Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

80results about How to "Increased reduction in area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-toughness medium-carbon quenched and tempered round steel of grade 120 KSI and manufacturing method thereof

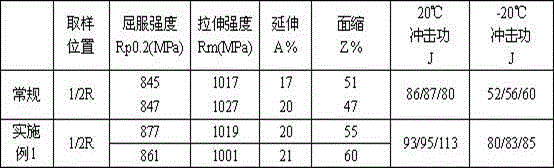

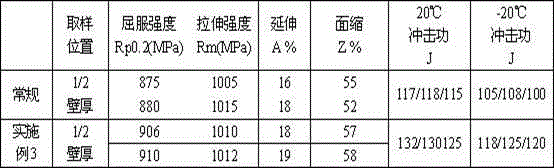

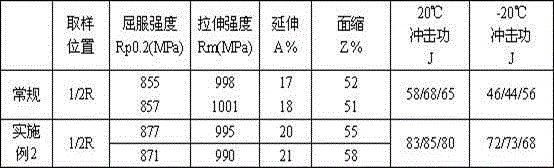

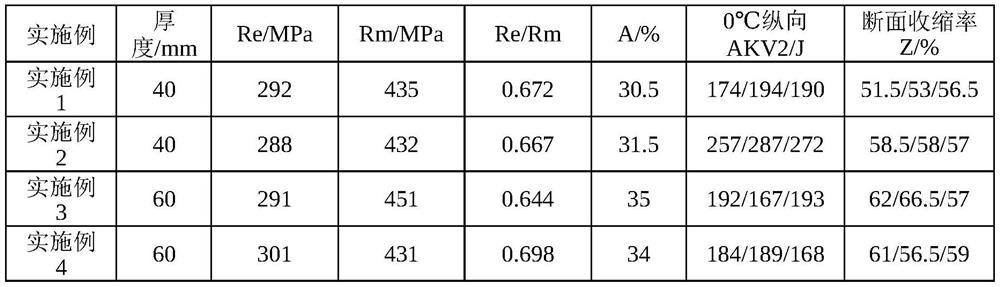

The invention discloses high-toughness medium-carbon quenched and tempered round steel of the grade 120 KSI. The high-toughness medium-carbon quenched and tempered round steel of the grade 120 KSI comprises, by mass, 0.35%-0.50% of C, 0.15%-0.40% of Si, 0.60%-1.30% of Mn, equal to or less than 0.015% of P, equal to or less than 0.040% of S, 0.75%-1.30% of Cr, 0.15%-0.35% of Mo, equal to or less than 0.25% of Ni, equal to or less than 0.25% of Cu, 0.015%-0.040% of Alt, equal to or less than 0.10% of V, equal to or less than 0.10% of Nb, equal to or less than 0.05% of Ti, equal to or less than 0.008% of N, equal to or less than 0.0010% of B and the balance Fe and unavoidable impurity elements, wherein the content of V, the content of Nb and the content of Ti are not equal to or less than 0.010% at the same time. The round steel with the maximum specification reaching 260 mm is manufactured through Kanbara reactor (KR) pretreatment, basic oxygen furnace (BOF) smelting, ladle furnace (LF) refining, Ruhrstahl Heraeus (RH) vacuum degassing, continuous casting, heating, continuous rolling, and hardening and tempering, so that the requirements for high specifications and toughness are met.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

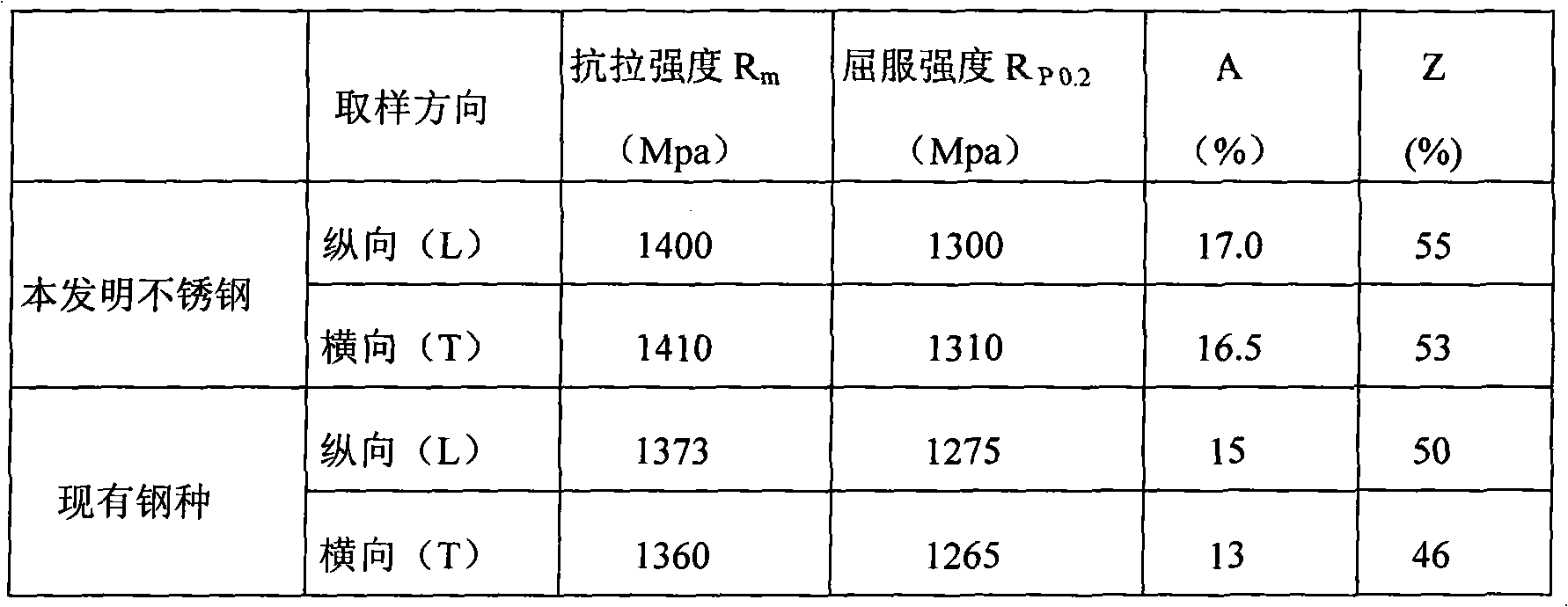

Martensite precipitation hardening stainless steel for structural member and manufacturing method thereof

The invention provides a martensite precipitation hardening stainless steel for structural member and a manufacturing method thereof. The martensite precipitation hardening stainless steel comprises the following chemical components in percentage by weight: less than or equal to 0.05 percent of C, 13.50 to 15.50 percent of Cr, 2.5 to 4.0 percent of Cu, 3.0 to 5.0 percent of Ni, 0.15 to 0.40 percent of Nb and Ta, 0.010 to 0.040 percent of N, 0.050 to 0.15 percent of V, less than or equal to 0.80 percent of Si, less than or equal to 1.00 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.010 percent of S, and the balance of Fe and inevitable impurities. The stainless steel is smelted by combining an electric furnace, AOD refining and vacuum self-consuming technology, so the stainless steel has the characteristics of high strength, good plasticity, good corrosion resistance and the like, and can meet the requirements of high-strength components such as high-pressure values, oil drill, efficient heavy-duty machinery and the like on material performance.

Owner:宝武特种冶金有限公司

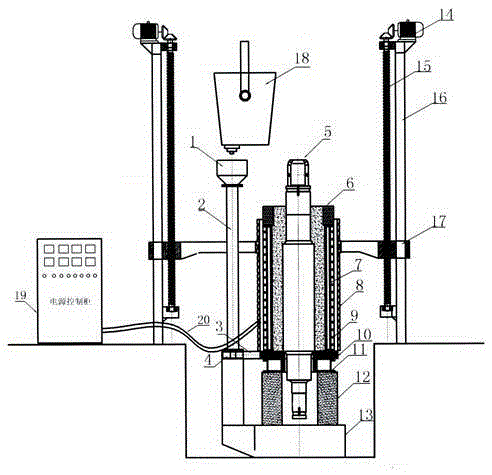

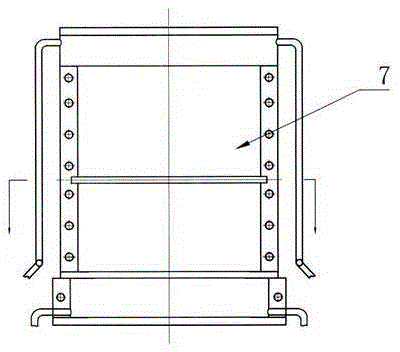

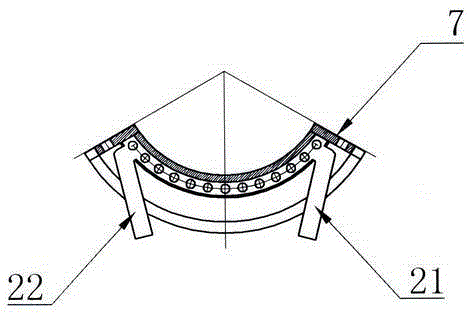

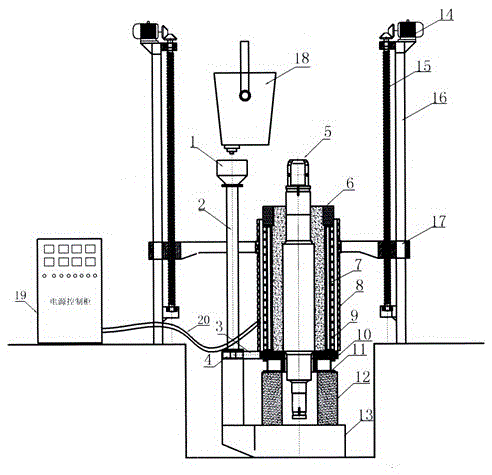

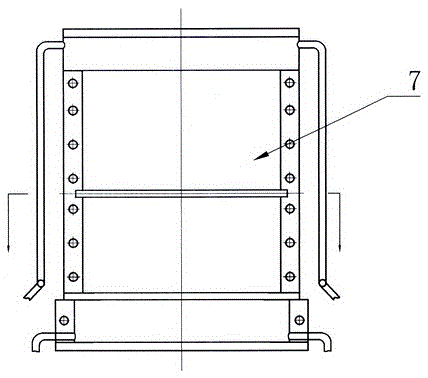

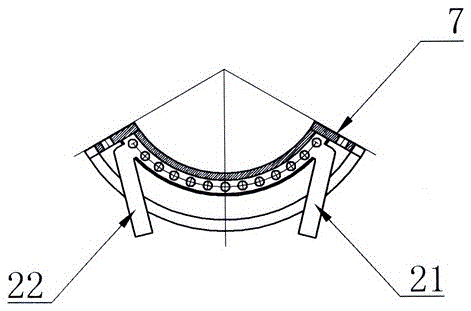

Manufacturing technology and device for improved forged steel roller neck high nickel chrome molybdenum alloy cast composite roller

ActiveCN105401059AEasy feedingOvercome the defect of prone to tissue segregationFurnace typesProcess efficiency improvementManufacturing technologyFerrosilicon

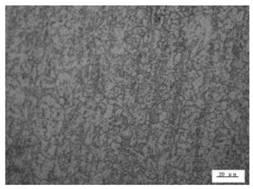

The invention discloses a manufacturing technology and device for an improved forged steel roller neck high nickel chrome molybdenum alloy cast composite roller. The roller comprises, by mass percent, 3.0%-3.6% of C, 0.60%-1.20% of Si, 0.30%-1.20% of Mn, 3.0%-5.0% of Ni, 1.0%-2.0% of Cr, 0.40%-1.2% of Mo, 0.1%-2% of W, 0.5%-1.0% of Cu, not larger than 0.05% of P, not larger than 0.03% of S, 0.04%-0.06% of Mg, 0.1%-0.3% of Nb, 0.1%-0.30% of Ti, 0.2%-0.6% of V, 0.05%-0.2% of B, 1.5%-2.5% of Ba, 1%-2% of Ca, 1%-3% of Sb, 0.02%-0.18% of N, 1.0%-2.0% of Y / RE and the balance Fe and inevitable micro elements. Yttrium base rare-earth nodulizing and Ba, Ca, and silicon iron composite inoculation are adopted, Nb, Ti, V, B and Sb are added for modification, and the mechanical performance of the roller is improved; by the adoption of the forged steel roller neck, the strength of the roller is improved, an induction heater is adopted to carry out in-mold whole heating casting on a core stick, a water cooled crystallizer is molded, a composite layer interface can be dynamically controlled, the technology is simple, the efficiency is high, power consumption is small, the cost is low, no composition segregation exists, and the service life of the roller is long.

Owner:丹阳恒庆复合材料科技有限公司

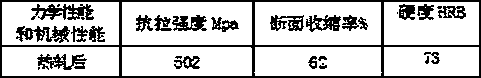

Production method of carbon cold-forging steel large coil for 8.8 level high-intensity fasteners

InactiveCN101456032AStrong toughnessReduce intensityTemperature control deviceFurnace typesRoom temperatureSteel bar

The invention provides a method for producing a carbon element cold forging steel big pony roll for a 8.8 grade high intensity fastening piece, which belongs to the technical field of cold forging steel. Twenty high rigidly short stress line red circle steel bar rolling mills are adopted to roll heated mid-carbon element cold forging steel billet. The billet heated to the temperature of between 1,000 and 1,150 DEG C taken out of a furnace is rough rolled by a 4+4 stander and is medially rolled by a 4 stander. A rolling piece after the mid rolling adopts the first section of water cooling to reduce the surface temperature to be between 770 and 790 DEG C, passes through the restoring section, enters four standers to be precisely rolled at a temperature of between 840 and 860 DEG C; the rolling piece after the precise rolling adopts the second water cooling to reduce the surface temperature to be between 760 and 780 DEG C, passes through the restoring section, enters four standers to be precisely rolled at a temperature of between 830 and 850 DEG C; and the rolling piece after the precision rolling enters the third section water cooling to reduce the temperature of between 830 and 850 DEG C to be curled, the curled piece enters an insulated shield to be cooled by 4,200 to 4,800 seconds at a cooling speed of between 0.08 and 0.30 DEG C per second, and the pony roll is cooled naturally to the room temperature. Phi20mm and Phi38mm pony roll strength Rm can be stably controlled to be less than or equal to 650Mpa, HBW is less than or equal to 170, and Z is more than or equal to 45 percent so that the mid-carbon element cold forging steel pony roll is softened on line and the quality of the pony roll is high.

Owner:SHOUGANG CORPORATION

Electroslag smelting casting method of fixed blades of water turbine

The invention relates to an electroslag smelting casting method of fixed blades of a water turbine. Consumable electrodes are prepared by adopting a voltaic arc furnace refining method and the fixed blades are prepared by adopting an electroslag smelting casting process through a mould. The chemical components of the consumable electrodes are controlled as follows: C is 0.14-0.19 percent, Si is less than or equal to 0.6 percent, Mn is 1.5-1.9 percent, P is less than or equal to 0.035 percent, S is less than or equal to 0.035 percent, V is 0.02-0.15 percent, Nb is 0.015-0.06 percent, Ti is 0.15-0.25 percent, Al is more than or equal to 0.015 percent, O is less than or equal to 0.0040 percent, N is less than or equal to 0.0080 percent, H is less than or equal to 0.00035 percent, and the balance is Fe. The electroslag smelting casting system and the electroslag guide are controlled as follows: CaF2 is 60-80 percent, Al2O3 is 40-20 percent, or less MgO and CaO (the total is less than or equal to 20 percent); and the electroslag amount is usually 1.5-5 percent of the weight of a casting. The invention has less amount of oxide and sulfide, small size, even distribution, clean casting base body, high cooling speed, large crystallization temperature gradient at the front of solid and fluid, compact casting texture, high size precision and little distortion, and can greatly improve the product property of the refined casting.

Owner:SHENYANG RES INST OF FOUNDRY

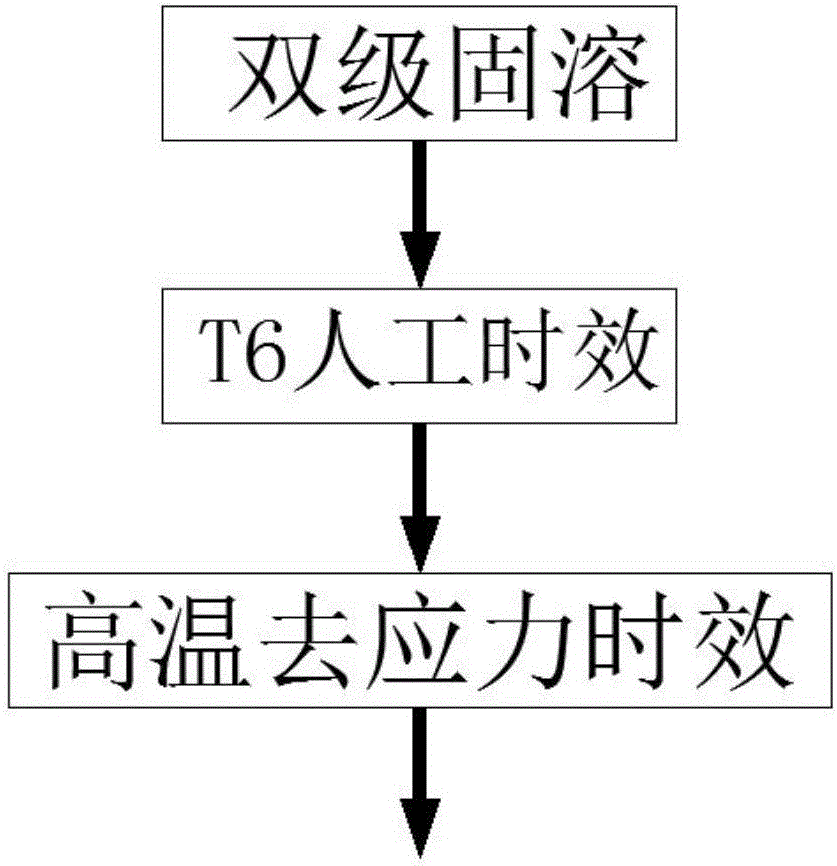

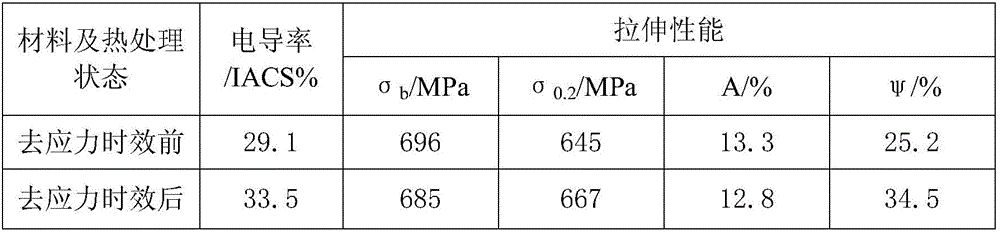

Heat treatment method capable of reducing stress of spray-formed 7000 series aluminum alloy products

The invention relates to 7000 series aluminum alloys, in particular to a heat treatment method capable of reducing stress of spray-formed 7000 series aluminum alloy products. The heat treatment method comprises a two-stage solid solution treatment step and an artificial ageing treatment step sequentially and is characterized in that after the artificial ageing treatment step and before rough machining or after the rough machining and before finish machining, high-temperature stress-relieving aging is performed, that is, heat preservation is performed at the temperature of 125-155 DEG C for 8-32 h. The heat treatment method can maintain the higher strength level of the spray-formed 7000 series aluminum alloy products, reduce residual stress efficiently and improve the comprehensive performance of the products, the problem of cracking of the products in follow-up machining process is solved, machining deformation of the products is reduced, the machining efficiency is improved, and the dimensional precision is improved.

Owner:JIANGSU HAORAN SPRAY FORMING ALLOY

Preparation method of fresh wet rice noodle

ActiveCN107912695AEasy to stretchIncreased reduction in areaFood thermal treatmentFood shapingGlutenLactic acid fermentation

The invention belongs to the field of preparation of special foods, and particularly relates to a preparation method of a fresh wet rice noodle. The preparation method comprises the following steps ofusing the milled early long-grain nonglutinous rice as the main raw material, and using 1.5 to 2 parts of vital gluten by weight, 5 to 8 parts of modified starch by weight and 1.0 to 1.5 parts of non-starch polysaccharide by weight as the auxiliary materials; soaking, grinding into pulp, extruding and shaping, steaming noodles, aging, cutting the noodles, sterilizing at superhigh pressure, and packaging under the vacuum condition, so as to obtain the fresh wet rice noodle. The preparation method has the advantages that one part of milled early long-grain nonglutinous rice is extruded and expanded, the other part of milled early long-grain nonglutinous rice is fully soaked, and the quality improving agents of vital gluten, modified starch and non-starch polysaccharide are used, so as to improve the toughness and elasticity of the fresh wet rice noodle; the processing methods of controlling of the water content in the fresh wet rice noodle, recirculating spraying and moisturizing and the like are adopted, so that the aging and uncooking-state return of the fresh wet rice noodle are prevented, and the palatability is improved; the techniques of lactic acid fermentation of starch gel,high-temperature extruding, pasting and shaping, constant-temperature humidity control and the like are adopted, so that the safe and sanitary fresh wet rice noodle with optimized eating quality canbe developed.

Owner:HUNAN YUXIANG FOODS

Preparation method based on single crystal copper bonding wire

InactiveCN102280388ALow priceImprove plastic deformationPolycrystalline material growthSemiconductor/solid-state device detailsEpoxyMicrocomputer

The invention discloses a preparation method based on single crystal copper bonding wire. The preparation method of the single crystal copper bonding wire is divided into two steps: (1) using continuous casting single crystal copper rod as the single crystal copper The starting material of the bonding wire, at the same time, the single crystal copper bonding wire is drawn by the drawing equipment driven by the AC servo motor with the microcomputer program control, active wire release, and the pulling force accuracy is less than 1mN; (2) The drawn single crystal copper bond The bonding wire is treated with electroplating precious metal palladium with a surface thickness of 0.5um~1um and an organic epoxy coating with a thickness of 1um for double-layer protection; in this way, a single crystal copper bonding wire with multiple protective coatings is finally obtained. Bonding wire has the advantages of low price, high elongation, good mechanical and electrical properties, and good oxidation resistance.

Owner:王一平

Manufacturing technique and device for improved bainite nodular cast iron composite roller provided with forged steel roller neck

The invention discloses a manufacturing technique and device for an improved bainite nodular cast iron composite roller provided with a forged steel roller neck. The improved bainite nodular cast iron composite roller provided with the forged steel roller neck is prepared from, by mass, 3.0%-3.6% of C, 0.60%-1.20% of Si, 0.30%-1.20% of Mn, 3.0%-5.0% of Ni, 1.0%-2.0% of Cr, 0.40%-1.2% f Mo, 0.1%-2% of W, 0.5%-1.0% of Cu, 0-0.05% of P, 0-0.30% of S, 0.04%-0.06% of Mg, 0.1%-0.3% of Nb, 0.1%-0.30% of Ti, 0.2%-0.6% of V, 0.05%-0.2% of B, 1.5%-2.5% of Ba, 1%-2% of Ca, 1%-3% of Sb, 0.02%-0.18% of N, 1.0%-2.0% of Y / RE, and the balance Fe and inevitable trace elements. According to the manufacturing technique and device for the improved bainite nodular cast iron composite roller provided with the forged steel roller neck, yttrium-based rare earth is used for nodularization, Ba, Ca and silicon iron are used for combined inoculation, Nb, Ti, V, B and Sb are added for modification treatment, and thus the mechanical property of the roller is improved; by the adoption of the forged steel roller neck, the strength of the roller is improved; integral in-mold heating and casting of a core rod are conducted through an induction heater, and a water-cooling crystallizer is used for formation; the interface of a composite layer can be controlled dynamically, the technique is simple, power consumption is low, the cost is low, composition segregation is avoided, and the service life of the roller is long.

Owner:丹阳恒庆复合材料科技有限公司

High-precision high-width nickel-base material strip or foil and preparation method thereof

The invention relates to a high-precision high-width nickel-base material strip or foil and a preparation method thereof. The high-precision high-width nickel-base material strip or foil comprises the following raw materials: 0.2-0.4% of magnesium Mg, 0.5-1.5% of aluminum Al, 0.05-0.15% of titanium Ti, 1-2% of silicon Si, 0.005-0.015% of manganese Mn, 0.1-0.3% of mixed rare earths, 0.05-0.15% of yttrium Y and the balance of nickel Ni. The preparation method comprises the following steps: melting, face milling, hot rolling, cold rolling, heat treatment, precision rolling, longitudinal cutting and surface cleaning. The invention fills up the blank in super-long super-wide nickel strip, is applicable to large-size power cells, adapts to the automatic production line processing trend of the nickel strip, greatly reduces the productive energy consumption, lowers the production cost, can greatly shorten the production cycle for processing the nickel strip, and enhances the production efficiency.

Owner:JIANGSU YUANHANG PRECISION ALLOY TECH +1

Method for producing ultralow-rigidity annealing-free cold forging steel

The invention relates to a method for producing ultralow-rigidity annealing-free cold forging steel. The ultralow-rigidity annealing-free cold forging steel comprises the following components in percentage by weight: 0.19%-0.22% of C, less than or equal to 0.08% of Si, 0.80%-1.00% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, more than or equal to 0.025% of Alt, 0.025%-0.050% of Ti, less than or equal to 0.035% of B and the balance of Fe and inevitable impurities. The production process comprises the following steps: smelting; continuously casting; heating; carrying out finish rolling; carrying out final rolling; slightly cooling; spinning into a ring; cooling a Stelmor roller way, wherein the heating temperature is 1090-1170 DEG C, the rolling starting temperature is 1000-1060 DEG C, the finish rolling temperature is 850-900 DEG C, the slight cooling temperature is 800-850 DEG C, the cooling speed of the Stelmor roller way is 0.10-0.40 m / s. The method disclosed by the invention can be used for reducing the usage amount of silicon and chromium, enhancing the plasticity of a product and reducing the rigidity of the steel.

Owner:张家港联峰钢铁研究所有限公司

Precipitation strengthened heat resistant steel and preparation process thereof

ActiveCN107587080AReduce the ductile-brittle transition temperaturePromote precipitationRoom temperatureIngot

The invention relates to precipitation strengthened heat resistant steel and a preparation process of the precipitation strengthened heat resistant steel. The components of an alloy meet the followingrange requirements by mass percent: 003-0.06% of C, 6-10% of Ni, 8-13% of Cr, 1.5-2.4% of Al, less than or equal to 3% of Co, less than or equal to 0.1% of Nb, less than or equal to 0.1% of Zr, and the balance of Fe; the prepared alloy is smelted into an alloy mother liquid and is finally prepared into an alloy ingot; the alloy ingot is rolled into a sheet at the temperature range of 850-1100 DEGC; and the rolled sheet is subjected to solid solution treatment and aging treatment to obtain the precipitation strengthened heat resistant steel. The heat resistant steel is excellent in room temperature toughness and has an excellent strength property at the same time. The room temperature tensile strength of the alloy is not lower than 1000 MPa, the yield strength exceeds 900 MPa, the room temperature elongation percentage is higher than 12%, and the reduction of area is higher than 50%.

Owner:CHINA HUANENG GRP CO LTD +1

Preparation method of nodular cast iron of alloy for roll

The invention discloses a preparation method of nodular cast iron of alloy for a roll. The nodular cast iron comprises the following components in percentage by mass: 3.6-3.8% of C, 1.8-2.0% of Si, 0.5-0.7% of Mn, 0.01-0.04% of P, 0.01% of S, 0.1-0.3% of Cr, 0.11-0.14% of Mo, 1.5-2.0% of Ni, 0.4-0.6% of Mg, 0.04-0.06% of Mo, 0.06-0.1% of Nb, 0.1-0.15% of Ti, 0.2-0.4% of V and the balance of Fe and inevitable trace elements. According to the preparation method, matching of alloy elements is reasonably optimized, the mass percentages of Ni and Cr are optimized and Nb, Ti and V are added for improving the components of the roll, so that the morphology of carbides in the roll can be improved, the bending strength, impact toughness, deflection, area reduction rate, after-fracture elongation percentage and yield strength of the roll can be enhanced further, the problems that the inner surface layer of a hole slot in a finished-rolled roll body is peeled off can be solved, and the single-slot rolling quantity of a rolling mill can be increased.

Owner:QINGDAO LIANGLI PRECISION CASTING

Centrifugal casting process for main pipeline of million kilowatt-grade nuclear power plant

ActiveCN102233417ATo achieve the effect of heat insulationAdjust the setting characteristicsFoundry mouldsFurnace typesMolten steelSubmarine pipeline

The invention relates to a centrifugal casting process for a main pipeline of a million kilowatt-grade nuclear power plant. The centrifugal casting process comprises the main steps of smelting, cylinder coating, centrifugal casting, heat treatment and the like, wherein the tapping temperature of pressure molten steel is 1,640+ / -10 DEG C; after a cylinder is coated, the cylinder is roasted to the temperature of more than or equal to 280 DEG C and heat is preserved for 1 to 2 hours; the temperature of pouring steel is 1,570+ / -10 DEG C; the calming time is not less than 4 minutes; the rotating speed of the cylinder is controlled to be 800 to 870 r / min; and the casting speed is more than or equal to 100 kg / s. In the centrifugal casting process, process parameters and the process are controlled strictly, so the main pipeline capable of meeting the requirements of the million kilowatt-grade nuclear power plant can be manufactured.

Owner:烟台台海玛努尔核电设备有限公司

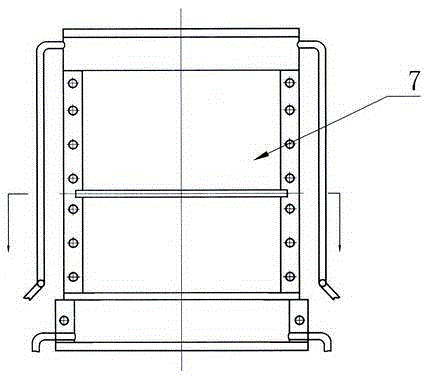

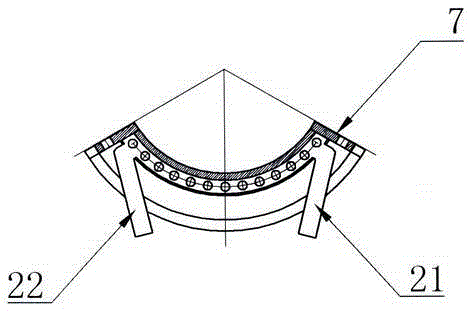

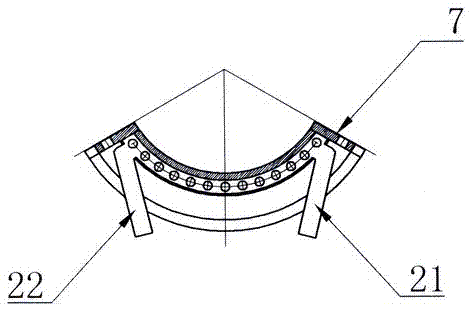

Manufacturing technology and device of forged steel roller neck alloy nodular cast iron composite roller

ActiveCN105397067AEasy feedingOvercome the defect of prone to tissue segregationManufacturing technologyFerrosilicon

The invention discloses a manufacturing technology and device of a forged steel roller neck alloy nodular cast iron composite roller. The forged steel roller neck alloy nodular cast iron composite roller comprises, by mass percent, 3.2%-3.9% of C, 1.6%-2.1% of Si, 0.4%-0.8% of Mn, not larger than 0.05% of P, not larger than 0.03% of S, 0.2%-0.5% of Cr, 0.3%-0.7% of Mo, 1.4%-2.0% of Ni, 0.04%-0.06% of Mg, 0.06%-0.2% of Nb, 0.1%-0.25% of Ti, 0.2%-0.5% of V, 1.5%-2.5% of Ba, 1%-2% of Ca, 1.0%-2.0% of RE and the balance Fe. Rare-earth nodulizing and Ba, Ca and silicon iron compound inoculation are adopted, and Nb, Ti and V are added for modification, so that the mechanical property of the roller is improved, a forged steel roller neck is adopted to improve the strength of the roller, and an induction heater is adopted to carry out in-mold whole heating casting on a forged steel or cast steel core stick; and a combined type water cooled crystallizer is molded, a lifting device lifts the heater upwards at a certain speed to form area directional solidification, a composite layer interface is dynamically controlled, the technology is simple, the efficiency is high, the electric consumption is small, the cost is low, no composition segregation exists in the composite layer, and the service life of the roller is long.

Owner:丹阳恒庆复合材料科技有限公司

Steel wire rod for bainite high-strength welding wire and production method thereof

The invention discloses a steel wire rod for a bainite high-strength welding wire and a production method thereof. The steel wire rod for the bainite high-strength welding wire comprises the followingchemical components of, in percentage by mass, 0.05%-0.11% of C, 0.35%-0.65% of Si, 1.60%-1.80% of Mn, less than or equal to 0.020% of P, less than or equal to 0.010% of S, 0.25%-0.37% of Cr, 1.45%-1.85% of Ni, 0.42%-0.52% of Mo, 0.13%-0.16% of Ti, and the balance Fe and unavoidable impurities. The mechanical property of the steel wire rod for welding wire meets the conditions that the tensile strength is larger than or equal to 900 MPa, the elongation is larger than or equal to 25%, the cross-section shrinkage rate is larger than or equal to 70%, and the steel wire rod can be applied to thefield of high-strength steel welding of coal mine machinery, containers, buildings, ships, bridges and the like.

Owner:BAOTOU IRON & STEEL GRP

Production method of high-plasticity steel wire rod for welding

The invention relates to a production method of a high-plasticity steel wire rod for welding, comprising the steps of heating, descaling, rough rolling, pre-finish rolling, finish rolling, spinning, cold control, cooling and transportation. The strength of steel for welding is reduced and the plasticity is improved through such methods as rolling temperature control, rolling mill cooling water control, air volume control and insulation measure; and the generation of bad phenomenon in the drawing machining process is effectively improved.

Owner:武钢集团有限公司

Austenitic stainless steel, preparation method thereof and application of austenitic stainless steel in hydrogen storage pressure vessel

ActiveCN114351051AReasonable design of ingredientsReduced ferrite contentFixed capacity gas holdersMetal rolling arrangementsMetallurgySS - Stainless steel

The invention belongs to the technical field of steel smelting, and relates to austenitic stainless steel, a preparation method thereof and application of the austenitic stainless steel in a hydrogen storage pressure container. The austenitic stainless steel provided by the invention comprises the following components in percentage by weight: 0.010%-0.030% of C, 0.40%-0.75% of Si, 1.3%-2.0% of Mn, 17.5%-18.0% of Cr, 13.05%-14.00% of Ni, 2.5%-3.0% of Mo, less than or equal to 0.030% of P, less than or equal to 0.002% of S, less than or equal to 0.06% of N, less than or equal to 0.5% of Cu, 0.002%-0.005% of B, 28.5%-35% of Nieq, and the balance of Fe and inevitable impurities. The austenitic stainless steel is stable in structure performance, low in ferrite content and good in hydrogen embrittlement resistance, the development requirement of a hydrogen storage pressure container of a hydrogen refueling station is met, and the austenitic stainless steel has important practical significance on safe and efficient development of the hydrogen energy storage technology.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

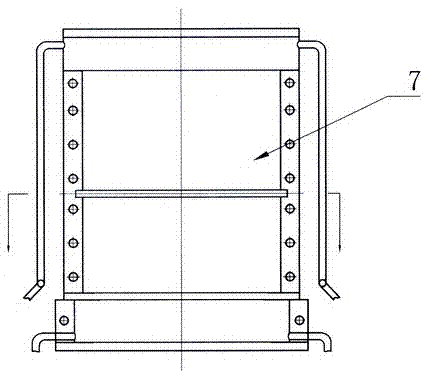

Forged steel roll journal indefinite chill high nickel-chromium-molybdenum composite roll process and equipment

ActiveCN105562647AAchieve regulationMeet manufacturingFurnace typesProcess efficiency improvementTrace elementInduction heater

The invention discloses a forged steel roll journal indefinite chill high nickel-chromium-molybdenum composite roll process and equipment. A material comprises the following components in percentages by mass: 3.1-3.5% of C, 0.70-1.20% of Si, 0.40-1.20% of Mn, 3.0-4.8% of Ni, 1.0-2.0% of Cr, 0.40-1.1% of Mo, 0.1-2% of W, 0.5-1.0% of Cu, less than or equal to 0.05% of P, less than or equal to 0.03% of S, 1-3% of Sb, 0.02-0.18% of N, 0.1-0.3% of Ce, and the balance Fe and inevitable trace elements; rare earth Ce and silicon iron are subjected to compound inoculation, Sb and N are added to carry out grain refinement, mechanical properties of a roll are improved, the strength of the roll is improved by a forced steel roll journal, a mandrel is subjected to internal integral heating fusion casting by an induction heater, forming is implemented by a water-cooled crystallizer, an interface of a composite layer can be controlled dynamically, the process is simple, the cost is low, composition segregation is avoided, and the service life of the roll is long.

Owner:丹阳恒庆复合材料科技有限公司

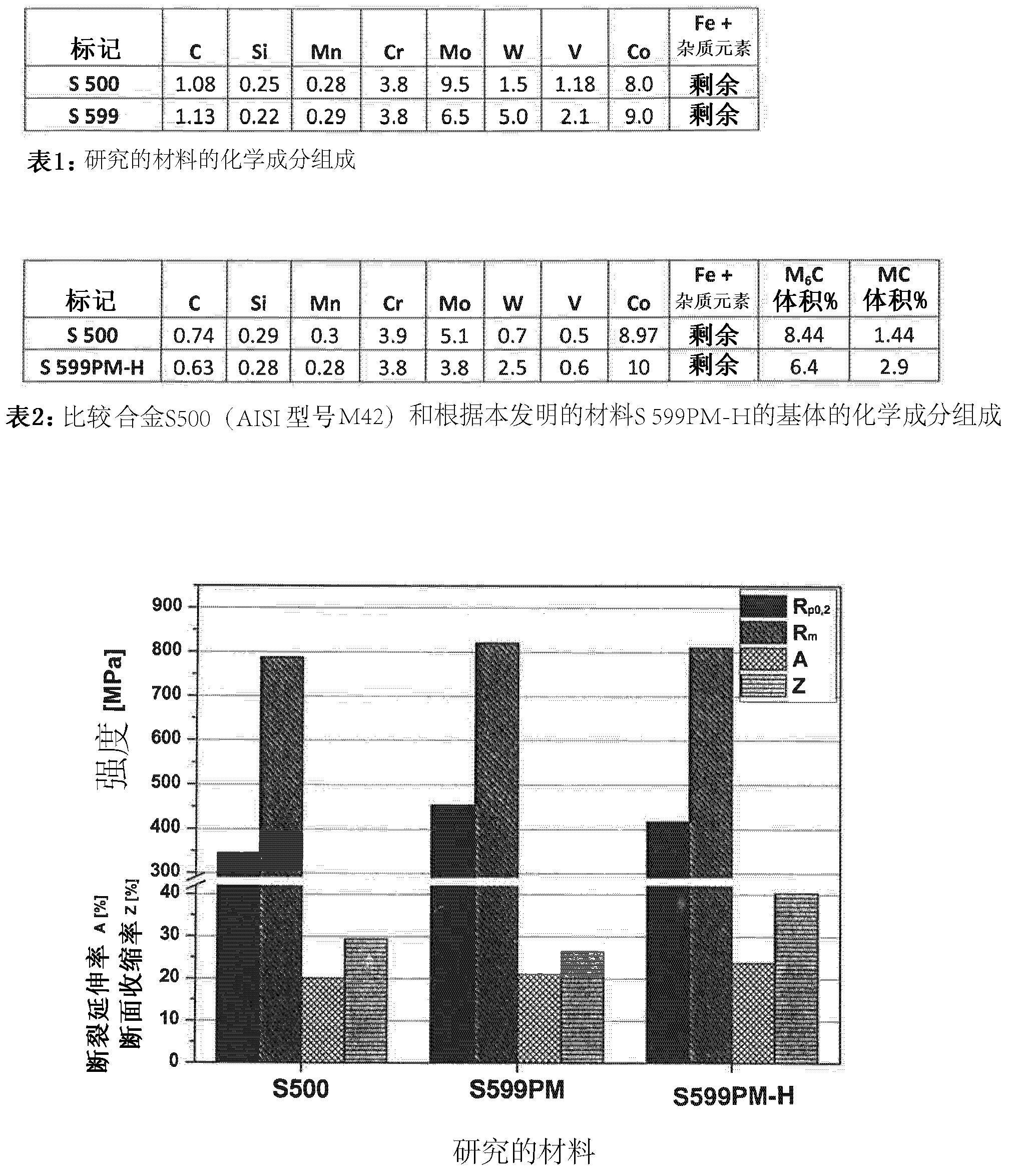

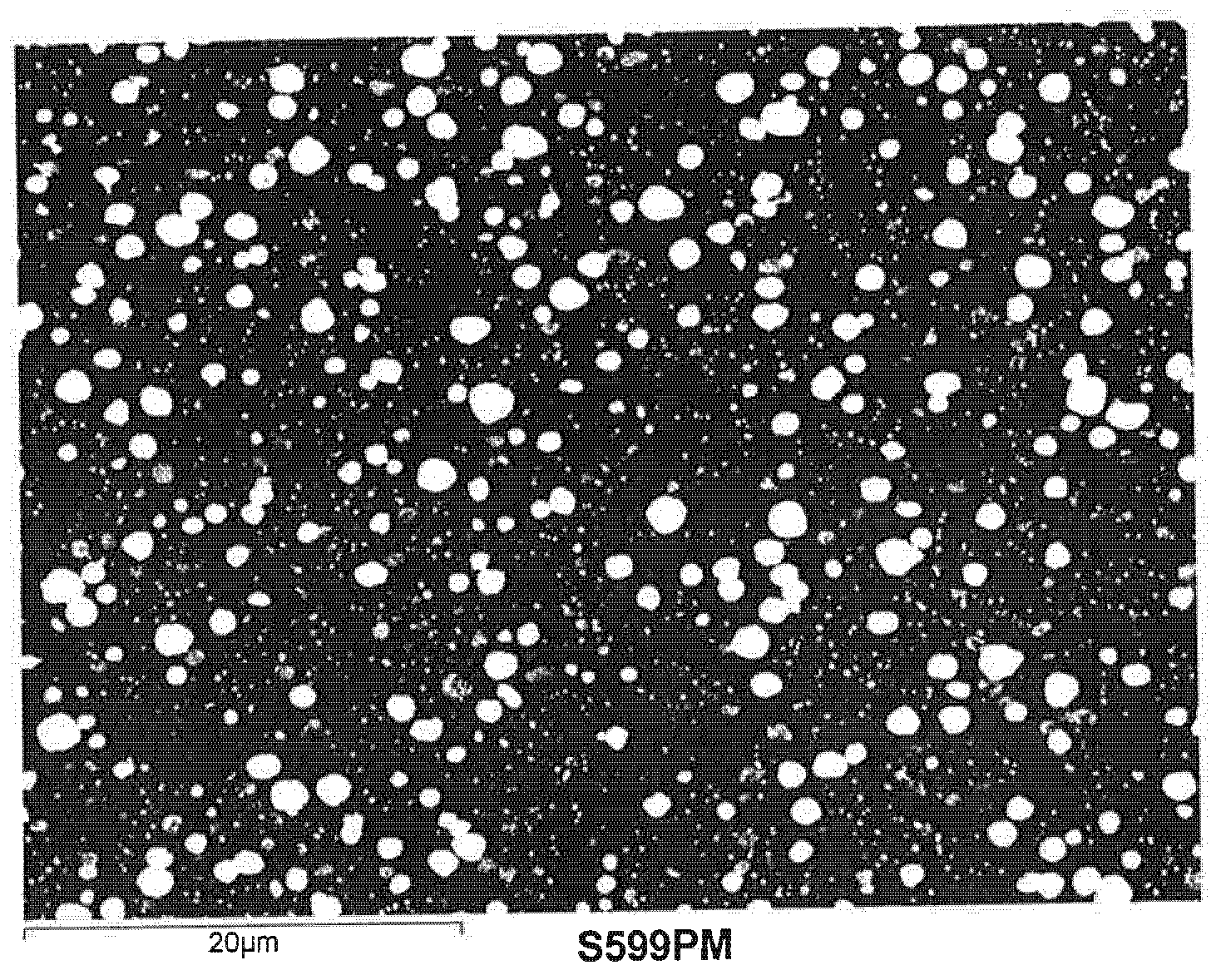

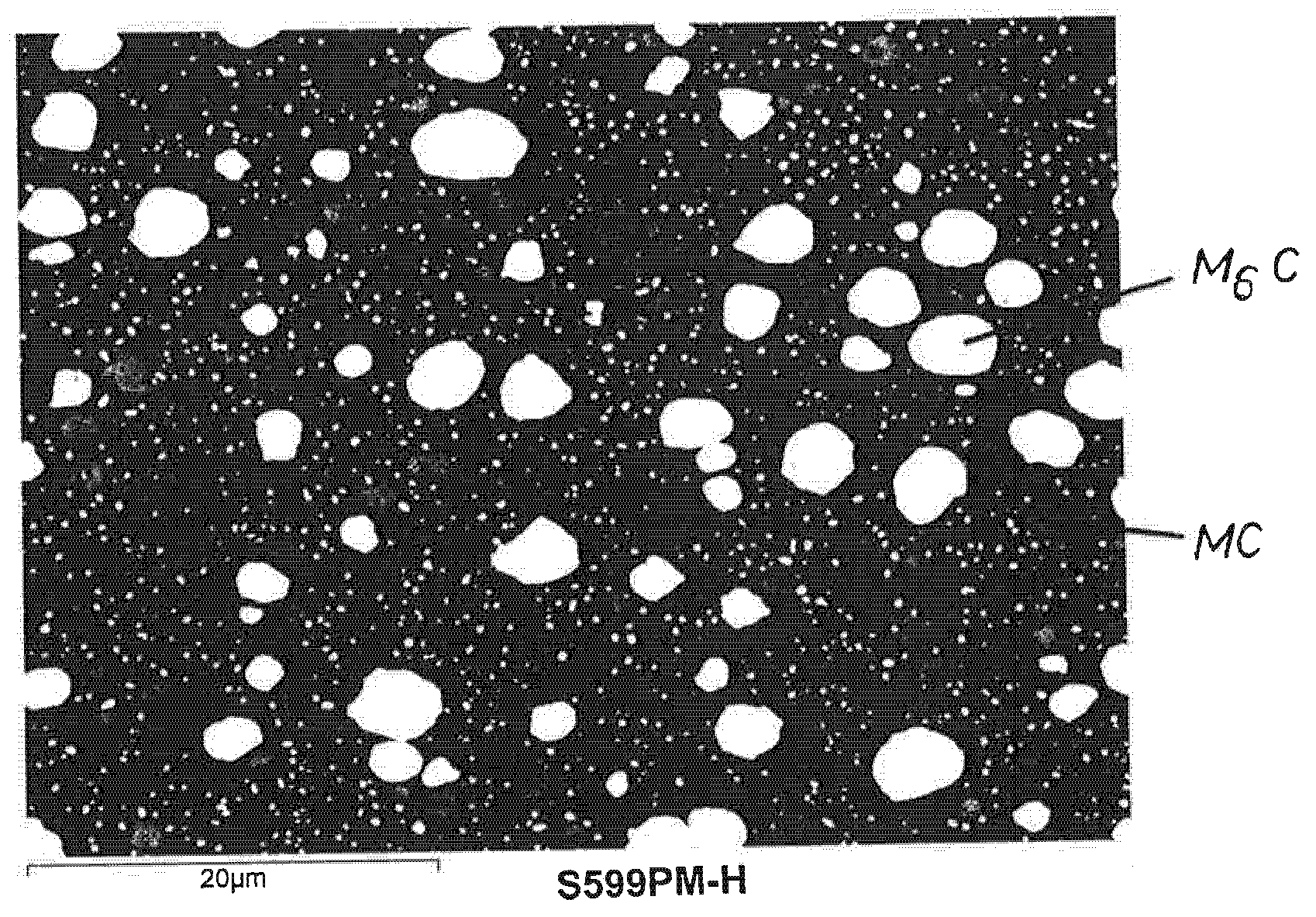

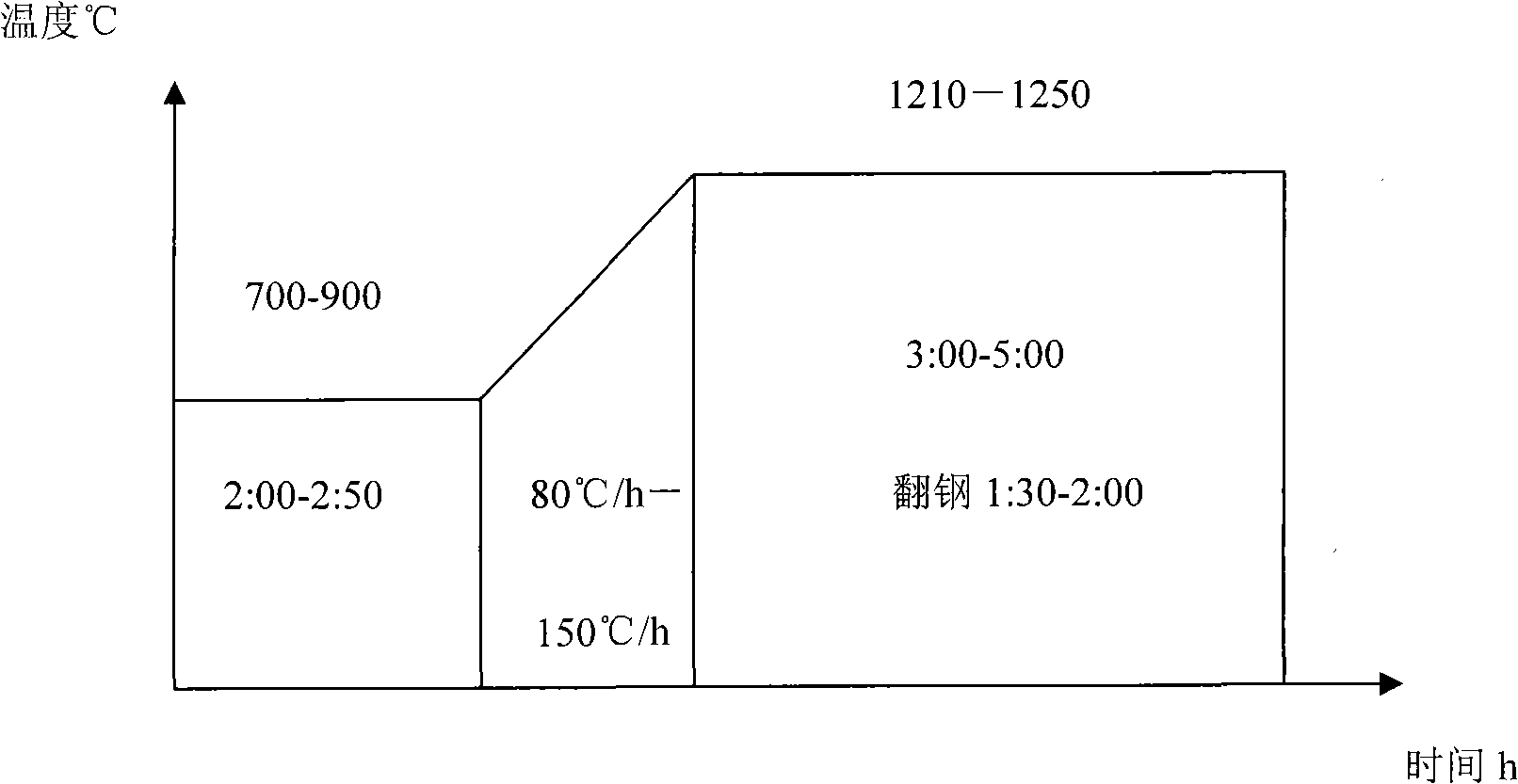

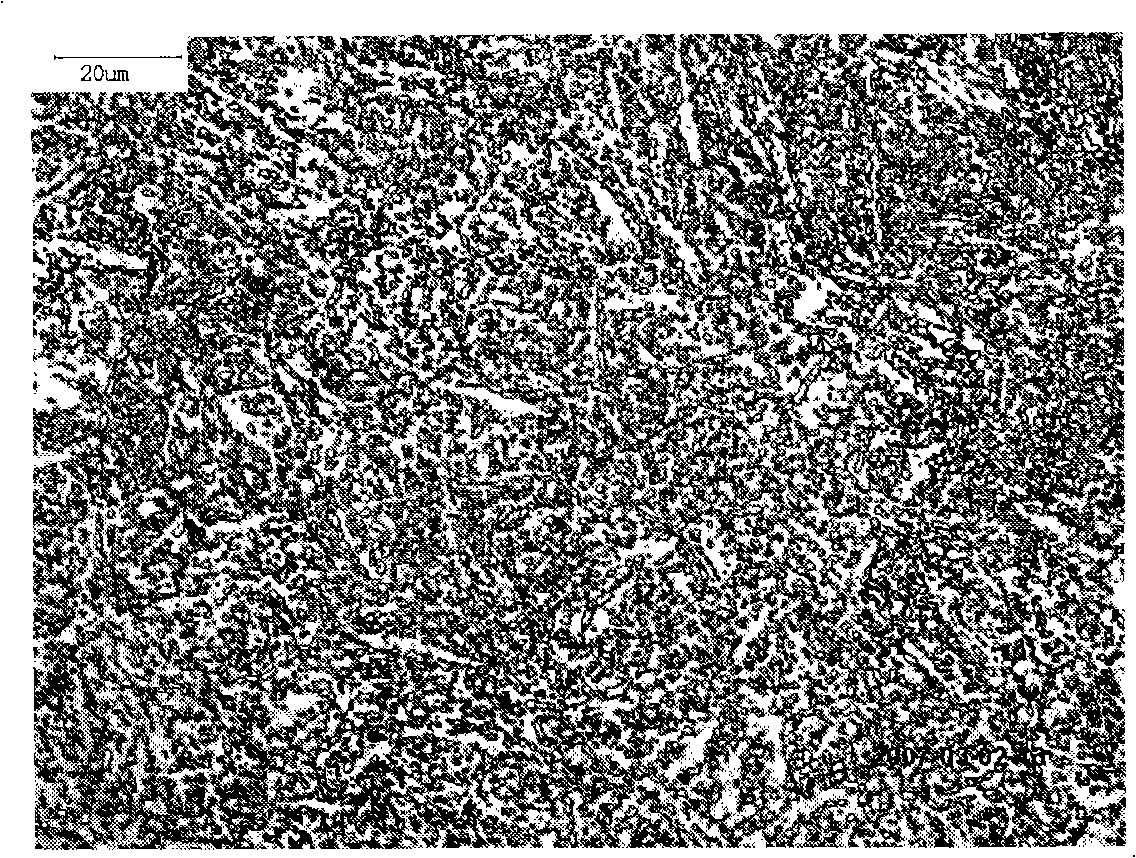

Material with high wear resistance

Preparing a material with isotropic, mechanical properties and improved wear resistance and high hardness potential, comprises preparing hot isostatic pressing (HIP) blank or HIP block from a ledeburitic tool steel alloy in a press molding process by spraying a liquid metal alloy with nitrogen to a powder and hot isostatic pressing, heating the HIP block and / or a semi-manufactured product from a coarse-grain, subjecting the HIP block to 10[deg] C below a melting temperature of the lowest melting structural phase, and further processing the blank to thermally treated tools. Preparing a material with isotropic, mechanical properties and improved wear resistance and high hardness potential, comprises preparing hot isostatic pressing (HIP) blank or HIP block from a ledeburitic tool steel alloy in a press molding process by spraying a liquid metal alloy with nitrogen to a powder and hot isostatic pressing, heating the HIP block and / or a semi-manufactured product from a coarse-grain at a temperature of 1100[deg] C, subjecting the HIP block to 10[deg] C below a melting temperature of the lowest melting structural phase with a time period of about 12 hours for increasing average carbide phase size of the material to at least 65%, and further processing the blank to thermally treated tools with high resistance to wear and abrasion. The material has surface in a round shape, and a matrix of the material is homogenized. An independent claim is included for material with isotropic, mechanical properties and improved wear resistance having thermally treated condition at a carbide phase ratio of in M 6C and Mc of 7 vol.%, where the matrix has an average carbide-phase size of 2.8 mm and a carbon concentration of 0.45-0.75 wt.%.

Owner:BAILE SPECIAL STEEL GMBH & CO KG

Production method for alloy filament

The invention discloses a 4J42 alloy filament for a discharge tube electrode and a production method for the alloy filament. The production method comprises the following steps: pouring a 4J42 raw material into a vacuum furnace for making steel and forming an ingot; performing forging cogging and hot rolling to form a wire rod; performing acid washing processing on the wire rod subjected to hot rolling; polishing and trimming after acid washing, and performing first drawing; performing annealing processing on a semi-finished product subjected to first drawing; performing acid washing and grinding on the semi-finished product subjected to annealing processing; performing secondary drawing after no crack is determined to exist; performing hot-processing annealing on the wire rod subjected to secondary drawing; detecting the case of the wire rod surface again, performing crude-filament finish drawing, performing hot processing after each time of the wire rod being drawn and entering a next specification, and stopping untie the wire rod reaches the finished-product dimension. According to the technical scheme, based on the real demands on the discharge tube electrode, various factors influencing 4J42 plasticity and rolling yield during production are researched and found, and the defects that 4J42 is bad in plasticity, low in rolling yield and the like in the subsequent processing process are solved by improving the 4J42 production technology.

Owner:丹阳市凯鑫合金材料有限公司

Steel for stamping die and method of manufacture

ActiveCN101311289AReasonable chemical composition ratioReduce billet costTemperature control deviceHeat treatment process controlPunchingChemical composition

The invention discloses steel used for punching die and a manufacturing method thereof. The weight percentages of the chemical composition of the steel are as follows: C, 0.35 to 0.40 wt percent; Mn, 0.30 to 0.60 wt percent; Cr, 4.70 to 5.50 wt percent; Si, 0.30 to 0.50 wt percent; Mo, 3.00 to 4.00 wt percent; V, 0.40 to 0.70 wt percent; Cu, less than or equal to 0.30 wt percent; Ni, less than or equal to 0.30 wt percent; P, less than or equal to 0.020 wt percent; S, less than or equal to 0.015 wt percent; the rest, Fe and inevitable impurity elements. The manufacturing method mainly comprises the following steps: 1) casting of ingots; 2) heating the ingots in a blooming mill furnace and carrying out heat preservation for three to five hours; 3) rolling and forging into products. The steel used for punching die produced by the invention has the advantages of improving performance indexes significantly, lowering production cost and improving the economic benefit of the products.

Owner:宝武特种冶金有限公司

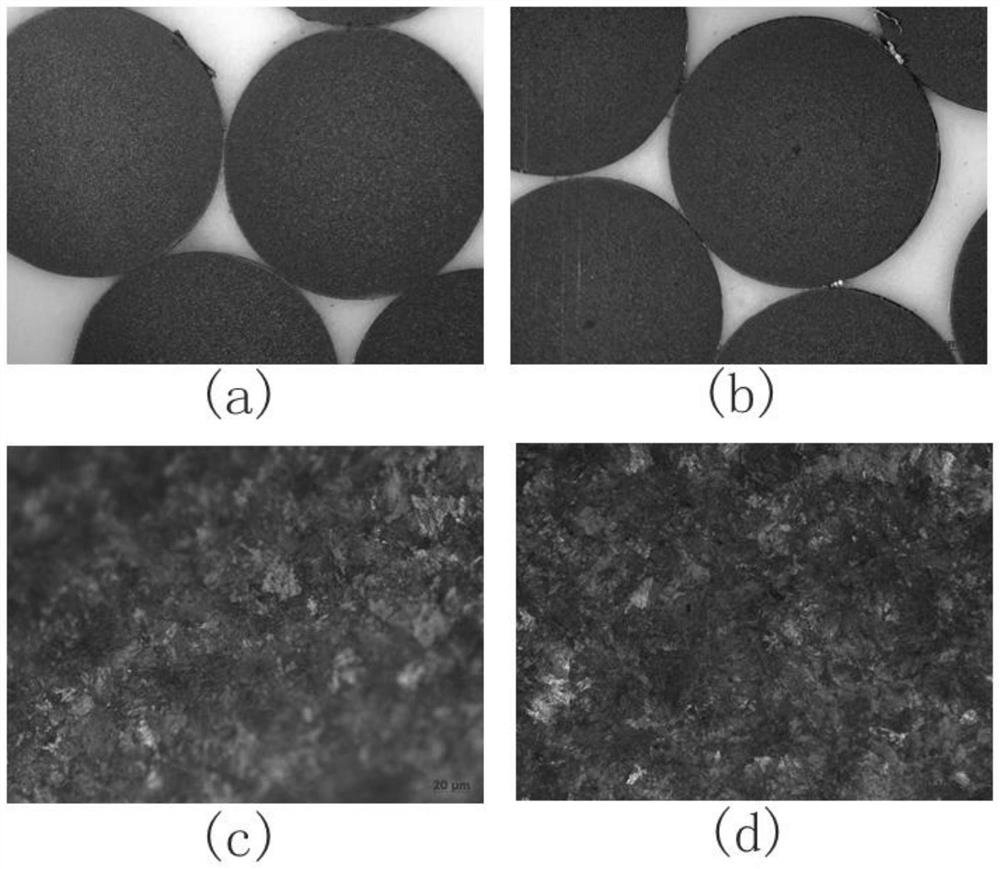

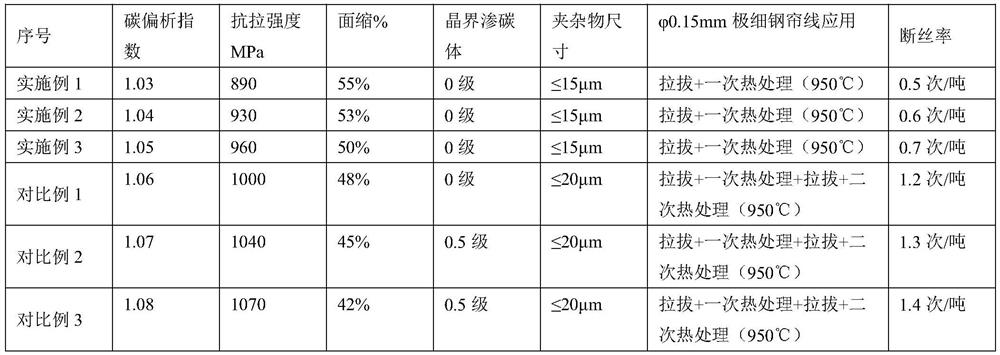

Steel wire rod for superfine steel cord subjected to heat reduction treatment and production process of steel wire rod

The steel wire rod comprises the following components in percentage by mass: 0.55 to 0.65 percent of C, 0.40 to 0.60 percent of Mn, 0.15 to 0.30 percent of Si, less than or equal to 0.015 percent of P, less than or equal to 0.010 percent of S, less than or equal to 0.05 percent of Cr, less than or equal to 0.05 percent of Ni, less than or equal to 0.05 percent of Cu, less than or equal to 0.03 percent of Mo, less than or equal to 0.0020 percent of Al, less than or equal to 0.0010 percent of Ti, less than or equal to 0.0020 percent of [O], less than or equal to 0.0050 percent of [N] and the balance of Fe and inevitable impurities. Special molten iron for low-titanium tire cord steel and special silicon iron for low-aluminum and low-titanium are adopted, and the process route of variable slag, constant pulling speed, low-superheat-degree pouring, forced cooling and low-strength controlled cooling is adopted, so that the dimensional precision of the wire rod reaches C-grade precision, the carbon segregation index of a continuous casting billet is within 1.07, the grain boundary cementite of the wire rod is 0 grade, and the maximum width of longitudinal inclusions of the wire rod is below 15 microns; the tensile strength of the steel wire rod is reduced, the percentage reduction of area of the steel wire rod is improved, the steel wire rod has excellent drawing performance, one-time heat treatment can be reduced when the steel wire rod is used for producing the superfine steel cord, carbon emission is reduced, the production efficiency is greatly improved, and the production cost is reduced.

Owner:JIANGSU YONGGANG GROUP CO LTD

4J42 alloy wire for discharge tube electrode and production method thereof

The invention discloses a 4J42 alloy wire for a discharge tube electrode and a production method thereof. The production method comprises the following steps that 4J42 raw material is put into a vacuum furnace for steelmaking, and an ingot is obtained; forging and cogging are conducted, and a wire rod is formed through hot rolling; acid dipping treatment is conducted on the hot-rolled wire rod; polishing and trimming are conducted after acid dipping, and first-time drawing is conducted; annealing treatment is conducted on a semi-finished product which is subjected to first-time drawing; acid dipping and coping are conducted on the semi-finished product which is subjected to the annealing treatment; second-time drawing is conducted when it is determined that cracks do not exist; heat treatment annealing is conducted on the drawn wire rod which is subjected to second-time drawing; the surface conditions of the wire rod are checked again, coarse wire fine drawing is conducted, and heat treatment is conducted once every time a coarse wire is downwards drawn a specification till the size of a finished product is reached. According to the 4J42 alloy wire for the discharge tube electrode and the production method thereof, all factors which affect the plasticity and the yield of 4J42 in the production process are researched and found according to the actual demands of the electrode of a discharge tube, and the defects of pool plasticity and low yield which occur in subsequent machining are overcome by improving the 4J42 production technology process.

Owner:丹阳市凯鑫合金材料有限公司

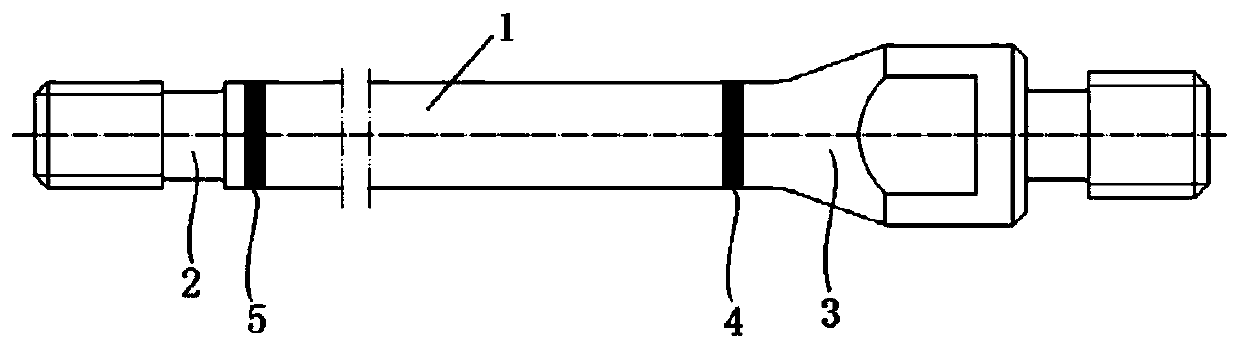

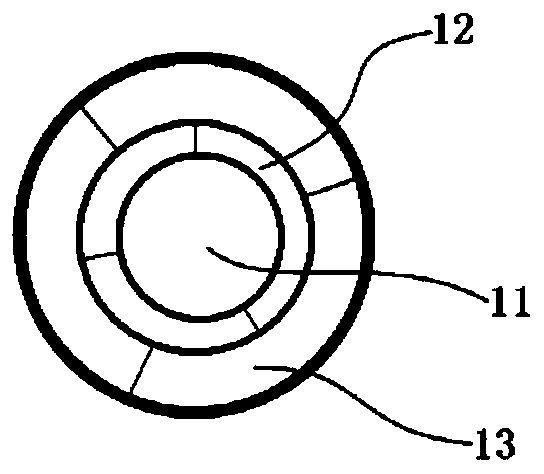

Anti-fatigue multilayer steel smooth sucker rod and processing process thereof

ActiveCN109798075AImprove bending resistanceImprove fatigue resistanceDrilling rodsDrilling casingsStress conditionsPerformance index

An anti-fatigue multilayer steel smooth sucker rod comprises an upsetting end, a rod body and a closed end. The rod body is positioned between the upsetting end and the closed end and comprises a solid steel mandrel and a tubular outer layer, the tubular outer layer at least comprises a first outer layer and a second outer layer, and the tubular outer layer is formed by arc steel strips. A coatingconcept is introduced to the steel smooth sucker rod without a coating, and bending resistance and fatigue resistance of the smooth sucker rod are remarkably improved by the multilayer tubular shelland sheeted structure. By a progressive structure of mechanical performance indexes including strength, plasticity and the like, high adaptability to deformation characteristics of the smooth sucker rod under complicated alternating stress is realized, complicated stress conditions of the smooth sucker rod are well met, and oilfield application and popularization are benefited.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Heat treatment method of high-strength and high-flexibility 7055 aluminum alloy

The invention discloses a heat treatment method of a high-strength and high-flexibility 7055 aluminum alloy. The heat treatment method comprises the steps of double-stage solid solution and T6 manual aging in sequence; after the T6 manual aging step is finished, the high-temperature destressed aging is performed, that is, the insulation is performed by 8-10 hours at 140-150 DEG C; the double-stage solid solution step is to heat a product from the room temperature to 445-455 DEG C along with a furnace for insulation by 0.5-4 hours, to heat the product to 465-480 DEG C by 0.5 hour for insulation 0.5-4 hours and to quench the product at a water temperature of 40-50 DEG C; and the T6 manual aging step is to heat the product from the room temperature to 115-125 DEG C along with the furnace for insulation by 20-26 hours. The heat treatmeetn method maintains higher material strength level, can efficiently reduce residual stress of a sprayed 7055 aluminum alloy product, and meanwhile, improves comprehensive performances of the product. The heat treatment method solves the cracking problem of the product in subsequent machining process, reduces the machining deformation of the product, and improves the size precision.

Owner:JIANGSU HAORAN SPRAY FORMING ALLOY

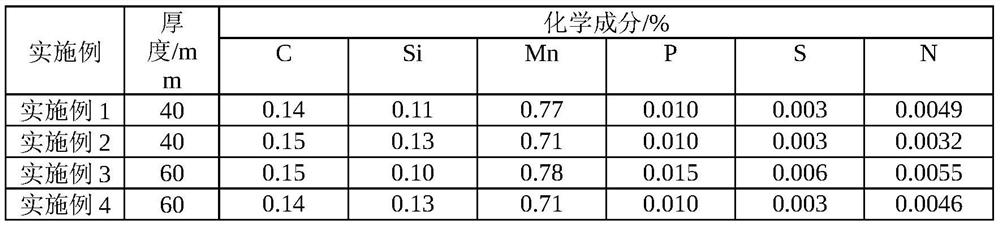

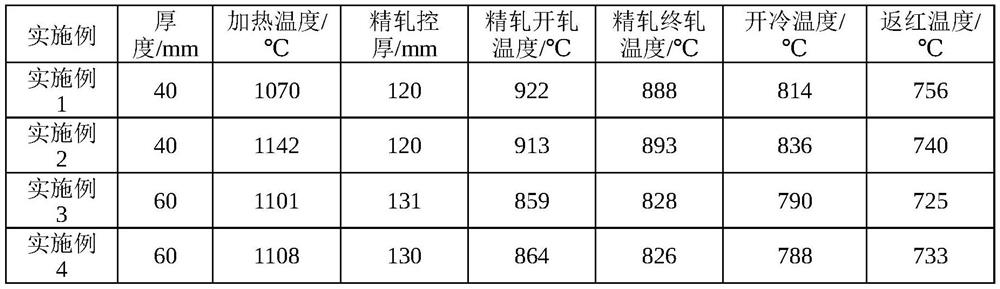

Resource-saving type 290 MPa-grade steel plate for building anti-seismic energy dissipation structure and manufacturing and application of steel plate

ActiveCN113444980AImprove performanceHigh yield strengthProcess efficiency improvementMechanical engineeringSeismic energy

The invention belongs to the technical field of metallurgy, and particularly discloses a resource-saving type 290 MPa-grade steel plate for a building anti-seismic energy dissipation structure and manufacturing and application of the steel plate. The steel plate comprises, by weight, 0.13%-0.18% of C, smaller than or equal to 0.15% of Si, 0.60%-0.80% of Mn, smaller than or equal to 0.030% of P, smaller than or equal to 0.020% of S, smaller than or equal to 0.0080% of N and the balance Fe and inevitable impurities. According to the 290 MPa-grade steel plate for the building anti-seismic energy dissipation structure, component design is economical and reasonable, the comprehensive mechanical performance is excellent, the alloy element content is low, resources can be effectively saved, and the cost is reduced.

Owner:CHONGQING IRON & STEEL CO LTD

High-temperature and low-temperature resisting ferrite material for cold heading bolt and production technology of high-temperature and low-temperature resisting ferrite material

InactiveCN110016620AImprove plastic indexHigh elongationFurnace typesHeat treatment furnacesHardnessYield ratio

The invention provides a high-temperature and low-temperature resisting ferrite material for a cold heading bolt and a production technology of the high-temperature and low-temperature resisting ferrite material. The high-temperature and low-temperature resisting ferrite material comprises following components including, by mass percent, 0.17 wt%-0.25 wt% of C, 0.40 wt%-0.80 wt% of Mn, larger than0 and smaller than or equal to 0.4 wt% of Si, larger than 0 and smaller than or equal to 0.025 wt% of P, larger than 0 and smaller than or equal to 0.025 wt% of S, 1.20 wt%-1.50 wt% of Cr, larger than 0 and smaller than or equal to 0.60 wt% of Ni, 0.55 wt%-0.80 wt% of Mo, larger than 0 and smaller than or equal to 0.030 wt% of Al, larger than 0 and smaller than or equal to 0.030 wt% of V and thebalance Fe and inevitable impurities. The ferrite material has high plasticity indexes, elongation rate and percentage reduction of area, during cold plastic deformation, the material deformation resistance is small, the machining hardening rate is low, the material yield ratio is low, and hardness is proper.

Owner:苏州誉高紧固系统有限公司

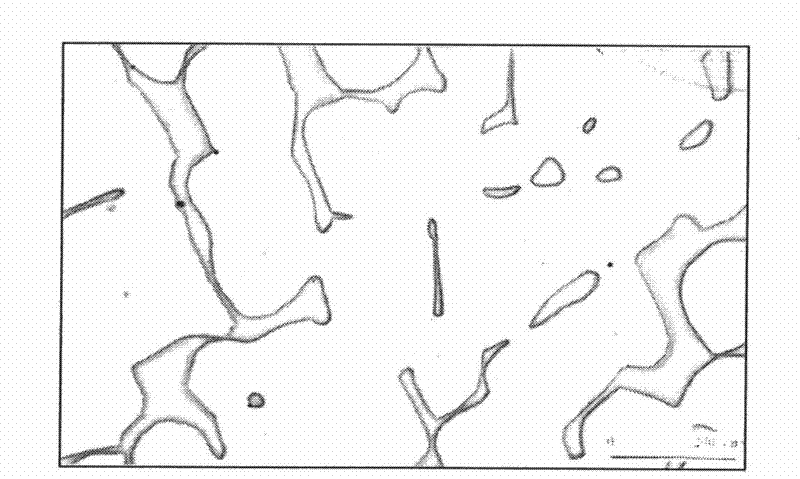

Tellurium-containing medium-carbon high-sulfur free-cutting steel, wire rod and production method of wire rod

The invention discloses tellurium-containing medium-carbon high-sulfur free-cutting steel, a wire rod and a production method of the wire rod, and belongs to the technical field of free-cutting steel. The tellurium-containing medium-carbon high-sulfur free-cutting steel comprises the following chemical components in percentage by mass: 0.40 to 0.50 percent of C, 0.10 to 0.4 percent of Si, 1.3 to 1.7 percent of Mn, 0 to 0.025 percent of P, 0.24 to 0.33 percent of S, 0.001 to 0.008 percent of Al, 0.001 to 0.005 percent of Pb, 0.005 to 0.03 percent of Te, 0.0001 to 0.0005 percent of Ca and the balance of Fe and inevitable impurities, wherein the mass percentages of Mn, S and Te meet the following relational expressions: Mn / Te: 43-300, and Te / S: 0.015-0.125. The preparation method of the free-cutting steel comprises the steps that after tellurium modification treatment and RH treatment are finished, 1.45-8 m / t of tellurium-containing cored wires are fed into molten steel, the wire feeding speed is 166-189 m / min, and the wire feeding angle is 75-105 degrees. The inclusions which are uniformly dispersed and distributed in the free-cutting steel mainly comprise type I MnS, type I MnTe and composite inclusions of the type I MnS and the type I MnTe, the material plasticity is improved, the problem that cracking and the like easily occur in the machining processes of continuous casting, hot rolling, follow-up drawing, hot forging, cutting and the like is solved, the percentage elongation after fracture and the percentage reduction of area are increased, and the cutting performance is improved.

Owner:SGIS SONGSHAN CO LTD

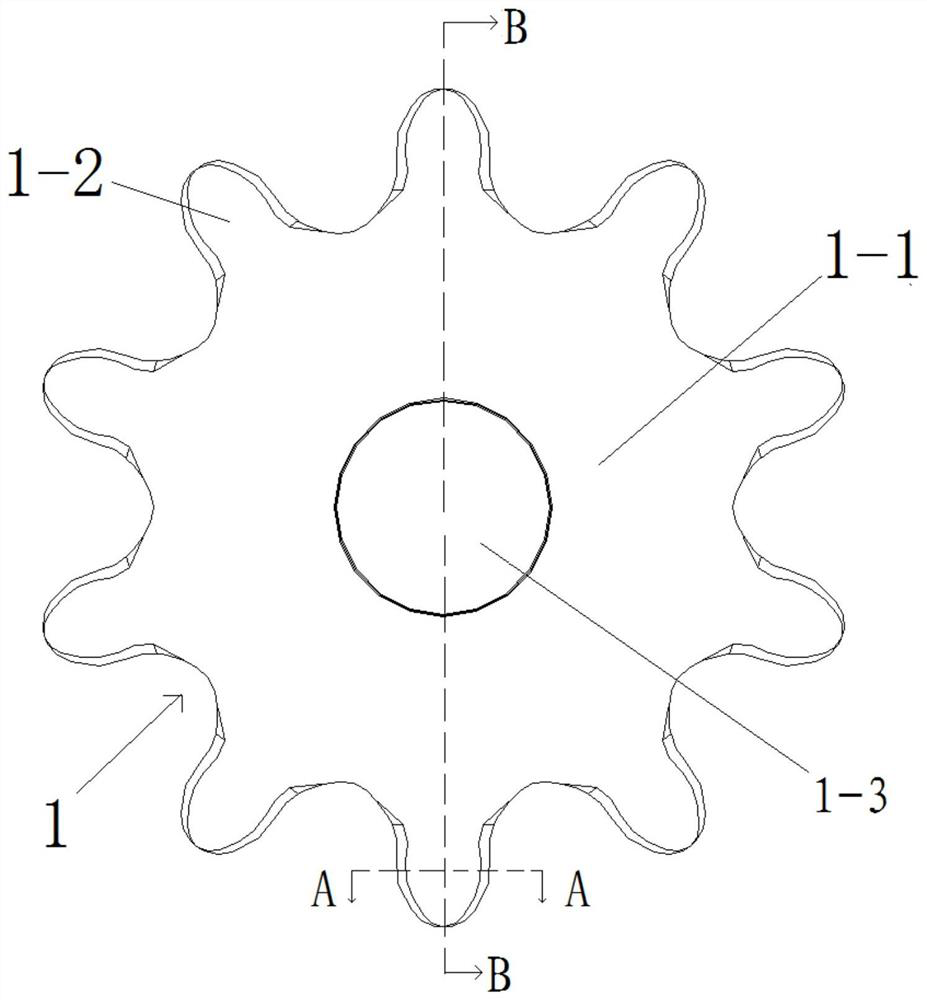

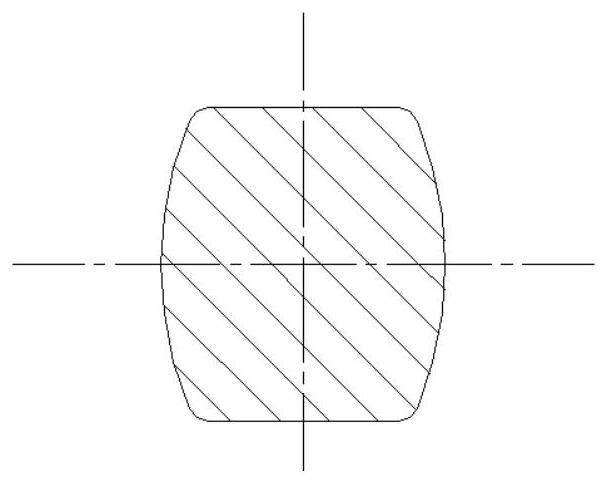

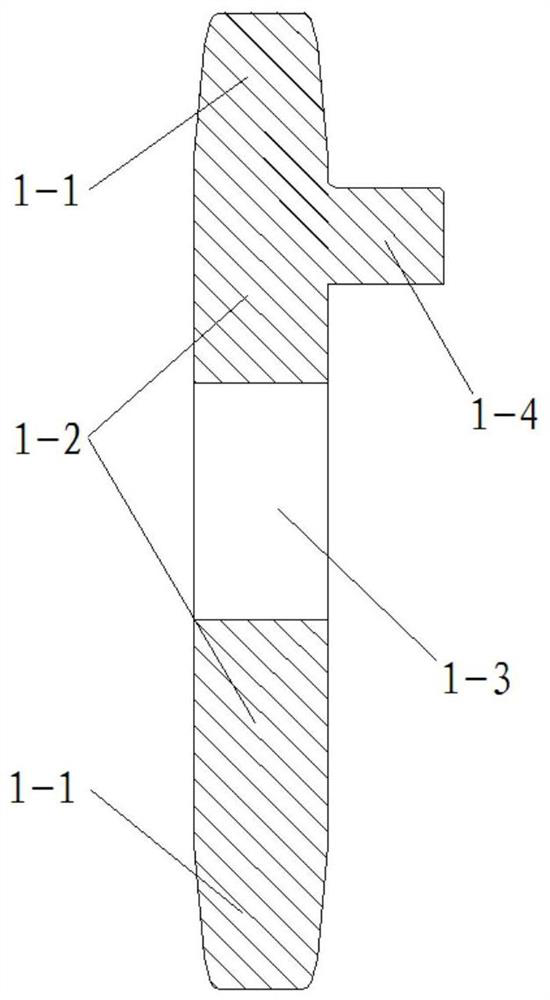

Drum-shaped toothed rail wheel for coal mining machine and preparing method of drum-shaped toothed rail wheel

ActiveCN112065952AExtended service lifeGuaranteed uptimePortable liftingSolid state diffusion coatingMachineAlloy steel

The invention discloses a drum-shaped toothed rail wheel for a coal mining machine. The drum-shaped toothed rail wheel comprises a toothed rail wheel main body and a plurality of drum-shaped teeth, wherein the tooth surface of each drum-shaped tooth smoothly transitions into an arc drum-shaped curved surface from the tooth surface center line to the two sides so as to form a drum-shaped tooth surface; a bearing matching through hole is formed in the center of the toothed rail wheel main body; and a plurality of connecting keys are arranged on the surface of the toothed rail wheel main body. The invention also discloses a preparing method of the drum-shaped toothed rail wheel for the coal mining machine, and the drum-shaped toothed rail wheel is obtained by processing 18Cr2Ni4WA alloy steelby means of the method. According to the drum-shaped toothed rail wheel for the coal mining machine and the preparing method of the drum-shaped toothed rail wheel, the meshing contact area between the drum-shaped toothed rail wheel and a pin row is increased through the drum-shaped tooth surfaces, the contact stress between the drum-shaped toothed rail wheel and the pin row is reduced, the service life of the drum-shaped toothed rail wheel is prolonged, and the drum-shaped toothed rail wheel has the advantages of excellent eccentric load resistance, stable transmission and strong bearing capacity; and through refining, forging, heat treatment, carburization and shot blasting, the tensile strength, bending strength, contact strength and toughness of the drum-shaped toothed rail wheel are improved.

Owner:XIAN COAL MINING MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com