Electrodeposited diamond wire saw production system

A technology of diamond wire saw and production system, which is applied in the direction of electrolytic inorganic material coating, etc., can solve the problems of low efficiency, achieve high production efficiency, improve efficiency and slicing quality, and improve abrasive grain holding force and matrix strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

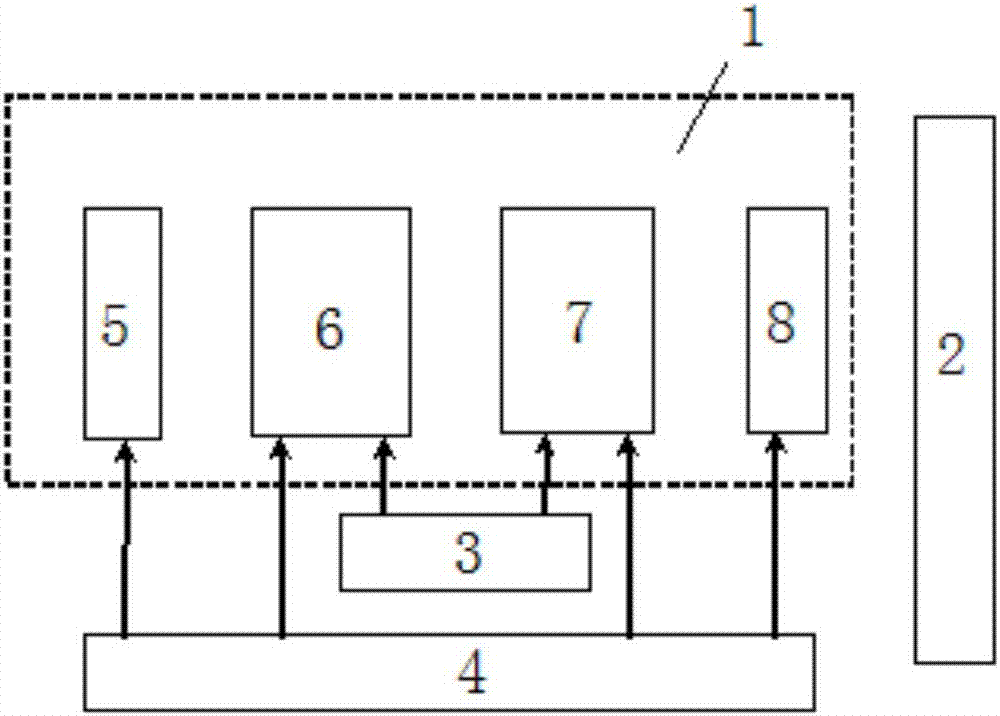

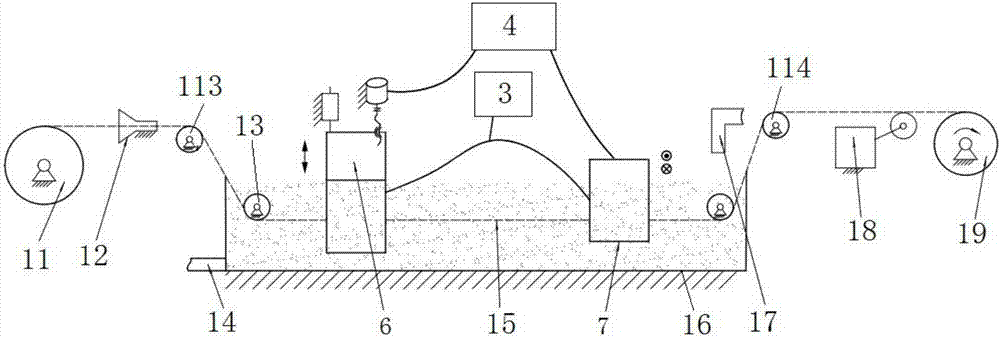

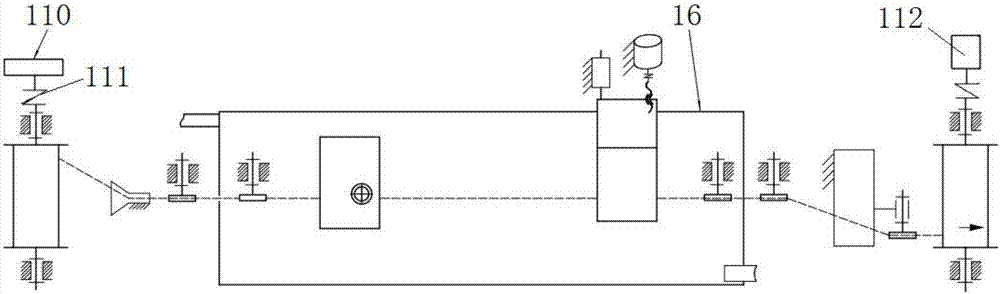

[0026] The production system of the consolidated abrasive wire saw wire of the present invention realizes the automatic production of the consolidated abrasive wire saw wire based on the electrodeposition technology. Its overall structure is as figure 1 As shown, it includes four parts: an electrodeposition unit 1 , a working medium control module 2 , an adjustable pulse power supply 3 and a motion controller 4 . Wherein the electrodeposition unit 1 includes four sub-parts of a wire-feeding unit 5, a vertical direction deposition unit 6, a horizontal direction deposition unit 7, and a wire-receiving unit 8. On both sides, the vertical direction deposition unit 6 and the horizontal direction deposition unit 7 are arranged in the working medium tank 16 (see figure 2 and image 3 ), the working medium tank 16 is connected to the working medium control module 22. The adjustable pulse power supply 3 is connected to the vertical direction deposition unit 6 and the horizontal dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com