Production device for diamond wire-saw wire through electrospark deposition

A technology of electric spark deposition and diamond wire sawing, which is applied in the direction of grinding device, electrophoretic coating, electrolytic coating, etc., can solve the problems of low abrasive grain holding force, complicated production process, poor sawing ability, etc., and achieve the improvement of abrasive grain High holding force, high bonding strength, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions protected by the present invention will be described below using specific embodiments and accompanying drawings.

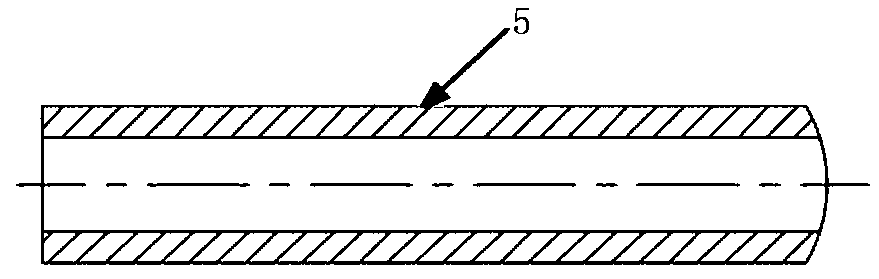

[0018] It can be seen from the accompanying drawings that the electric discharge deposition diamond wire saw wire production device of this program includes: a liquid supply device for providing a mixed liquid medium; a liquid spray electrode 5 for spraying liquid deposition on the wire saw wire substrate 18, The liquid spray electrode 5 is connected with the pulse power supply 4; the liquid spray electrode 5 is connected with the liquid supply device, and the electric spark deposition device is arranged on the rotating device; the translation device for promoting the liquid spray electrode 5 to move is arranged on the rotating device, The rotating device is also provided with a swinging device for driving the liquid spraying electrode 5 to swing. The middle part of the liquid spraying electrode is provided with a liquid flow channel,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com