Manufacturing technique and device for improved bainite nodular cast iron composite roller provided with forged steel roller neck

A technology of bainitic nodular ink and composite roll, which is applied in the field of metal pressure processing, can solve the problems of rapid decrease in hardness and wear resistance, poor thermal fatigue resistance, low thermal fatigue resistance, etc., and achieve good red hardness and high temperature resistance. Abrasiveness, good mechanical properties, and excellent crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

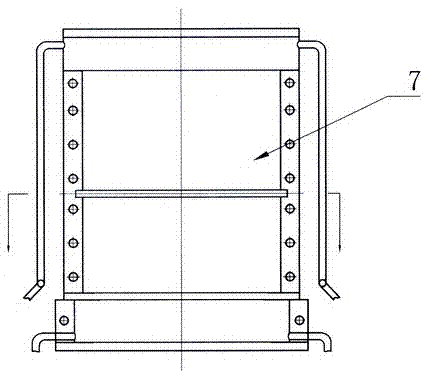

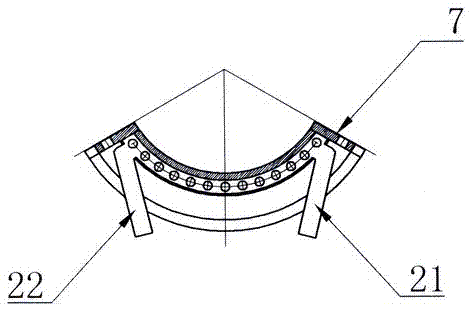

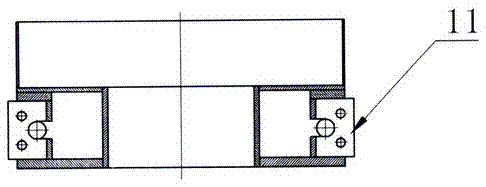

[0067] Example 1: In figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 In the equipment, the equipment has a gantry-type regional directional solidification lifting device 16, a lifting platform 17 is installed on the gantry-type regional directional solidification lifting device 6, and an electromagnetic induction heater 8 is installed on the lifting platform 17, which is rotated and lifted by a lifting motor 14. The screw 15 or hydraulic equipment drives the lifting platform 17 to move up and down at a set speed. An electromagnetic induction power supply control cabinet 19 is installed on the side of the gantry-type area directional solidification lifting equipment 16, and the two output ends of the electromagnetic induction power control cabinet 19 are cooled by water The cable 20 is connected to the two ends of the electromagnetic induction heater 8. There is a base support at the lower part of the gantry type area directional solidification lifting equipmen...

Embodiment 2

[0087] Example 2: In figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 In the equipment, the equipment has a gantry-type regional directional solidification lifting device 16, a lifting platform 17 is installed on the gantry-type regional directional solidification lifting device 6, and an electromagnetic induction heater 8 is installed on the lifting platform 17, which is rotated and lifted by a lifting motor 14. The screw 15 or hydraulic equipment drives the lifting platform 17 to move up and down at a set speed. An electromagnetic induction power supply control cabinet 19 is installed on the side of the gantry-type area directional solidification lifting equipment 16, and the two output ends of the electromagnetic induction power control cabinet 19 are cooled by water The cable 20 is connected to the two ends of the electromagnetic induction heater 8. There is a base support at the lower part of the gantry type area directional solidification lifting equipmen...

Embodiment 3

[0106] Example 3: In figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 In the equipment, the equipment has a gantry-type regional directional solidification lifting device 16, a lifting platform 17 is installed on the gantry-type regional directional solidification lifting device 6, and an electromagnetic induction heater 8 is installed on the lifting platform 17, which is rotated and lifted by a lifting motor 14. The screw 15 or hydraulic equipment drives the lifting platform 17 to move up and down at a set speed. An electromagnetic induction power supply control cabinet 19 is installed on the side of the gantry-type area directional solidification lifting equipment 16, and the two output ends of the electromagnetic induction power control cabinet 19 are cooled by water The cable 20 is connected to the two ends of the electromagnetic induction heater 8. There is a base support at the lower part of the gantry type area directional solidification lifting equipment 16, a supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com