Modified hexagonal boron nitride as well as preparation method and application thereof

A technology of hexagonal boron nitride and modification, which is applied in the field of modified hexagonal boron nitride and its preparation, can solve the problems of reduced dispersibility and reduced thermal conductivity of modified hexagonal boron nitride, and can reduce thickness and improve thermal conductivity. , improve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

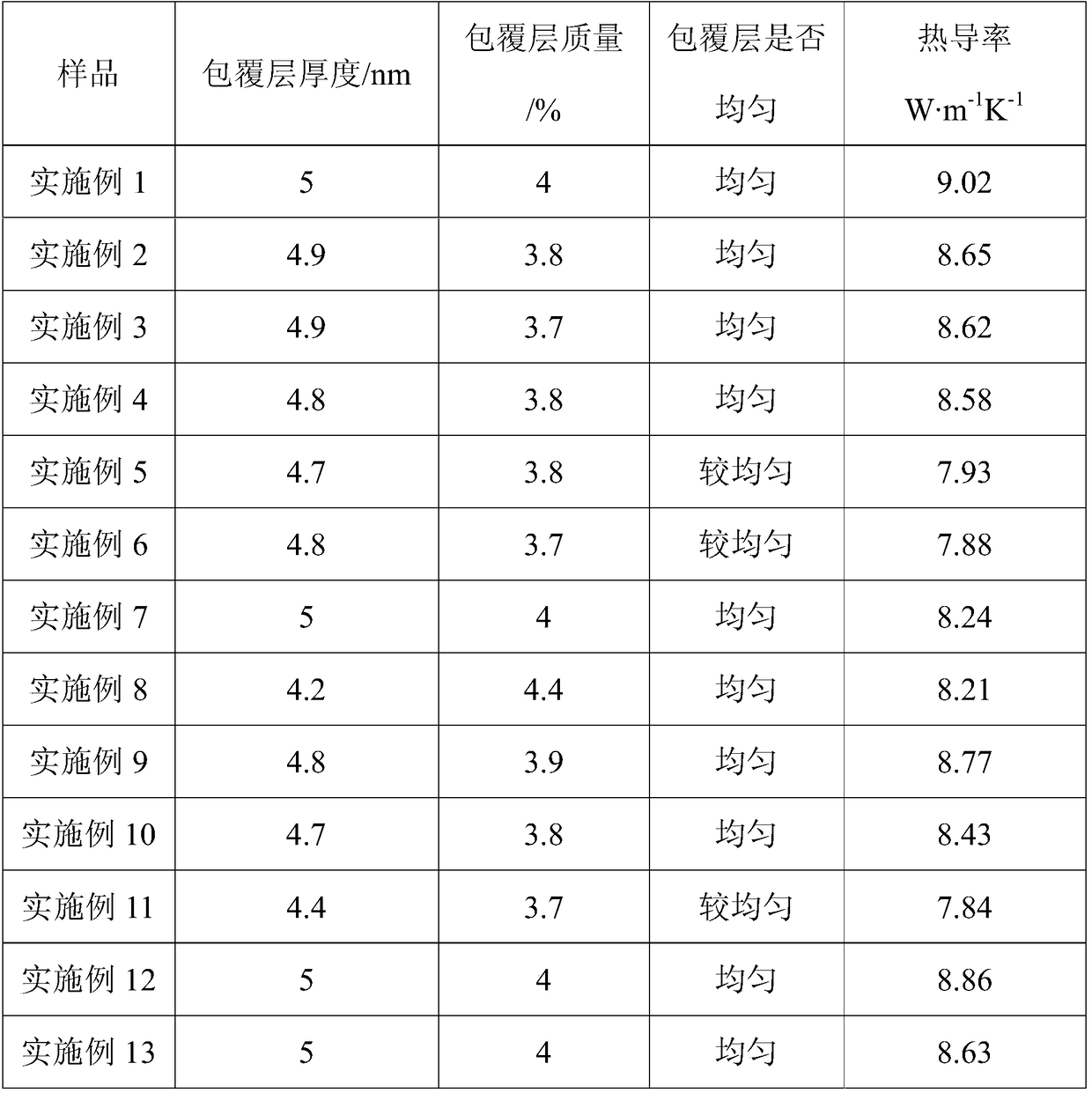

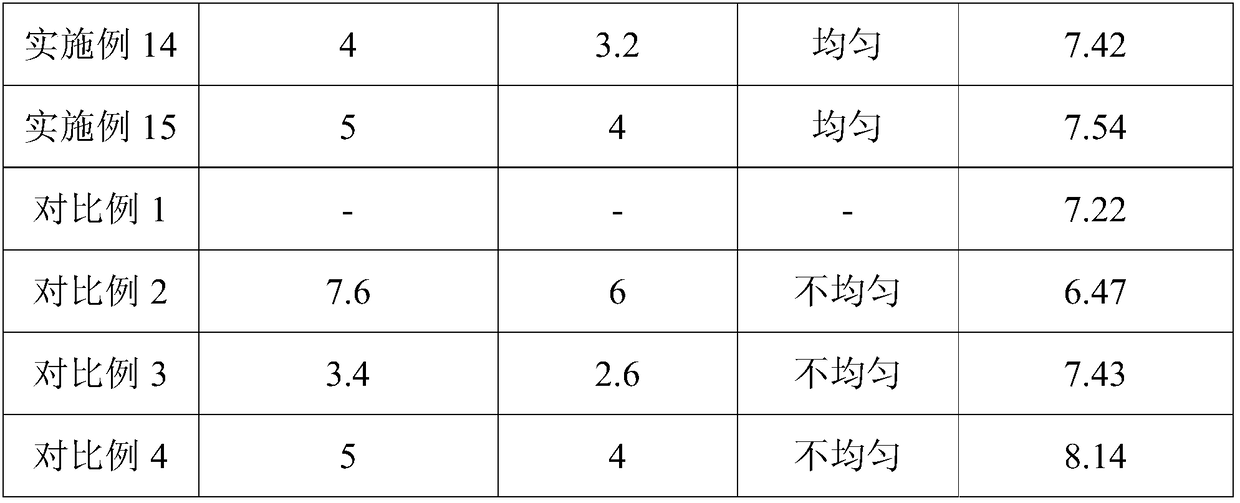

Examples

Embodiment 1

[0044] A heat-conducting polyvinyl alcohol composite material, wherein the volume ratio of modified hexagonal boron nitride and polyvinyl alcohol is 1:4.

[0045] The preparation method is as follows:

[0046] (1) Mix hexagonal boron nitride and polyethyleneimine at a mass ratio of 9:1, and add a mixed solvent formed by deionized water and absolute ethanol at a mass ratio of 5:3, and continue magnetic stirring after ultrasonic stirring for 2 hours 24h, obtain the preliminary product of modified hexagonal boron nitride;

[0047] (2) Centrifuge the preliminary product of modified hexagonal boron nitride obtained in step (1) at a centrifugal rate of 2500 rpm, wash and remove polyethyleneimine not coated on the surface of hexagonal boron nitride, and then dry it at 50°C to obtain Modified hexagonal boron nitride;

[0048] (3) Magnetically stir the formulated amount of polyvinyl alcohol, modified hexagonal boron nitride and deionized water at 65°C for 4 hours, then defoam, coat a...

Embodiment 2

[0051] The only difference from Example 1 is that in step (1), the mass ratio of hexagonal boron nitride and polyethyleneimine is 10:1.

Embodiment 3-6

[0053] The only difference with Example 1 is that in step (1), the solvent is a mixed solvent (Example 3) formed by deionized water and absolute ethanol with a mass ratio of 4:3, and the solvent is deionized water and anhydrous Ethanol is the mixed solvent (embodiment 4) that 6:3 forms with mass ratio, and solvent is the mixed solvent (embodiment 5) that deionized water and absolute ethanol form with mass ratio as 1:1, and solvent is deionized water and The mixed solvent (embodiment 6) that absolute ethanol is formed as 7:3 with mass ratio.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com