Precipitation-hardening copper alloy and application thereof

A technology of precipitation strengthening and copper alloy, which is applied in the direction of metal/alloy conductors, conductive materials, conductive materials, etc., can solve the problems of high processing cost, high price, poisonous beryllium, etc., achieve excellent comprehensive performance, reduce preparation cost, and improve the matrix The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

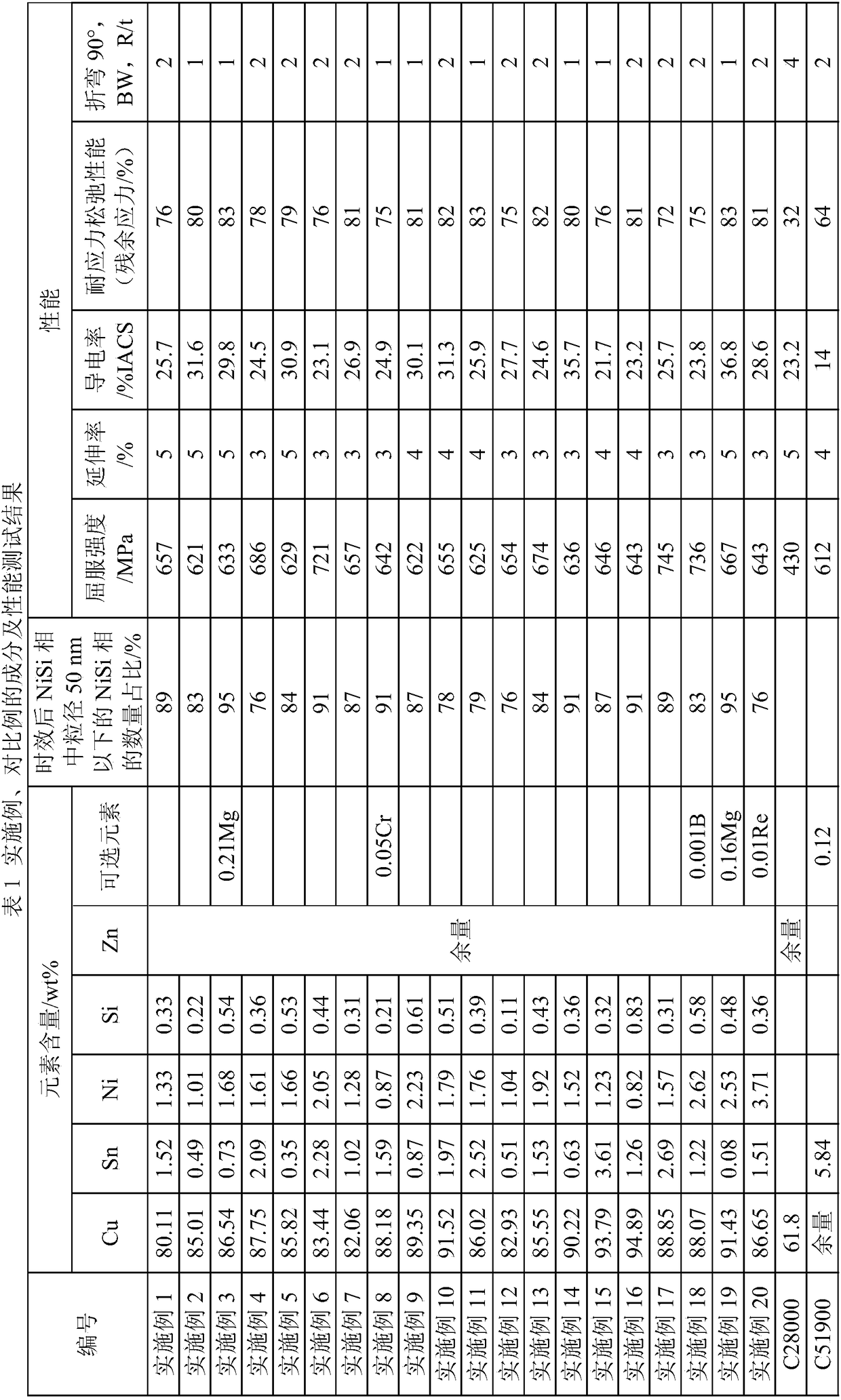

[0045] 20 embodiment alloys and 2 comparative alloys (C28000 brass and C51900 tin phosphor bronze) were selected, and the added elements were added to the melting furnace according to their respective contents, and the semi-continuous casting cast ingots with a specification of 170mm×320mm, and the casting temperature was 1150°C.

[0046] Other main preparation process parameters are:

[0047] Hot rolling: heating temperature 780°C, heat preservation 5h, hot rolling to 16.5mm;

[0048] Milling: Up and down milling to 15mm;

[0049] One-time cold rolling: 15mm cold rolling to 2mm;

[0050] Primary aging: the aging temperature is 550°C, and the temperature is kept for 6 hours;

[0051] Secondary cold rolling: 2mm cold rolling to 0.35mm;

[0052] Secondary aging: aging temperature 380°C, holding time 8h;

[0053] Three cold rolling: 0.35mm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com