Wide thick plate hot-straightening machine working roll and manufacturing method thereof

A technology of straightening machines and work rolls, which is applied in the direction of manufacturing tools, heat treatment furnaces, heat treatment equipment, etc., and can solve problems such as insufficient matrix strength and red hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

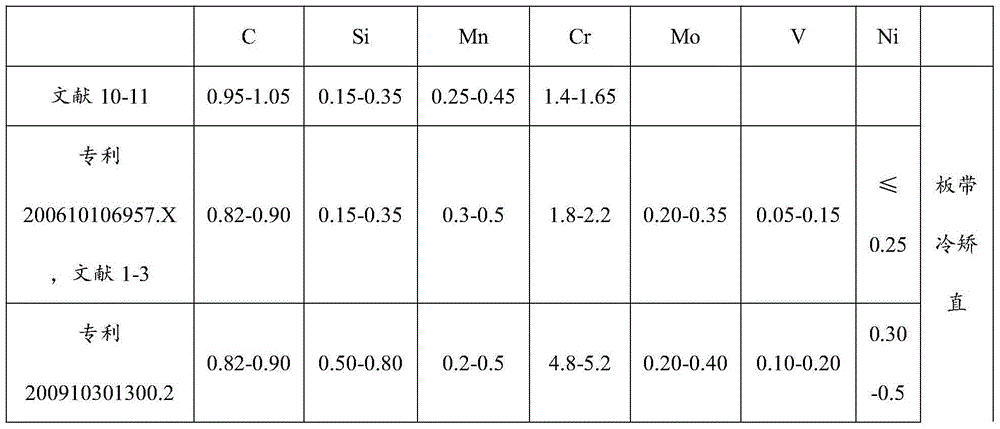

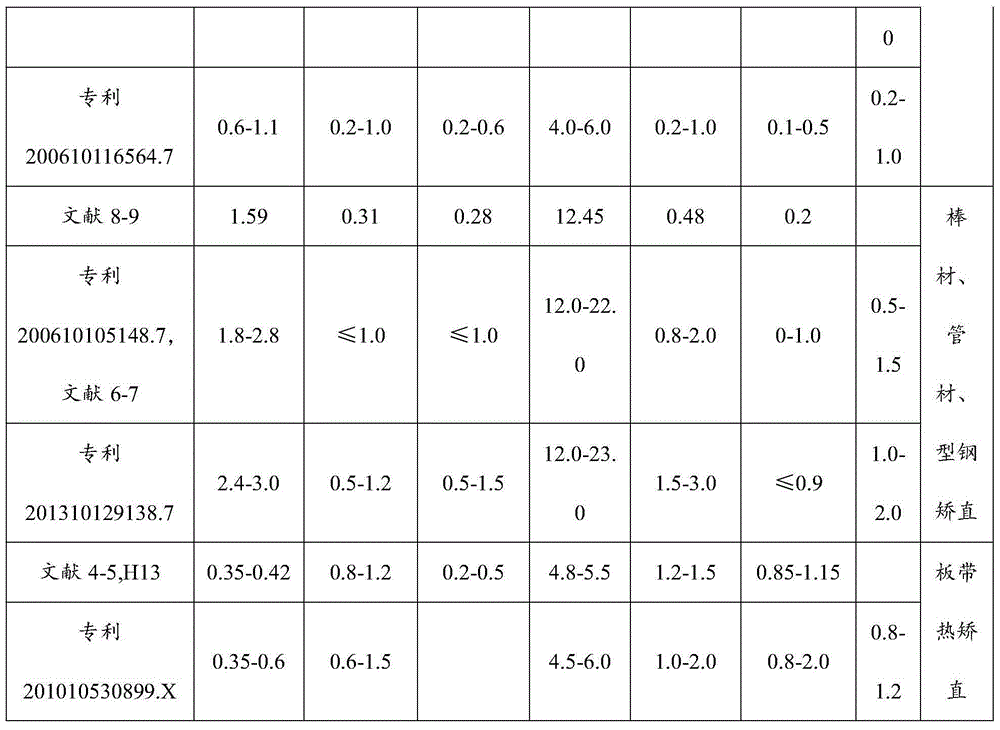

Method used

Image

Examples

Embodiment 1

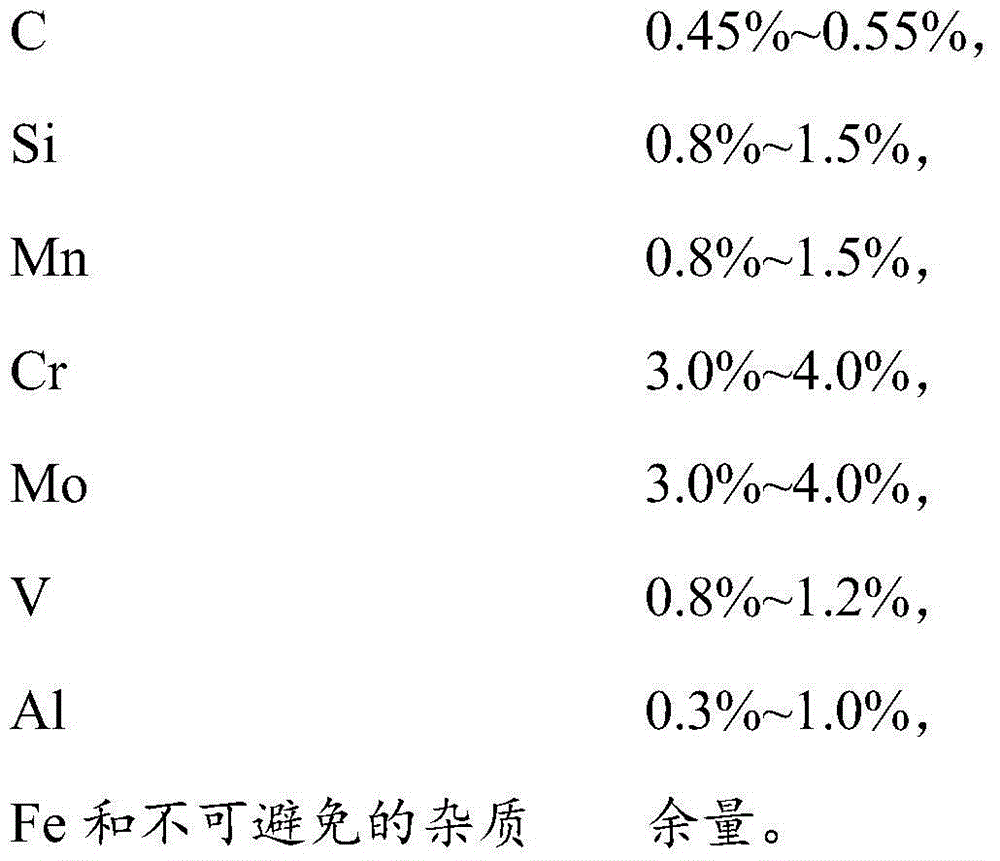

[0052] Embodiment 1 is a kind of work roll for wide and thick plate heat straightening machine with a width of 1300-4900mm and a thickness of 10-100mm, and its chemical composition includes according to mass percentage:

[0053]

[0054] The diameter of the finished straightening machine work roll is 360mm, the length of the roll body is 5200mm, and there are cooling water holes in the middle.

[0055] The preparation method includes the following steps: (1) Roughly processing the raw material into a roll billet through forging and post-forging heat treatment; (2) Quenching and tempering heat treatment; (3) Final heat treatment; (4) Tempering treatment; (5) Finishing.

[0056] The diameter of the finished straightening machine work roll is 360mm, the length of the roll body is 5200mm, and there are cooling water holes in the middle.

[0057] During preparation,

[0058] The forging process in step (1) is as follows: the heating temperature is 1150°C, the initial forging te...

Embodiment 2

[0067] Embodiment 2 is a work roll for a wide and thick plate thermal straightening machine with a width of 1300-4900 mm and a thickness of 10-100 mm. Its chemical composition includes:

[0068]

[0069] The diameter of the finished straightening machine work roll is 360mm, the length of the roll body is 5200mm, and there are cooling water holes in the middle.

[0070] The preparation method includes the following steps: (1) Roughly processing the raw material into a roll billet through forging and post-forging heat treatment; (2) Quenching and tempering heat treatment; (3) Final heat treatment; (4) Tempering treatment; (5) Finishing.

[0071] The diameter of the finished straightening machine work roll is 360mm, the length of the roll body is 5200mm, and there are cooling water holes in the middle.

[0072] During preparation,

[0073] The forging process in step (1) is as follows: the heating temperature is 1150°C, the initial forging temperature is 1100°C, and the final...

Embodiment 3

[0082] Embodiment 3 is a work roll for a wide and thick plate thermal straightening machine with a width of 1300-4900 mm and a thickness of 10-100 mm. Its chemical composition includes:

[0083]

[0084]

[0085] The diameter of the finished straightening machine work roll is 360mm, the length of the roll body is 5200mm, and there are cooling water holes in the middle.

[0086] The preparation method includes the following steps: (1) Roughly processing the raw material into a roll billet through forging and post-forging heat treatment; (2) Quenching and tempering heat treatment; (3) Final heat treatment; (4) Tempering treatment; (5) Finishing.

[0087] The diameter of the finished straightening machine work roll is 360mm, the length of the roll body is 5200mm, and there are cooling water holes in the middle.

[0088] During preparation,

[0089] The forging process in step (1) is as follows: the heating temperature is 1150°C, the initial forging temperature is 1100°C, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Compressive yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com