compared with various insulation boards, the insulation material can form the whole insulation layer on a wall and is firmly bound with a wall surface, and a cavity is avoided between the material and a wall base course; an external wall insulation system formed by the powdery external wall insulation material is simple in structure, simple and convenient to construct, short in construction period and low in construction cost.

Owner:CHINA MCC17 GRP

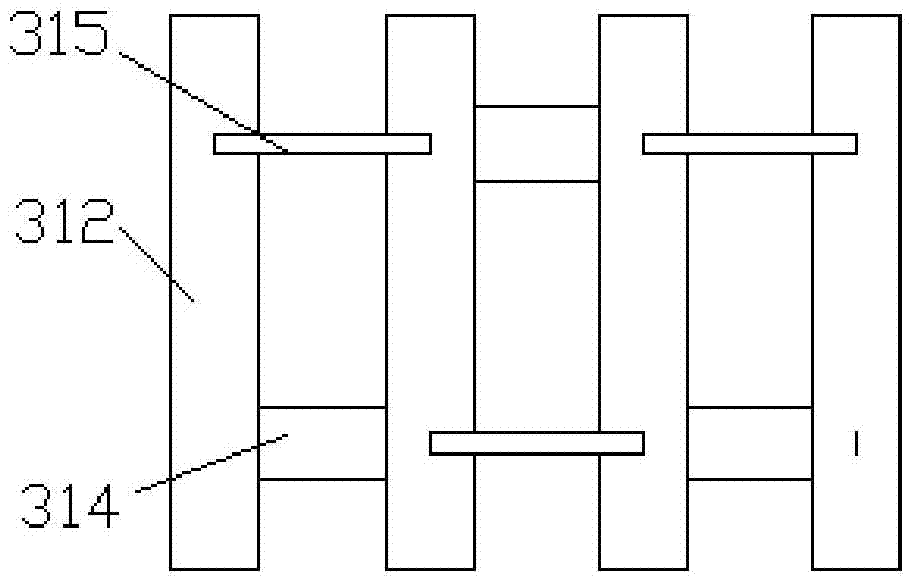

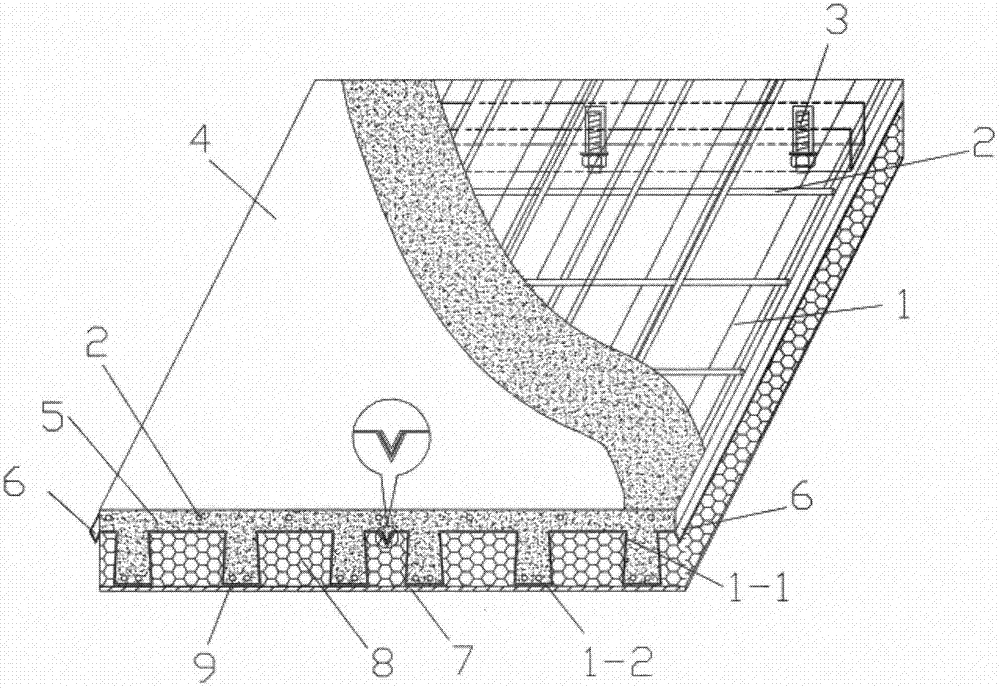

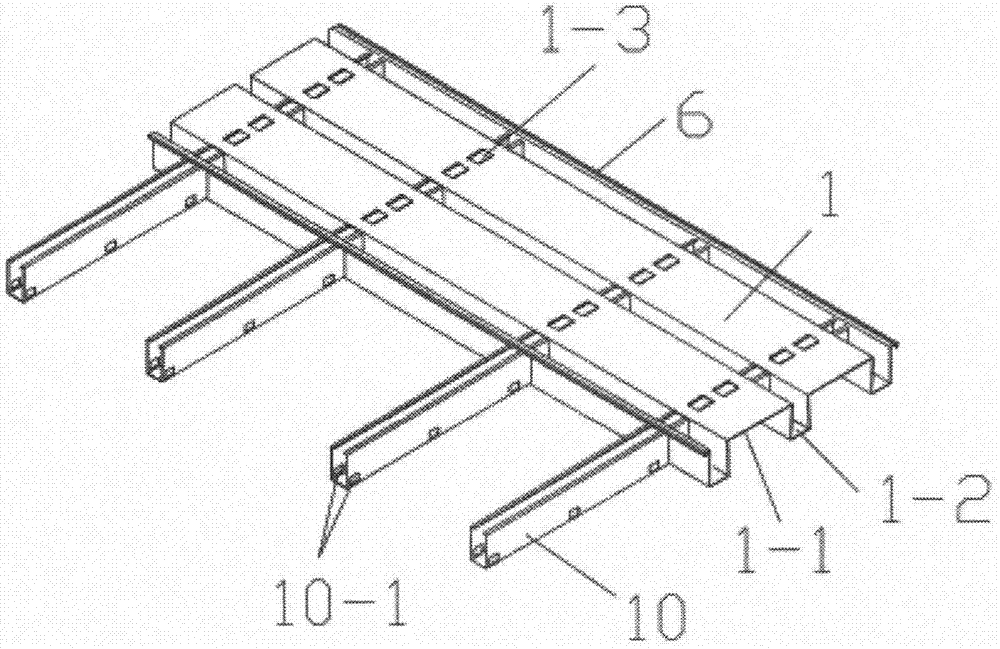

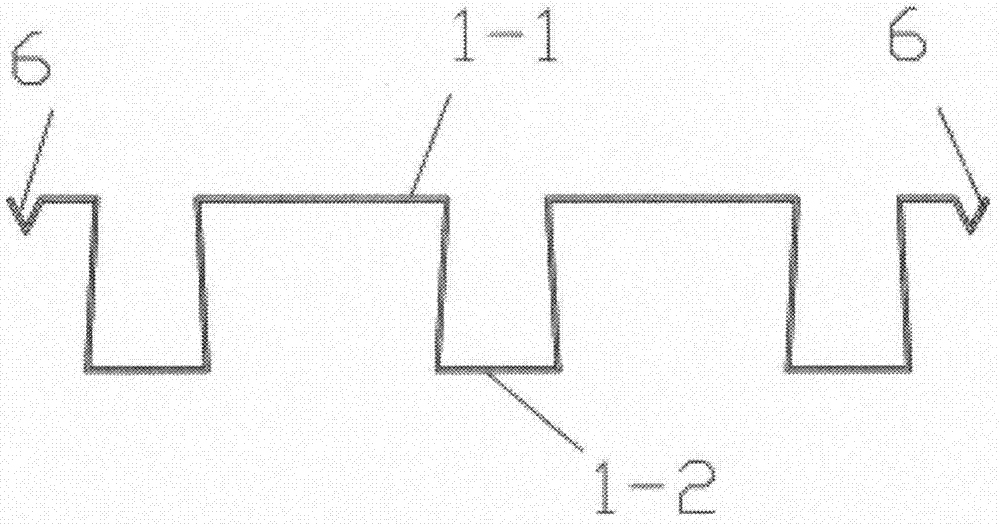

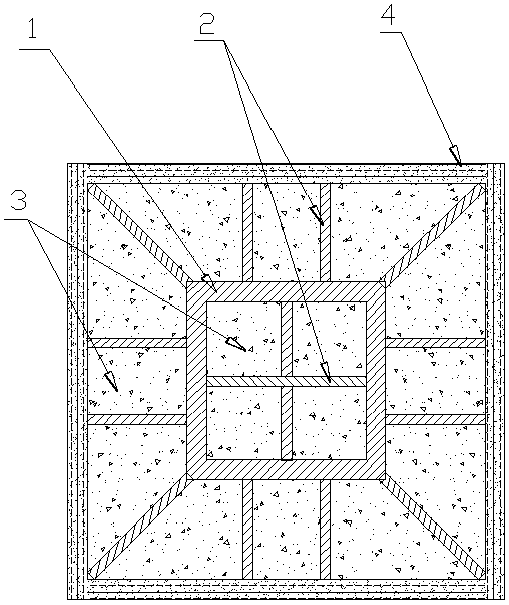

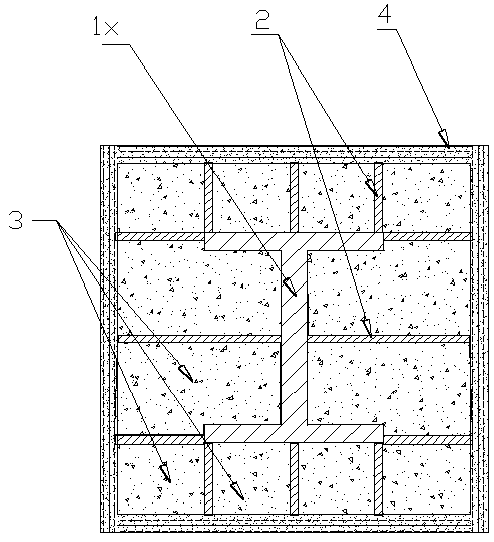

Fabricated steel-concrete structure light composite external wall plate

The invention relates to the technical field of building materials, in particular to a fabricated steel-concrete structure light composite external wall plate. The fabricated steel-concrete structure light composite external wall plate comprises a steel plate transversely pressed into a wave shape, a light aggregate concrete layer poured onto the outer side face of the steel plate, a foam concrete layer poured onto the inner side face of the steel plate, an ornamental face layer covering the surface of the light aggregate concrete layer and a glass fiber grid piece layer laid on the surface of the foam concrete layer. V-shaped grooves extending in the longitudinal direction are formed in the two sides of the steel plate correspondingly, and the V-shaped grooves in one side can contain the V-shaped grooves in the other side. The fabricated steel-concrete structure light composite external wall plate is formed by means of the method that the characteristics that steel plate leakproofness and ductility are high, and concrete plasticity is high are mainly used and combined with the advantages of different materials in a recombined mode, so that all the requirements of the fabricated external wall plate are met.

Owner:赵燕娣

Preparation method for diatomite calcium plastic composite plate

InactiveCN107722311AGood fireproof and waterproof effectEffectively remove formaldehydeMethyl salicylateActivated carbon

The present invention proposes a preparation method of diatomite calcium plastic composite board, the steps are as follows: (1) Prepare the upper board and the lower board: ① prepare raw materials in parts by weight as follows: PVC resin, diatomite, calcium carbonate , wood powder, 1010 antioxidant, glycerin, hydroxymethyl cellulose, ceramic particles, methyl salicylate, silicon carbide; The thickness of the plate is twice the thickness of the lower plate; ③ dig out an adsorption cavity on the lower surface of the upper plate; ④ frost the lower surface of the upper plate and the inner wall of the adsorption cavity; ⑤ fill the adsorption cavity with activated carbon, and Coating a layer of adhesive on the lower surface of the upper plate ⑥ Pressing the lower plate on the upper plate and fixing it into shape, the prepared plate has a good fireproof and waterproof effect, and can effectively absorb formaldehyde at the same time, with good adsorption.

Owner:镇江市星耀智能装备有限公司

Thermal-insulation mortar

The invention discloses a thermal-insulation mortar. The thermal-insulation mortar comprises the following components in parts by weight: 30-40 parts of Portland cement, 20-30 parts of glazed hollow beads, 10-15 parts of thermal-insulation aggregates, 5-10 parts of anti-crack materials and 5-10 parts of functional materials. The thermal-insulation mortar has the advantages that the anti-cracking ability is excellent, and common problems that the thermal-insulation mortar is cracked, flaked and the like can be solved; the bonding strength is high, the adhesive force is strong, and the heat preservation and heat insulation properties, the weather resistance, the fire resistance, water resistance, and the frost resistance are excellent; furthermore, the volume stability of the thermal-insulation mortar is good; the thermal-insulation mortar generates volume microdilatancy during condensation and hardening and is not cracked and hollowed; the water resistance is high; the thermal-insulation mortar is aging-resistant and long in service life.

Owner:陕西腾基实业有限公司

Method used for preparing light calcium silicate boards from waste silica fume

InactiveCN104844136AReduce moisture contentRaise the response ratioSolid waste managementCalcium silicateFiber

The invention provides a method used for preparing light calcium silicate boards from waste silica fume, production cost of calcium silicate boards is reduced, and both economic benefits and social benefits are achieved. The method comprises following steps: A, silica fume collected from different ferroalloy plants is subjected to component analysis, and mixing and combination are carried out based on analysis indexes so that indexes of silica fume obtained via mixing and combination are capable of satisfying production requirements; B, full decomposition of composite fiber is realized using a pulping machine, a thickening agent is dissolved in water so as to obtain an aqueous solution, decomposed fiber and the thickening agent aqueous solution are added into pulping water, an obtained mixed material is stirred to be uniform, weighed silica fume, quartz sand, slaked lime, cement, and coal ash microsphere are added, and a slurry needed by calcium silicate board production is prepared using a mixinghollander, wherein the coal ash microsphere is obtained via pre-wetted treatment; and C, the slurry is subjected to board preparation machine moulding, pressurization, maintenance and sizing, high pressure steaming, drying, sanding, and the like so as to obtain the light calcium silicate boards.

Owner:娜仁满都拉

Rare earth power cable

PendingCN108831606AImprove high temperature resistanceFunction increaseConductive materialPower cables with screens/conductive layersEpoxyElectrical conductor

The invention discloses a rare earth power cable, which comprises a cable core and a filling layer, wherein the cable core and the filling layer are wrapped with a wrapping tape layer, a shielding layer, an inner sheath, a metal armor layer, an outer sheath, a rare earth refractory layer and a rare earth water-blocking layer; shielding tapes are coated and lap-jointed with one another by means ofwave-shaped overlapping sections on two sides; armoring steel tapes are in lap joint with one another by means of steel tapes on two sides; rare earth aluminum alloy material of rare earth aluminum alloy conductors comprises the components of Fe, Cu, B, Mg, Si, Zr, Ni, Ag, Cr, Mn, Ti, V, Zn, RE, and the balance is AL; a rare earth refractory layer material comprises the components of fluororubber,aluminium hydroxide, rare earth oxide, glycerin, silicon carbide, lanthanum phosphate, gadolinium zirconate, and the balance is epoxy resin; and a rare earth water-blocking layer material comprises the components of epoxy resin, tung oil, rare earth oxide, magnesium oxide, zinc oxide, and the balance is nitrile butadiene rubber. The rare earth power cable has good electrical conductivity and mechanical strength, and has high temperature resistance and water blocking performance.

Owner:JIANGSU DONGQIANG

Coating method of fabric flame-retardant coatings

ActiveCN105420965AImprove fire and water resistanceIncrease tape glue volumeLiquid surface applicatorsCoatingsAdhesiveChemistry

The invention discloses a coating method of fabric flame-retardant coatings. The upper surface and / or the lower surface of a fabric are / is coated with the fabric flame-retardant coatings. Primer coating, medium adhesive coating and surface adhesive coating are performed on the coating device of coatings in sequence. Medium adhesives are added for coating two times. During coating, according to the first-time coating, the medium adhesives with the amount being two thirds that of dried adhesives are added, and according to the second-time coating, the medium adhesives with the amount being one third that of the dried adhesives are added. Due to the fact that the medium adhesives are added for coating two times, the amount of the medium adhesives in the fabric can be effectively increased, the problem of the upper limit of the flame-retardant waterproof performance is effectively solved, and the flame-retardant performance can be improved by a level.

Owner:ZHEJIANG SHENGFA TEXTILE PRINTING & DYEING

Scandium-contained aluminum-alloy-conductor water-blocking low-voltage power cable

ActiveCN105761827ALow costCreep resistantPlastic/resin/waxes insulatorsConductive materialElectrical conductorLow voltage

The invention discloses a scandium-contained aluminum-alloy-conductor water-blocking low-voltage power cable. A wire core of the cable contains at least three power wire cores. A water-blocking tape wrapping layer, an aluminum plastic tape longitudinal wrapping layer, a polyvinyl chloride inner sheath, a galvanized steel tape armor layer and a polyvinyl chloride outer sheath are successively arranged outside the wire core. Each power wire core is formed by wrapping a polyethylene insulating layer outside a power wire core conductor. The power wire core conductor adopts a scandium-contained aluminum alloy conductor. A water blocking filling strip is filled between the wire core and the water-blocking tape wrapping layer. In the invention, the power wire core conductor adopts the scandium-contained aluminum alloy conductor; on one hand, many disadvantages caused because pure aluminum is served as a wire and cable conductor are solved, and the cable possesses advantages of creep resistance, high flexibility, high extension, low rebound, stable connection, good water blocking performance and the like; on the other hand, cost of the cable is reduced by 50%.

Owner:ANHUI LINGYU CABLE TECH

Fiber cloth gel layer winding combined building materials or products and manufacturing method and application of fiber cloth gel layer winding combined building materials or products

InactiveCN110397843AExtended service lifeLow costStrutsElongated constructional elementsRebarBuilding material

The invention discloses fiber cloth gel layer winding combined building materials or products and a manufacturing method and application of the fiber cloth gel layer winding combined building materials or products. The plurality of layers of fiber cloth filled with inorganic cementing materials wind around and wrap materials or components with required functions which are taken as core materials or internal filling structural materials to combine and form the various building materials or products; and the various light high-strength building materials or products with high-performance fiber-reinforced gel shells are manufactured by adopting a method of die-free winding, wrapping and forming, and the light high-strength building materials or products are used as columns, beams, large arched members, floors, roofs and walls of buildings as well as integral houses, large pipelines, large containers and ship bodies instead of traditional reinforced concrete or section steel.

Owner:徐林波

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com