Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59 results about "Matrix strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Brake pad friction plate manufactured by powder metallurgy and used for high-speed train and preparation process of brake pad friction plate

InactiveCN102605209AGuaranteed densificationImprove wear resistanceFriction liningMatrix strengthSilicon dioxide

The invention discloses a brake pad friction plate manufactured by powder metallurgy and used for a high-speed train and a preparation process of the brake pad friction plate. The brake pad friction plate comprises the following components in percentage by weight: 65-70% of copper, 3-5% of zinc, 8-10% of iron, 5-8% of graphite, 2-6% of lead powder, 1-3% silicon dioxide and 1-4% of silicon carbide. The preparation process comprises the following steps: (1) preprocessing raw materials: grinding into powder, and baking; (2) preparing and mixing the materials; (3) carrying out compression moulding: compressing a mixture into a pressed shape; (4) sintering: heating the pressed shape to 800-900 DEG C at a constant pressure, holding the temperature, controlling a heat preservation pressure to be 1.3-2.0MPa, and feeding hydrogen to protect; (5) cooling: naturally cooling the pressed shape to below 100 DEG C in the hydrogen, and discharging; and (6) carrying out mechanical processing. By the brake pad friction plate provided by the invention, a friction component is led to be alloyed and diversified, so that the wear-resisting and heat-resisting performances of the friction plate are improved, therefore, not only the matrix strength of the materials is ensured, but also the friction plate has good thermophysical properties and stable friction properties, and the service life and the brake performance of the brake pad can be remarkably improved.

Owner:锦州捷通铁路机械股份有限公司

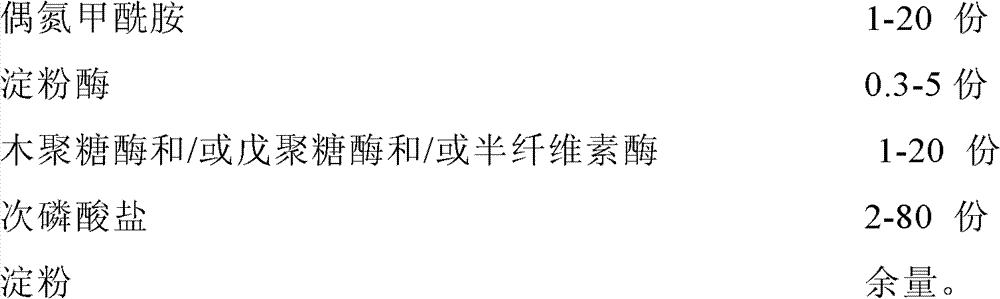

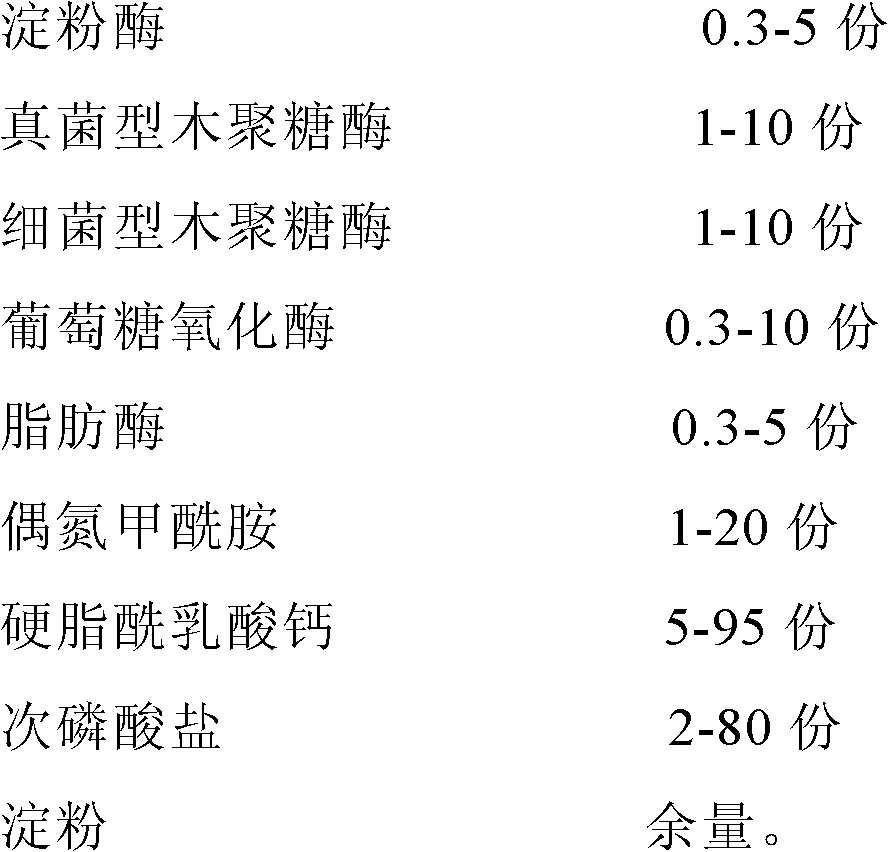

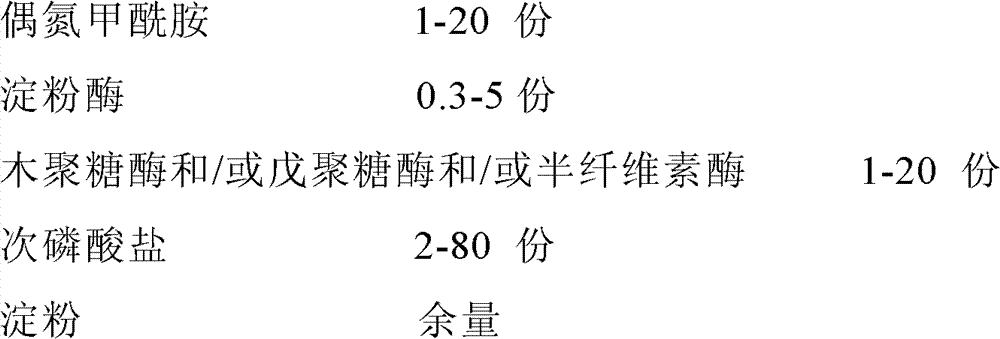

Flour improver or flour product improver

ActiveCN102763697AImprove finenessIncrease bread volumeDough treatmentConfectioneryMatrix strengthFermentation

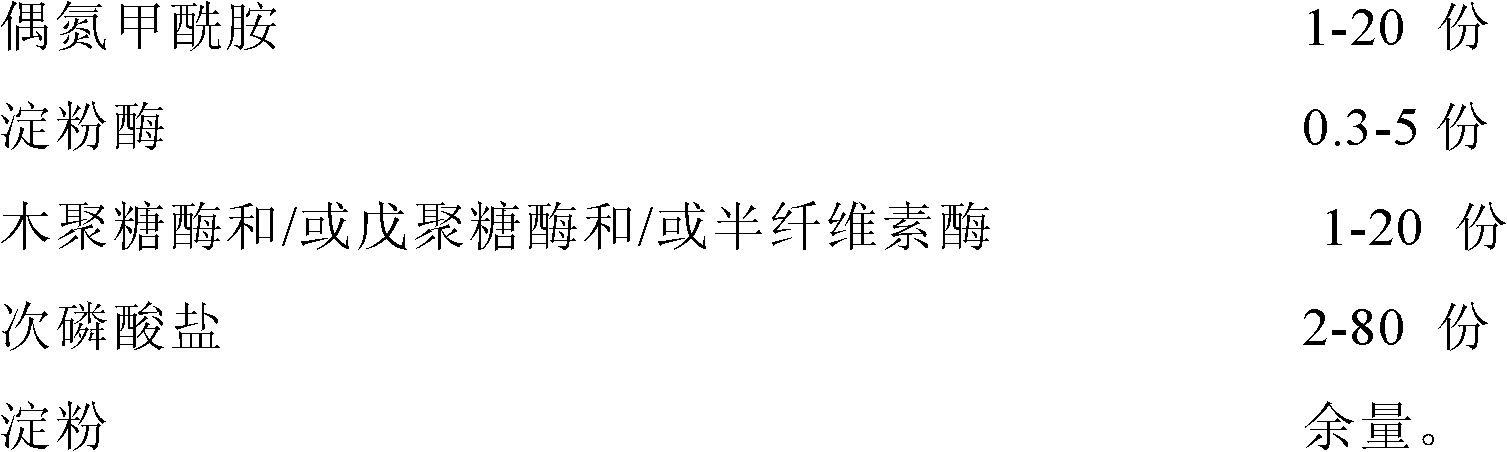

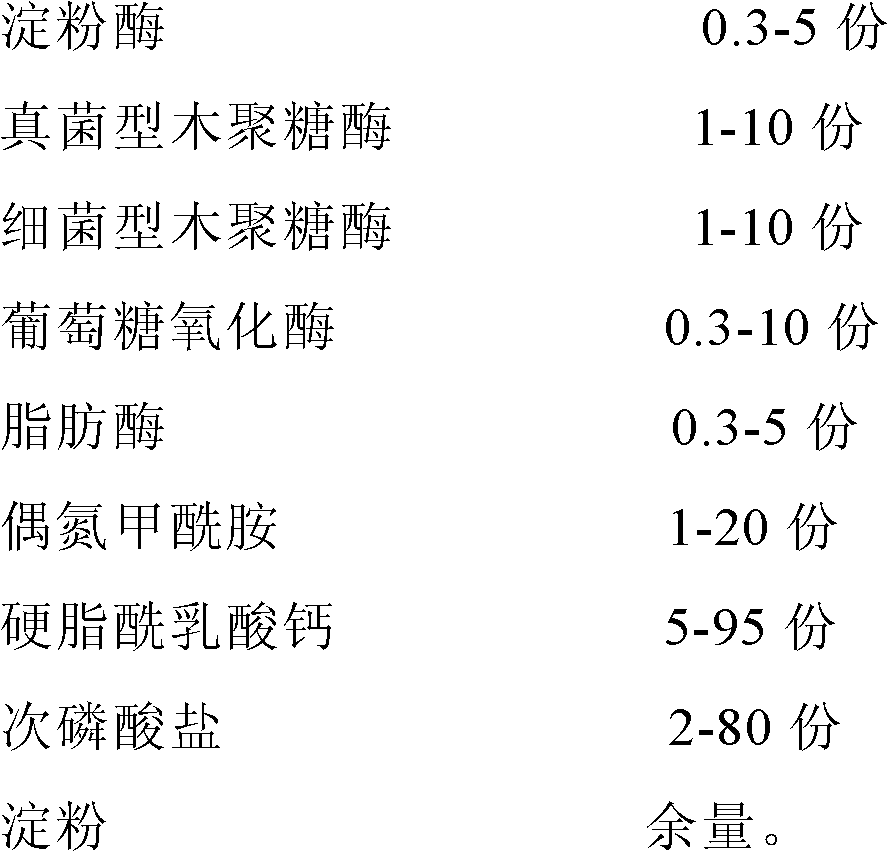

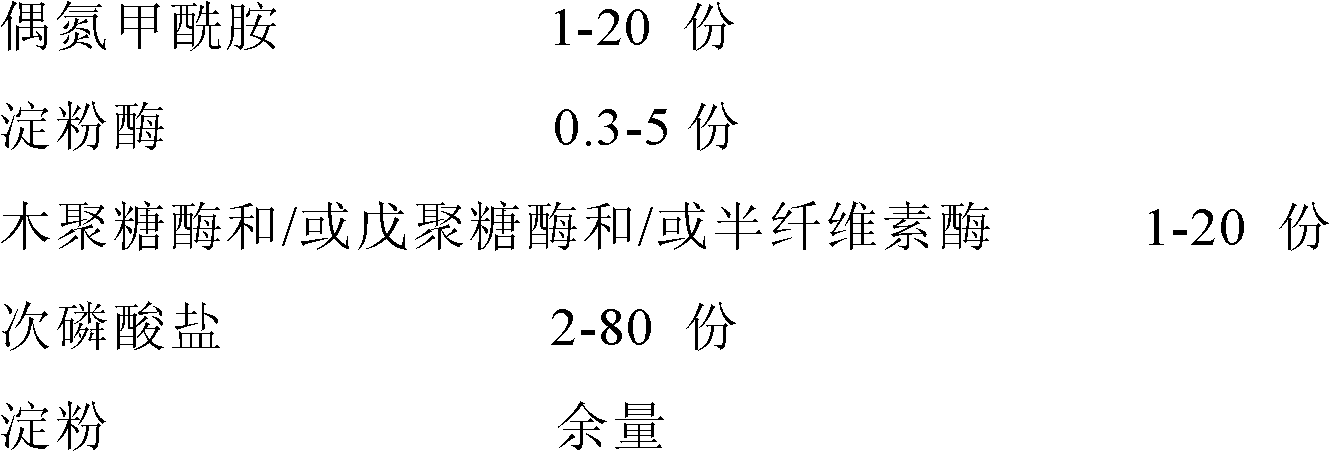

The invention discloses a flour improver or flour product improver, wherein the flour improver or flour product improver contains hypophosphite. The invention also discloses flour or flour products containing the flour improver or flour product improver provided by the invention. Compared with the flour improver or flour product improver containing no hypophosphite, the gluten matrix strength of dough using the improver provided by the invention is high, the gluten quality is improved obviously, the gas holdup property is good; in the later operation period, the dough turns to be dry and comfortable, elastic and resistant to last fermentation; produced bread is large in size and expands quickly in an oven, the stiffness is high, the texture is delicate, and both the taste and the softness are improved obviously.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

Dispersion-strengthened copper-based powder metallurgy brake pad and preparation for same

The invention discloses preparation for the brake pad of a high-speed train via a powder metallurgy method and by taking dispersion-strengthened copper as a matrix material. According to the oxide dispersion-strengthened copper, a copper matrix is strengthened by oxide dispersion particles, and the dispersion-strengthened copper chooses dispersion-strengthened copper powder in which nanometre Al2O3 is in a ratio of 0.03-5% by weight; and the formula of the brake pad comprises 50-70wt% of dispersion-strengthened copper powder, 5-20wt% of Fe powder, 4-15wt% of (flaky) C powder, 1-10wt% of SiO2 powder, 1-7wt% of Al2O3 powder, 1-7wt% of Sn powder, 1-3wt% of Pb powder, and 1-10wt% of MoS2 powder. The dispersion-strengthened copper-based brake pad is obtained by uniformly mixing the powders in a ratio, moulding by cold-pressing, then performing pressure sintering with a steel backing. Compared with the traditional copper-based brake pad, the brake pad taking the dispersion-strengthened copper as a matrix is enhanced in matrix strength, high in thermal conductivity, good in stability, good in fatigue performance and wear resistance, and less in wear on dual discs.

Owner:UNIV OF SCI & TECH BEIJING

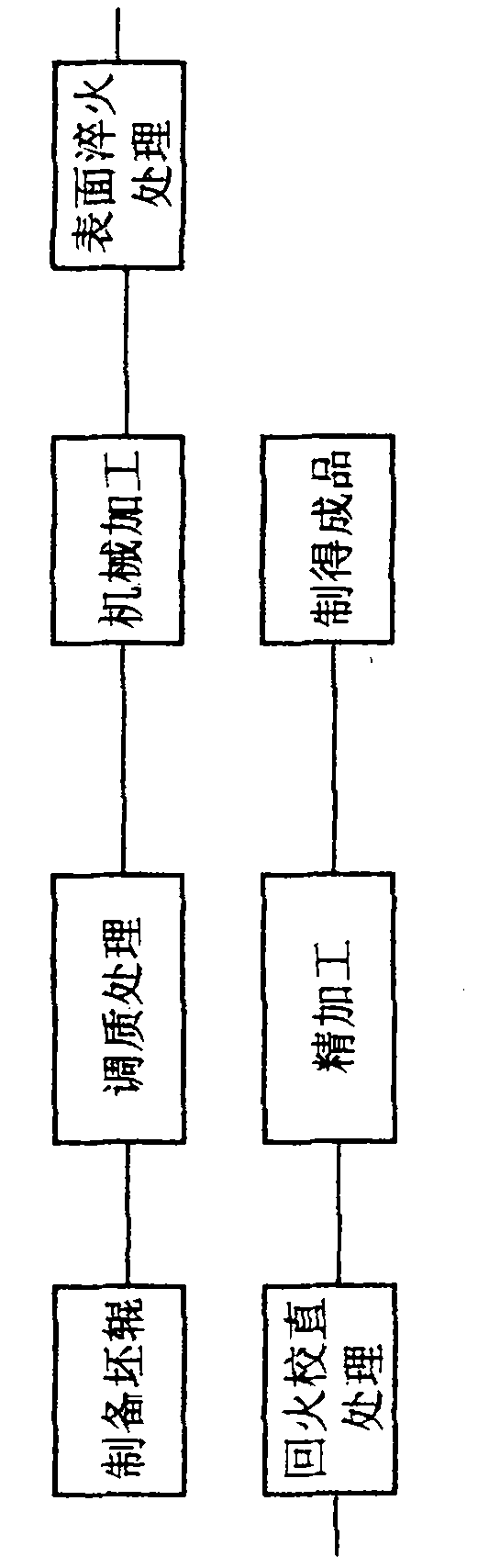

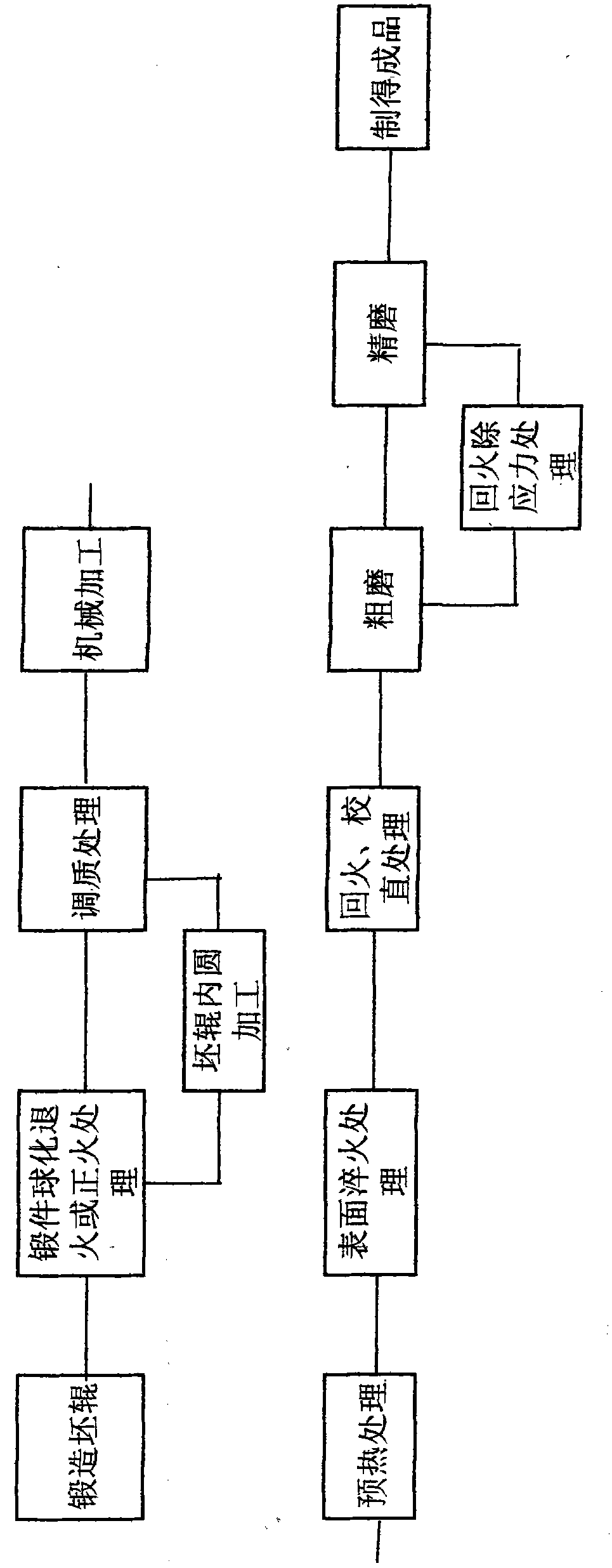

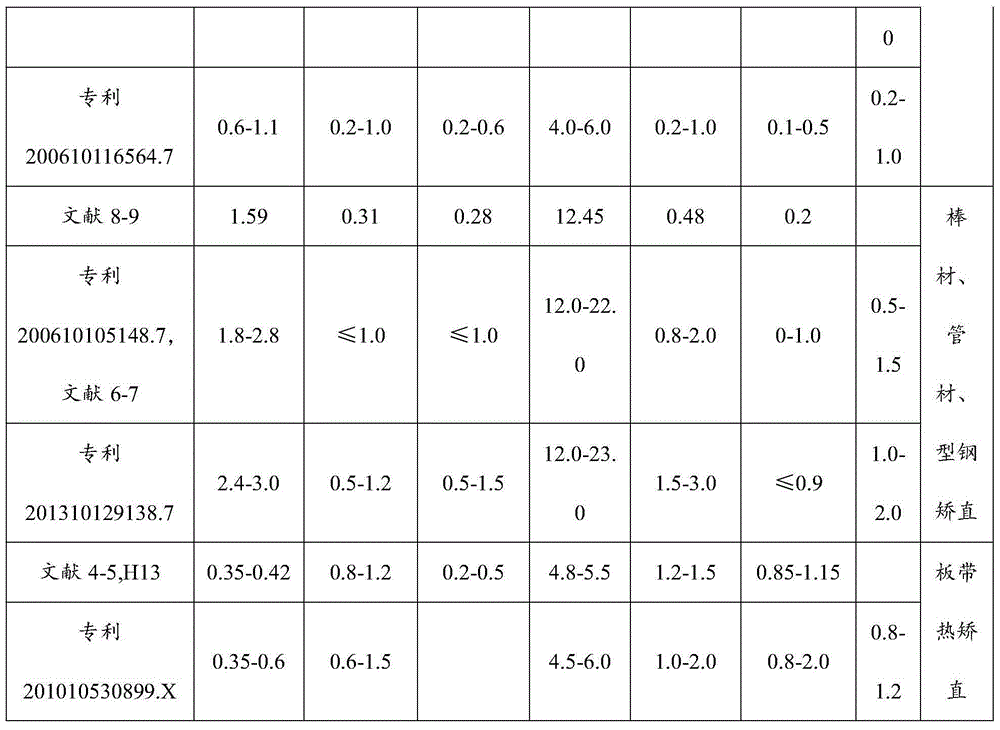

Hot rolling hot straightening roll suitable for thick steel plates with thickness of less than or equal to 60mm and preparation method thereof

InactiveCN102108469AImprove matrix strengthGood resistance to cold and heat fatigueFurnace typesHeat treatment furnacesSheet steelMatrix strength

The invention discloses a hot rolling hot straightening roll suitable for thick steel plates with thickness of less than or equal to 60mm and a preparation method thereof. The hot straightening roll comprises the following components in percentage by weight: 4.5 to 6.0 percent of Cr, 1.0 to 2.0 percent of Mo, 0.6 to 1.5 percent of Si, 0.8 to 1.2 percent of Ni, 0.8 to 2.0 percent of V, 0.35 to 0.6 percent of C, less than or equal to 0.02 percent of P, less than or equal to 0.01 percent of S, and the balance of Fe and inevitable impurities. The preparation method sequentially comprises the following steps of: preparing a blank roll; conditioning; machining; performing surface quenching treatment; annealing; and performing finish machining, wherein the surface quenching temperature is 1,130 to 1,170 DEG C; the annealing temperature is 520 to 580 DEG C and the annealing time is more than or equal to 10 hours; and during annealing, roll straightening treatment that pressure straightening is performed on high points through heavy objects is carried out. The hot straightening roll product has the characteristics of high matrix strength, high comprehensive performance, high surface hardness and wear resistance, high cold and hot fatigue resistance, and the like; and the preparation method has the characteristics of simplicity, convenience, reliability, low process cost, high quality of product and the like.

Owner:CHANGZHOU BAOLING HEAVY IND MACHINERY

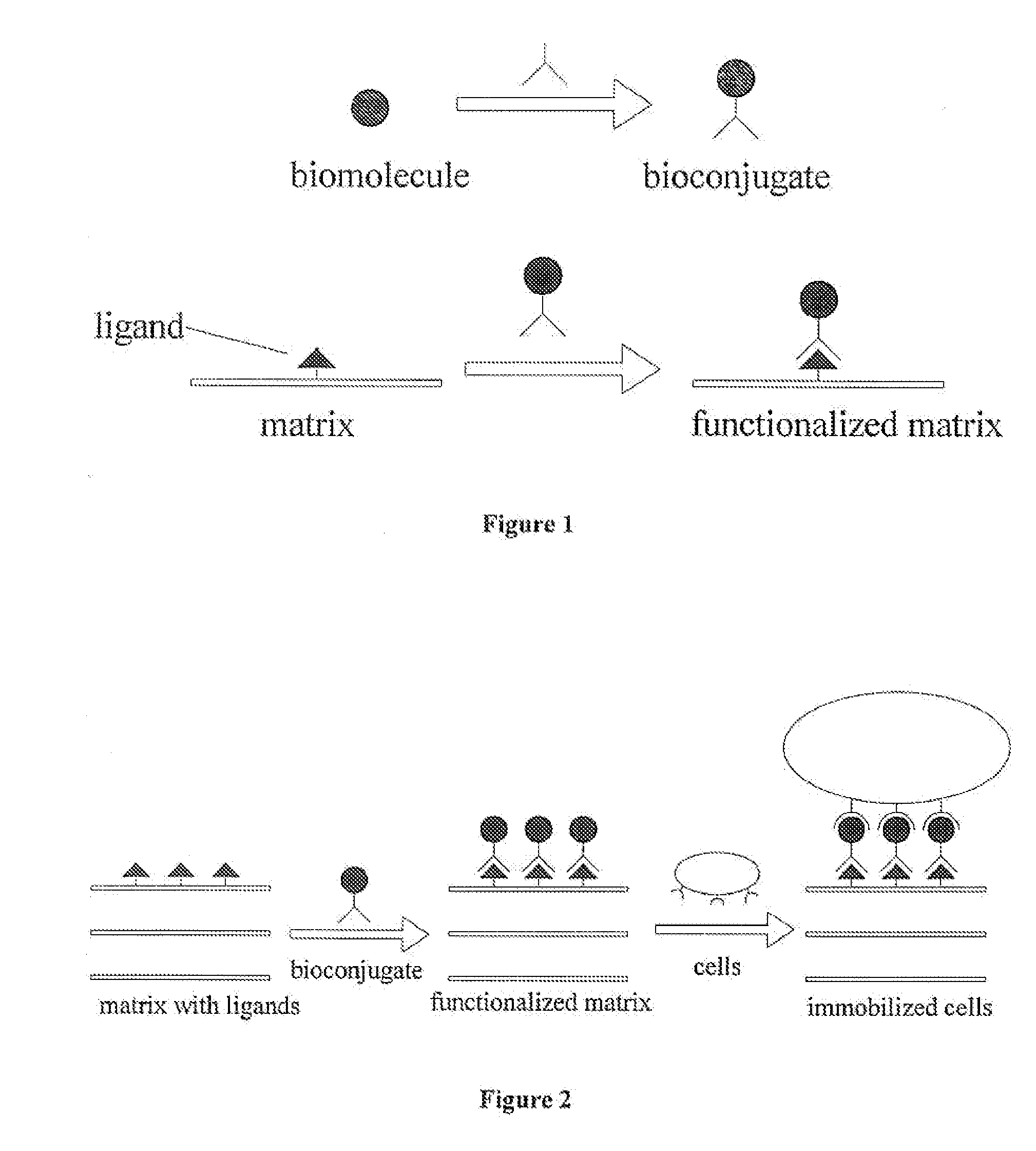

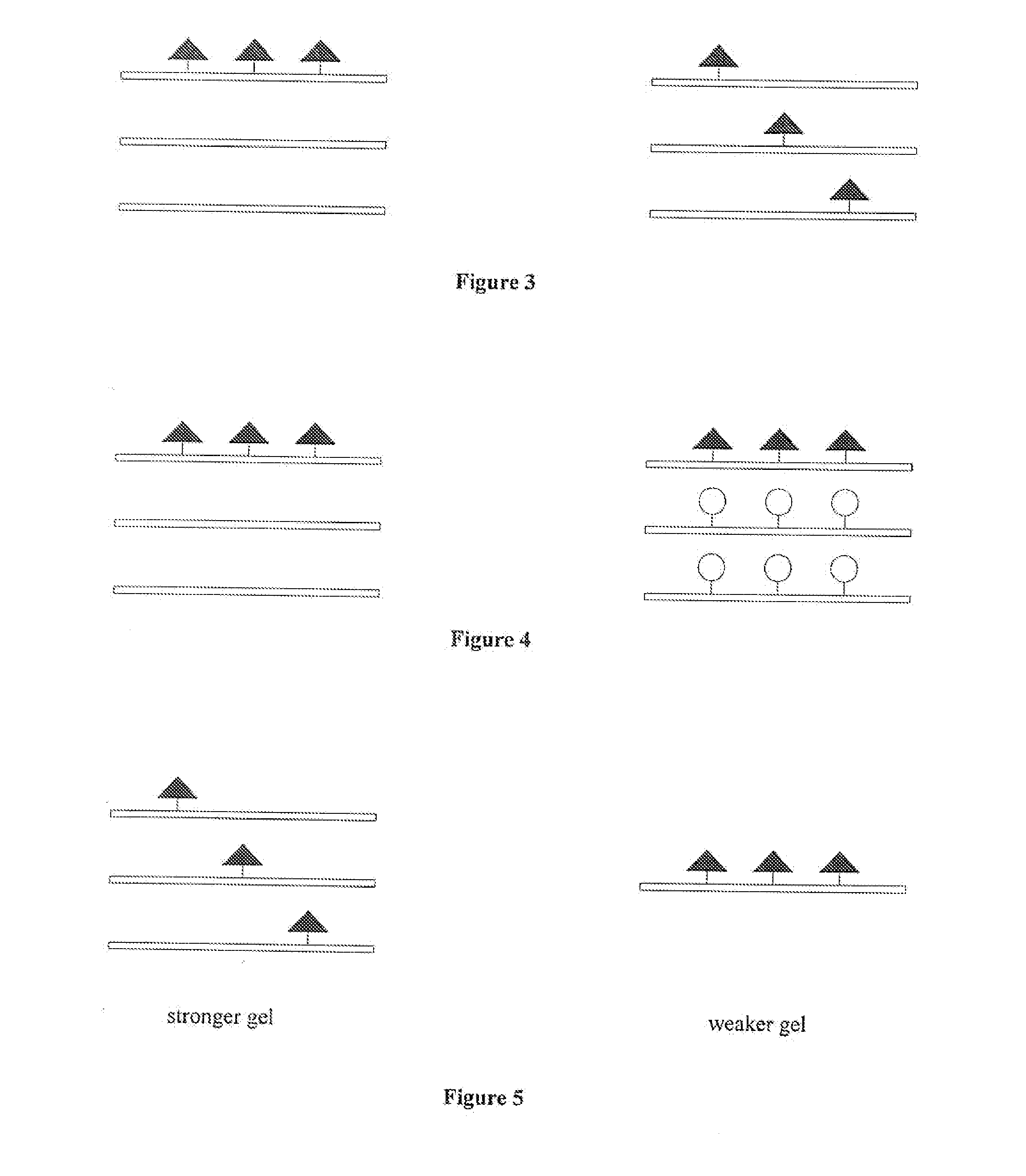

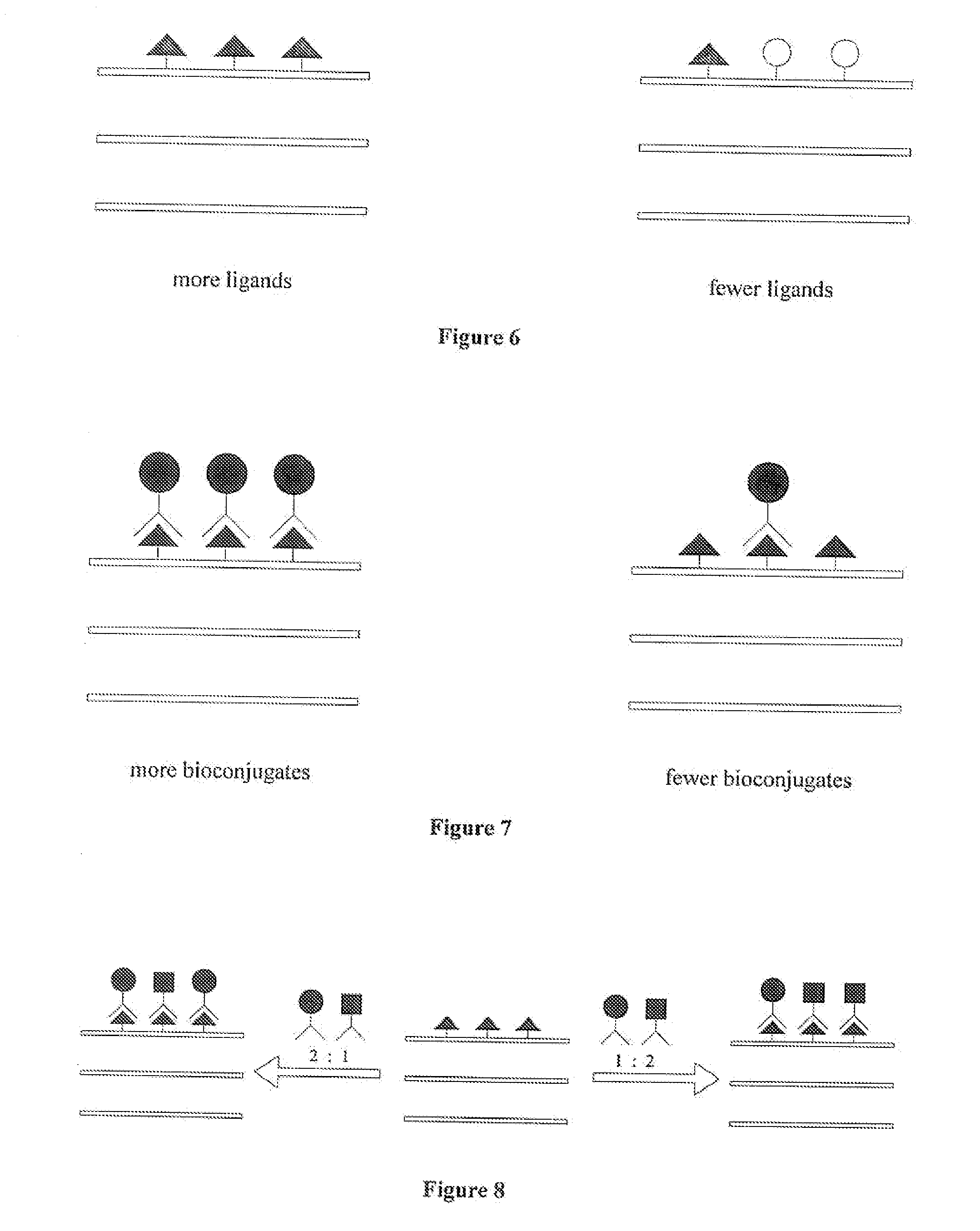

Engineered Biological Matrices

InactiveUS20070141105A1Improve mobilityPowder deliveryCell culture supports/coatingBoronic acidMatrix strength

Biocompatible matrices or implants on which one or more specific cell-interactive molecules (“biomolecules”) can be immobilized have been developed. The matrices allow for the independent control of ligand concentration and matrix strength. In one embodiment, the matrix or implant is modified with one or more moieties capable of complexing bioconjugates prepared from one or more biomolecules. Suitable moieties include phenyl boronic acid complexing agents, such as salicylhydroxamic acid, which can complex to one or more biomolecules containing one or more phenyl boronic acid moieties. The biomolecules may be anchored to the matrix via a spacer molecule, which may allow for greater mobility of the biomolecules in aqueous solution. In one embodiment, the matrix is a hydrogel material which has been doubly-derivatized, wherein ligand concentration and matrix strength can be independently controlled. The matrices and implants can be used in vivo and in vitro applications including diagnostics, biosensors, bioprocess engineering, tissue engineering, regeneration and repair, and drug delivery.

Owner:CAMBREX BIO SCI WALKERSVILLE

Preparation method of metal-matrix nanocomposite

ActiveCN108796251ALow tendency to hot tearHot tear suppressionAdditive manufacturing apparatusWelding/cutting media/materialsMaterials preparationMolten salt

The invention discloses a preparation method of a metal-matrix nanocomposite, and belongs to the field of metal material preparation. According to the preparation method of the metal-matrix nanocomposite, high-content and evenly distributed nano-reinforcement bodies are added into target metal through molten salt assisting, thus the hot-crack tendency of matrix metal is reduced and the forming property of the matrix metal is improved while the matrix structure is refined and matrix strength is improved. The prepared metal-matrix nanocomposite can be widely applied to the field of casting, welding and 3D printing.

Owner:迈特李新材料(深圳)有限公司

Preparation method of oriented conductive hydrogel fiber material

ActiveCN109750387AMake up for the lack of physical performanceImprove conductivityElectroconductive/antistatic filament manufactureFilament/thread formingMatrix strengthUltrasonic dispersion

The invention discloses an oriented conductive hydrogel fiber material and a preparation method thereof. The preparation method comprises the steps: firstly, conductive particle dispersion solutions with different concentrations are obtained through an ultrasonic dispersion method, and dispersed conductive particles are turned into an evenly dispersed state from a mutually agglomerated or wound state so as to meet the subsequent requirements of enhancing the matrix strength and conductivity; then the conductive particles are composited into an organic polymer solution capable of being gelifiedto form a composite electrospinning precursor solution meeting the electrospinning concentration and viscosity; and electrospinning is conducted through a liquid rotary receiving disc, and a polymercomposite conductive particle hydrogel fiber with an oriented micro-nanofiber structure is prepared. Different from the traditional design of hydrogel single physical factor introduction, the orientedmicro-nanofiber structure, sensitive variable conductivity and mechanical strength are simultaneously introduced into a hydrogel system, the hydrogel fiber material with excellent performance is prepared, and a new preparation technique is provided for material preparation of the fields such as biomedical stent materials, flexible electrode materials and biosensors.

Owner:UNIV OF SCI & TECH BEIJING

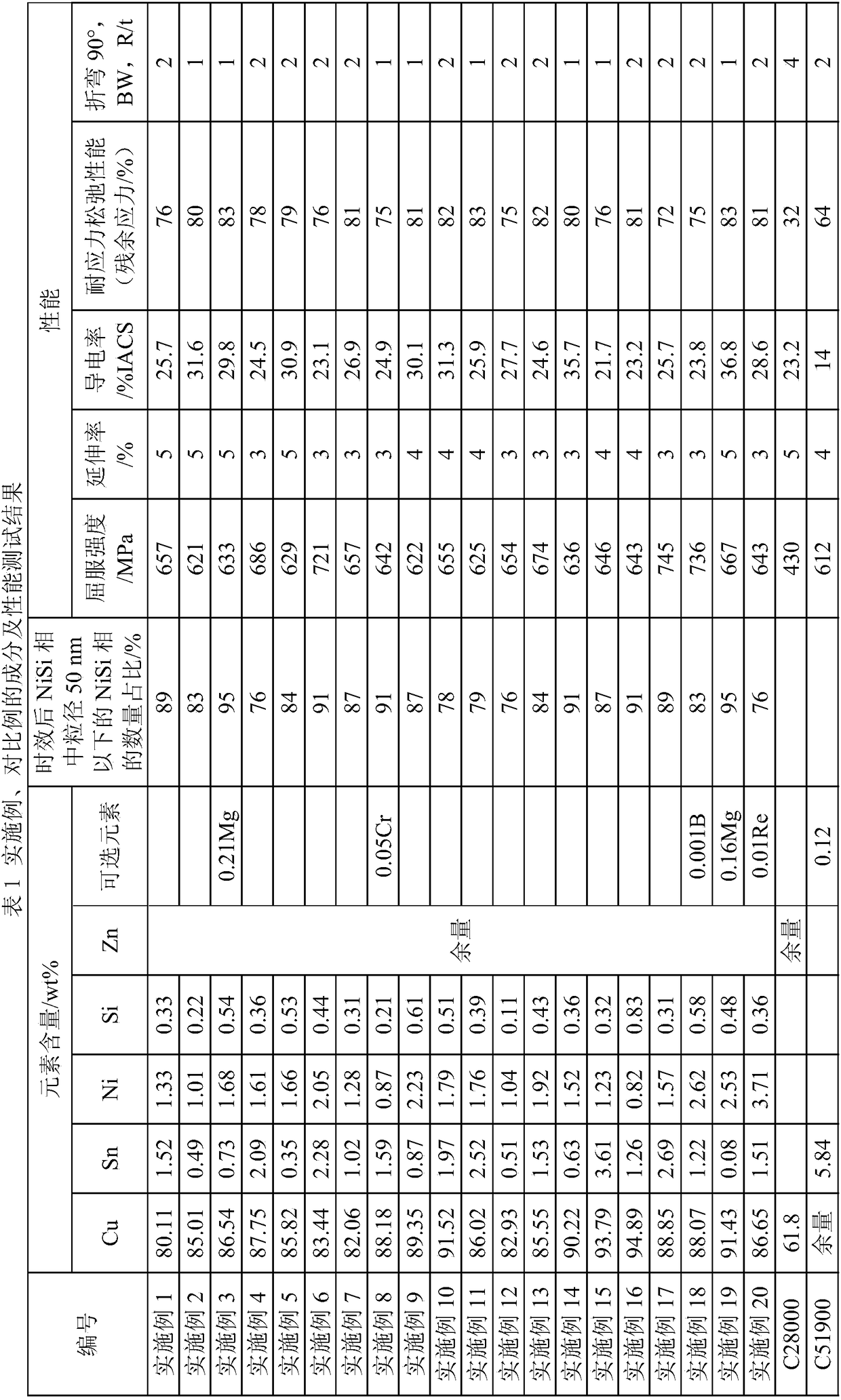

Precipitation-hardening copper alloy and application thereof

ActiveCN108285988AHigh strengthLittle effect on conductivityConductive materialMetal/alloy conductorsStress relaxationMatrix strength

The invention discloses a precipitation-hardening copper alloy which is prepared from the components in percentage by weight: 80 percent to 95 percent of Cu, 0.05 percent of to 4.0 percent of Sn, 0.01percent of to 3.0 percent of Ni, 0.01 to 1.0 percent of Si, and the balance Zn and inevitable impurities. According to the precipitation-hardening copper alloy provided by the invention, through solid solution strengthening and precipitation hardening, a combination performance of the alloy is improved, the matrix strength is improved, meanwhile, the influence on the conductivity of the alloy isless, a bending processing performance meets the requirement, and the alloy has a stress relaxation property as same as tin-phosphor bronze. The alloy provided by the invention has a better combination performance than C51900, is low in raw material cost, has remarkable advantages in welding and electroplating, can solve the utilization problem of multiple waste materials, and is widely applied toelectronic and electrical industry products such as connectors and connector assemblies.

Owner:NINGBO POWERWAY ALLOY MATERIAL

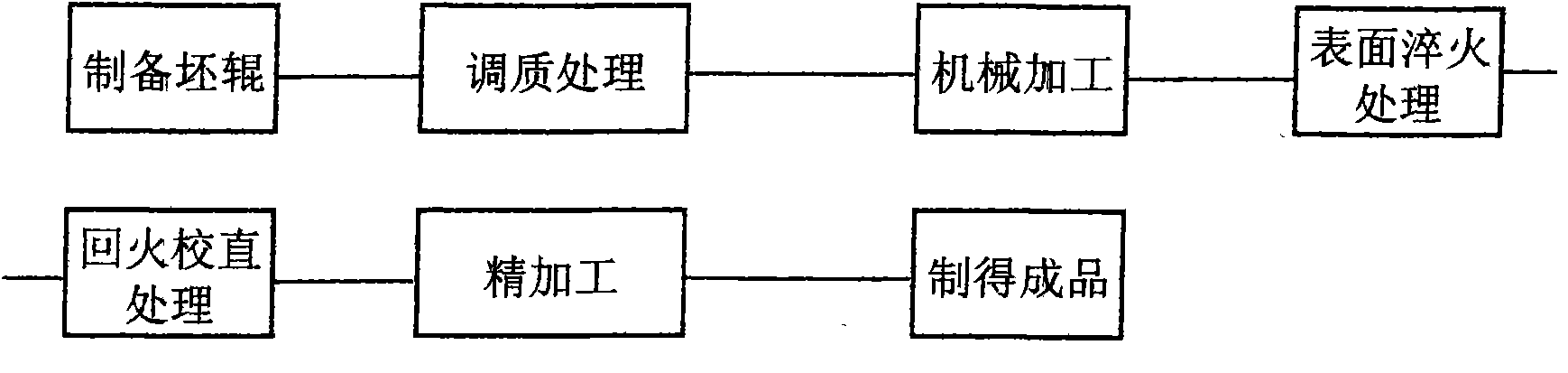

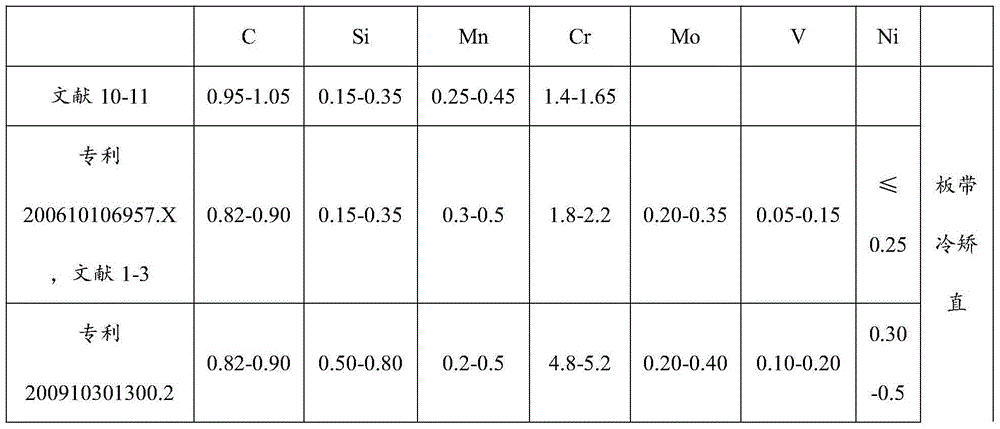

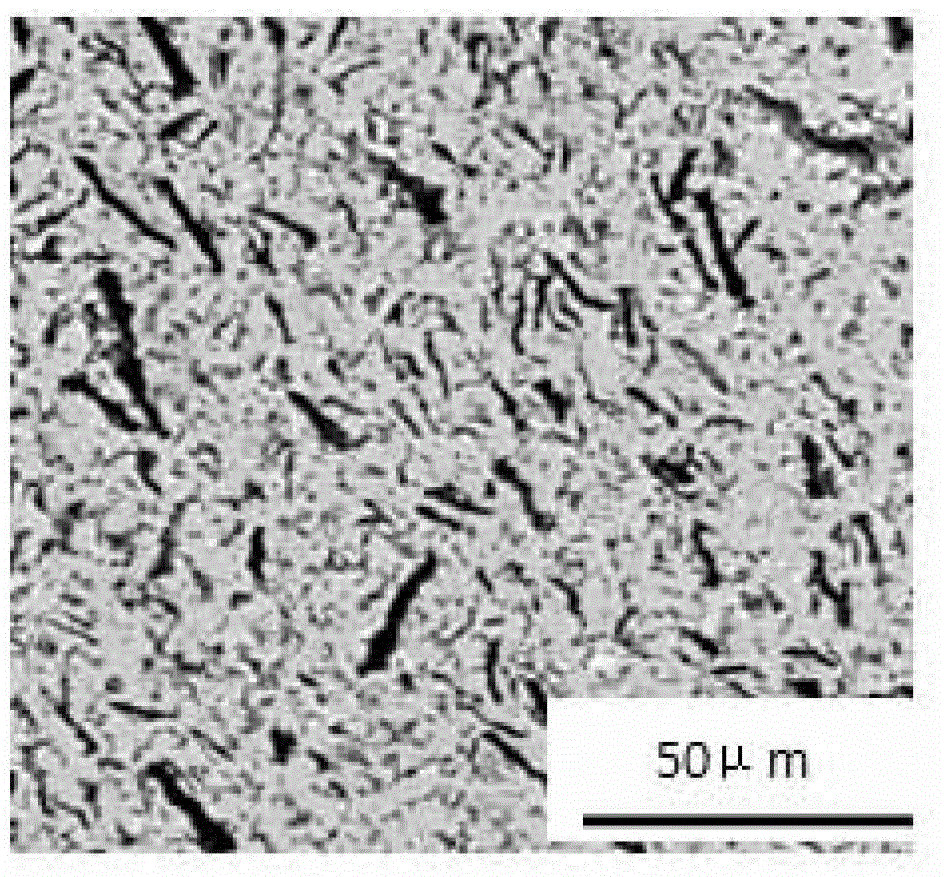

Contact fatigue-highly resistant cold-rolling intermediate roller and manufacture method thereof

ActiveCN104294168AReduce contentIncrease contentFurnace typesHeat treatment furnacesMo elementMatrix strength

The invention discloses a contact fatigue-highly resistant cold-rolling intermediate roller and a manufacture method thereof, the roller comprises the following components by weight percentage: 0.70-0.85% of C, 0.40-1.00 of Si, 0.20-0.60% of Mn, 2.80-3.50% of Cr, 0.25-0.60% of Ni, 0.30-0.50% of Mo, 0.10-0.30% of V, less than or equal to 0.02 of P; less than or equal to 0.015 of S, and the balance of Fe and inevitable impurities. The manufacture method comprises the following steps: smelting in an electric furnace, refining outside the electric furnace, degassing under vacuum, casting an electrode bar, remelting electroslag, forging, annealing and performing heat treatment, roughly machining, tempering and performing heat treatment, semifinishing, performing heat treatment on the roller body, finely tempering, and acquiring the finished product roller. By reducing the content of an element C and increasing the content of Si, Ni and Mo elements, strength and toughness performance as well as the matrix strength of the intermediate roller can be increased, and tissue can be refined, and the cold-rolling intermediate roller has high contact fatigue resistance through heat treatment.

Owner:YIXING YONGCHANG ROLL

Method for improving function stability of nickel-titanium shape memory alloy

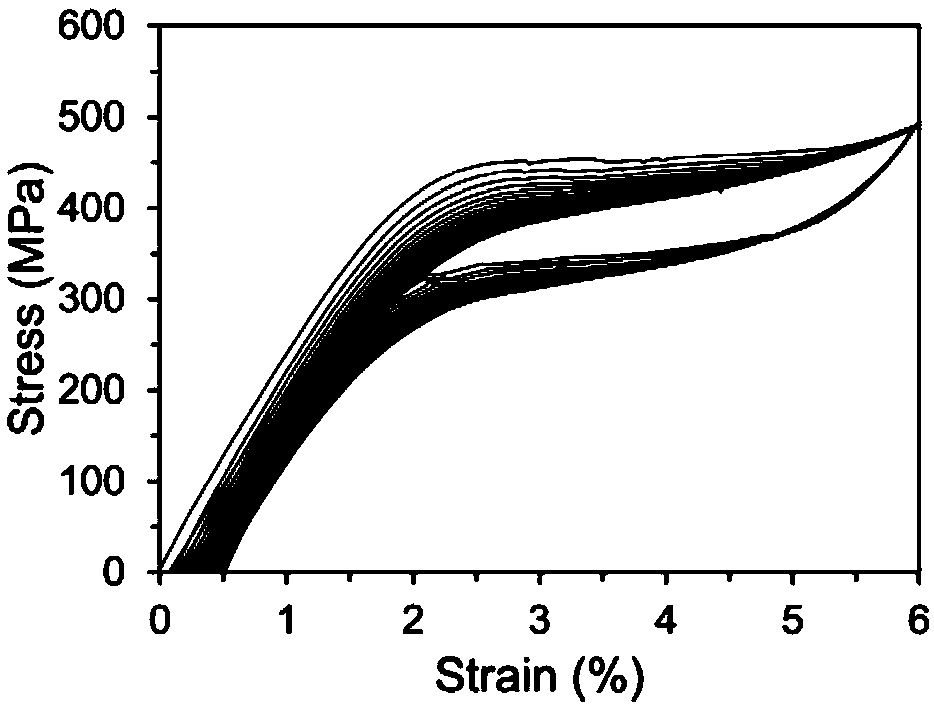

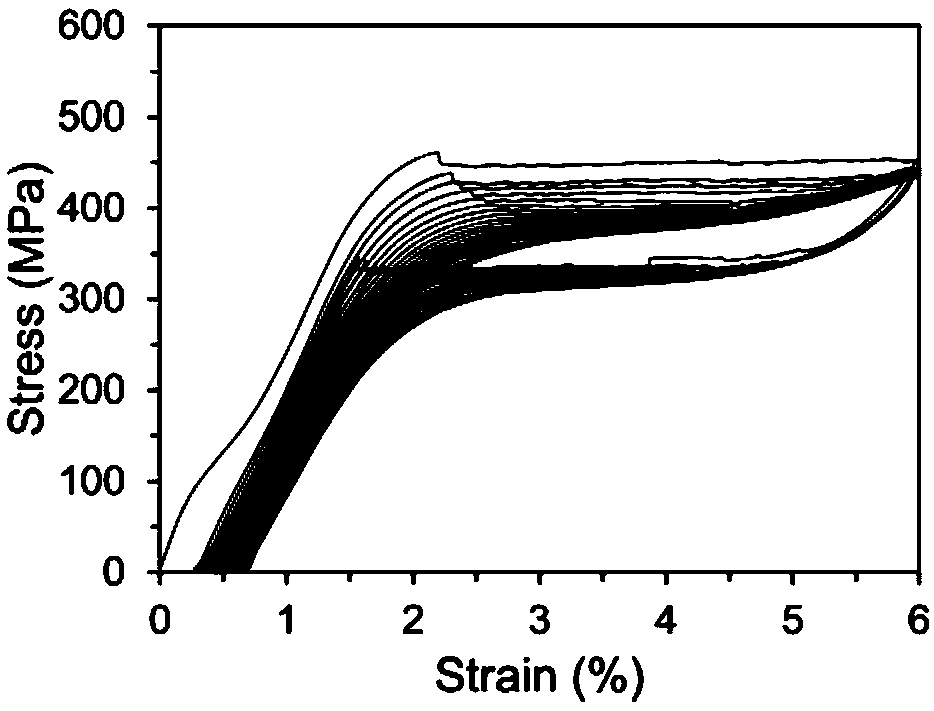

The invention relates to a method for improving the function stability of a nickel-titanium shape memory alloy, and belongs to the field of nickel-titanium shape memory alloys. According to the method, dislocations and other defects are introduced into the nickel-titanium shape memory alloy, the dislocations serve as activity position points for promoting second phase nucleation, then, fine and evenly-distributed nano reinforcement phases are formed in a matrix structure of the nickel-titanium shape memory alloy through later aging treatment, accordingly, the matrix strength of the nickel-titanium shape memory alloy is obviously improved, and then the function stability of the alloy is improved. Meanwhile, in the method, only temperature martensite phase change induction circulation or stress martensite phase change induction circulation need to be conducted on a nickel-titanium shape memory alloy component before aging treatment, and operation is simple and convenient; and the methoddoes not have the requirement for the shape of the nickel-titanium shape memory alloy component, and the method is adaptive to the complex nickel-titanium shape memory alloy component and capable of effectively improving the function stability of the complex nickel-titanium shape memory alloy component.

Owner:SHANDONG UNIV

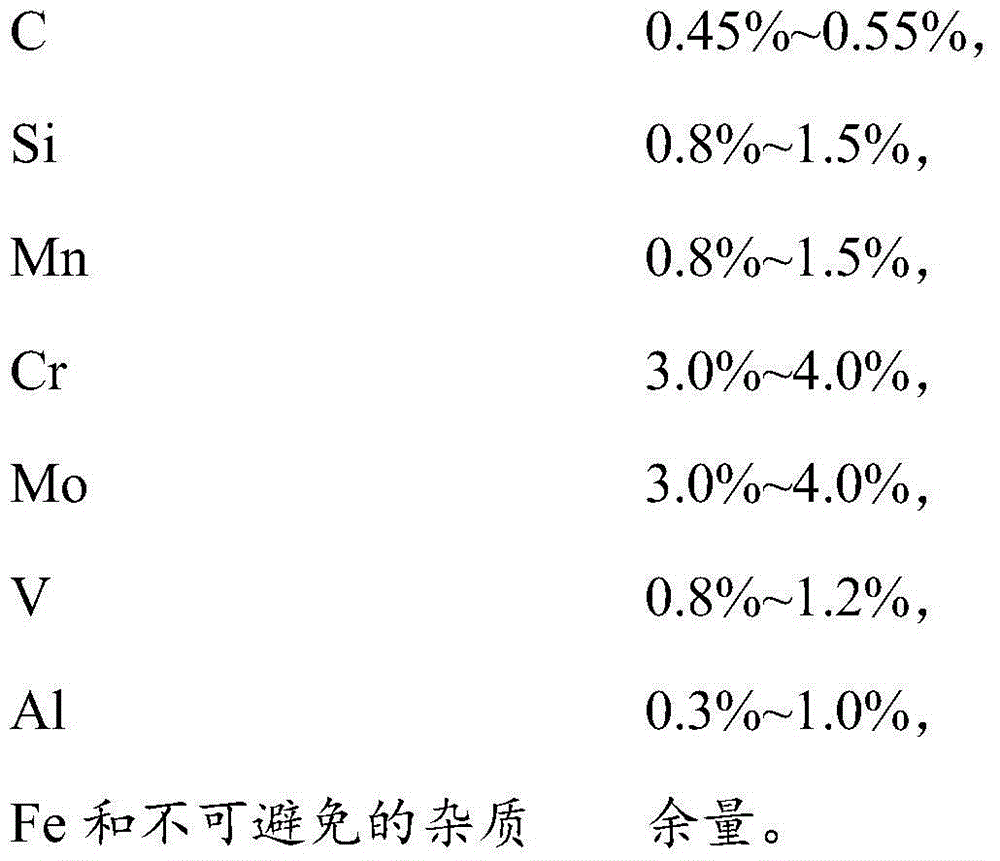

Wide thick plate hot-straightening machine working roll and manufacturing method thereof

ActiveCN104946982AReduce difficultyFurnace typesHeat treatment furnacesChemical compositionThick plate

The invention discloses a wide thick plate hot-straightening machine working roll which comprises the following chemical components in percentage by mass: 0.45-0.55% of C, 0.8-1.5% of Si, 0.8-1.5% of Mn, 3.0-4.0% of Cr, 3.0-4.0% of Mo, 0.8-1.2% of V, 0.3-1.0% of Al, and the balance of Fe and inevitable impurities. The wide thick plate hot-straightening machine working roll can satisfy the technical requirements for the wide thick plate hot-straightening roll, and has higher matrix strength and red hardness than the existing H13 material. The invention also discloses a preparation method of the wide thick plate hot-straightening machine working roll.

Owner:BAOSHAN IRON & STEEL CO LTD

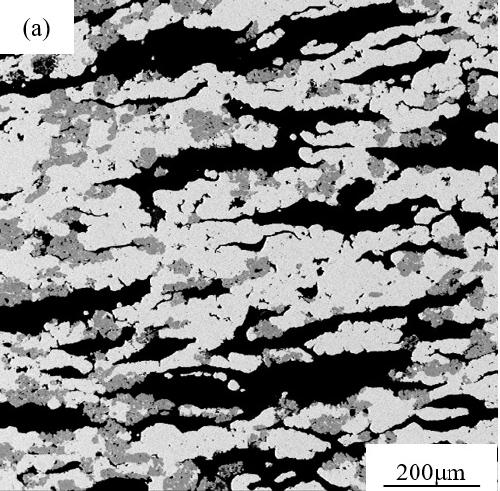

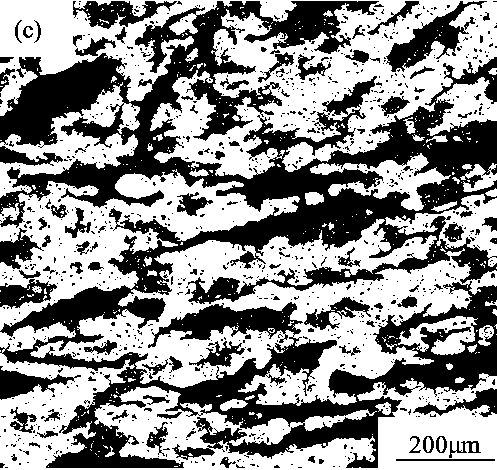

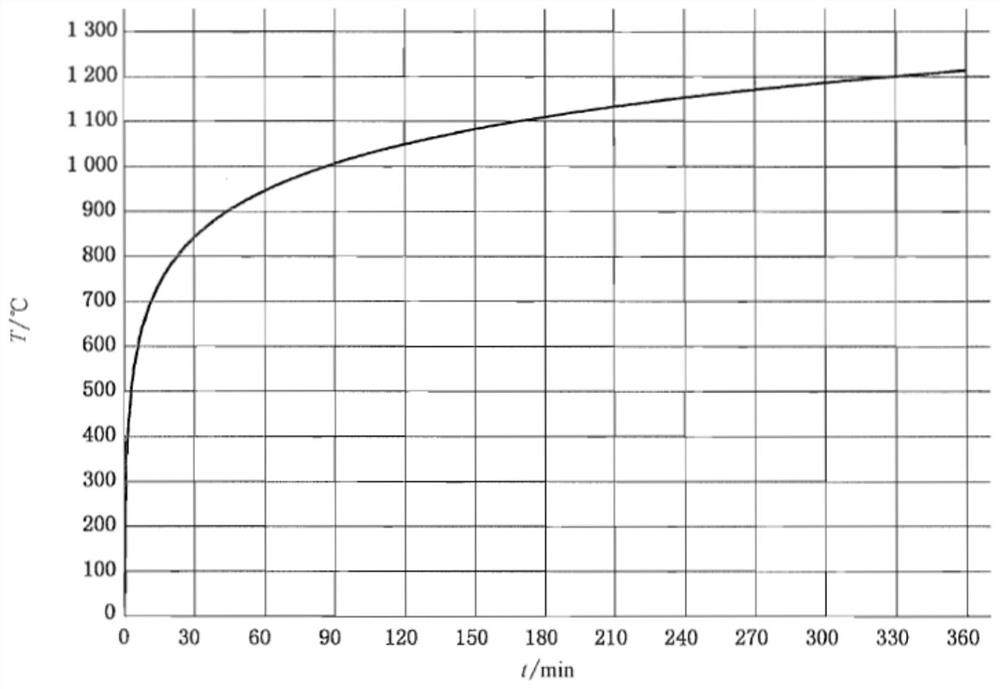

Method for brazing ZrB2-SiC composite ceramic material by using Pd-Co-Ni brazing filler metals

InactiveCN103331499AActive connectionReduced responseWelding/cutting media/materialsWelding/soldering/cutting articlesMetallurgyComposite ceramic

The invention discloses a method for brazing ZrB2-SiC composite ceramic material by using Pd-Co-Ni brazing filler metals, which relates to the method for brazing the ZrB2-SiC composite ceramic material and aims at solving the problem that the performance of a base metal is degraded due to interaction between brazing filler metals and a base metal reinforcement body SiC during a brazing process of the existing Pd-Co brazing filler metals. The method comprises the following steps of 1, preparation of Pd-Co-Ni brazing filler metals; 2, sample assembling; and 3, brazed connection, wherein the brazing technology parameters are set in a way that the vacuum degree of a brazing furnace is less than 6*10<-3>Pa, the connection temperature is 1240-1270 DEG C, the heat preservation time is 0-30 min, and the pressure of a connector is 2*10<3>Pa. According to the method disclosed by the invention, the four-point bending strength of the obtained connector is 120MPa and reaches to 65% of the matrix strength of the base metal. The method disclosed by the invention is applied to the field of brazing.

Owner:HARBIN INST OF TECH

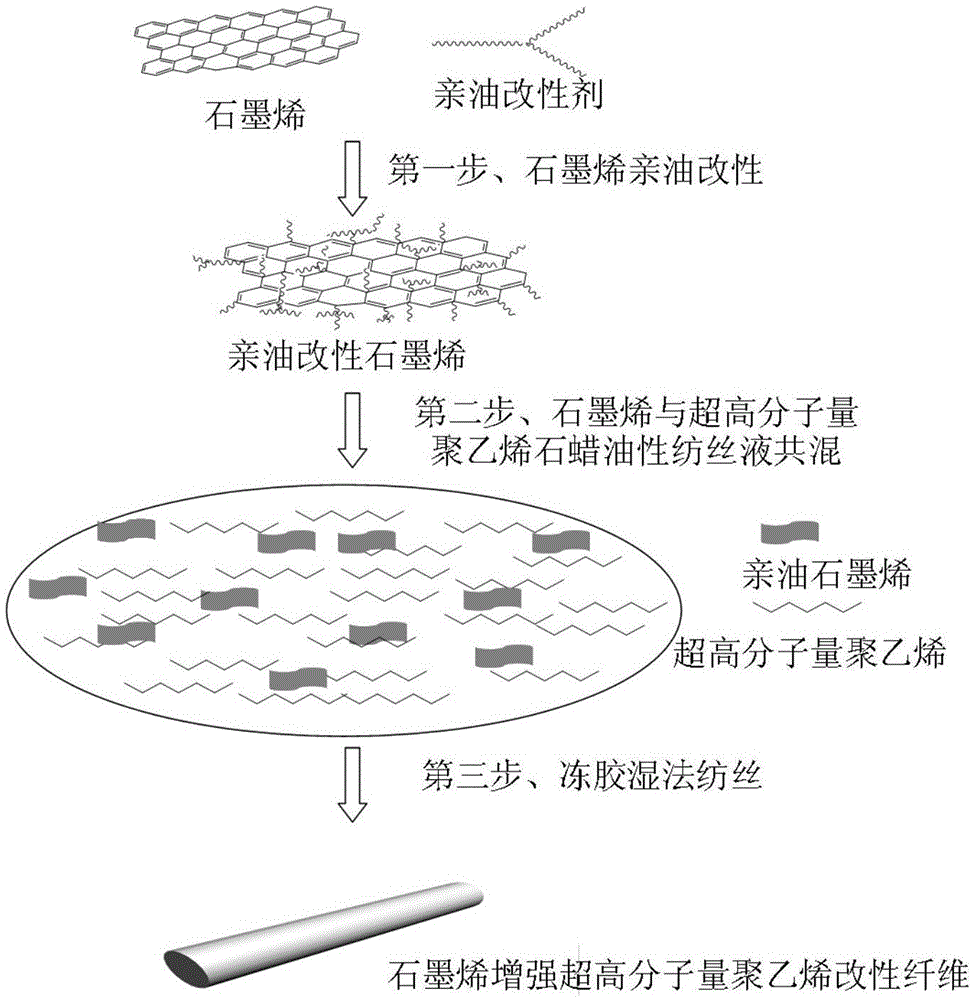

Preparation method of graphene ultra-high molecular weight polyethylene hybrid fiber

InactiveCN105483848AHigh strengthImprove lipophilicityMonocomponent polyolefin artificial filamentArtifical filament manufactureStress concentrationPolymer science

The invention belongs to the technical field of high-performance fiber preparation and relates to a preparation method of a graphene ultra-high molecular weight polyethylene hybrid fiber. The preparation method comprises three technological steps of graphene (or oxidized graphene) lipophilic modification, oleophilic modified graphene dispersion liquid and ultra-high molecular weight polyethylene paraffin oil spinning solution co-mixing and gel wet spinning, and particularly comprises the following steps: dispersing graphene or oxidized graphene in an ethanol solution; adding an oleophilic modifier for co-mixing; performing oleophilic graft modification; adding an antioxidant and ultra-high molecular weight polyethylene into paraffin to prepare an ultra-high molecular weight polyethylene paraffin oil spinning solution; co-mixing an oleophilic modified graphene dispersion liquid and the ultra-high molecular weight polyethylene paraffin oil spinning solution. The prepared fiber is high in matrix strength, has the mechanical properties of creep resistance, good heat resistance, improved stress concentration and the like; the preparation method is simple, convenient to operate and wide in application.

Owner:QINGDAO UNIV

High-strength and high-conductivity copper-iron alloy and preparation method thereof

The invention relates to a high-strength and high-conductivity copper-iron alloy. The high-strength and high-conductivity copper-iron alloy is characterized by comprising, by mass, 5.0-15.0 wt% of Fe,0.0125-0.12 wt% of C, 0.05-0.30 wt% of Mo, 0.01-1,00 wt% La or / and Ce, and the balance Cu and unavoidable impurities. As the specific proportion of C and Mo are added in the copper-iron alloy, the electric conductivity is not reduced while the matrix strength is improved, the addition of La or / and Ce is beneficial to inhibiting the segregation of iron in the copper-iron alloy, and the performanceis more stable.

Owner:NINGBO POWERWAY ALLOY MATERIAL

Tungsten carbide enhanced copper-based powder metallurgy friction material and preparing method thereof

ActiveCN109468487AImprove adverse effectsIncrease coefficient of frictionTransportation and packagingMetal-working apparatusMatrix strengthMaterials science

The invention discloses a tungsten carbide enhanced copper-based powder metallurgy friction material. The friction material comprises following raw materials including, by weight percent, 50%-70% of copper powder, 10%-20% of iron powder, 1%-5% of tin powder, 6%-11% of graphite and 0.01%-15% of tungsten carbide. Compared with similar materials, the novel tungsten carbide enhanced copper-based powder metallurgy friction material has the advantages that the matrix strength is high, hardness is high, the friction coefficient is high, the friction performance is stable, the abrasion amount is low,the preparing technology is simple, and the production cost is low; the comprehensive performance of the material is improved, and it is guaranteed that the material has stable friction performance, the high friction coefficient and good abrasion resistance; few microelement kinds exist, lead, asbestos and other components doing harm to health are not contained, the requirements for health safetyand environment protection are met; and in the preparing technology, the technology is simple, large-batch production is conveniently achieved, and the manufacturing cost is low.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Aluminum alloy bodywork welding deformation flame correction method

InactiveCN101920428AFilling the gap in welding repair technologyGood application effectTechnical objectMatrix strength

The invention discloses an aluminum alloy bodywork welding deformation flame correction method, which is characterized by comprising the following steps of: adjusting a baking gun with a middle blue fire length of 10 to 14 millimeters; uniformly heating a welding seam by using blue fire tip at a heating speed of 50 to 90 centimeters per minute; controlling the heating temperature to be between 120 and 200 DEG C; and cooling the welding seam. The method has very good application effect in production, reduces the welding deformation correction frequency, reduces the production cost, improves the production efficiency, improves the welding quality, fills the blank of aluminum alloy welding correction technology, and lays a technical foundation for large-batch aluminum alloy vehicle production. After aluminum alloy welding pieces of plates with lengths of 300 millimeters and different thicknesses are corrected twice by adopting the flame correction process, influence on strength is inspected. The results show that the matrix strength of the experimental piece corrected by adopting flame is reduced by about 2 to 3 percent compared with the strength of the aluminum alloy welding piece without adopting the flame correction, so the method meets the aluminum alloy welding strength and integrally ensures the technical object of 60 percent of base material matrix length.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

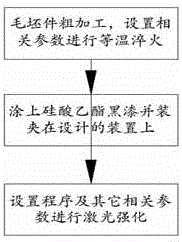

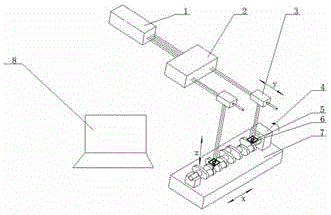

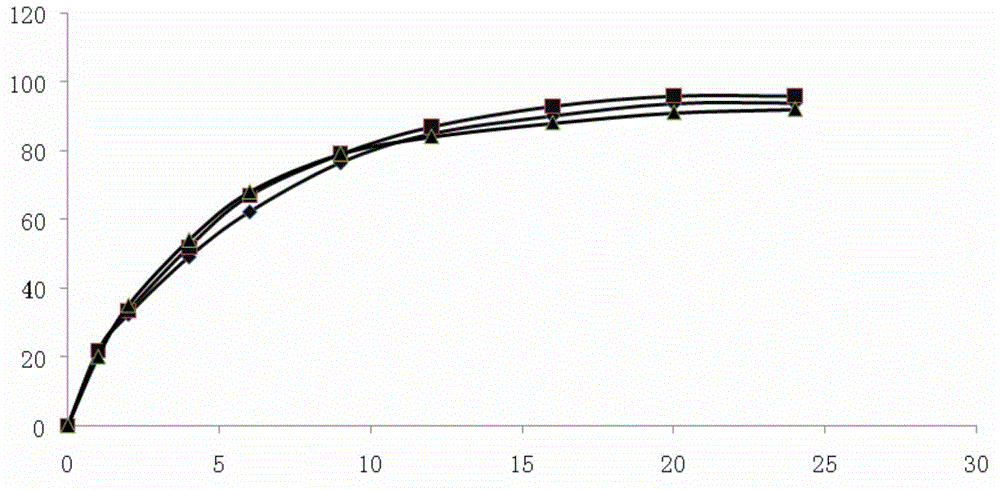

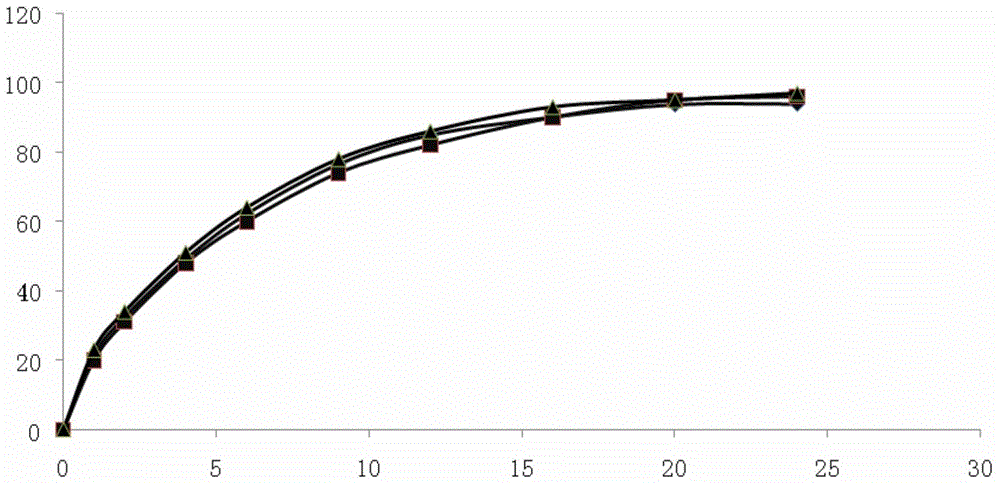

Method of manufacturing engine crankshaft and laser shock reinforcing device of engine crankshaft

ActiveCN105755215AImprove impact toughnessExtended service lifeFurnace typesHeat treatment furnacesNumerical controlMatrix strength

The invention relates to a method of manufacturing an engine crankshaft and a laser shock reinforcing device of the engine crankshaft.The method comprises the steps: (1), heating in a rotary trolley type quenching furnace, to 850 + / - 20 DEG C, and holding the temperature for 90 min; (2), soaking in a nitrate bath for isothermal maintaining at isothermal temperature of 350 DEG C for 60 min.After isothermal quenching, crankshaft surface is reinforced by laser shock reinforcement.A laser shock reinforcing apparatus comprises a high-power pulse laser, a laser splitter, a movable laser reflector, a movable laser focusing lens, a crankshaft rotation drive device, a water nozzle, a guide rail sliding mechanism and a CNC (computer numerical control) device; by superposing two processes, matrix strength, surface hardness and wear resistance of a crankshaft are improved effectively; in addition, the reinforcing apparatus of the invention uses two laser beams to reinforce fillets of the crankshaft, and the production efficiency is high.

Owner:JIANGSU UNIV

Pramipexole dihydrochloride slow-release tablets and preparation method thereof

InactiveCN104367562ASimple processGood content uniformityOrganic active ingredientsNervous disorderPramipexole DihydrochlorideMatrix strength

The present invention provides pramipexole dihydrochloride slow-release tablets and a preparation method thereof. The pramipexole dihydrochloride slow-release tablets comprise, by weight, 0.1-1.5% of a pramipexole dihydrochloride dihydrate, 40.0-75.0% of a matrix material with no swelling in water, 0.5-3.0% of a glidant, 0.5-3.0% of a lubricant, and 20.0-58.9% of other pharmaceutically acceptable carriers. According to the present invention, the pharmaceutically acceptable carrier with no swelling in water is provided, wherein swelling and deformation can not be produced when the formed matrix tablet contacts the aqueous medium so as to maintain the strong matrix strength in the body and not to cause dose burst release due to the food influence; and the preparation method of the present invention adopts the direct powder tableting process, the produced pramipexole dihydrochloride slow-release tablets have the good content uniformity, and the method of the present invention is simple, is suitable for industrial production, and has the great application value.

Owner:SHANGHAI SUNTECH PHARMA

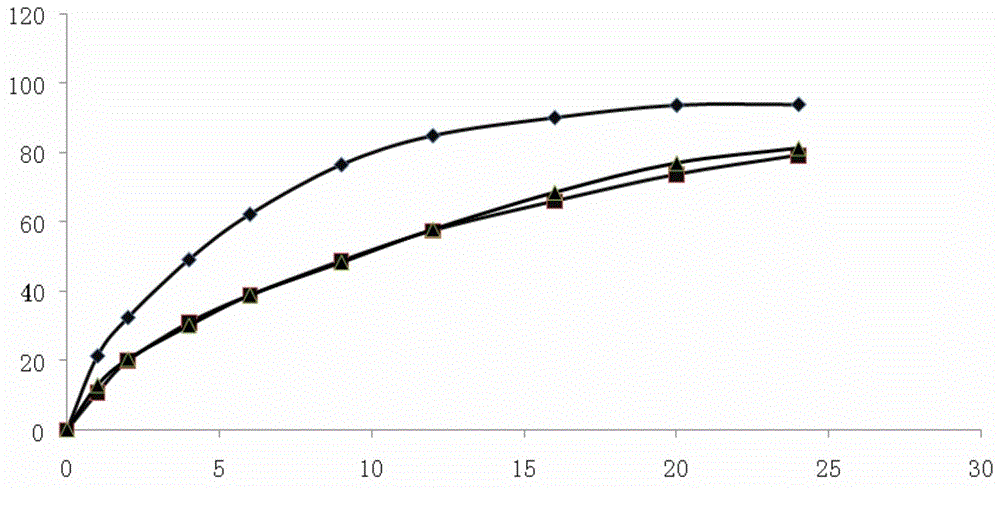

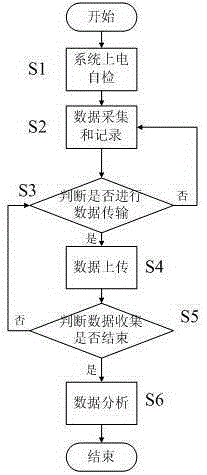

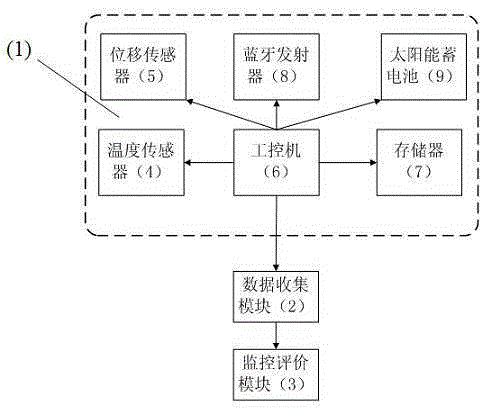

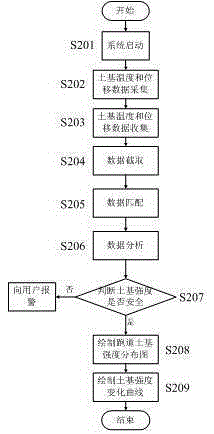

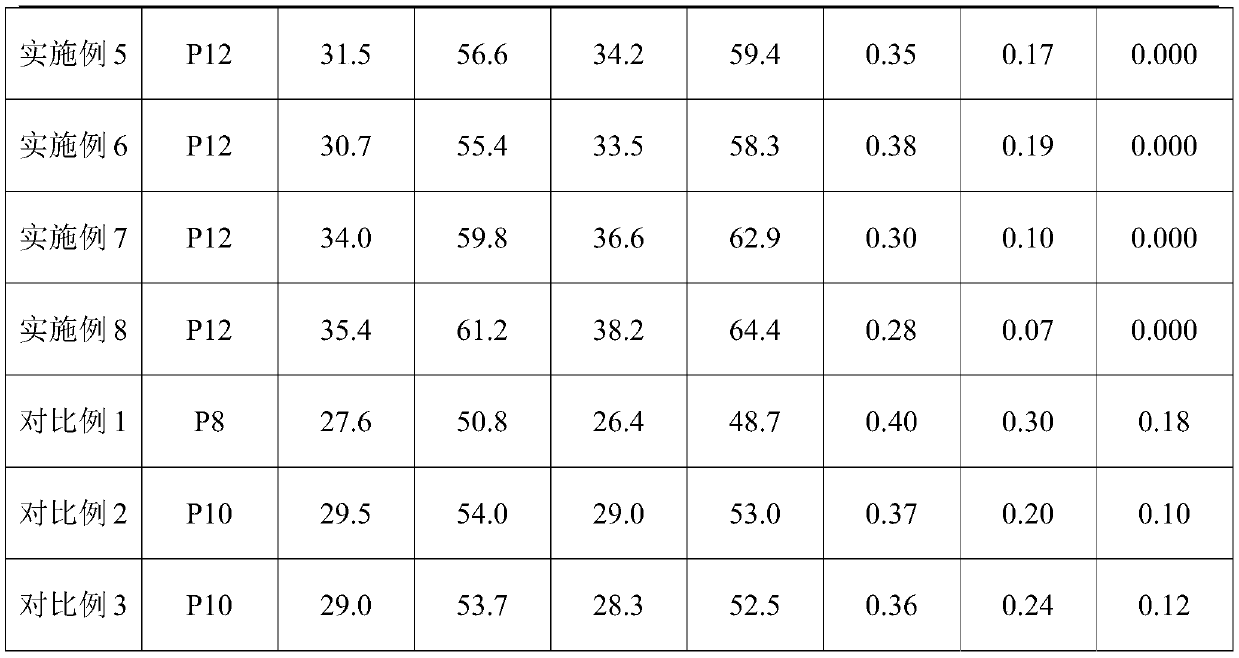

Frozen soil zone airport runway soil matrix strength monitoring system and control evaluation method

ActiveCN105277672AReal-time monitoring of intensity changesImprove predictive reliabilityEarth material testingData acquisitionMatrix strength

The present invention is a frozen soil zone airport runway soil matrix strength monitoring system and a control evaluation method, the frozen soil zone airport runway soil matrix strength monitoring system includes a plurality of buried type data acquisition modules, a data collection module and a monitoring evaluation module, theburied type data acquisition module comprises a temperature sensor, a displacement sensor, an industrial computer, a memory, a Bluetooth transmitter and a solar storage battery, the data collection module is a tablet personal computer with Bluetooth connectivity function, and the monitoring evaluation module is a computer with monitor evaluation software. According to the frozen soil zone airport runway temperature rise effect monitoring evaluation system and the control method, soil matrix deformation in aircraft take-off and landing and taxiing processes can be dynamically tested and recorded, influence of the temperature rise effect on a frozen soil zone airport runway can be detected and evaluated, a method to enhance the safe operation support capabilities of airports in cold zones is provided, and the method is scientific and rational, convenient in construct, and easy to promote and use.

Owner:NORTHWEST INST OF ECO ENVIRONMENT & RESOURCES CAS

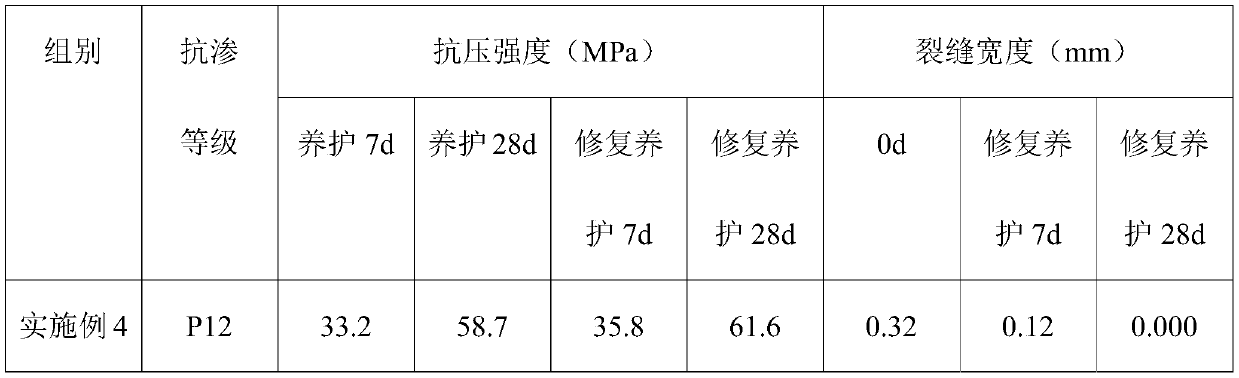

Bionic self-repairing concrete and preparation method thereof

ActiveCN110395884AHigh mechanical strengthSmall mechanical propertiesGlass shaping apparatusMicrosphereCarbon nanotube

The invention discloses bionic self-repairing concrete and a preparation method thereof. The bionic self-repairing concrete is characterized by being prepared from the following raw materials in partsby weight: 240 to 360 parts of cement, 180 to 250 parts of active admixture, 1300 to 1600 parts of aggregate, 60 to 90 parts of mesoporous bioactive glass composite microspheres, 20 to 30 parts of calcium peroxide microspheres, 20 to 30 parts of carbon nanotubes, 8 to 16 parts of polycarboxylate water reducing agent and 190 to 220 parts of water. The bionic self-repairing concrete provided by theinvention has a rapid self-repairing capability, can continuously and automatically repair micro-cracks or micro-damages of different deep layers in the concrete, promotes the continuous increase ofthe matrix strength after crack repairing, and improves the strength and durability of the concrete. The self-repairing concrete has the advantages of being wide in repairing range, rapid in repairingand lasting in repairing.

Owner:GUANGDONG NO 2 HYDROPOWER ENGINEERING COMPANY LTD

Low-chromium and high-silicon wear-resistant vanadium-nitrogen-boron reinforced steel belt for kitchen cutter

The invention discloses a low-chromium and high-silicon wear-resistant vanadium-nitrogen-boron reinforced steel belt for a kitchen cutter. The low-chromium and high-silicon wear-resistant vanadium-nitrogen-boron reinforced steel belt is characterized in that the low-chromium and high-silicon wear-resistant vanadium-nitrogen-boron reinforced steel belt comprises the specific components by weight percentage: 0.50-0.60% of C, 0.3-0.7% of Mn, 2.5-3.5% of Si, less than or equal to 0.010% of P, less than or equal to 0.010% of S, 9.00-10.00% of Cr, less than or equal to 0.6% of Ni, 0.16-0.32% of V, 0.04-0.08% of N, 0.0008-0.002% of B and the balance of Fe. According to the low-chromium and high-silicon wear-resistant vanadium-nitrogen-boron reinforced steel belt for the kitchen cutter, the matrix strength is high; a cutting edge of the cutter has good sharpness, wear resistance and corrosion resistance; and the production cost is low. The low-chromium high-silicon wear-resistant vanadium-nitrogen-boron reinforced steel belt is mainly used for the kitchen cutter and can also be used for the production of shears.

Owner:SHANDONG TAISHAN STEEL GROUP

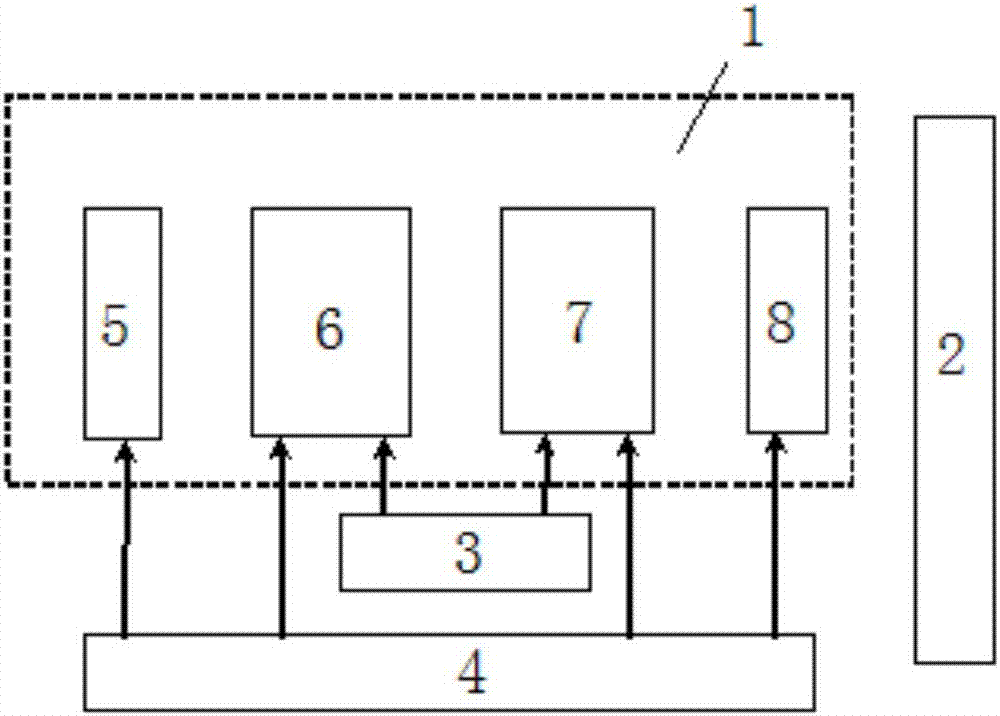

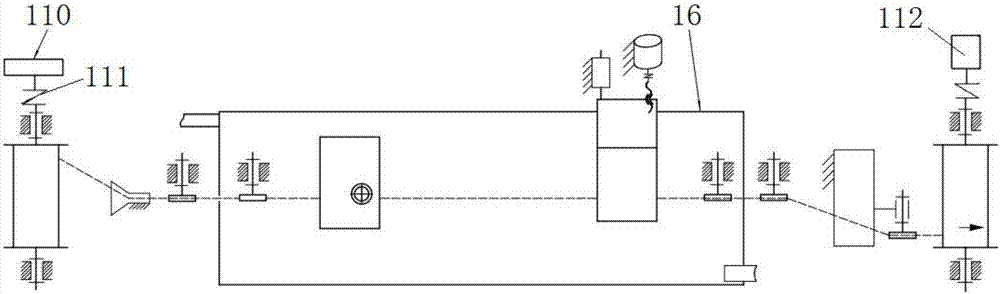

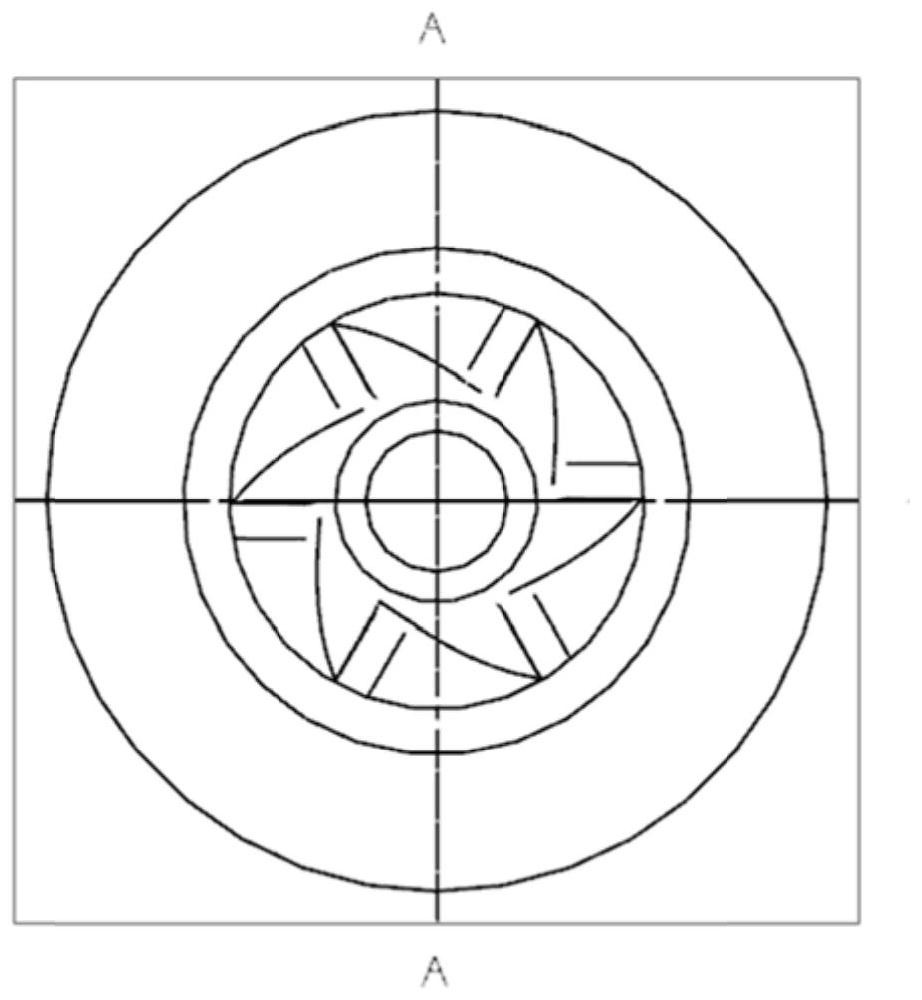

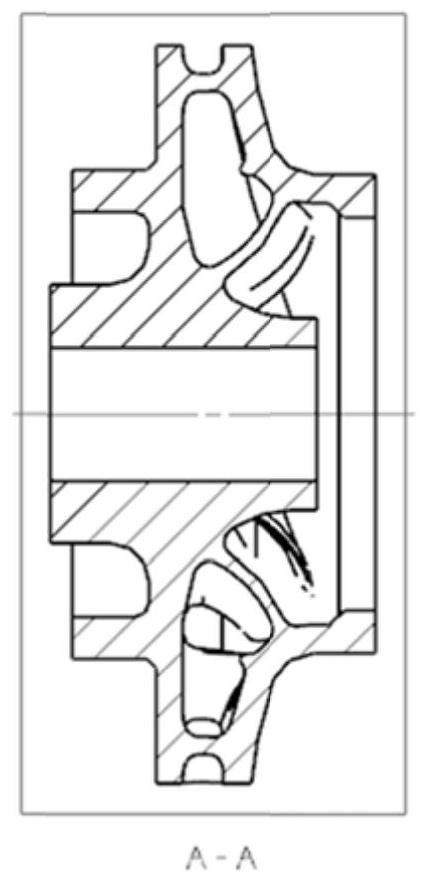

Electrodeposited diamond wire saw production system

ActiveCN106917124AImprove abrasive grain holding powerHigh strengthElectrolytic inorganic material coatingMedia controlsElectricity

An electrodeposited diamond wire saw production system comprises an electrodeposition unit, a working medium control module, an adjustable pulsed power supply and a motion controller; the electrodeposition unit comprises a working medium tank, a pay-off unit, a vertical direction deposition unit, a horizontal direction deposition unit and a take-up unit, the pay-off unit and the take-up unit are respectively arranged at two sides of the working medium tank, the vertical direction deposition unit and the horizontal direction deposition unit are arranged in the working medium tank, and the working medium tank is connected with the working medium control module; and the adjustable pulsed power supply is respectively connected with the vertical direction deposition unit and the horizontal direction deposition unit through cables, and the motion controller is respectively connected with the pay-off unit, the vertical direction deposition unit, the horizontal direction deposition unit and the take-up unit through cables. The system has the advantages of realization of fixed grinding of a wire saw through electrode deposition, high production efficiency, improvement of the abrasive grain holding strength and the matrix strength of the wire saw, and improvement of the processing efficiency and the quality of high-hardness crystal slices.

Owner:SHANDONG UNIV

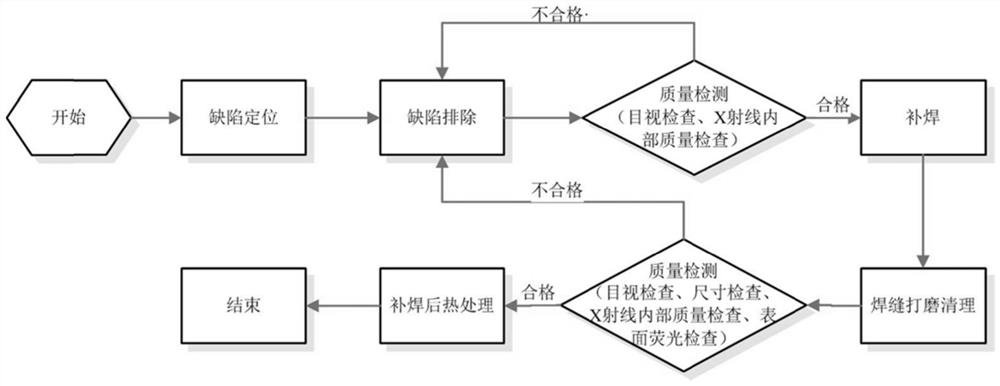

Defect repairing method of investment precision casting for liquid rocket engine

ActiveCN112059531AEliminate unevennessControl the rate of diffusionArc welding apparatusWelding/cutting media/materialsDefect repairEngineering

The invention provides a defect repairing method of an investment precision casting for a liquid rocket engine. The defect repairing method comprises the following steps of: positioning defects; removing the defects; machining a groove; treating a repair welding part; performing welding; and performing postweld treatment. According to the defect repairing method, welding wires for ZG03Cr13Ni5Co9Mo5 and ZG06Cr14Ni7Mo castings are defined, and a welding process database based on the initial thickness of repair welding parts of the castings and a postweld heat treatment system are established; acorresponding repair process is adopted; the tensile strength of an obtained ZG03Cr13Ni5Co9Mo5 weld joint at a room temperature is greater than 1070 MPa (the matrix strength is not lower than 1180 Mpa), the rate of elongation is not lower than 15%, and the low-temperature impact toughness at the temperature of minus 196 DEG C is not lower than 39 J; the tensile strength of a ZG06Cr14Ni7Mo weld joint at a room temperature is greater than 900 MPa (the matrix strength is not lower than 980 Mpa), the rate of elongation is not lower than 12%, and the low-temperature impact toughness at the temperature of minus196 DEG C is not lower than 31 J; the internal quality and the surface quality of the weld joints are qualified; and the weld joints meet the I-grade weld joint standard of QJ1842-95 structural steel and stainless steel fusion welding technical conditions and the use requirements of spaceflight products.

Owner:XIAN SPACE ENGINE CO LTD

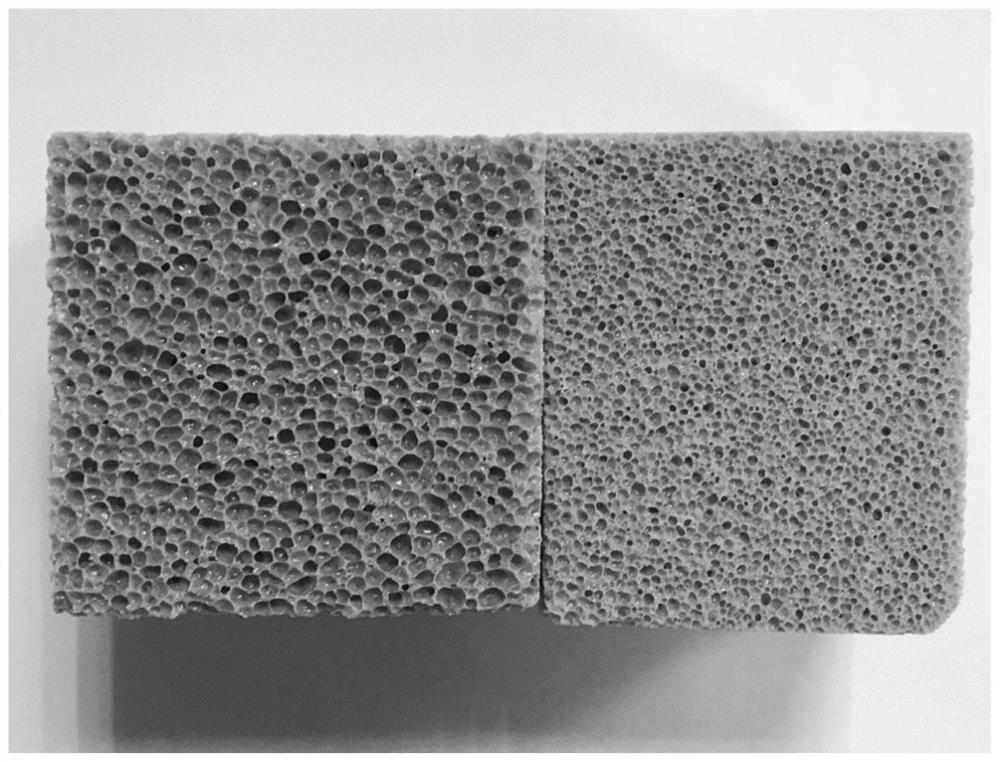

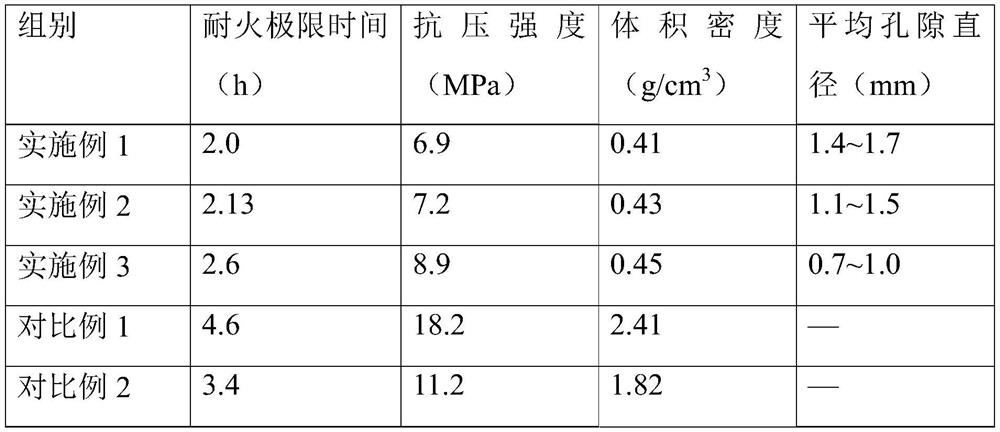

Foamed ceramic and preparation method and application thereof

PendingCN112592156AIncrease hole wall thicknessReduced obturator diameterWallsFloorsFoaming agentSlag

The invention discloses foamed ceramic as well as a preparation method and application thereof. The foamed ceramic is prepared from the following raw materials in parts by weight: 60-70 parts of polishing slag, 8-18 parts of medium-temperature sand, 5-10 parts of foamed ceramic fine powder, 2-8 parts of bentonite, 1-5 parts of talc particles, 5-15 parts of granite stone powder, 5-25 parts of modified soil and 0.4-1 part of a foaming agent. The modified soil is prepared from the following chemical components in percentage by weight: 52 percent to 56 percent of SiO2, 35 percent to 40 percent ofAl2O3, 1 percent to 3 percent of CaO, 1.5 percent to 2 percent of Fe2O3, 0.1 percent to 0.3 percent of TiO2, 0.1 percent to 0.3 percent of MgO, 1.5 percent to 2.5 percent of K2O, 0.8 percent to 1.5 percent of Na2O and 0.01 percent to 0.05 percent of L.O.I. Specific ceramic raw materials are selected and scientifically proportioned, and modified soil is added, so that the matrix strength of the foamed ceramic is improved, and the fire endurance of the foamed ceramic is improved.

Owner:GUANGDONG KITO CERAMICS GROUP CO LTD +4

Engine belt wheel hub production process

InactiveCN107267853AReduce unevennessImprove machining accuracyFurnace typesHeat treatment furnacesRheniumX-ray

The invention discloses an engine belt wheel hub production process. The engine belt wheel hub production process comprises the steps of a, ingredient preparing, b, blank manufacturing, c, heat treatment, d, machining, e, spraying, and f, inspecting and packing; in the step b, blank manufacturing comprises the steps that the processing materials prepared in the step a are melted through an oil furnace or an electric furnace at first, then molten metal is subjected to casting cooling molding, and X-ray flaw detection is conducted on a molded blank finally; wherein, before molten metal casting operation, an inoculant is added into the molten metal to conduct furnace front deoxidation inoculation treatment, and the inoculant is obtained in the mode that montmorillonite, rhenium, graphite powder, silicon barium and a silane coupling agent are mixed, heated, melted and crushed into particles with the average grain diameter being 10-15 mm after water cooling and drying finally. The engine belt wheel hub production process is simple in step and easy to operate and master; meanwhile, the structure nonuniformity can be reduced; and the machining precision, the matrix strength and the durability are improved.

Owner:WUHU CHENGTUO AUTO PARTS

PVA fiber reinforced cement-based composite material

PendingCN112624679AImprove cohesionIncreased durabilitySolid waste managementAdhesive glueMatrix strength

The invention discloses a PVA fiber reinforced cement-based composite material, and relates to the technical field of fiber reinforced cement-based composite materials, wherein the PVA fiber reinforced cement-based composite material comprises the used main materials in percentage by mass: 18-23% of cement, 60-67% of fly ash, 10-15% of tailing sand, 1.7-2.1% of PVA fibers, 6-7.5% of a waterproof agent, 0.8-1.0% of sand glue, 13-15% of water, 0.35-0.6% of a water reducer, 0.03-0.05% of a thickening agent, and 0.03-0.05% of a defoaming agent. The fly ash replaces 2 / 3 of cement, so that the mixture has better cohesive force, the surface of the PVA fiber is coated with an oil agent, the tensile strain resistance of the PVA fiber can be improved, the connection characteristic of the matrix strength and the PVA fiber is improved, and a structural member is certainly endowed with higher durability.

Owner:WUHAN UNIV OF SCI & TECH

Organic-inorganic composite phase change heat storage material and preparation method thereof

InactiveCN111187600AAvoid the Phenomenon of VariabilityPrevent leakageHeat-exchange elementsMatrix strengthDocosanedioic acid

The invention relates to the technical field of composite phase change heat storage materials, and discloses an organic-inorganic composite phase change heat storage material and a preparation methodthereof. Raw materials comprise aminated graphene, docosanedioic acid, lanthanum carbonate hydrate, diamond and nano copper powder. According to the material and the method, the docosanedioic acid isused as a phase change material; a hydrothermal synthesis-melt blending method is adopted so that the docosanedioic acid and the aminated graphene are combined together in a manner of forming an amidogroup; the problems that an organic phase is easy to leak and a matrix is easy to denature in the phase change process of the material are avoided; La<3+> is embedded into a crack defect part in an internal interface of the diamond-Cu compound, so that a bonding interface between diamond and Cu is improved, the density of the diamond-Cu compound is improved, the porosity is reduced, and the matrix strength and the structural stability of the compound are enhanced, and therefore, the diamond-Cu compound has higher heat absorptivity and heat conductivity.

Owner:管玲飞

Water-tolerant type magnesium phosphate cement-based material and preparation method thereof

Owner:常州市万昌化工有限公司

Flour improver or flour product improver

ActiveCN102763697BImprove finenessIncrease bread volumeDough treatmentConfectioneryMatrix strengthFermentation

The invention discloses a flour improver or flour product improver, wherein the flour improver or flour product improver contains hypophosphite. The invention also discloses flour or flour products containing the flour improver or flour product improver provided by the invention. Compared with the flour improver or flour product improver containing no hypophosphite, the gluten matrix strength of dough using the improver provided by the invention is high, the gluten quality is improved obviously, the gas holdup property is good; in the later operation period, the dough turns to be dry and comfortable, elastic and resistant to last fermentation; produced bread is large in size and expands quickly in an oven, the stiffness is high, the texture is delicate, and both the taste and the softness are improved obviously.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

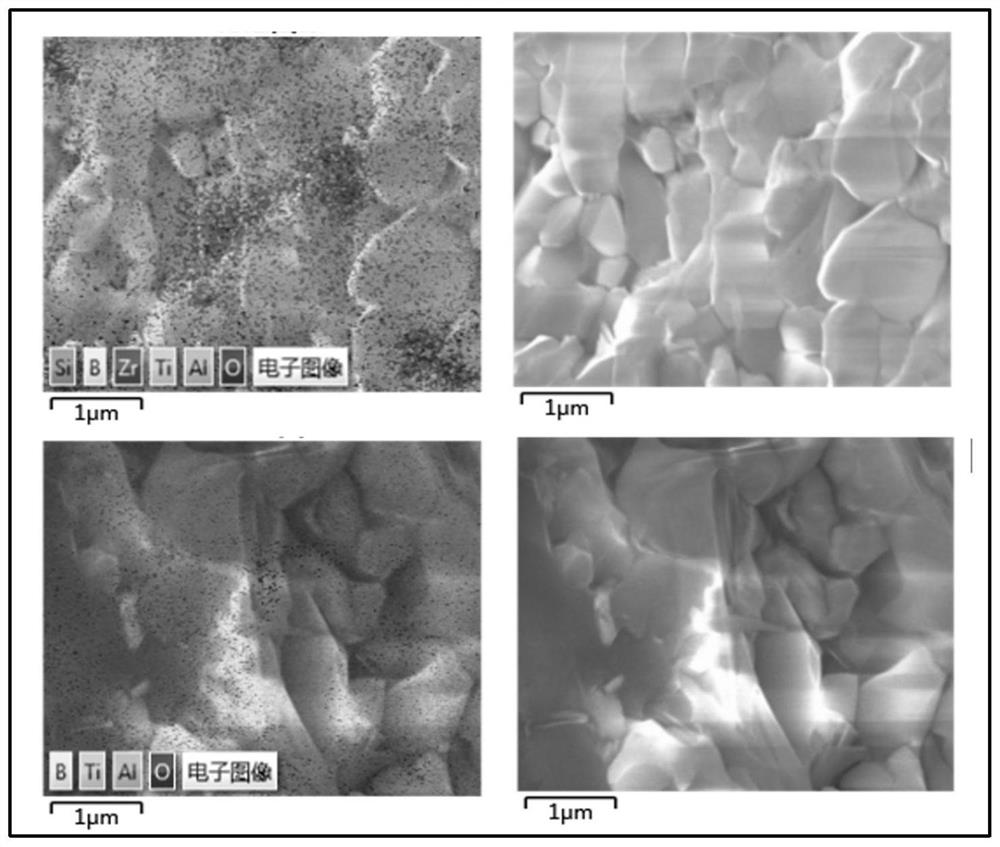

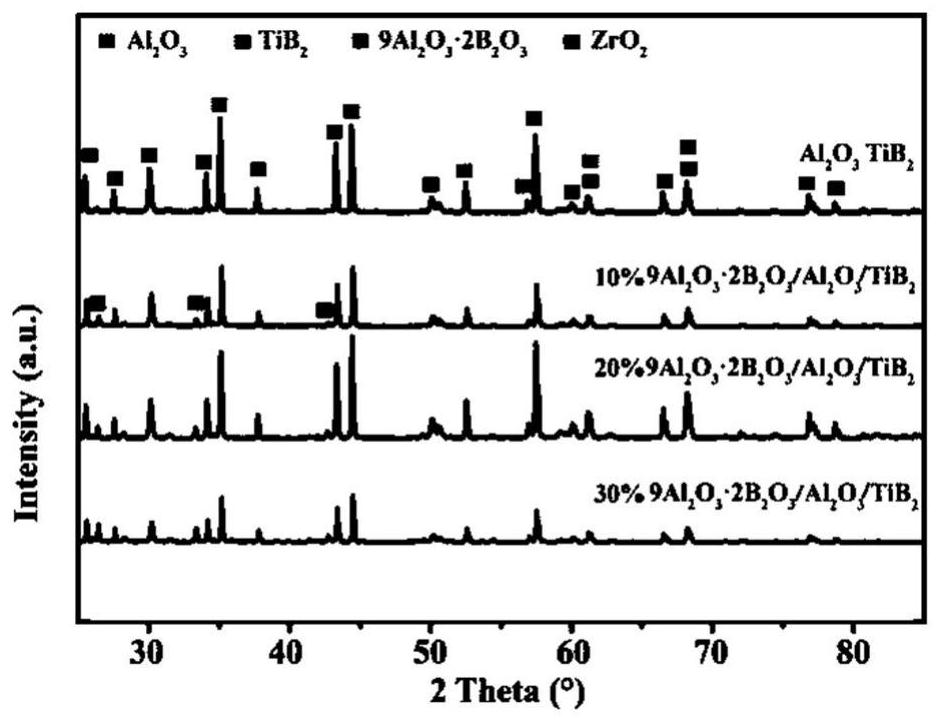

Aluminum borate whisker reinforced and toughened nonmetal-based composite material and preparation method thereof

The invention discloses an aluminum borate whisker reinforced and toughened nonmetal-based composite material. An aluminum borate whisker reinforced and toughened nonmetal material is adopted; and the bending strength and fracture toughness of the nonmetal-based composite material are improved by reinforcing and toughening the nonmetal-based composite material through the aluminum borate whiskers, and the wear resistance of the nonmetal-based composite material is reduced. Firstly, after forming a liquid phase, the aluminum borate whiskers flow into a crystal boundary and are recrystallized to coat crystal grains, so that the effect of inhibiting the growth of the crystal grains is achieved, and pores are filled to increase the density; secondly, the liquefied aluminum borate crystal whiskers are extruded by the crystal grains and recrystallized on the surfaces of the crystal grains to form crystal whiskers, and the matrix strength is improved due to the insertion and extraction mechanism of the crystal whiskers; and thirdly, the liquefied aluminum borate crystal whiskers are reduced by solid phase C and part of gasified C from isolation carbon paper, a graphite mold, a graphite heating body and carbon felt and then react with ZrO2 at the internal grain boundary to generate ZrB2, and ZrB2 has a very good toughening effect.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com