Method for manufacturing metal composite plate

A technology of metal composite plate and manufacturing method, which is applied in the direction of metal rolling, etc., to achieve the effects of improving bonding strength, simple operation, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment relates to the preparation of a wear-resistant steel and carbon structural steel composite plate.

[0028] In this embodiment, the model of the clad metal 1 is NM360, with a size of 600 mm×350 mm×85 mm (length×width×thickness); the base metal 1 is Q235 carbon structural steel, with a size of 600 mm×350 mm×115 mm (length x width x thickness).

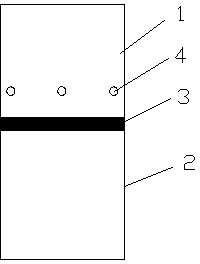

[0029] Use a milling machine to grind the sides of the wear-resistant steel plate and carbon structural steel that need to be combined to remove the rust and oxide layer on the side; drill Φ5mm ventilation holes 4 at the corners and middle parts of the two ends of the wear-resistant steel plate; The sides of wear-resistant steel plates and carbon structural steel plates are cleaned and dried in cool air.

[0030] Stack the wear-resistant steel plate and the carbon structural steel plate together. When stacking, the side of the wear-resistant steel plate that has been polished, cleaned, and dried is placed opposite...

Embodiment 2

[0038] This embodiment relates to the preparation of a wear-resistant steel and carbon structural steel composite plate.

[0039] In this embodiment, the model of the clad metal 1 is NM400, with a size of 580 mm×320 mm×75 mm (length×width×thickness); the base metal 2 is Q345 carbon structural steel, with a size of 580 mm×320 mm×125 mm (length x width x thickness).

[0040] Use a milling machine to grind the side of the wear-resistant steel plate and the carbon structural steel that need to be combined to remove the rust and oxide layer on the side; drill Φ4mm air holes 4 at the corners and middle parts of the two ends of the wear-resistant steel plate; The sides of wear-resistant steel plates and carbon structural steel plates are cleaned and dried in cool air.

[0041] Stack the wear-resistant steel plate and the carbon structural steel plate together. When stacking, the side of the wear-resistant steel plate that has been polished, cleaned, and blown dry is placed opposite ...

Embodiment 3

[0049] This embodiment relates to the preparation of a stainless steel and carbon structural steel composite plate.

[0050] In this embodiment, the model of the stainless steel clad metal 1 is 304 austenitic stainless steel, with a size of 520 mm × 260 mm × 5 mm (length × width × thickness); the base metal 2 is Q235 carbon structural steel, with a size of 520 mm ×260mm×45mm (length×width×thickness).

[0051] Use a milling machine to grind the side of the stainless steel plate and carbon structural steel that need to be combined to remove the rust and oxide layer on the side; drill Φ8mm air holes 4 in the corners and middle parts of the stainless steel plate at both ends; grind the stainless steel plate Clean the side of the carbon structural steel plate and dry it with cool air.

[0052] The stainless steel plate and the carbon structural steel plate are stacked together, and the side of the polished, cleaned, and blown stainless steel plate and the side of the carbon struct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com