Flour improver or flour product improver

A flour improver and flour product technology, which is applied in bakery food, food preparation, dough processing and other directions, can solve problems such as insufficient bread texture, and achieve the improvement of wheat gluten quality, air retention and gluten network improvement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

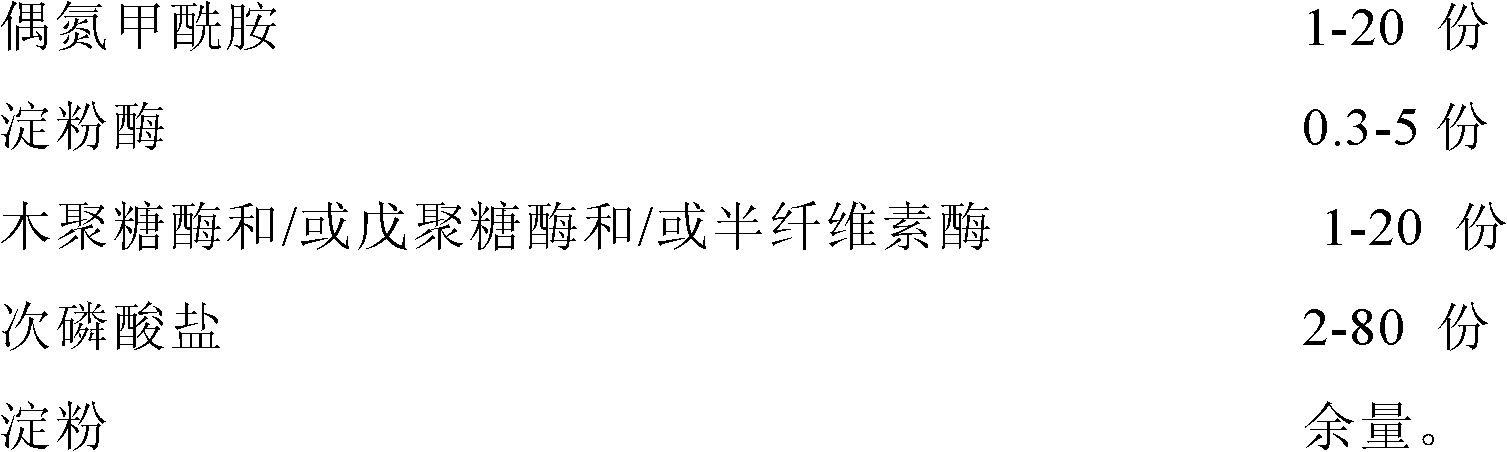

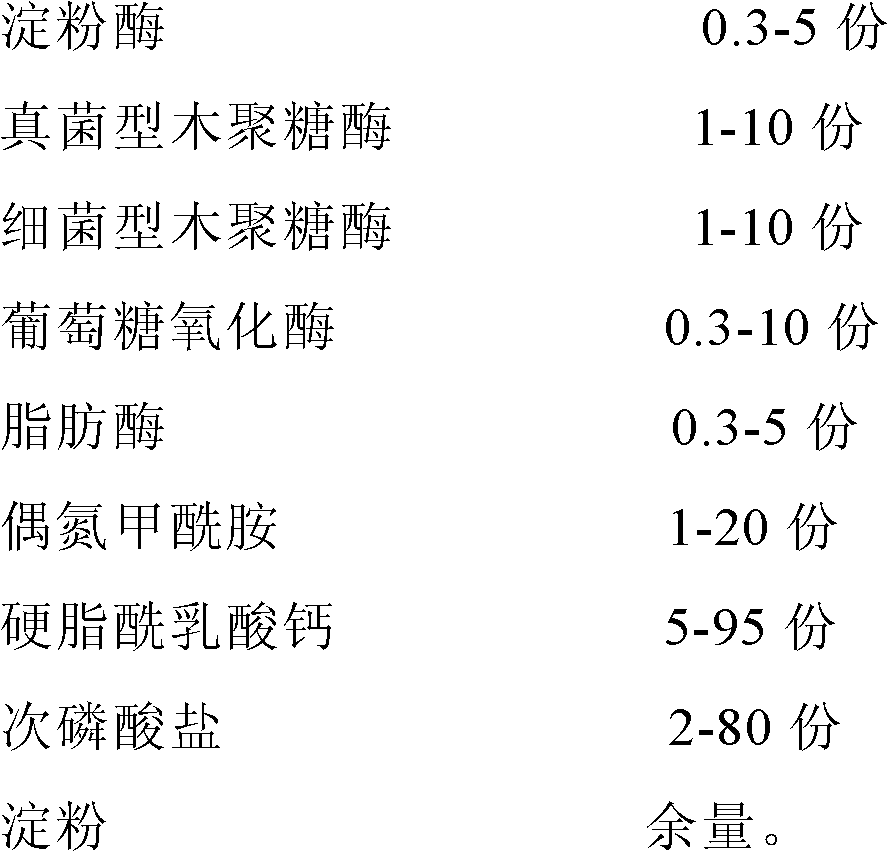

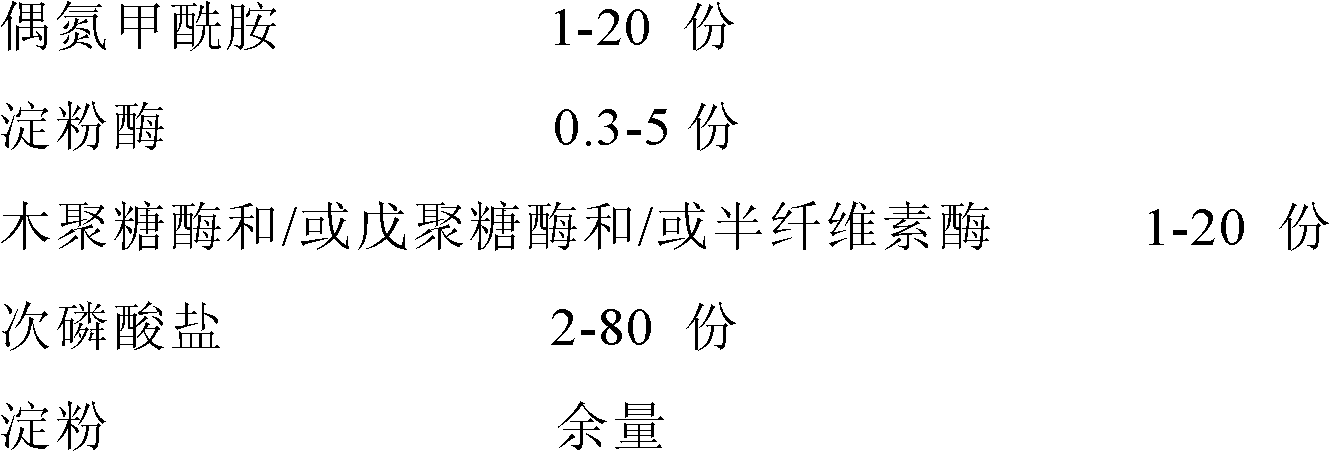

Method used

Image

Examples

Embodiment 1

[0054] Nine raw materials of amylase, fungal xylanase, bacterial xylanase, glucose oxidase, lipase, azodicarbonamide, calcium stearoyl lactylate, sodium hypophosphite and corn starch that meet food grade requirements Carry out 80 mesh sieves respectively, take by weighing the amylase 10kg that sieves, fungal type xylanase 30kg, bacterial type xylanase 20kg, glucose oxidase 12kg, lipase 5kg, azodicarbonamide 40kg, stearin Calcium Acyl Lactate 600kg, Sodium Hypophosphite 20kg, Corn Starch 263kg. The 9 kinds of raw materials are fully mixed and stirred until the 9 kinds of raw materials are mixed evenly.

Embodiment 2

[0056] Nine raw materials of amylase, fungal xylanase, bacterial xylanase, glucose oxidase, lipase, azodicarbonamide, calcium stearoyl lactylate, sodium hypophosphite and corn starch that meet food grade requirements Carry out 80 mesh sieves respectively, take by weighing the amylase 10kg that sieves, fungal type xylanase 30kg, bacterial type xylanase 20kg, glucose oxidase 12kg, lipase 5kg, azodicarbonamide 40kg, stearin Calcium Acyl Lactate 600kg, Sodium Hypophosphite 2000kg, Corn Starch 283kg. The 9 kinds of raw materials are fully mixed and stirred until the 9 kinds of raw materials are mixed evenly.

Embodiment 3

[0058] Nine raw materials of amylase, fungal xylanase, bacterial xylanase, glucose oxidase, lipase, azodicarbonamide, calcium stearoyl lactylate, sodium hypophosphite and corn starch that meet food grade requirements Carry out 80 mesh sieves respectively, take by weighing the amylase 10kg that sieves, fungal type xylanase 30kg, bacterial type xylanase 20kg, glucose oxidase 12kg, lipase 5kg, azodicarbonamide 40kg, stearin Calcium Acyl Lactate 600kg, Sodium Hypophosphite 5000kg, Corn Starch 283kg. The 9 kinds of raw materials are fully mixed and stirred until the 9 kinds of raw materials are mixed evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com