Fiber cloth gel layer winding combined building materials or products and manufacturing method and application of fiber cloth gel layer winding combined building materials or products

A manufacturing method and technology of fiber cloth, applied in the direction of building structure, building, building components, etc., can solve the problems of not being too large in span, low overall strength, limited bending strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

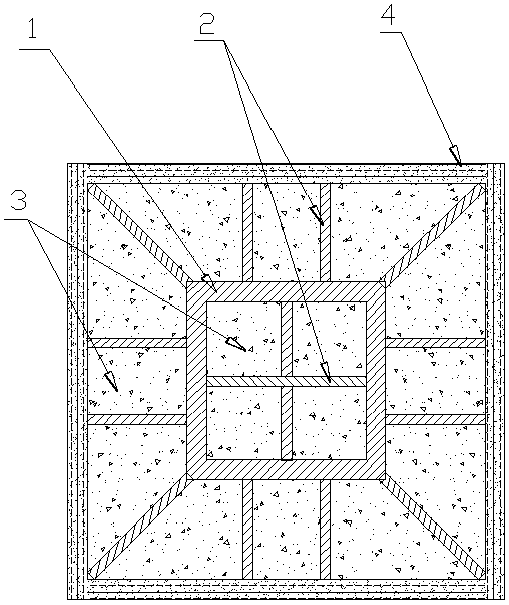

[0037] figure 1 , image 3 Among them, a certain number of longitudinal ribs 2 are arranged around each longitudinal side of the above-mentioned section steel core material; concrete materials 3 are poured in each groove surrounded by the ribs 2 and the sides of the steel pipe core material 1; fiber cloth glue The cementitious layer 4 is wound on the outside of the entire structure; the fiber cloth cementitious layer wound composite building material of this structure has larger bearing capacity, greater rigidity, better seismic performance than traditional reinforced concrete structures, and can be assembled on site in factory production. Advantages: Compared with the section steel structure, it has the advantages of good fire resistance, water resistance and corrosion resistance, good local and overall structural stability and steel saving.

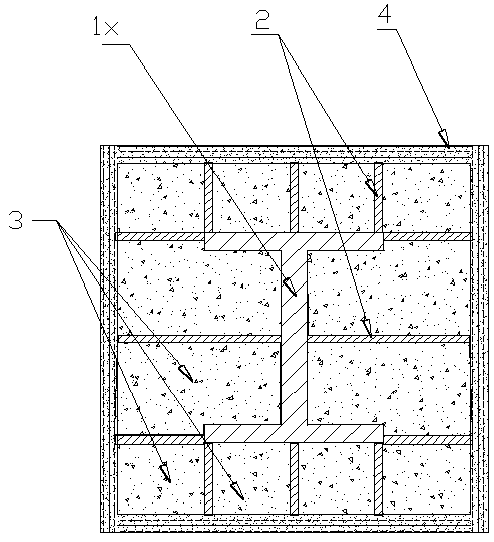

[0038] figure 2 Among them, the ribs surrounding each longitudinal side of the steel pipe core material 1 are corrugated plates 2a....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com