Solar spectrum selective absorbing coating and preparation method thereof

An absorbing coating, selective technology, applied in coatings, solar thermal devices, solar thermal power generation, etc., can solve the problems of low emissivity or thermal stability index, can not meet the needs and other problems, to avoid oxidation problems, improve thermal stability Sexual, colorful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preparation of Cu / TiNbN / TiNbON / SiON is taken as an example below, which is only used to illustrate the present invention, but not to limit the present invention.

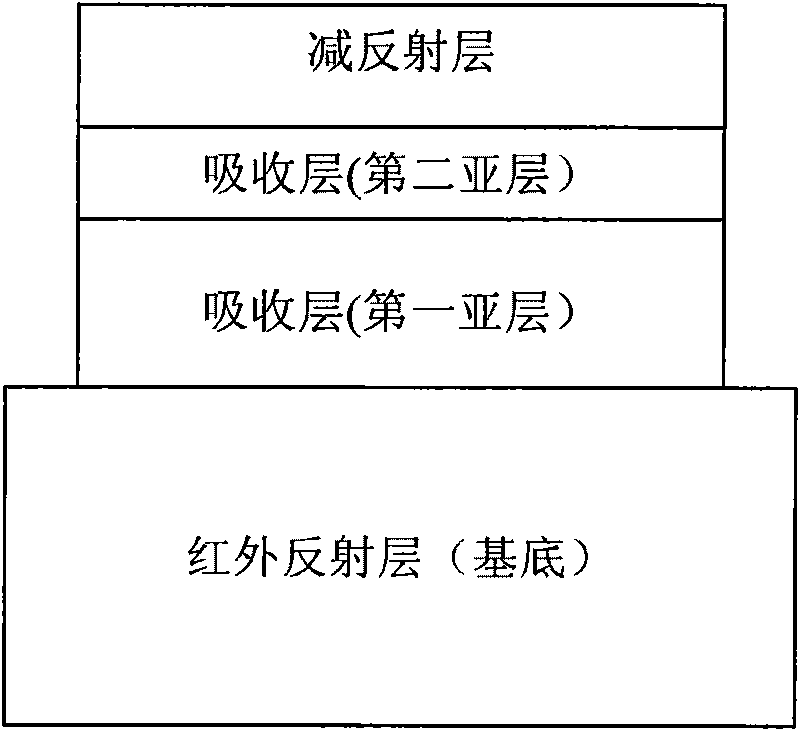

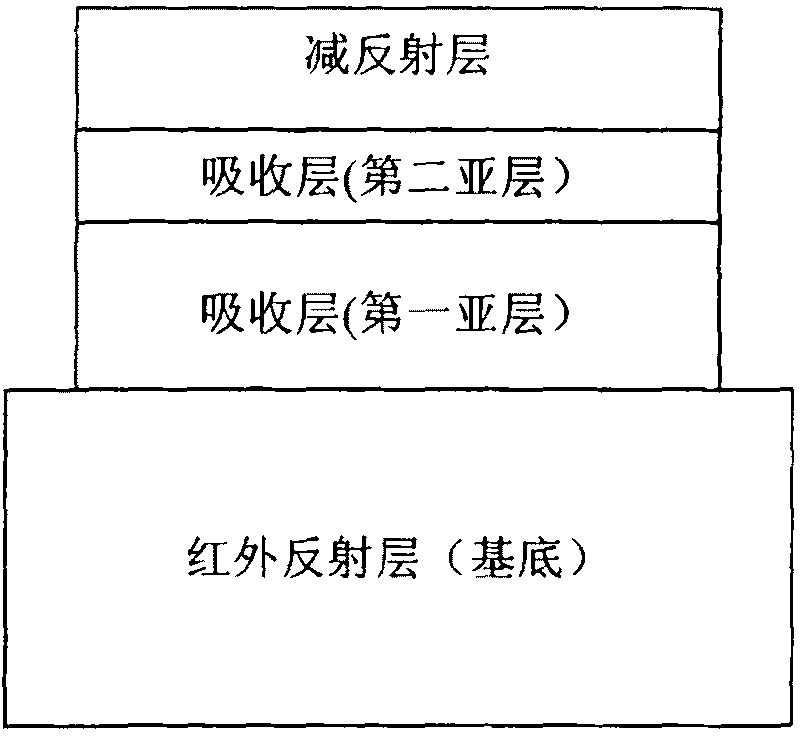

[0019] See figure 1 As shown, a solar spectrum selective absorbing coating of the present invention is prepared by magnetron sputtering technology, and the surface of the heat absorbing body substrate forms a three-layer film structure from the bottom to the top, and its composition and proportion are as follows:

[0020] The first layer is made of 0.5mm thick copper sheet as the infrared reflection layer; the second layer is the absorption layer, which includes two sublayers (ie, the first sublayer and the second sublayer) of the metal-like layer and the dielectric-like layer, and the metal-like layer It is composed of metal titanium, niobium mixed with titanium nitride and niobium nitride, the thickness is 90nm, and the metal phase volume ratio is 60%. The dielectric-like layer is composed of metal phas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com