Compound silicate external wall insulation material

A composite silicate and external wall thermal insulation technology, applied in the field of building materials, can solve problems such as a large amount of capital and manpower and material resources, fire prevention, poor waterproof performance, environmental pollution, etc., and achieve good fireproof and waterproof performance, low cost, and good thermal insulation performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

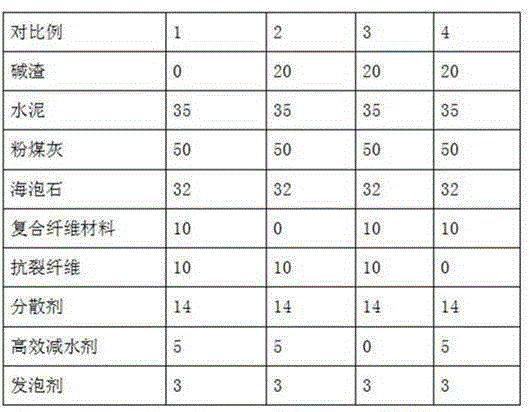

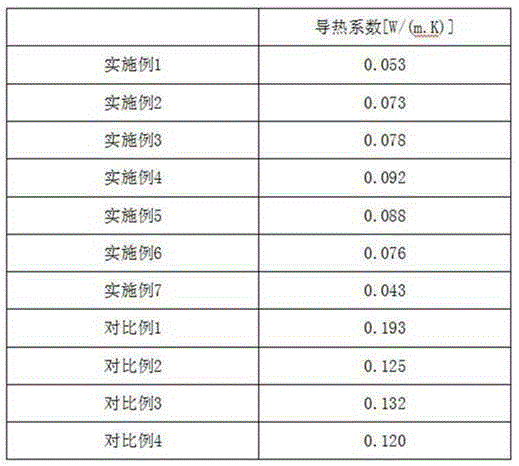

[0022] Table 1 Examples 1-7 Composition examples of the composite silicate external wall insulation material of the present invention

[0023]

Embodiment 8

[0027] Example 8: Example 1-3 and Example 7 Preparation method of composite silicate external wall insulation material

[0028] The technological process is as follows:

[0029] (1) Prepare the following raw materials according to the above embodiments: alkali slag, cement, fly ash, sepiolite, composite fiber materials, anti-cracking fiber, dispersant, superplasticizer and foaming agent;

[0030] (2) Dry grind the alkali slag, cement and fly ash at 120 rpm for 12 minutes to fully mix;

[0031] (3) Activate the sepiolite in a muffle furnace for 2 hours at an activation temperature of 250°C, mix it with the composite fiber material and the anti-cracking fiber to obtain a mixed homogeneous material, and add 57% of the total mass of the mixed homogeneous material to the mixed homogeneous material Then add the dispersant, soak for 1 hour, then pour the mixed powder of alkali slag, cement and fly ash obtained in step (2), and the superplasticizer, stir for 55 minutes to form a slurry;

[003...

Embodiment 9

[0034] Example 9: Example 4 Preparation method of composite silicate external wall insulation material

[0035] The technological process is as follows:

[0036] (1) Prepare the following raw materials according to the above embodiments: alkali slag, cement, fly ash, sepiolite, composite fiber materials, anti-cracking fiber, dispersant, superplasticizer and foaming agent;

[0037] (2) Dry grind the alkali slag, cement and fly ash for 150 minutes at 120 revolutions / min to fully mix them;

[0038] (3) Activate the sepiolite in a muffle furnace for 3 hours at an activation temperature of 350°C, mix it with the composite fiber material and the anti-cracking fiber to obtain a mixed homogeneous material, and add 60% of the total mass of the mixed homogeneous material to the mixed homogeneous material Then add the dispersant, soak for 5 hours, then pour the mixed powder of alkali slag, cement and fly ash obtained in step (2), and the superplasticizer, stir for 75 minutes to form a slurry;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com