Defect repairing method of investment precision casting for liquid rocket engine

A defect repair, liquid rocket technology, applied in welding media, arc welding equipment, welding/cutting media/materials, etc., can solve problems such as uneven distribution of residual stress, improve delivery qualification rate, avoid grain growth, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

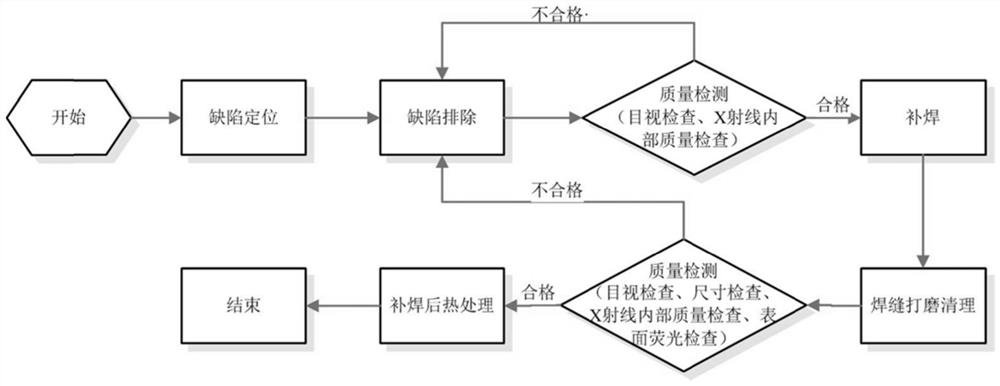

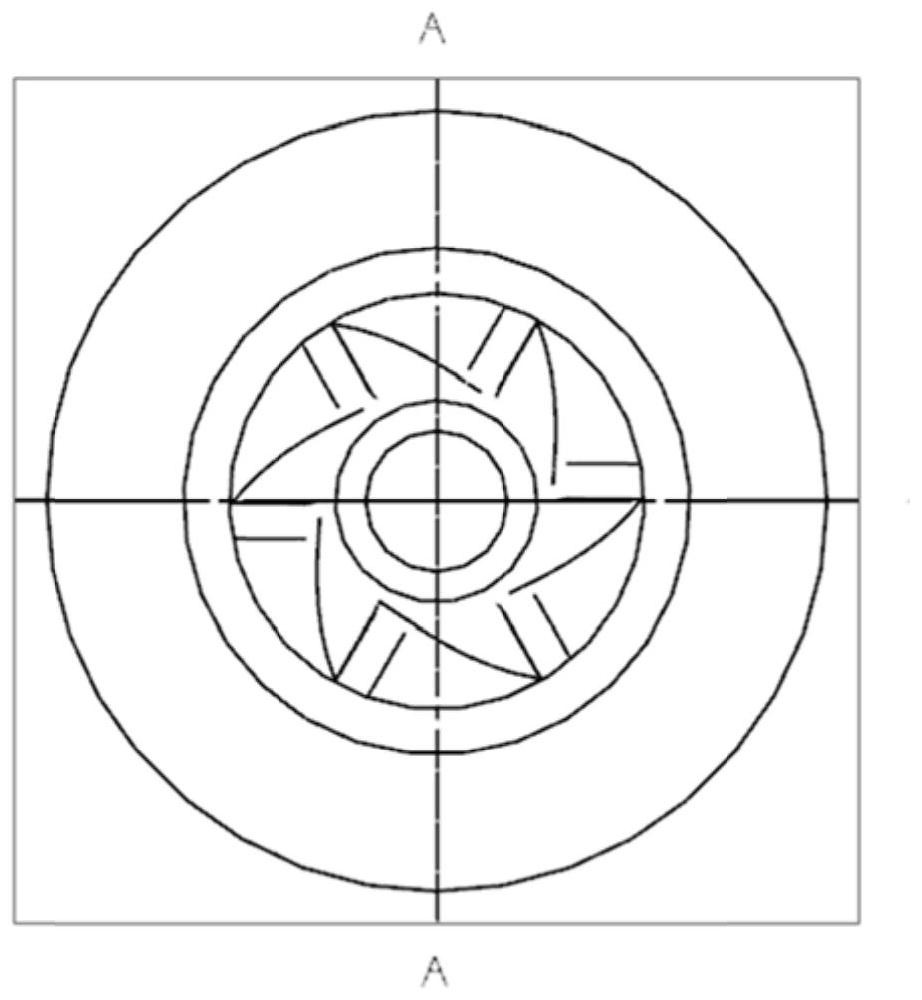

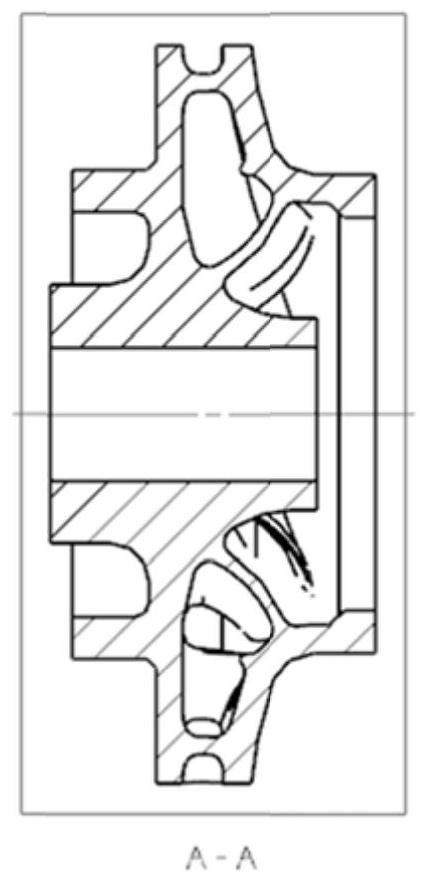

[0066] In this example, the investment casting is the primary pump impeller of a certain type of fuel pump, the material is ZG06Cr14Ni7Mo, and the structure is as follows figure 2 and image 3 shown.

[0067] (1) Defect location.

[0068] The internal quality inspection method of the casting is X-ray inspection, the surface quality inspection method is fluorescent inspection, and the inspection level in the design drawing is Class B, and the allowable defects comply with the provisions in Table 2 and Table 3. If the above two inspection methods find defects beyond those specified in Table 2 and Table 3, the results shall be displayed on the X-ray film and the surface, and the position and size of the defects shall be marked on the casting.

[0069] Table 2 X-ray Inspection Standards for Castings

[0070]

[0071] Table 3 Fluorescent Inspection Standards for Castings

[0072]

[0073]

[0074] (2) Defect exclusion. Determine the size and location of the defect ac...

Embodiment 2

[0085] In this embodiment, the investment casting is a certain type of turbine oxygen pump centrifugal wheel, the material is ZG03Cr13Ni5Co9Mo5, and the structure is as follows Figure 8 and Figure 9 As shown, the primary impeller of the fuel pump has the same structure as the centrifugal impeller of the turbo oxygen pump in Embodiment 1 except that the blades rotate in the opposite direction.

[0086] The defect repair method is consistent with that in Embodiment 1, the only difference is:

[0087] The welding wire is wire-cut from the master alloy bar for casting, and the chemical composition should meet the requirements of the casting master alloy GJB7961. The specific chemical composition: 13.0% to 15.0% of Cr element, 6.0% to 8.5% of Ni element, 0.5% to 1.0% % Mo element, the rest is Fe element. The initial thickness of the repair welding part in this implementation is 5mm, and the welding process parameters are selected: the welding current A is 170A, the number of we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com