Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

133 results about "Winterization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Winterization is the process of preparing something for winter.

Camellia oil preparation method for cosmetics

ActiveCN101305974AImprove quality requirementsCrystal clear appearanceCosmetic preparationsToilet preparationsCamellia oleiferaFiltration

The invention relates to a preparation method of cosmetics camellia oil. High-quality camellia seeds are selected to be used as the raw material; the camellia seeds are roasted under the negative pressure and at the lower temperature, and are husked after natural cooling and are squeezed at the room temperature to obtain high-quality crude oil with low acid value and pale yellow color; impurities are removed through filtration under the heating condition, alkali refining and ethanolic extracting two-stage process is utilized for acid stripping and de-coating; then the mixture composed of active carbon and floridin is used as de-coloring agent for de-pigmentation; peroxide and unclean flavor are removed through deodorization; then the drying winterization is acted; finally, the cosmetics camellia oil is obtained, wherein, the acid value is less than 0.1 mgKOH / g, the peroxide value is less than 0.5 mmol / kg, the appearance is colourless approximately as well as clear and translucent, and no unclean flavor exists. The cosmetics camellia oil reaches or exceeds the requirement of the national standard GB11765-2003 on first level expressed tea-seed oil, and can be directly used for manufacturing the cosmetic such as skin care oil for babies; in addition, an edible camellia oil fabrication plant can be improved for production, thereby lowering the investment cost greatly.

Owner:广东新大地生物科技股份有限公司

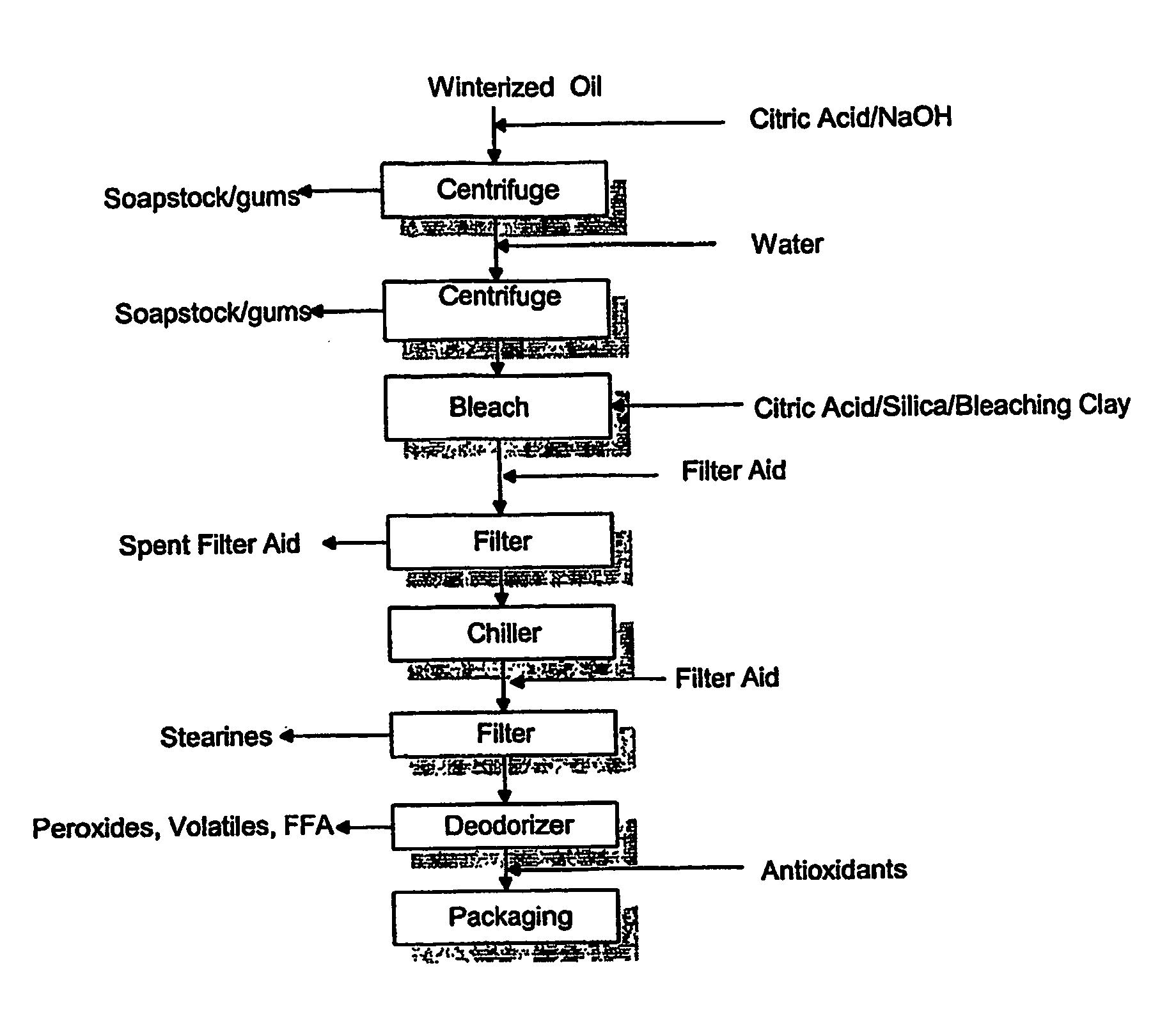

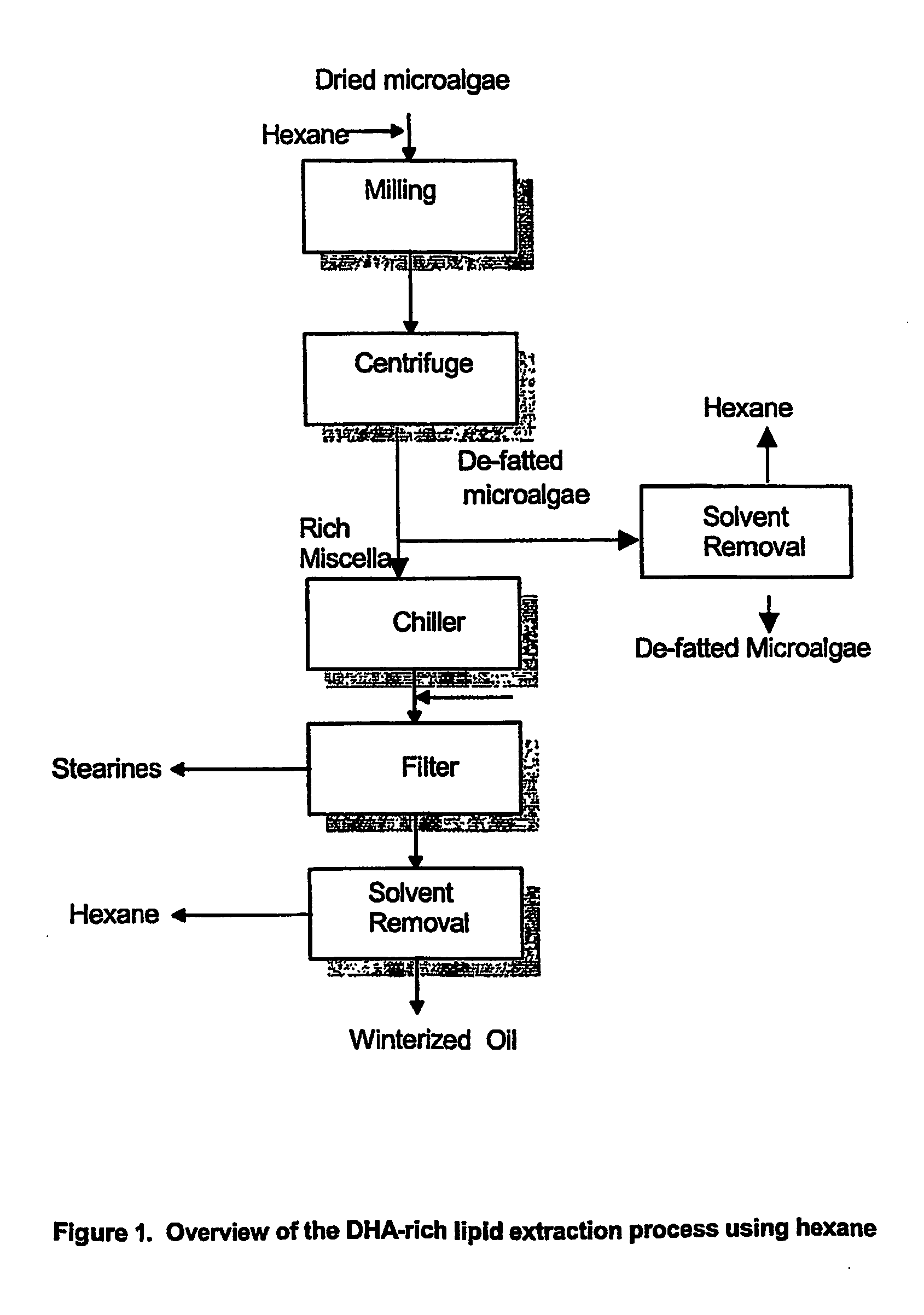

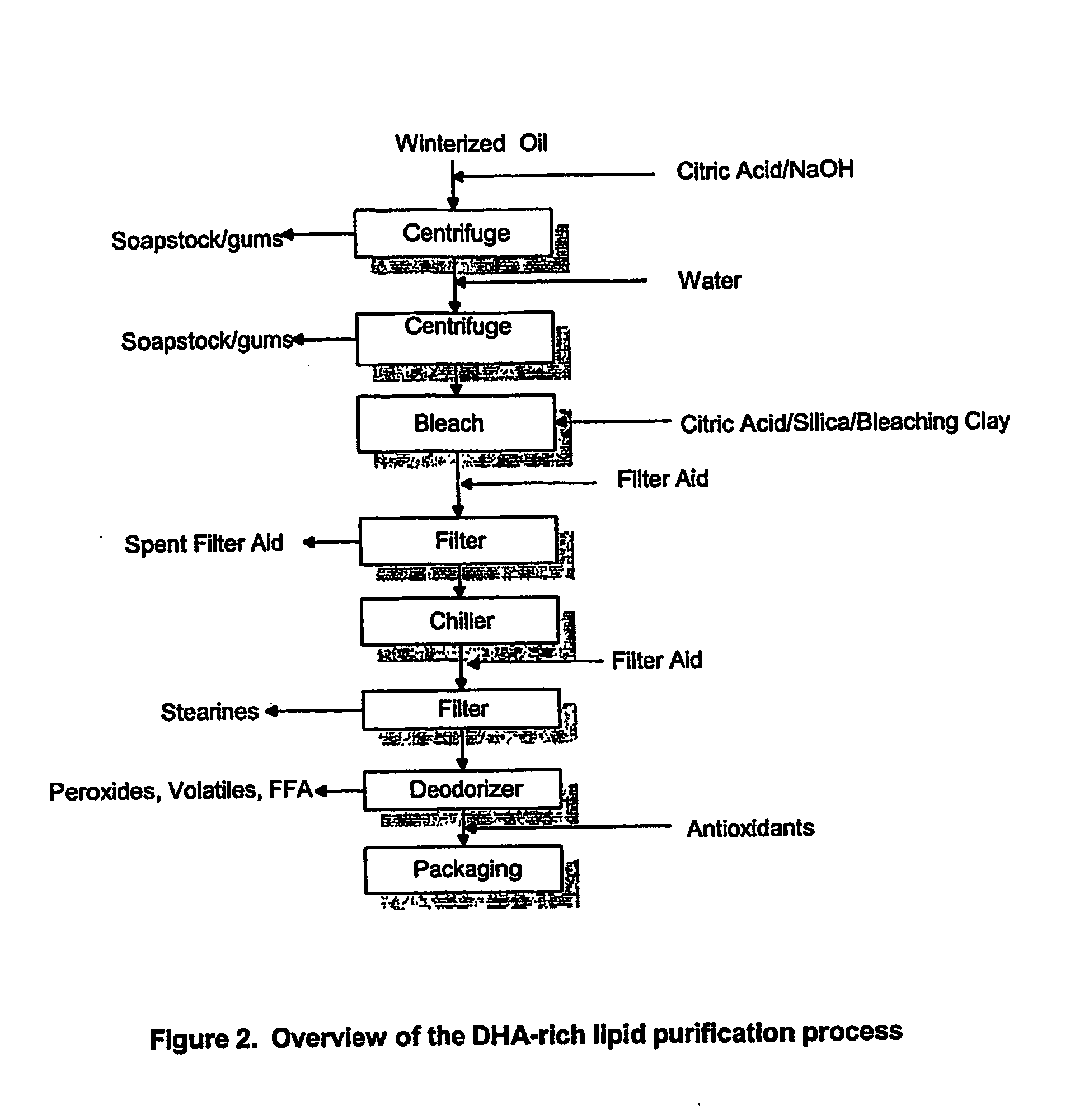

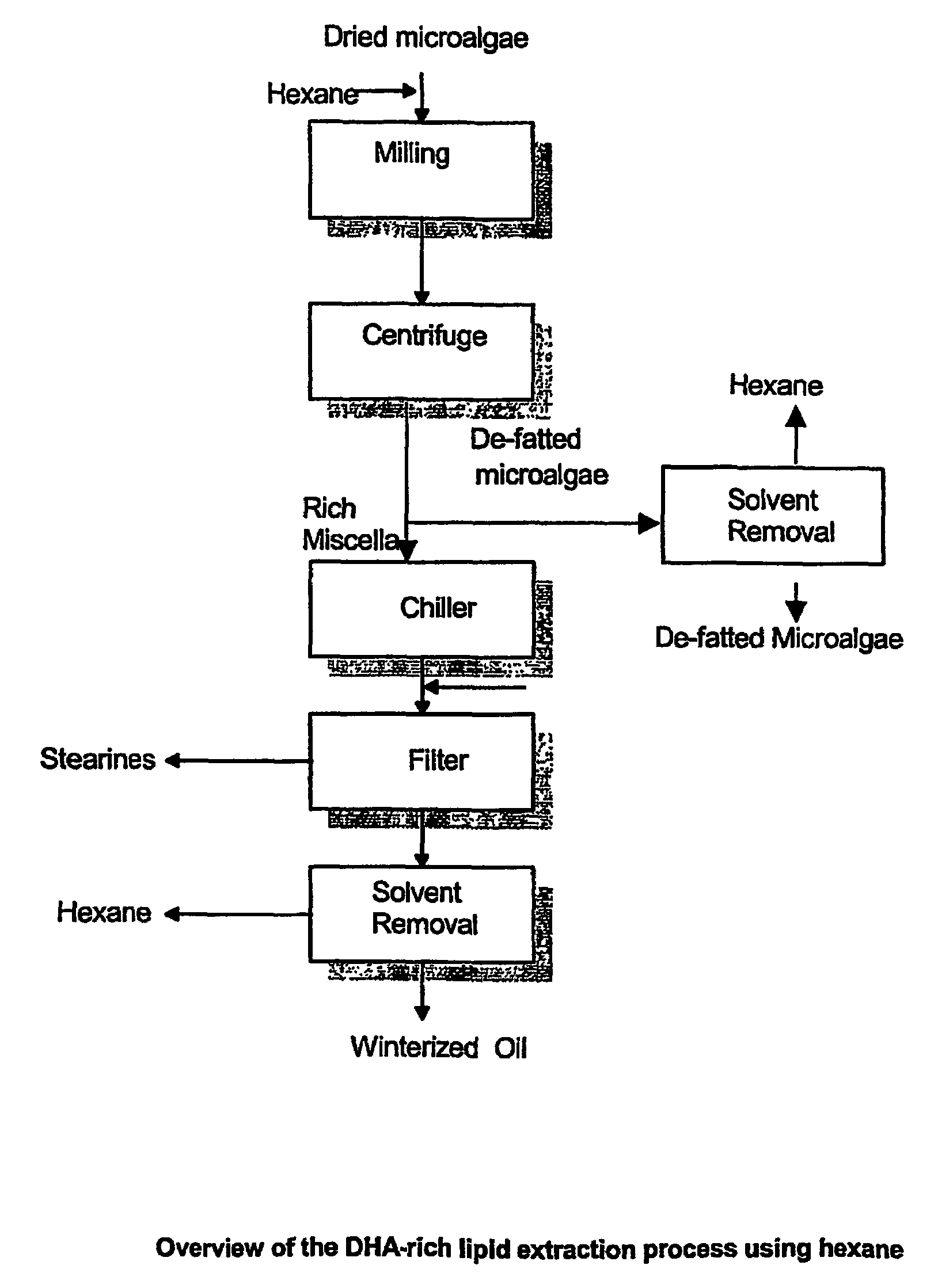

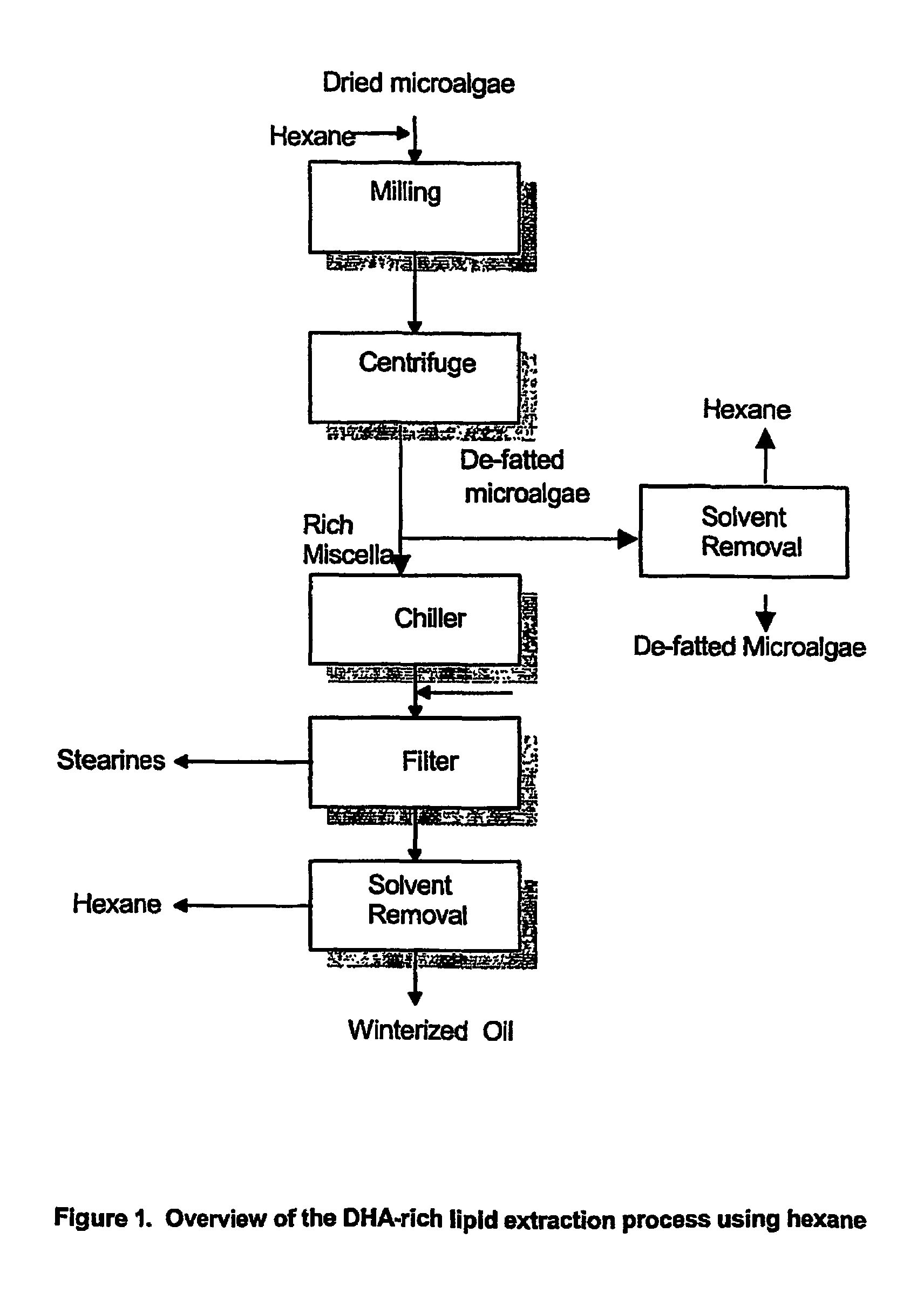

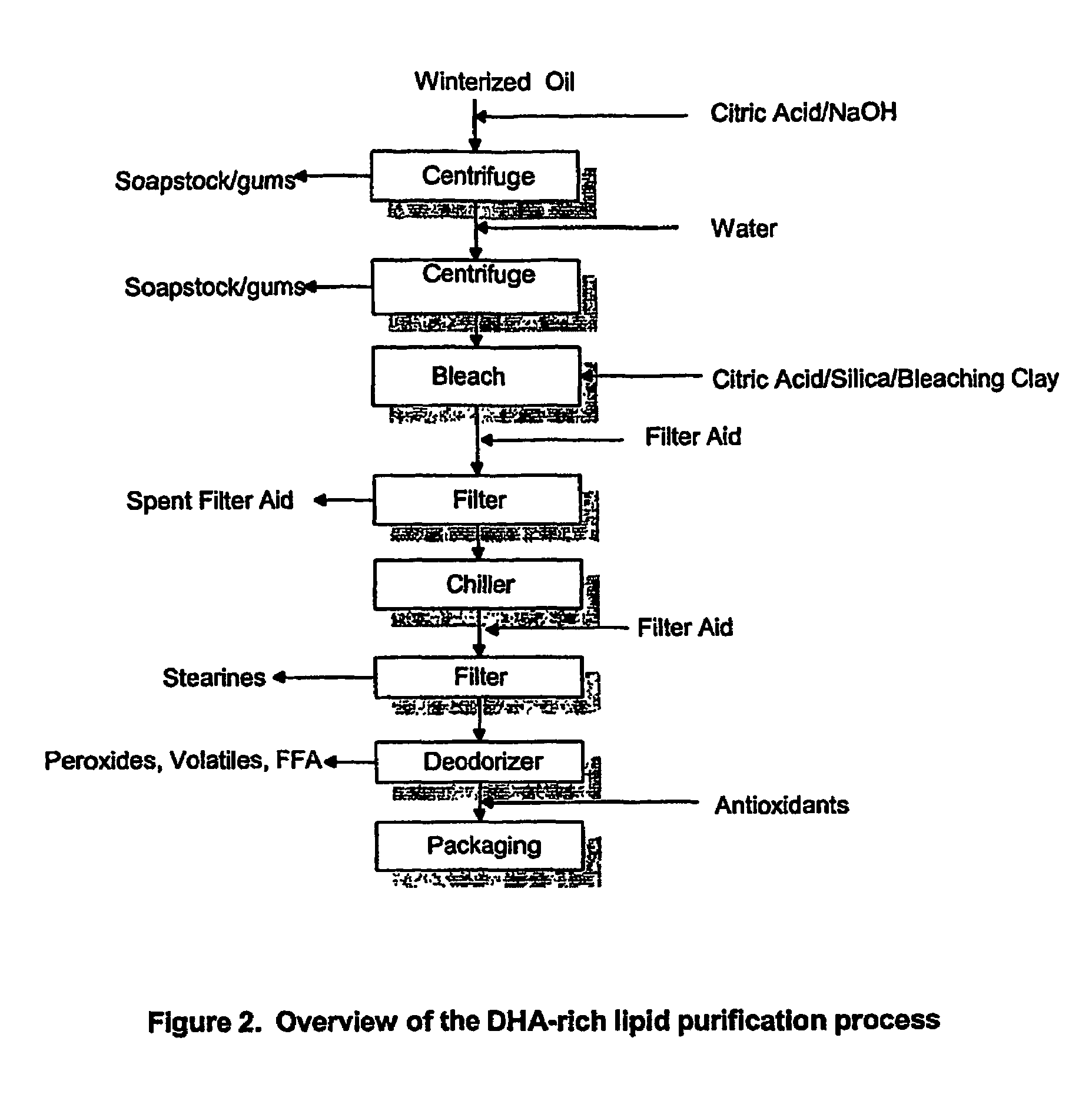

Extraction and winterization of lipids from oilseed and microbial sources

ActiveUS20050115897A1Solve many processesReduce degummingFatty-oils/fats refiningMicroorganism based processesLipid formationMicroorganism

A process for purifying a lipid composition having predominantly neutral lipid components having at least one long chain polyunsaturated fatty acid is disclosed. The process employs contacting the lipid composition with a polar solvent, such as acetone, wherein the solvent is selected such that the contaminants are less soluble in the solvent than in the long chain polyunsaturated fatty acid. The process is typically conducted at cooler temperatures including about 0° C. Upon precipitation of the contaminants from the lipid composition, a separation is conducted to remove the precipitated material from the lipid composition. The long chain polyunsaturated fatty acids can include ARA, DPA, EPA and / or DHA. The process effectively winterizes lipid compositions, thereby reducing the tendency of such compositions to become hazy.

Owner:DSM IP ASSETS BV

Extraction and winterization of lipids from oilseed and microbial sources

ActiveUS7419596B2Solve many processesReduce degummingFatty-oils/fats refiningMicroorganism based processesLipid formationSolubility

A process for purifying a lipid composition having predominantly neutral lipid components having at least one long chain polyunsaturated fatty acid is disclosed. The process employs contacting the lipid composition with a polar solvent, such as acetone, wherein the solvent is selected such that the contaminants are less soluble in the solvent than in the long chain polyunsaturated fatty acid. The process is typically conducted at cooler temperatures including about 0° C. Upon precipitation of the contaminants from the lipid composition, a separation is conducted to remove the precipitated material from the lipid composition. The long chain polyunsaturated fatty acids can include ARA, DPA, EPA and / or DHA. The process effectively winterizes lipid compositions, thereby reducing the tendency of such compositions to become hazy.

Owner:DSM IP ASSETS BV

Method for extracting high-quality soybean germ oil by using subcritical butane

ActiveCN102161932AAccelerate the speed of desolvationResidue reductionFatty-oils/fats productionEdible oils/fatsBiotechnologySoy germ

The invention relates to a method for extracting high-quality soybean germ oil by using subcritical butane and relates to the field of grain fine and deep processing. The method comprises: cutting purified soybean germs into slices which are 0.3 to 0.4 millimeters thick; placing the slices in an extraction kettle; performing 1 to 5 times of countercurrent leaching of the cut soybean germs by using liquefied butane as a solvent, wherein the extraction time is 10 to 120 minutes, the material to liquid ratio is 1:(1-6), the extraction temperature is 10 to 90 DEG C, and the extraction pressure is0.2 to 0.1MPa; delivering extracted mixed oil and wet dregs into an evaporation system and desolventizing under reduced pressure; and subjecting the obtained soybean germ crude oil to normal winterization, alkali refining and decolorization processes to obtain a soybean germ oil product with high beta-sitosterol content. In the invention, the soybean germ oil is extracted by using subcritical butane, the manufacturing cost of equipment is reduced considerably, the operation cost is low, the production period is shorter, the yield is high, and the method represents a low-consumption and environment-friendly practical technique for producing soybean germ oil.

Owner:江苏鸿祺生物科技有限公司

Production method for linseed oil

ActiveCN103045356AResidue reductionHigh yieldFatty-oils/fats refiningFatty-oils/fats productionLinseed oilSolvent

The invention discloses a production method for linseed oil. The production method comprises the processing steps as follows: (1) extracting, namely extracting crude linseed oil from a linseed cake subjected to squeezing and oil extraction by using a subcritical fluid; (2) degumming and deacidifying, namely degumming the crude linseed oil at the temperature of 40 DEG C by using citric acid, deacidifying by using sodium hydroxide, and separating to obtain alkali refining oil; (3) washing, namely heating the alkali refining oil to be 80-85 DEG C, and adding hot water of 90-95 DEG C for washing; (4) decolorizing and dewaxing, namely heating the washed oil to be 90 DEG C in a vacuum state under a negative pressure of 0.06-0.07 MPa, adding activated clay and active carbon, stirring for decolorizing, gradually cooling the oil in the stirring process for winterization, and filtering; and (5) deodorizing, namely deodorizing the winterized oil under the condition that the temperature is 150-155 DEG C and the vacuum degree is less than 200 Pa, and obtaining the linseed oil. The production method has the characteristics of simple process, convenience for operation, high extraction efficiency, low solvent residue content and low loss of product nutrient content.

Owner:河北丝路晨光油脂有限公司

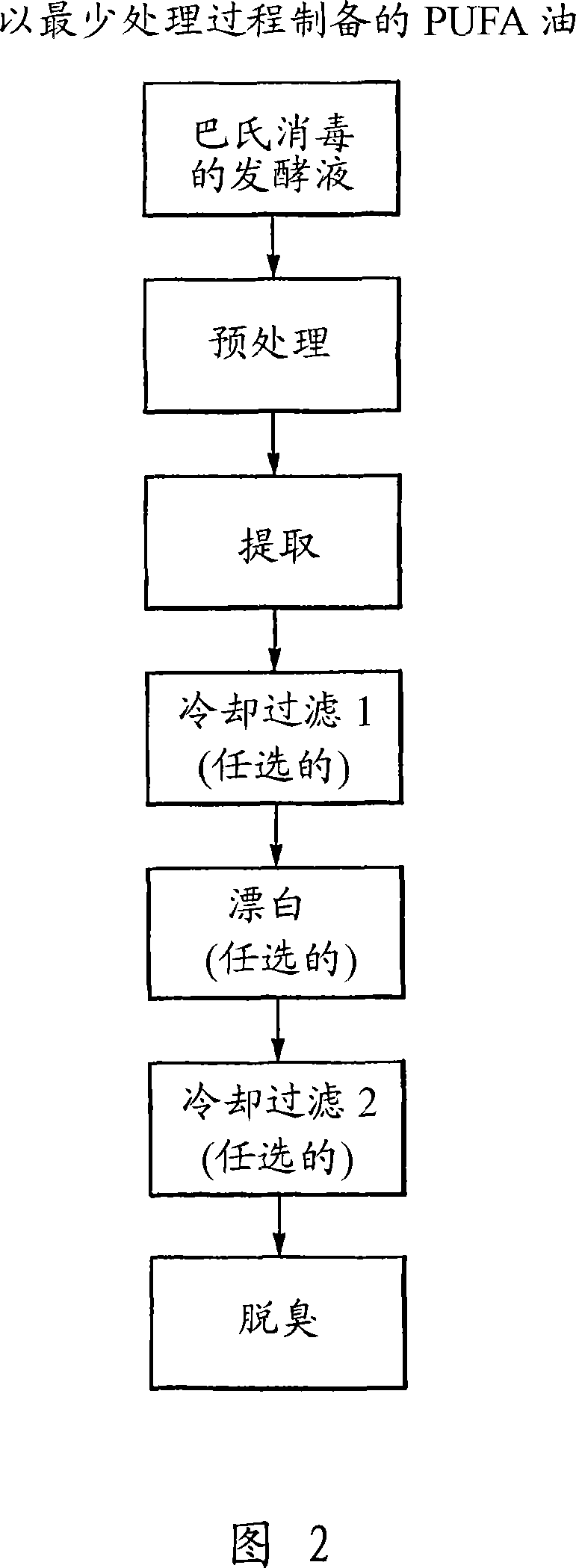

Polyunsaturated Fatty Acid-Containing Oil Product and Uses and Production Thereof

InactiveUS20080026103A1Function increaseNervous disorderFatty-oils/fats/waxes solidificationMicrobial oilFiltration

Owner:DSM IP ASSETS BV

Preparation method for tea oil by double helix low-temperature squeezing

InactiveCN102757858AAvoid heatingAvoid processing powerFatty-oils/fats refiningFatty-oils/fats productionChemical treatmentFiltration

The invention relates to a preparation method for tea oil by double helix low-temperature squeezing, which comprises the following steps: a) drying at low temperature; drying screened tea seeds by a flat dryer and an induced fan, wherein the drying temperature is 45-55 degree C, the drying time is 55-65 minutes, and the moisture content of dried tea seed is 6-10%; b) husking for separation; c) squeezing at low temperature; d) making squeezed oil stand for filtration; e) performing winterization treatment; and f) obtaining the finished product. Through low-temperature drying, squeezing by a double helix squeezer as well as the filtration technology by standing, the preparation method disclosed by the invention can avoid overheating and excessive chemical treatment to the oil, avoid residues of harmful substances generated during high-temperature processing, and avoid residues of acid, alkali and heavy metals due to addition of chemical addition agents; in addition, the technology disclosed by the invention can retain the pure natural quality of the tea-seed oil, and as much as possible retains physiological characteristic substances in the tea oil, such as vitamin E, gamma-linolenic acid and other beneficial components.

Owner:ANHUI YIHONG BIOTECH

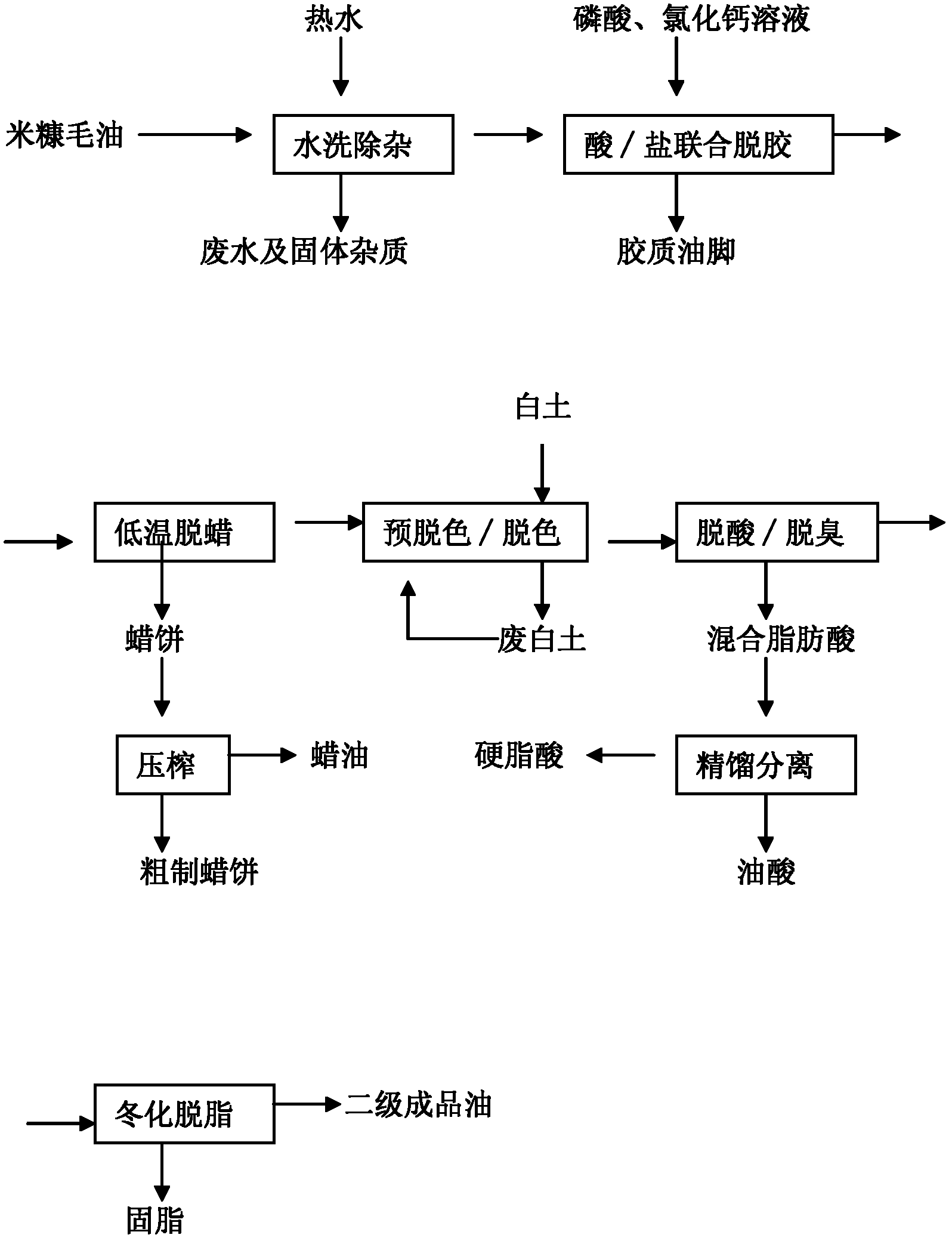

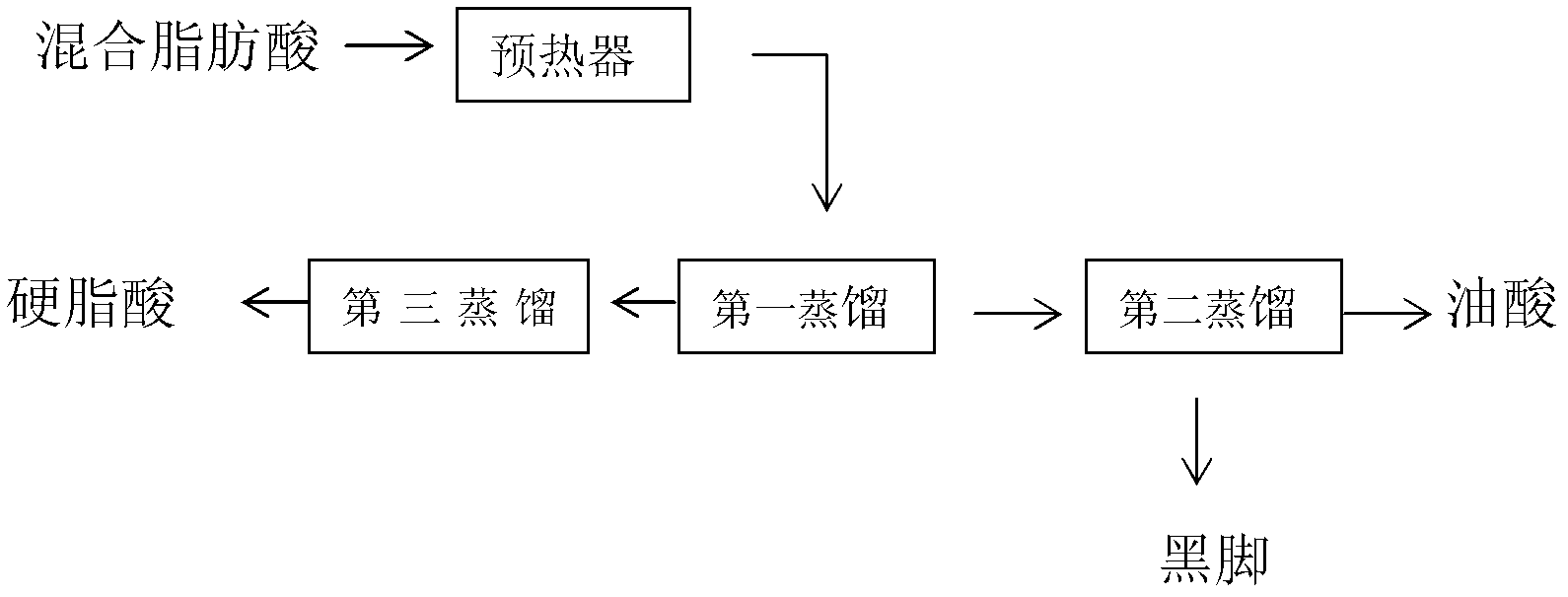

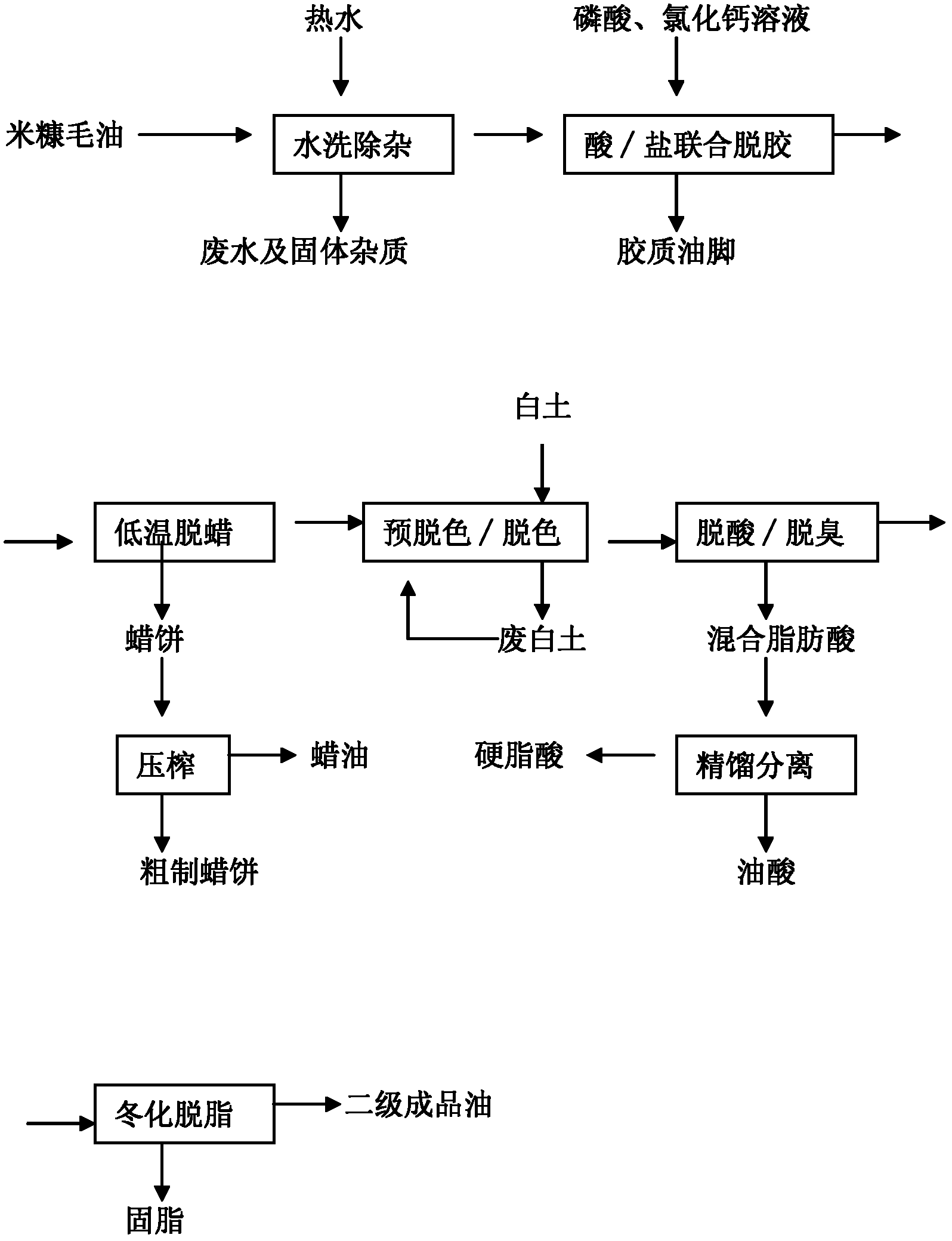

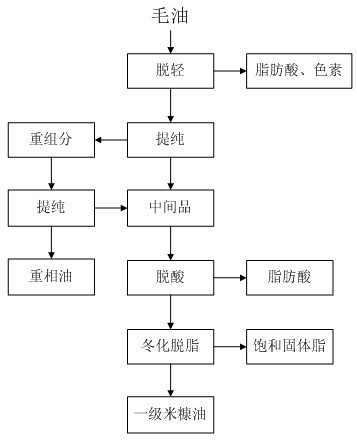

Rice bran oil refinement and byproduct production method

InactiveCN102492546AOvercome efficiencyOvercome the cycleFatty substance recovery/refiningFatty acids production/refiningWaxMixed fatty acid

The invention relates to a rice bran oil refinement and byproduct production method, and solves the problems of poor quality, low product and byproduct yield, low purity, complex technique, small production scale and the like in the existing product oil refined from rice bran oil. The technical scheme is as follows: the method comprises the following steps: carrying out acid / salt combined degumming on rice bran raw oil, dewaxing at low temperature, decolorizing, deacidifying / deodorizing, and degreasing by winterization to obtain tertiary rice bran oil and byproducts (crude wax cake, mixed fatty acids and solid grease). The technique provided by the invention is simple to control, can stably obtain Chinese standard tertiary rice bran oil and byproducts thereof, and can implement large-scale production.

Owner:WUHAN POLYTECHNIC UNIVERSITY +2

Biodiesel fuel for cold, temperate and hot weather climates and for aviation jet fuel

InactiveUS20090183420A1Reduce needProduction is limitedFatty acid esterificationFatty acids production/refiningAviationDistillation

This invention permits biodiesel (Fatty Acid Methyl Esters—FAMES) fuel and / or fuel blends to be used in cold weather climates without crystallization / precipitation of solids which plug fuel lines. The high melting point components are removed by physical separation from the biodiesel. Crystallization or distillation are used to separate the high melting temperature components. The low melting temperature components are used for blending with petroleum diesel with reduced or no winterization; low melting temperature components are used as a biodiesel with reduced or no winterization; low melting temperature components are blended into aviation jet fuel; or low melting temperature components are used as aviation jet fuel. The high melting temperature components are blended with petroleum diesel for temperate and / or hot weather climates.

Owner:COBB ARNOLD J

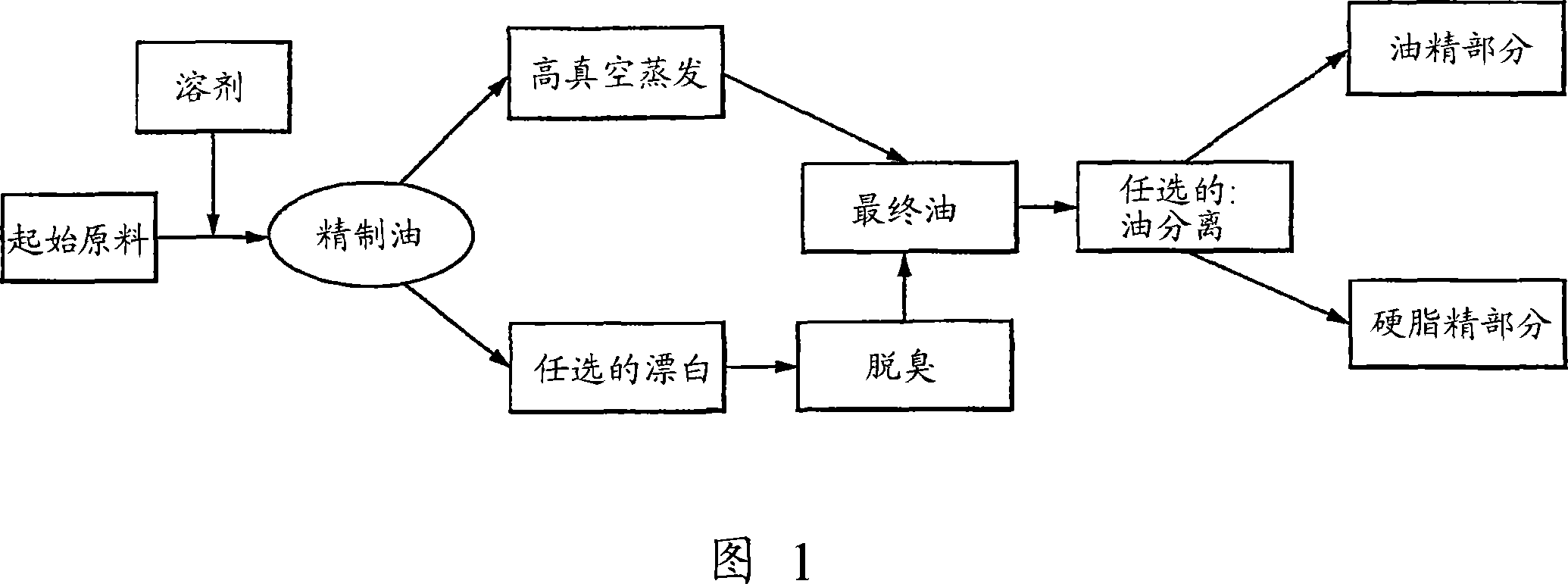

Polyunsaturated fatty acid-containing oil product and uses and production thereof

The present invention includes a solid fat composition that includes an oil having saturated fat and a microbial oil having a long chain polyunsaturated fatty acid and an emulsifier. In particular, the solid fat composition can have high levels of long chain polyunsaturated fatty acid and low amounts of emulsifiers. In preferred embodiments, the polyunsaturated oil is an unwinterized microbial oil. The invention also relates to methods for making such compositions and food, nutritional, and pharmaceutical products comprising said compositions. The present invention also includes a microbial oil product prepared by extracting an oil-containing fraction comprising at least one LC-PUFA from a microbial biomass, and treating the fraction by a process of vacuum evaporation, wherein the oil product has not been subject to one or more of a solvent winterization step, a caustic refining process, a chill filtration process, or a bleaching process.

Owner:DSM IP ASSETS BV

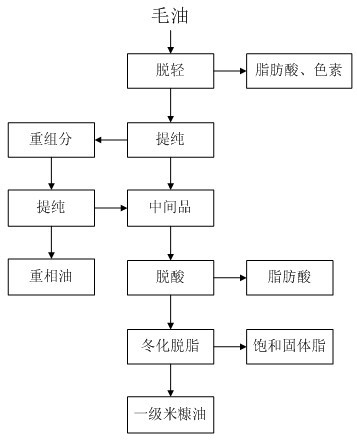

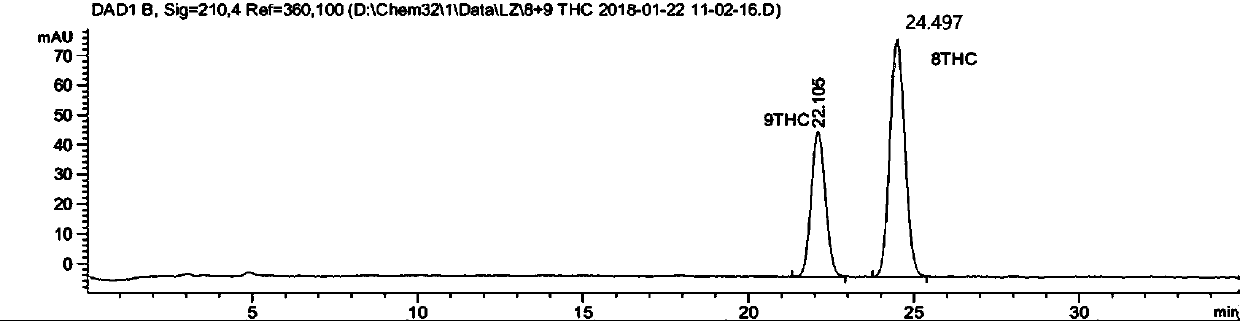

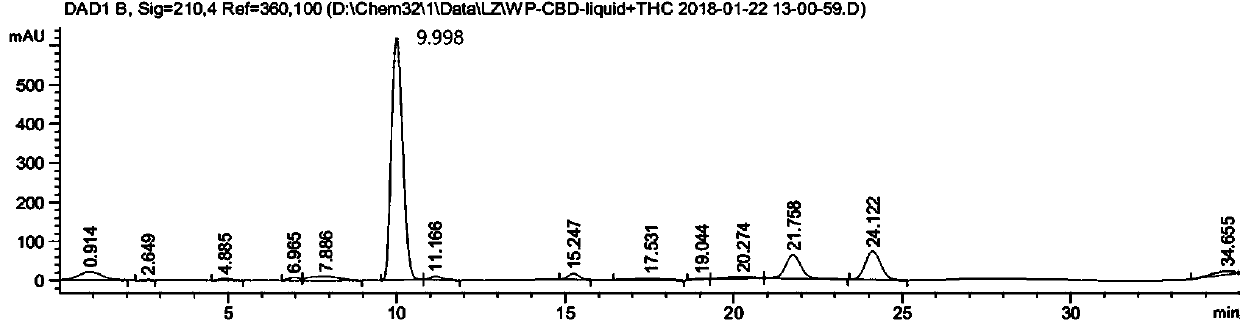

Method for extracting cannabidiol-containing hemp extract

InactiveCN107898826AImprove extraction efficiencyHigh in CBDPlant ingredientsFood scienceActivated carbonCentrifugation

The invention discloses a method for preparing cannabidiol-containing hemp extract. The method comprises the following steps: taking mature industrial hemp seeds, drying the hemp seeds, removing impurities, and crushing the hemp seeds for later use; carrying out extraction on the crushed hemp seeds with ethanol with the concentration being 95-100% (V / V) according to a solid-liquid ratio of 1:5 to1:20; filtering the obtained extract, and carrying out reduced pressure concentration to obtain industrial hemp seed extract; dissolving the obtained hemp seed extract in ethanol, and carrying out low-temperature winterization; centrifuging the obtained winterized suspension by using a centrifuge or a filtration technique; decolorizing a supernatant obtained after the centrifugation by using activated carbon, and filtering the supernatant; and carrying out rotary evaporation on a filtrate obtained after the filtration to obtain the cannabidiol-containing hemp extract. The product obtained in the invention has the advantages of high CBD content, good color and good physiological characteristics. The method has the advantages of simple process, easiness in industrial application, and promotion of the development and utilization of high added value products of hemp.

Owner:云南谷益美农业开发有限公司

Method for refining pressing flaxseed oil through solid adsorption and vacuum filtration

The invention relates to a method for refining edible flaxseed oil. The method for refining pressing flaxseed oil through solid adsorption and vacuum filtration is characterized by comprising the following steps of: 1) adsorption: contacting 100 weight parts of pressing flaxseed oil with 0.5 to 10 weight parts of kieselguhr adsorbent calcined by a flux at the temperature of between 30 and 50 DEG C for 30 minutes or more; 2) winterization: cooling to the temperature of between 5 and 10 DEG C, freezing for not less than 3 hours, and filtering to remove solids; 3) vacuum filtration: at the temperature of between 50 and 55 DEG C, performing vacuum filtration on the flaxseed oil of which the solids are removed in an active alumina / silicon oxide filled vacuum filtering machine to obtain the refined clean flaxseed oil; and 4) storage under the protection of inert gas: filling the inert gas into the refined clean flaxseed oil for protective storage. By the method, harmful substances can be removed from the flaxseed oil, the quality grade of the flaxseed oil is improved, and the flavor of the oil cannot be influenced. The method has a simple and effective process and is convenient to implement and apply industrially.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

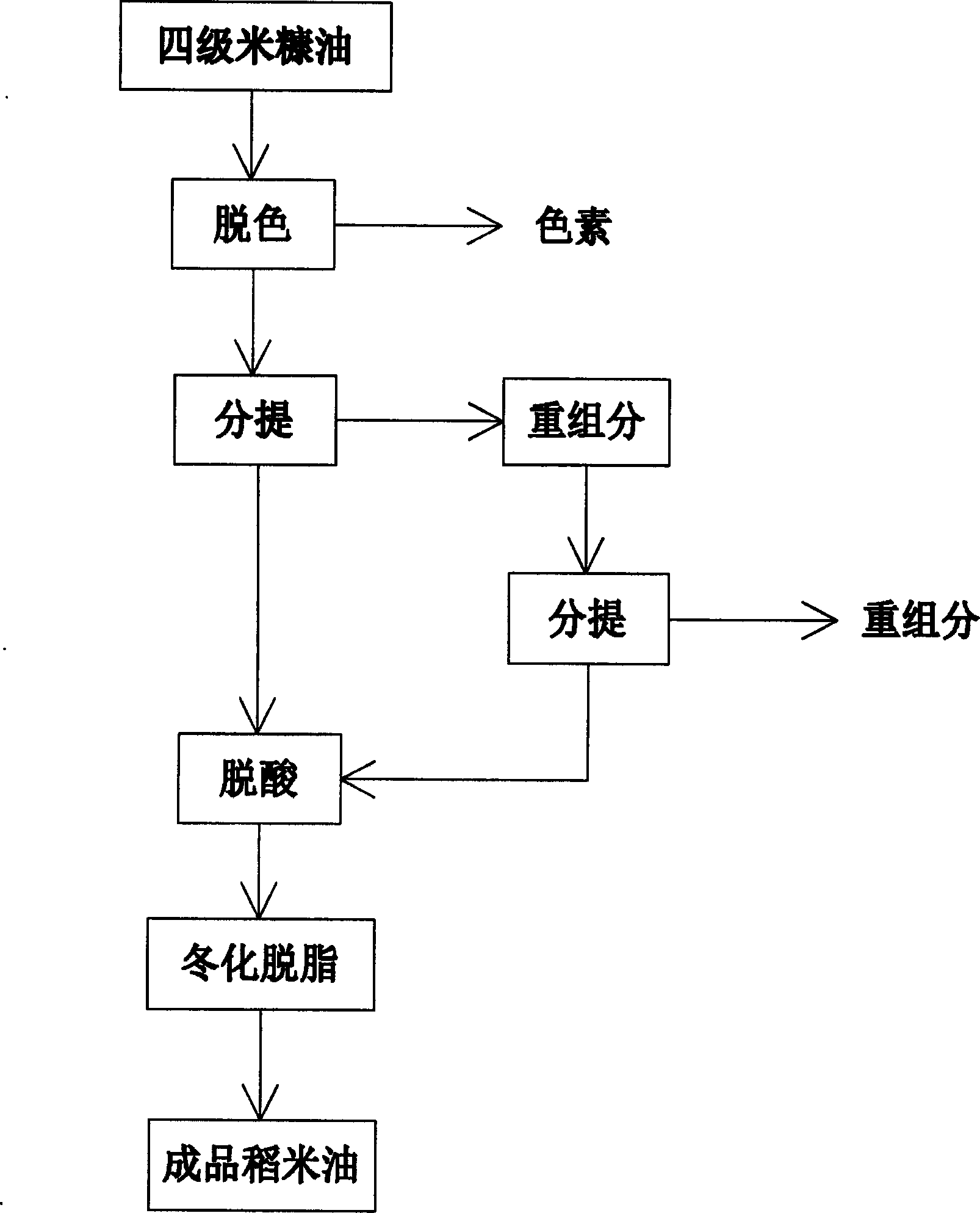

Refining method of rice oil

ActiveCN102934700AHigh retention rateHigh yieldEdible oils/fats production/working-upOil and greaseHigh energy

The invention discloses a refining method of rice oil and belongs to the technical field of refined grease. The refining method is used for solving the problems of high energy consumption, large oil refining loss, nutrient loss and environmental pollution. The refining method of rice oil comprises the following steps of: heating rice bran oil of four-level standard to 150-170 DEG C through a heat exchanger, conveying the rice bran oil into a molecular still, distributing the rice bran oil on an evaporation surface through a material distributor, wherein the temperature of the evaporation surface is 190-245 DEG C, cooling the light component pigment to 35-42 DEG C through a built-in condenser, and the light component pigment flows into a light component collection tank, the heavy component directly enters a heavy component collection tank, and the vacuum degree of a decolorizing system is 5-40 Pa, and performing fractionation, deacidification and winterization degreasing to obtain the rice oil. The refining method of rice oil can be extensively used for refining the rice oil.

Owner:陈汉卿

New technology for processing thick-aroma tea oil

The invention relates to a new technology for processing thick-aroma tea oil, which comprises the steps of feeding the refined tea oil into a winterization tank by a pump, and reducing the temperature from normal temperature to 1-3 DEG C; preserving heat for 60-90 hours; filtering the defatted refined tea oil, and heating to 60 DEG C; stir-frying tea siftings in an oil pressing process in a wok at 60-90 DEG C; feeding the heated tea oil and the stir-fried tea siftings into a soaking device, and soaking; then separating the oil from the tea siftings to obtain the thick-aroma tea oil. By adopting the new technology provided by the invention, the indexes of the obtained thick-aroma tea oil reach the national standards for edible oil while the unique aroma of the tea oil is maintained, thus the new technology is a new production technology with low cost and high benefits.

Owner:湖南山润油茶科技发展有限公司

Method for extracting wheat germ oil by compression solvent

InactiveCN101121910AReduce consumptionPrevent oxidationFatty-oils/fats productionOil and greaseEmbryo

The invention discloses a method for preparing wheatgerm oil by pressurized solvent extraction. The process includes the following steps: (1) fresh wheatgerms are separated from a plansifter, and directly sent into a microwave drying machine through a chute, and dried and enzyme-deactivated under low temperature; (2) under 0.2-0.8MPa, a plurality of counter current leachings are conducted on the wheatsgerms undergone microwave processing at Step (1) by using liquefied butane, ethanol or isopropyl-alcohol or other solvents, and then precipitation of the solvents contained in the oil mixtures and wet embryo dregs is conducted under reduced pressure; (3) the solvents vaporized from the oil mixtures and wet embryo dregs are vaporized, and the vaporized solvent gas is then compressed and condensed in a compressor for recycled use; (4) the crude wheatgerm oil adopts conventional winterization, caustic-refining and decolorizing techniques. The invention is capable to reduce solvent consumption, reduce the extraction duration and restrain lipidic oxidation and denaturation of embryo-dreg protein. Besides, the method can be applied to massive industrial production.

Owner:JIANGSU UNIV

Production method of edible rice bran oil

InactiveCN102690723AImprove food safetyIncrease peroxide valueFatty-oils/fats refiningEdible oils/fatsPesticide residueRice bran oil

The invention discloses a production method of edible rice bran oil. The production method comprises the following steps of: firstly, heating four-stage standard rice bran oil by a preheater and charging into a separator, evenly distributing the materials under high vacuum degree, due to the boiling point difference of various substances, separating light components of raw material oil in an evaporating way by a pressure reducing technology, heating heavy components, charging into a purifier, quickly evaporating, separating aflatoxin and pesticide residue in an evaporating way, filtering the treated rice bran oil, contacting with protective gas in a stripping tower, and discharging in a separating way, wherein the acid value of the rice bran oil discharged out of the tower bottom achieves the standard of first-stage rice bran oil; and dewaxing in a winterization way to obtain the first-stage rice bran oil. According to the production method, the first-stage rice bran oil product with high oryzanol content can be produced. The whole technical process separates by a pure physical method, so that nutrition components can not be damaged; the production method does not need adding of any annexing agents, so that the safety of the product can be guaranteed; and the production method does not generate any waste gas, sewage or solid waste.

Owner:江苏迈克化工机械有限公司 +1

Method of extracting high-purity cannabidiol from industrial hemp

ActiveCN110304994AIncrease contentLow content of polar impuritiesOrganic chemistrySolvent extractionDistillationCannabidiol

The invention discloses a method of extracting high-purity cannabidiol from industrial hemp. The method includes: pretreatment of raw materials, subcritical extraction, winterization, thermal treatment, short-course molecular distillation and crystallization refining. THC content in CBD prepared by the method meets related legal provisions, CBD content is greater than 98.0%, purity is up to higherthan 99.8%, individual impurity is lower than 0.1%, total impurity is lower than 0.2%, and THC is absent. Compared with existing extraction methods, the method has the advantages of being efficient,energy-saving, environment-friendly and high in product purity.

Owner:吴平

Production method of tea seed blend oil

ActiveCN103173277AIncrease frictionImprove oil yieldFatty-oils/fats refiningFatty-oils/fats productionArachidic acidFiltration

The invention provides a production method of tea seed blend oil. 76-83% of tea kernel and 18-22% of rape seed by weight are prepared through crude oil preparation, alkali refining, washing, deodorization and winterization filtration to obtain the tea seed blend oil. The friction force and oil yield can be increased during oil expression, and the problems that the friction force is low during oil expression and consequently the oil yield can only reach about 80% and the raw material increasing the friction force is not favorable for increasing the oil yield of tea kernel oil expression are solved. According to the production method of the tea seed blend oil provided by the invention, the tea seed and rape seed are mixed and squeezed, the tea oil cost is lowered, the tea oil has rich nutrition, the content of vitamin E of the obtained tea seed blend oil can reach 350mg / 100g for sure, and the problem that the tea oil has insufficient nutritional ingredients such as vitamin E, arachidic acid and the like is solved; and moreover, the tea seed blend oil is convenient to operate and easy to store and can be stored for a long time.

Owner:安徽万佳现代农业(集团)有限公司

Appropriate processing method for squeezing camellia oleosa seed oil

ActiveCN104004584ANo input requiredQuality improvementFatty-oils/fats refiningFatty-oils/fats productionTime rangeCamellia oleifera

An appropriate processing method for squeezing camellia oleosa seed oil belongs to the technical field of camellia oleosa seed processing methods and comprises the following process steps: taking fresh and mature camellia oleosa seeds with impurity content smaller than 0.5%; feeding the camellia oleosa seeds into a rotating oven to be fried, wherein the seed frying temperature ranges from 140-150 DEG C, and the seed frying time ranges from 30-40 minutes; spraying water on the camellia oleosa seeds while the camellia oleosa seeds are hot, enabling the moisture content of the camellia oleosa seeds to be increased to 4%-6%; feeding the camellia oleosa seeds into an oil press for oil squeezing to obtain squeezed crude oil of the camellia oleosa seeds; filtering the crude oil in a fine mode; directly feeding the camellia oleosa seed oil into a winterization tank, and conducting winterization for 24 hours at the temperature of 2-5 DG C; conducting polishing filtration on the camellia oleosa seed oil, inspecting the camellia oleosa seed oil, and obtaining a finished product. The appropriate processing method for squeezing the camellia oleosa seed oil is convenient to operate, the steps are simple, no chemical products need to be input, the yield is improved, nutrition components possibly lost in the refining process is further reserved, and meanwhile the highly flavored type camellia oleosa seed oil with high quality further can be obtained.

Owner:RES INST OF SUBTROPICAL FORESTRY CHINESE ACAD OF FORESTRY

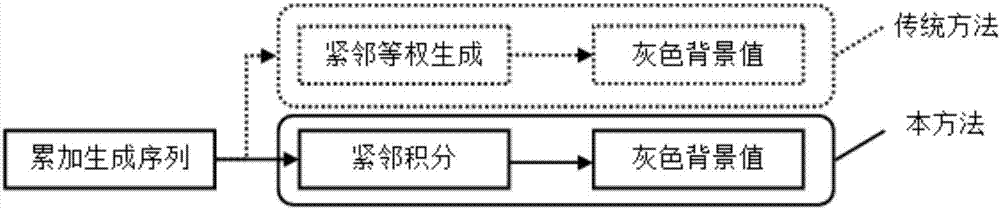

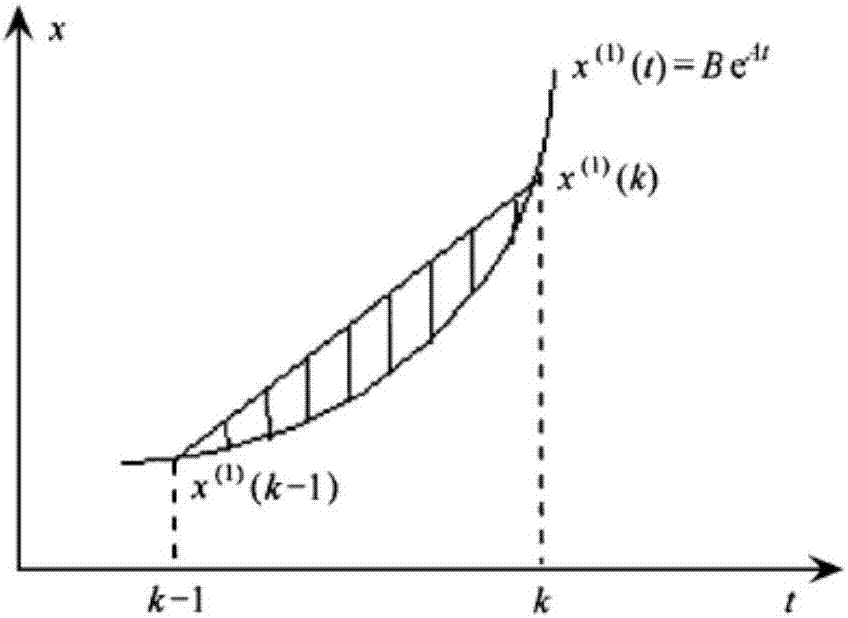

Grey-forecasting-model-based method for predicting weak fault degrees of autonomous underwater vehicle propeller

InactiveCN107133376AEasy to adjustImprove forecast accuracyDesign optimisation/simulationSpecial data processing applicationsPropellerTectonic phase

The invention provides a grey-forecasting-model-based method for predicting weak fault degrees of an autonomous underwater vehicle propeller. In a grey background value construction stage, the proximate integral of an accumulative generation sequence is calculated to serve as a grey background value; in a winterization equation solving stage, through a difference value between a predicted original-sequence value and an actual original-sequence value, a point with the minimum predictive residual is determined, and an original sequence value corresponding to the point with the minimum predictive residual serves as an initial value of a winterization equation solution; in a predicted sequence construction stage, on the basis of a residual sequence between a predicted sequence and an original sequence, secondary prediction is conducted, and on the basis of a residual sequence obtained by the secondary prediction, the predicted sequence of the original sequence is amended to make a prediction result adjustable. By the adoption of the grey-forecasting-model-based method for predicting the weak fault degrees of the autonomous underwater vehicle propeller, the problem is solved that prediction errors are relatively large when the weak fault degrees of the AUV propeller are predicted, and a grey background value construction method, winterization equation solving method and predicted sequence construction method of a traditional grey method are improved separately.

Owner:HARBIN ENG UNIV

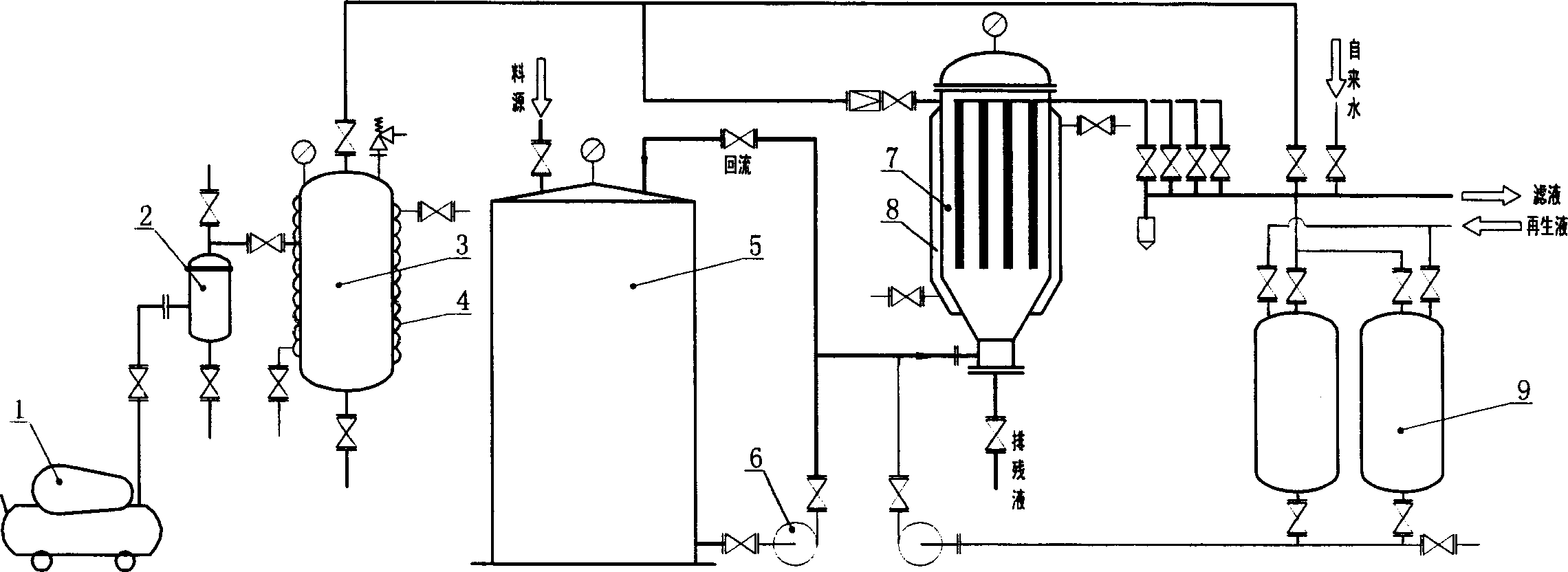

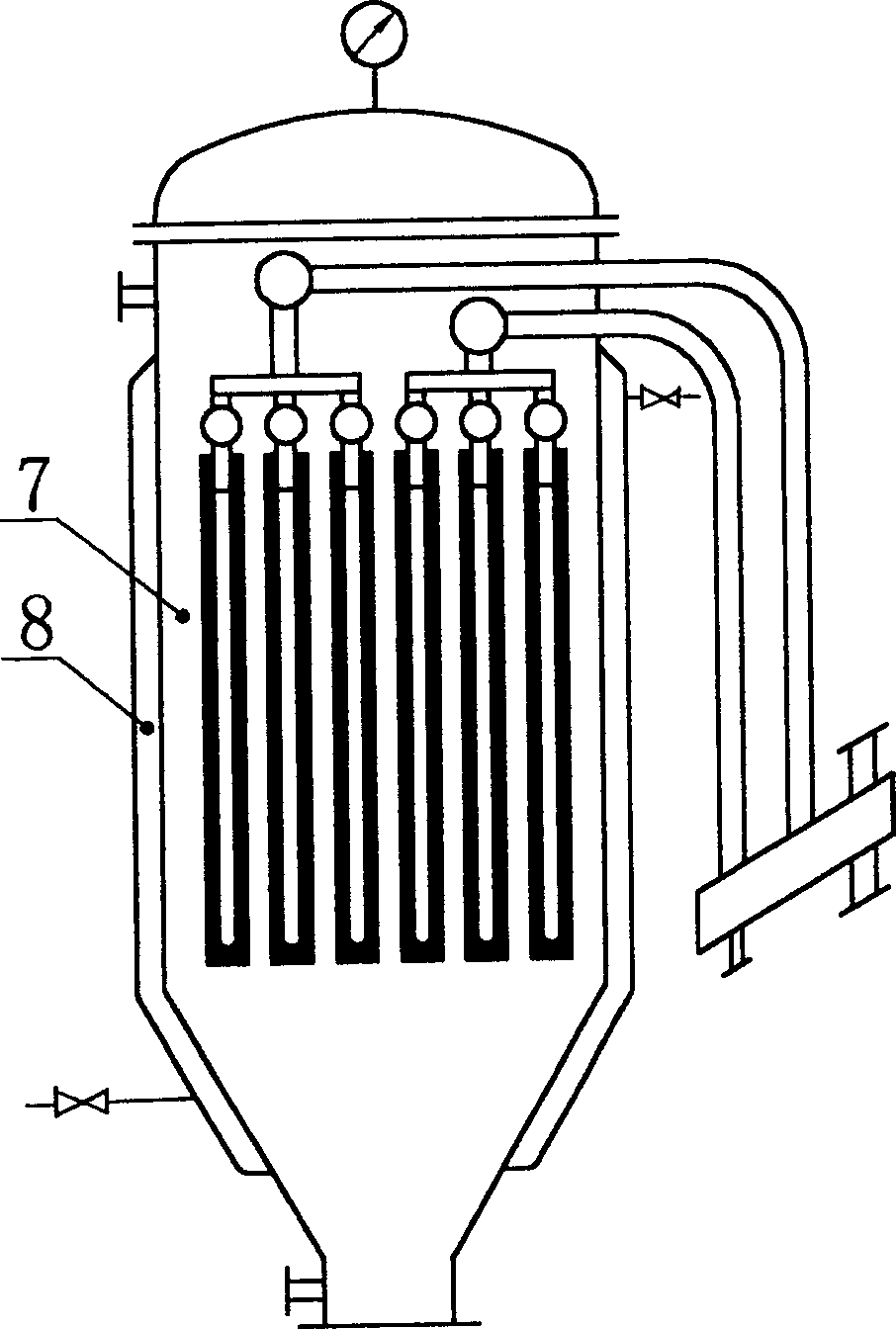

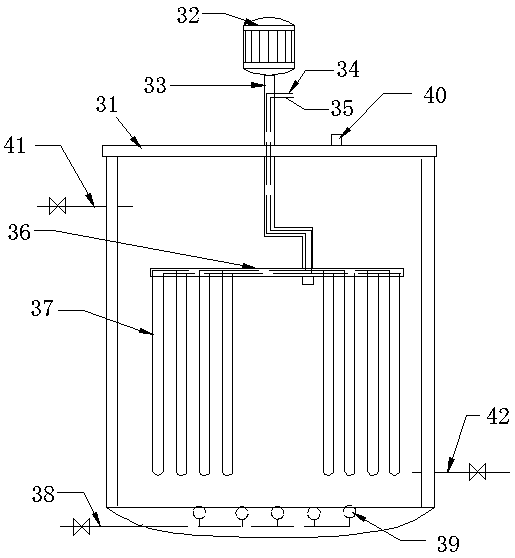

Precision micro hole filtering method and device for winterization edible oil defatted wax

InactiveCN1605617ARemove completelyReduce resistanceFatty substance recovery/refiningFatty-oils/fats refiningWaxPhospholipid

The present invention is the precise microporous filtering process and apparatus for defatting and dewaxing winterized edible oil. The process includes the following steps: filtering the winterized edible oil in precise microporous filtering machine to obtain filtrate as refined edible oil; back blowing with normal temperature compressed air for 4-6 times or back blowing with hot compressed air at 65-70 deg.c in raised filtering pressure difference; and chemical regeneration of the precise microporous filtering machine with regenerating solution capable of dissolving niger and phospholipid from regenerating solution tanks. The apparatus includes compressor tank with outer coiled pipe jacket, precise microporous filtering machine with water cooling jacket, and rigid microporous filtering pipe. The present invention has the advantages of complete defatting and dewaxing, high filtering precision, high filtering efficiency, high regeneration efficiency, etc.

Owner:宋志骥

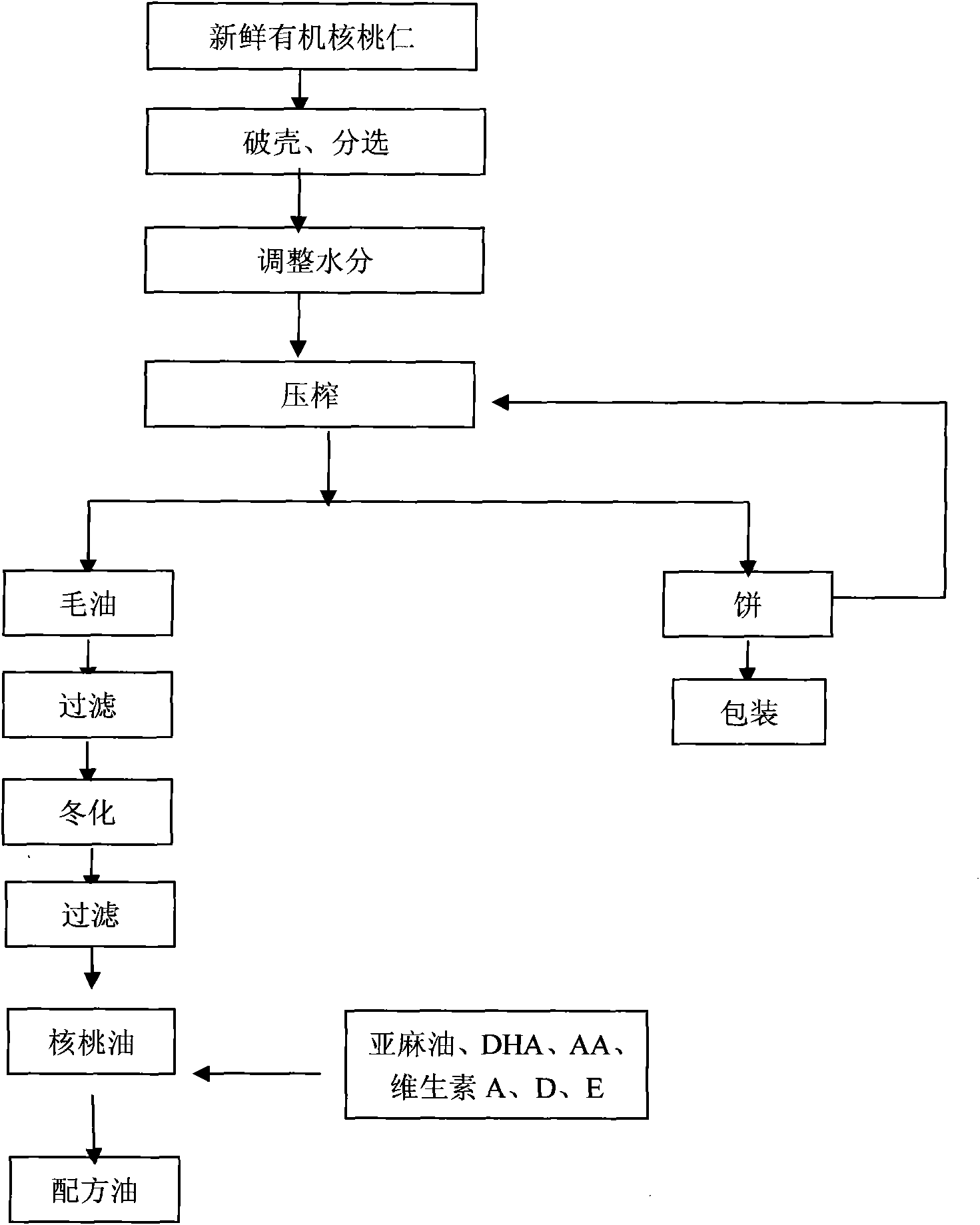

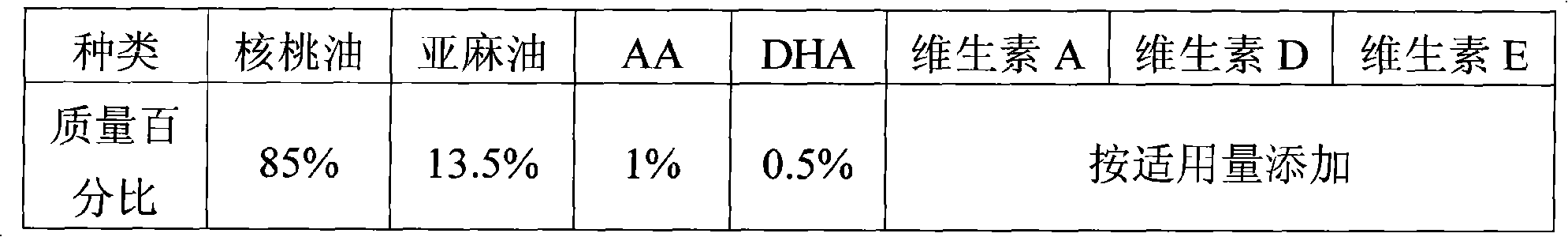

Method for preparing walnut oil and formulated product taking walnut oil as stroma

The invention relates to a method for preparing walnut oil and a formulated product taking walnut oil as stroma. The method mainly comprises the steps: crushing shell, sorting, squeezing, filtering I, winterization and filtering II; wherein, the squeezing process comprises: cakes made of walnut meat are evenly mixed with the walnut meat according to the mass ratio of 1:0.5-5, the mixture is squeezed to obtain crude oil and secondary cakes; the obtained secondary cakes are continuously recycled for use in the squeezing process when oil is made the next time, and then the obtained third-time cakes are used in the next time of oil making process; the process is repeatedly carried out in this way, so that the aim of recycling the cakes can be achieved; every 100g of the formulated product contains 79-99.8g of walnut oil, 0.1-20g of flax seed oil, 0.01-0.5g of DHA, 0.01-1.0g of AA, 300-900mug of vitamin A (based on retinol equivalent), 5-10mug of vitamin D and 4-7mg of vitamin E (based on da tocopherol). The method saves energy and reduces the production cost.

Owner:SANMARK CORP

Preparation method for moringa-oleifera camellia oil

InactiveCN105154208AImprove qualityHas health benefitsFatty-oils/fats refiningFatty-oils/fats productionFlavorCarcinogen

The invention discloses a preparation method for moringa-oleifera camellia oil, and relates to the technical field of edible oil production. The method comprises mixing camellia seed and moringa oleifera seed and performing oil pressing, and then performing dephosphorization, deacidification, decoloring, deodorization and winterization processing, so as to obtain the moringa-oleifera camellia oil with the acidity of 0.5-0.8. The moringa-oleifera camellia oil is good in mouthfeel, excellent in flavor and high in nutrition value, and by combining camellia seed and moringa oleifera seed, the moringa-oleifera camellia oil is relatively good in quality, the matching ratio enables camellia seed and moringa oleifera seed to bring out the best in each other. The advance technology guarantees the product to be truly organic, originally ecological, green and environment-friendly, and the product does not contain benzopyrene, lead, mercury and other strong carcinogens, possesses the nutrient content higher than that of high-quality olive oil by 45%, and also possesses health-care efficacy.

Owner:ANHUI LOVE ON YOUR FOOD

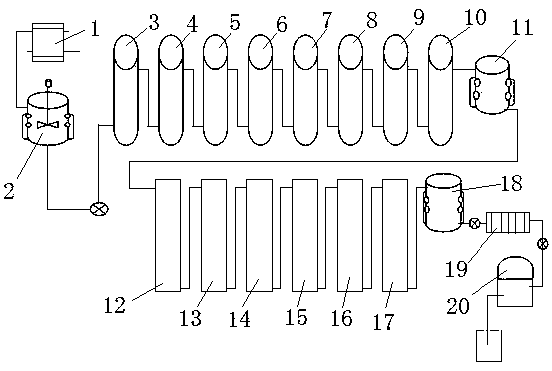

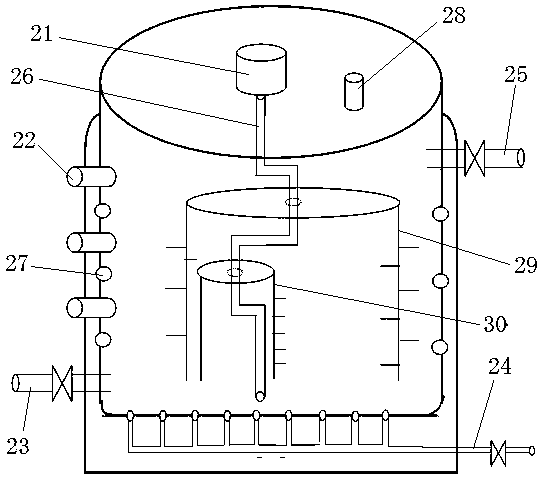

Method and equipment for improving quality of vegetable oil through continuous crystallization, crystal growing, and dewaxing refining

ActiveCN107746746ALess destructiveDestructiveFatty-oils/fats refiningFatty-oils/fats separationOil and greaseVegetable oil

A method and equipment for improving quality of vegetable oil through continuous crystallization, crystal growing, and dewaxing refining are disclosed. Oil and grease dewaxing is performed through eight-stage staged cooling crystallization, six-stage constant-temperature crystal growing, and two-stage low-temperature filtration. Special crystallization and crystal growing devices are adopted, interferences of transmission on crystallization and crystal growing processes are effectively solved as a whole, the heat conduction efficiency is higher, crystal damage caused by a transmission device and relative movement in an oil and grease system is less, energy consumption is lower, crystal dispersibility is significantly improved, and aggregation effects of wax, esters and high-melting-point fat are better. The method and the equipment can further improve dewaxing, winterization and dewaxing effects in crystallization and crystal growing processes of wax-containing vegetable oil, prolong oil product refrigeration time to 60 h or above, improve flavor and quality of oil and make oil palatability good. The method and the equipment are suitable for corn oil, sunflower seed oil, soybean oil, rice bran oil, and the like, and are particularly suitable for corn oil, sunflower seed oil, and the like.

Owner:SHANDONG XIWANG FOOD

Preparation method and application of medical tea oil

InactiveCN104611127ASave low temperature winterizationOrganic active ingredientsFatty-oils/fats refiningPhysical chemistryOrganic chemistry

The invention relates to a preparation method and application of medical tea oil. The preparation method comprises the following steps: (1) performing refined extraction; (2) deacidifying, namely, agitating and heating tea essential oil, dissolving KOH with soft water to obtain an alkaline solution after the oil temperature raises to 70-75 DEG C, rapidly and uniformly spraying into soil, fully mixing, stopping agitating after nigre particles appear, heating to 80 DEG C, standing at the constant temperature for 12 hours to completely precipitate, transferring upper clear oil to a washing pot, heating the oil to 85 DEG C, adding hot water to wash, standing at the constant temperature for 1 hour, separating out the upper clear oil, and then dewatering and drying under a vacuum condition to obtain the deacidified oil; (3) discoloring; (4) deodorizing; and (5) fractionating. Compared with the prior art, the method focuses on the selection of technological conditions; the tea oil is heated to be 70 to 75 DEG C during deacidifying, then the alkaline solution is added, and the tea oil is precipitated at the constant temperature of 80 DEG C. The medical tea oil prepared under the technological conditions has the advantages that the fractionating is carried out at 19 to 21 DEG C, and the low-temperature winterization can be saved.

Owner:GANNAN MEDICAL UNIV

Preparation method of high-quality edible tea oil

ActiveCN106221895AKeep the scentLight colorFatty-oils/fats refiningFatty-oils/fats productionFreeze-dryingAcid value

The invention discloses a preparation method of high-quality edible tea oil. The preparation method comprises the steps of vacuum freeze drying, dehusking, low-temperature squeezing, alkali refining, degumming, deacidifying, decoloring, purification and winterization. The method disclosed by the invention can retain effectively active substances in the tea oil and also cull useless or harmful impurities; the acid value of the tea oil is less than or equal to 0.1 mgKOH / g, the VE value is greater than 35 (mg / 100g), the monounsaturated fatty acid content is greater than or equal to 70 percent, and the unsaturated fatty acid content is greater than or equal to 15 percent; an oil product has a shallow color, and all the other indexes meet the national level-I edible tea oil standard; furthermore, the mellow fragrance of the tea oil can be retained; the tea oil is nutritional and healthy edible oil and is well received by consumers.

Owner:黎平县霞宇油脂有限公司

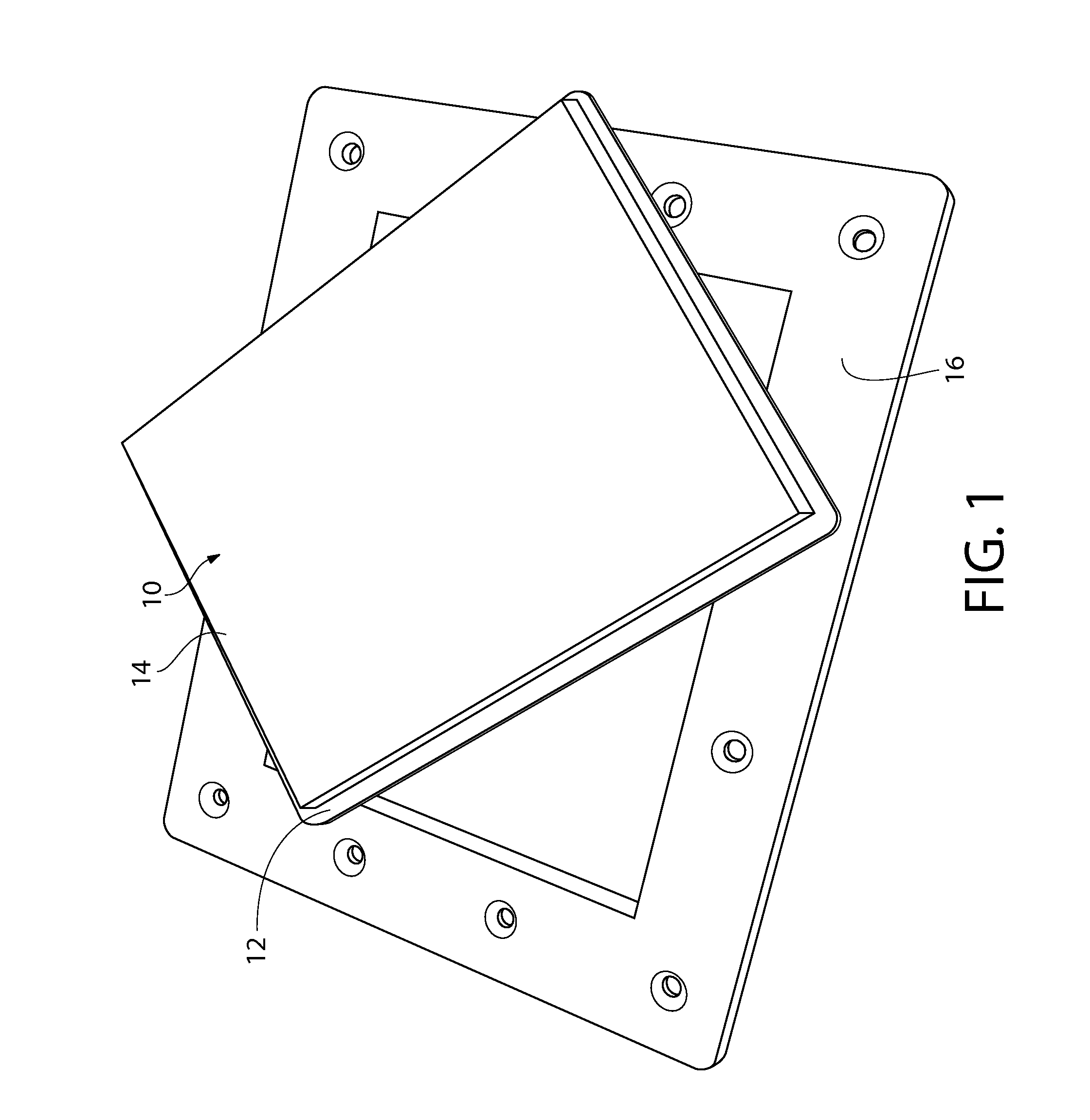

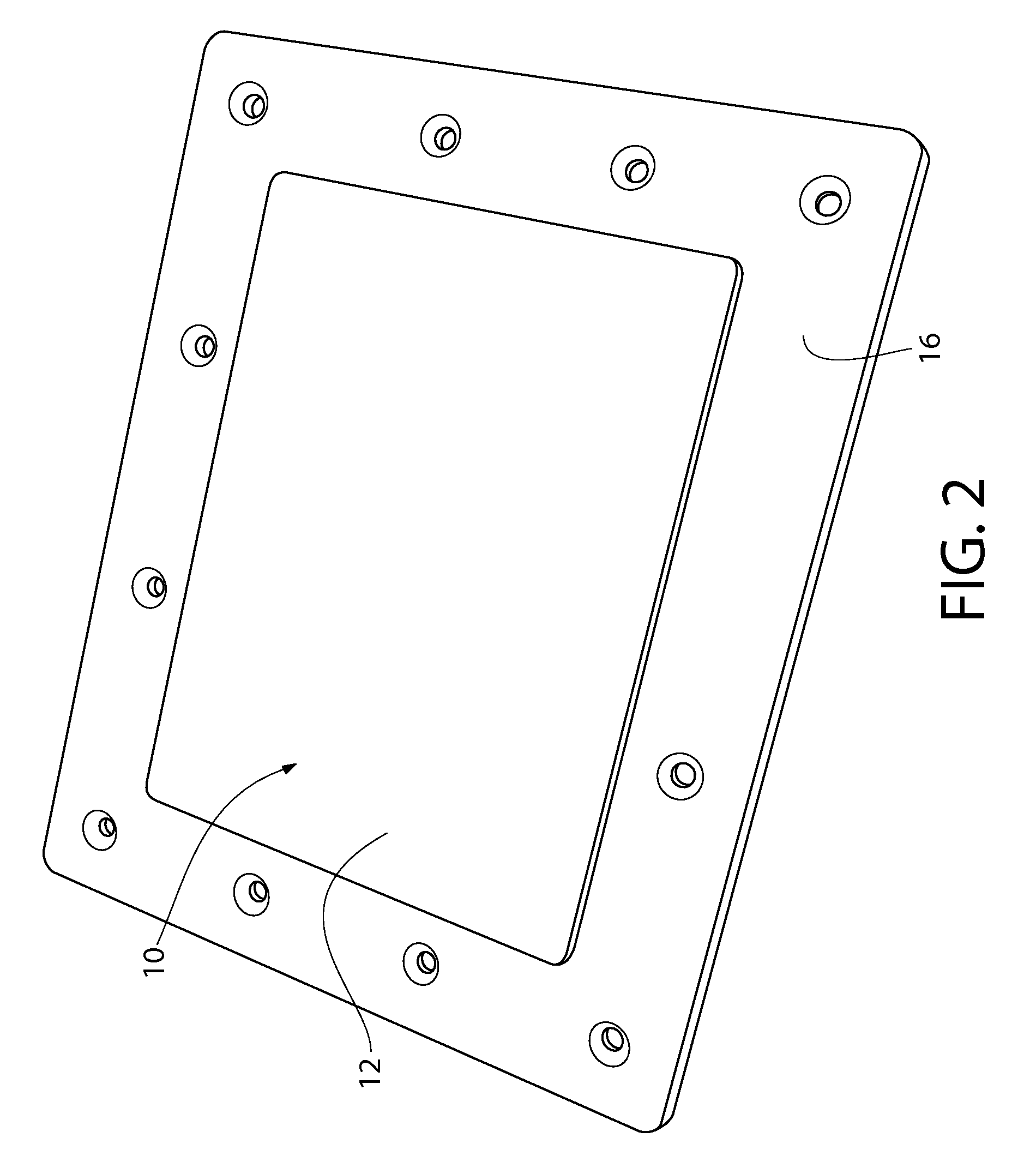

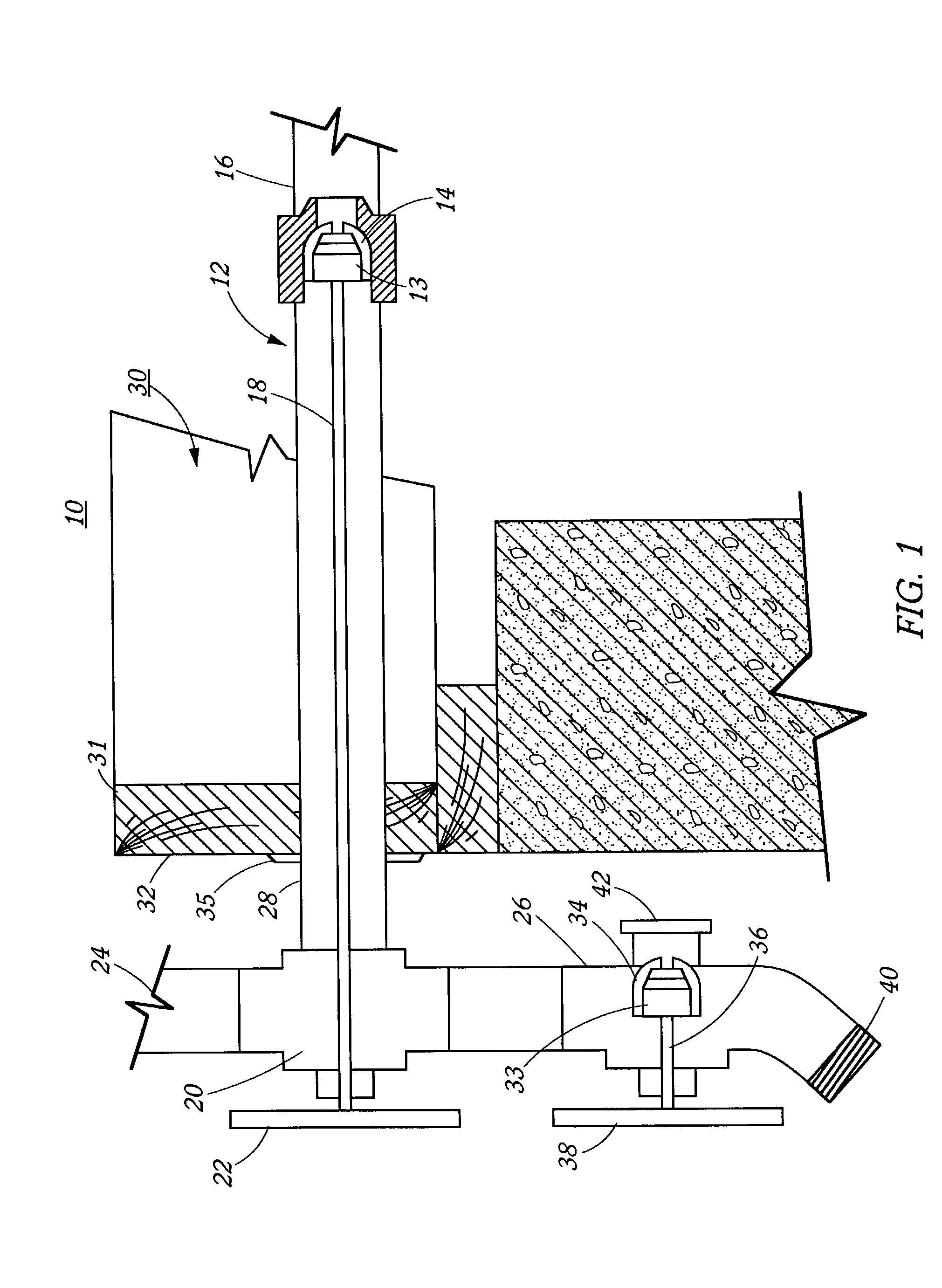

Swimming pool skimmer plug and winterization system

ActiveUS20110296601A1Unusual griping abilityLow costWash-standsGymnasiumService personnelWinterization

The present invention is skimmer plug for winterizing a pool. The skimmer plug inserts and grips into the fluid opening, where there is fluid passage from the pool to the skimmer housing and filter assembly. In this manner, the surface of the skimmer plug when installed is slightly raised from the factory skimmer faceplate or skimmer opening by only the thickness of the skimmer plug's outer plate. The fasteners which secure the factory skimmer faceplate and the skimmer housing to the pool sidewall still remain accessible for adjustment by the pool owner or pool service personnel while the skimmer plug is securely in place.

Owner:HODAK JERRY

Method for extracting sodium lignin sulfonate from papermaking black liquor employing sulphur treatment

InactiveCN103665390ANo personal injuryQuick responseRegeneration of alkali lyeSulfite saltPrecipitation

The invention discloses a method for extracting sodium lignin sulfonate from a papermaking black liquor employing sulphur treatment. The method is characterized by comprising the following steps: 1, injecting a black liquor into a reaction circulating tank, pumping the black liquor to the top of a reaction absorption tower by using a pump, and spraying down from a solution distribution sieve at the top; 2, feeding an SO2 acid gas generated by a burner into the bottom of a reaction tower by using an exhaust fan through a pipeline, and generating reverse gas-liquid reaction by a gas inside the tower and the black liquor sprayed down from the top; 3, absorbing SO2 in a cycle to carry out sulfuration reaction, so as to control the pH value to 3.5-4.0; 4, sulfonating lignin and finishing winterization to sink into the bottom of the tank after foam of reaction liquid disappears in a precipitation tank, and discharging upper brown liquid to obtain lignin pulp; 5, pumping the pulp into a filter press to filter the liquid by a pump, baking and packaging after crushing a filter cake, so as to obtain the product. The method is low in cost, safety production is achieved, the liquid after reaction is a sodium sulfite solution, and a pulping material, and the solution after lignin is filtered and pressed can be prepared into an alkaline pulp. Thus, cyclic utilization of resources is achieved.

Owner:潘增强

Preparation method of camellia oil used for cosmetics

InactiveCN106350208ARetain activityNon-irritatingFatty-oils/fats refiningFatty-oils/fats separationFreeze-dryingAdditive ingredient

The invention discloses a preparation method of camellia oil used for cosmetics. The preparation method comprises the following steps: carrying out vacuum freeze drying, unshelling, low-temperature squeezing, alkali refining, degumming, deacidification, decolorization, winterization and the like. The method can be used to keep the activity of target ingredients in the camellia oil and also can be used to remove useless or harmful impurities, wherein the acid value of the camellia oil is less than or equal to 0.1mgKOH / g, the peroxide value of the camellia oil is less than or equal to 0.3mmoL / kg, the VE (Vitamin E) value of the camellia oil is greater than or equal to 28 (mg / 100g), the yellow value of the camellia oil is less than or equal to 0.4, and the red value of the camellia oil is less than or equal to 0.1. The camellia oil is near colorless, flavourless and smokeless and is not sour; meanwhile, the preparation method has the advantages of simple preparation technology, low energy consumption, small environment pollution, short production period, low cost and the like, and can be widely applied in the field of high-quality cosmetics.

Owner:广西茶仔龙科技股份有限公司

Exterior sprinkler system shutoff and drainage system

A sprinkler winterization and drainage device and method for use in new and existing sprinkler systems that is capable of operation completely from the outside of a building. The devices and methods of the present invention may be used for sprinkler systems in residential homes, commercial or residential rentals, parks, schools and any other application where the main water supply conduit and main sprinkler supply line is located within the interior of a building. The device and method include a valve assembly including a valve located inside a building for shutting off the main sprinkler supply line from outside the building, while also providing for drainage of residual water in the valve assembly to the outside of the building. The device and methods of the present invention completely eliminate the necessity of entry into a building in order to perform sprinkler winterization.

Owner:ADRIAN ROBERT

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com