Method for removing titanium from ladle by using stirring method

A technology of ladle and stirring method is applied in the field of titanium removal from molten iron, which can solve the problems of large fluctuation of titanium content, increase in production cost, and decline in steel quality, and achieve the effect of solving the difficulty of removing titanium, improving production efficiency and improving the quality of molten steel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0016] Processing step of the present invention is:

[0017] (1) Stir the molten iron with an agitator to provide dynamic conditions for the chemical reaction of titanium removal; the depth of the agitator inserted into the molten iron tank or ladle is: the distance between the bottom of the agitator and the bottom of the molten iron tank or ladle is 200-400mm The rotational speed of the agitator is 10-140 rpm; the agitator is composed of a rotating motor, an agitating shaft, an agitating paddle, and a connecting flange, etc., the agitating head is in the shape of a four-piece cross, and the agitating shaft has a circular cavity. Internal air cooling;

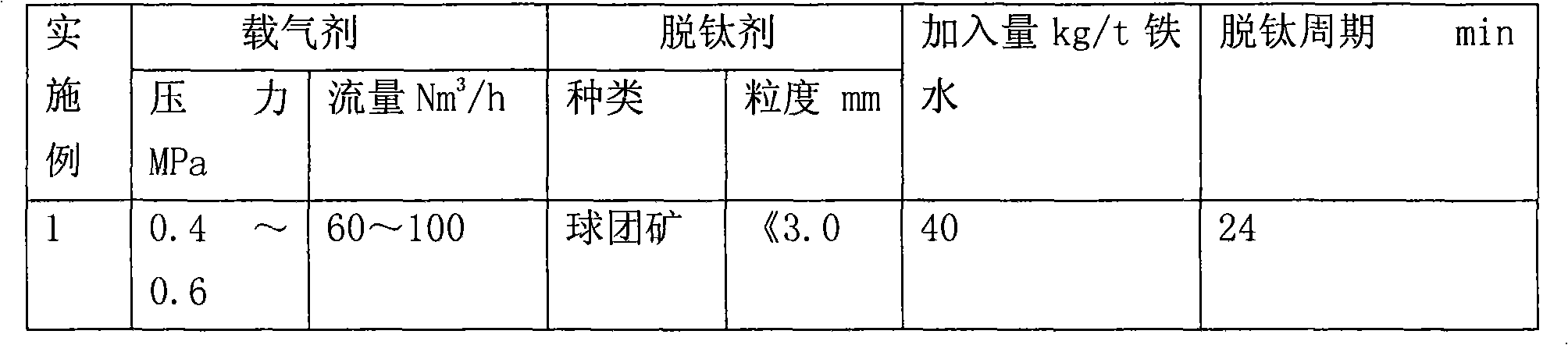

[0018] (2) The titanium removal agent is conveyed by pneumatic force, with nitrogen as the carrier gas, and transported to the ladle through storage tanks, blowing tanks, and pipelines. The pressure of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com