Objective table partition temperature control system for 3D printing

A temperature control system and 3D printing technology, applied in the field of 3D printing, can solve the problems of the machine not rising to the working temperature, the user waits for a long time, and the large working current, etc. Plug-in oxidation and ablation problem solving, high temperature control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

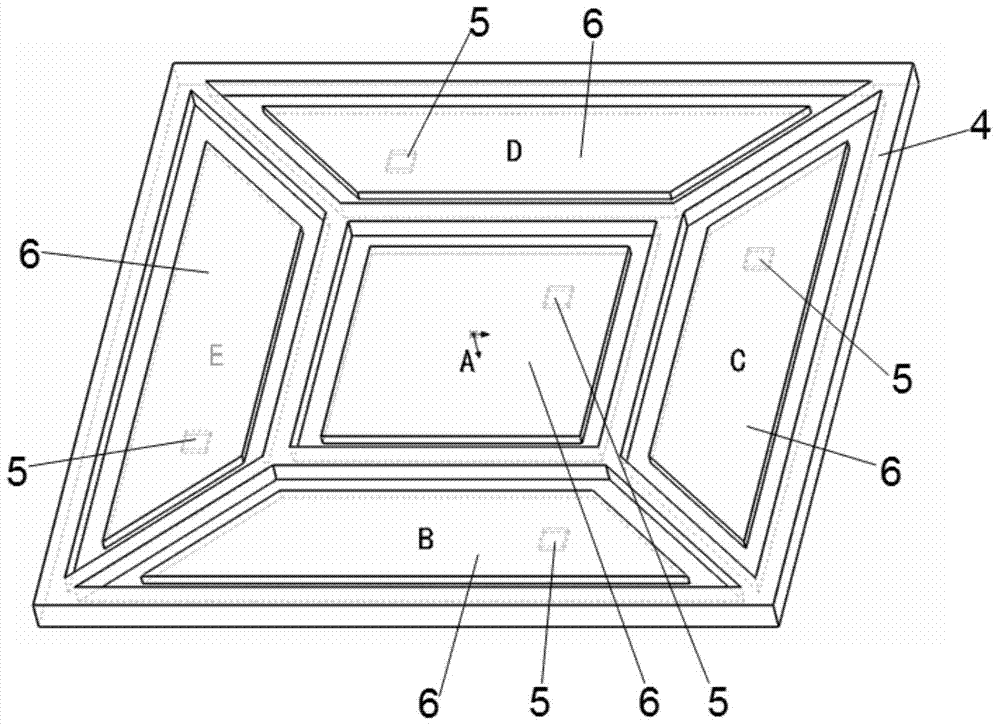

[0020] Such as figure 1 As shown in FIG. 1 , the schematic diagram of the temperature control system for the stage partitions of the present invention is also a schematic diagram of an implementation process of the present invention. Wherein, the stage 4 is divided into five partitions according to design requirements, respectively A, B, C, D, E, each partition is a temperature control unit, and each temperature control unit includes an independent temperature detection probe 5 and heating Device 6. After the host computer 1 reads the information of the user file 9, according to the size and position of the parts to be printed in the file, it can automatically or manually print in the five partitions A, B, C, D, and E of the stage 4. Assign work zones, and start the temperature detection and control of the corresponding work zones; the control circuit 2 obtains and recognizes instructions from the host computer 1, and outputs the signal to the heater 6 of the temperature cont...

Embodiment 2

[0027] Such as Figure 4 , Figure 5 As shown, the schematic diagram of the front of the stage and the top view of the bottom of the stage in Embodiment 2 of the present invention. In embodiment 2, when the size of the stage is relatively large, the stage is divided into 9 partitions of A, B, C, D, E, F, G, H, and I, and each partition is a temperature control zone. unit, the bottom of each partition is installed with an independent temperature detection probe 5 and a heater 6 to detect and control the temperature of the corresponding partition. The implementation process and implementation effect of Embodiment 2 are basically the same as Embodiment 1.

[0028] According to the size and shape of the stage, other partition schemes can also be carried out on the stage. The essence is to choose a suitable partition method for the stage of different sizes and shapes, and divide it into multiple temperature control units to realize It has the characteristics of fast heating spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com