Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

439results about How to "Solve Oxidation Problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Membrane electrode for proton exchange membrane water electrolysis battery and preparation thereof

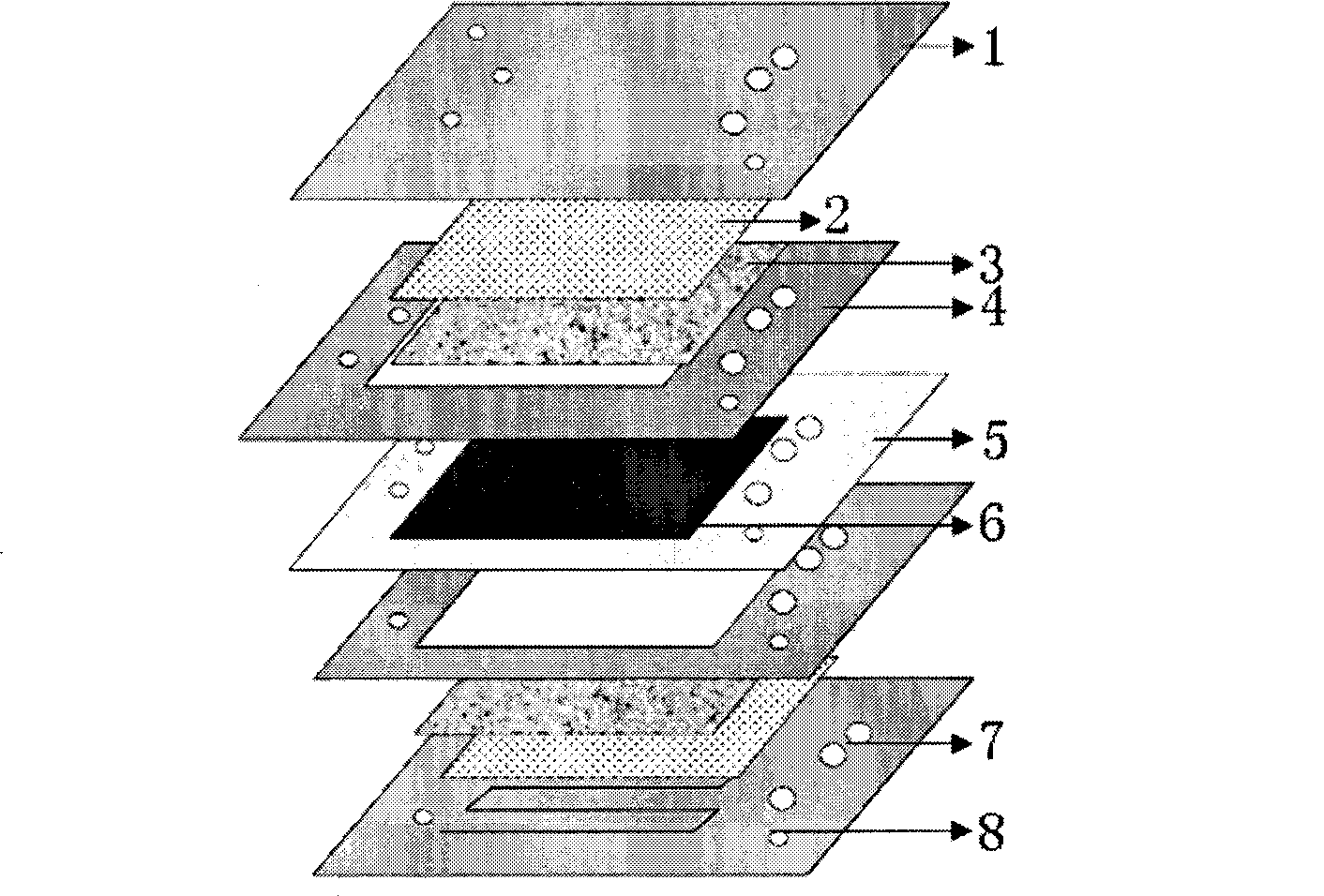

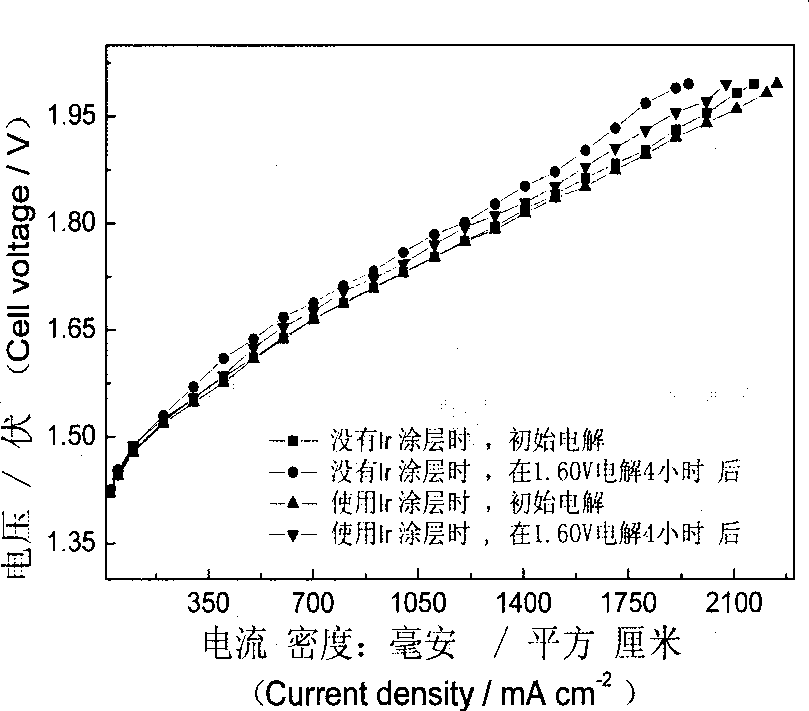

InactiveCN101388463AReduce loadReduce contact resistanceCell electrodesSolid electrolyte fuel cellsNano catalystElectrolysis

The invention discloses a proton exchange membrane water electrolyte battery membrane electrode and a process for preparation thereof, which belongs to the technical field of preparing hydrogen gas through electrolyzing water, wherein the proton exchange membrane water electrolyte battery membrane electrode comprises a polymer electrolyte membrane, an anode catalyst layer, a cathode catalyst layer, an anode diffusion layer, a cathode diffusion layer, a support layer and a flow field plate, wherein hydrophilic thin layer structures which are formed by catalyst are respectively brushed on both surfaces of the polymer electrolyte membrane. Anode catalyst is noble metal or metallic material, and the diffusion layer is carbon material or metallic material. A catalyst layer and the relative diffusion layer and the support layer are compacted in a titanium plate to prepare membrane electrode through utilizing external force under normal temperature. The invention lowers the load of catalyst, improves the operating factor of catalyst, avoids the deformation of membranes in the process of heat pressing, and is drawn supported from the catalytic and corrosion resistance property of an anti-corrosion diffusion layer with catalytic property, and the electrolytic property and the stability of a battery are improved. The invention has the advantages of simple technique, convenient operation and excellent repeatability.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of stainless steel-carbon steel composite board

ActiveCN102069289ASolve oxidationImprove service life and application rangeElectron beam welding apparatusWelding/soldering/cutting articlesCarbon steelFlat panel

The invention relates to a preparation method of a stainless steel-carbon steel composite board, which belongs to the technical field of material and comprises the following steps: (1) removing and cleaning rusted layers and oxidative layers of stainless steel board material and carbon steel board material; (2) alternately stacking the stainless steel board material and the carbon steel board material; (3) arranging a composite blank between two metal panels to constitute a clamped composite blank, or welding two composite blanks together by electric welding to constitute a combined structure of the composite blank, a blocker and the composite blank, and arranging the combined structure between two metal panels to constitute a clamped composite blank; (4) welding the peripheries of contact surfaces of two adjacent steel boards under a vacuum condition; (5) arranging the composite board in a resistor furnace for heating and heat preservation; and (6) rolling the composite board by a rolling mill. The method disclosed by the invention prolongs the service life and enlarges the application scope of the stainless steel-carbon steel composite board. Compared with an explosive compounding method, the method causes small environmental pollution, and has low requirements on the production environment, in addition, the shape of the board is flat, and the product yield is high.

Owner:沈阳科安捷材料技术有限公司

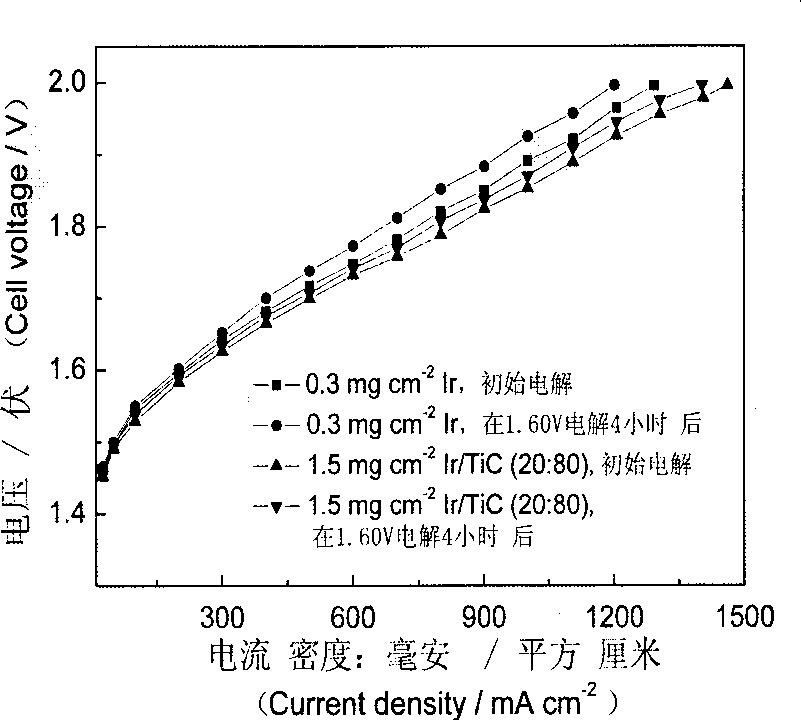

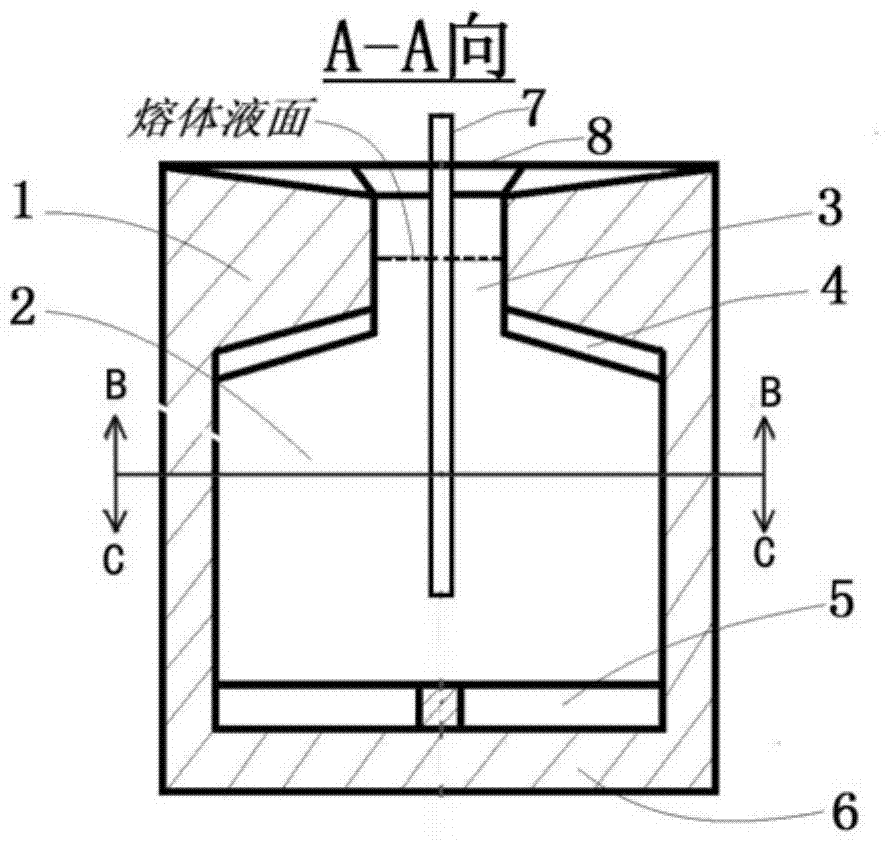

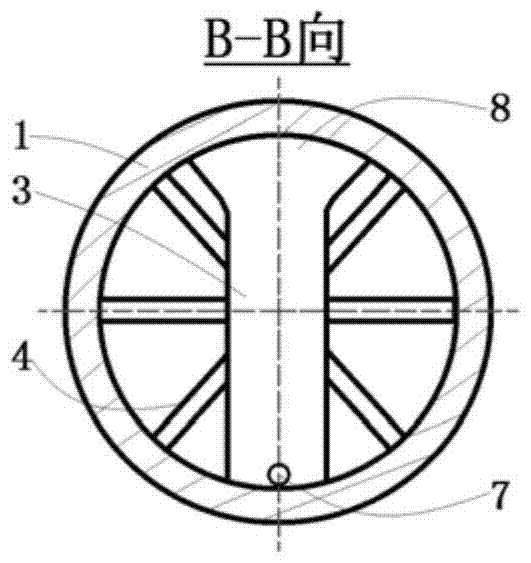

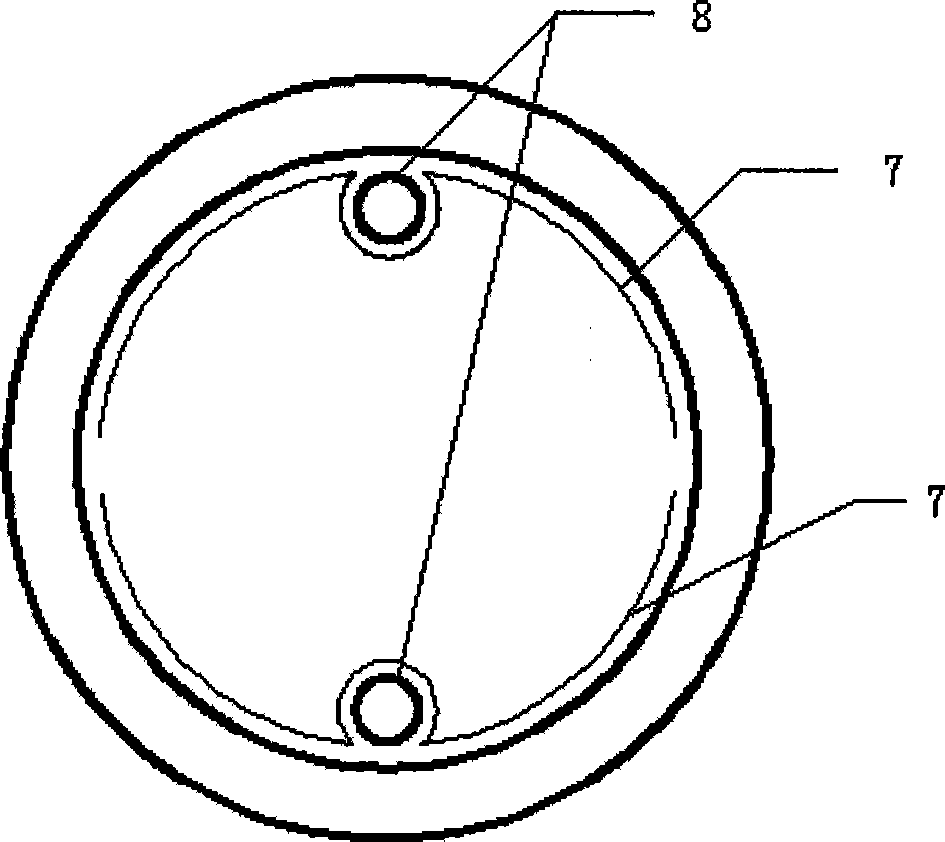

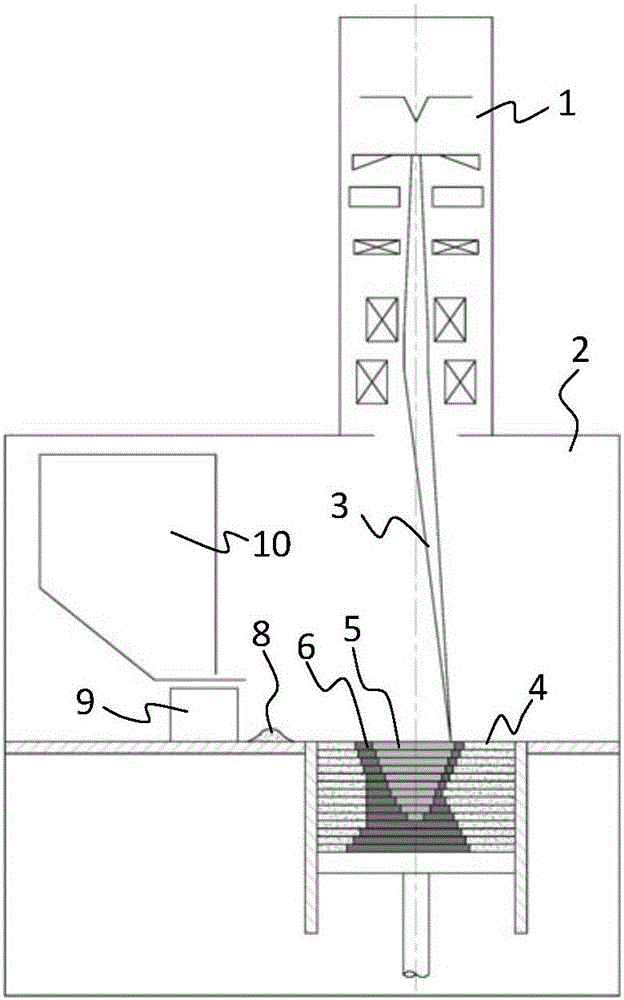

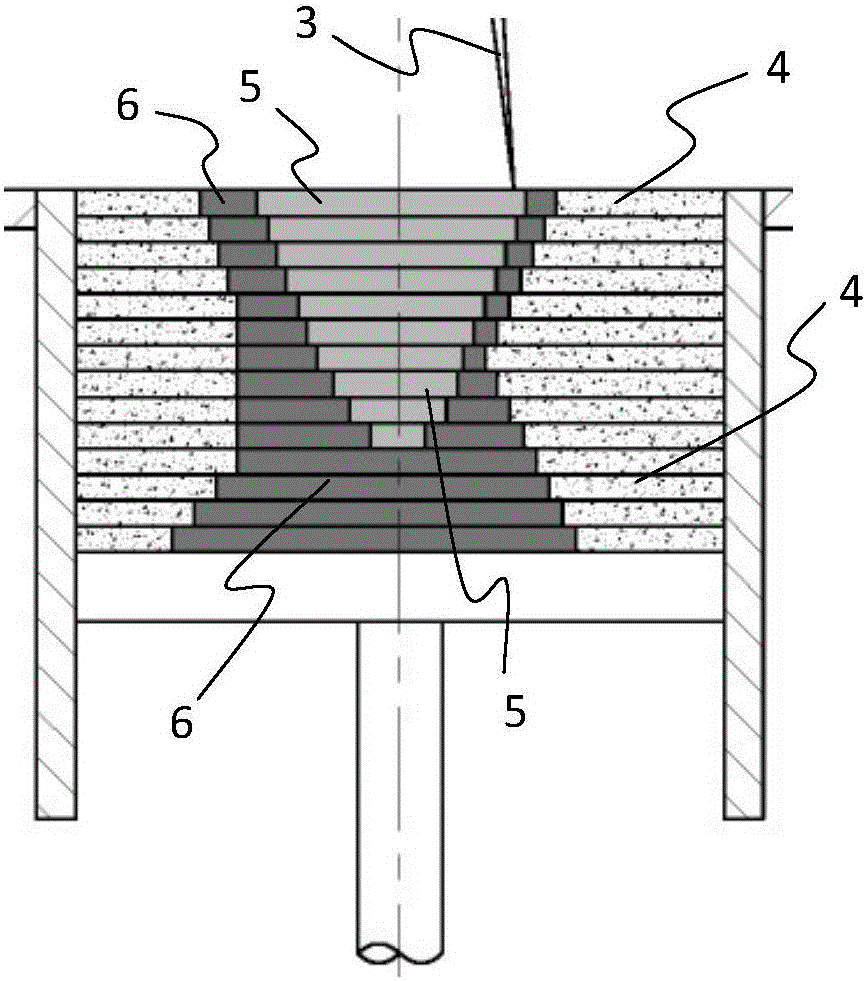

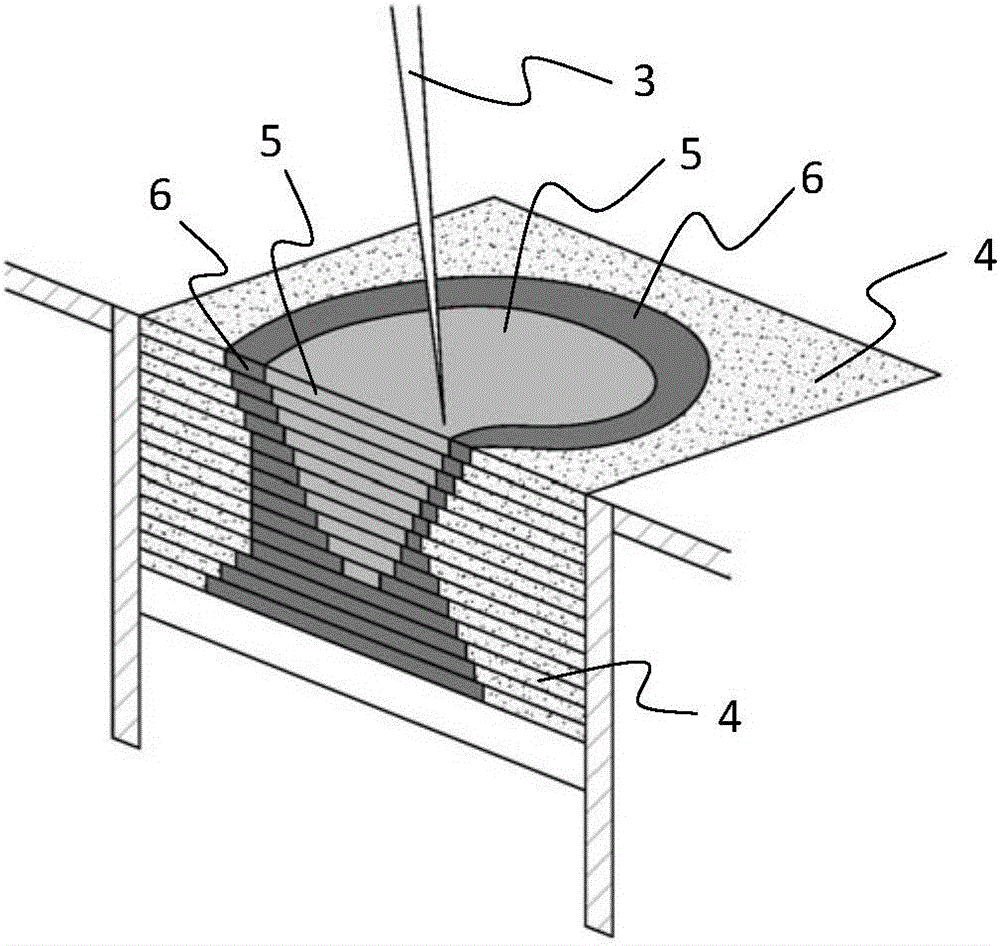

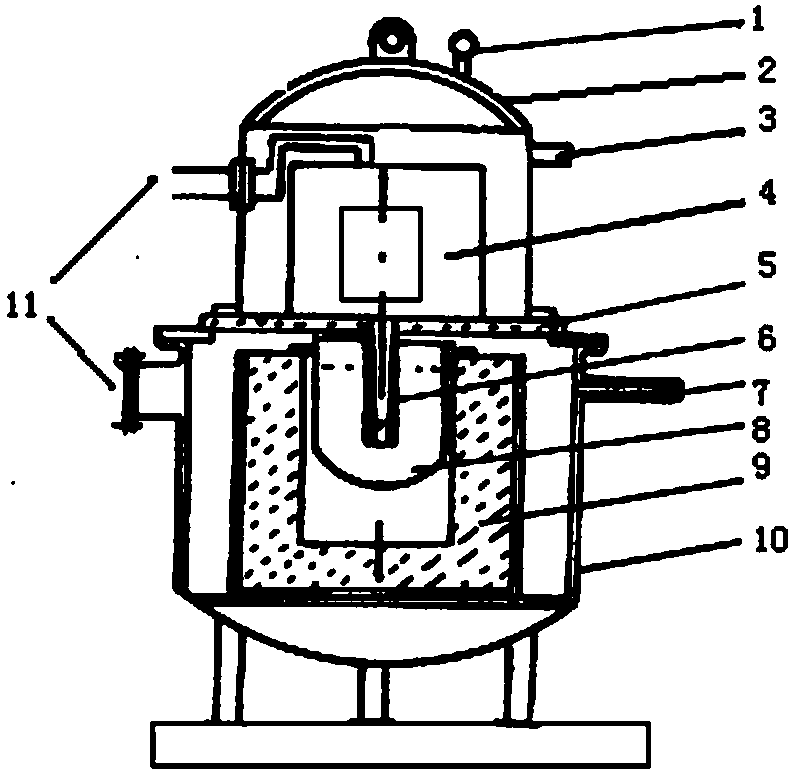

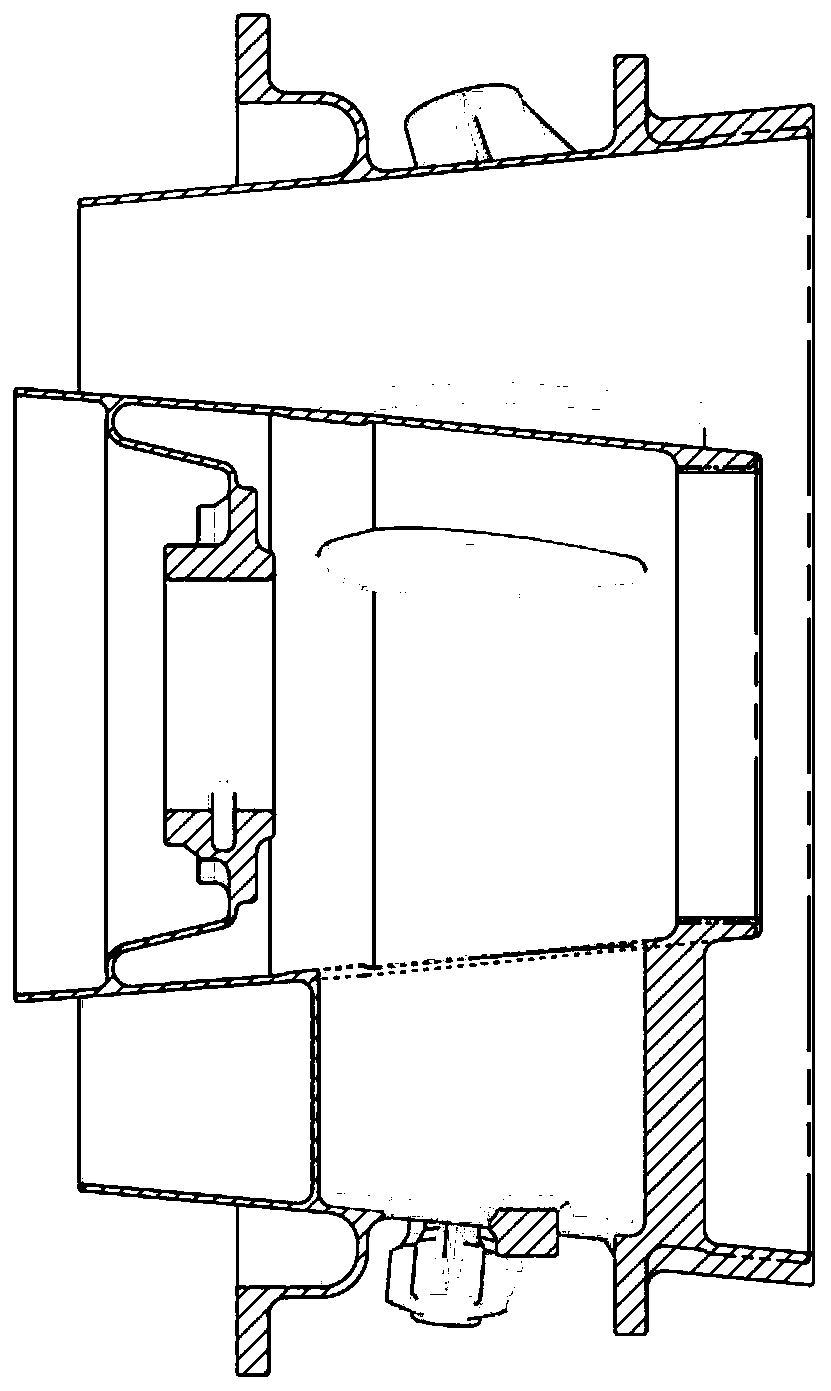

Stirring chamber for stirring molten metal and using method thereof

The invention discloses a stirring cavity used for stirring metal melt and a use method thereof, which belong to the field of material processing apparatuses for metallurgy, casting, chemical engineering and the like. The stirring cavity structurally consists of a melt container, a stirring cavity body, an upper stop opening, an upper blocking flange, a lower blocking flange, a lower bottom, a temperature sensor and a liquid taking / pouring port. According to the stirring cavity, the melt liquid level inside the stirring cavity is narrowed, so the stirring effect is effectively stopped from transferring to the liquid level, and the problems of melt oxidation and entrapped air risk are solved. The stirring cavity can be applied to various metal melt stirring and casting occasions; when the stirring cavity is used for batch-type casting such as pressure casting, the stirring cavity is adopted as the internal cavity structure of a pouring ladle; when the stirring cavity is used for continuous casting, the stirring cavity is adopted as the internal cavity structure of a melt hot top and can be directly connected with a continuous casting crystallizer; and full automation is realized in the whole process of melt stirring, chemical refining and casting in a pressure casting site.

Owner:GRIMAT ENG INST CO LTD

Production method of aluminum and copper composite metal band

ActiveCN101758071ASolve Oxidation ProblemsUniform thicknessTension/compression control deviceMetal rolling arrangementsCopperUltimate tensile strength

The invention discloses a production method of an aluminum and copper composite metal band. In the method, the aluminum and copper composite metal band is manufactured by anaerobic continuous casting and rolling of semisolid aluminum or aluminum alloy and a solid copper band. In the production method of the invention, the anaerobic metallurgical combination of the solid copper band and molten aluminum is realized, the aluminum oxidization problem is solved, the combined strength is high, and the aluminum and copper bonding strength is more than or equal to 100MPa; the continuous casting and rolling of the copper band and the molten aluminum are adopted to produce the aluminum and copper composite metal band, so the production efficiency is greatly improved by scores of times and the product quality is stable; the produced aluminum and copper composite metal band retains the original surface quality of the copper band, has a uniformly-thick copper layer and can be deeply processed by cold rolling; and the copper band and the molten aluminum, which comprise different components, can be used, and products are diversified and widely applicable. The method has the advantages that: the production process of the copper and aluminum composite band is advanced and comprises a few working procedures; and the energy-saving, material-saving and economic effects are obvious.

Owner:LUOYANG TONGYI METAL MATERIAL DEV +2

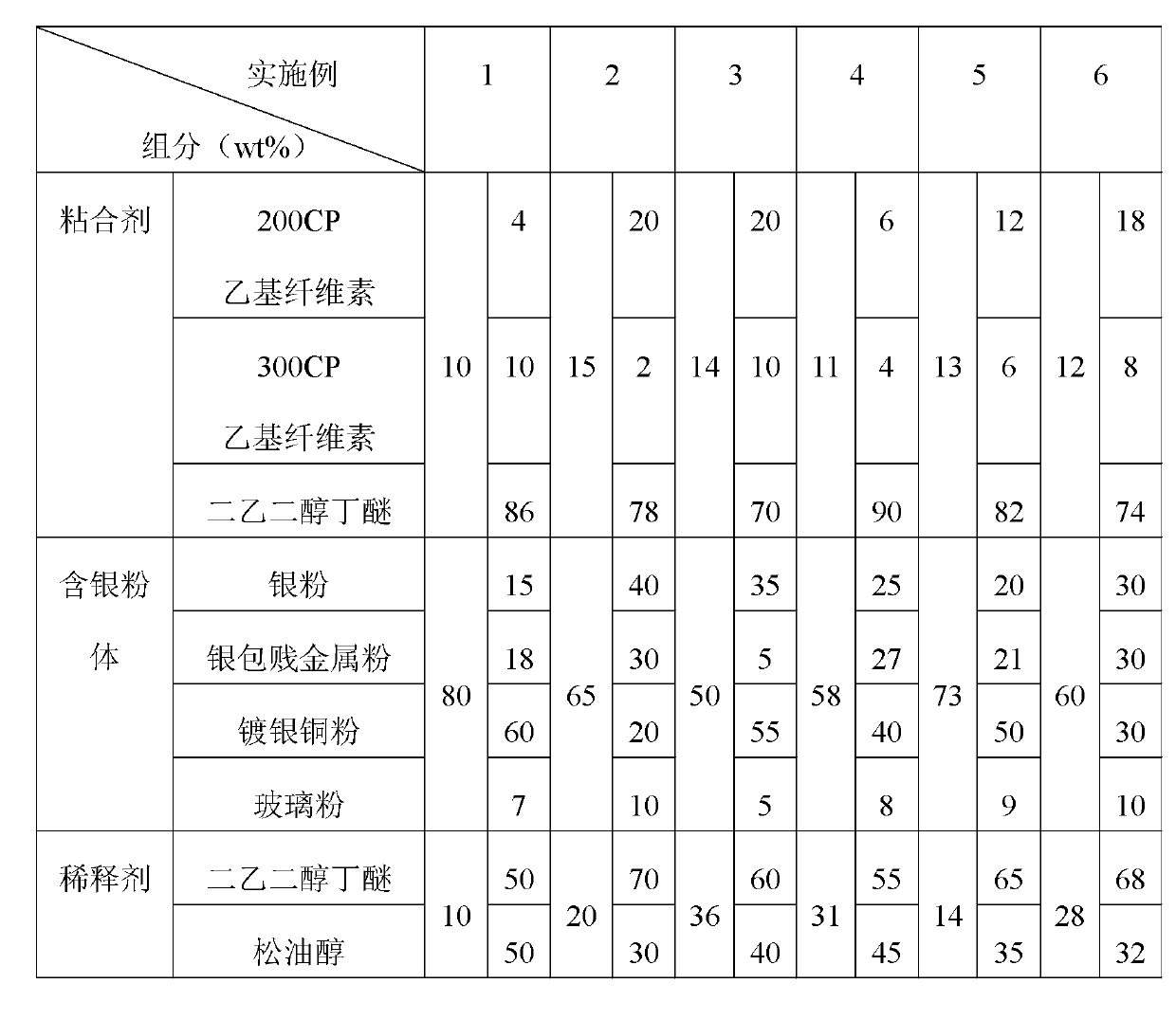

Tin-doped silver-wrapped base metal slurry of back electrode of solar cell, and preparation method of slurry

InactiveCN103106952AExpensive to fixImproves solderability and adhesionNon-conductive material with dispersed conductive materialCable/conductor manufactureAdhesiveSolar cell

The invention discloses tin-doped silver-wrapped base metal slurry of a back electrode of a solar cell, and a preparation method of the tin-doped silver-wrapped base metal slurry. The tin-doped silver-wrapped base metal slurry comprises an adhesive, silver-containing powder and a diluent, wherein the silver-containing powder is formed by mixing silver powder, tin powder, silver-wrapped base metal powder and glass powder; and the silver-wrapped base metal powder refers to at least one of silver-wrapped nickel powder and silver-wrapped copper powder. By replacing part of pure silver powder by the silver-wrapped base metal powder, the problem of oxidation of pure base metal slurry in a sintering process of a cell piece can be solved, and the problems of high price and easiness in displacement of the pure silver powder can be solved; and furthermore, the tin powder is added into the slurry, so that the weldability and the adhesive force of the slurry are improved. Therefore, the tin-doped silver-wrapped base metal slurry is low in cost, adopts the simple preparation method, is suitable for industrial production, and has the advantages of low contact resistance, high cell conversion efficiency and high weldability and adhesive force.

Owner:ENVIRONMENTAL NATURAL CHEM JIANGSU

Medium temperature glass-metal structure solar vacuum thermal-collecting tube

InactiveCN101392965AMeet solar air conditioningFulfil requirementsSolar heating energySolar heat devicesMaterials scienceMetallic Nickel

The invention discloses an intermediate temperature glass-metallic structure solar vacuum thermal-collecting tube, which belongs to the technical field of solar utilization, wherein a layer of temperature-resistant anti-oxidation film is plated on the outer surface of a heat-transfer pipe provided with a heat-conductive wing in the intermediate temperature glass-metallic solar vacuum thermal-collecting tube, and the film layer is aluminum or zinc or nickel or chromium or stainless steel; the heat-conductive wing is a thin aluminum plate which is coiled into the shape of an opening cylinder or a semicircular cylinder, and is tightly connected or welded with a U-shaped copper tube or a copper heat pipe of the temperature-resistant anti-oxidation film; and a heat-conductive wing tube is arranged inside the all-glass solar vacuum thermal-collecting tube, and closely contacts the inner wall of the all-glass solar vacuum thermal-collecting tube. A non-evaporable getter can be arranged inside a vacuum interlayer of the all-glass solar vacuum thermal-collecting tube, thereby improving the vacuum service life of the all-glass solar vacuum thermal-collecting tube after the long-term operating temperature is extended to more than 140 DEG C. The invention is a novel intermediate temperature glass-metallic solar vacuum thermal-collecting tube with high cost performance, and can meet the requirements of solar air-conditioners and industrial heat.

Owner:TSINGHUA UNIV

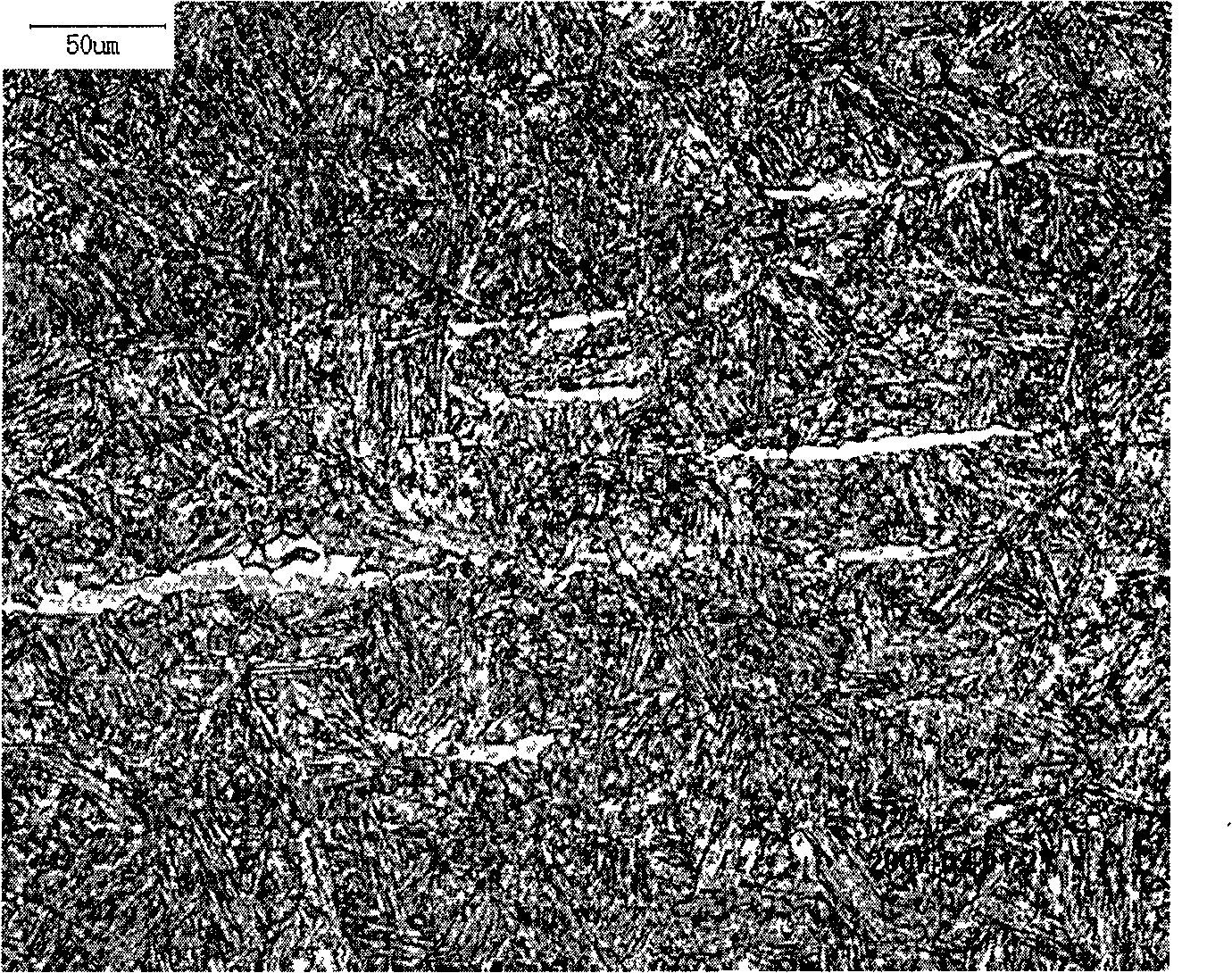

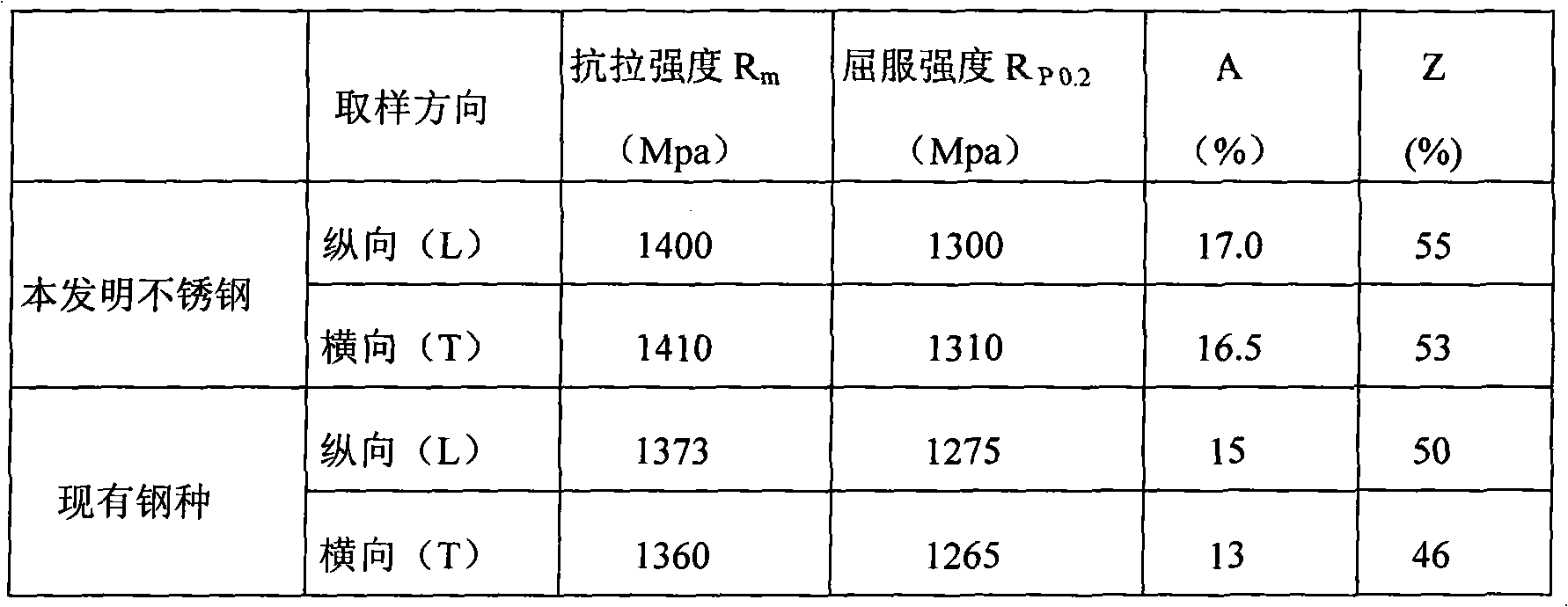

Martensite precipitation hardening stainless steel for structural member and manufacturing method thereof

The invention provides a martensite precipitation hardening stainless steel for structural member and a manufacturing method thereof. The martensite precipitation hardening stainless steel comprises the following chemical components in percentage by weight: less than or equal to 0.05 percent of C, 13.50 to 15.50 percent of Cr, 2.5 to 4.0 percent of Cu, 3.0 to 5.0 percent of Ni, 0.15 to 0.40 percent of Nb and Ta, 0.010 to 0.040 percent of N, 0.050 to 0.15 percent of V, less than or equal to 0.80 percent of Si, less than or equal to 1.00 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.010 percent of S, and the balance of Fe and inevitable impurities. The stainless steel is smelted by combining an electric furnace, AOD refining and vacuum self-consuming technology, so the stainless steel has the characteristics of high strength, good plasticity, good corrosion resistance and the like, and can meet the requirements of high-strength components such as high-pressure values, oil drill, efficient heavy-duty machinery and the like on material performance.

Owner:宝武特种冶金有限公司

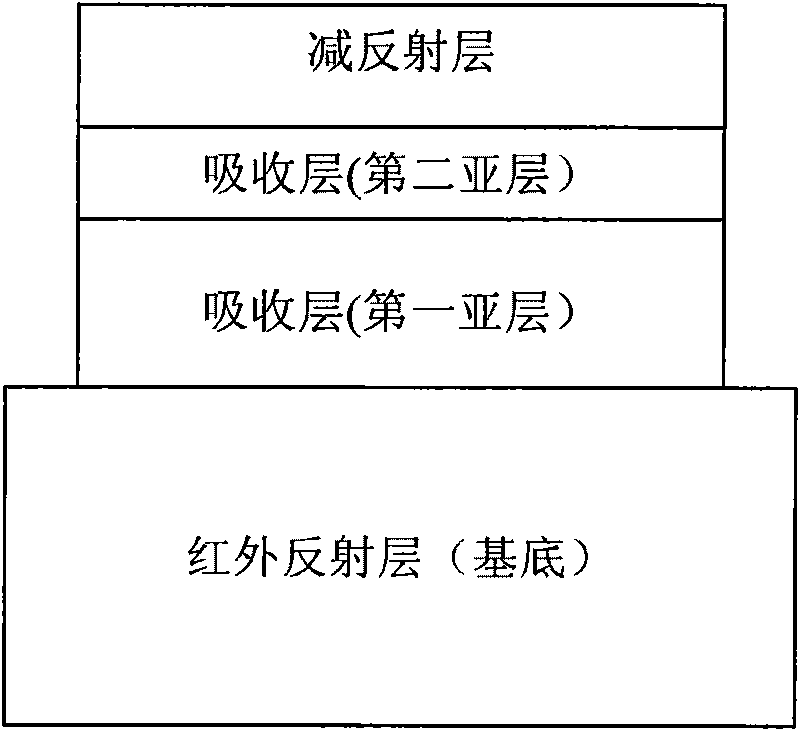

Solar spectrum selective absorbing coating and preparation method thereof

ActiveCN101737983AImprove thermal stabilityMeet the requirements of sustainable developmentSolar heat devicesLayered productsRefractive indexAlloy

The invention relates to a solar spectrum selective absorbing coating which is prepared by adopting magnetron sputtering technology. The absorber of the coating comprises the following three layers of films from substrate to top: a first layer adopts copper with infrared reflectivity or aluminium substrate as an infrared reflecting layer; a second layer uses a metalloid layer and a medium type layer which have different refractive indexes and thicknesses; and a third layer uses SiON film as an antireflection layer. The preparation method comprises the following steps: the first layer (infrared reflecting layer): cleaning copper or aluminium sheets with ultrasonic wave or polishing the copper or aluminium sheets; the metalloid layer of second layer: using two metals as alloy target, argon gas as sputtering gas and nitrogen gas as reaction gas and adopting DC electrical source to perform reactive sputtering; the medium type layer of the second layer: using two metals as alloy target, argon gas as sputtering gas and nitrogen and oxygen gas as reaction gas and adopting DC electrical source to perform reactive sputtering; the third layer (antireflection layer): uses SiN as target, argon gas as sputtering gas and nitrogen and oxygen gas as reaction gas and adopting radio frequency power source to perform reactive sputtering; and finally obtaining the absorber.

Owner:安徽科鑫光热技术有限公司

Additive manufacturing method for multi-material heterogeneous part

ActiveCN105945280ASimple processEasy to implementAdditive manufacturing apparatusIncreasing energy efficiencyMulti materialVapor pressure

The invention discloses an additive manufacturing method for a multi-material heterogeneous part. The additive manufacturing method for the multi-material heterogeneous part comprises the following steps that A, alloy powder is formed into forming layers through electron beam or laser selective melting, and the alloy powder comprises at least two elements, the elements are different in saturated vapor pressure and in volatilization degree; in the electron beam or laser selective melting process, different kinds of electron beam or laser energy are applied to different areas of each forming layer and / or the different forming layers, and the elements contained in the alloy powder are volatilized at the different degrees so that alloy with the different element contents can be obtained in the different areas and / or on the different forming layers; and B, the multiple forming layers and the different areas of the forming layers are subjected to fusion and stacking layer by layer, and finally the heterogeneous gradient part with the element component being in a three-dimensional change mode is obtained. The additive manufacturing method has the advantages of being simple in process, convenient to carry out, low in implementing cost and equipment requirement and the like.

Owner:TSINGHUA UNIV

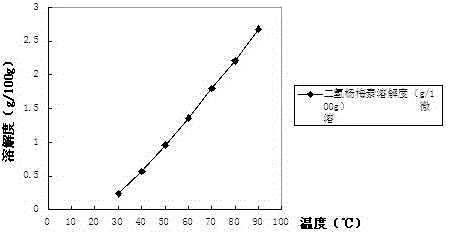

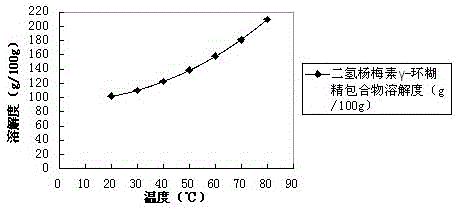

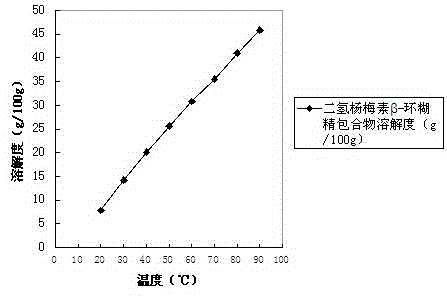

Dihydromyricetin cyclodextrin inclusion compound and preparation method thereof

InactiveCN104666293AImprove solubilityImprove stabilityAntibacterial agentsOrganic active ingredientsSolubilityNatural substance

The invention discloses a dihydromyricetin cyclodextrin inclusion compound, which comprises cyclodextrin and dihydromyricetin, wherein the dihydromyricetin is embedded into a cyclodextrin cavity; and the inclusion compound employing the cyclodextrin as a host molecule and dihydromyricetin as a guest molecule is formed. The dihydromyricetin cyclodextrin inclusion compound has the beneficial effects that 1 the dihydromyricetin cyclodextrin inclusion compound is embedded by the cyclodextrin, and the solubility, the stability and the bioavailability of the dihydromyricetin are improved; 2 the preparation method of the dihydromyricetin cyclodextrin inclusion compound disclosed by the invention is simple in process and suitable for industrialized production; 3 a spray drying process is adopted, the process from spray drying to dust collection is finished within 20 seconds, the problem of product oxidation in the drying process is avoided, the method is simple in process, simple and convenient to operate; the production conditions are easy to control, and the inclusion rate of the dihydromyricetin is high; and 4 the dihydromyricetin used by the dihydromyricetin cyclodextrin inclusion compound is extracted from vitaceae ampelopsis, and the dihydromyricetin in the vitaceae ampelopsis is high in content, and is a natural substance and free of toxicity.

Owner:江苏丰园生物技术有限公司

Plaster casting method for large-sized complex thin-walled magnesium alloy part

ActiveCN104209497ASolve Oxidation ProblemsImprove filling abilityFoundry mouldsFoundry coresVacuum castingMold filling

The invention relates to a plaster casting method for a large-sized complex thin-walled magnesium alloy part. The method comprises the following steps of coating the surface of an assembled form with a coating in situ, and arranging shapeless cold iron on a hot spot part, wherein a mixture for manufacturing the shapeless cold iron comprises the following components in percentage by mass: 1.25 percent of phenolic resin, 0.4 percent of toluenesulfonic acid, 1 to 1.5 percent of boric acid, 2 percent of bentonite and the balance of 70 to 140-mesh chromite sand; pouring a casting in an adjustable pressure casting device, arranging a plaster mold poured by the form at the casting position of the adjustable pressure casting device, filling a tank with dry air or a CO2 atmosphere with SF6 content of 0.1 to 1.0 percent, and performing vacuum casting and pressurized solidification, wherein the casting temperature is 710 to 750 DEG C, vacuum degree for primary mold filling is minus 0.6Mpa to minus 0.8Mpa, and the solidification pressure is 0.020 to 0.025Mpa. According to the method, oxidization can be prevented, the mold filling capability can be improved, shrinkage cavities and shrinkage porosities in the casting are reduced, and the obtained magnesium alloy casting is higher in density.

Owner:山西银光华盛镁业股份有限公司

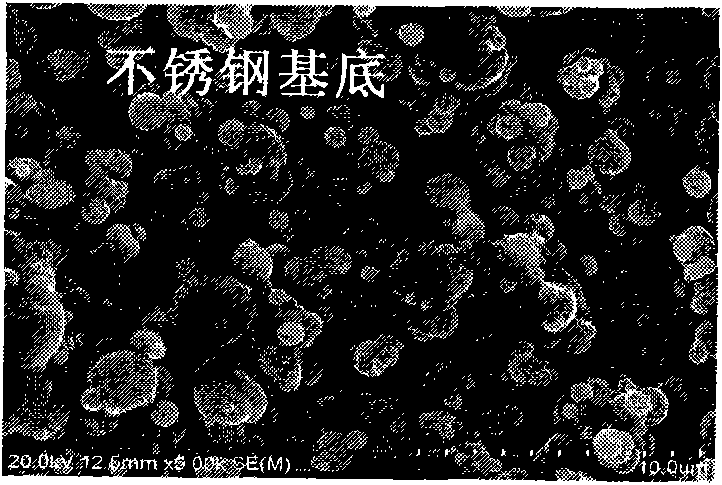

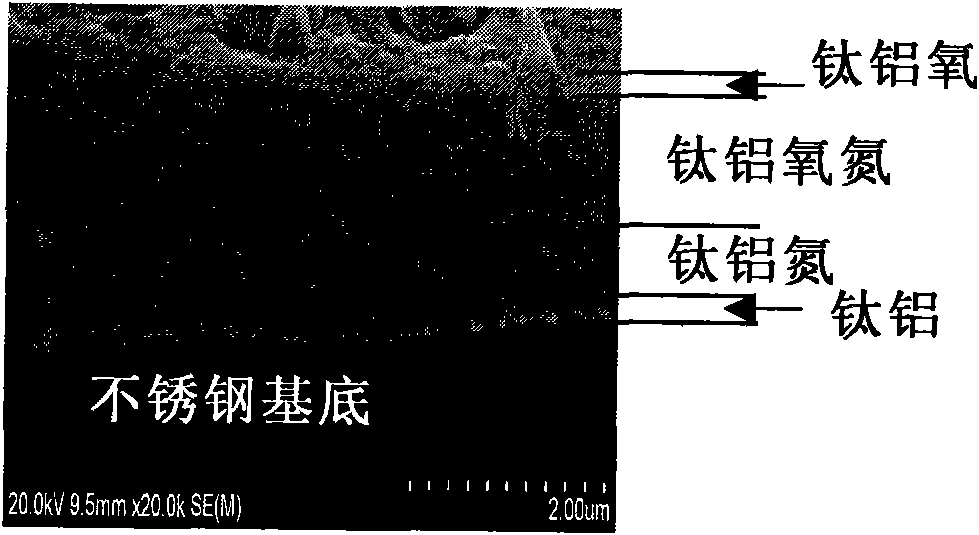

Non-vacuum solar spectrum selective absorption film and preparation method thereof

ActiveCN101666557AImprove bindingFacilitates selective absorptionSolar heat devicesVacuum evaporation coatingCooking & bakingLow emissivity

The invention provides a non-vacuum solar spectrum selective absorption film and a preparation method thereof. The absorption film comprises a stainless steel or copper substrate which is successivelyprovided with a titanium-aluminum film, a titanium-aluminum-nitrogen film, a titanium-aluminum-oxygen-nitrogen film and a titanium-aluminum-oxygen film from inside to outside, wherein the films are prepared by adopting multi-arc ion plating; a target material adopts titanium-aluminum alloy target of which the atomic ratio of titanium to aluminum is 50:50; and the content of nitrogen and / or oxygenin the films is controlled by controlling the flow of argon, nitrogen and oxygen in the atmosphere of multi-arc ion plating. The method comprises: (1) selecting and cleaning a substrate material; (2)baking the substrate material in a vacuum sputtering chamber of a multi-target compound coating machine; (3) performing argon-ion bombardment on the surface of the substrate material; (4) coating thesubstrate material; and (5) performing annealing treatment. The absorption film has the advantages of high absorptivity alpha in a solar spectral range (0.3 to 2.5 microns), low emissivity epsilon inan infrared region (2 to 50 microns) and the characteristic of resisting high-temperature oxidation, thereby meeting the requirements of solar high-temperature utilization.

Owner:GRIMAT ENG INST CO LTD

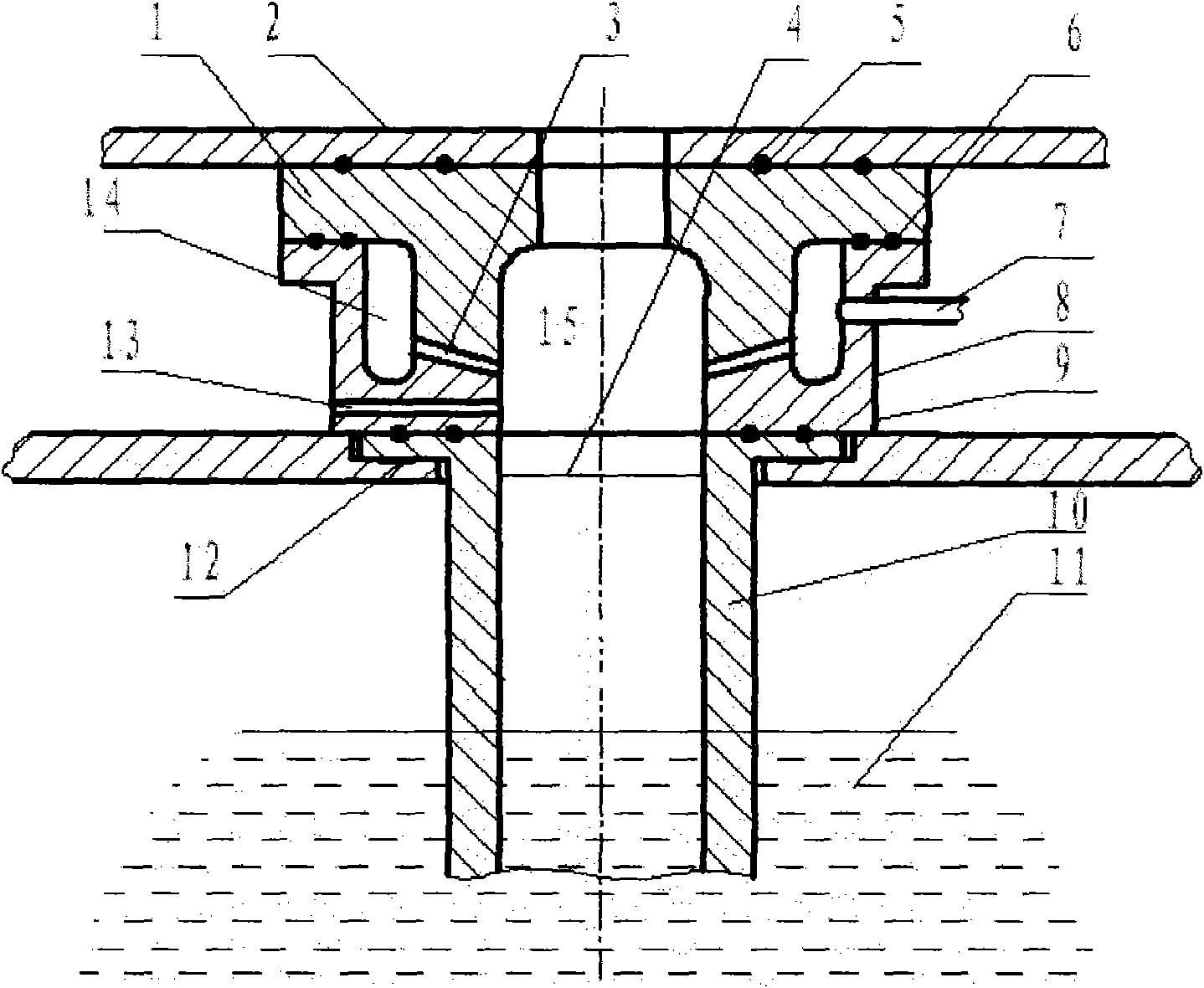

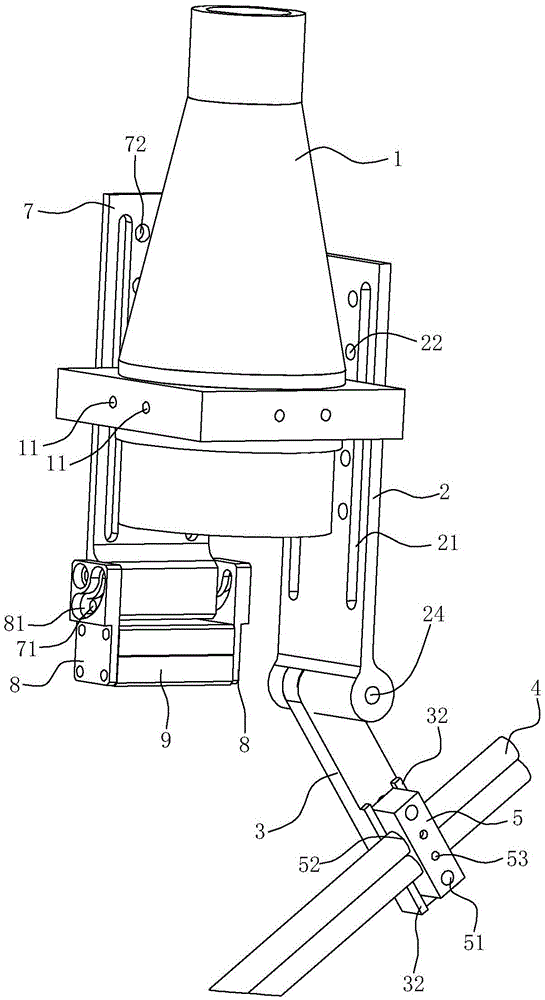

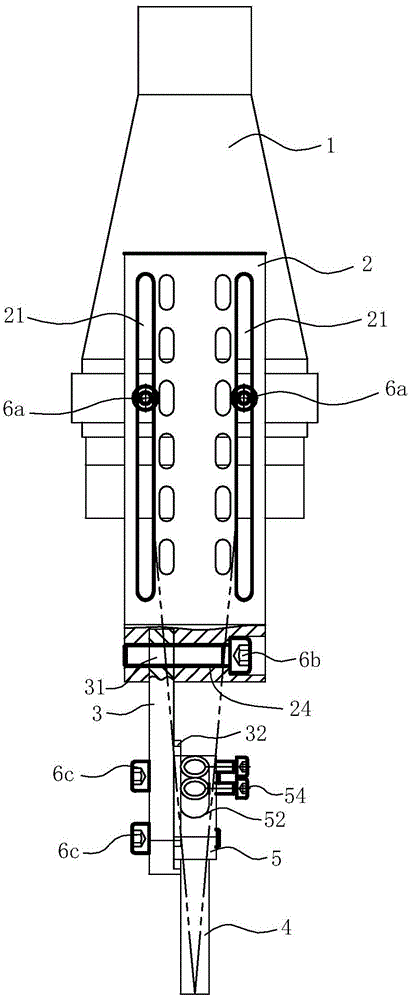

Low-pressure casting filling method and low-pressure casing filling equipment used by same

The invention relates to a low-pressure casting filling method comprising the steps of arranging a reducing sleeve arranged on an upper port of a riser tube (10), guiding magnesium alloy liquid from the riser tube (10) to a cast through the reducing sleeve; arranging a protective gas inlet on the reducing tube, and enabling the protective gas into the space above the magnesium alloy liquid in the riser tube (10) for protecting the magnesium alloy liquid in the riser tube (10) and reducing oxidation. The a low-pressure casting filling method uses a low-pressure casting filling device which includes the reducing sleeve composed of an upper part (1) of the reducing sleeve, a lower part of the reducing sleeve; wherein a magnesium alloy liquid sensor mounting hole (10) is arranged on a lower side wall of the lower part of the reducing sleeve; a plurality of subsize air suctions with enough section width are arranged on a joint face of the upper part (1) and the lower part (8) of the reducing sleeve, and the air suctions are slit structures with rectangular sections. The low-pressure casting filling method of the invention can obviously reduce the oxidation of the magnesium liquid in the riser tube and improve the quality of a magnesium alloy low-pressure casting member.

Owner:沈阳铸研科技有限公司

Laser additive repair method for titanium alloy valve rod

InactiveCN111451500AEasy to implementLow costAdditive manufacturing apparatusIncreasing energy efficiencySurface cleaningTest sample

The invention discloses a laser additive repair method for a titanium alloy valve rod. The laser additive repair method for the titanium alloy valve rod comprises the following steps: optimizing parameters and carrying out a multi-pass multi-layer laser additive experiment through an earlier-stage single-pass laser additive process experiment for a titanium alloy powder, and carrying out metallographic observation on a cladding layer to obtain the optimal process parameters; carrying out laser additive manufacturing printing for a performance test sample piece of the titanium alloy on a titanium alloy substrate, completing a performance test, evaluating a test result, and determining a repair process; carrying out photographing recording on an area to be repaired, and completing surface cleaning; carrying out accurate clamping on the titanium alloy valve rod, and locking the end part by a center; reserving machining allowance in an additive repair damage area carrying out coaxial powder feeding through laser, setting a scanning path to be spiral forward, enabling the left end and the right end of a starting point position to be alternating and rotate clockwise with time difference,and controlling temperature rise of the workpiece; and adopting fluorescence detection, machining according to the requirement of a drawing to restore a size, and delivering and using. According to the laser additive repair method for the titanium alloy valve rod, the requirement of safe use for the titanium alloy valve rod in a life cycle is guaranteed by optimizing the laser additive process parameters and a scanning path strategy.

Owner:航发优材(镇江)增材制造有限公司

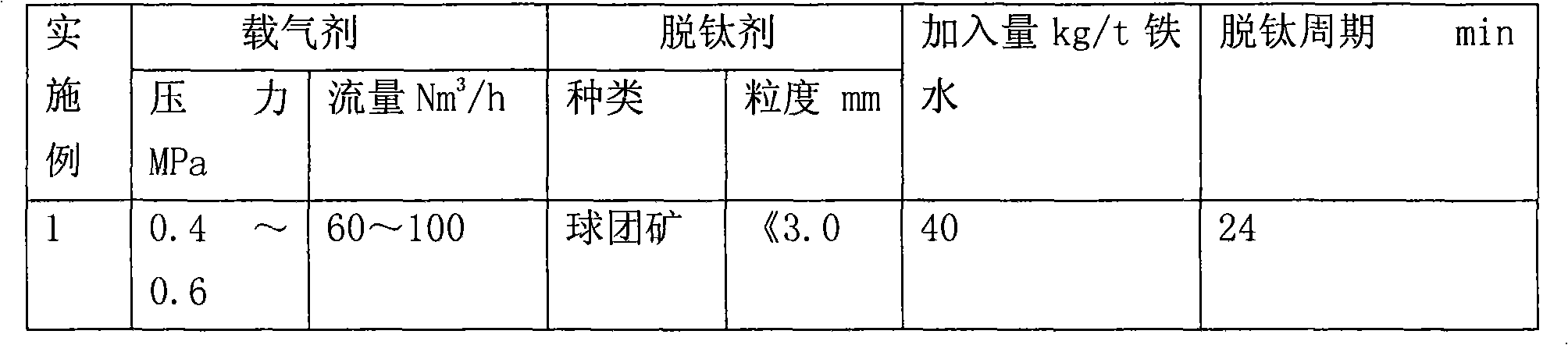

Method for removing titanium from ladle by using stirring method

ActiveCN101805818ASolve Oxidation ProblemsQuality improvementProcess efficiency improvementChemical reactionSlag

The invention discloses a method for removing titanium from ladle by using a stirring method and belongs to the technical field of molten iron titanium removal. The method comprises the process step of stirring molten iron by using a stirring paddle for providing a dynamical condition for a titanium-removing chemical reaction. The depth of the stirring paddle inserted into the ladle is that the distance from the bottom of a stirrer to the bottom of a molten iron tank or the bottom of a molten iron ladle is 200-400mm and the rotating speed of the stirring paddle is 10-140r / min; a titanium removing agent is pneumatically delivered to the inside of the molten iron ladle through a storage tank, a spraying tank and a pipeline by taking nitrogen gas as carrier gas; and the weight ratio of the titanium removing agent to the nitrogen gas is 3-10:1. The addition of the titanium removing agent is 5-50kg / t; the temperature reduction of the molten iron is less than or equal to 40DEG C; and after the titanium removing is finished, titanium removing slag is raked by a slag-raking machine. The invention has the advantages that the titanium removing effect is good, the titanium content in the molten iron is reduced to be less than or equal to 0.015 percent from 0.14 percent, the temperature reduction is less than or equal to 40DEG C and the titanium removing agent has low consumption which is 5-50kg of molten iron; and the invention is particularly applicable for producing high-quality steel grades.

Owner:CENT IRON & STEEL RES INST

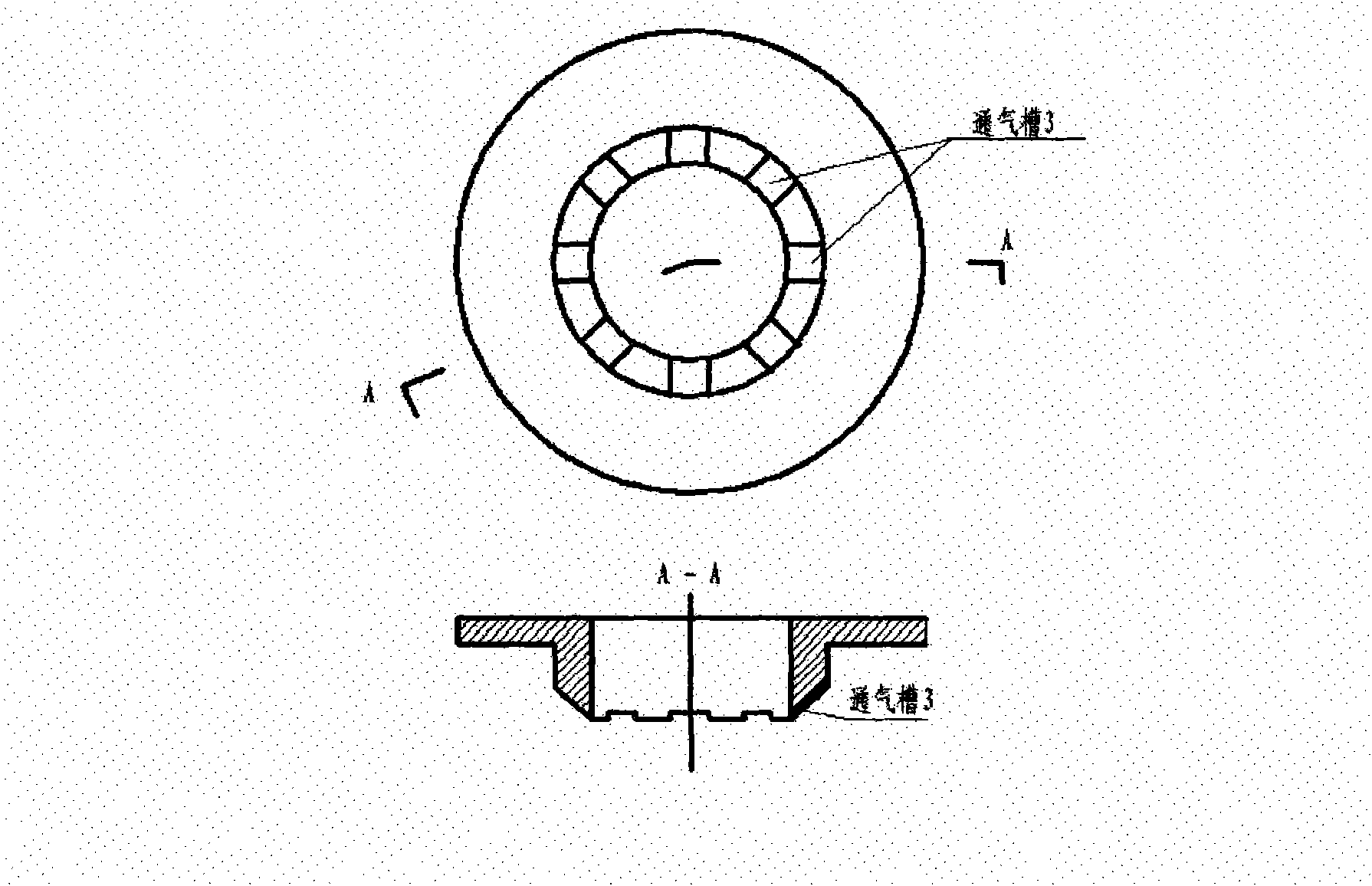

Method for manufacturing metal composite plate

ActiveCN103658175ALow costEasy to operateMetal rolling arrangementsManufacturing technologyComposite plate

The invention discloses a method for manufacturing a metal composite plate, and belongs to the technical field of metal composite plate manufacturing technology. The method comprises the following steps that firstly, the rusty layer and the oxide layer of multiple layer metal and parent metal are removed, the corners at the two ends and the middle of the metal layer placed on the upper face in the process of heating are respectively drilled, and each position of the corners at the two ends and the middle of the metal layer is provided with a vent hole with the diameter ranging from 4mm to 8mm; secondly, the multiple layer metal and the parent metal are stacked, and the periphery of the contact face is welded and sealed; thirdly, the air inside the contact face space is completely exhausted by injecting argon through the vent hole in one end, and the vent holes in the two ends are sealed; fourthly, the metal composite plate is placed inside a heating furnace to be heated according to the production requirements for the composite layer metal; fifthly, the metal composite plate is rolled on a rolling mill; sixthly, if the multiple layer metal needs to be later processed in a heat mode, the composite plate is processed in the heat mode according to the demands. By means of the method, the oxidation of the contact face of the metal composite plate can be reduced, the shearing strength of the contact face of the metal composite plate is improved, vacuumizing is not needed, operation is easy, and cost is low.

Owner:HEBEI IRON AND STEEL

Silver-plated copper containing paste for solar cell back electrode and method for preparing silver-plated copper containing paste

InactiveCN102810344AImprove conversion efficiencyGood welding adhesionNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver plateAdhesive

The invention discloses silver-plated copper containing paste for a solar cell back electrode and a method for preparing the silver-plated copper containing paste. The silver-plated copper containing paste for the solar cell back electrode is made by mixing adhesives, silver containing powder and diluents, wherein the silver containing powder is made by mixing silver powder, silver-plated copper powder and glass powder according to a weight ratio of (15%-40%): (50%-80%): (1%-10%). Existing pure silver power is replaced by the silver containing powder made by mixing the silver powder, the silver-plated copper powder and the glass powder, cost of back electrode paste is greatly lowered, and production cost of cells is further reduced. In addition, the preparation method of the silver-plated copper containing paste is simple and suitable for industrial production, the problem of oxidation of pure base metal paste during sintering of cells is solved, and the prepared silver-plated copper containing paste for the solar cell back electrode is low in contact resistance, high in cell conversion efficiency and high in weldability adhesion.

Owner:ENVIRONMENTAL NATURAL CHEM JIANGSU

Precision casting process of high-temperature alloy turbine

InactiveCN110181001ALow shrinkageSolve Oxidation ProblemsFoundry mouldsFoundry coresPorosityAviation

The invention belongs to the technical field of aviation precision casting, and particularly relates to a precision casting process of a high-temperature alloy turbine. The precision casting process of the high-temperature alloy turbine comprises the following steps of designing and manufacturing a part mold, preparing a ceramic core, preparation of a shell slurry, preparation of a part shell, dewaxing of a shell, pre-roasting of the shell and casting of the part, wherein the part mold is designed to ensure the integral punching of a wax mold by adopting a bottom injection type design. An inner cavity of the part is filled with the ceramic core, the ceramic core is an aluminum-based ceramic coated with cobalt aluminate on the surface, the surface of the inner cavity of the part can be effectively reduced by coating the surface of the ceramic core with cobalt aluminate, so that the problems of oxidation and shrinkage in the inner cavity of a traditional casting process casting are successfully solved, and meanwhile, the high porosity can ensure that the ceramic core can be removed by a high-pressure water gun after being poured.

Owner:鹰普航空科技有限公司

Aluminum alloy and LED lamp substrate applying same

InactiveCN101591747AImprove thermal conductivityImprove antioxidant capacityPoint-like light sourceLight fasteningsComposite substrateThermal expansion

The invention discloses aluminum alloy and an LED lamp substrate applying the aluminum alloy. The aluminum alloy comprises the following compositions in percentage by weight: more than or equal to 0.5 percent and less than or equal to 12 percent of Si, more than or equal to 0.1 percent and less than or equal to 1.5 percent of Mn, less than or equal to 1.2 percent of Fe, less than or equal to 4.5 percent of Cu, less than or equal to 0.5 percent of Mg, more than or equal to 0.005 percent and less than or equal to 0.85 percent of RE, less than or equal to 0.5 percent of inevitable impurities, and the balance of Al, wherein the RE is selected from at least one of La, Ce, Nd and Yb. The LED lamp substrate is provided with a copper plate and an aluminum alloy plate, and the copper plate and the aluminum alloy plate are jointed into a whole through high pressure forming. The aluminum alloy has excellent thermal conductivity and high temperature antioxidation performance, and is suitable for manufacturing the LED lamp substrate. The LED lamp composite substrate completely solves the problems of deformation and oxidation caused by uneven thermal expansion coefficients of two materials for the substrate and a lamp shell in the prior art, and contributes to manufacture of high power LED lamps in low cost.

Owner:宁波银风能源科技股份有限公司

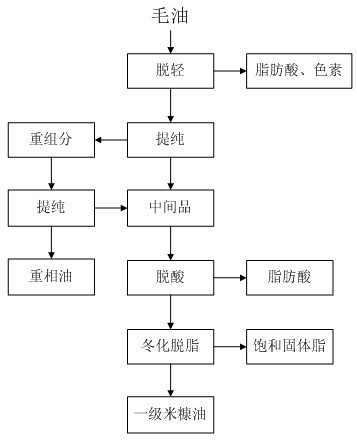

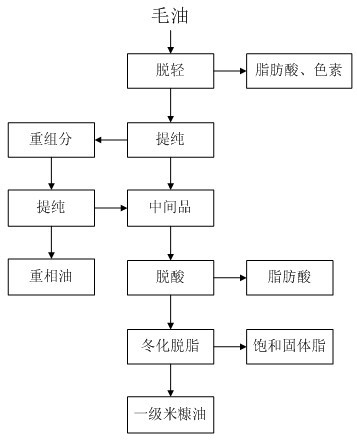

Production method of edible rice bran oil

InactiveCN102690723AImprove food safetyIncrease peroxide valueFatty-oils/fats refiningEdible oils/fatsPesticide residueRice bran oil

The invention discloses a production method of edible rice bran oil. The production method comprises the following steps of: firstly, heating four-stage standard rice bran oil by a preheater and charging into a separator, evenly distributing the materials under high vacuum degree, due to the boiling point difference of various substances, separating light components of raw material oil in an evaporating way by a pressure reducing technology, heating heavy components, charging into a purifier, quickly evaporating, separating aflatoxin and pesticide residue in an evaporating way, filtering the treated rice bran oil, contacting with protective gas in a stripping tower, and discharging in a separating way, wherein the acid value of the rice bran oil discharged out of the tower bottom achieves the standard of first-stage rice bran oil; and dewaxing in a winterization way to obtain the first-stage rice bran oil. According to the production method, the first-stage rice bran oil product with high oryzanol content can be produced. The whole technical process separates by a pure physical method, so that nutrition components can not be damaged; the production method does not need adding of any annexing agents, so that the safety of the product can be guaranteed; and the production method does not generate any waste gas, sewage or solid waste.

Owner:江苏迈克化工机械有限公司 +1

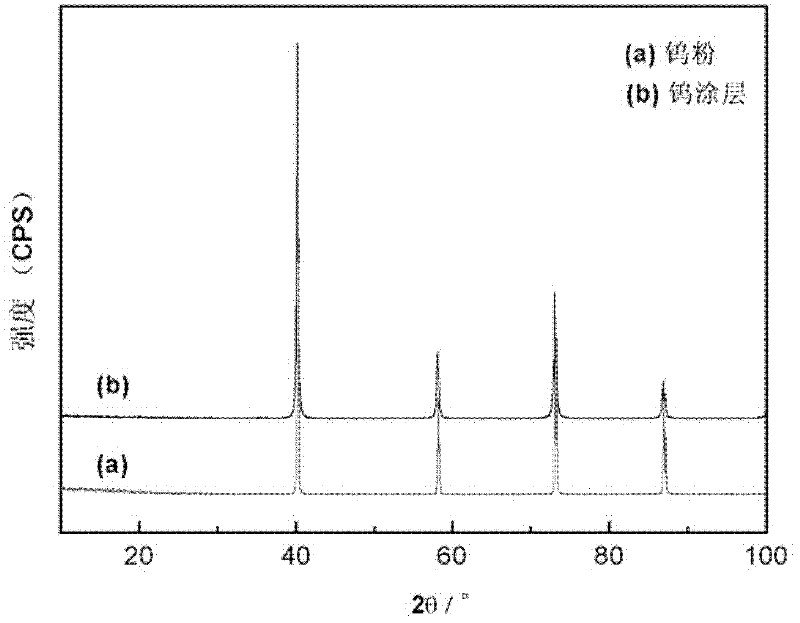

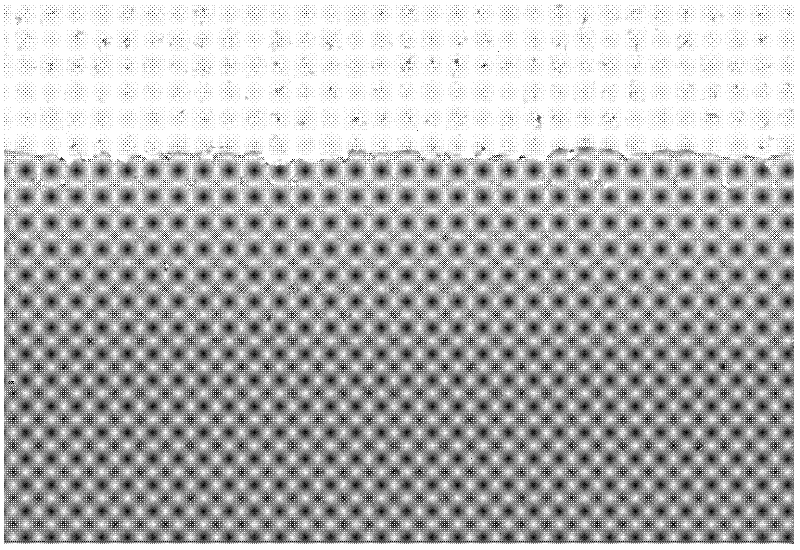

Preparation method of dense tungsten coating

InactiveCN102400084AIncrease profitReduce manufacturing costMolten spray coatingPorositySurface engineering

Belonging to the technical field of surface engineering, the invention provides a preparation method of a dense tungsten coating. The method is characterized in that: it takes ultrafine tungsten powder as a raw material, employs radio-frequency plasma as a high temperature heat source for providing sufficient heat, and adopts argon as a working gas and a powder carrier gas for conveying tungsten powder into a plasma high temperature area, while passing through the plasma high temperature area, the tungsten powder rapidly adsorbs heat and fuses, and the completely fused tungsten powder deposits, covers and solidifies on a matrix surface so as to form a dense tungsten coating. The method has the advantages that: radio-frequency plasma has high energy density so that powder can be totally fused and spheroidized, and the prepared tungsten coating has high density, low porosity, and high bonding strength with the matrix; meanwhile, the method has high powder utilization rate and low production cost. A tungsten coating prepared by the method of the invention has good thermal radiation resistance and thermal shock resistance, and is suitable for application in fields like plasma facing materials in nuclear fusion devices.

Owner:UNIV OF SCI & TECH BEIJING

Copper nanofluid solar cooling liquid and preparation method thereof

InactiveCN103045181ASolve Oxidation ProblemsDoes not affect thermal conductivityHeat-exchange elementsPhosphatePropanediol

The invention provides a copper nanofluid solar cooling liquid and a preparation method thereof, and belongs to the field of synthesis technologies of inorganic materials. The copper nanofluid solar cooling liquid comprises deionized water, glycol and propylene glycol, nano-copper powder, vinylpyridine, azodiisobutyronitrile, acylamino compound, phosphates and benzotriazole. The preparation method comprises the following steps of: uniformly dispersing the nano-copper powder into alcoholic solution by rapid dispersing; polymerizing on the nanometer copper surface to obtain a monomolecular film; adding a dispersing agent; mixing the obtained alcoholic solution with phosphate aqueous solution; dispersing and mixing at a medium speed again; dispersing by an ultrasonic oscillating instrument; and then homogenizing through a fold-type reducer pipe, so as to obtain the copper nanofluid solar cooling liquid. The prepared copper nanofluid has the characteristics that the thermal conductivity is four times higher than that of the deionized water, the uniformity in dispersing is realized, the stability is excellent, the stability is remained after placing for 2400 hours at the normal state, the freezing point is low, no icing occurs at the temperature of -40 DEG C, the corrosion resistance is excellent, and the copper nanofluid is suitable for an anti-freezing liquid, and the material source is rich; the raw materials are directly sourced, low in price and easy to obtain; low requirement is brought to the running of the equipment; and the massive industrial production can be easily realized.

Owner:济南道生一新能源科技有限公司

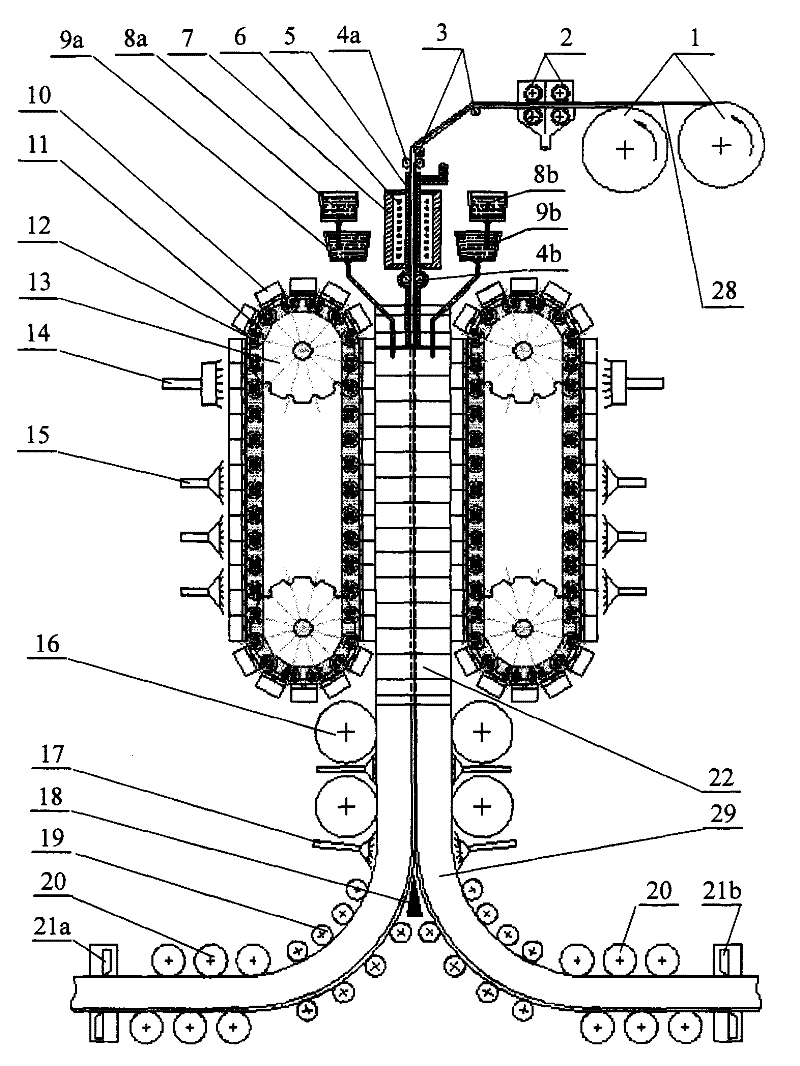

Solid-liquid phase continuous compounding device for stainless steel compound plate slabs

The invention discloses a solid-liquid phase continuous compounding device for stainless steel compound plate slabs. By adopting the device, stainless steel compound plate slabs can be produced continuously with high efficiency, low cost and high quality. The solid-liquid phase continuous compounding device for stainless steel compound plate slabs comprises two uncoilers, two wire brushes, guide rollers, casting systems, protective atmosphere heating systems, crawler-type crystallizers and cooling separation systems; the two uncoilers are arranged in the feeding position in a mutually staggered manner; the two wire brushes are arranged behind the uncoilers; the guide rollers are arranged behind the wire brushes; the protective atmosphere heating systems are arranged below the guide rollers; the casting systems are arranged on two sides of the protective atmosphere heating systems; the crawler-type crystallizers are arranged below the casting systems; and the cooling separation systems are arranged at the bottom. By adopting the device, not only are thin plate slabs of single metal material can be produced, but also compound thin plate slabs of different metal materials can be produced continuously; and the device is particularly suitable for continuous production of stainless steel composite plate slabs.

Owner:UNIV OF SCI & TECH LIAONING

Gas blowing protective device used during stainless steel sheet pulse laser welding and welding process

ActiveCN105149777AInhibition of shieldingPlay the role of "repression"Welding/soldering/cutting articlesMetal working apparatusEngineeringLaser

The invention relates to a gas blowing protective device used during stainless steel sheet pulse laser welding. The device comprises a side gas blowing protection part installed on a collimating focusing head and is characterized in that the side gas blowing protection part comprises a first adjusting plate, a rotary rod, a slider and a side gas blowing pipe; the first adjusting plate is fixed on the side wall of the collimating focusing head and can be adjusted up and down; the rotary rod is arranged at the lower end of the first adjusting plate in a rotary manner and the angle of swing relative to the first adjusting plate can be adjusted; the slider is fixed on the outer side wall of the rotary rod and the axial position of the slider along the length direction relative to the rotary rod can be adjusted; the side gas blowing pipe is fixed on the slider in a penetrating manner and can be adjusted along the thickness direction relative to the slider. The gas blowing protective device used during stainless steel sheet pulse laser welding is convenient in adjustment of height and angular positions. After the protective device is adopted, side gas blowing can be adjusted to an optimum position, so that welded product weld surfaces are oxidation-free and have good gloss. The invention also relates to a welding process.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Preparation method for aluminum-stainless steel clad metal plate and strip

ActiveCN101797583ASolve Oxidation ProblemsUniform thicknessTension/compression control deviceMetal rolling arrangementsComposite strengthBond strength

The invention discloses a preparation method for an aluminum-stainless steel clad metal plate and strip. The method comprises: carrying out anaerobic continuous casting and rolling on semisolid aluminum or aluminum alloy and a solid stainless steel plate strip to prepare the aluminum-stainless steel clad metal plate strip. In the preparation method of the invention, the non-oxidation metallurgy composite of the solid stainless steel plate strip and aluminum liquid is realized, the oxidation problem of the aluminum is solved, the composite strength is high, and the bond strength of the stainless plate and the aluminum is larger than or equal to 100Mpa; continuous casting and rolling is carried out on the stainless plate strip and the aluminum liquid to prepare the aluminum-stainless steel clad metal plate strip, the production efficiency is greatly improved by up to dozens of times, and the product quality is stable; the prepared aluminum-stainless steel clad metal plate strip product maintains the intrinsical surface quality of the stainless steel plate strip, and the stainless steel layer has even thickness and can be performed with cold rolling and deep processing; various stainless steel plate and strips with different components and the aluminum liquid can be adopted, the sorts of products are more, and the applicability is wide; and the invention has the advantages of advanced production process, less working procedure, energy conservation, materials saving and remarkable economic effects.

Owner:LUOYANG TONGYI METAL MATERIAL DEV +2

Method for preparing large-size molybdenum plates for sputtering targets of liquid crystal display (LCD) flat-panel displays

ActiveCN102534519ASolve Oxidation ProblemsSolve the serious temperature drop of the billetVacuum evaporation coatingSputtering coatingFlat panel displayCrystallite

The invention discloses a method for preparing large-size molybdenum plates for sputtering targets of liquid crystal display (LCD) flat-panel displays, which comprises: 1), uniformly brushing an antioxidation coating on the surface of a molybdenum plate blank by pressing and sintering by the conventional process; 2), covering the molybdenum plate blank with the antioxidation coating with a steel capsule; 3), rolling the molybdenum plate blank covered with the steel capsule by one time of heating, and cooling the rolled molybdenum plate blank on a cold bed; 4), rolling the cooled molybdenum plate blank till the thickness (including the steel capsule) of the molybdenum plate blank is between 19 and 24 millimeters; 5), leveling the rolled molybdenum plate blank, removing the steel capsule, cutting the molybdenum plate blank and obtaining semi-finished molybdenum plates; and VI, performing the vacuum heat treatment of the semi-finished molybdenum plates, and obtaining the large-size molybdenum plates for the sputtering targets of the LCD flat-panel display. The large-size molybdenum plates for the sputtering targets of the LCD flat-panel display, which are prepared by the method of the invention, have flat surfaces, the density of the plates is more than or equal to 10.15g / cm<3>, the microscopic structure of the plates is uniform equiaxial structure, and the average grain size of the plates is not more than 200 mu m.

Owner:XIAN REFRA TUNGSTEN & MOLYBDENUM

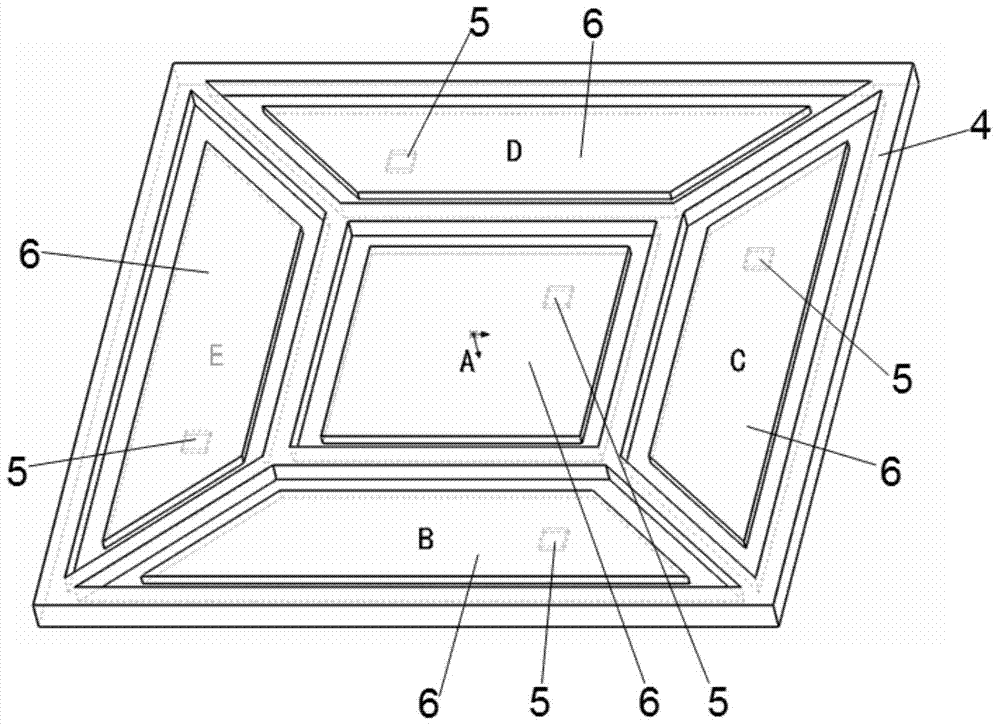

Objective table partition temperature control system for 3D printing

InactiveCN103941768APartition power is smallSufficient power headroomTemperatue controlTemperature controlControl circuit

The invention provides an objective table partition temperature control system for 3D printing. The objective table partition temperature control system comprises an upper computer, a control circuit and a partition-type objective table. After the upper computer reads user file information, working partitions can be automatically or manually distributed according to the size and position of an object needing to be printed in a file, temperature detection and control over the corresponding partition are started, and multi-partition distribution and temperature control can also be achieved under the situation that a plurality of components are printed at the same time. The control circuit can identify instructions of the upper computer, complete temperature detection and control over the partitions, and upload data to the upper computer. The partition-type objective table is composed of a plurality of temperature control units. Each temperature control unit comprises an independent temperature probe and a heater. Compared with an existing objective table temperature control system, the objective table partition temperature control system has the advantages that the corresponding temperature control partitions can be automatically or manually started according to the sizes and the positions of the printed components, the heating speed is high, energy consumption is low, safety is high, and precision of temperature control is high.

Owner:UNIV OF SCI & TECH OF CHINA

Titanium and titanium alloy low-cost continuous casting technology and equipment

The invention relates to a titanium and titanium alloy low-cost continuous casting technology and equipment. Under argon protecting or inert gas atmosphere, a plasma gun of at least 65 KW is used as a heat source. Through a crystallizer, a plasma gun and a down-pulling mechanism, continuous casting of titanium and titanium alloy circular and flat cast ingots is achieved. The machining cost of titanium alloy is lowered by about at least 15%. The produced titanium and titanium alloy are even in components, segregation is avoided, and metallurgical quality problems are avoided.

Owner:SHANGI INST FOR ADVANCED MATERIALSNANJING CO LTD

Scale and corrosion inhibiting method for industrial boiler

InactiveCN1609019ASolve Oxidation ProblemsAdaptableScale removal and water softeningAlkalinitySulfite salt

The scale and corrosion inhibiting method for industrial boiler includes preparing stable sodium sulfite with sodium sulfite and isoascorbic acid, adding polyepoxy succinic acid into the boiler system, adding stable sodium sulfite and maintaining the amount inside the boiler system in 2-10 mg / L to make these two kinds of green scale inhibitor and deoxidant take synergistic effect, so as to provide environment friendly, high efficiency scale and corrosion inhibiting method for industrial boiler.

Owner:BEIJING UNIV OF CHEM TECH

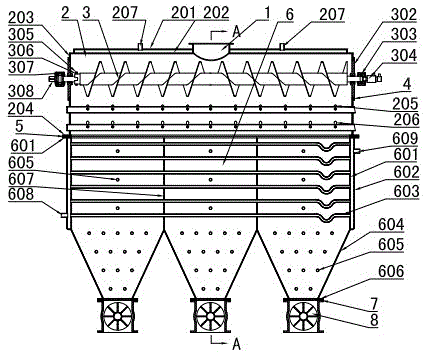

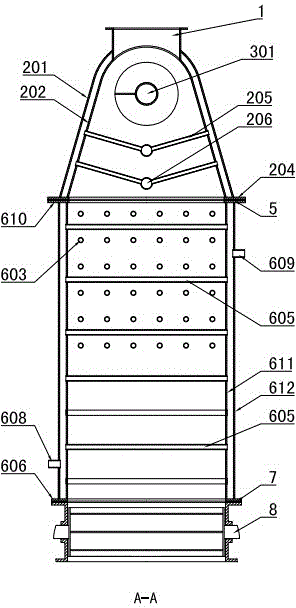

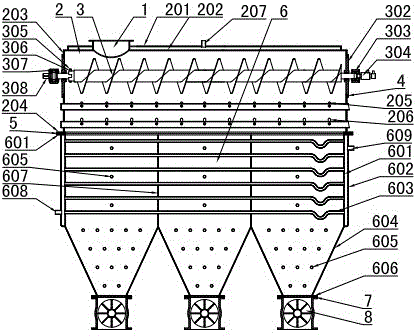

Large box type high-temperature material heat exchanger

ActiveCN104697371ALarge flow cross-sectional areaLarge cooling capacityMoving conduit heat exchangersImpellerEngineering

The invention provides a large box type high-temperature material heat exchanger, and belongs to the field of high-temperature solid material cooling equipment. The large box type high-temperature material heat exchanger is characterized by sequentially comprising a water cooling box cover (2), a heat exchanging box (6) and necking-down type hoppers from top to bottom, wherein a water cooling jacket is arranged on a wall of the water cooling box cover (2); end water cavities and / or side water cavities are formed in the wall of the heat exchanging box (6) and the walls of the necking-down hoppers; a plurality of heat exchanging pipelines are respectively arranged in the water cooling box cover (2), the heat exchanging box (6) and cavities of the necking-down type hoppers; a feeding opening (1) is formed in the upper portion of the water cooling box cover (2); a water cooling spiral distributor (3) which can convey and cool down materials is arranged in the water cooling box cover (2); the necking-down type hoppers are arranged side by side; and an impeller discharging valve (8) is arranged at an outlet of the bottom of each necking-down type hopper. The large box type high-temperature material heat exchanger is large in material cooling amount, low in energy consumption and long in service life; and abrasion of heat exchanging components is small.

Owner:SHANDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com